Rotary whiskered zinc electrode cylindrical reaction tank air battery

A technology for air batteries and zinc electrodes, applied in the direction of electrode carriers/collectors, electrical components, battery electrodes, etc., can solve the problems of lower raw material utilization, increased battery internal resistance, and obstacles, and achieve economical production methods and easy scale The effect of production and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

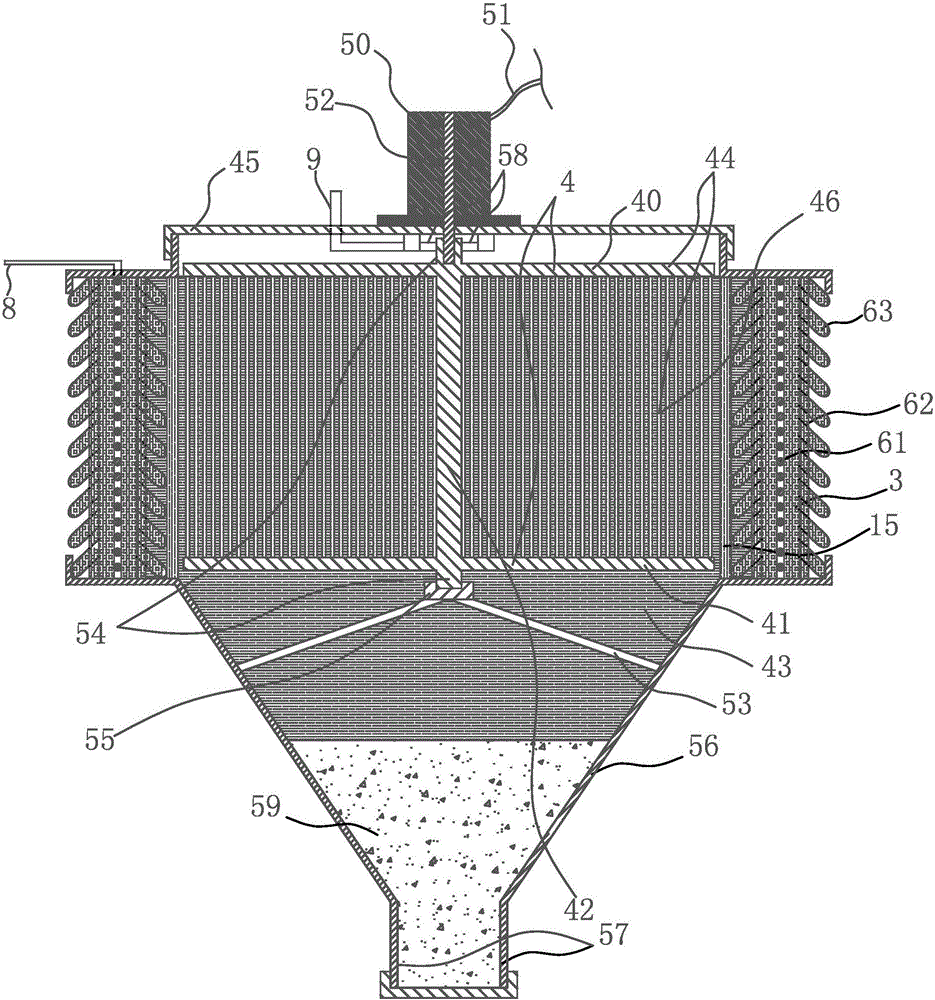

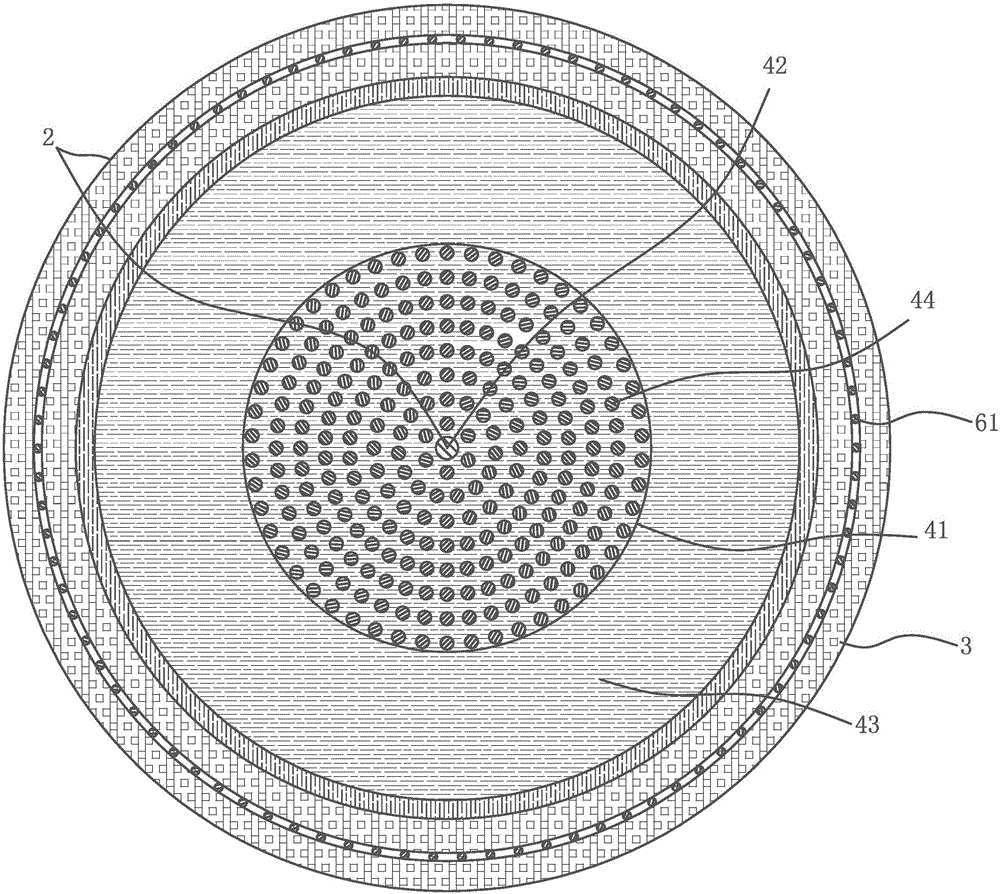

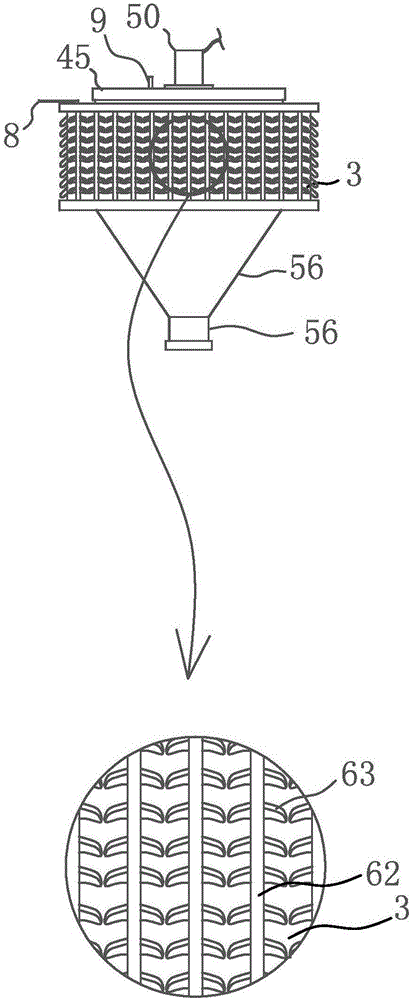

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0014] like Figure 1-3 As shown, a rotating whisker-shaped zinc electrode cylindrical reaction tank air battery includes a battery reaction tank (2), an air electrode lead wire (8), and a zinc electrode lead wire (9). It is characterized in that: the battery reaction tank (2) ) is an open mouth, and is provided with a movable reaction tank cover (45); the side of the battery reaction tank (2) is surrounded by the air electrode (3) into a cylindrical shape, and the surface of the air electrode (3) is provided with gill-shaped protrusions. The object (60); the bottom of the battery reaction tank (2) is provided with a cone (56), and the lower end of the cone (56) is provided with a zinc oxide discharge port (57); the battery reaction tank (2) is filled with electrolyte (43), and a zinc electrode (44) is provided.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com