Flame-proof ball convenient for fast transferring and manufacturing method for composite material casing thereof

A composite material and shell technology, which is applied in the field of composite flameproof balls, can solve the problems of incomplete explosion-proof effect of explosion-proof tanks and explosion-proof cylinders, heavy explosion-proof balls, and difficulty in removing and detonating explosions, achieving light weight and designable strength. , easy to carry and move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

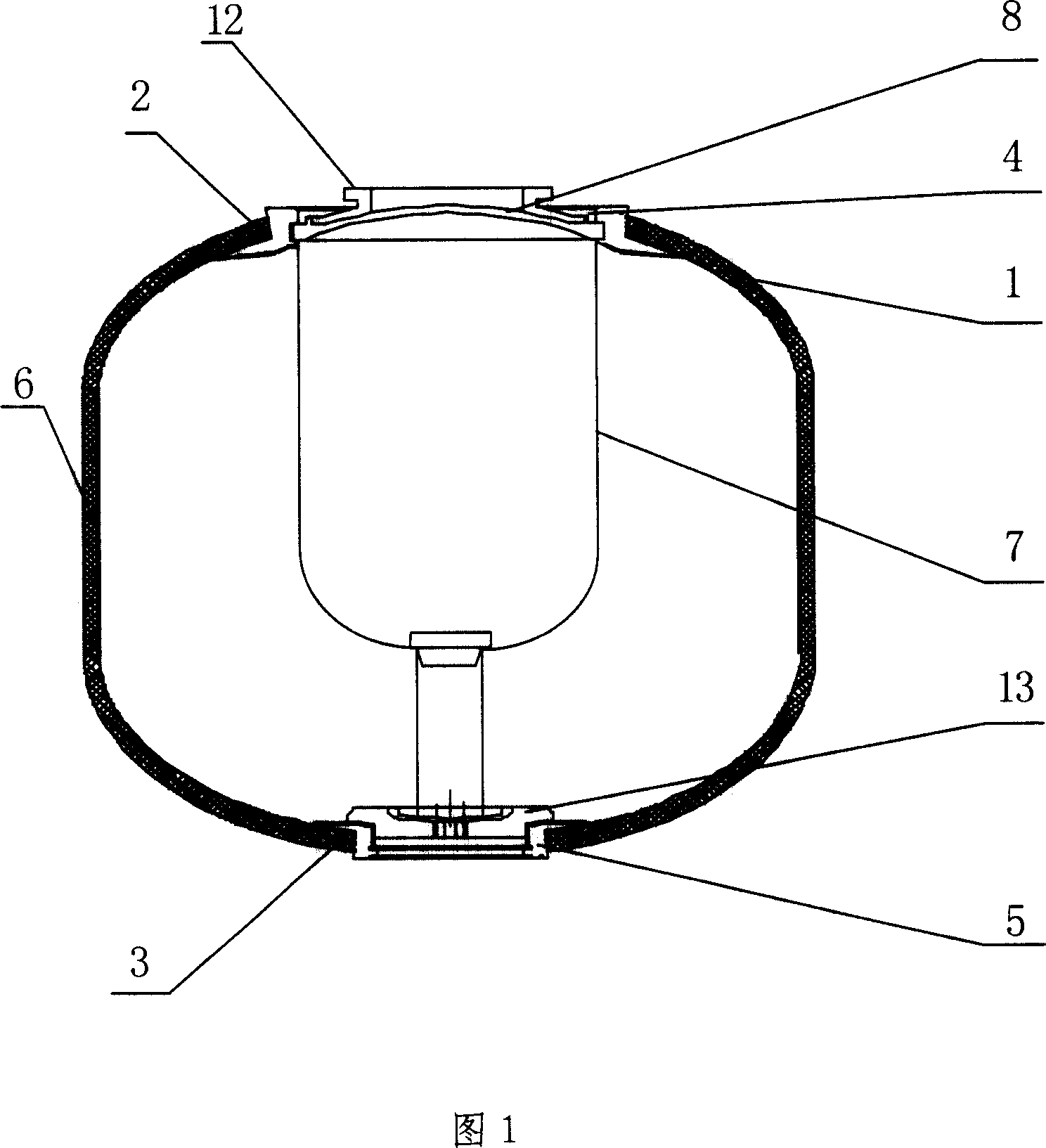

