Patents

Literature

345results about How to "Quick opening and closing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

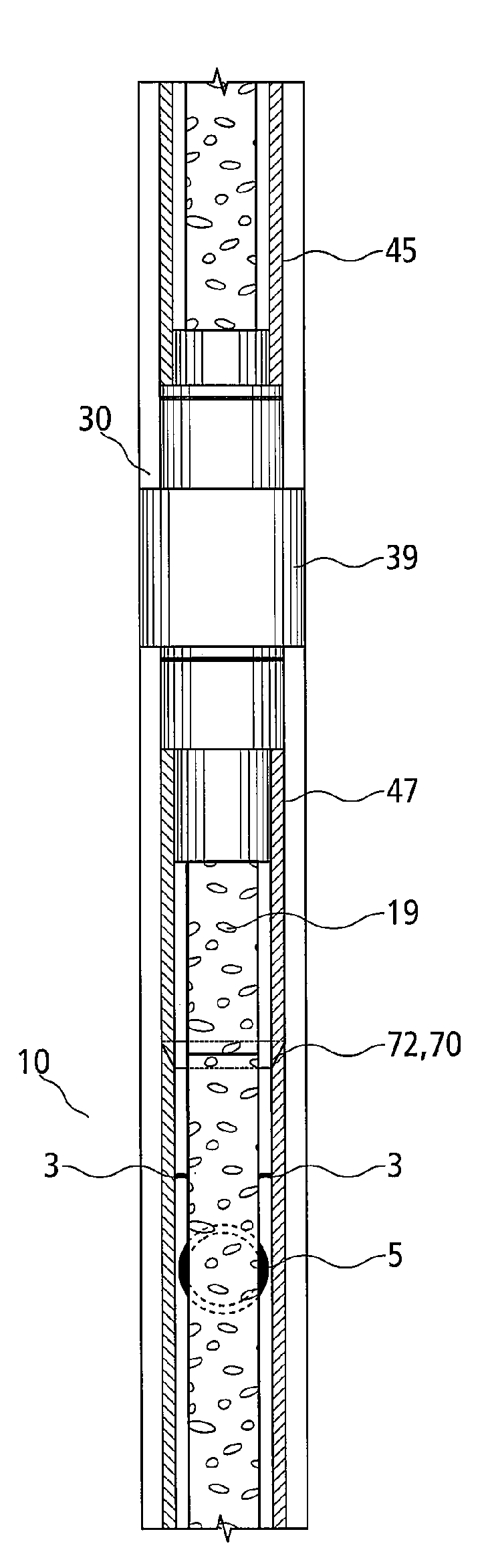

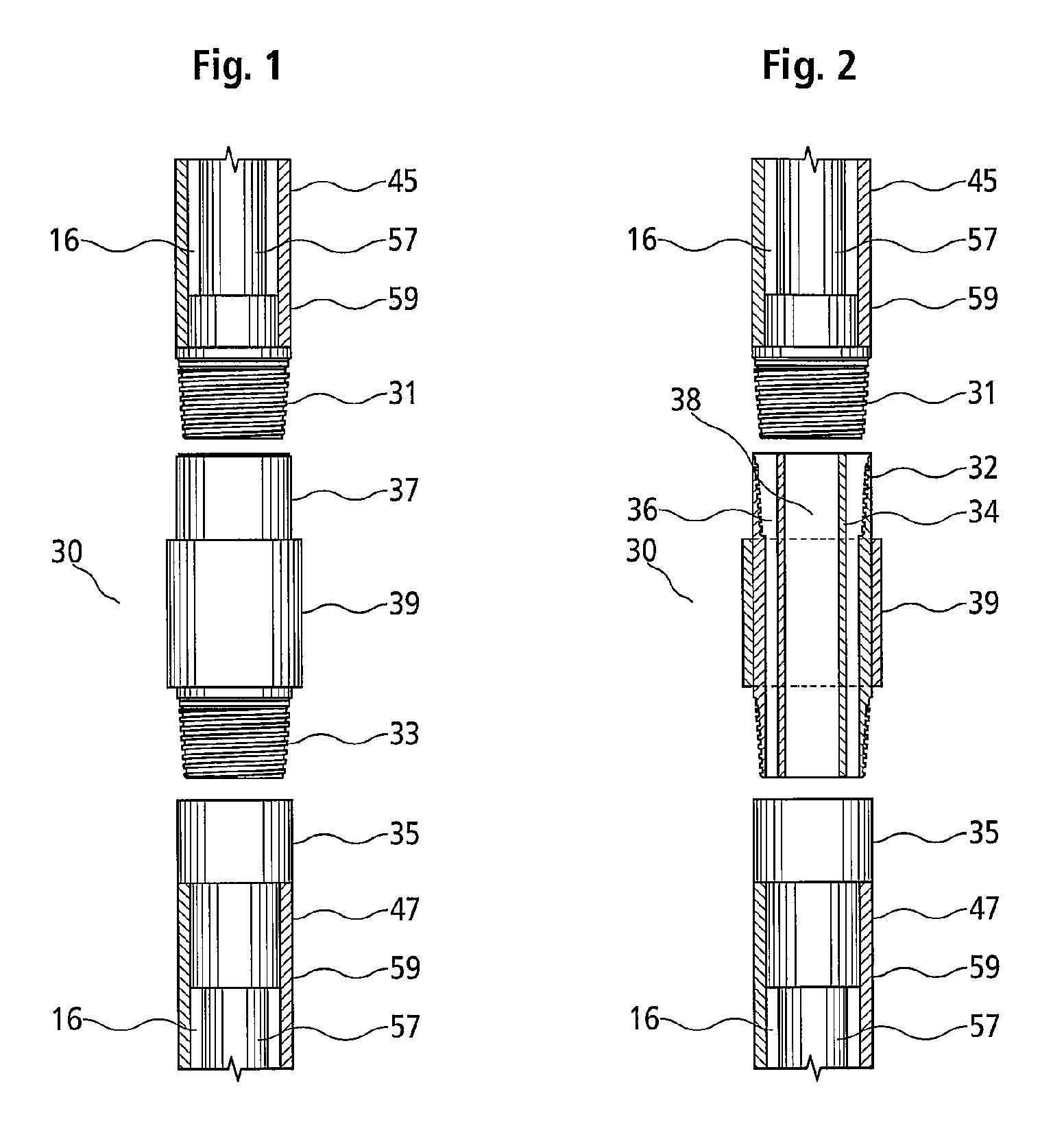

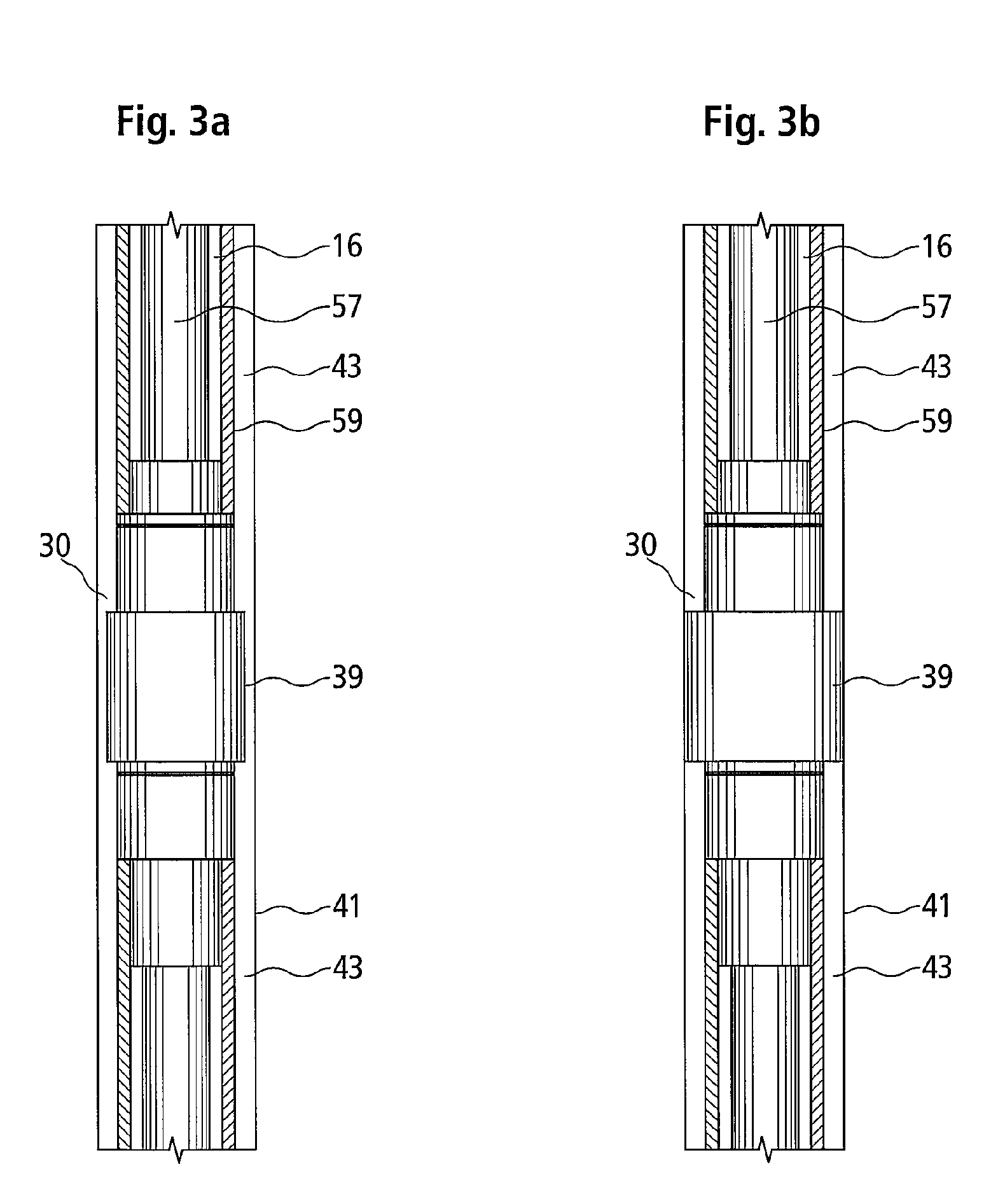

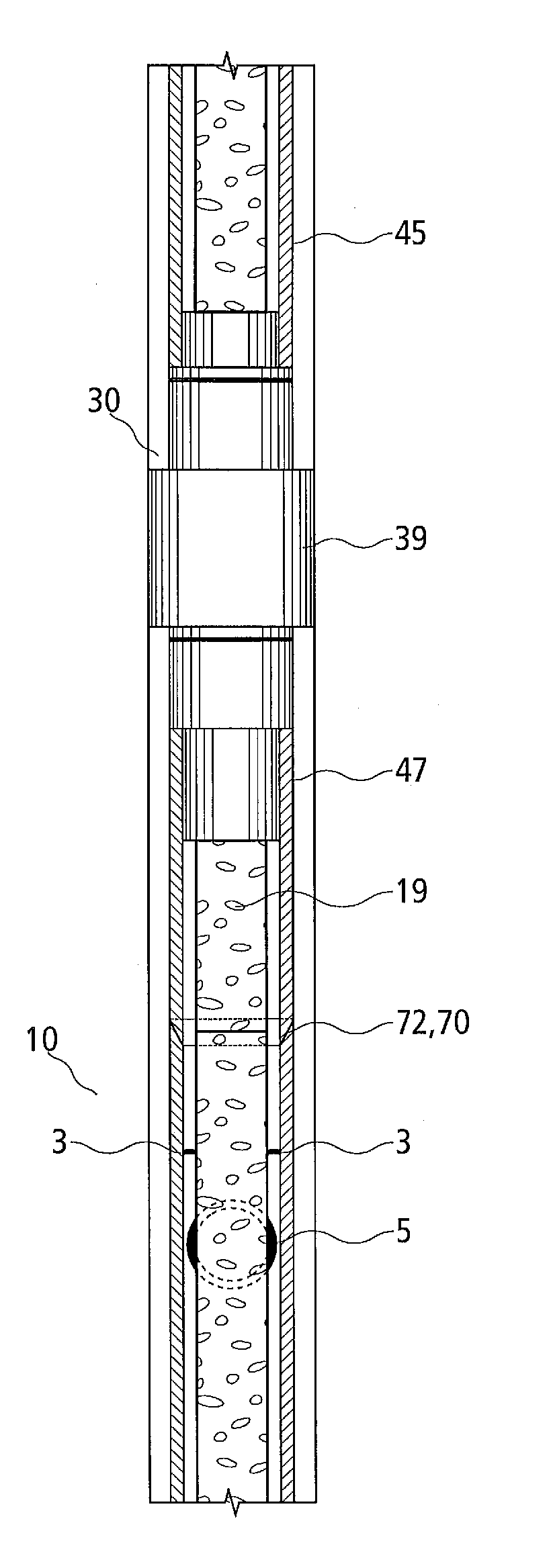

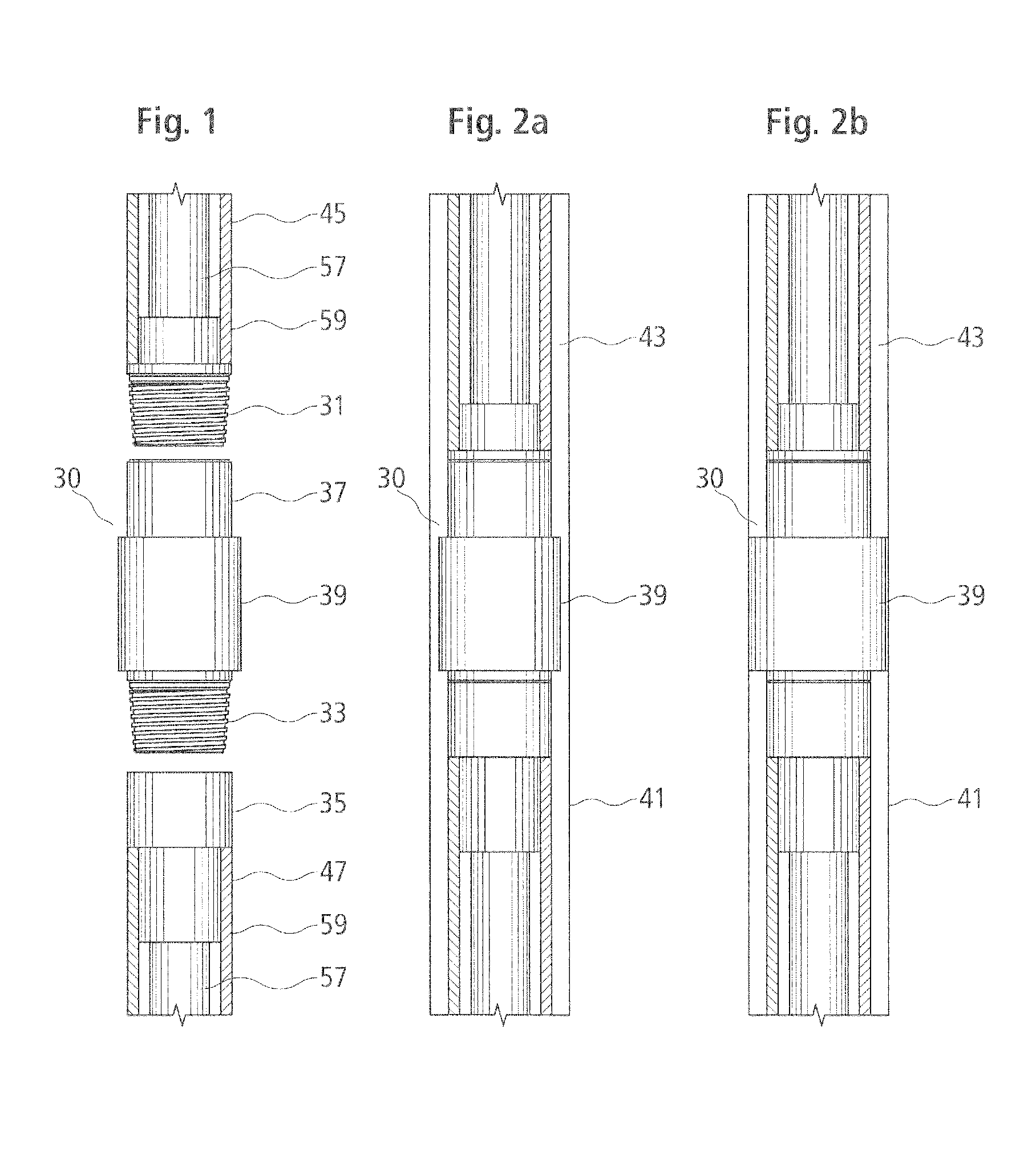

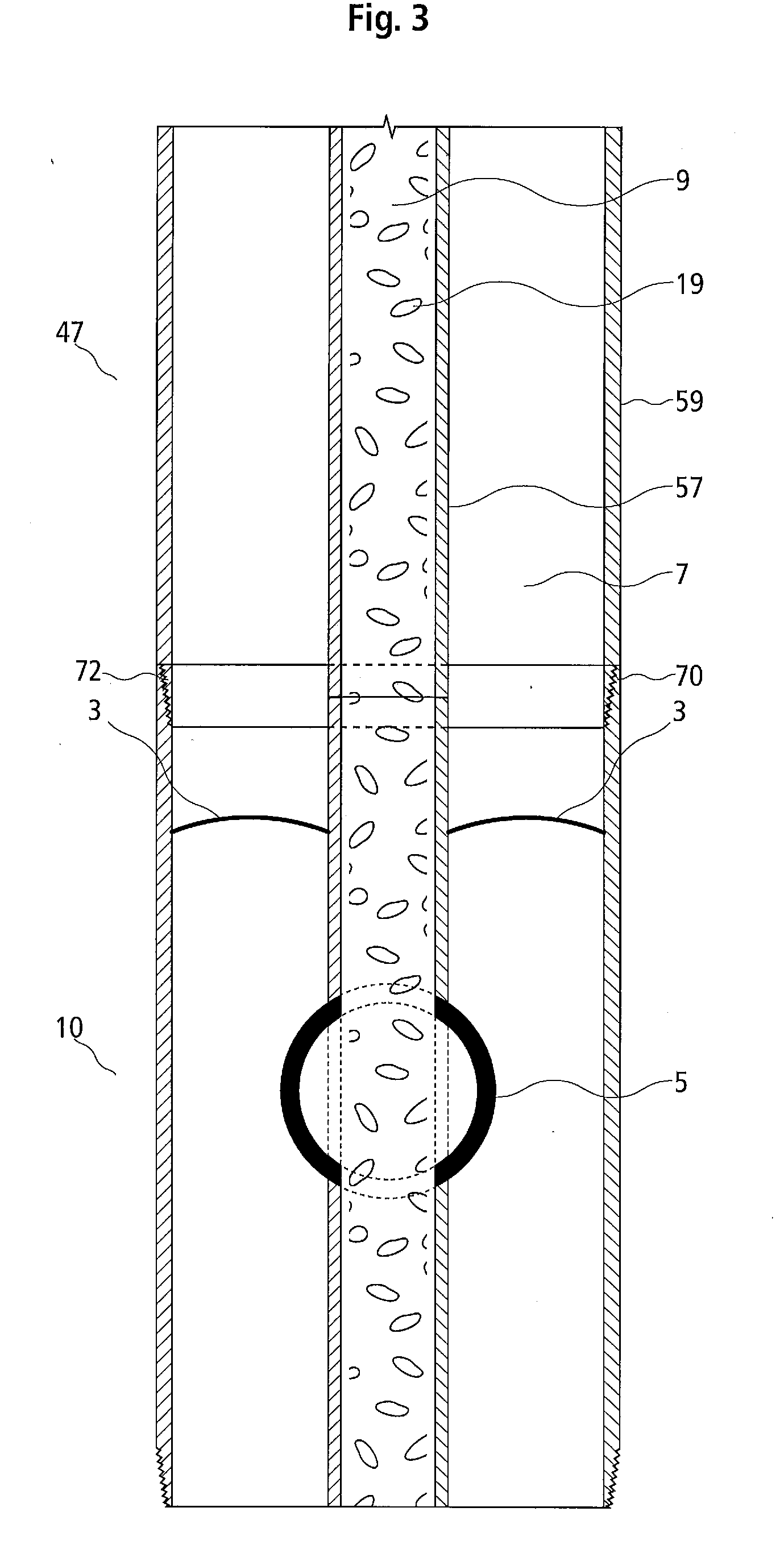

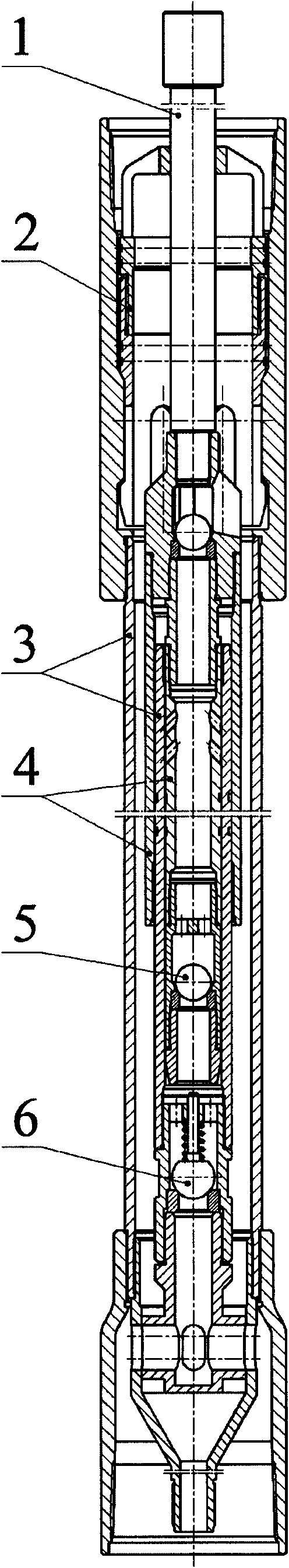

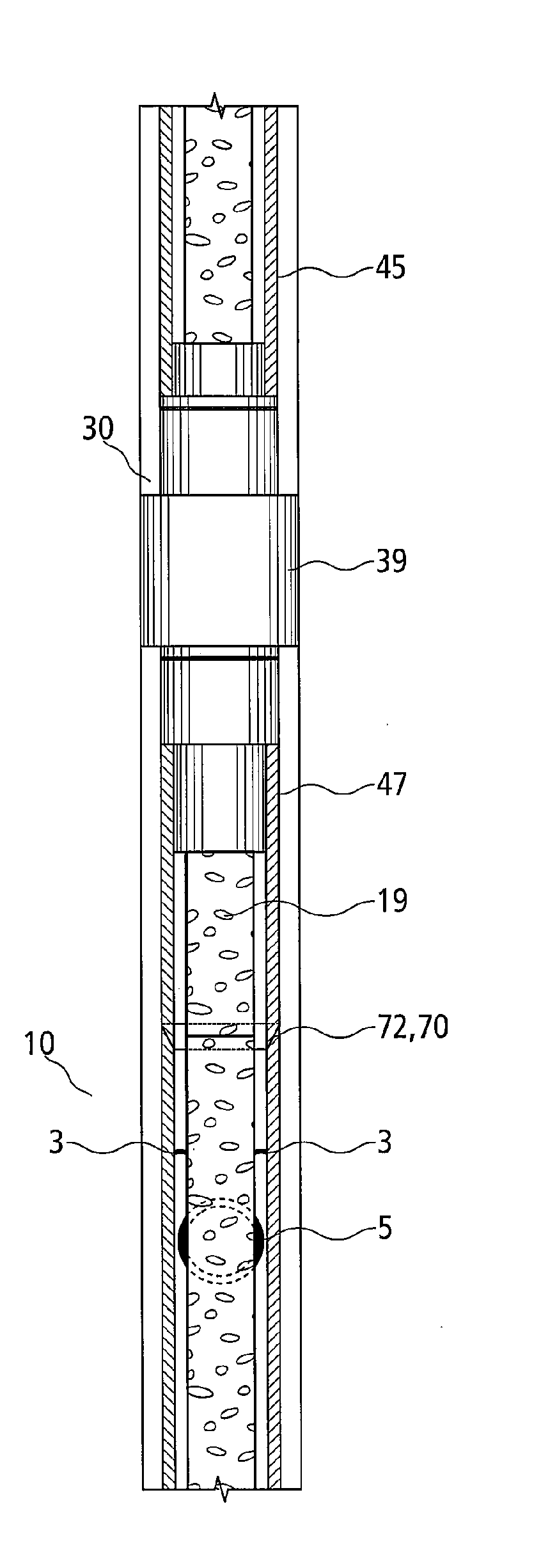

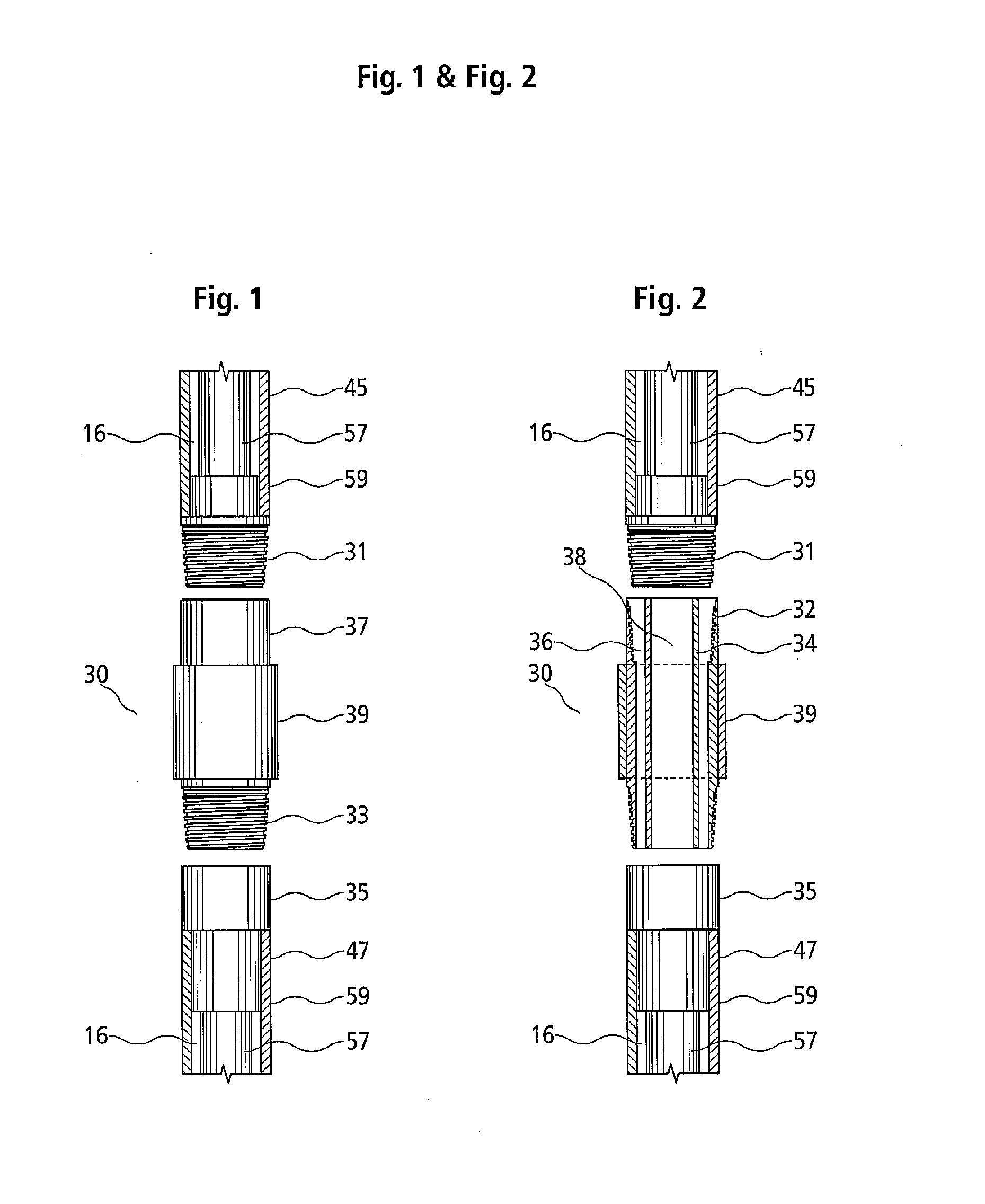

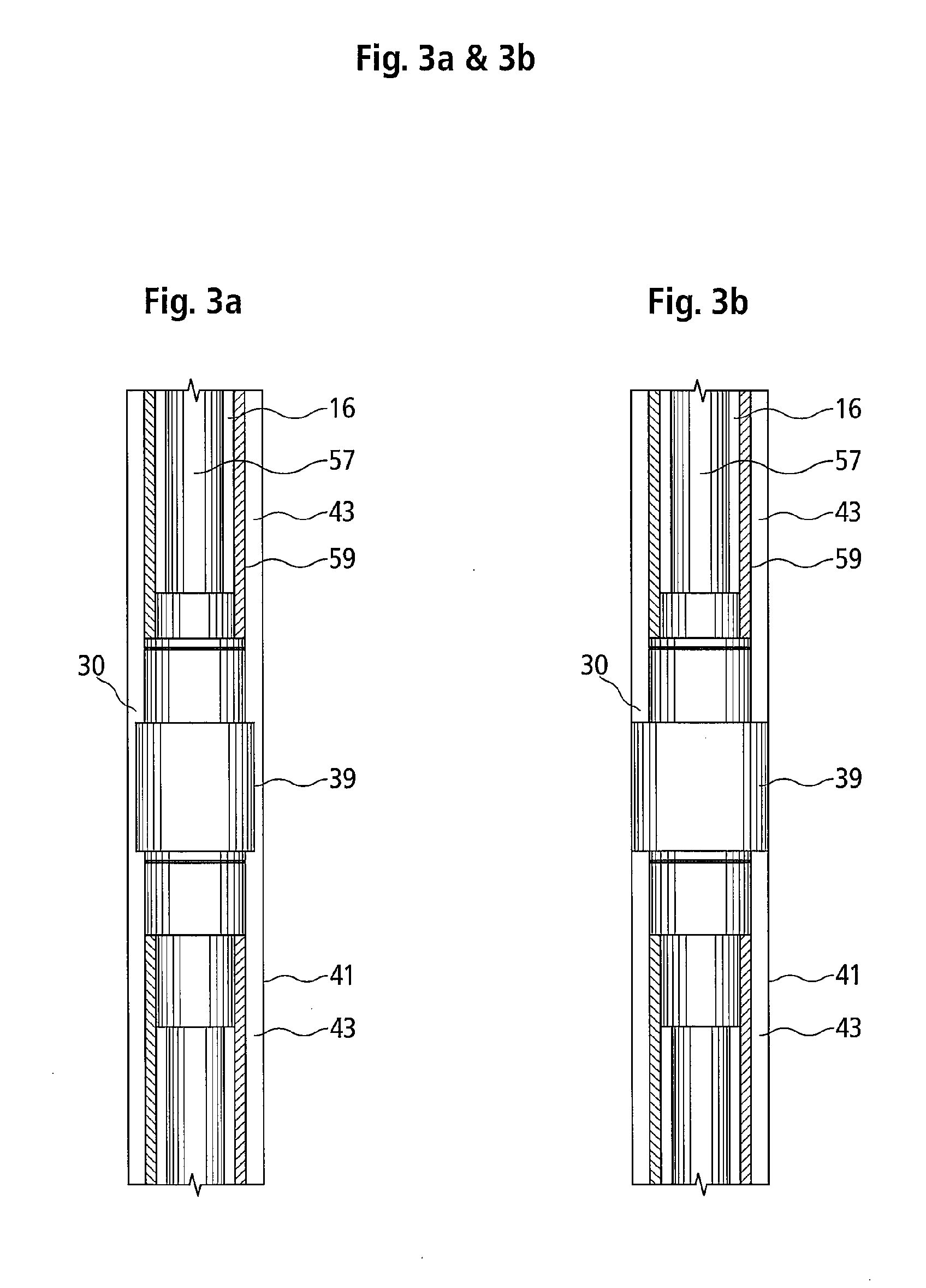

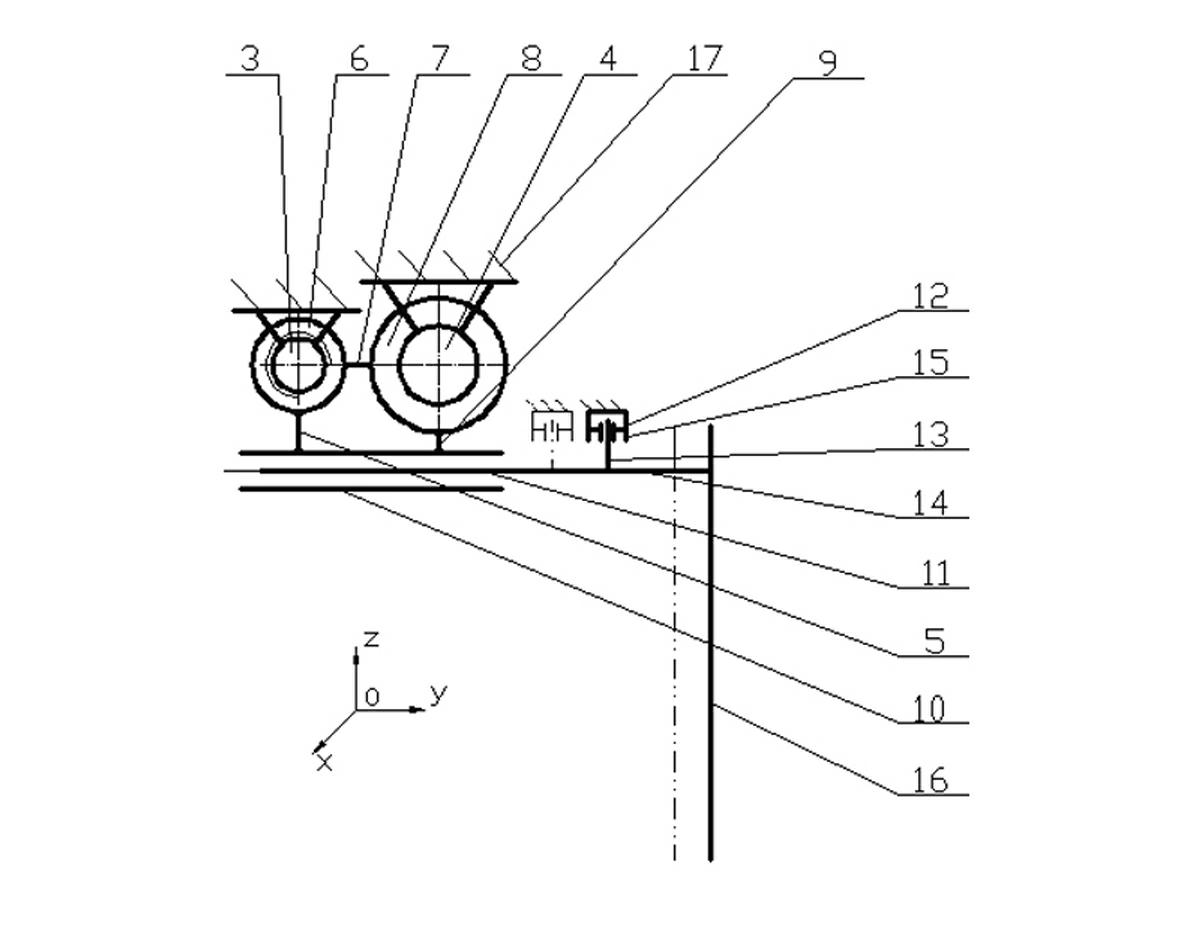

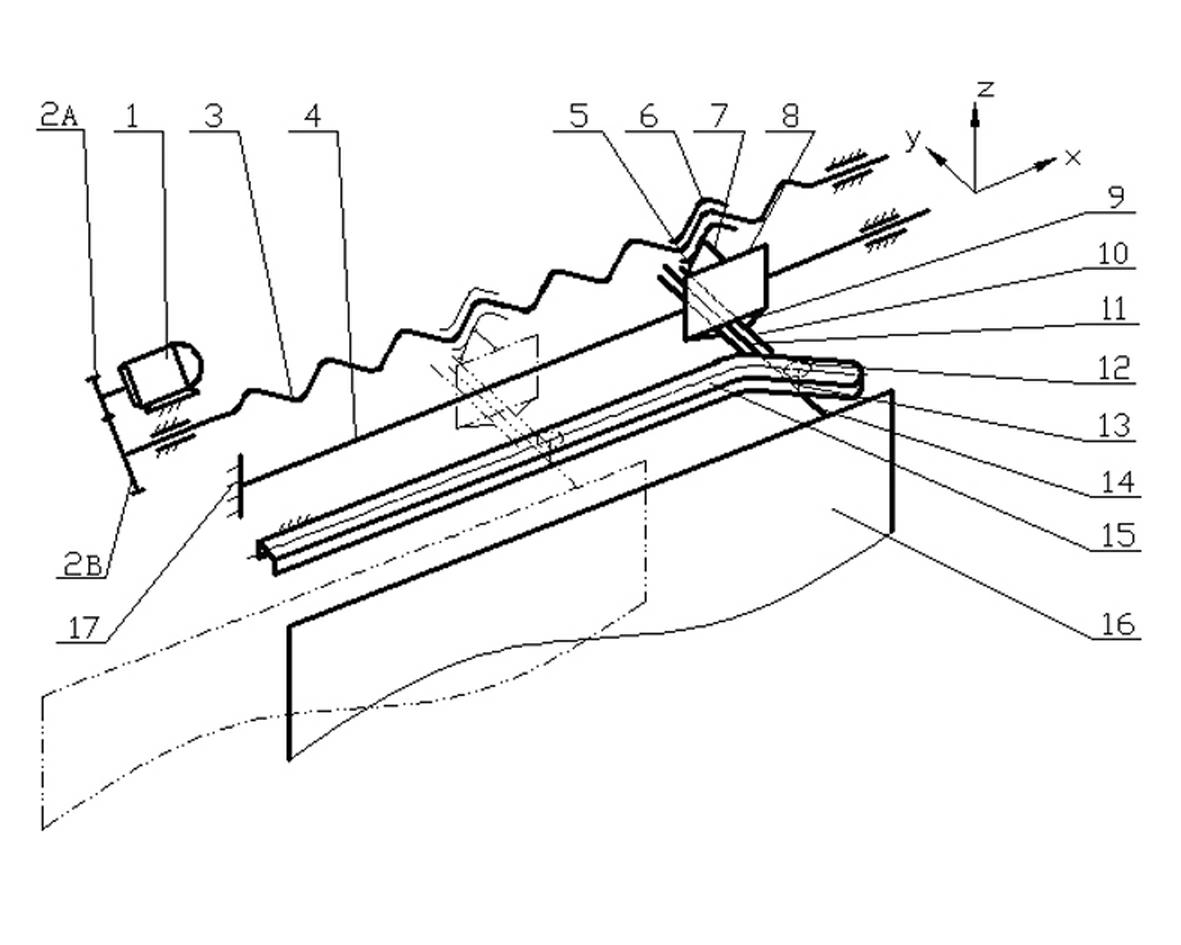

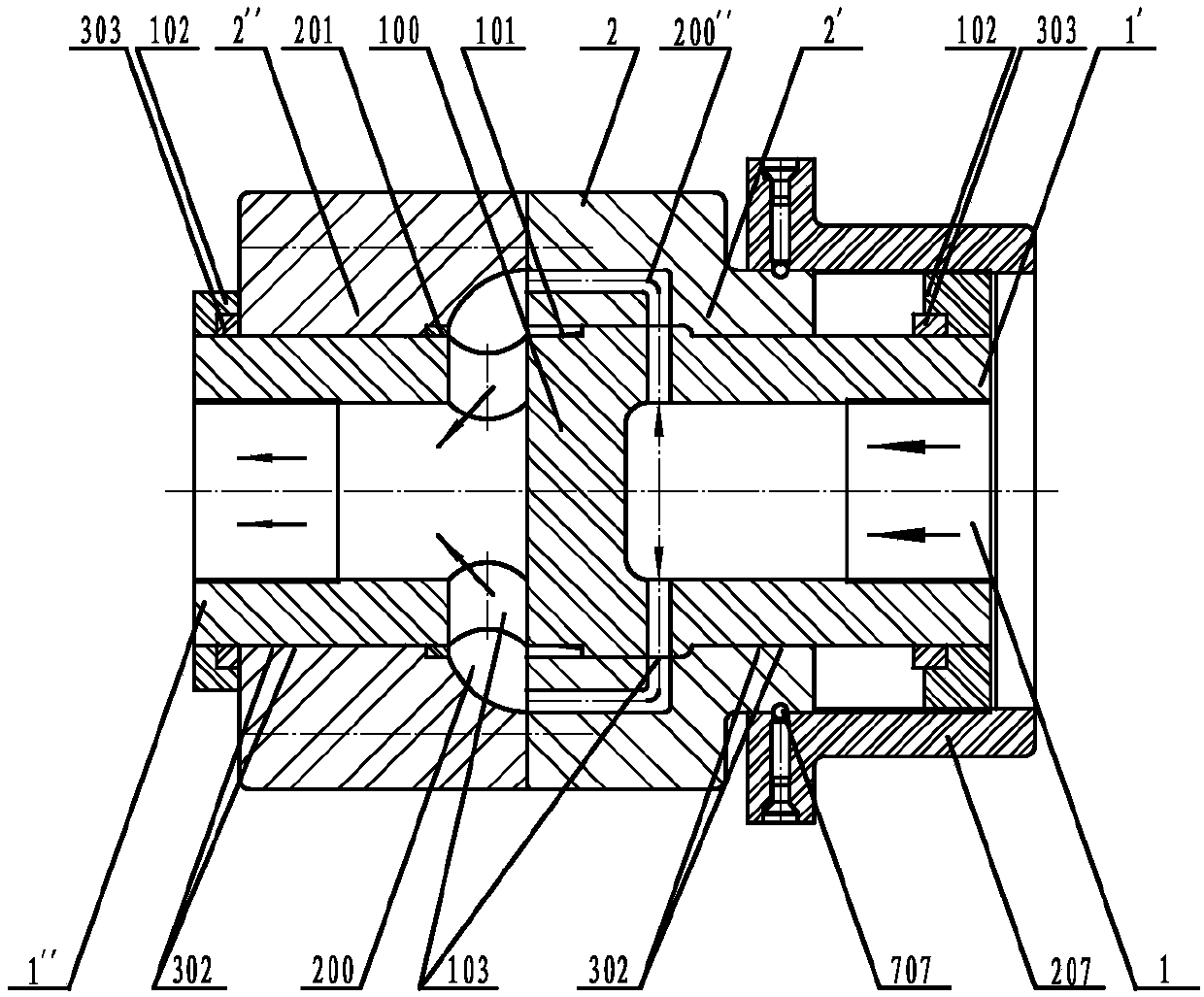

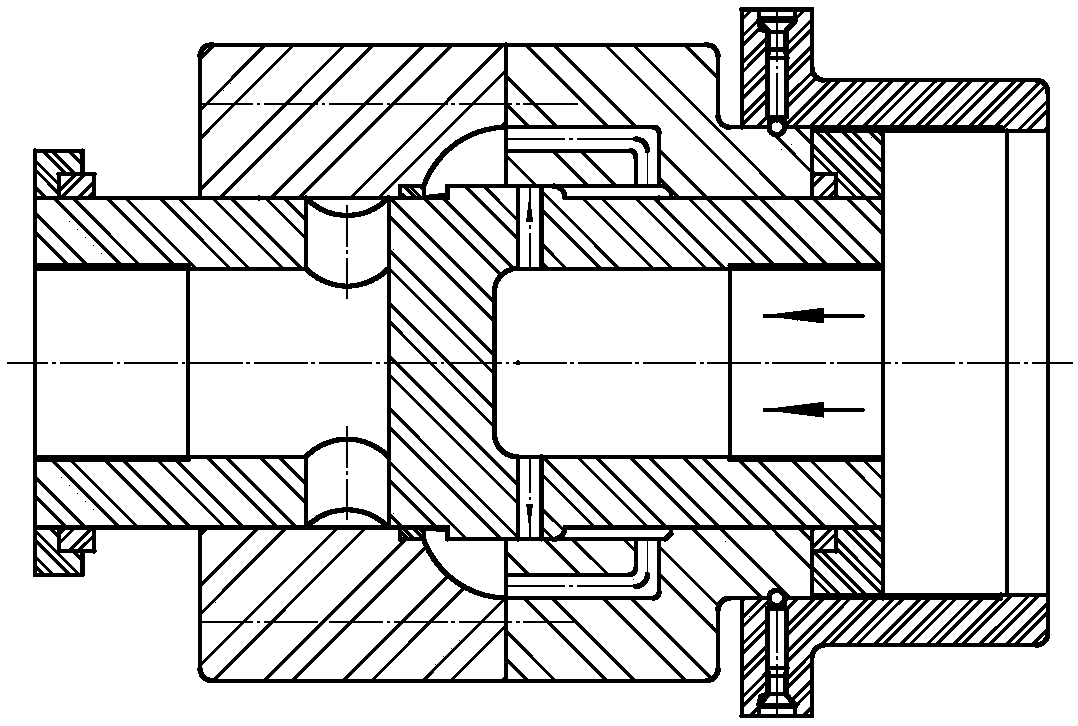

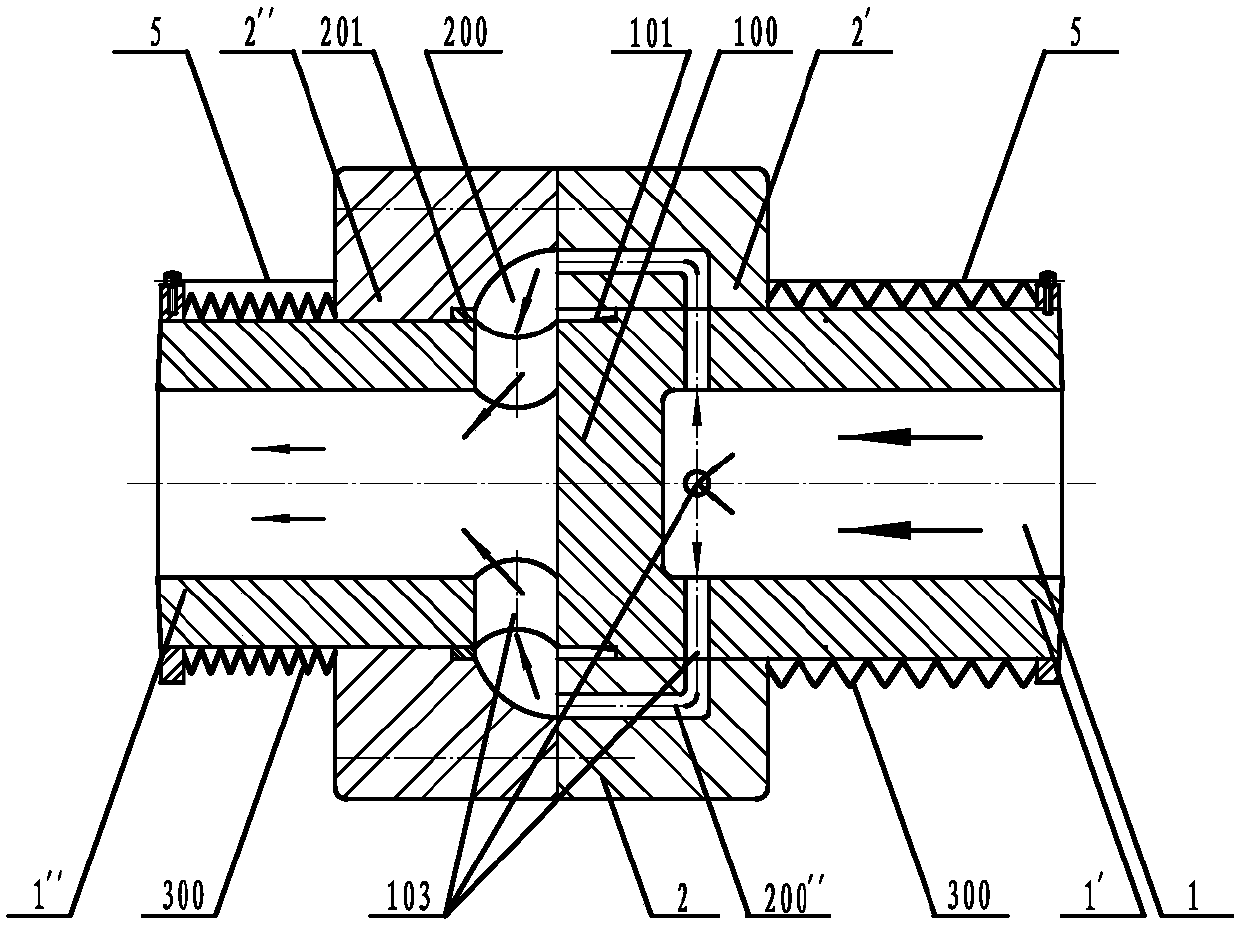

Method and apparatus for isolating and testing zones during reverse circulation drilling

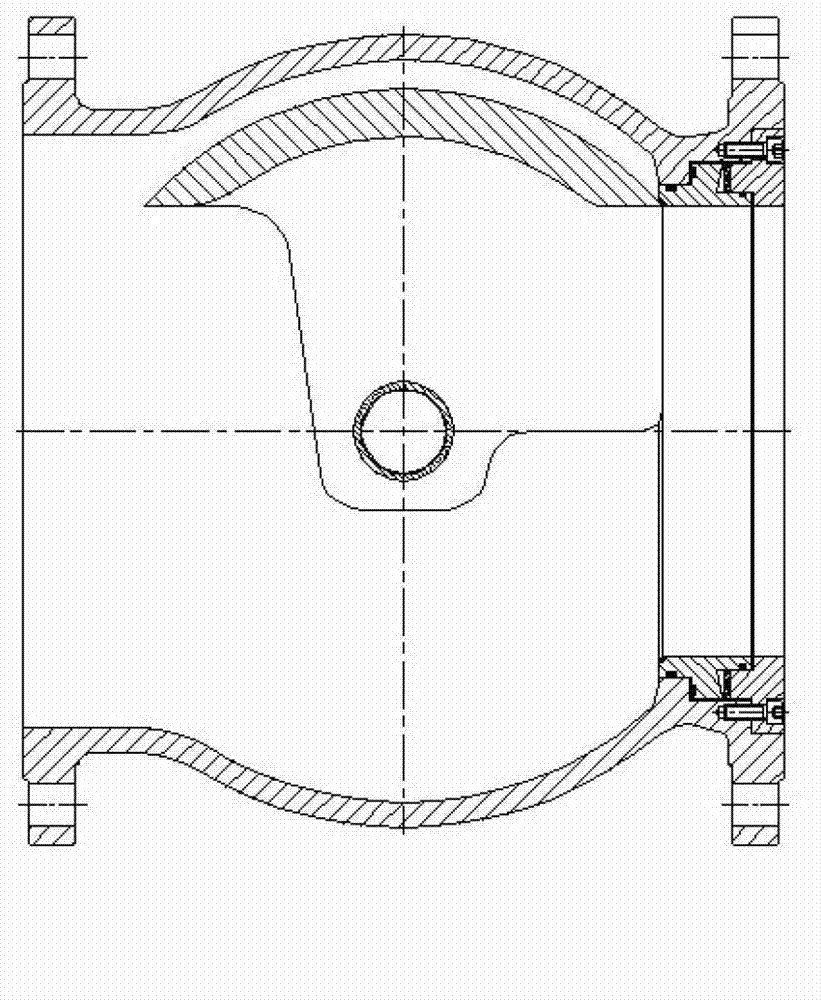

A zone isolating and testing apparatus comprising an isolation tool and a downhole flow control means and a method of using such apparatus. The zone isolating and testing apparatus is particularly useful for testing zones during reverse circulation drilling using concentric drill string such as concentric drill pipe or concentric coiled tubing. The isolation tool of the zone isolating and testing apparatus comprises an expandable packer means and is adapted to connect to concentric drill string near the drilling means and be in fluid communication with the concentric drill string. The downhole flow control means of the zone isolating and testing apparatus comprises at least two valves, one for closing off the annular conduit between the inner tube and outer tube of the concentric drill string and the other for closing off the inner conduit of the inner tube. The downhole flow control means is also adapted to connect to concentric drill string