Dual-structure core tube valve

A binary structure, core tube technology, applied in the direction of the valve housing structure, sliding valve, valve details, etc., can solve the problems of high purchase cost and use cost, inability to open and close quickly, valve core erosion, etc., to achieve simple structure, High cost performance and low opening and closing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

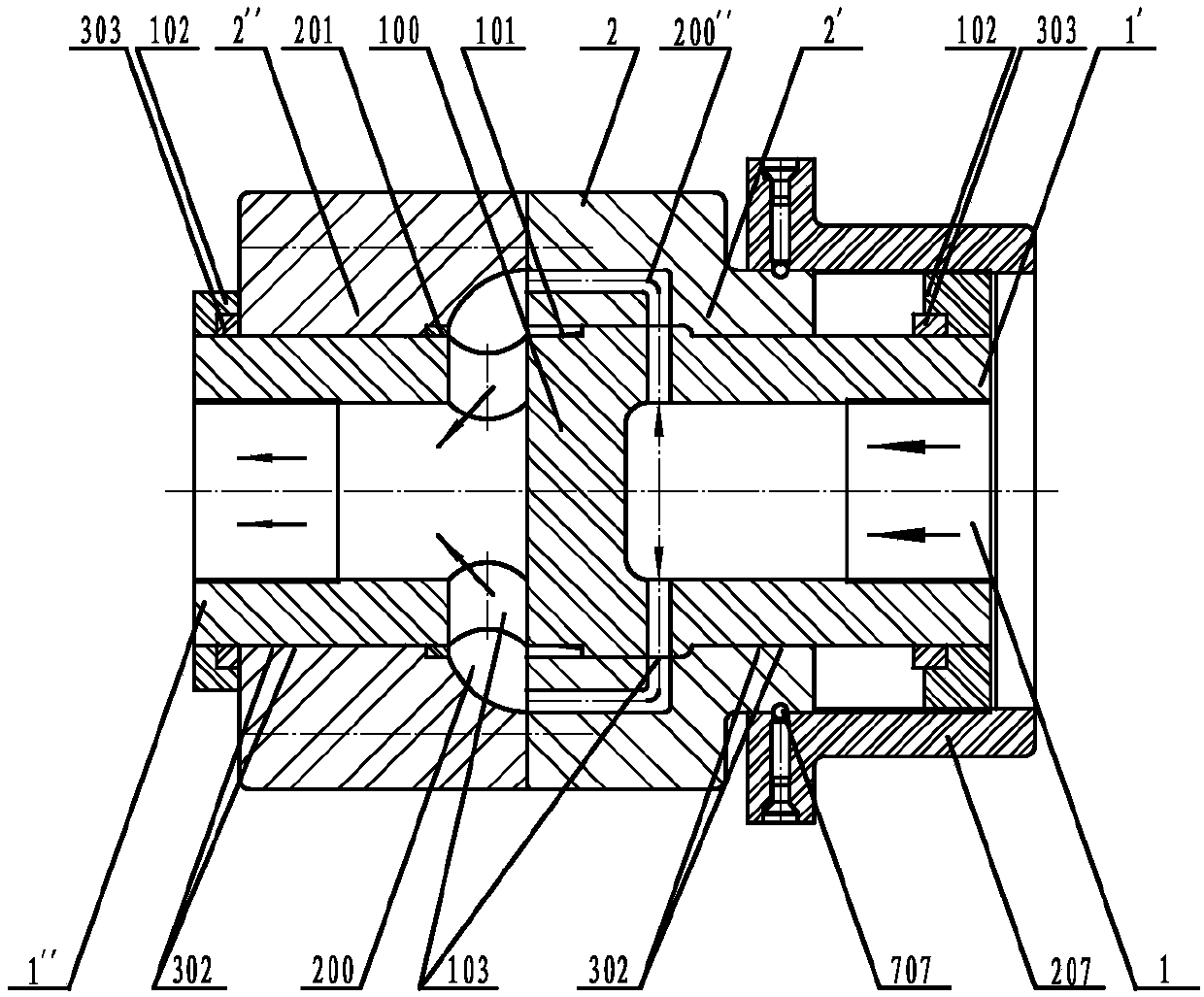

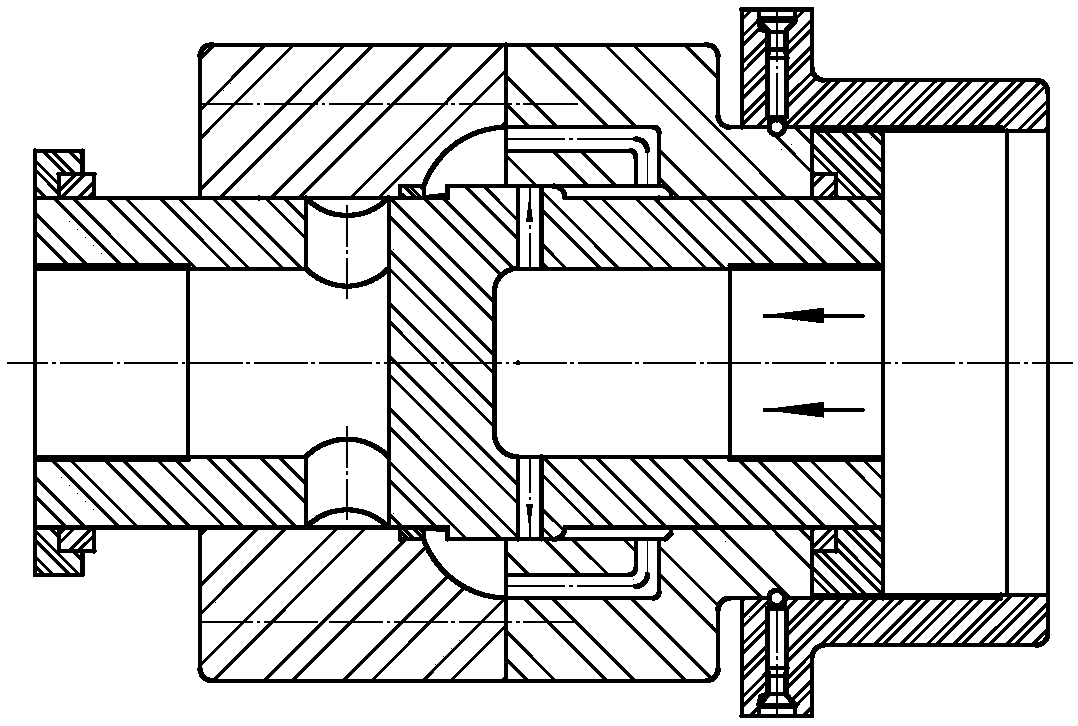

[0033] See attached figure 1 , 2 , the dual-structure core tube valve described in this embodiment is used for opening and closing, slow release, and current limiting; the valve core tube 1 is the sleeve tube I2' that runs through the valve body 2 in the same axial direction as the fixing member, and the valve body 2 Inner cavity 200, and the sleeve tube II2" of the valve body 2; there is an axial partition 100 in the middle of the valve core tube 1, and the partition 100 is composed of the inner core and the middle section of the valve core tube 1 radially radiating from the inner core, and the inner core of the partition 100 The two axial end faces are planes; the axially adjacent two sides of the partition 100 are the input section 1' and the output section 1", the input section 1' is evenly arranged with two small radial flow holes 103, and the output section 1" is well-proportioned Two large radial flow holes 103 are arranged; the cavity part of the inner cavity 200 of t...

