A honeycomb type zinc-air cell

A zinc-air battery, honeycomb type technology, applied in the direction of fuel cell type half cell and primary battery type half cell, can solve the problems that the replacement method cannot meet the power supply for vehicles, unfavorable commercial operation, etc., and achieves the production method. Economical, long interval, large zinc loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

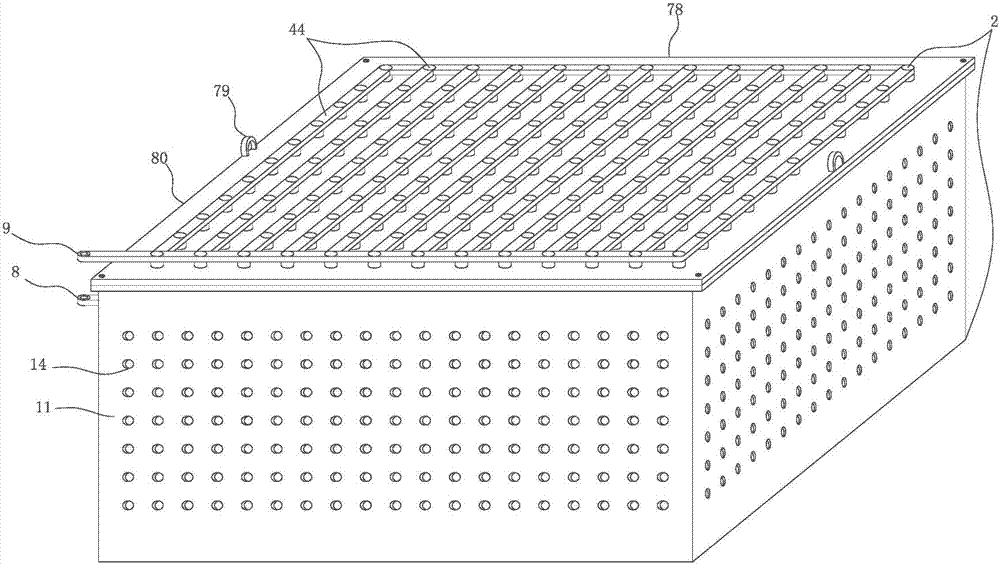

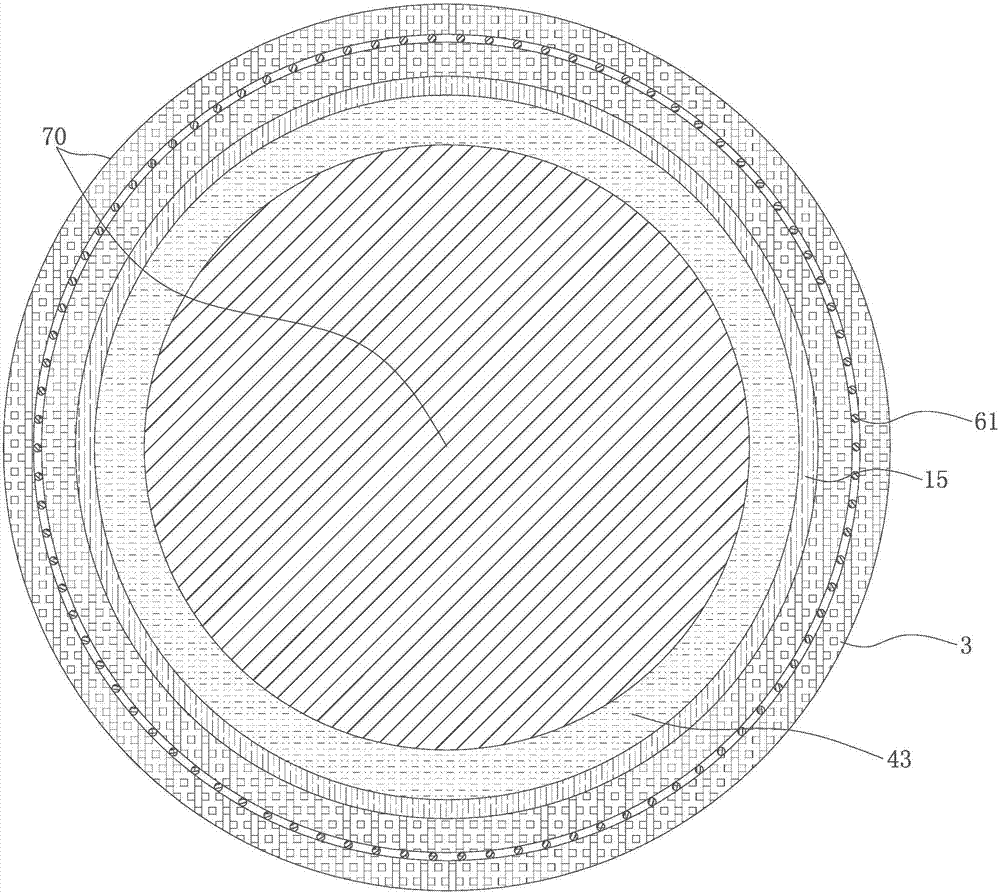

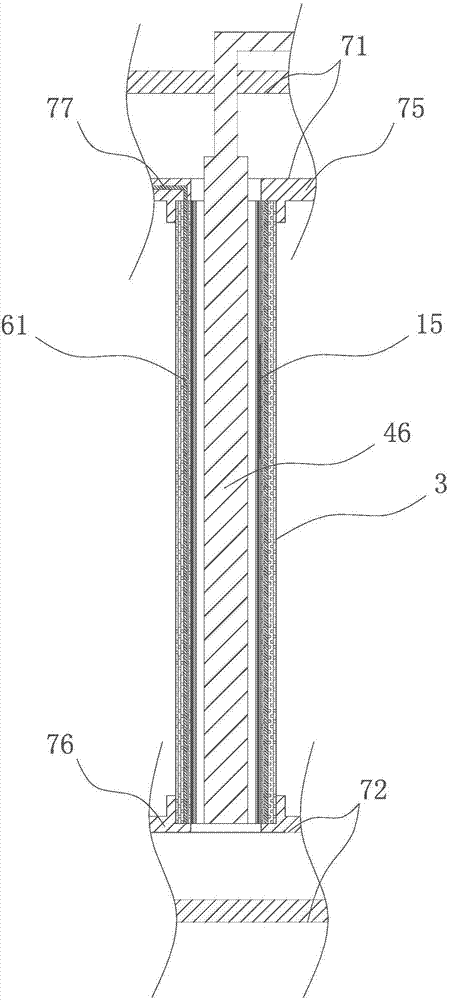

[0015] Such as Figure 1-6 Shown, a kind of honeycomb type zinc-air battery, comprises battery reaction tank (2) and air electrode lead-out wire (8), zinc electrode lead-out wire (9), it is characterized in that: battery reaction tank (2) is made up of tubular reaction tank single The body (70) is arranged and combined, and there is an air gap (74) between the tubular reaction tank monomers (70), and the upper and lower ends of the tubular reaction tank monomer (70) are respectively provided with ) the upper liquid collection tank (71) and the lower liquid collection tank (72) that communicate with each other; the tubular body formed by the tubular reaction tank monomer (70) surrounded by the air electrode (3), its upper end and the upper liquid collection tank The bottom plate (75) of (71) joins, and the lower end jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com