near the drilling means and be in fluid communication with the concentric drill string. During testing, the isolation tool seals off the annular passage between the concentric drill string and the walls of the wellbore and the downhole flow control means seals off either the annular conduit or the inner conduit of the concentric drill string.

Owner:PRESSSOL

Method and apparatus for isolating and testing zones during reverse circulation drilling

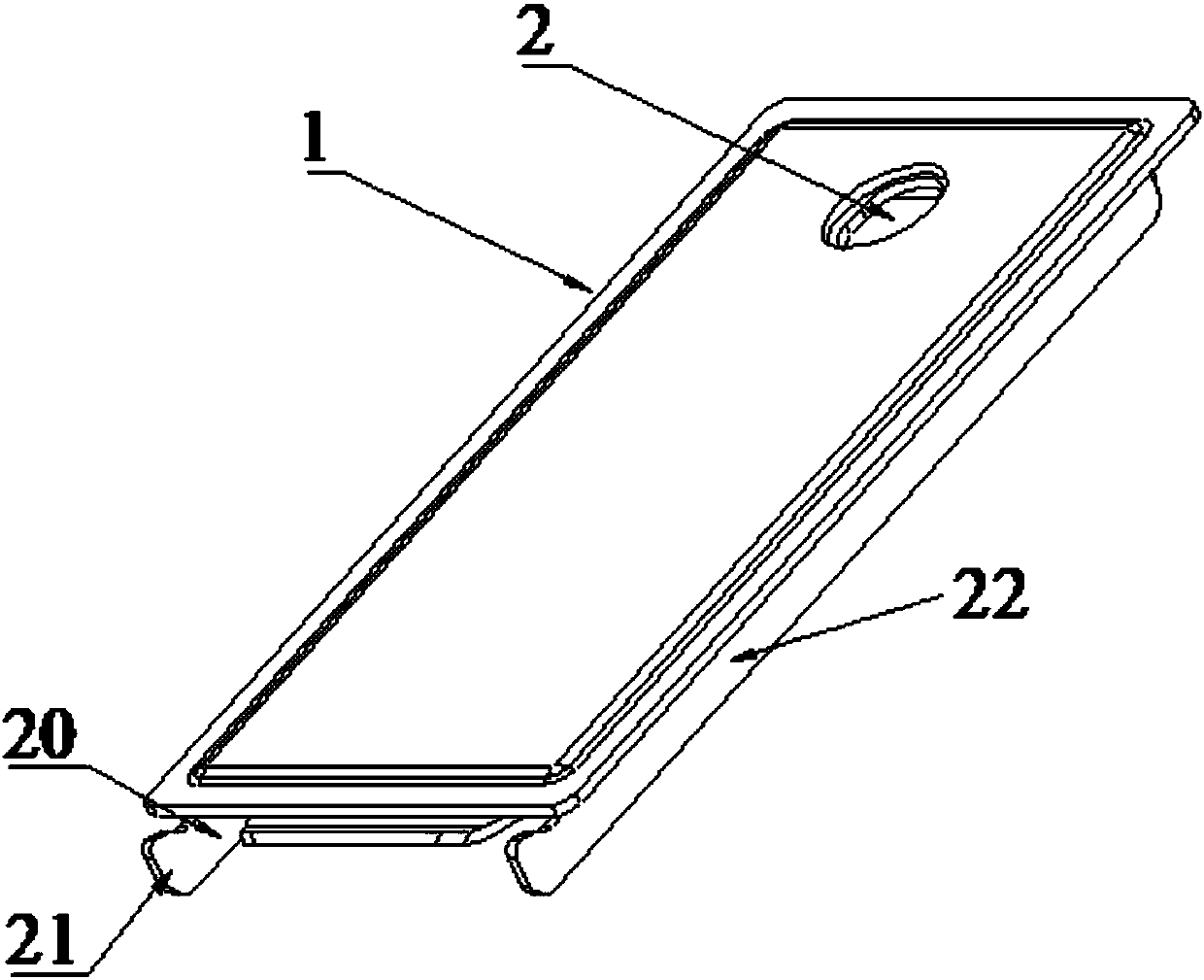

InactiveUS20050178562A1Quick opening and closingEasy to measureSurveyDrilling rodsInterior spaceWell drilling

A zone isolating and testing apparatus comprising an isolation tool and a downhole flow control means and a method of using such apparatus is disclosed. The zone isolating and testing apparatus is particularly useful for testing zones during reverse circulation drilling using concentric drill string such as concentric drill pipe or concentric coiled tubing. The isolation tool of the zone isolating and testing apparatus comprises an expandable packer means and is adapted to connect to concentric drill string near the drilling means. The downhole flow control means of the zone isolating and testing apparatus comprises two valves, one for closing off the annulus between the inner tube and outer tube of the concentric drill string and the other for closing off the inner space of the inner tube. The downhole flow control means is also adapted to connect to concentric drill string near the drilling means. During testing, the isolation tool seals off the annulus between the concentric drill string and the walls of the wellbore and the downhole flow control means seals off either the annulus between the inner tube and outer tube of the concentric drill string or the inner space of the inner tube of the concentric drill string.

