Rotary cutting valve

A technology of rotary cutting valves and discs, which is applied in the direction of sliding valves, valve details, valve devices, etc., and can solve problems such as sedimentation and scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

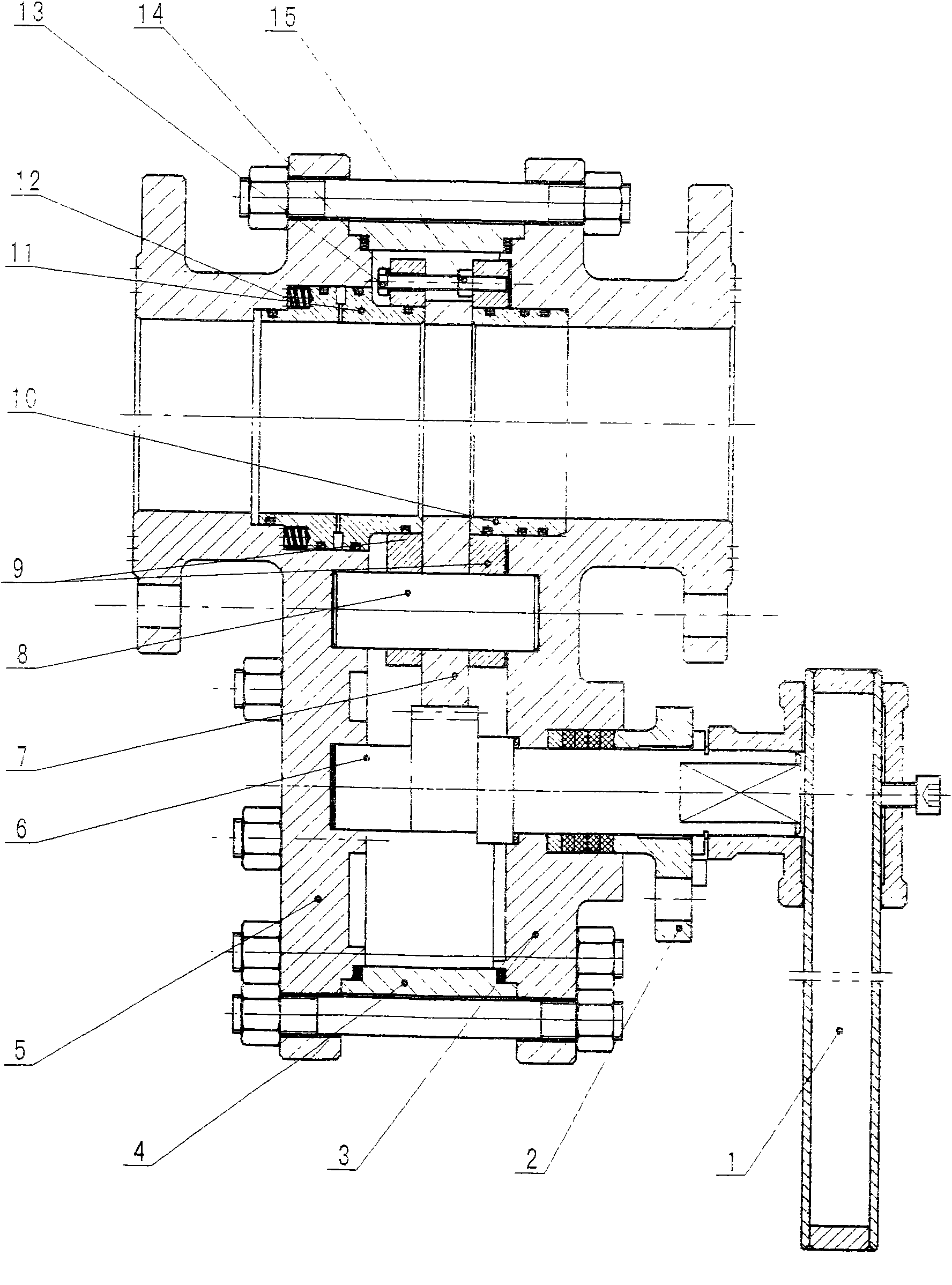

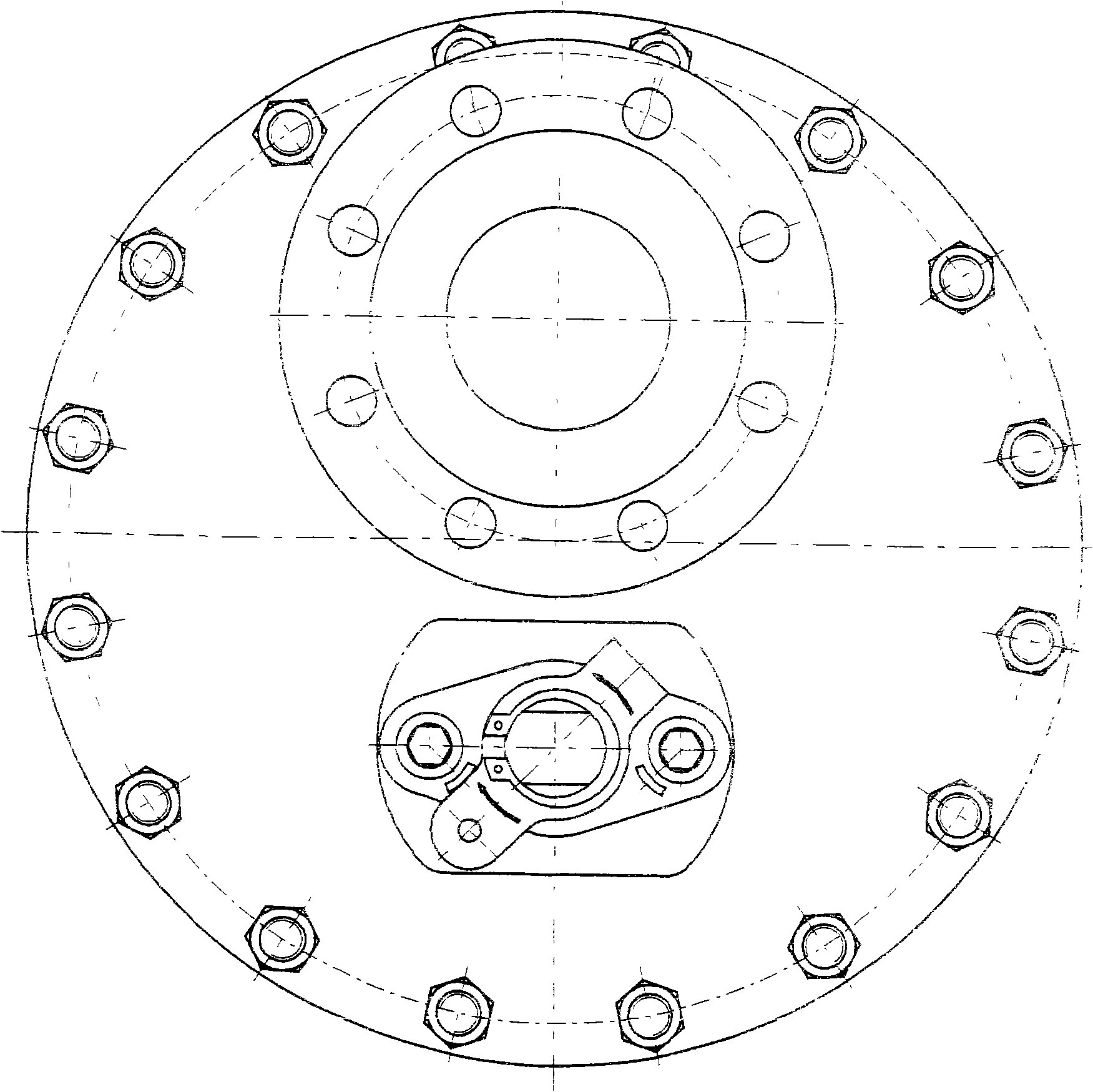

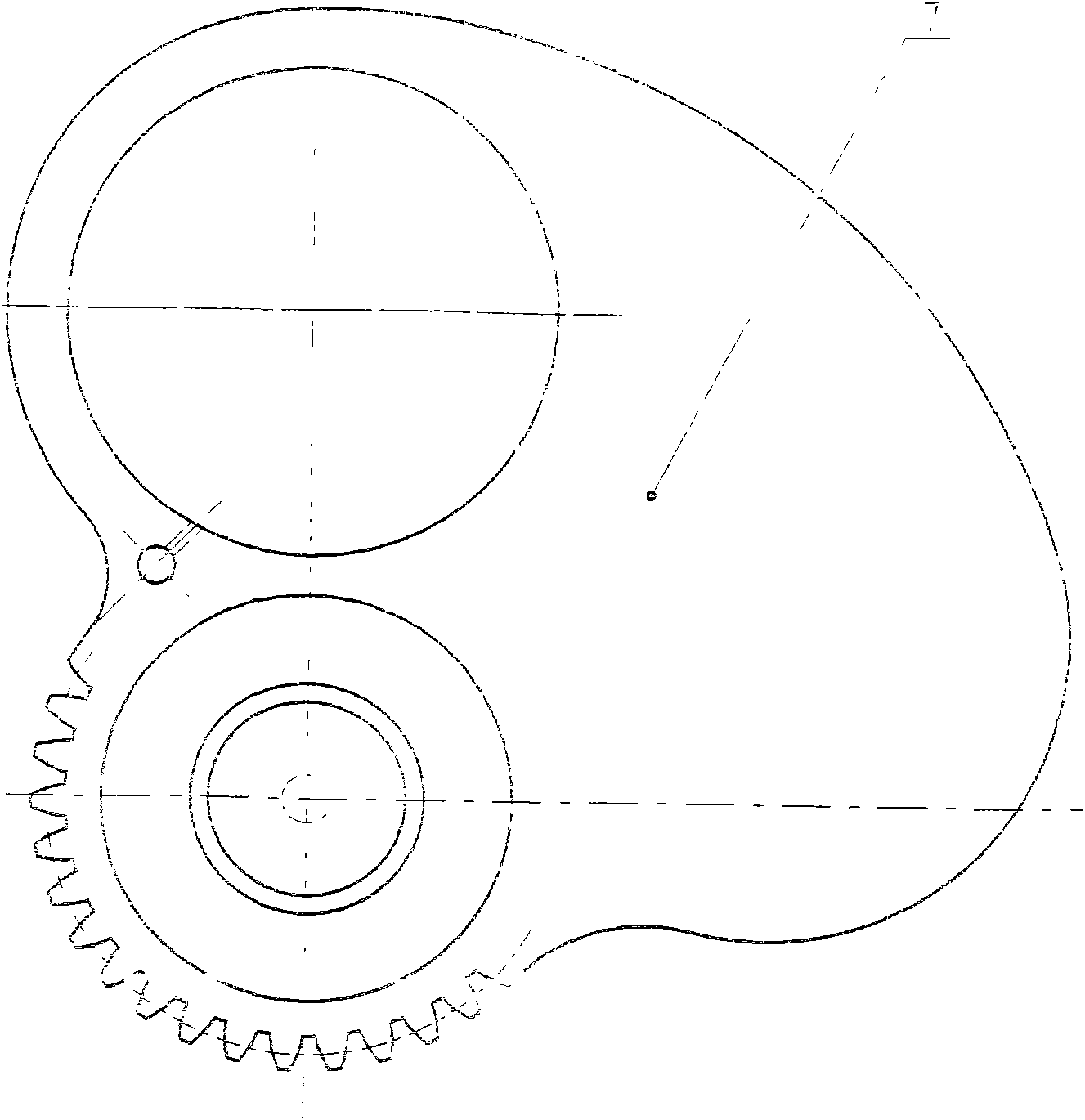

[0014] As shown in the figure, the right valve body 3, the intermediate body 4, and the left valve body 5 form a shell. The handle 1, the packing gland 2, the right valve body 3, the left valve body 5, and the valve stem 6 are connected, and the valve stem 6 is inserted in the left In the positioning hole of the valve body 5, the fixed shaft 8 passes through the splint 9 and the valve disc 7 on both sides, and the two ends are inserted into the positioning holes of the right valve body 3 and the left valve body 5. The right valve body 3, the right valve seat 10, Valve disc 7, left valve seat 11, cylindrical compression spring 12, left valve body 5 are connected, hexagon head bolt 13, butterfly spring 14, hexagon nut 15 are used as fasteners, connecting splint 9, valve disc 7, right valve seat 10. There is an "O" seal between the outer circle of the left valve seat 11 and the right valve body 3, the left valve body 5 and the clamping plate 9. The valve stem 6, the valve disc 7 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com