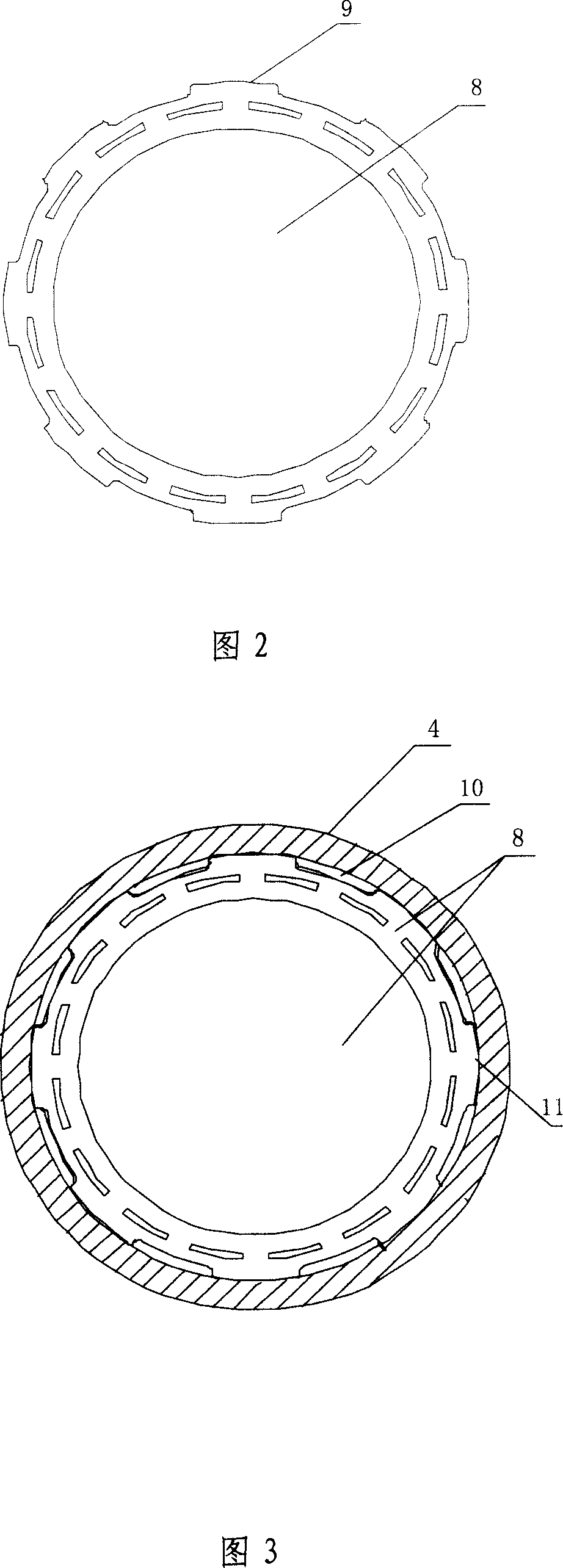

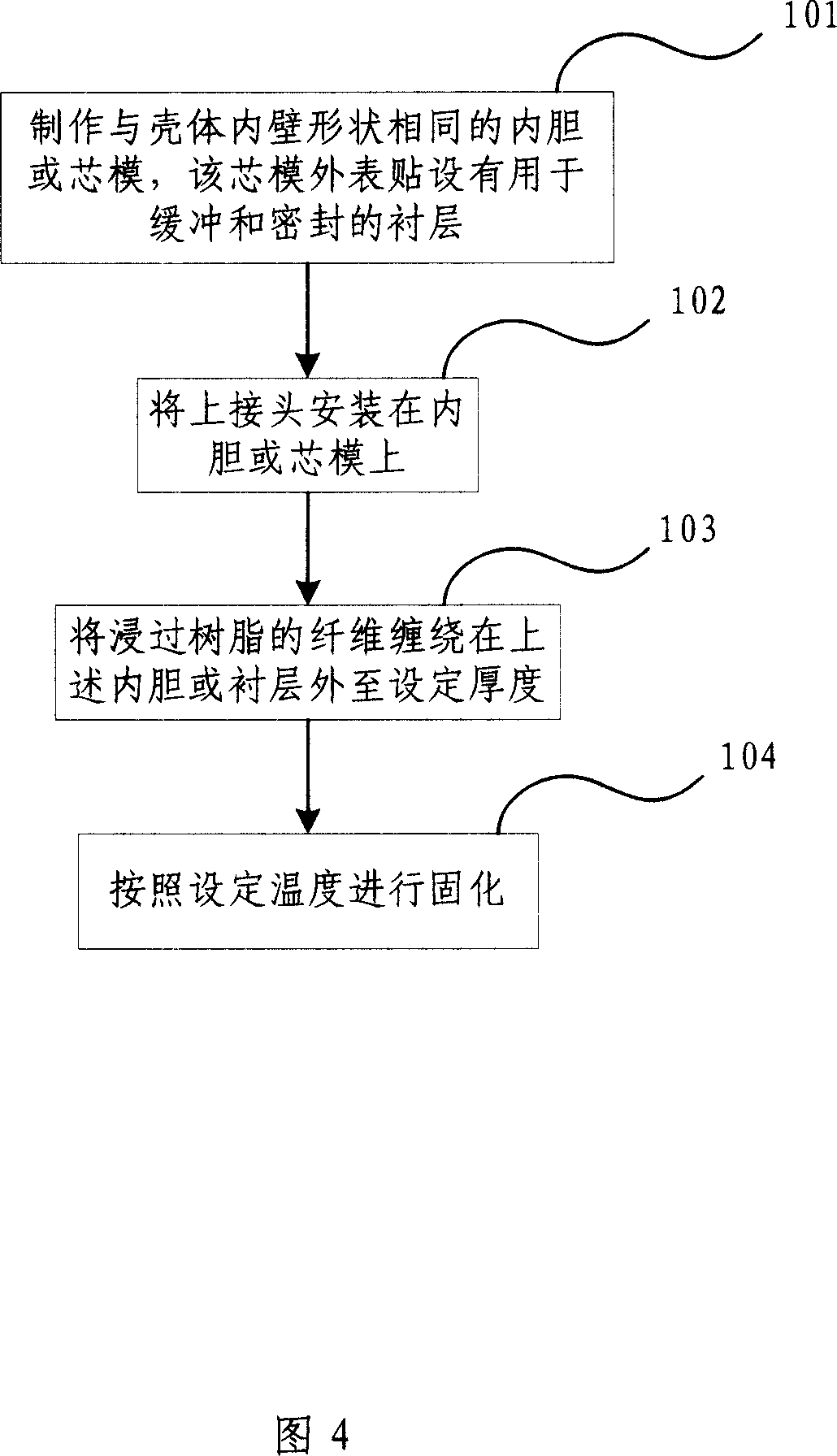

[0025] Fig. 1 is a schematic structural diagram of a first preferred embodiment of the present invention. Fig. 2 is a structural schematic diagram of the top cover of the present invention. Fig. 3 is a schematic diagram of the assembly of the top cover and the upper joint of the present invention. As shown in the figure, the present invention includes a flameproof spherical shell 1 with an inner cavity. The shell is spherical or the middle section 6 of the shell is cylindrical, and the middle section is closed up and down with an ellipsoidal curved surface to form a head. The upper end of the housing 1 is provided with an upper pole hole, and the upper pole hole 2 is fixed from the inner cavity of the housing 1 to the outside with a ring-shaped upper joint 4, and the upper joint 4 is located on the inner cavity side of the housing 1 along the inner wall of the housing 1 to the housing The curved surface part extends for a section; the casing 1 is vertically provided with a me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com