Owner:PRESSSOL

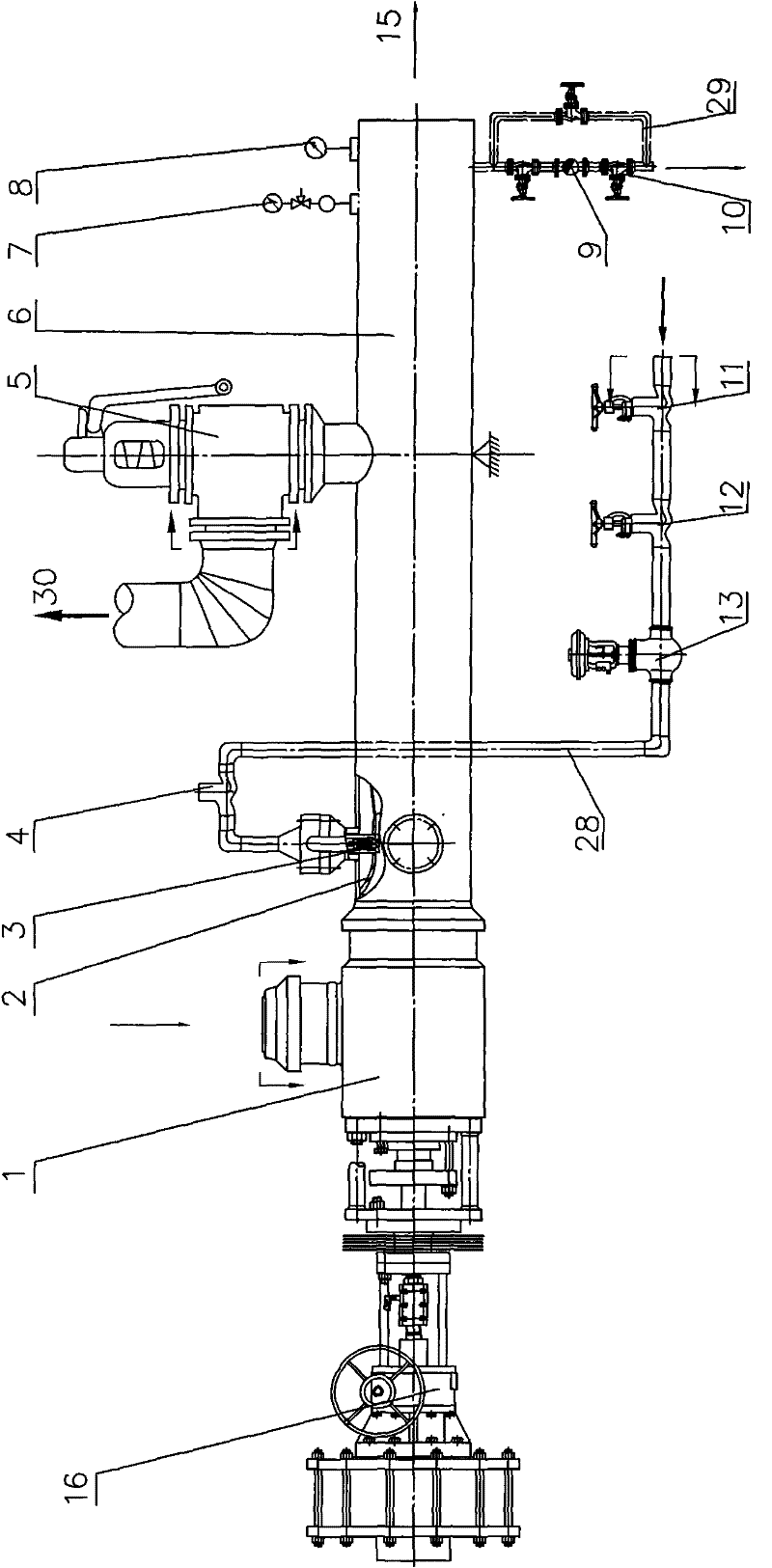

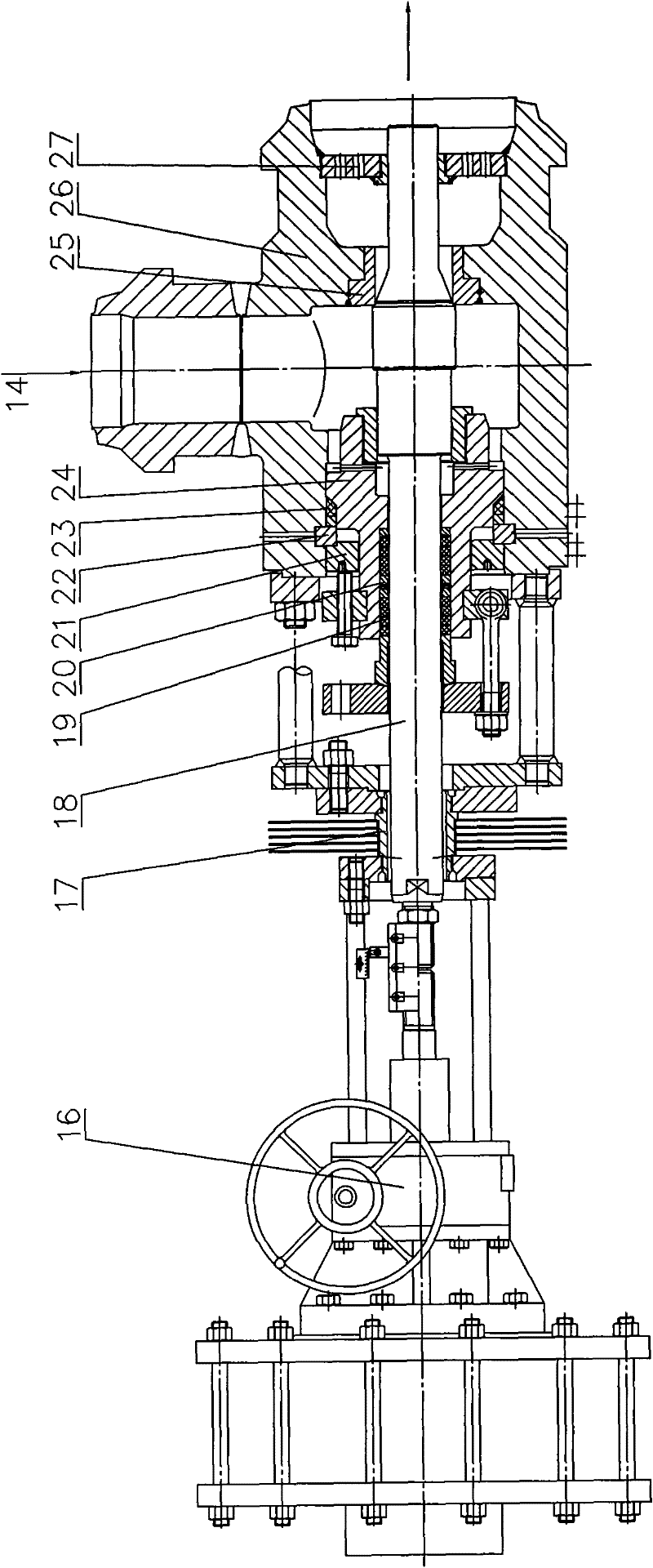

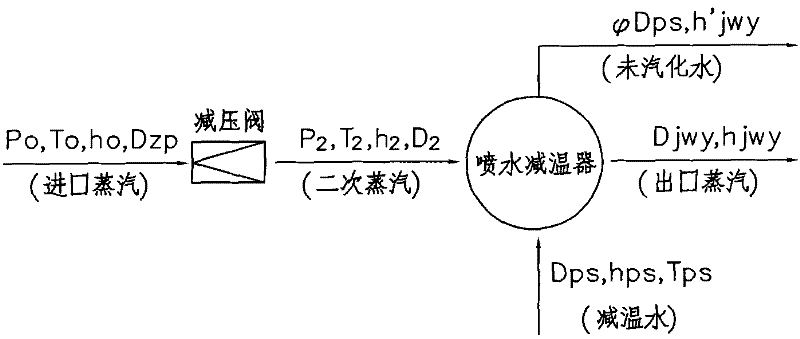

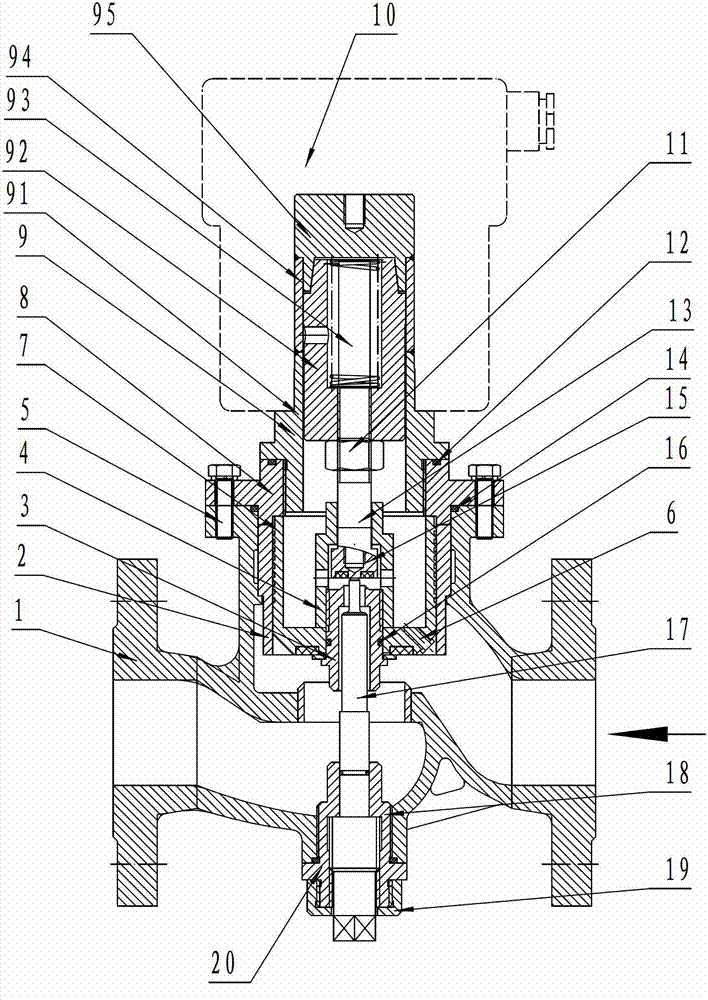

High-temperature high-pressure temperature-reducing pressure-reducing device capable of being started and stopped rapidly

InactiveCN102183006AAvoid alternating stressIncreasing the thicknessValve members for heating/coolingValve members for absorbing fluid energyEngineeringHigh pressure

The invention relates to a high-temperature high-pressure temperature-reducing pressure-reducing device capable of being started and stopped rapidly. The device comprises a pneumatic actuating mechanism, a steam mixing pipeline and a pressure-reducing valve, wherein the steam mixing pipeline is connected with a steam inlet and a steam outlet; the pressure-reducing valve is composed of a valve body, a valve plug, a valve seat and an upper valve cover; and a water-supplying temperature-reducing system, a safety protection system and a dewatering system are arranged on the steam mixing pipeline. The device provided by the invention has the beneficial effects that the device is a steam temperature-reducing pressure-reducing system which is connected in parallel with a steam turbine, can introduce steam generated by the boiler to a steam pipeline or a condenser of the next stage pressure and temperature, the device has the functions of rapid starting and stopping, safe overflowing, safe protection and the like, and is mainly applied to industrial fields, such as a thermal power unit, the coal chemical industry and the coal oil.

Owner:HANGZHOU WORLDWISE VALVE

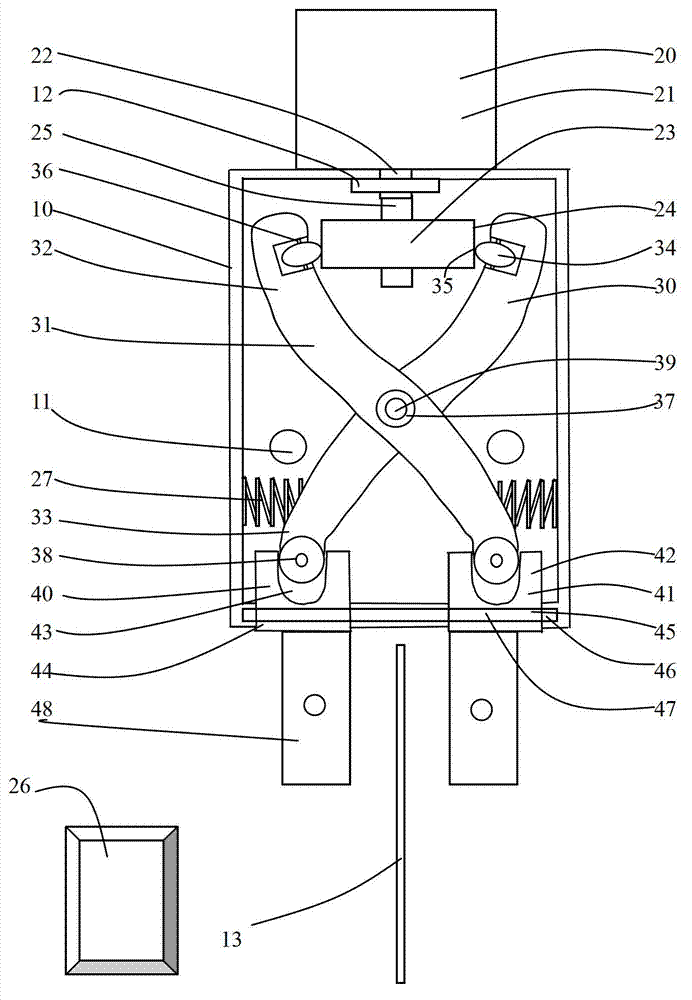

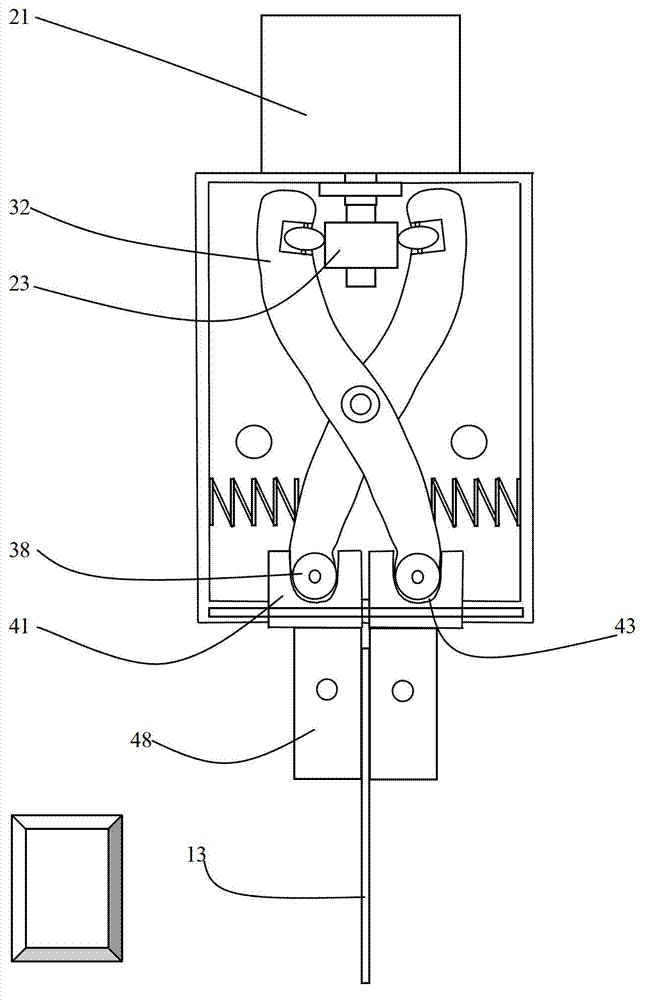

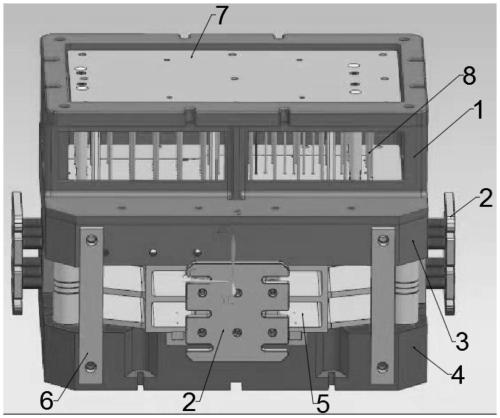

X-shaped electric fixture for cam

The invention discloses an X-shaped electric fixture for a cam, and relates to a mechanical device. An X-shaped transmission mechanism is formed by two transmission pieces which are crossed in the middle part and only can rotate at a cross point, the cam is clamped in the middle of the upper ends of the transmission pieces, the outer ends of opening and closing parts are arranged outside a shell, clamping jaws are fixedly arranged on the outer ends of the opening and closing parts, two transmission points of transmission chains are respectively in two driven recesses, and when the distance between the two transmission points is changed, the two opening and closing parts are also changed, the two clamping jaws fixedly arranged on the opening and closing parts are also opened and closed along with the change of an included angle, a rotating motor capable of controlling a rotating angle is used for driving the cam with a designed shape to rotate so as to enable the clamping jaws to open and close according to needs, the shapes and the positions of the cam, the upper ends of the transmission pieces and the lower ends of the transmission pieces are set and adjusted, and the electric fixture meeting different requirements can be manufactured. The X-shaped electric fixture for the cam can be used for mechanical automation.