Embodiment 2

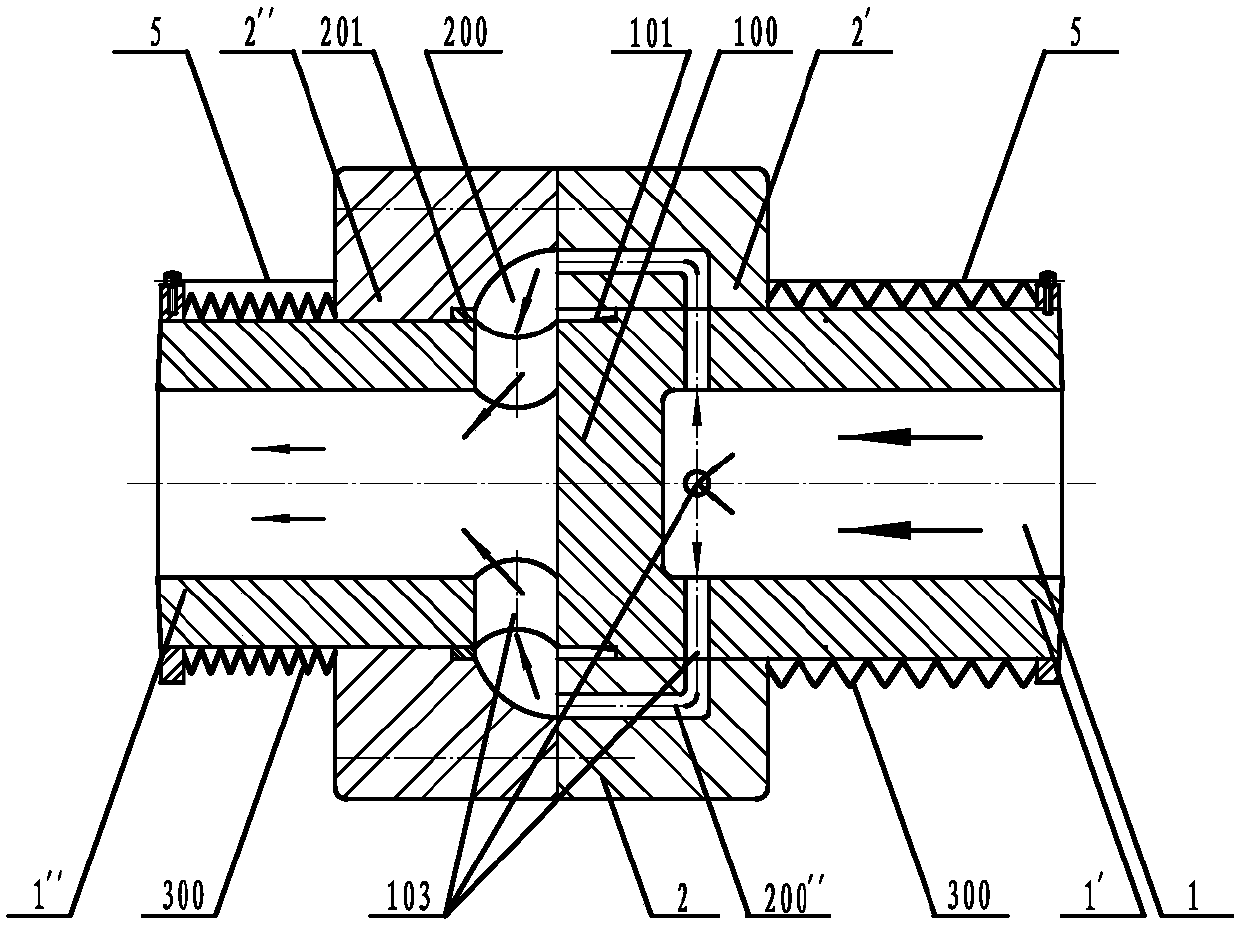

[0037] See attached image 3 , 4, 5, the dual structure core tube valve described in this embodiment is used for opening and closing, slow release, and current limiting; the valve core tube 1 is the sleeve tube I2' that runs through the valve body 2 in the same axial direction as the fixing member, and the valve core tube 1 Body 2 inner cavity 200, and sleeve pipe II 2" of valve body 2; there is an axial partition 100 in the middle of the valve core tube 1, and the partition layer 100 is composed of the inner core and the middle pipe section of the valve core tube 1 radially radiating from the inner core, and the partition layer 100 The two axial end faces of the core are planes; the axially adjacent two sides of the partition 100 are the input section 1' and the output section 1", and the input section 1' is evenly arranged with four small radial flow holes 103, and the output section 1 "Two large radial flow holes 103 are evenly arranged; the cavity part of the inner cavity...

Embodiment 3

[0042] See attached Image 6 , 7 , the dual-structure core tube valve described in this embodiment is used for opening and closing; the valve core tube 1 is a sleeve tube I2' coaxially penetrating through the valve body 2, the inner cavity 200 of the valve body 2, and the valve core tube 1. Sleeve II 2″ of body 2; there is an axial partition 100 in the middle of the valve core tube 1, and the partition 100 is composed of the inner core and the middle section of the valve core tube 1 radially radiating from the inner core, and the two axial end faces of the inner core of the partition 100 are Plane; the axially adjacent two sides of the interlayer 100 are respectively the two radial flow holes 103 of the input section 1' and the output section 1 "; the cavity part of the inner chamber 200 of the valve body 2 is half, and the other half is solid , the solid part has two hollow holes 200" that enter radially from the annular inner wall of the sleeve I2', and then turn and axiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com