Cylindrical liquid flow circulating honeycomb type zinc air battery

A zinc-air battery, honeycomb-type technology, which is applied in the direction of fuel cell type half-cell and primary battery type half-cell, etc., can solve the problem of unfavorable commercial operation, the replacement method cannot meet the power supply for vehicles, and has not been widely promoted. and other problems, to achieve the effect of economical production method, long interval and safe use

Inactive Publication Date: 2017-07-07

陈学琴

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to its characteristics, zinc-air batteries have long been favored in the selection of electric vehicle power sources, but they have not been widely promoted. The main reason is that the existing zinc-air battery negative electrode structure and replacement methods cannot meet the requirements. The requirements of power supply for vehicles are not conducive to commercial operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

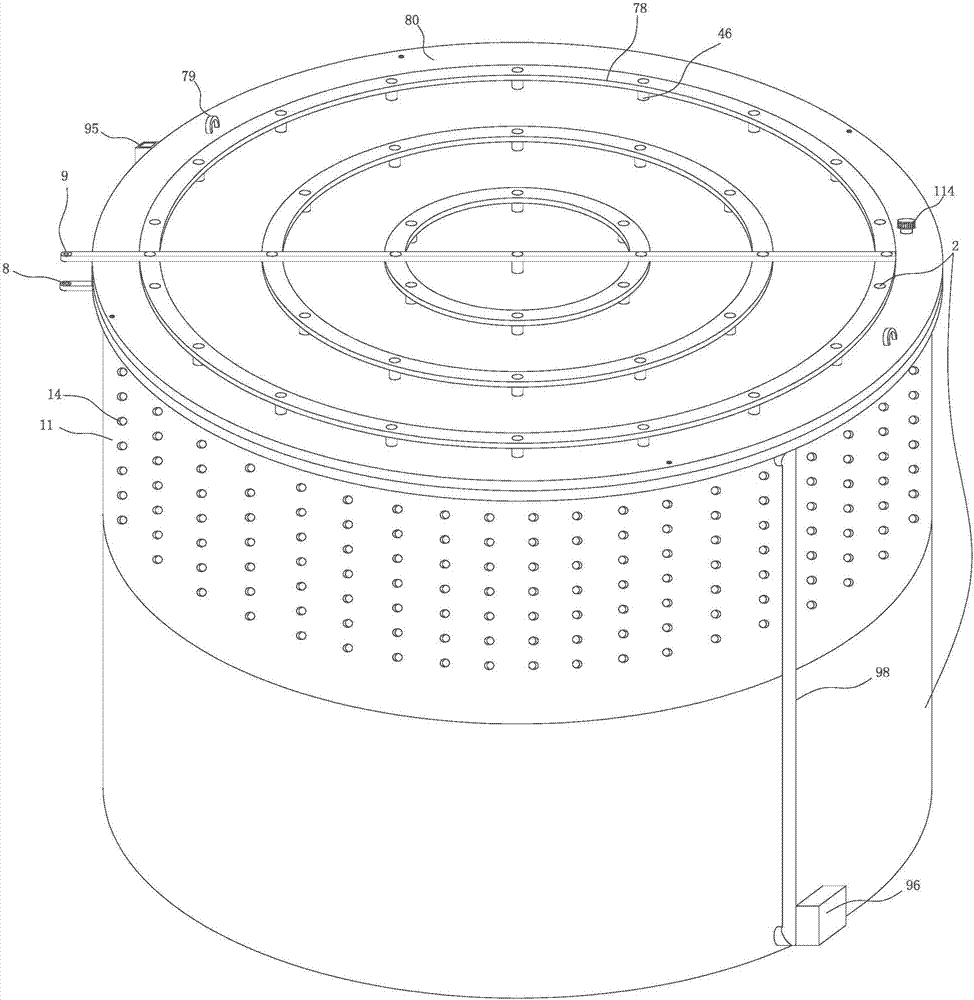

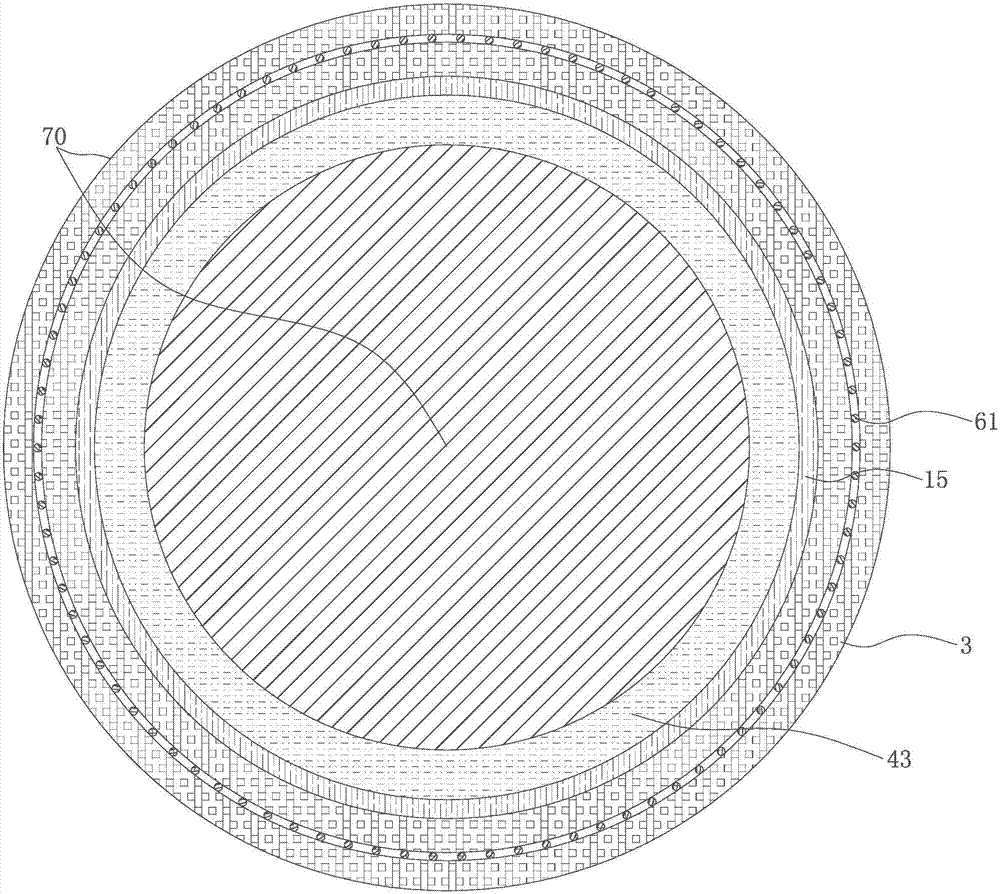

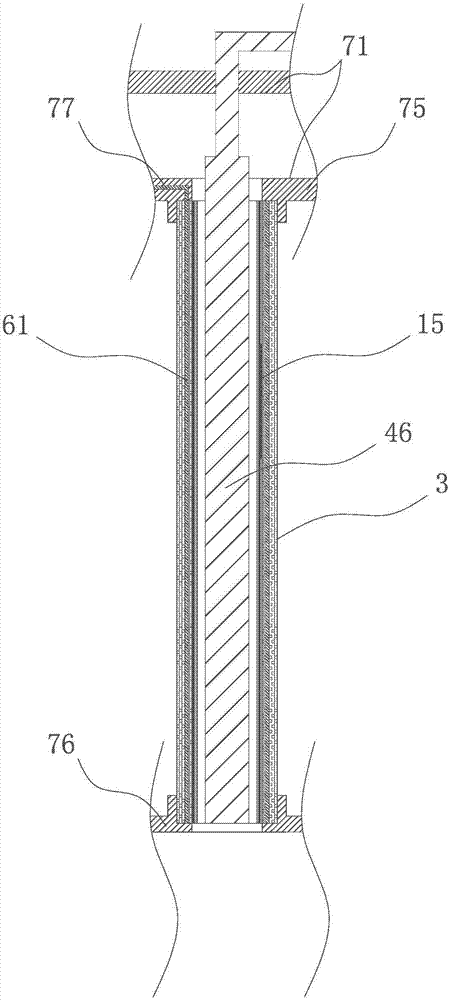

A cylindrical liquid flow circulation honeycomb zinc-air battery, including a battery reaction tank, air electrode lead-out wires, and zinc electrode lead-out wires. The battery reaction tank is formed by arranging and combining tubular reaction tank monomers. The ends are respectively provided with cylindrical upper and lower sumps connected with the tubular reaction tank monomer, the center of the tube body of the tubular reaction tank monomer is provided with a columnar zinc electrode unit, and the bottom of the lower sump is Inverted conical shape, a conical conical filter is set at the bottom of the filter