Owner:SHANGHAI HONGQU ELECTRONICS TECH

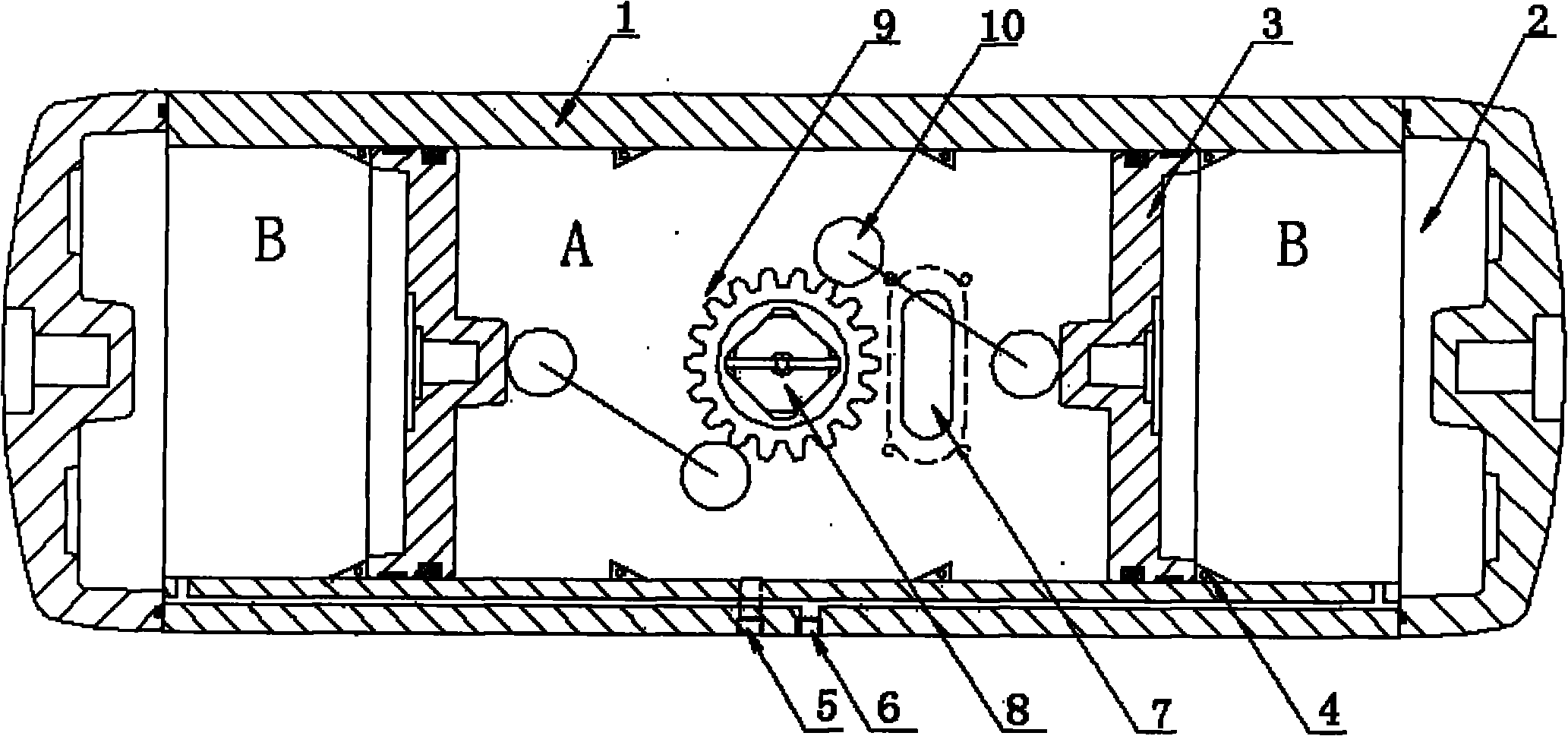

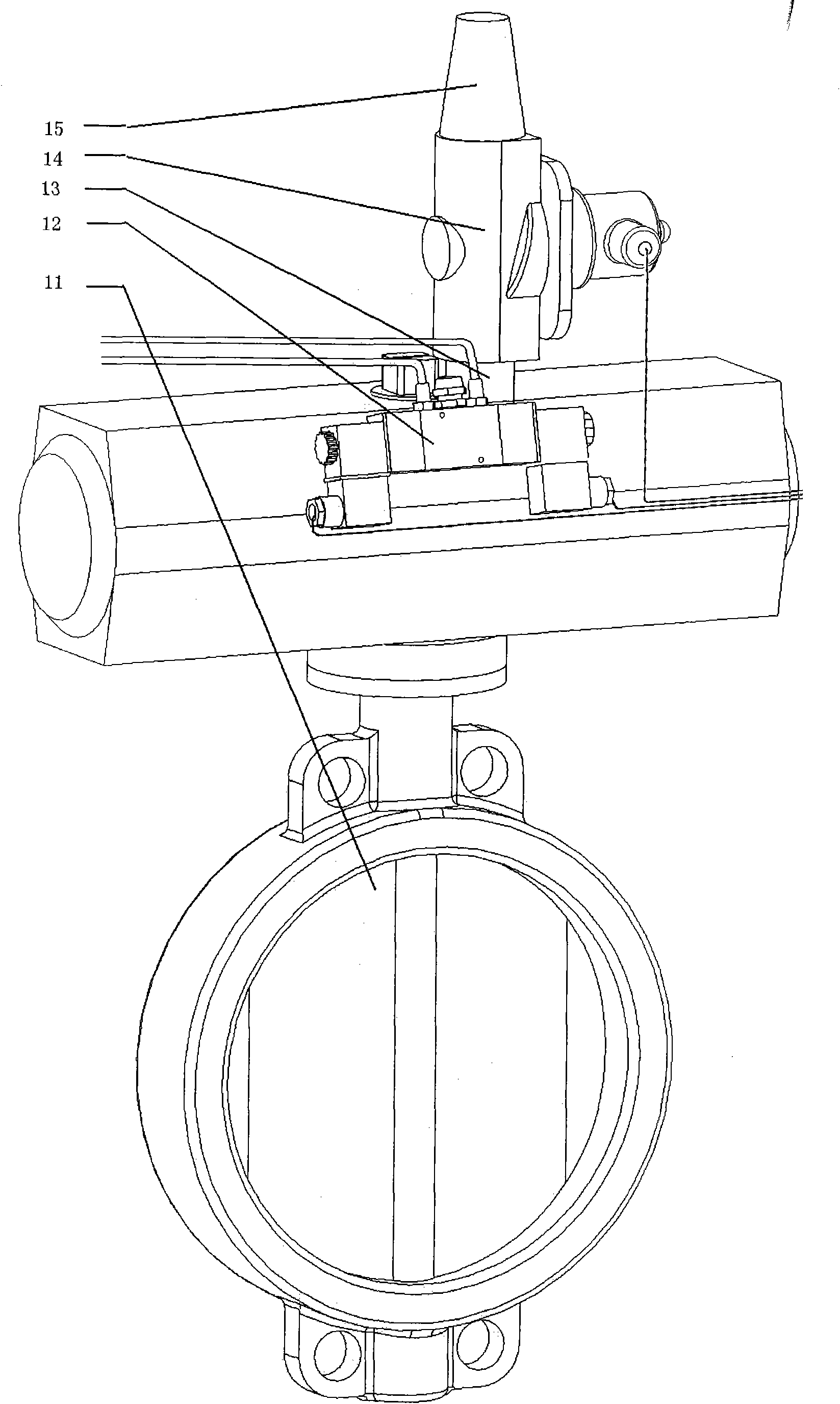

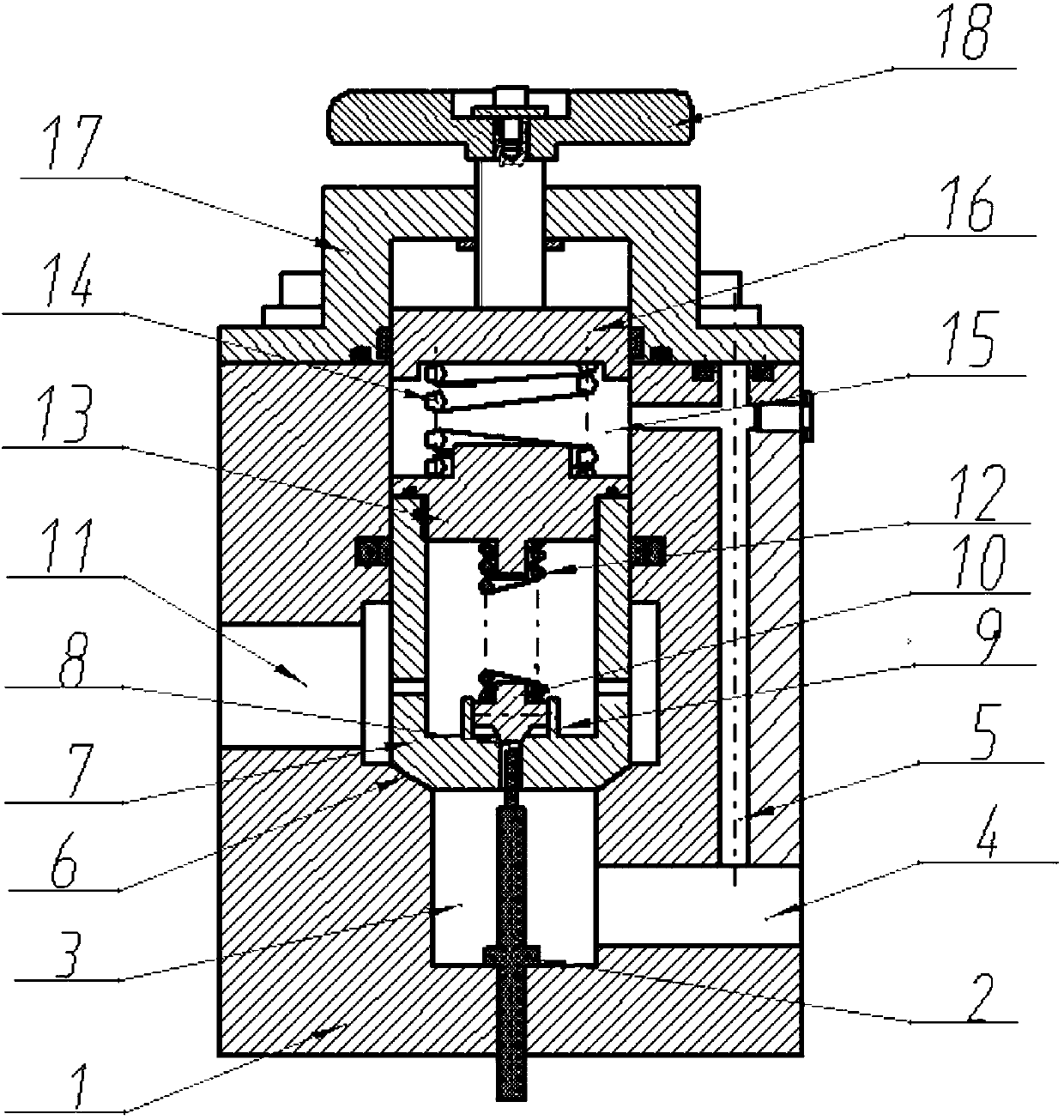

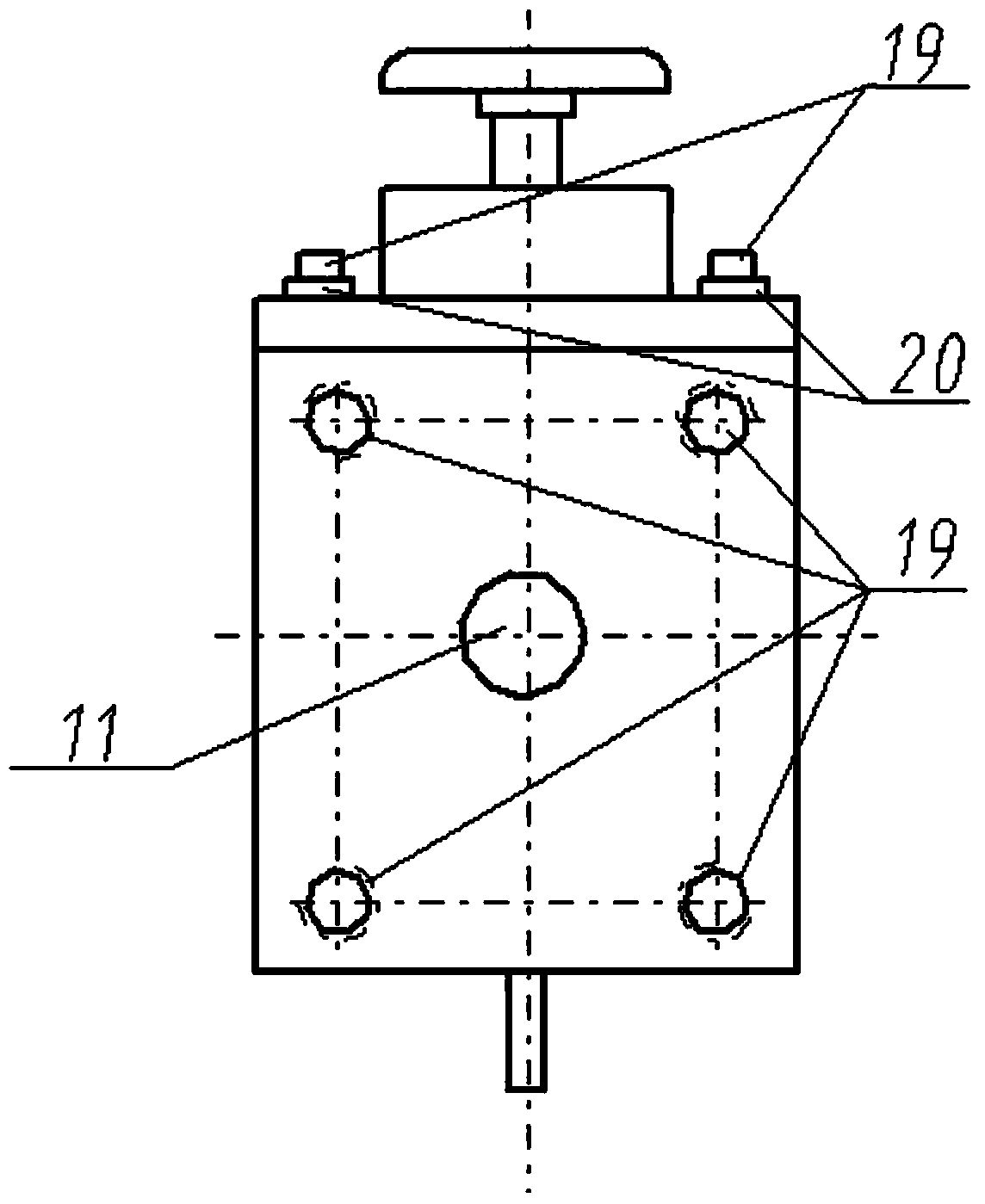

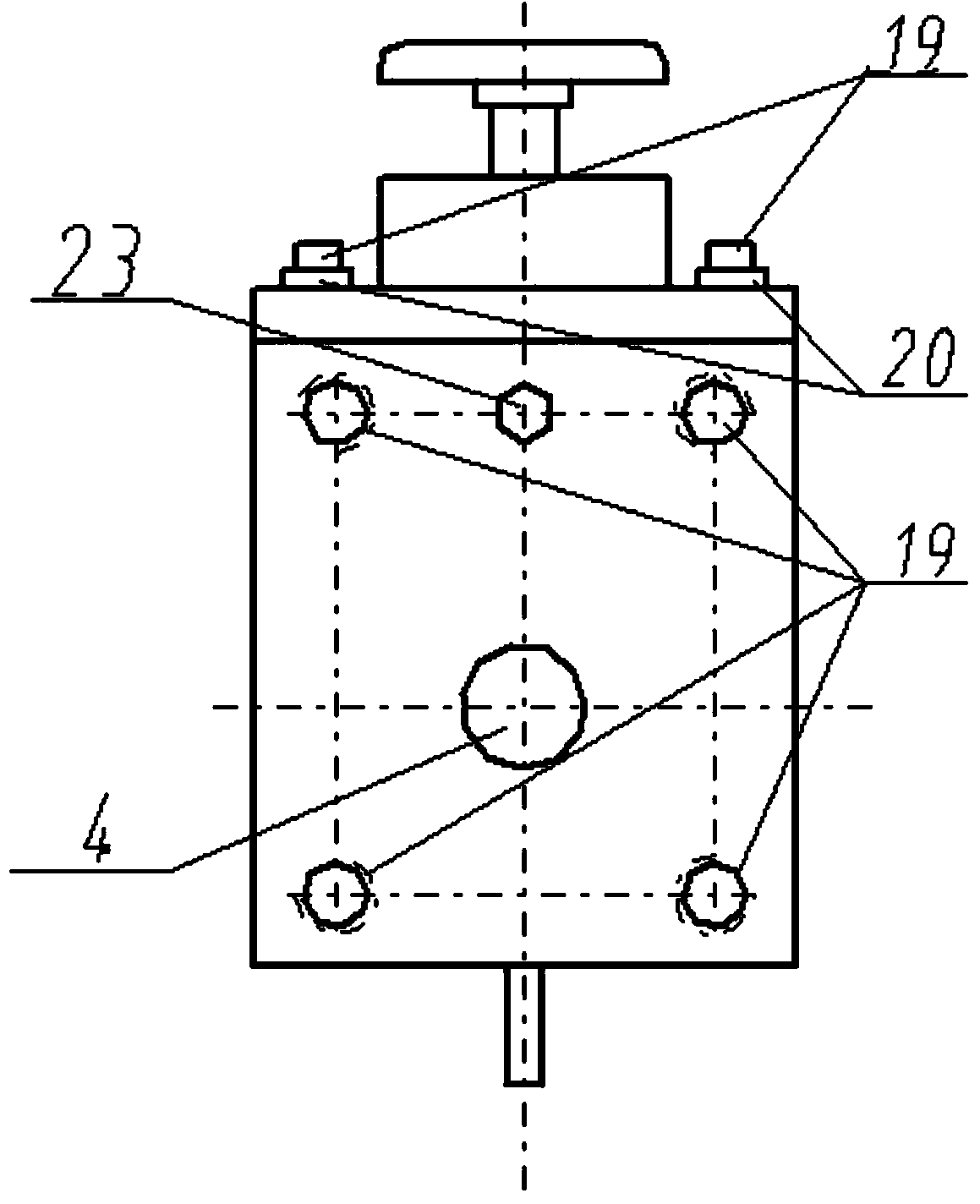

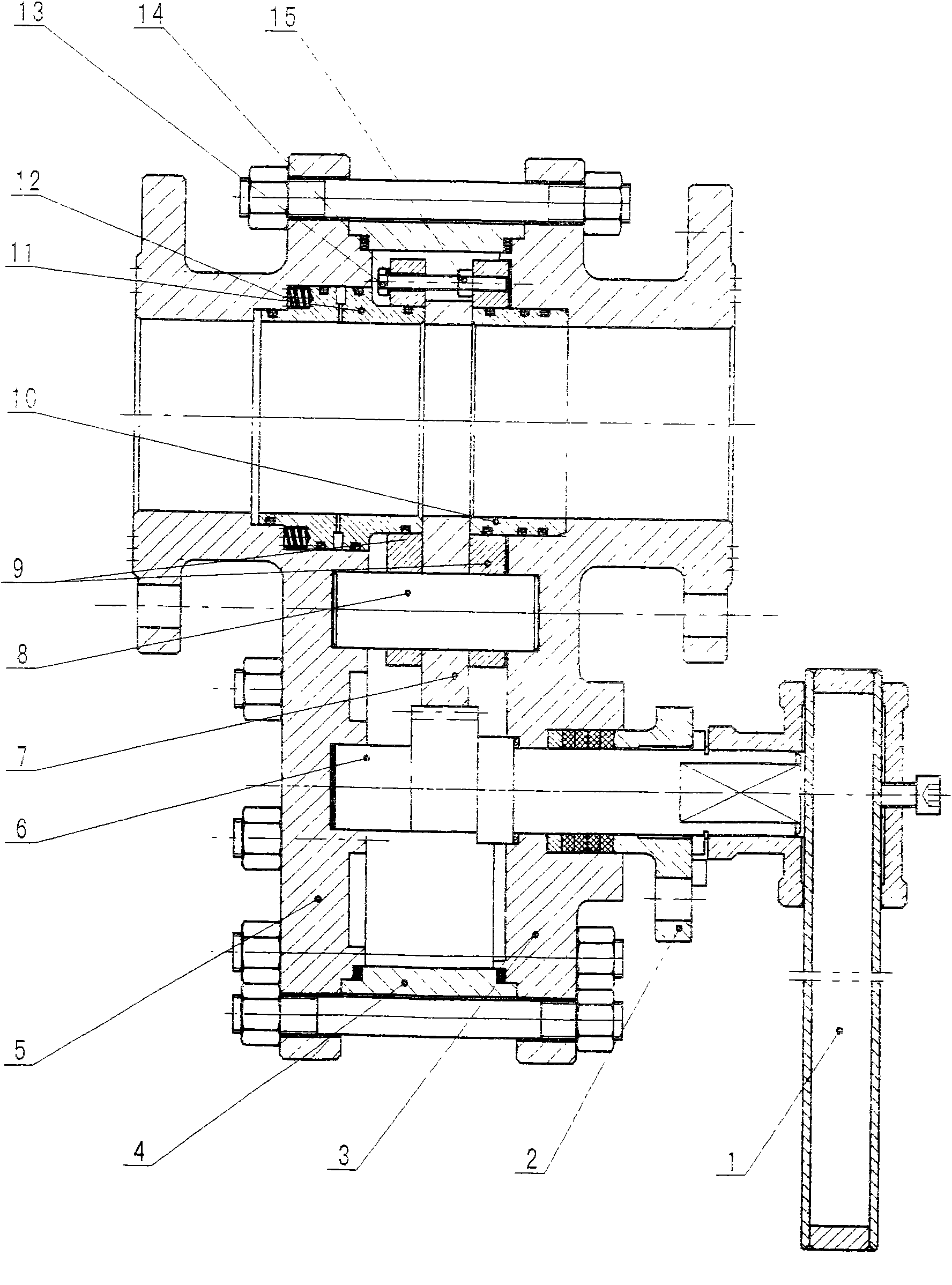

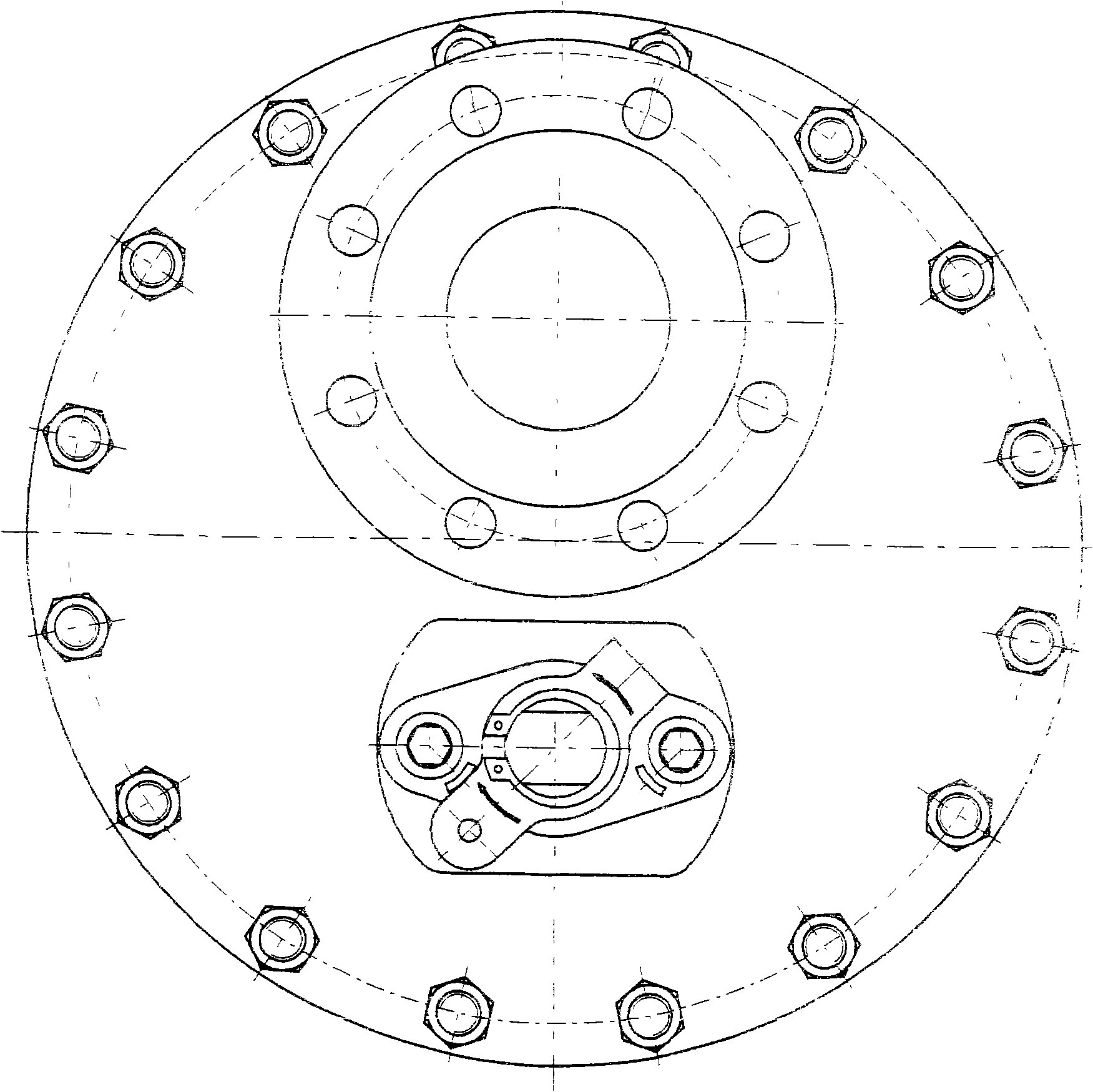

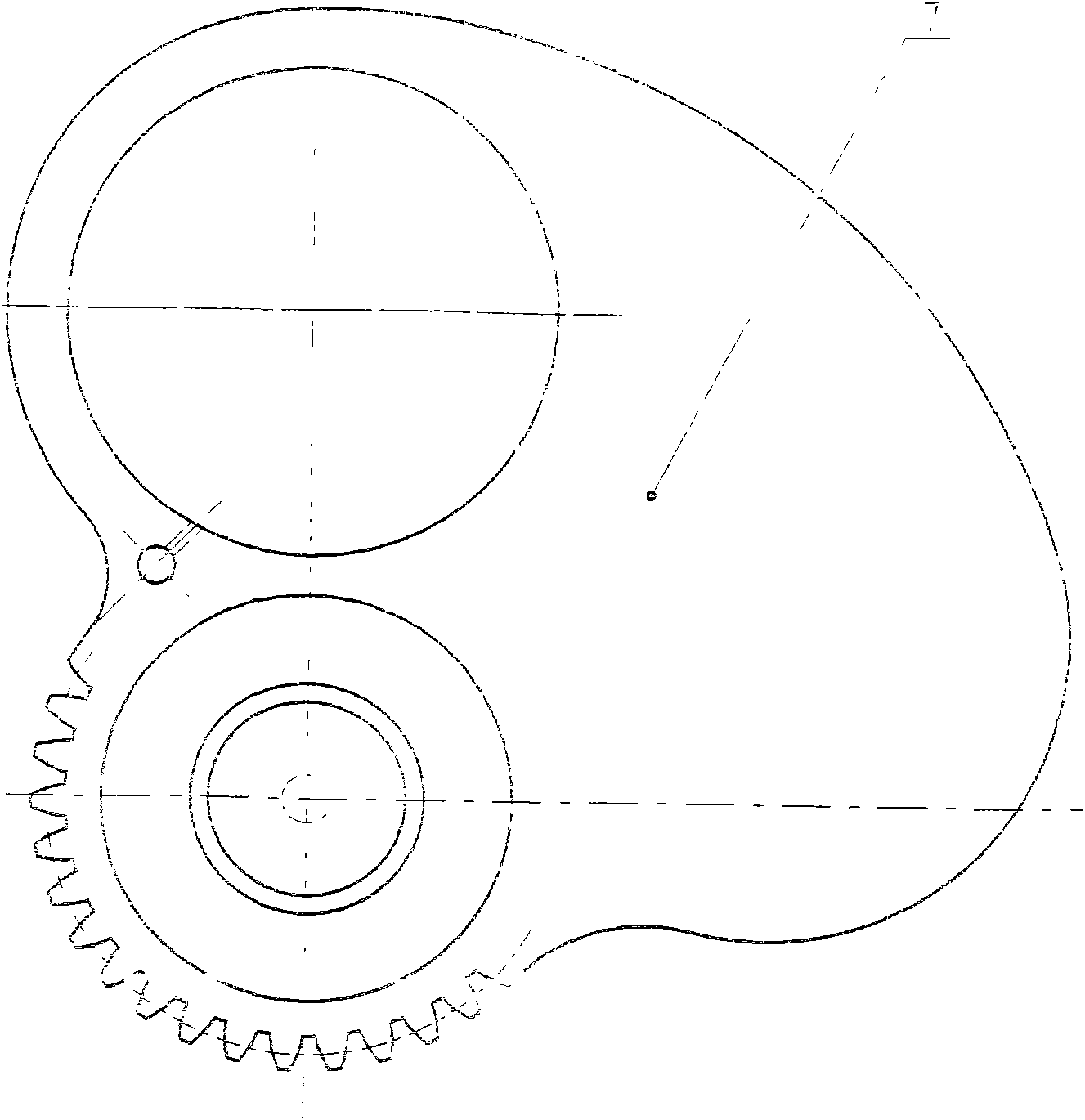

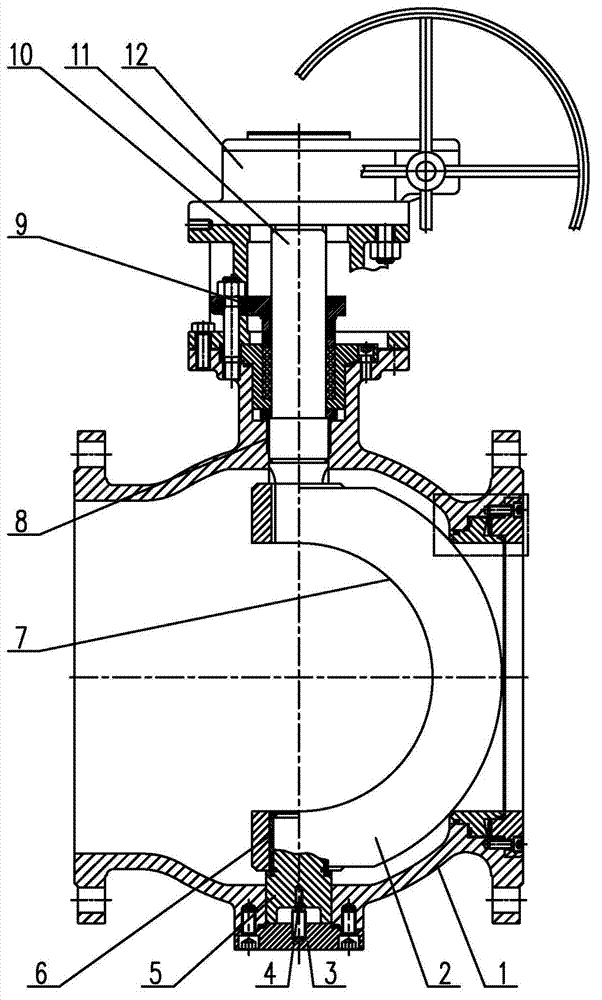

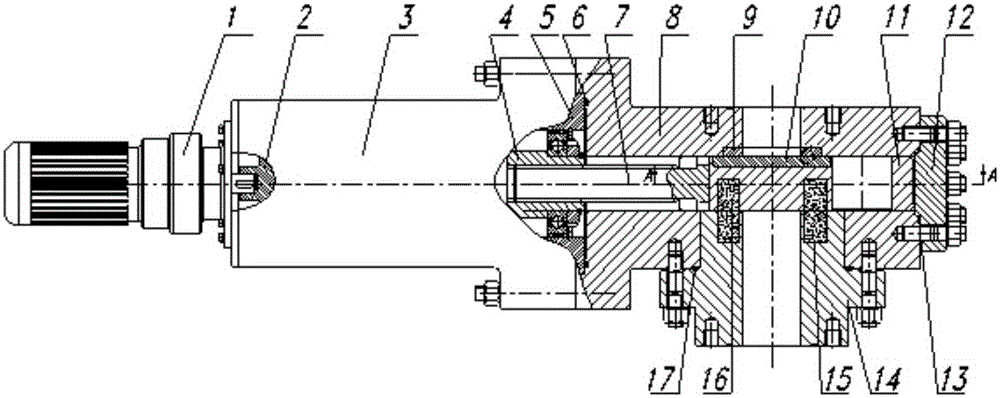

Pneumatic executor for driving valve

InactiveCN101858458AFast actionQuick connectionOperating means/releasing devices for valvesCylindersEngineeringButterfly valve

The invention relates to a pneumatic executor for driving a valve, which comprises a cylinder body, a piston arranged in the cylinder body, a limit mechanism of the piston, end covers arranged at two ends of the cylinder body, a transmission mechanism for connecting the piston and an executor shaft driven by the transmission mechanism, wherein the cylinder body is separated into an inner cavity and an outer cavity by the piston, and the inner cavity and the outer cavity are connected with an air source control valve through an air passage. The pneumatic executor is characterized in that the wall of the inner cavity is provided with a vent hole communicated with the atmosphere, a gap is reserved between the hole position of the inner cavity and the limit position of the piston stroke, the area of the hole is not less than 50 percent of the area of the piston, preferably over 1 percent of the area of the piston, and a control valve is arranged outside the vent hole. The opening-closing of the vent hole control valve and linked control of air connection and disconnection of the inner and outer cavities can realize quick communication among the inner and outer cavities, the air source and the atmosphere so as to quickly open and close a butterfly valve and a ball valve according to a set motion order. The pneumatic executor can be widely applied to a driving process of various valves with large calibers of over 200 millimeters.

Owner:TSINGHUA UNIV

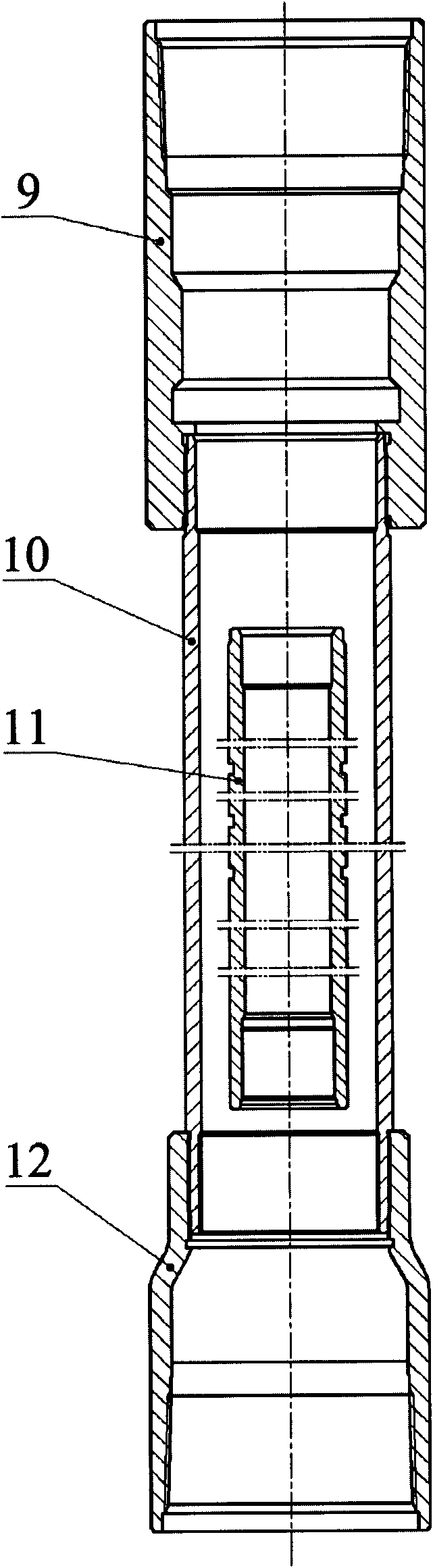

Long plunger type double barrel anti-coal powder drainage pump

InactiveCN102287358AAvoid swingingAvoid depositionPositive displacement pump componentsFlexible member pumpsCouplingInlet valve

The invention provides a long-plunger type dual-barrel coal-dust resistant discharging and extracting pump capable of preventing eccentric wear and coal dust from burying pump, blocking pump and prolonging the pump detection period. The pump consists of a centering body, a pump barrel assembly, a piston assembly, a liquid outlet valve and a liquid inlet valve assembly; a centering locking claw is inserted in a lock sleeve of an upper coupling to realize positioning and sealing of the centering body and avoiding eccentric wear between the plunger and the pump barrel; an internal barrel can prevent the deposited coal dust in the annulus of a bar pipe from entering the gap between the plunger and the pump barrel; the coal dust is dropped back to a tail pipe through the annual cavity between the external barrel and the pump barrel to prevent the coal dust from burying the pump; the structure of the long-plunger short pump barrel can promptly discharge the coal dust in the gap between the plunger and the pump barrel, so as to protect the internal and external working surfaces of the pump barrel and preventing the pump from being blocked; the well liquid stored in the coal-dust resistant tank washes the coal dust in the liquid outlet valve cover and the coal dust deposited at the upper part of the liquid outlet valve through a jet orifice, so as to realize an automatic washing function of the liquid outlet valve and preventing the coal dust from jamming the pump; and a spring is cooperated with a liquid inlet valve ball positioning pin, so that the liquid inlet valve ball can be fast reset, and the pump valve under a low submergence can be realized in smooth on and off.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method and apparatus for isolating and testing zones during reverse circulation drilling

ActiveUS20050224228A1Quick opening and closingEasy to measureSurveyDrilling rodsWell drillingCoiled tubing

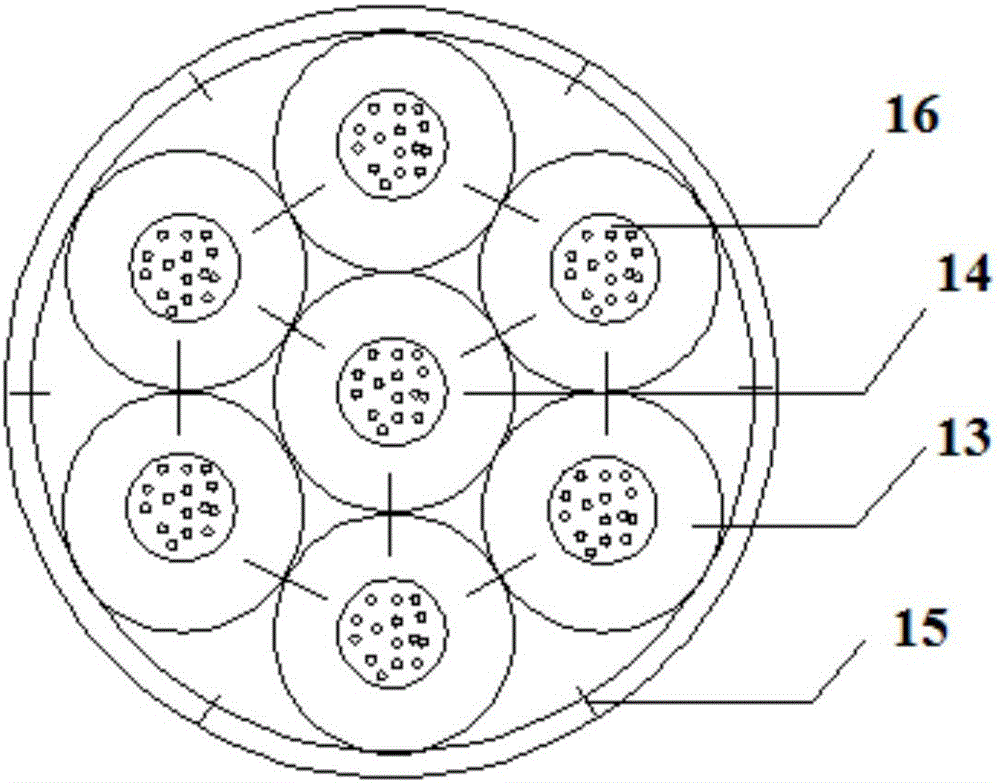

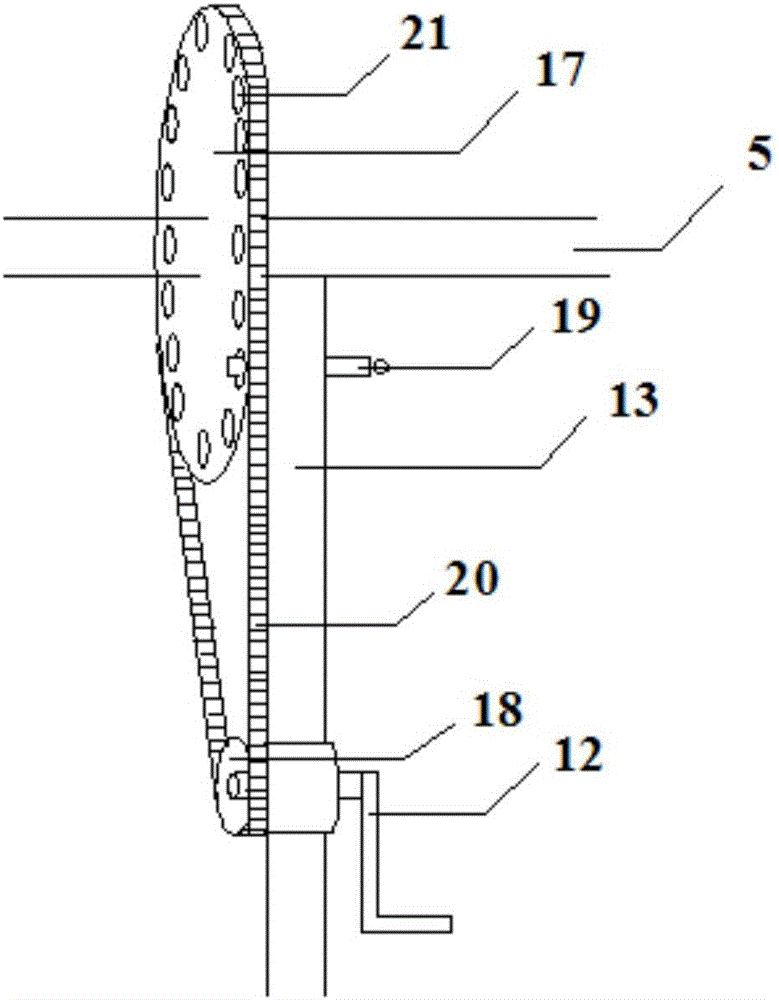

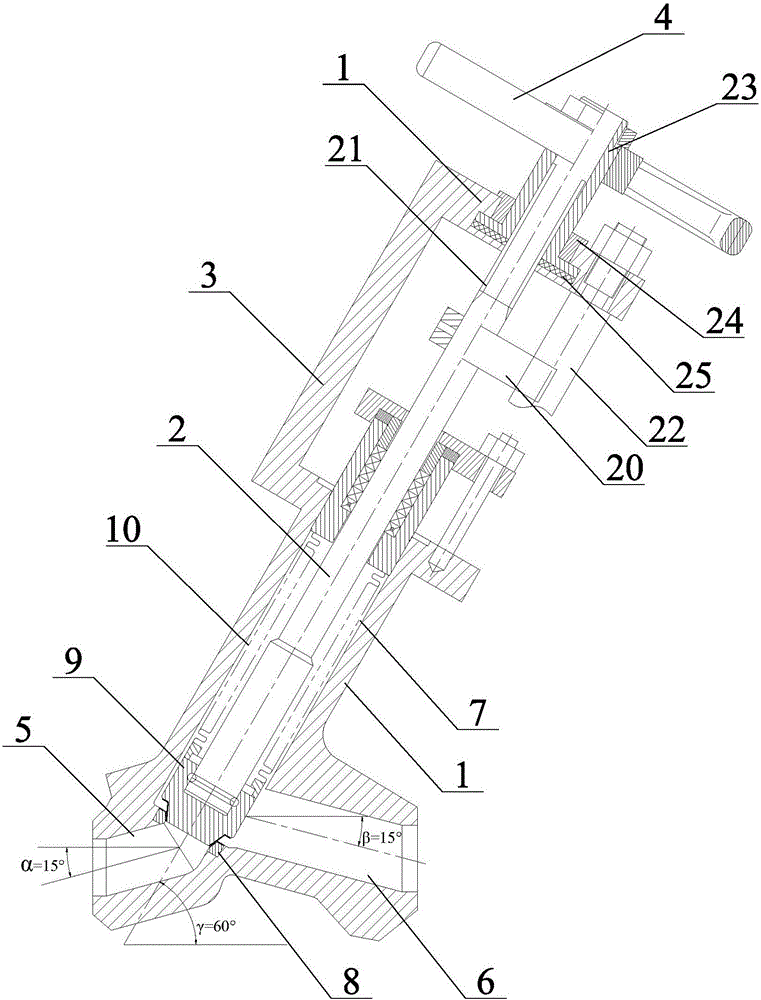

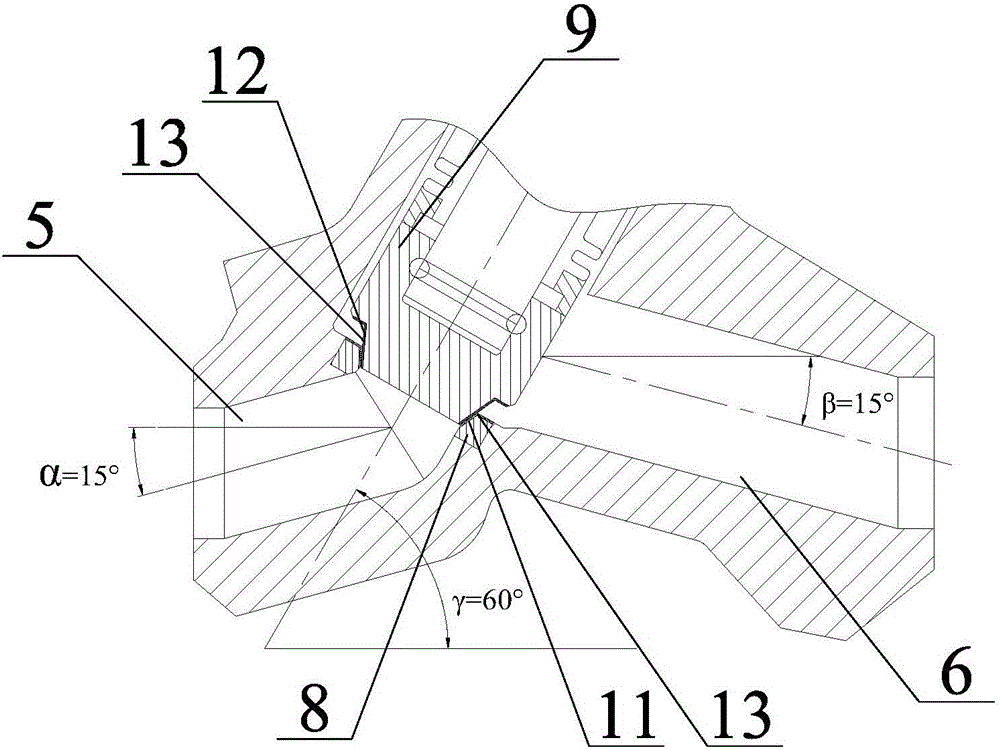

A zone isolating and testing apparatus comprising an isolation tool and a downhole flow control means and a method of using such apparatus is disclosed. The zone isolating and testing apparatus is particularly useful for testing zones during reverse circulation drilling using concentric drill string such as concentric drill pipe or concentric coiled tubing. The isolation tool of the zone isolating and testing apparatus comprises an expandable packer means and is adapted to connect to concentric drill string near the drilling means and be in fluid communication with the concentric drill string. The downhole flow control means of the zone isolating and testing apparatus comprises at least two valves, one for closing off the annular conduit between the inner tube and outer tube of the concentric drill string and the other for closing off the inner conduit of the inner tube. The downhole flow control means is also adapted to connect to concentric drill string near the drilling means and be in fluid communication with the concentric drill string. During testing, the isolation tool seals off the annular passage between the concentric drill string and the walls of the wellbore and the downhole flow control means seals off either the annular conduit or the inner conduit of the concentric drill string.

Owner:PRESSSOL

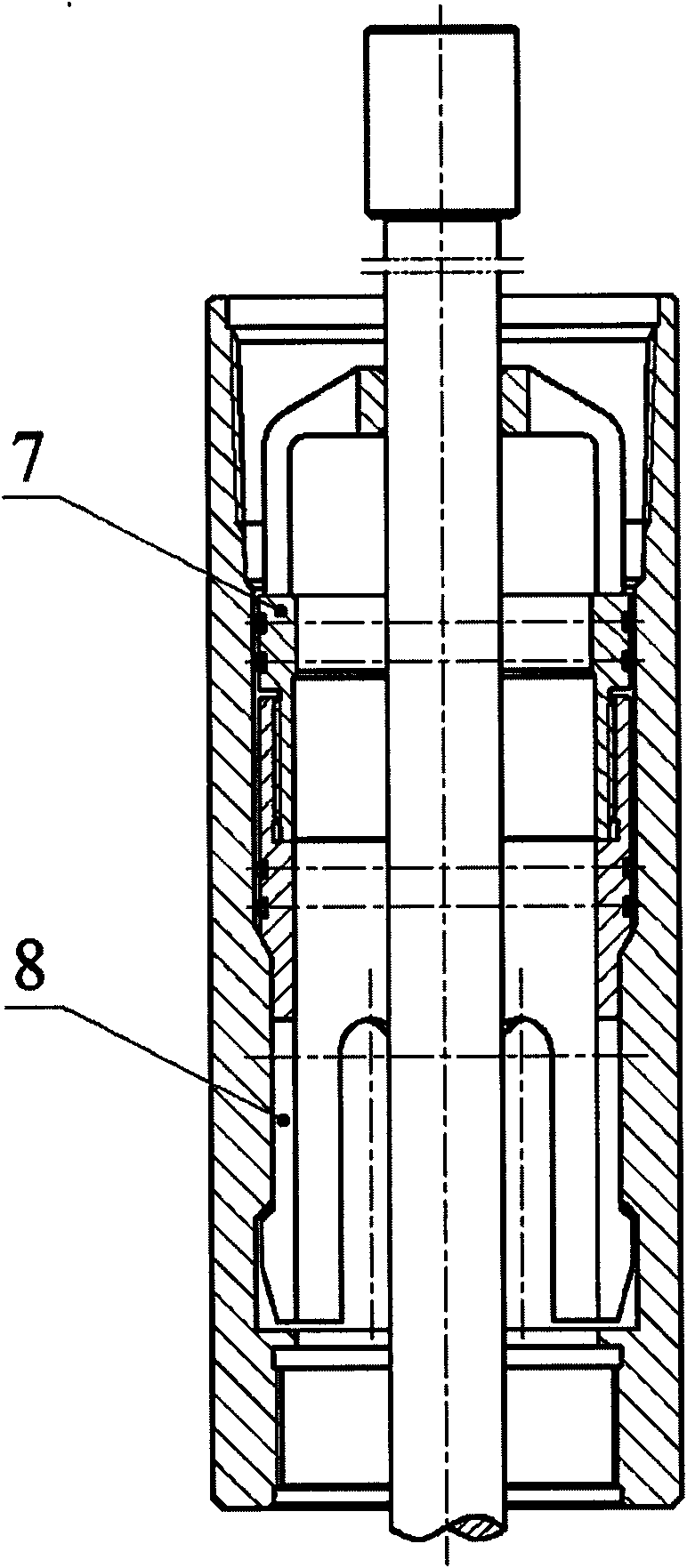

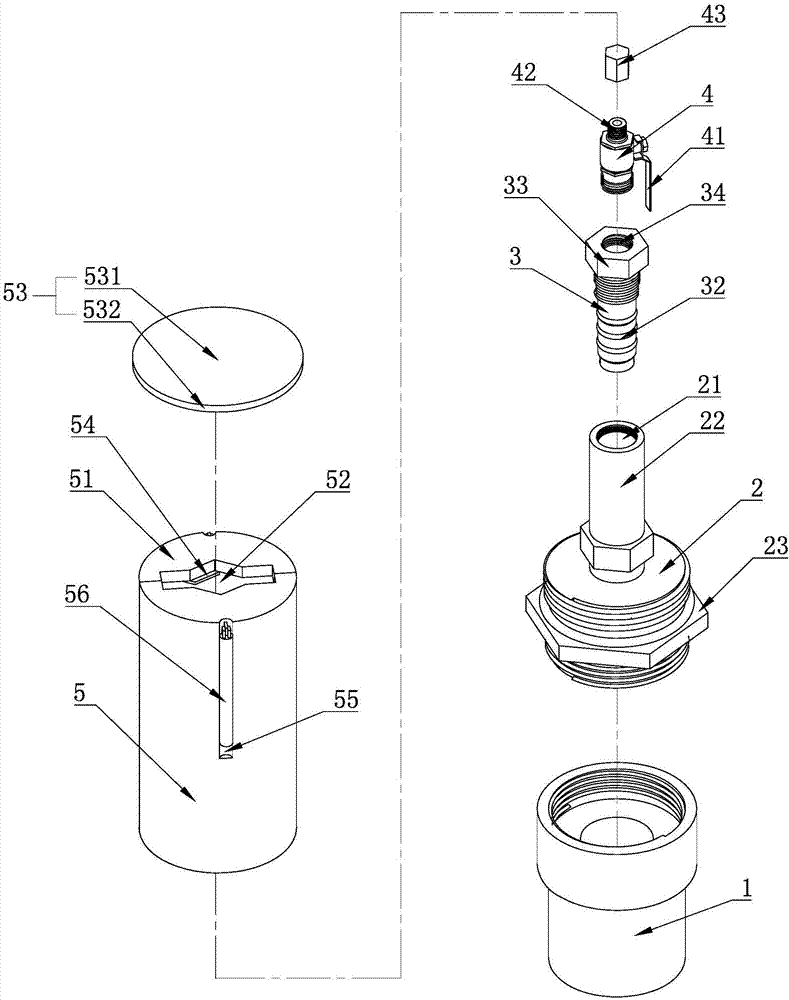

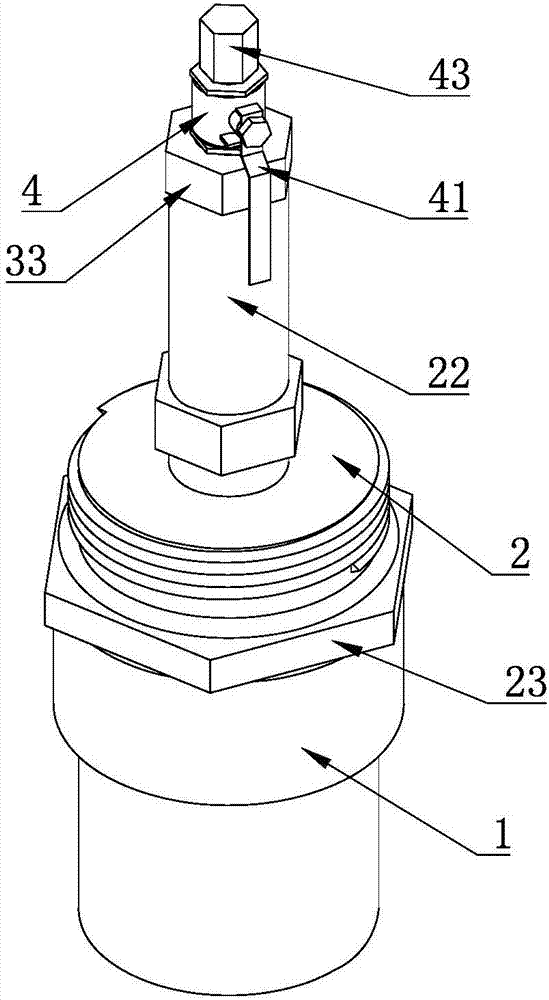

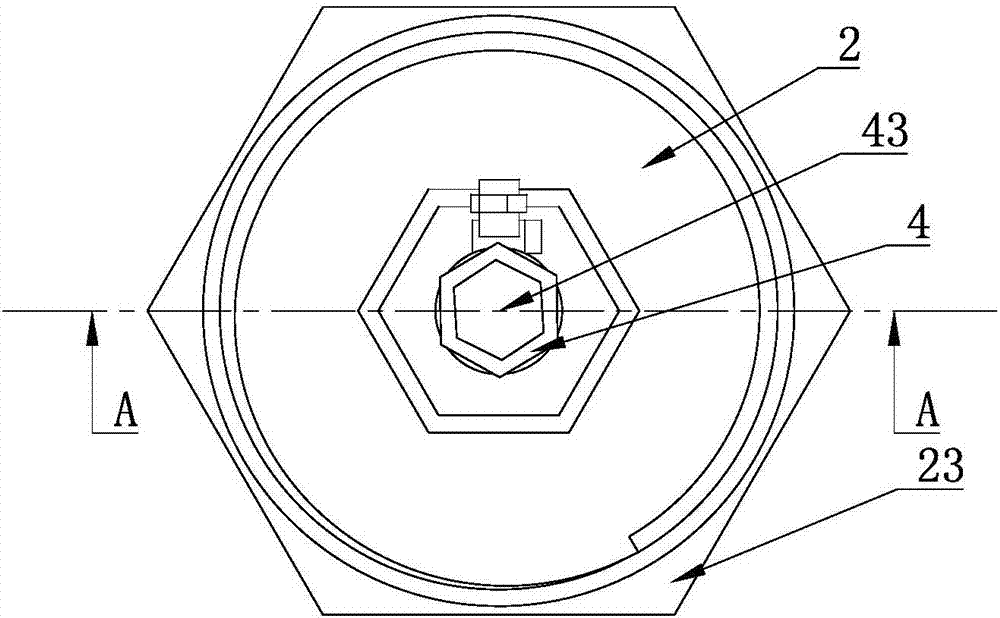

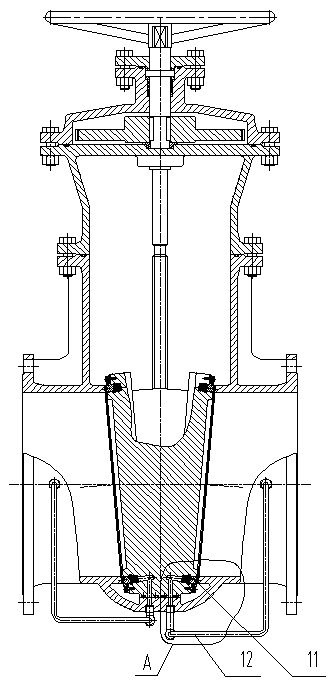

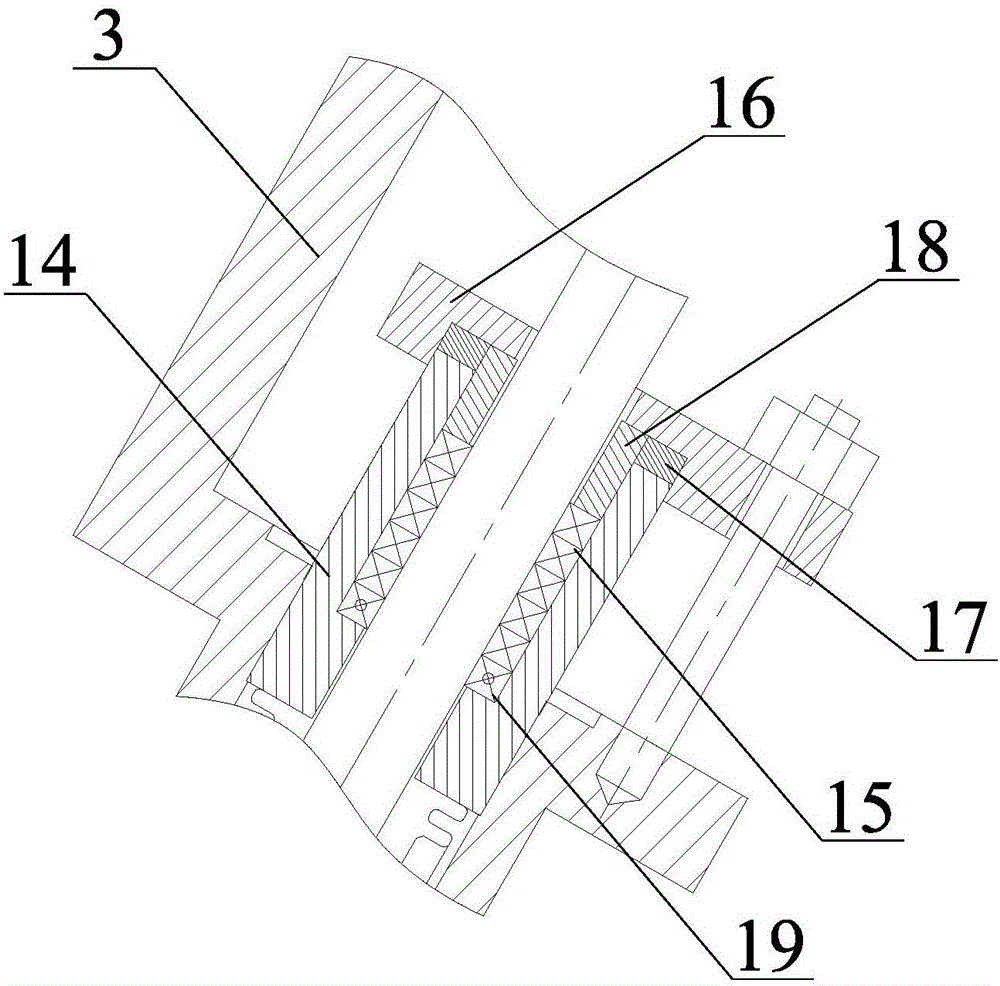

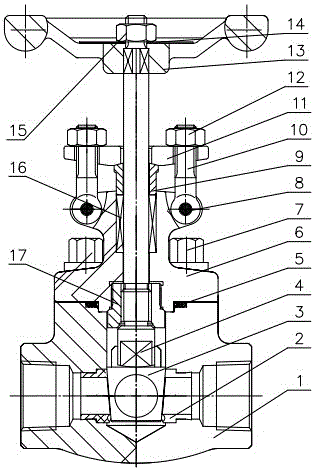

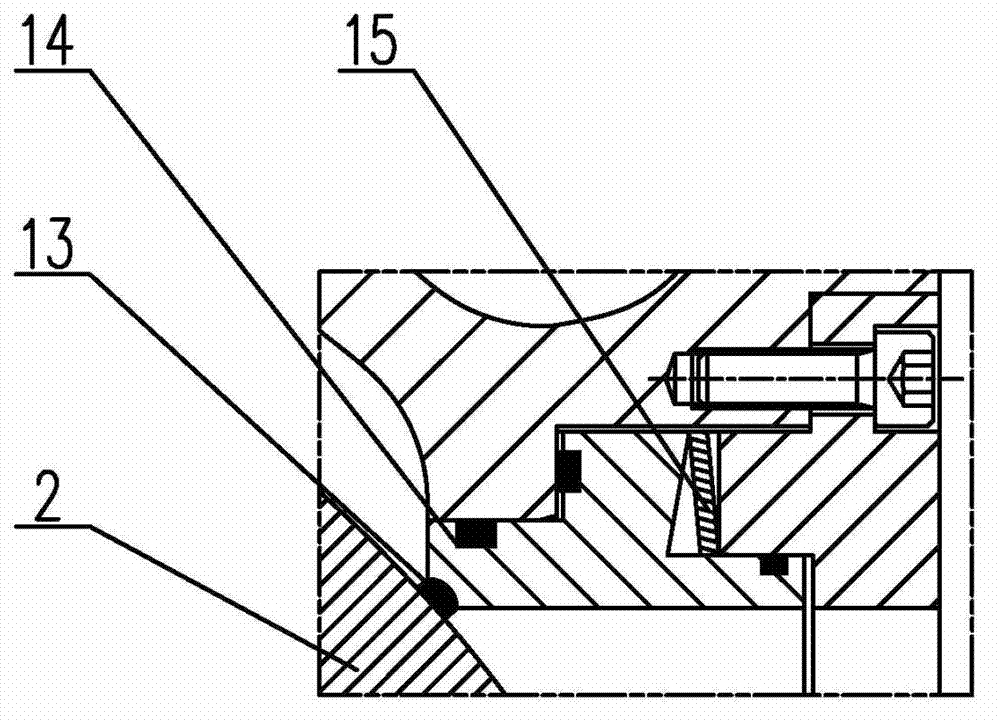

Portable and quick-open type high-pressure stop valve

The invention relates to a portable and quick-open type high-pressure stop valve and belongs to key hydraulic components for opening and closing of high-pressure hydraulic pipelines. The portable and quick-open type high-pressure stop valve comprises a valve body, a valve spool push bar, a main valve spool, an auxiliary valve spool, an auxiliary valve spool spring, a main valve spool gland, a main valve spool spring, a valve spool pressure bar, a bonnet and an adjusting hand wheel. The main valve spool is disposed in the cavity of the valve body, the main valve spool grand is fixedly connected to the top of the main valve spool, four throughflow holes are evenly formed along the circumferential direction in the side wall of the main valve spool, and a water inlet in the valve body and the cavity inside the main valve spool are communicated through the throughflow holes. A tapered auxiliary valve port is formed in the bottom of the main valve spool, and the valve spoon push bar is of a stepped shaft structure with thin top and thick bottom and sequentially penetrates the valve body and the auxiliary valve port to push the auxiliary valve spool to move axially. A fluid flow channel is arranged in the position of the water outlet of the valve body so that the water outlet is communicated with the cavities formed by the main valve spool grand, the valve spool pressure bar and the valve body. The auxiliary valve spool spring is connected between the main valve spool grand and the auxiliary valve spool. The main valve spool spring is connected between the main valve spool grand and the valve spool pressure bar.

Owner:BEIJING UNIV OF TECH

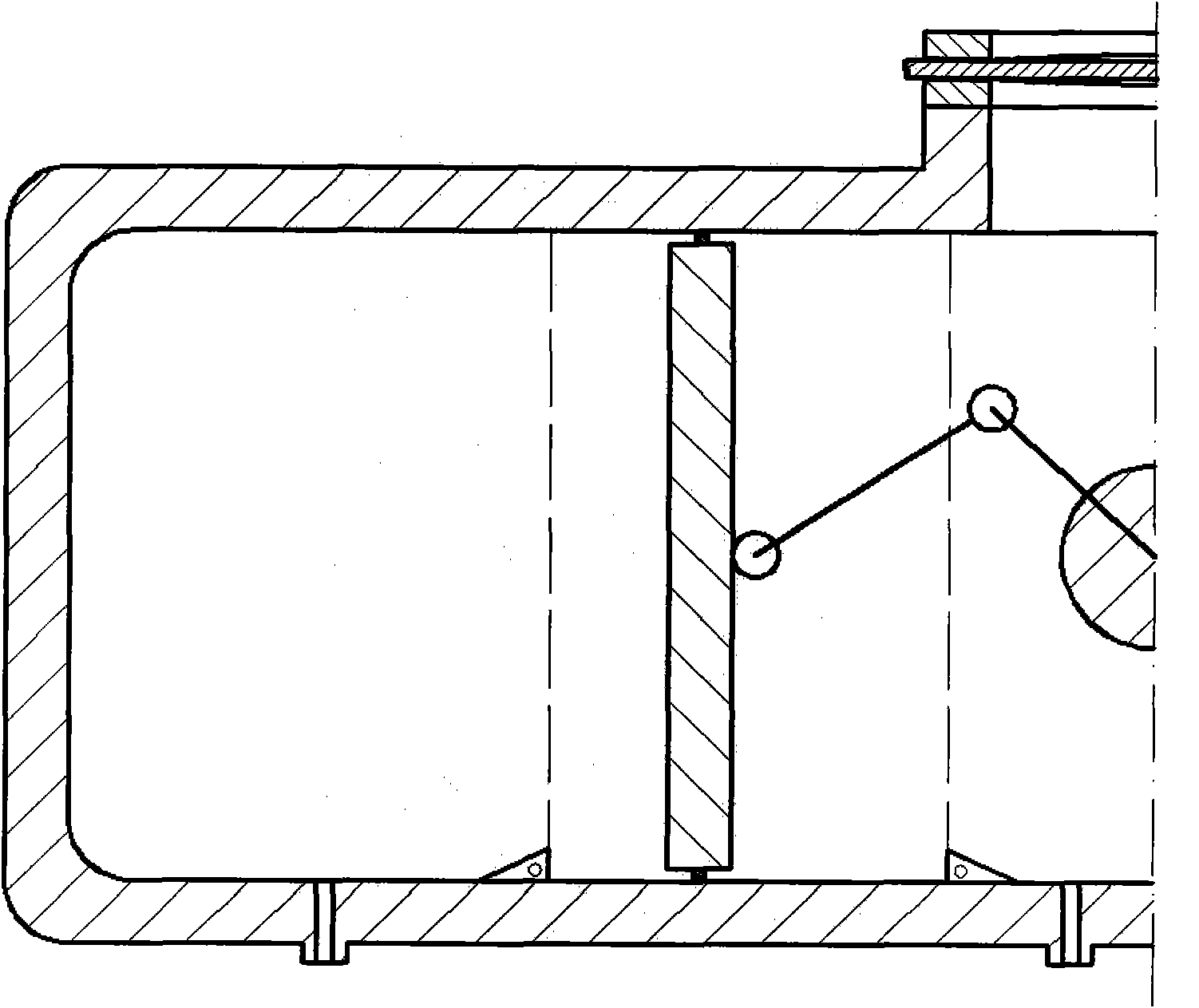

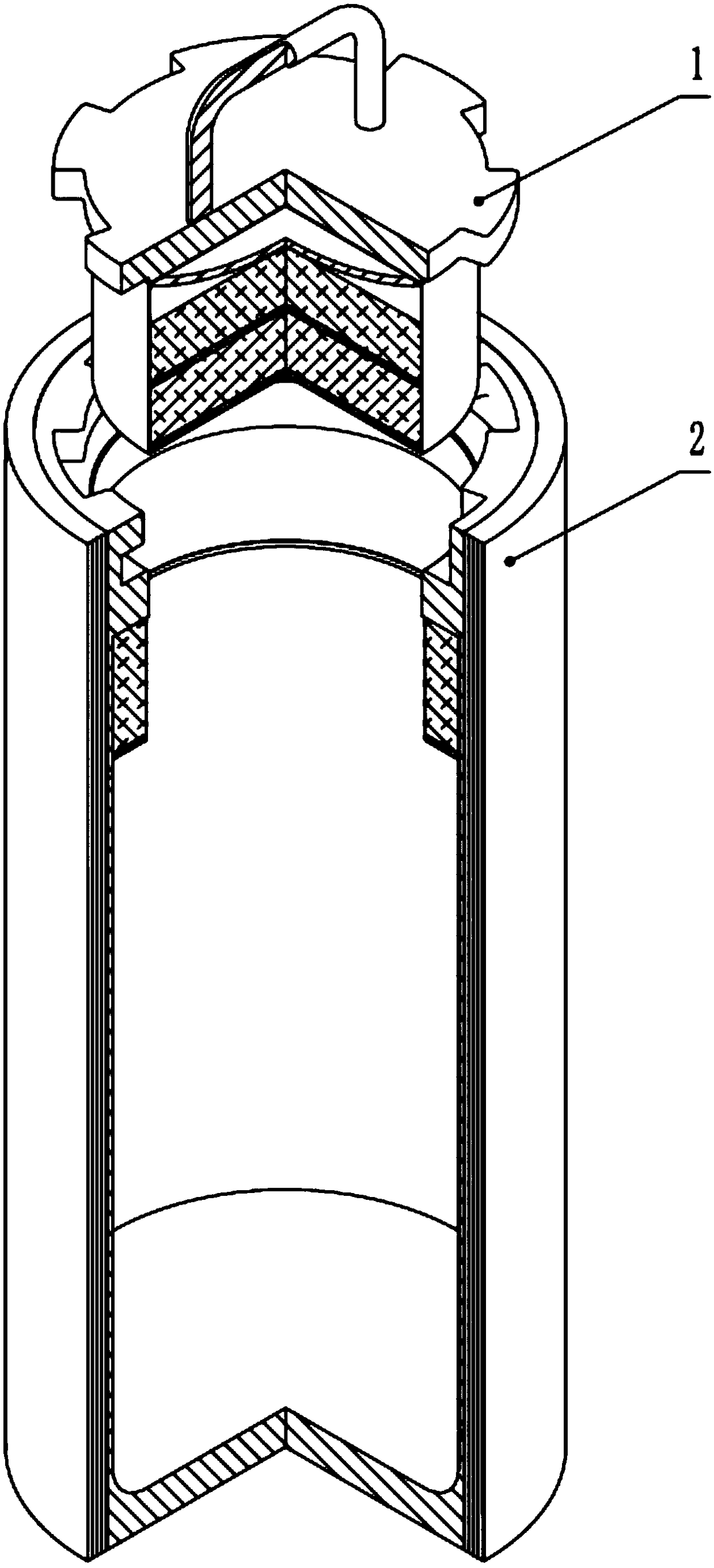

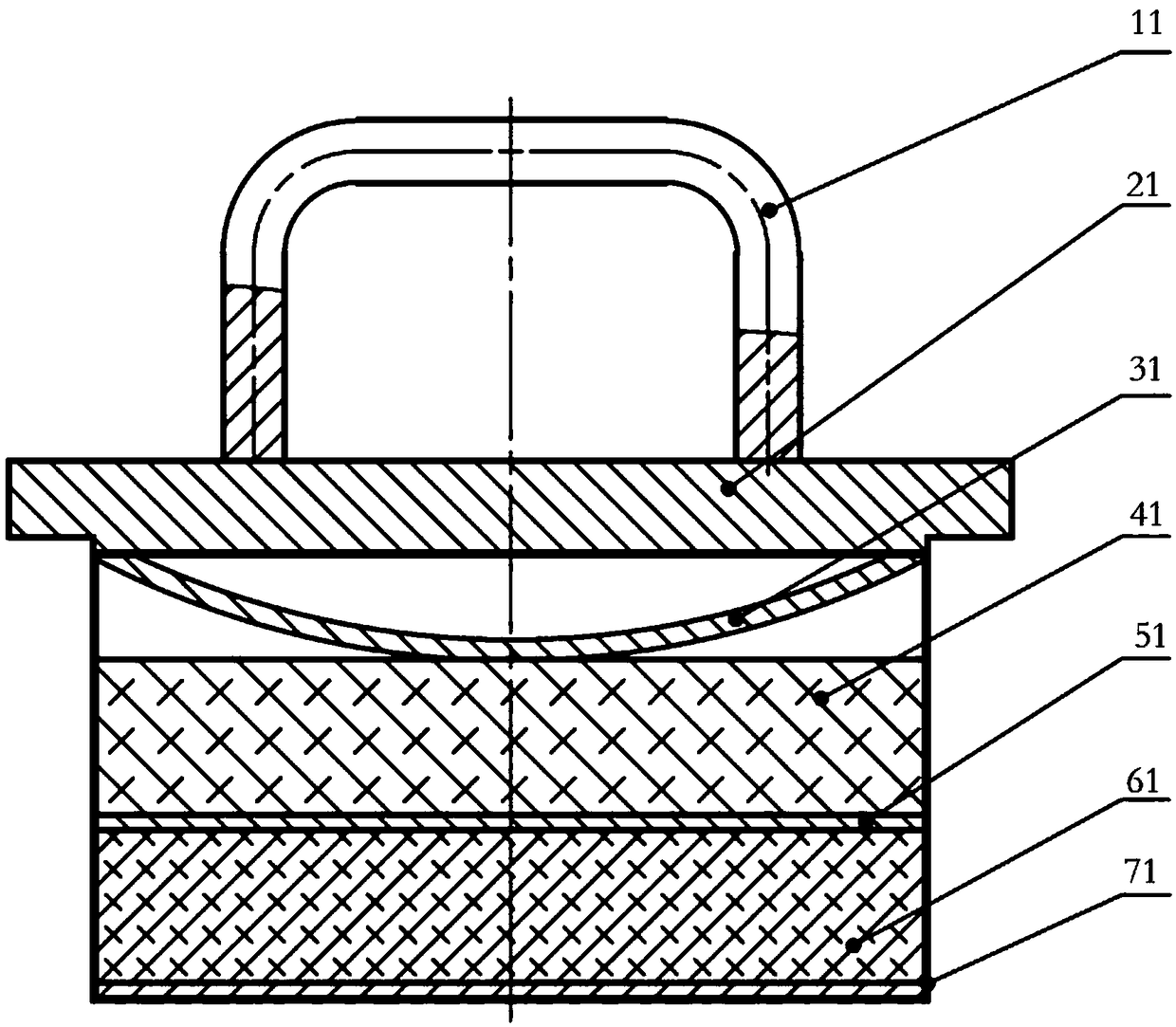

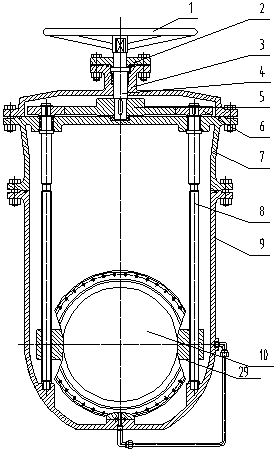

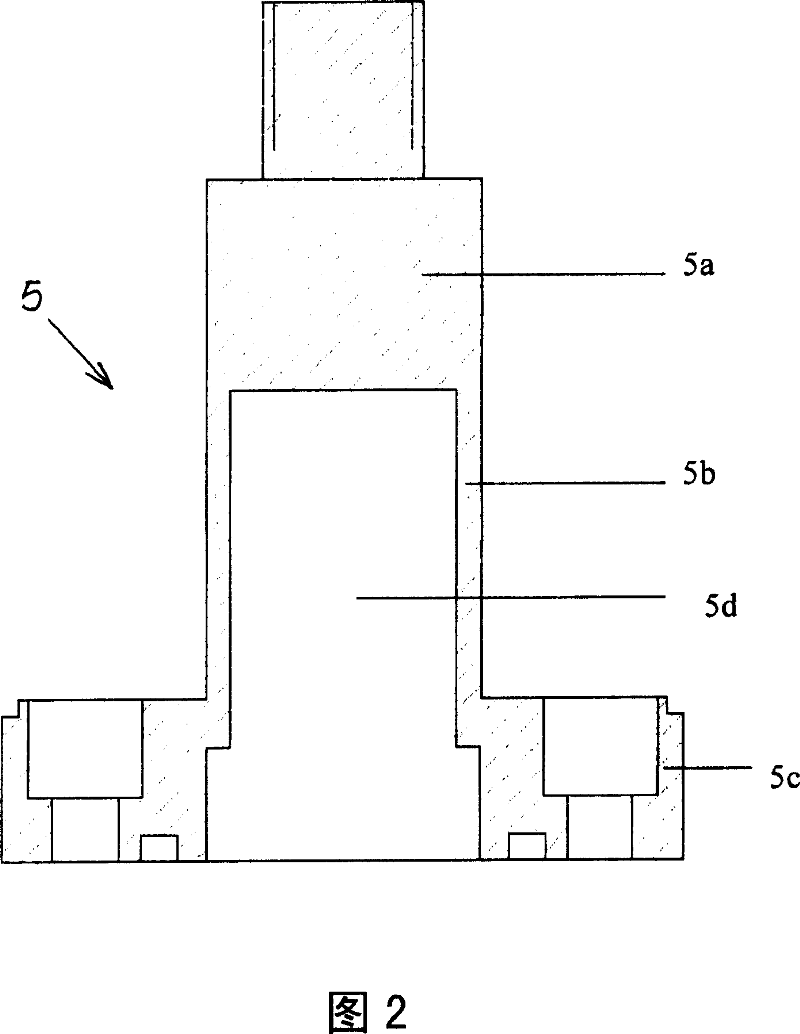

Fully sealed composite explosion-proof container

The invention discloses a fully sealed composite explosion-proof container comprising an end cover component and a container body. The end cover component is engaged and connected with the container body through a multi-tooth structure, and the end cover component comprises a cover plate of which the lower part is provided with a stainless steel jacket; the stainless steel jacket is internally provided with a high density aluminum foam layer, a separating plate, a low density aluminum foam layer and a spherical film from bottom to top in sequence; and the container body comprises a composite outer layer of which the interior is a metal inner barrel, and the upper part of the metal inner barrel is provided with an annular aluminum foam layer of which the bottom is provided with a separatingplate layer. According to the fully sealed composite explosion-proof container provided by the invention, the barrel is wound by carbon fiber reinforced epoxy resin matrix composites; and the structural strength is high, and the weight is light. The explosion-proof container has the advantages of the simple structure, quick opening and closure, reliable sealing and no fire phenomenon during explosion; the overpressure within the 30cm radius of the opening part is low, and less 20 kPa than the threshold that a human body can bear; and the explosion-proof container is light in weight, and can be handled by one person easily.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