tank, the electrolyte is pumped into the upper liquid collection tank through the reflux pump and the reflux pump return pipe, and a double-membrane structure is installed on the cover of the reaction tank. valve. The present invention has a large amount of zinc loaded at one time, can realize energy supply like an ordinary internal combustion engine, the battery can be quickly opened and closed, and the safety valve has double gradient protection. The above-mentioned characteristics enable the zinc-air battery to meet the requirements of the vehicle power supply, and it is safer to use.

Description

Cylindrical flow circulating honeycomb zinc-air battery technical field The invention relates to a battery, in particular to a cylindrical liquid flow circulating honeycomb zinc-air battery, which belongs to the technical field of battery processing and manufacturing. Background technique A zinc-air battery is a chemical power source that uses oxygen in the air as the positive active material and metal zinc as the negative active material, and generates electrical energy by chemical reaction under the catalysis of electrocatalysts. Since the zinc-air battery uses the oxygen in the air outside the battery as the positive electrode active material, the positive electrode active material does not occupy the volume and weight of the battery, so the battery has high specific energy by weight and volume. Zinc-air batteries have received extensive attention due to their large capacity, high specific energy, stable comprehensive performance, safe use, readily available and inexpen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M12/06

CPCH01M12/06

Inventor 陈学琴

Owner 陈学琴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com