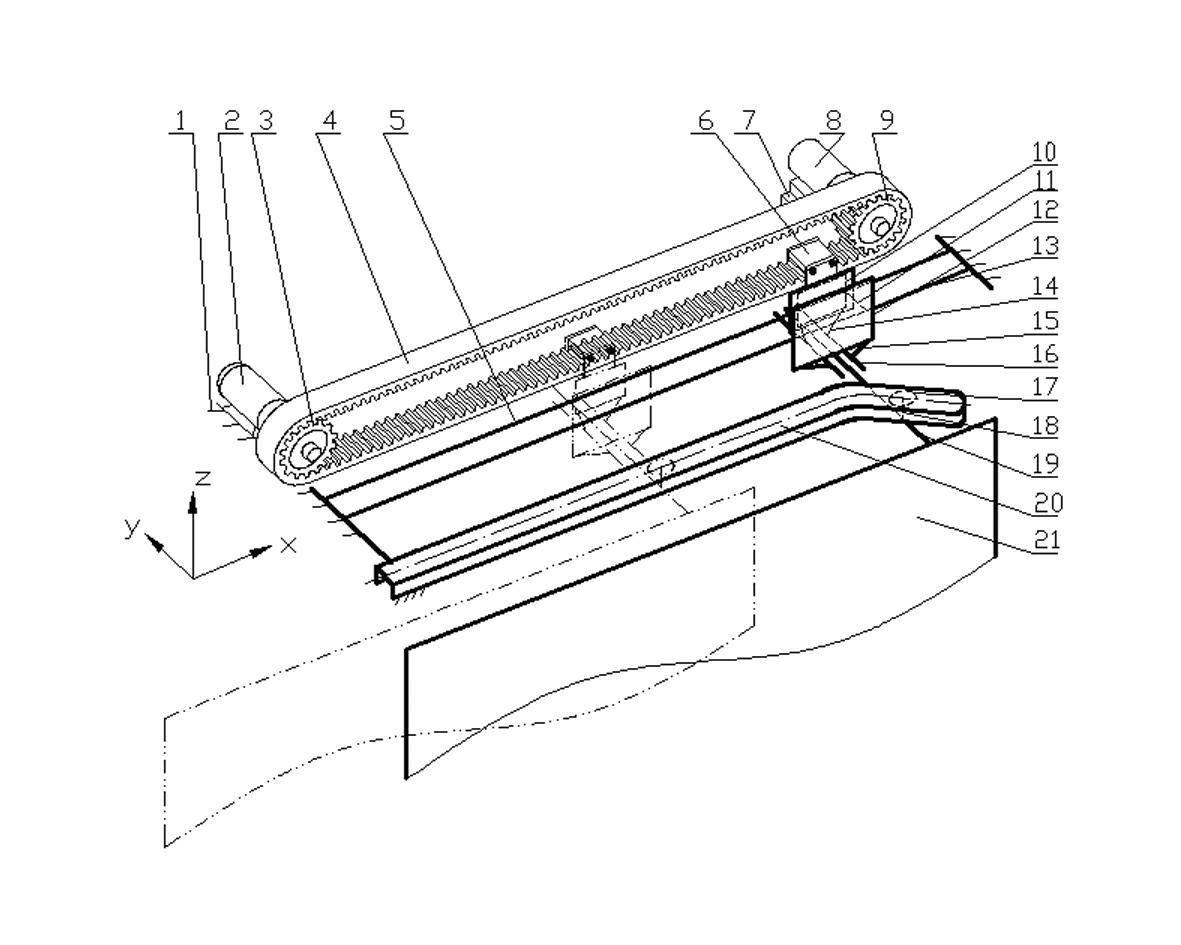

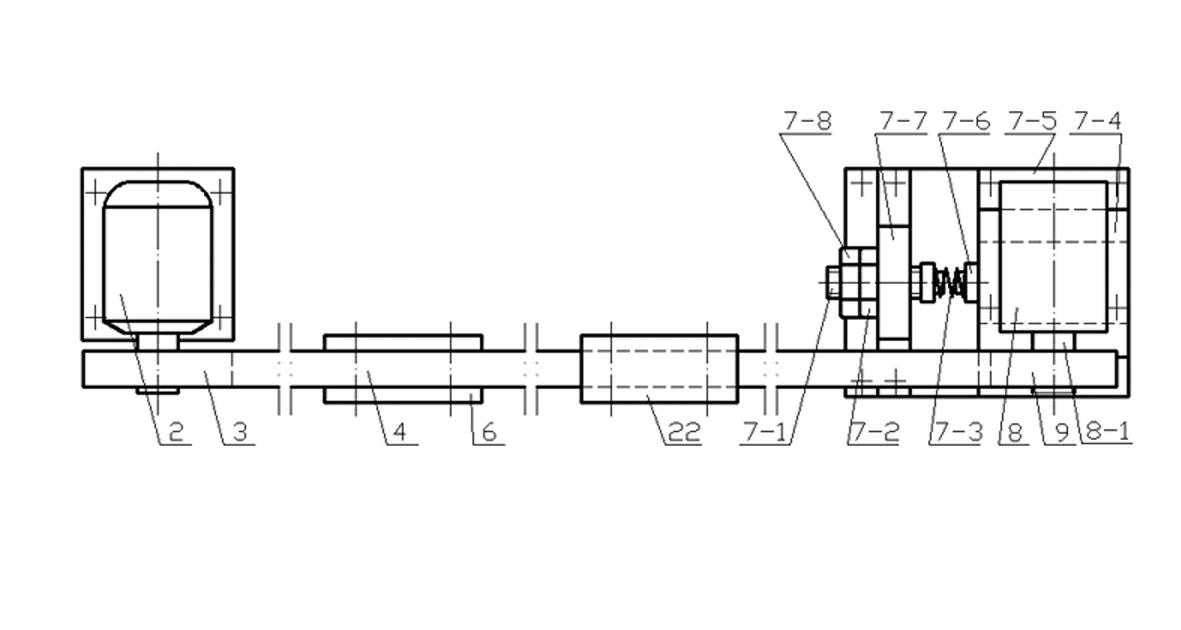

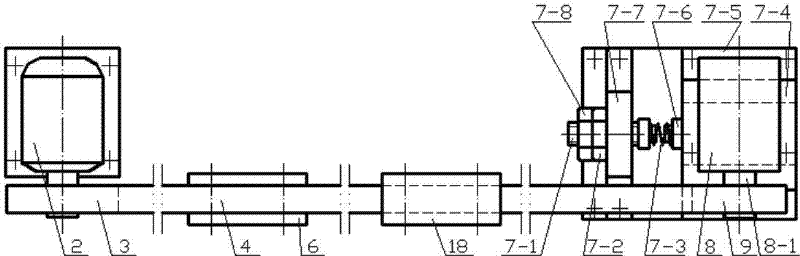

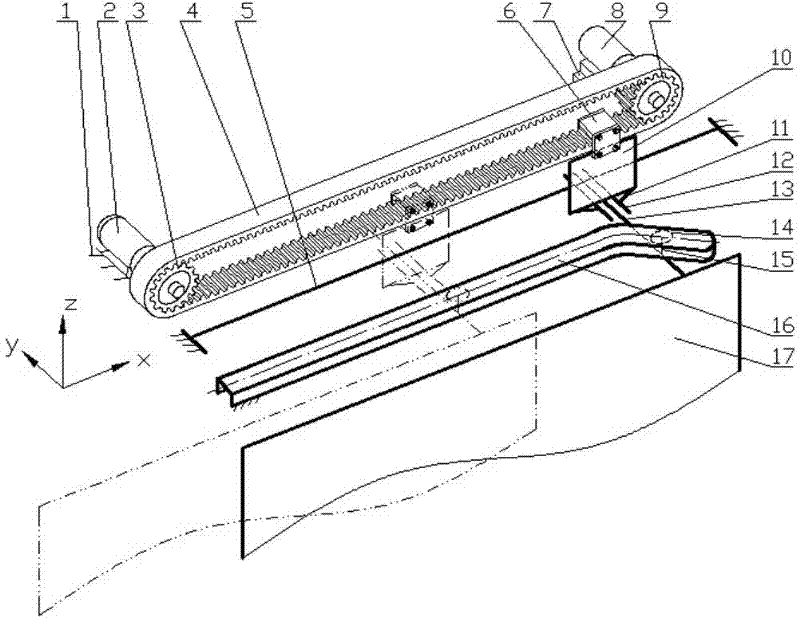

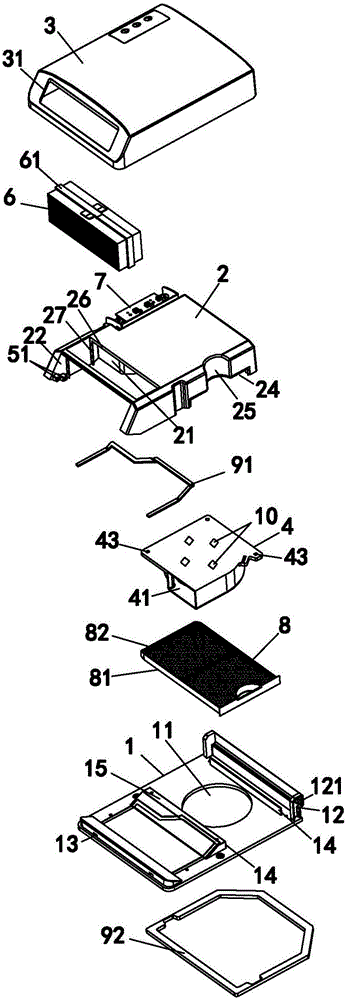

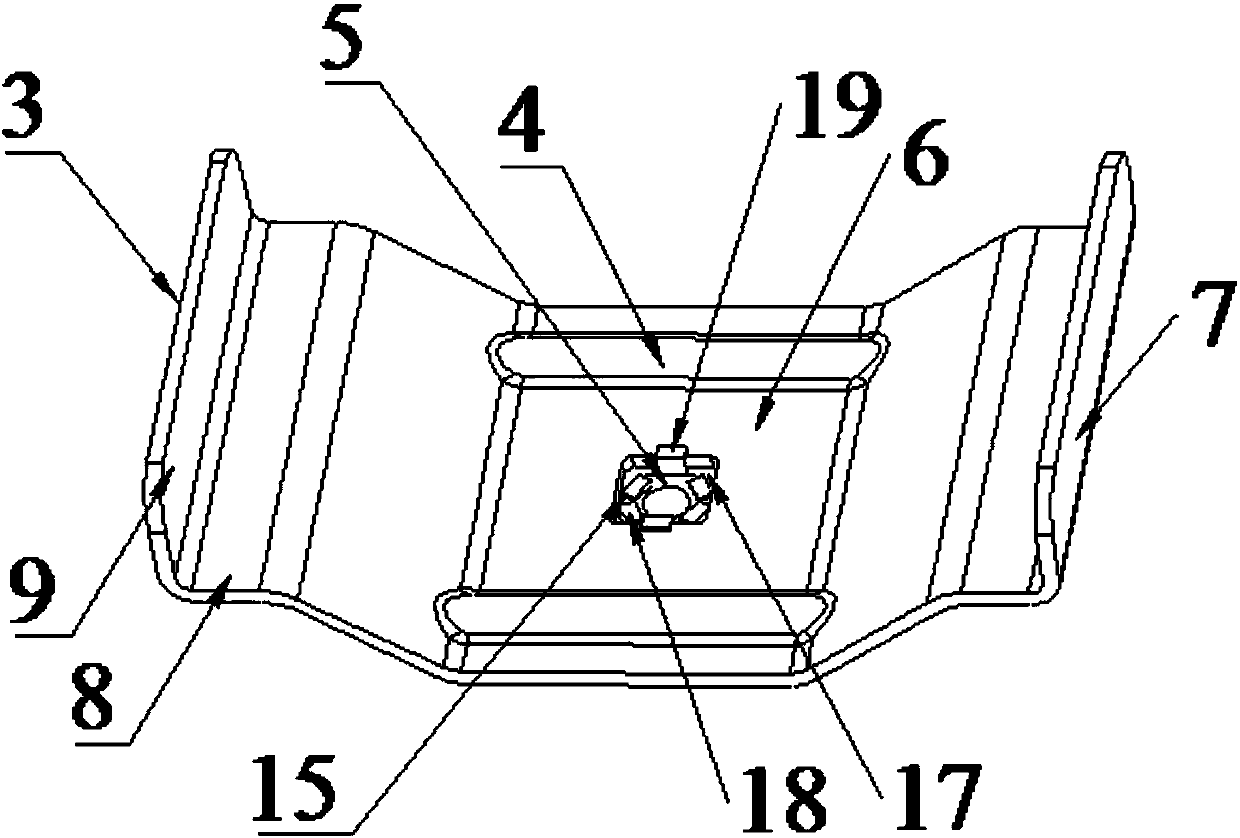

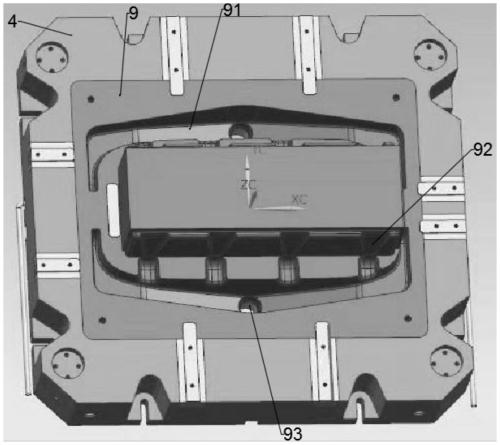

Tooth belt double-shaft guide rod groove cam combination space mechanism for sliding-plug door

InactiveCN102305009AQuick sealQuick opening and closingPower-operated mechanismDoor arrangementDrive wheelCoupling

The invention discloses a tooth belt double-shaft guide rod groove cam combination space mechanism for a sliding-plug door, relates to a sliding and plug, sealing, opening and closing mechanism for the sliding-plug door for a vehicle, in particular to the tooth belt double-shaft guide rod groove cam combination space mechanism for high-speed rail or other railway vehicles. The mechanism comprises a door frame, a motor, a driving wheel, a tooth belt, an auxiliary bearing shaft, a belt clamp, a tension device, a bearing pedestal, a driven wheel, an auxiliary shaft sleeve, a coupling rod A, a main shaft sleeve, a main bearing shaft, a coupling shaft B, a coupling shaft C, a guide rod sleeve, a roller, a roller shaft, a door carrying guide rod, a groove cam and a door leaf; a tooth belt transmission mechanism consists of the driving wheel, the tooth belt, a lower belt clamp, the tension device, the bearing pedestal, and the driven wheel; a double-shaft guide rod mechanism consists of the coupling rod A, the main shaft sleeve, the coupling rod B, the coupling rod C and the guide rod sleeve which are connected fixedly and integrally, the main bearing shaft, the auxiliary shaft, and the door frame; and a groove cam mechanism consists of the main shaft sleeve, the main shaft, the coupling rod C, the roller, the roller shaft, the door carrying guide rod, the groove cam, the door leaf, the main shaft sleeve and the door frame.

Owner:NANJING INST OF TECH

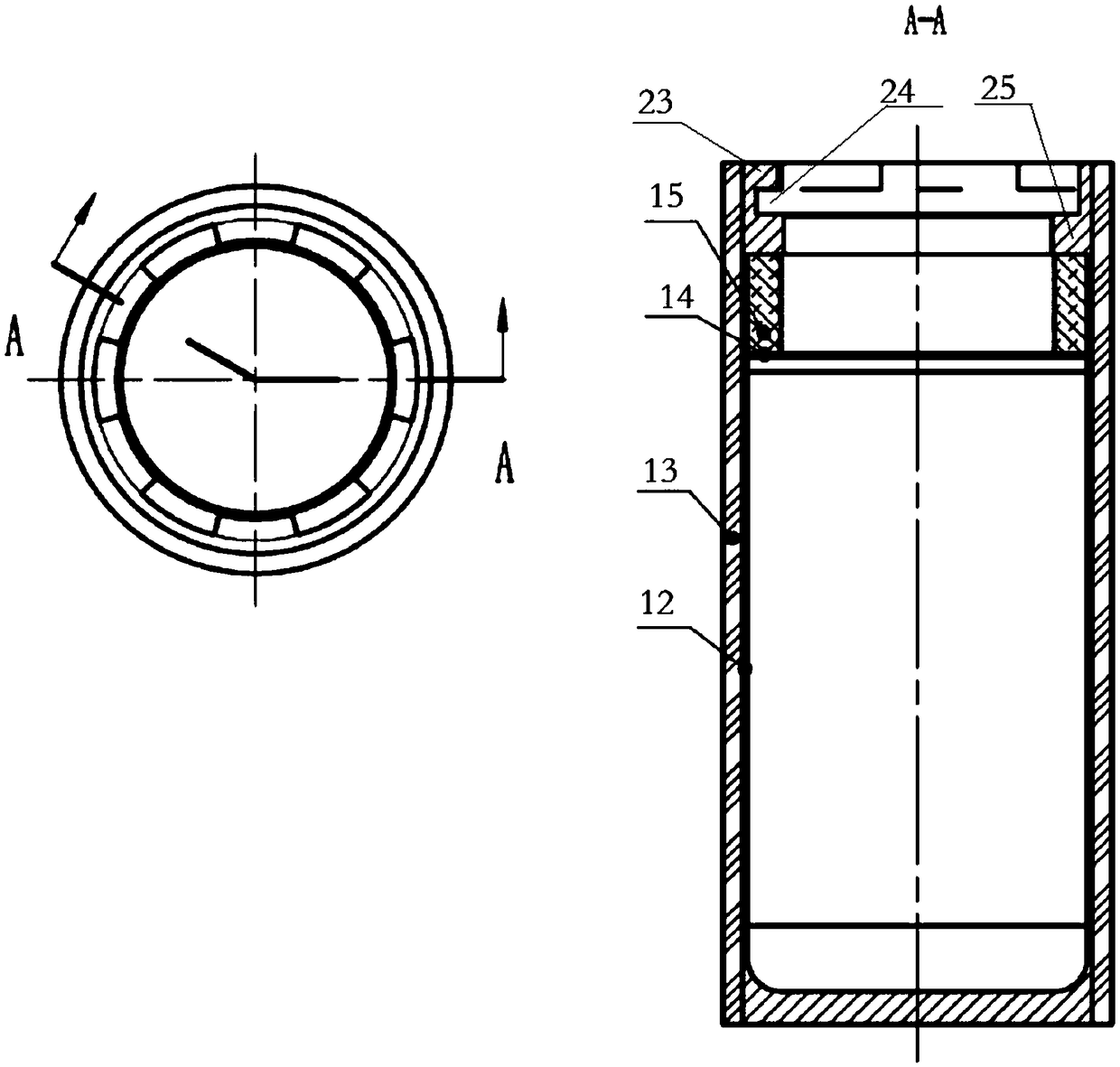

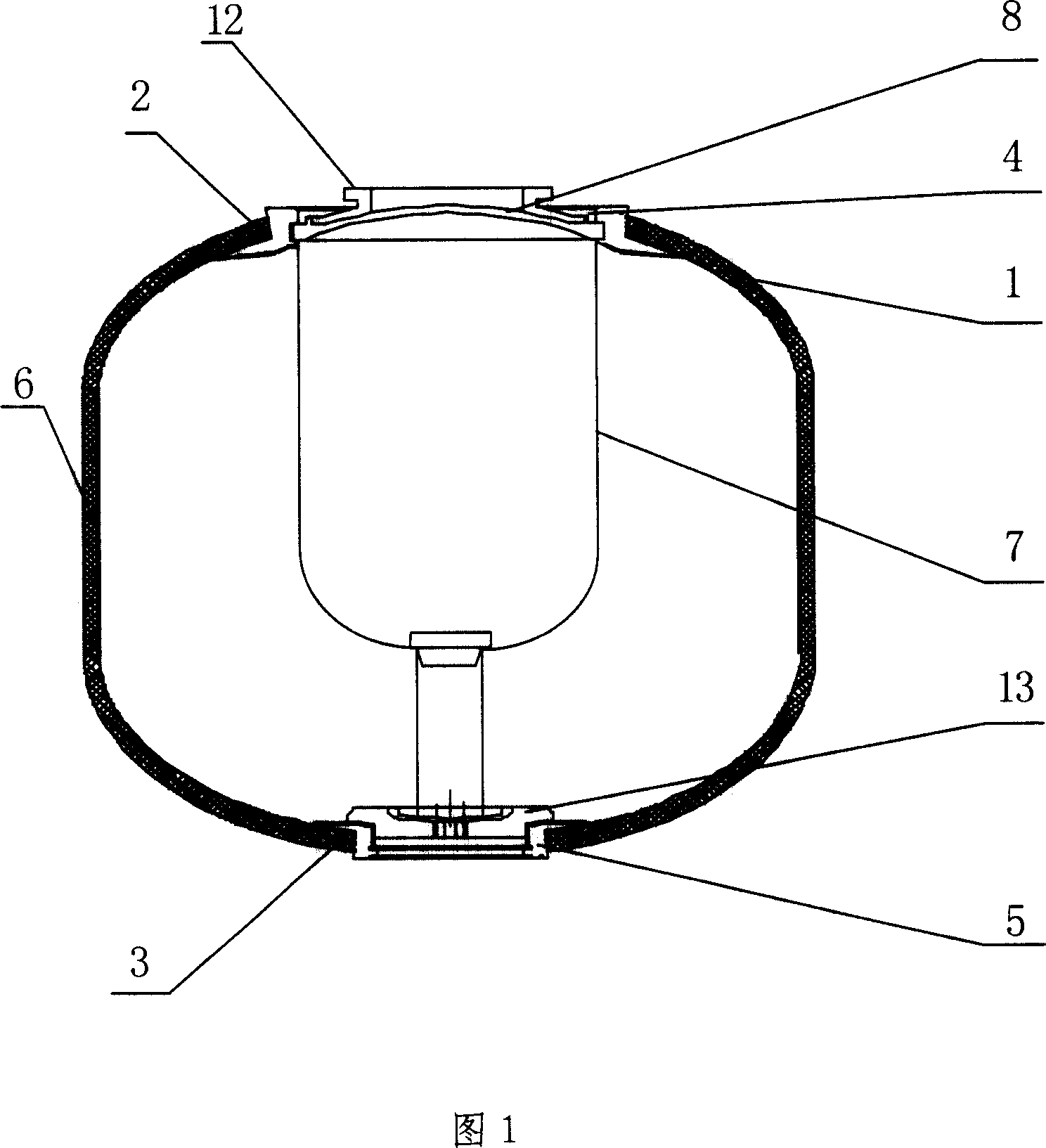

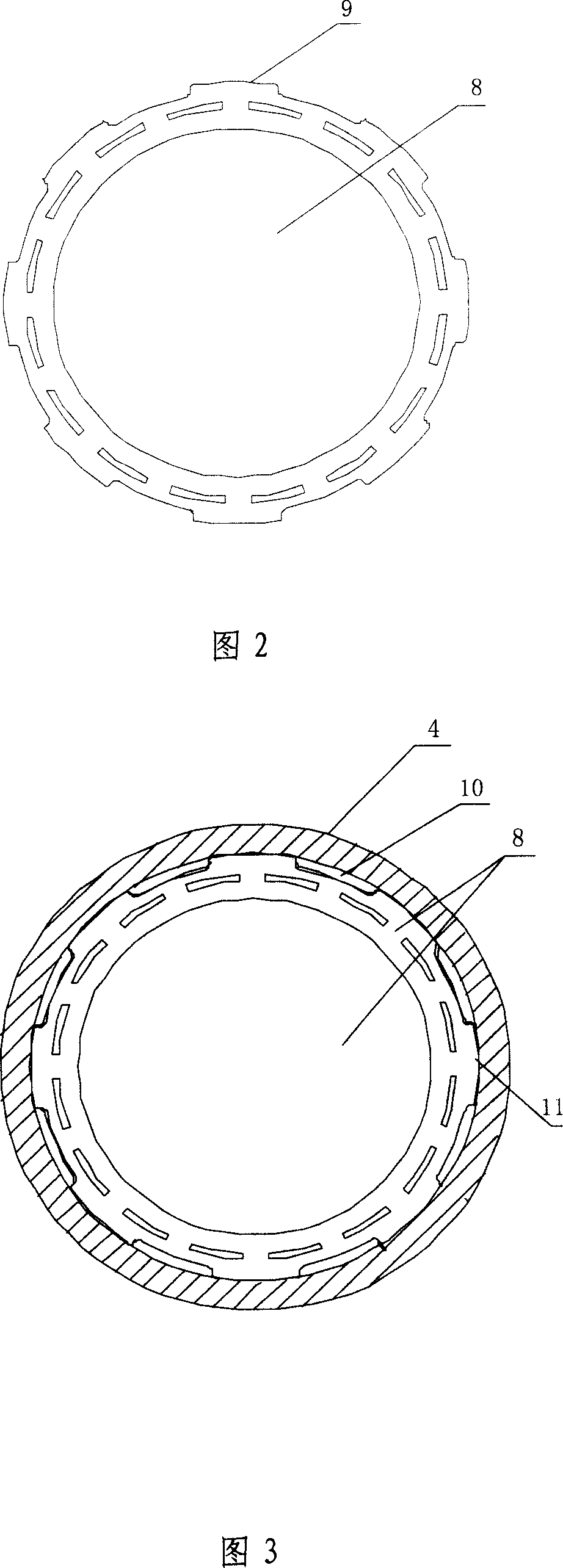

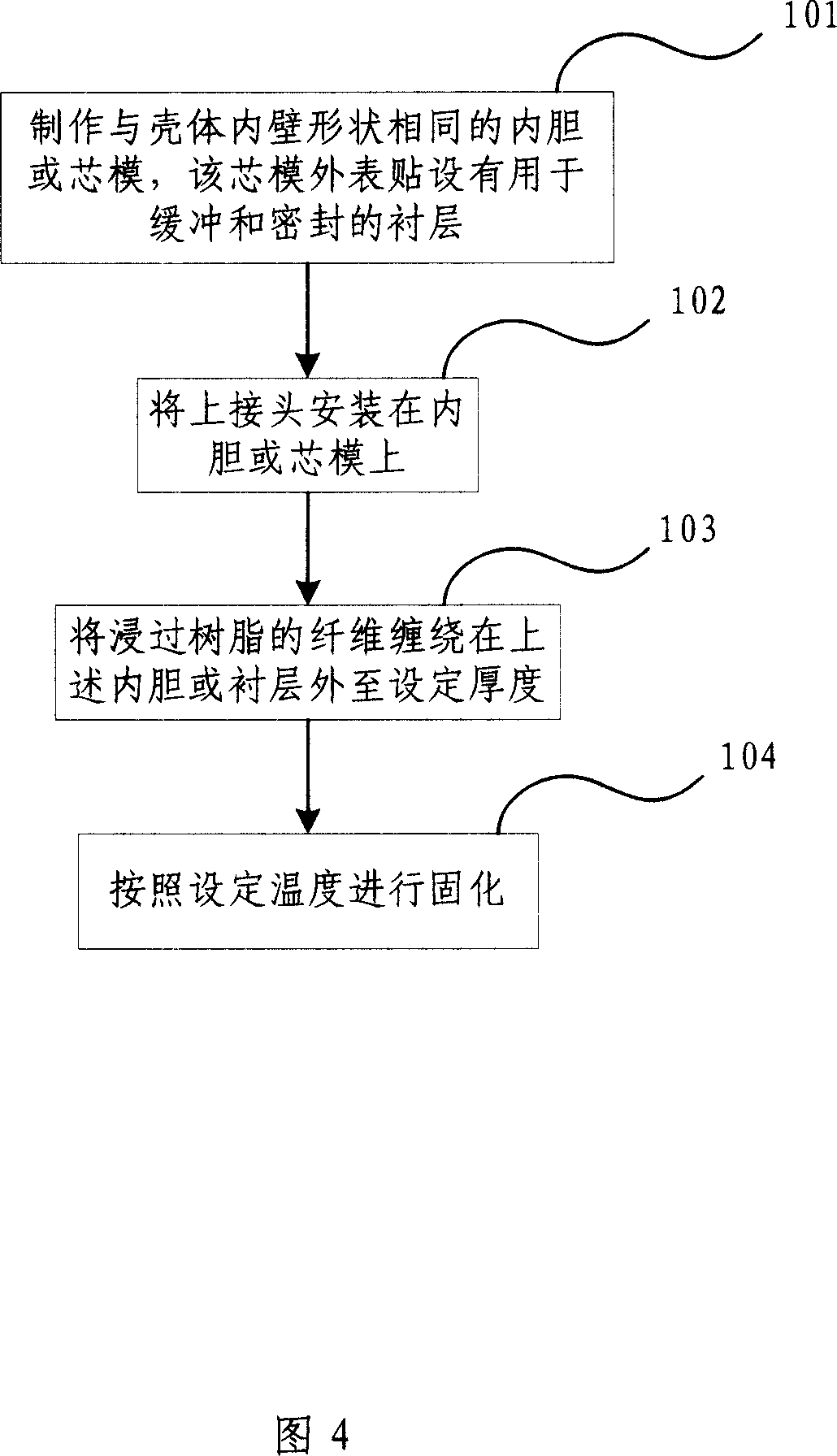

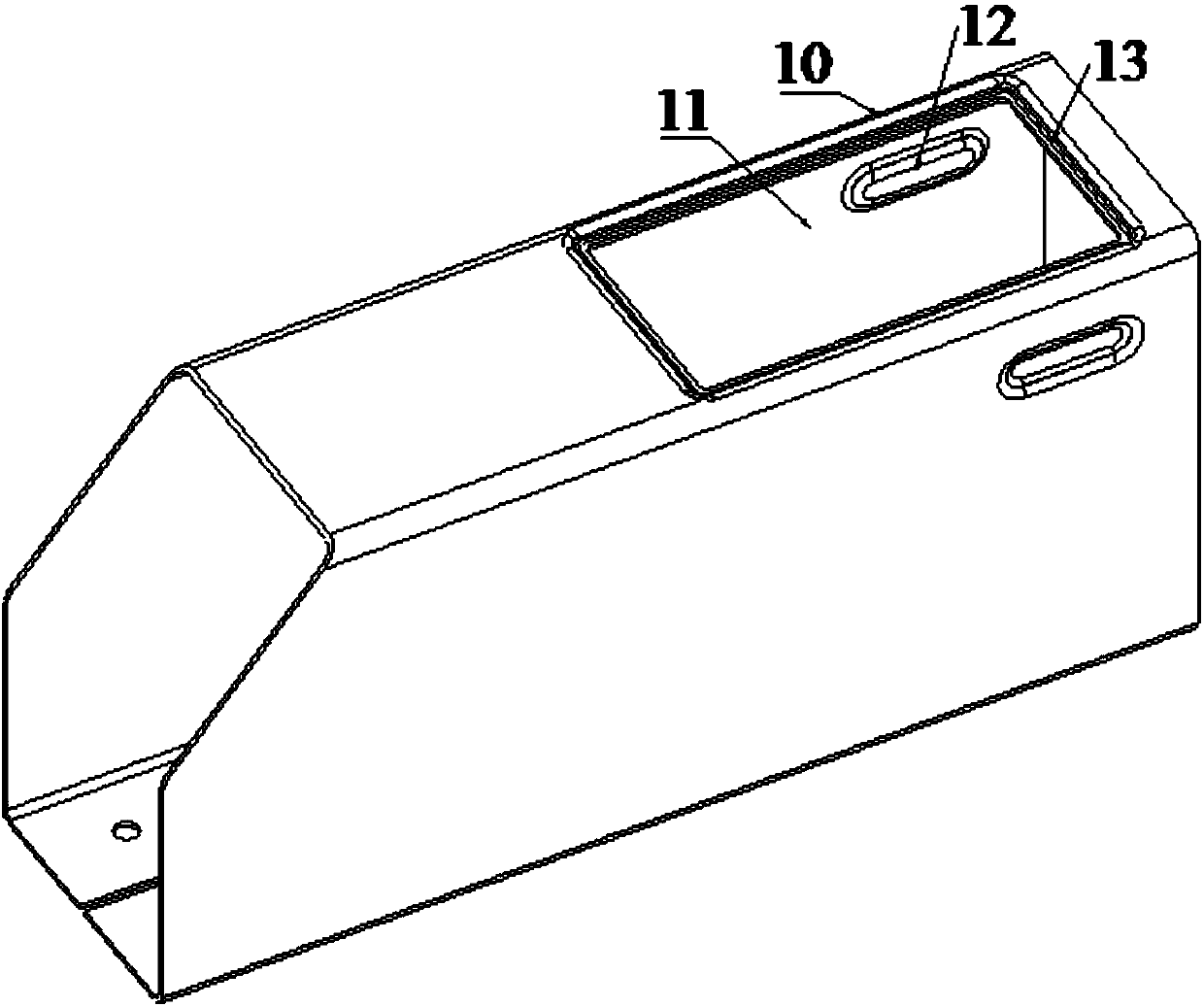

Flame-proof ball convenient for fast transferring and manufacturing method for composite material casing thereof

A composite material explosive ball for quick moving comprises the shell, ring upper joint, inner barrel, top cover, cover teeth around the edge of the top cover, inner ring teeth at the top joint inner ring, said cover teeth without inner ring teeth sinking under the bottom surface of the inner ring teeth, rotating the said cover teeth right under the inner ring teeth to knuckle them together. Shell making goes like making inner container with the same shape of the inner wall or core mold coated with releasing agent, installing said joint on the said inner container or core mold, winding the soaked resin around the said top joint said inner container or said liner to set thickness, and solidifying them based on set temperature. Through complex structure, top cover uses inner knuckling connection, with quick opening, reducing danger of explosion, convenient for carrying.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

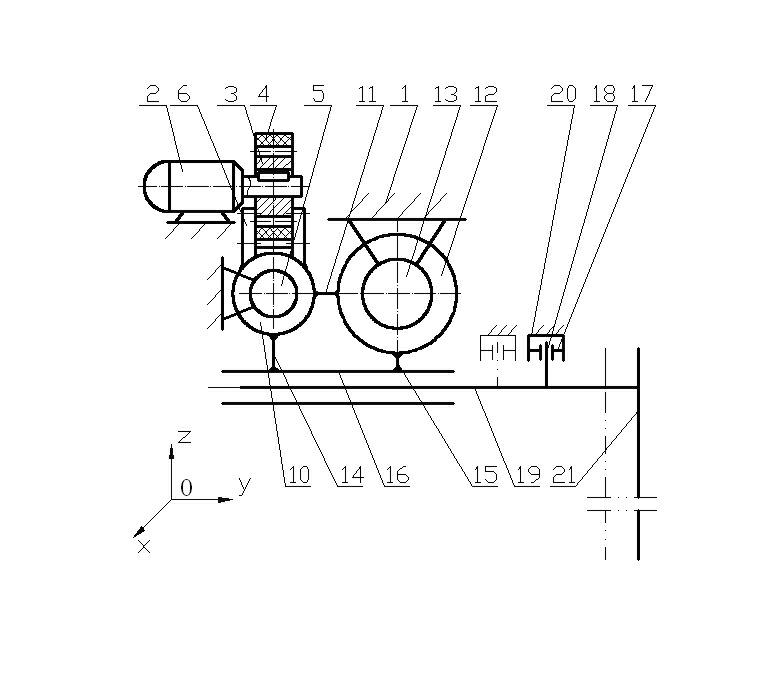

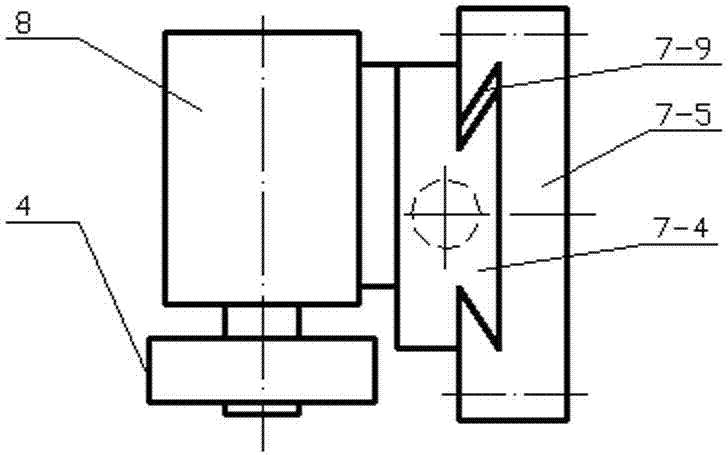

A combination space mechanism of plug tooth with uniaxial guide rod groove type cam

InactiveCN102296904AQuick opening and closingSierra seal is reliablePower-operated mechanismDoor arrangementEngineeringCam

The invention relates to a tooth strap, single shaft and guide rod, and groove-shaped cam combined spatial mechanism of a sliding plug door, which relates to an open and close mechanism of sliding plug hermetization of the sliding plug door of a vehicle, in particular to the tooth strap, single shaft and guide rod, and groove-shaped cam combined spatial mechanism of the sliding plug door of a high-speed railway vehicle and other railway vehicles. The tooth strap, single shaft and guide rod, and groove-shaped cam combined spatial mechanism comprises a door frame, a motor, a driving tooth gear, a tooth strap, a load-bearing shaft, a strap clamp, a tensioning device, a bearing seat, a driven tooth gear, a load-bearing shaft sleeve, a connecting rod, a guide rod sleeve, a door carrying guide rod, a roller, a roller shaft, a groove-shaped cam and a door leaf; a tooth strap mechanism comprises the driving tooth gear, the tooth strap, the strap clamp, the tensioning device, the bearing seat and the driven tooth gear, and the strap clamp is fixedly connected with the load-bearing shaft sleeve, the connecting rod and the guide rod sleeve into a whole so as to form a single shaft and guide rod mechanism with the load-bearing shaft, the door carrying guide rod, the door frame and the like; and a groove-shaped cam mechanism comprises the load-bearing shaft, the load-bearing shaft sleeve, the guide rod sleeve, the roller, the roller shaft, the door carrying guide rod, the groove-shaped cam and the door leaf, and the three mechanisms are connected with one another to form the tooth strap, single shaft and guide rod, and groove-shaped cam combined spatial mechanism.

Owner:NANJING INST OF TECH

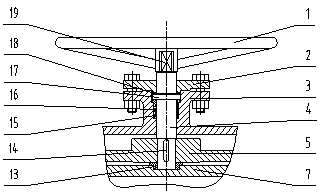

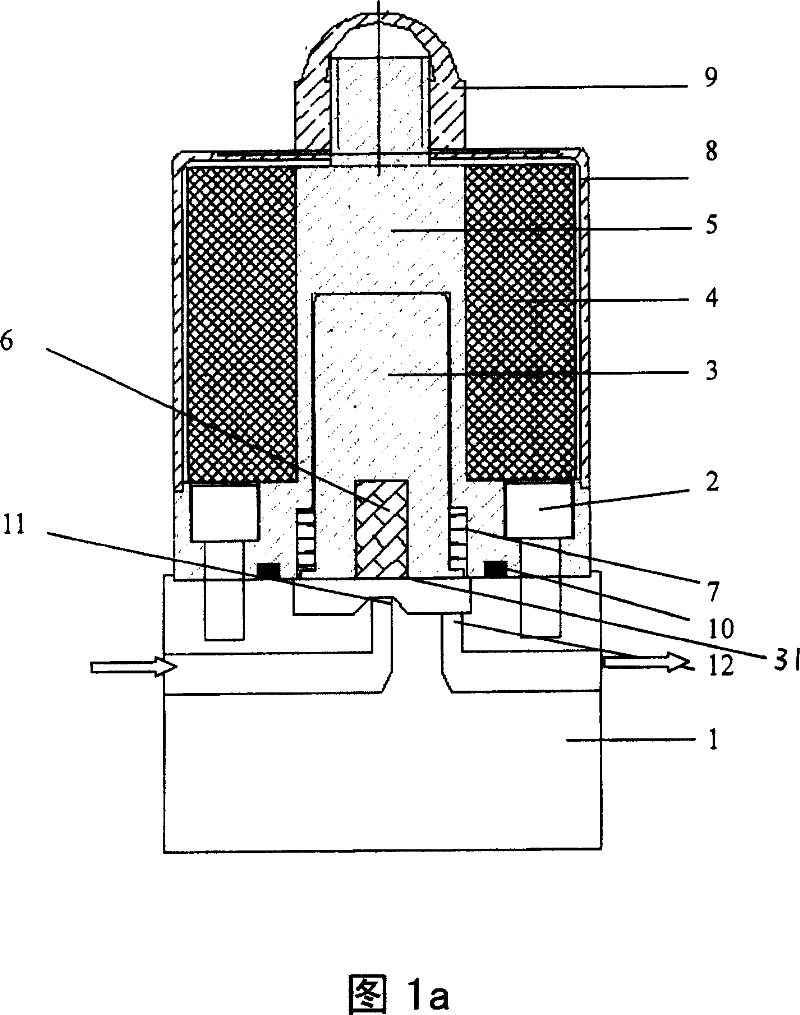

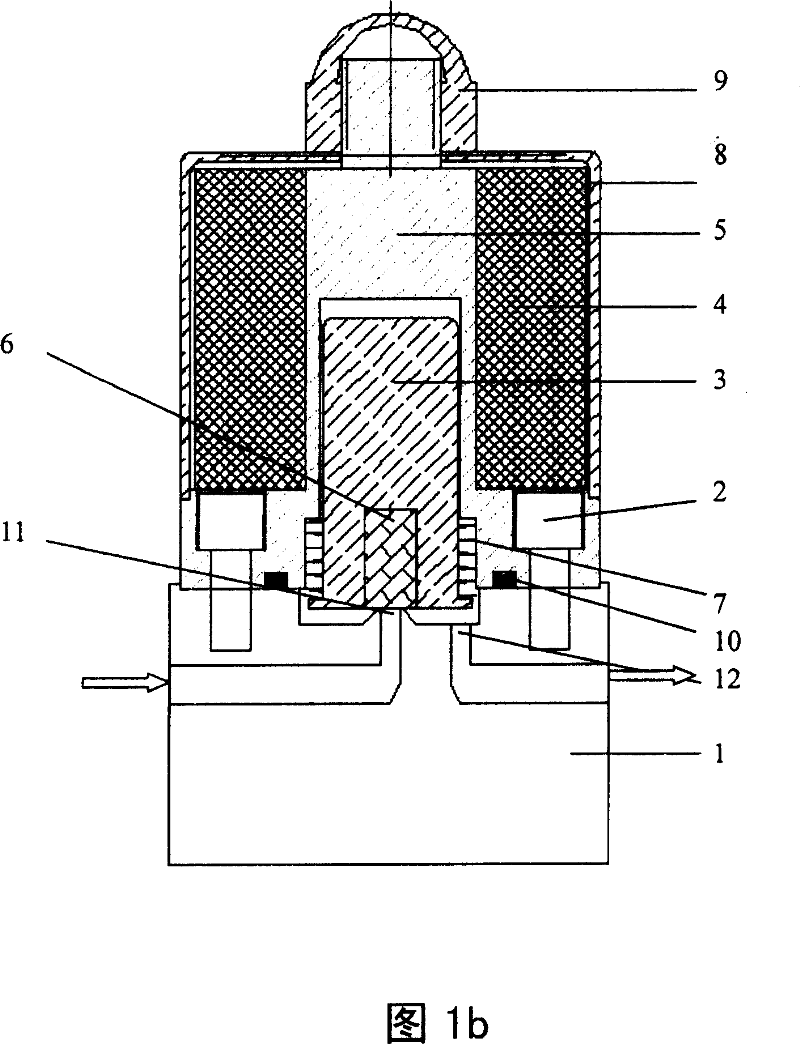

Normally closed type guide type gas anti-explosion valve

ActiveCN102865373AEasy to openSimple structureOperating means/releasing devices for valvesLift valveProduct gasEngineering

The invention discloses a normally closed type guide type gas anti-explosion valve, belongs to gas valves and particularly relates to a gas anti-explosion valve with a guide structure. The normally closed type guide type gas anti-explosion valve comprises a valve body, a valve cover, a valve cup and an electromagnetic controller and is characterized in that the valve body and an upper valve cover are connected through a fixed bolt, the upper portion of the upper valve cover is connected with the electromagnetic controller composed of a non-magnetic pipe assembly and an electromagnetic head, a guide sleeve is arranged in an upper opening of the valve body, a valve cup assembly is installed in the guide sleeve, an upper connection nut and a lower connection nut which are mutually connected are installed in the valve cup assembly, a guide valve assembly is installed in a connection nut inner hole, a movable iron core is installed in a non-magnetic pipe inner hole, the top of a non-magnetic pipe is welded with a static iron core, and a vertical inner hole used for installing a manual assembly is arranged at the center of the valve body. The valve adopts the guide structure in design, adopts the operation mode that the manual mode and the electric mode are combined, and is simple in structure, quick in opening and closing, good in sealing performance, convenient to operate and use and capable of being used in high pressure gas pipe network.

Owner:济南市大秦机电设备有限公司

Headspace type vacuum oil sample taking method

InactiveCN107063751AControl flow rateImprove sealingWithdrawing sample devicesTransformerSampling valve

The invention discloses a headspace type vacuum oil sample taking method. The method is based on a headspace type vacuum oil sample taking apparatus. The method comprises the steps of installing an oil taking nozzle on an oil outlet of a transformer sampling valve; unscrewing a protective cylinder from a first oil taking valve connected through threads; sleeving a protective cylinder installation hole onto a prism of an oil taking rod; rotating an operation rod on a side wall of the protective cylinder along a hinge shaft to be parallel to a support board; pushing the operation rod to drive the protective cylinder to rotate; pushing a sealing ball by the oil taking rod so as to enable an oil guide hole of the oil taking rod to communicate with a first oil taking hole; enabling an oil sample to flow into the oil guide hole through the first oil taking valve; taking off the protective cylinder; rotating a handle on a second oil taking valve to open the second oil taking valve; and enabling the oil sample to flow out of an oil outlet nozzle through the second oil taking valve. In the method, the protective cylinder is rotated so as to drive the oil taking rod to rotate, maintenance workers can take the oil sample without carrying tools, so that the oil sampling method is easier, faster and more effort-saving; the oil sample can be taken at a constant speed in a relatively vacuum state through two-level sealing and ball valve control.

Owner:国网浙江台州市路桥区供电有限公司 +2

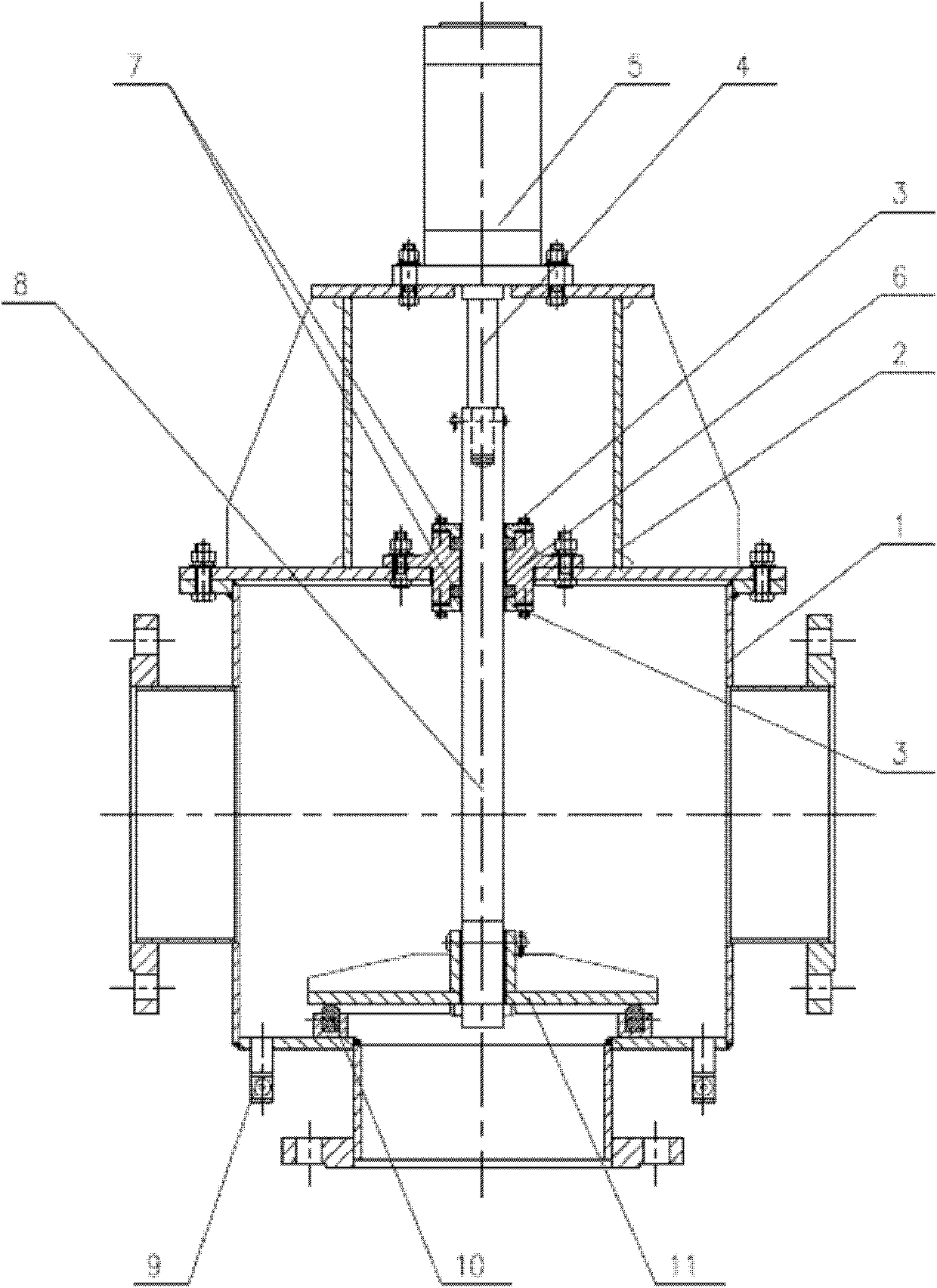

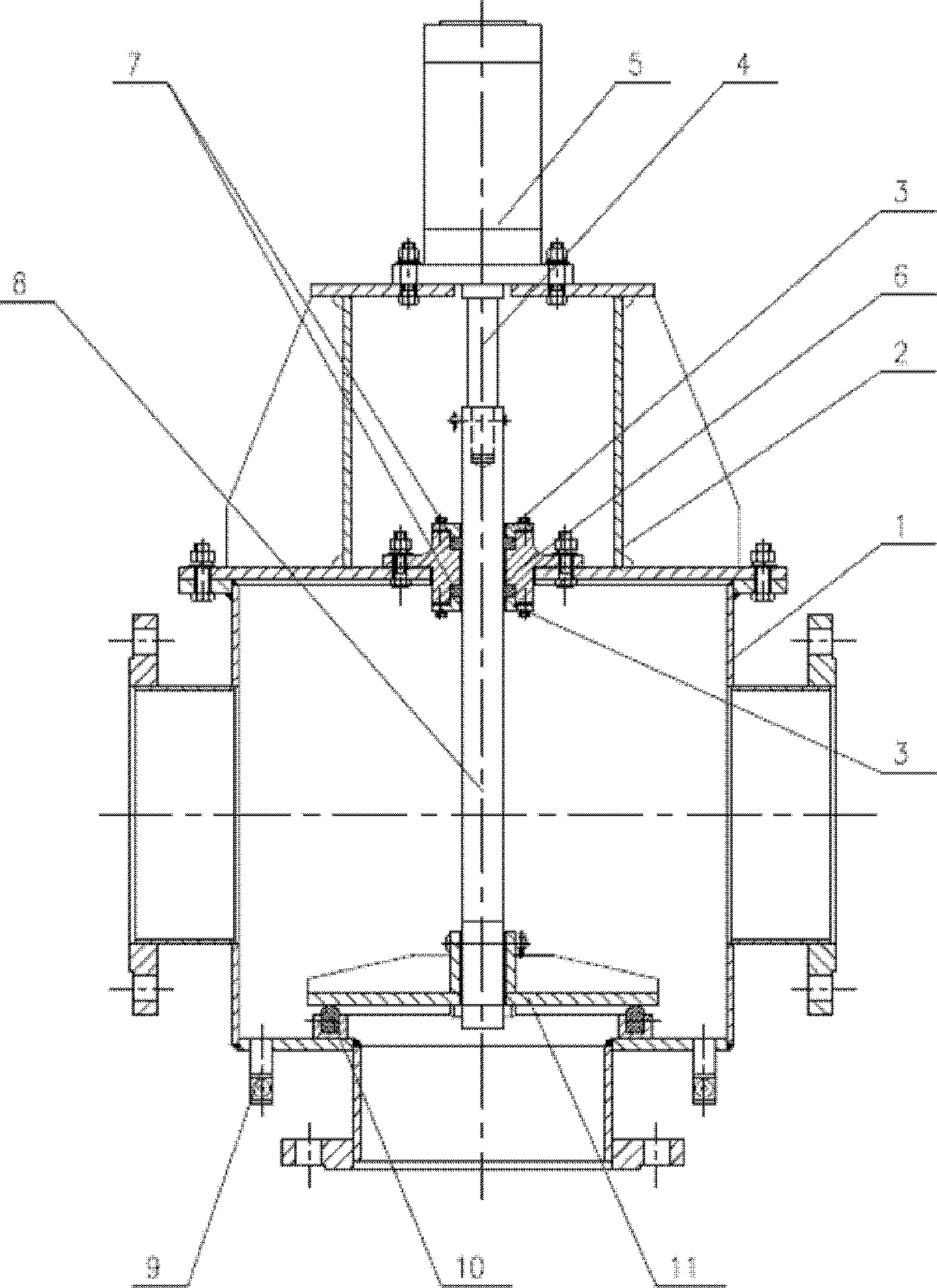

Bidirectional sealing gate valve and using method thereof

PendingCN109163110AHigh matching precisionSmooth up and down motionOperating means/releasing devices for valvesSlide valveWheel driveGear drive

The invention discloses a bidirectional sealing gate valve and a using method thereof. The bidirectional sealing gate valve comprises a valve deck, a valve shaft, a valve body, a valve plate, a valveseat, a valve body sealing surface and a valve seat sealing surface, wherein the valve seat is connected to the valve plate through a valve seat gland in a floating mode, an elastic connecting piece is arranged between the inner end face of the valve seat and the valve plate, a gear box cover is fixedly connected to the valve deck, the gear box cover is fixedly connected with a valve shaft gland,the part, located below the gear box cover, of the valve shaft is connected with a center gear in a key mode, the outer edges of the two sides of the center gear are meshed with a left gear and a right gear respectively, the left gear and the right gear are connected with screw rods which penetrate through the valve deck to extend downwards through flat keys respectively, and the tail ends of thescrew rods are rotationally connected with the inner surface of the valve body. The bidirectional sealing gate valve has the beneficial effects that 1, a hand wheel drives the gear, the gear drives the screw rods, the screw rods drive a gate plate, the matching precision is high, and due to the fact that the gate plate is supported at the two ends of the screw rods, the gate plate moves up and down stably; and 2, after the gate plate is closed, the valve seat realizes bidirectional sealing of the gate valve under the double acting force of the spring force and the thrust of a medium on the valve seat.

Owner:YINGNUOWEI VALVE IND

Three-way valve

InactiveCN102705567AOpen and closeQuick opening and closingSpindle sealingsOperating means/releasing devices for valvesLinear motionPlaying card

The invention belongs to the field of environment-friendly equipment and discloses a three-way valve. The three-way valve comprises a valve body and a valve switch control device, wherein the valve switch control device comprises silicon rubber sealing rings on the inner side of a valve port, a valve plate, a valve rod, a cylinder seat, a piston rod, a cylinder with two-way buffer and a sealed connecting part; the cylinder seat is fixed on a valve body on an opposite side of a valve port to be controlled; the cylinder on the cylinder seat is connected with one end of the valve rod through the piston rod in the cylinder seat; the valve rod is positioned at the other end in the valve body and is connected with one side of the valve plate which is positioned inside the valve body; and the sealed connecting part is positioned on a part of the valve rod which penetrates through the valve body. By the three-way valve, the switch control device has a playing card type structure; the valve plate is controlled to be contacted with the silicon rubber sealing rings, so that opening and closing of the valve are realized; and moreover, the valve plate is in linear motion, and the three-way valve is rapidly opened and closed and low in leakage rate and long in service life.

Owner:JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

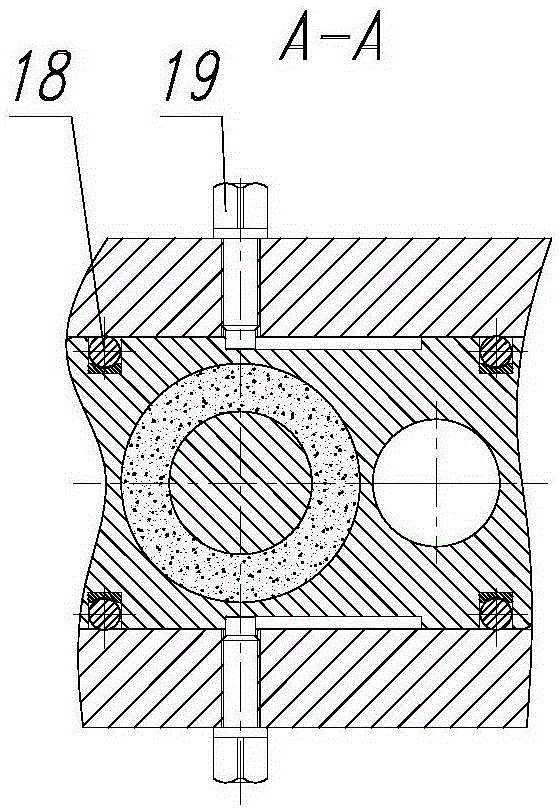

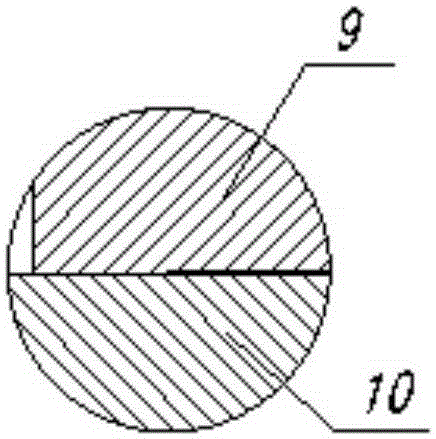

Rotary cutting valve

InactiveCN101943272AOpen and closeQuick opening and closingOperating means/releasing devices for valvesSlide valveGear wheelEngineering

The invention discloses a rotary cutting valve. A left valve body, an intermediate body and a right valve body form a housing; a handle, a valve rod, a gland cover, the right valve body and the left valve body are connected; the valve rod is inserted into the positioning hole of the left valve body; a fixing shaft passes through a splint and a valve clack on the two sides; the two ends of the fixing shaft are inserted into the positioning holes of the left and right valve bodies; the right valve body, a right valve seat, the valve clack, a left valve seat, a cylindrical compression spring and the left valve body are connected; the splint and the valve clack are connected; a hexagonal bolt, a belleville spring and a hexagonal nut serve as fasteners which is a structure floating with the position of the valve clack; the outer circles of the left and right valve seats and the left and right valve bodies and the splint are sealed by O-shaped sealing rings; the valve rod and the valve clack transversely rotate around a gear pair; the splint is a semicircular plate of which the upper part is provided with a medium channel hole, the lower part is provided with a fixing shaft hole and the two sides are provided with blind plates; the valve clack is a sector plate of which the upper part is provided with a medium channel hole, the right side is provided with a blind plate and the lower part is provided with a fixing shaft hole; the outer side of the shaft hole is provided with a semicircular gear; and the valve rod is also provided with a semicircular gear. The valve can ensure that deposit or scale is not generated in the inner cavity.

Owner:江苏江恒阀业有限公司

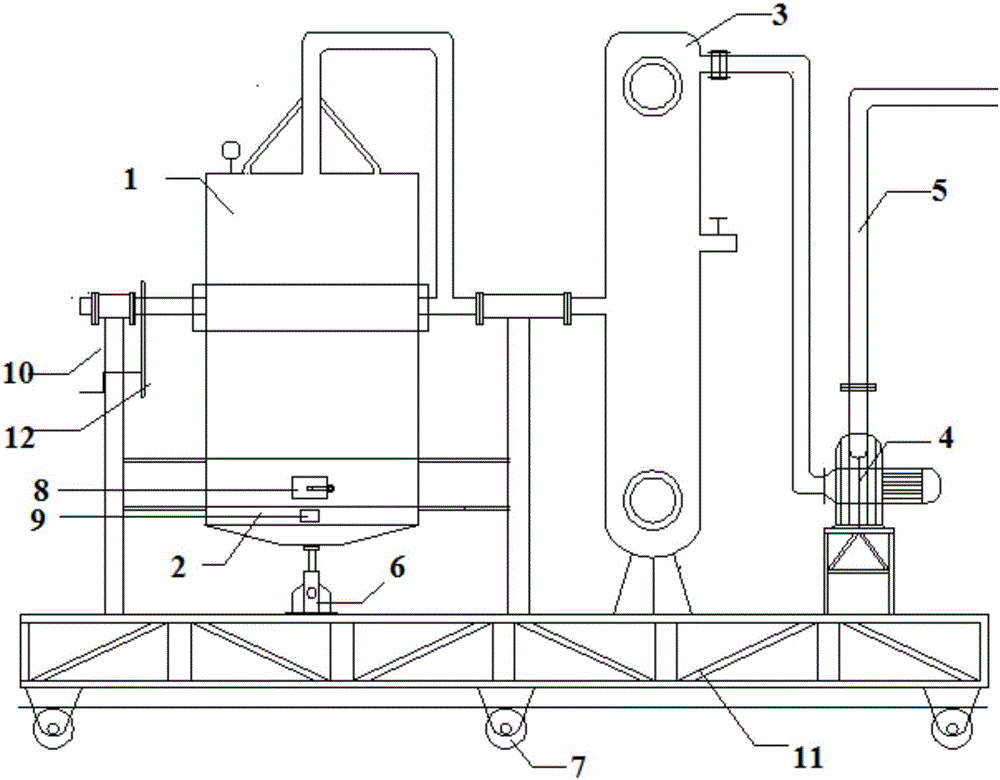

Low-consumption environment-friendly biochar production equipment

ActiveCN106010599ANo crushing requiredSave energyCombination devicesGas treatmentCombustion chamberCombustible gas

The invention relates to low-consumption environment-friendly biochar production equipment, which consists of a pedestal, a carbonization furnace, a gas purification device, a draught fan, an exhaust pipeline, a thermometer, a carbonization chamber support, a combustion chamber fixation bracket and a rotary handle. The carbonization furnace is composed of a carbonization chamber and a combustion chamber. The combustion chamber bottom is fixed on the pedestal through the combustion chamber bracket. The upper part of the carbonization chamber is movably fixed on a cross beam, and the carbonization chamber can turn freely and rotate around the cross beam. A set of gear linkage system is fixed on a steel pipe at the front end of the carbonization chamber support to adjust the inclination angle of the carbonization chamber. The carbonization chamber, the exhaust gas purification device and the draught fan are communicated through the exhaust pipeline. The carbonization chamber is internally provided with several independent pyrolysis chambers. While saving energy and protecting the environment, the equipment provided by the invention also can rapidly and effectively pyrolyze biomass into biochar, and utilizes the combustible gas generated by biomass pyrolysis to heat itself.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Novel photo-thermal power generation fused salt valve capable of avoiding residues

InactiveCN106051175AEasy maintenanceSimple structureSpindle sealingsLift valveInlet channelMolten salt

The invention discloses a novel photo-thermal power generation fused salt valve capable of avoiding residues. The novel photo-thermal power generation fused salt valve is a Y-shaped valve and comprises a valve body, a valve rod, a support, a hand wheel, a medium inlet channel and a medium outlet channel. The valve body and the support are integrally formed and integrally forged. A valve rod cavity is formed in the valve body, the valve rod extends into the valve rod cavity and is sleeved with a corrugated pipe in an embedded manner, and the corrugated pipe is located in the valve rod cavity. A packing box is arranged above the corrugated pipe, the valve rod is sleeved with the packing box in an embedded manner, a packing ring is placed in the packing box and is tightly pressed through a packing gland above the packing ring, and the packing gland is connected with the valve body through a bolt. The angle alpha formed between the medium inlet channel and the horizontal plane ranges from 10 degrees to 20 degrees, and the angle beta formed between the medium outlet channel and the horizontal plane ranges from 10 degrees to 20 degrees. The fused salt valve is simple in structure, good in sealing performance and convenient and rapid to operate; during work, no leakage happens, safety and reliability are achieved, and the service life is longer; and when a fused salt system stops operating, the situation that due to the fact that fused salt is left and solidified in the valve, the valve is blocked is avoided.

Owner:陈金环

Hard sealing lifting type brake plug valve and control method thereof

ActiveCN105065701AReduce frictionExtended service lifeOperating means/releasing devices for valvesSlide valveEngineeringHigh pressure

The invention relates to a hard sealing lifting type brake plug valve and a control method thereof. The hard sealing lifting type brake plug valve comprises a valve body, a valve seat, a valve plug, a valve rod, a gasket, a valve deck, studs, pins, a packing bushing, swing bolts, a packing pressing plate, swing bolts, a hand wheel, a hand wheel gasket, a nut, packing and a valve rod nut. The valve body and the valve deck are connected through the studs. The valve deck and the packing pressing plate are connected through the swing bolts. The valve rod is connected with the valve plug through a head flat-square part. A full-bore partial-rotation structure is adopted, the flow coefficient is large, and the opening and closing space is small. The metal-sealing, fireproof, anti-static and blowout prevention valve rod structure is adopted, and the hard sealing lifting type brake plug valve is suitable for high-temperature-resistant, high-pressure-resistant and strong-corrosion-resistant working conditions and is wide in application range. The packing structure can be replaced on line, and online maintenance is convenient. During operation, a sealing pair is disengaged, friction between opening and closing torque and the sealing pair is reduced, and the service life of the valve is prolonged.

Owner:浙江福瑞科流控机械有限公司

U-shaped ball valve for slurry mixing and ash discharging

InactiveCN102966751AExtended service lifeLow operating failure ratePlug valvesFailure rateManufacturing cost reduction

The invention discloses a U-shaped ball valve for slurry mixing and ash discharging. The U-shaped ball valve comprises a valve body, a ball body and a lower end cover, wherein the lower end of the valve body is provided with the lower end cover; the lower end cover is connected with a lower stationary shaft through a set screw; the lower stationary shaft is movably connected with a rotating shaft at the bottom of the ball body through a lower shaft sleeve; the rotating shaft at the top of the ball body is connected with the bottom end of a valve rod through an upper shaft sleeve; and the valve rod penetrates through a filler system structure and the rear top end of a bracket to be connected with an executing mechanism. The U-shaped ball valve has the beneficial effect that the design of a non-eccentric wear-resistant ball body with a U-shaped flow passage port, a streamline-shaped outlet and valve cavity ball hiding is adopted by the designed and developed U-shaped ball valve for slurry mixing and ash discharging. A valve seat with a scraper port is designed to be provided with a labyrinth type disc spring pre-tightening mechanism. The U-shaped ball valve has the advantages of capability of effectively solving the problems, low operation failure rate, capability of greatly prolonging the service life of the valve, compact structure, light weight, capabilities of reducing the manufacturing cost and realizing mounting at any position, quick opening and closing and remote control and the like.

Owner:DAZHONG VALVE FACTORY ZHEJIANG PROV

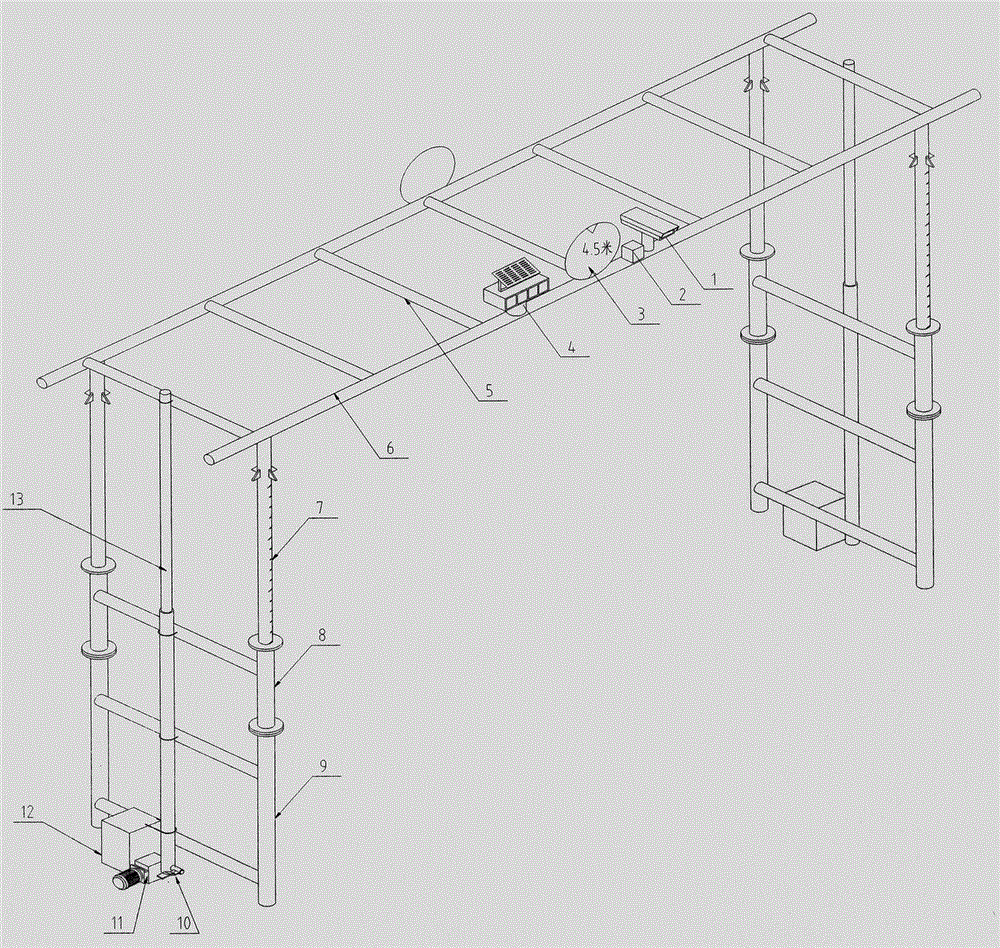

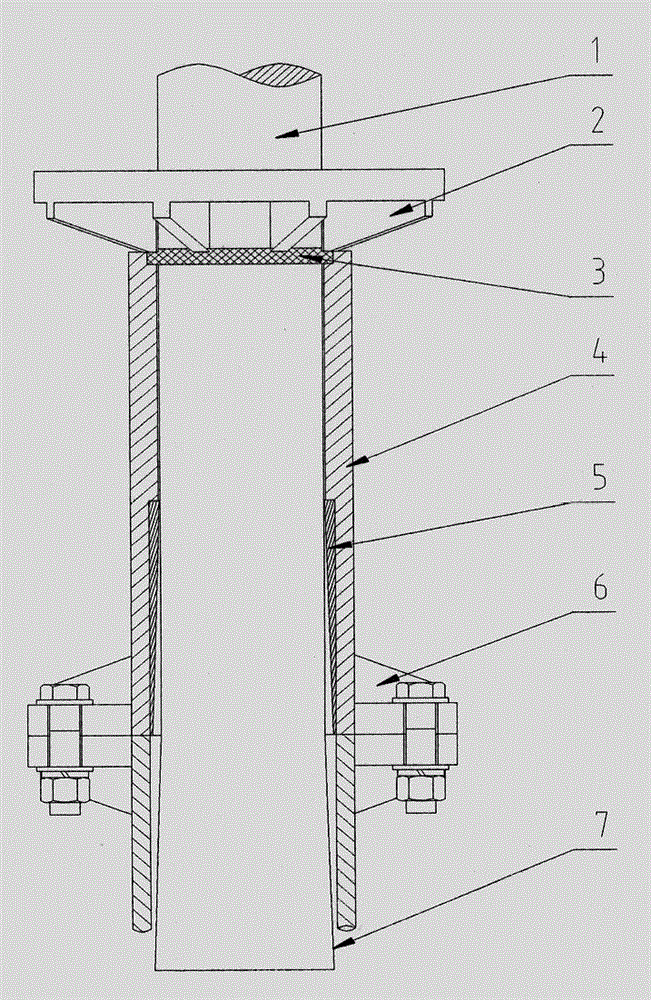

Combined type electric hydraulic lifting height limiting portal

InactiveCN105780683ASimple structureQuick opening and closingTraffic signalsRoad signsRemote controlElectro hydraulic

The invention provides a combined type electric hydraulic lifting height limiting portal and relates to road and bridge height limiting facilities. The combined type electric hydraulic lifting height limiting portal comprises two sets of uprights, cross beams capable of being lifted, a height limiting signboard, a strobe lamp, a wireless bridge photographing and recording instrument, a Bluetooth reading head, motors and hydraulic systems. The portal can be opened and closed in electric, manual, Bluetooth, remote control, electronic manners and the like. The two sets of uprights are arranged on the two sides of a lane. Each set of uprights is composed of two parallel uprights spaced at a certain distance, and the two uprights are connected through the corresponding cross beam. Each upright is composed of three parts, wherein the lower part is connected with a ground foundation, the middle part is a middle short joint, and the upper part is an inner pipe which can be lifted and is provided with scale marks. The side of each set of uprights is provided with the corresponding motor and the corresponding hydraulic system. The height of the height limiting portal is adjusted in two directions through the supporting force of hydraulic rods, and after the motors are powered off, the hydraulic systems are controlled through pedals, work is stable, and noise is low. The portal is simple in structure, safe, reliable, high in operability and suitable for various road sections.

Owner:刘广来

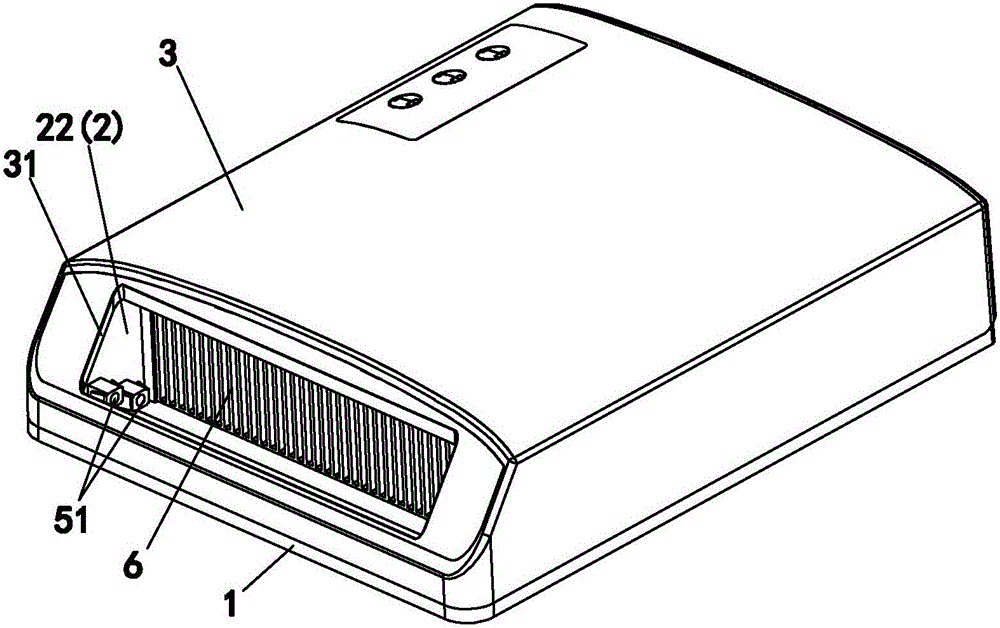

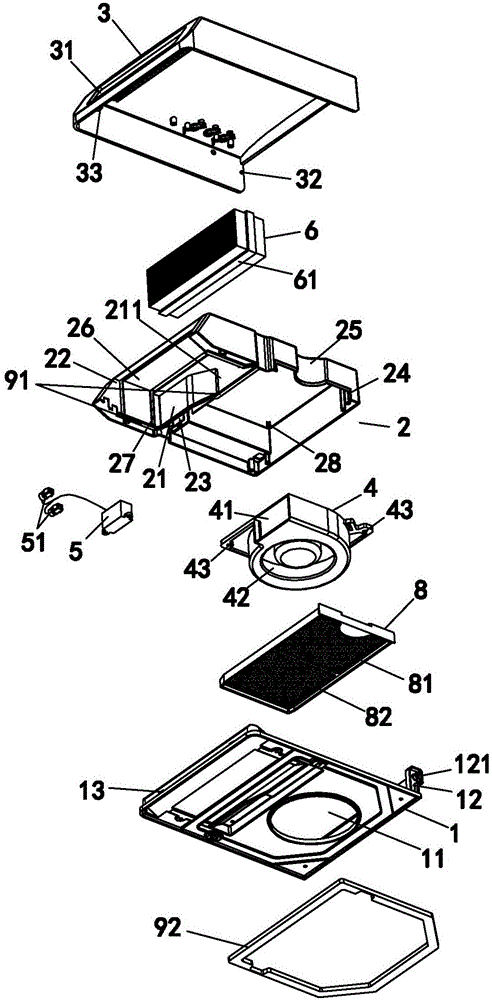

Wall-mounted air intake fan

ActiveCN106016566AQuick opening and closingEasy to open and closeMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir purification

The invention discloses a wall-mounted air intake fan which comprises a mounting base, an inner shell, an outer shell, an exhaust fan, a negative-ion generator, an air outlet filter and a control module. The exhaust fan, the negative-ion generator and the air outlet filter are arranged on the inner shell. A partition plate is arranged on the inner shell to divide the inner shell into two areas. The partition plate is provided with a connector connected with an air outlet of the exhaust fan. An inner exhaust opening is formed in the position, corresponding to the air outlet filter, of the inner shell. The inner shell is locked and fixed to the mounting base. Probes of the negative-ion generator are arranged on the inner exhaust opening. An air intake opening corresponding to an air inlet is formed in the mounting base. The outer shell is arranged outside the inner shell in a covering manner and connected with the mounting base. The control module is arranged in the outer shell. An outer exhaust opening is formed in the position, corresponding to the inner exhaust opening, of the outer shell. The exhaust fan and the negative-ion generator are connected with the control module. The air intake fan of the structure is especially suitable for being arranged in a small space room for use, has a good air purification effect and is convenient to clean and replace.

Owner:FUJIAN ALLEN ELECTRONICS

Electromagnetic valve

InactiveCN101042195ARealize on-off controlQuick opening and closingOperating means/releasing devices for valvesMultiple way valvesValve openingElectromagnetic coil

The electromagnetic valve comprises the non electromagnetic valve base locating at the utmost bottom of the electromagnetic valve, an air chamber formed at the upper center, guide valve opening and main valve opening from the air chamber to the outside wall, cross section of a valve being T shape and hallow, and the said valve connected with the non electromagnetic valve base through screw, with screw thread at the top, a magnetic valve core being a column, a round hole at the center of its end located at the center hollow part of the valve, a spring at the bottom of the said magnetic valve core and the valve, with the spring cased around the outside wall of the electromagnetic valve core, a Freon glue bar with the same size and shape of the magnetic valve core, putting into the hole of the magnetic valve core, an electromagnetic coil twisted around the outside wall of the valve, an outside shell cased outside of the valve with a round opening at the top, and the size being the same with the top of the magnetic valve and with nut fixed them in between.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Magnetically-driven valve device

ActiveCN105202210ASolve the problem that it is difficult to achieve full sealingQuick opening and closingOperating means/releasing devices for valvesSlide valveDrive shaftHigh pressure

The invention discloses a magnetically-driven valve device. The magnetically-driven valve device comprises a power source, driver and a valve body which are connected in sequence, wherein a valve body flange is fixed to the other end of the valve body in a sealed mode, a drive shaft and a gate plate which are connected movably are arranged in a channel of the valve body, the drive shaft is connected with the driver, a magnetic flange penetrates through the side wall of the valve body to be arranged, a through medium channel penetrating through the magnetic flange, the gate plate and the valve body is radially formed, and the power source drives the driver to drive the gate plate to move in the channel of the valve body. The magnetically-driven valve device adopts a magnetic pair made of a high-temperature-resisting permanent-magnet material to provide the acting force required by valve sealing without a backpressure condition and adopts a high-temperature-resisting high-pressure corrosion and radiation resistance sealing pair to achieve planar and linear-contact rigid sealing of a valve. Reliable outer sealing can be achieved by adopting connection modes including the driver, static sealing structures of sealing rings and flanges, welding and the like. Smooth passing of a fluid and a large-particle medium can be achieved by adopting the full-sized medium channel.

Owner:CHENGDU TAIHUA ZHONGCHENG TECH GRP CO LTD

Commercial washing machine

ActiveCN107945421AEasy to open and closeQuick opening and closingOther washing machinesApparatus for meter-controlled dispensingScrew cap

The invention relates to a commercial washing machine. The commercial washing machine comprises a coin box, a service port is formed in the coin box, an upper lid used for sealing the service port isarranged at the service port and is connected with the coin box through a bolt, a special-shaped fifth pressing die is arranged on the end face of a nut of the bolt, and / or the periphery of the nut ofthe bolt is in a special shape, so that a screwdriver opens and closes the upper lid by screwing on / off the bolt through the fifth pressing die and / or the periphery of the nut of the bolt. By means of the commercial washing machine, the upper lid is connected with the coin box through the bolt, so that opening and closing of the upper lid are simpler and quicker; meanwhile, by arranging the special-shaped pressing dies on the nut of the bolt, the bolt can be screwed off only by using a matched tool, and the safety of the coin box is guaranteed. Maintenance personnel can conduct correspondingmaintenance and detection simply by using the tool matched with the bolt to screw off the bolt, the safety is guaranteed, and the whole operation is also more convenient. Besides, the commercial washing machine is low in cost and suitable for industrialized production.

Owner:QINGDAO JIAOZHOU HAIER WASHING APPLIANCE CO LTD +1

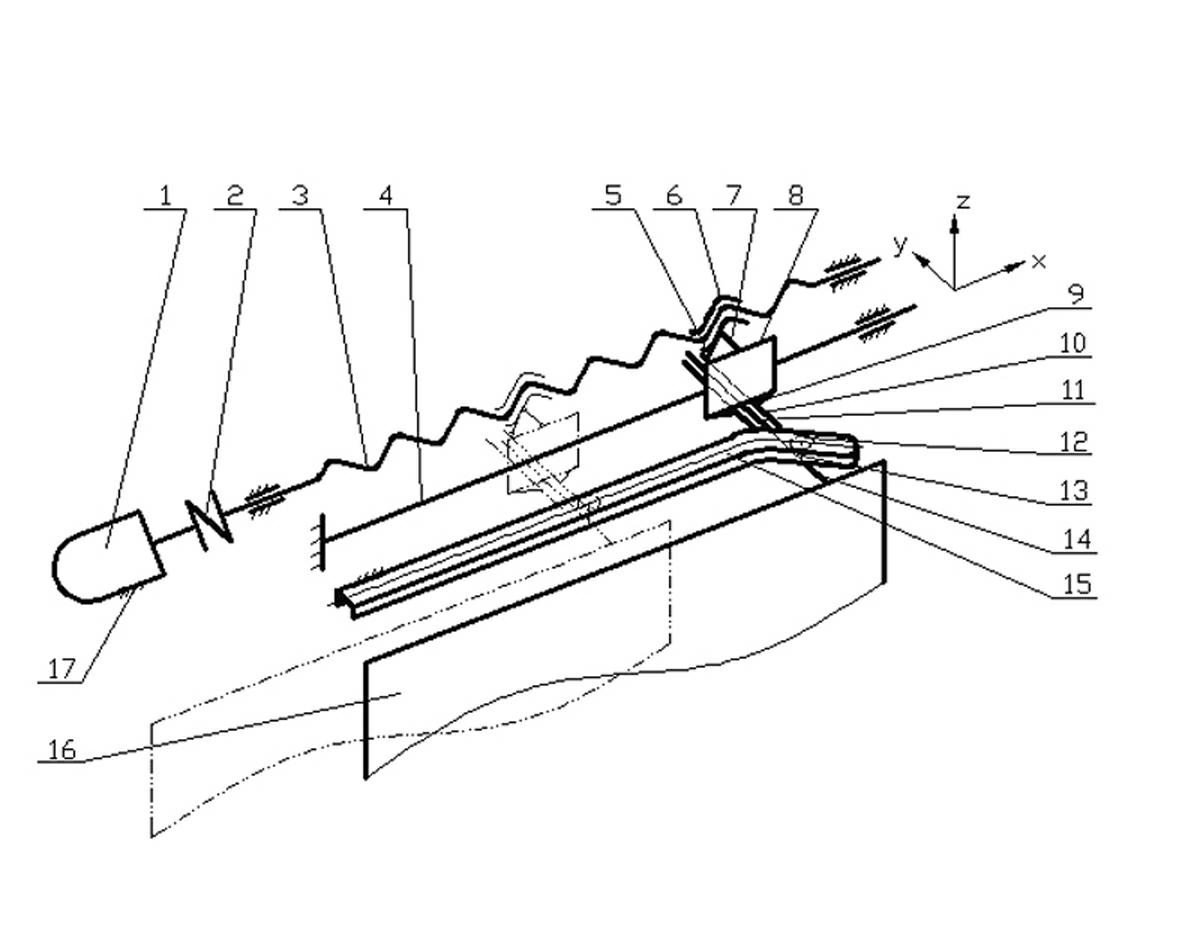

Spiral door carrying guide rod groove cam combination space mechanism for sliding-plug door

ActiveCN102305006ASierra seal is reliableImprove sealingPower-operated mechanismDoor arrangementCouplingEngineering

The invention discloses a spiral door carrying guide rod groove cam combination space mechanism for a sliding-plug door and relates to a sliding and plug, sealing, opening and closing mechanism for the sliding-plug door of a vehicle, in particular to the spiral door carrying guide rod cam combination space mechanism for the sliding-plug door of high-speed rail or other railway vehicles. The mechanism comprises a motor, a coupler, a screw, a bearing shaft, a coupling rod A, a nut, a coupling rod B, a shaft sleeve, a coupling rod C, a door carrying rod sleeve, a door carrying guide rod, a roller, a roller shaft, a door handle, a groove cam, a door leaf and a door frame, wherein a spiral mechanism consists of the nut, the screw and the door frame; a door carrying guide rod mechanism consists of the nut, the door carrying rod sleeve, and the shaft sleeve which are connected fixedly and integrally through the coupling rod A, the coupling rod B, and the coupling rod C, the bearing shaft, the door carrying guide rod, and the door frame; a groove cam mechanism consists of the door carrying guide rod, the door handle, and the door leaf which are connected fixedly and integrally, and the bearing shaft, the groove cam, the roller shaft, and the roller; and the three mechanisms are connected with one another to form the spiral door carrying guide rod groove cam combination space mechanism for the sliding-plug door.

Owner:HAIMEN BIWEI INTPROP SERVICE CO LTD

Dual-structure core tube valve

InactiveCN110319227ASimple structureEasy to manufactureSpindle sealingsOperating means/releasing devices for valvesEngineeringHigh pressure

The invention discloses a dual-structure core tube valve. The valve is one of conventional core tube valve plate blocks in the original core tube valve main series. A valve core tube is a fixed part and coaxially penetrates through a sleeve I of a valve body, a valve body inner cavity and a sleeve II of the valve body, an axial interlayer is arranged in the middle of the valve core tube, two axialadjacent sides of the interlayer are each provided with at least one radial circulation hole of an input segment and an output segment, a hollow-out inverted-L-shaped hole way is arranged on the halfsolid part of the valve body inner cavity, and a radial hole opening corresponds to and is matched with the radial circulation hole of the paired input segment, an annular valve element surrounding the interlayer and an annular valve base on the throat of the sleeve II form a seal pair, the difference of the outer diameters of the input segment and the output segment is larger than or equal to 0,the input segment and the sleeve I are in shaft hole type fit, the output segment and the sleeve II are in shaft hole type fit, and a seal is arranged on at least one combination part. A driving element and an elastic element for enabling the valve body to axially move in a reciprocating manner are arranged on the outer end of the valve body. The structure is simple, reliability is high, the valve adapts to high-pressure and strict conditions, medium erosion is prevented, and flexible characteristics are achieved.

Owner:卢星霖

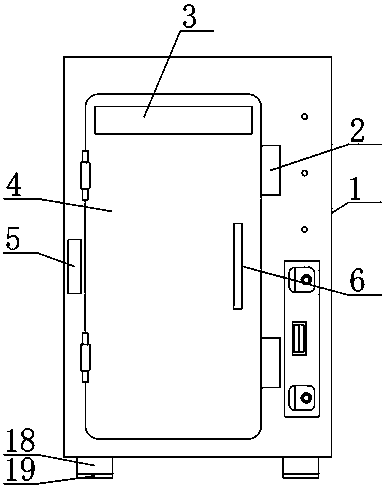

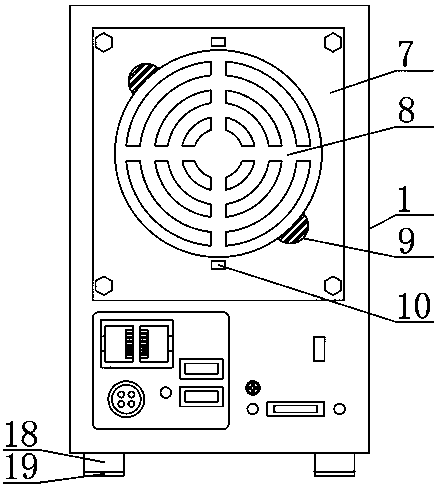

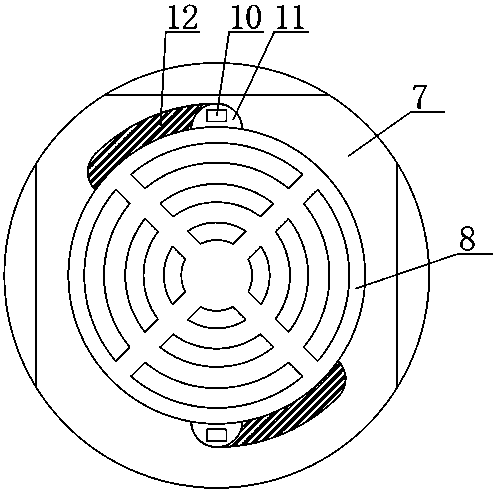

Network security supervision platform and use method thereof

PendingCN110377123ASimple and convenient disassemblyAvoid the inconvenience of disassemblyDigital processing power distributionTransmissionComputer engineeringOriginal Device

The invention discloses a network security supervision platform. The platform comprises a machine body and a rear cover plate arranged on the rear surface of the machine body. A ventilation hood is arranged in the rear cover plate. A storage groove is formed in the machine body. The top end of the storage groove communicates with the front surface of the machine body. Two semi-circular sliding blocks are symmetrically arranged on the surface of the ventilation hood, and a circular mounting notch consistent with the ventilation hood in size is formed in the rear cover plate. A semi-circular sliding block, an arc-shaped sliding groove, a semi-circular mounting notch, a triangular telescopic clamping pin, a spring chamber, a rectangular popup hole and a pressing hole are arranged so that theventilation hood is more convenient and faster to disassemble and assemble. The problem that the ventilation hood is inconvenient to disassemble due to the fact that an original device fixes the ventilation hood through a plurality of bolts is solved. An operator can rapidly take down the ventilation hood and thoroughly clean accumulated dust in the daily use process.

Owner:广东申立信息工程股份有限公司

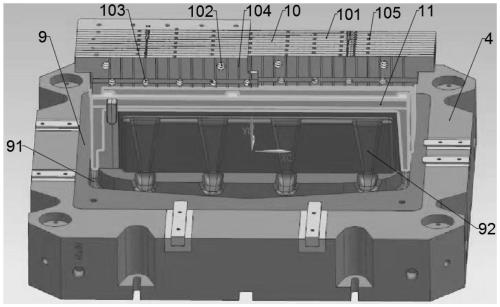

Radiator case for maglev train and casting method thereof

ActiveCN111182752AGuaranteed temperatureCrystallize fastCasings/cabinets/drawers detailsMetal casingsPressure castingMold filling

The invention discloses a radiator case for a maglev train in the field of train part manufacturing. The radiator case comprises a case body and reinforcing ribs, and the thickness of the reinforcingribs is less than or equal to 2.6 mm. The casting method comprises the following steps that: 1, a mold is installed on a low-pressure casting machine; 2, the mold is heated to 170-200 DEG C for the first time, and then the surface of an inner cavity of the mold is sprayed with heat preservation paint; 3, a thermal insulation coating is sprayed on the mold to perform heating the mold to 350-380 DEGC, a heating tube is electrified, it is ensured that the temperature of the upper mold blade is 350-380 DEG C, and the mold is closed; and 4, after the mold is closed, the liquid rising pipe orificecommunicates with the molten aluminum feeding end, and then the molten aluminum is cast and formed to obtain the radiator case; molten aluminum casting forming comprises three stages. In the first stage, molten aluminum is cast for 9s to 11s under the mold filling pressure of 300 mbar to 320 mbar; molten aluminum is subjected to first-stage casting and then subjected to mold-filling pressure casting for 11-13 s at 450-480 mbar, and the molten aluminum is subjected to second-stage casting and then subjected to mold-filling pressure casting for 10-12 s at 680-720 mbar. The radiator case for themaglev train prepared by the scheme has the characteristics of high strength and small thickness.

Owner:贵州蓝辉新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com