Patents

Literature

241results about How to "Open and close" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

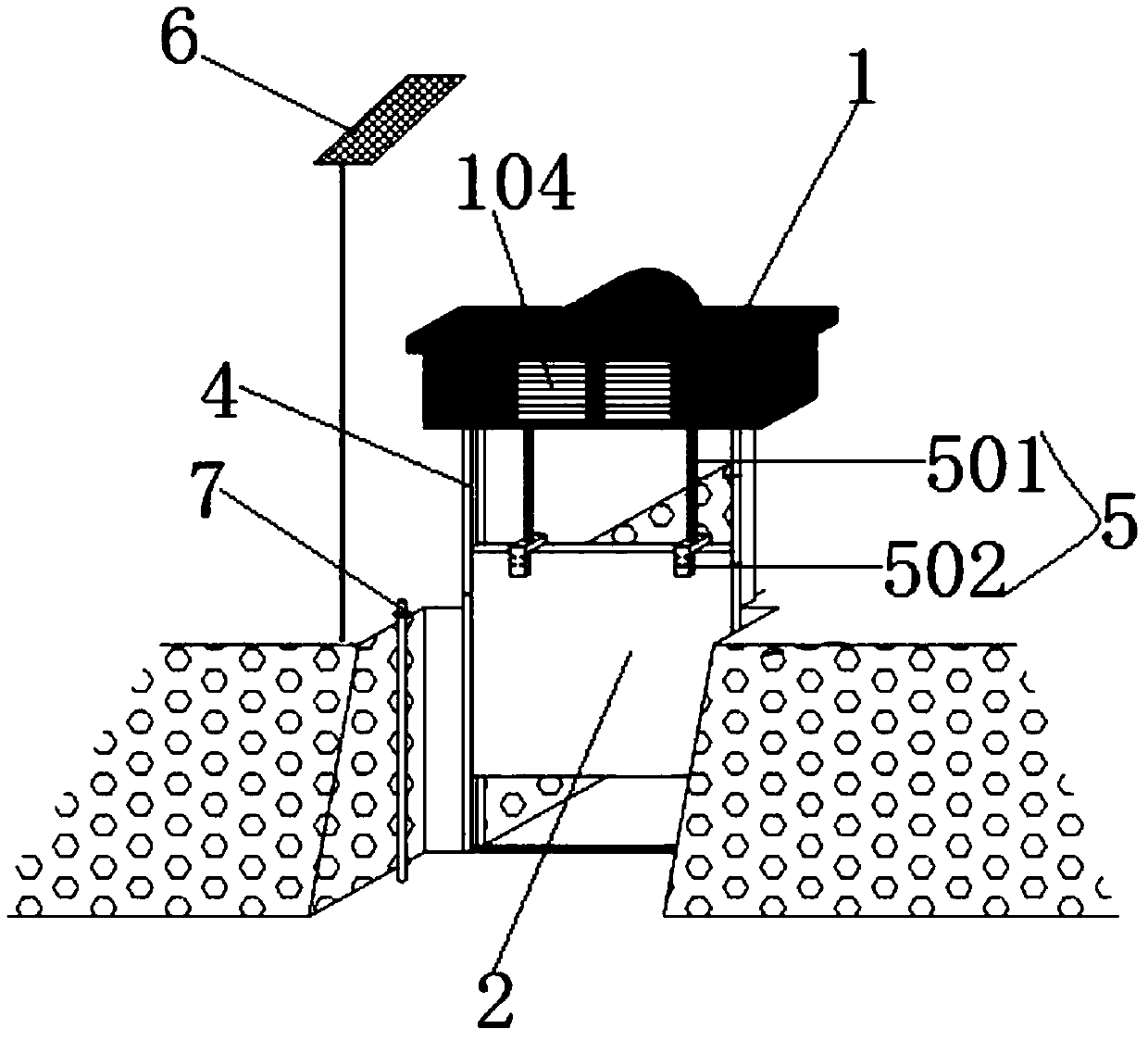

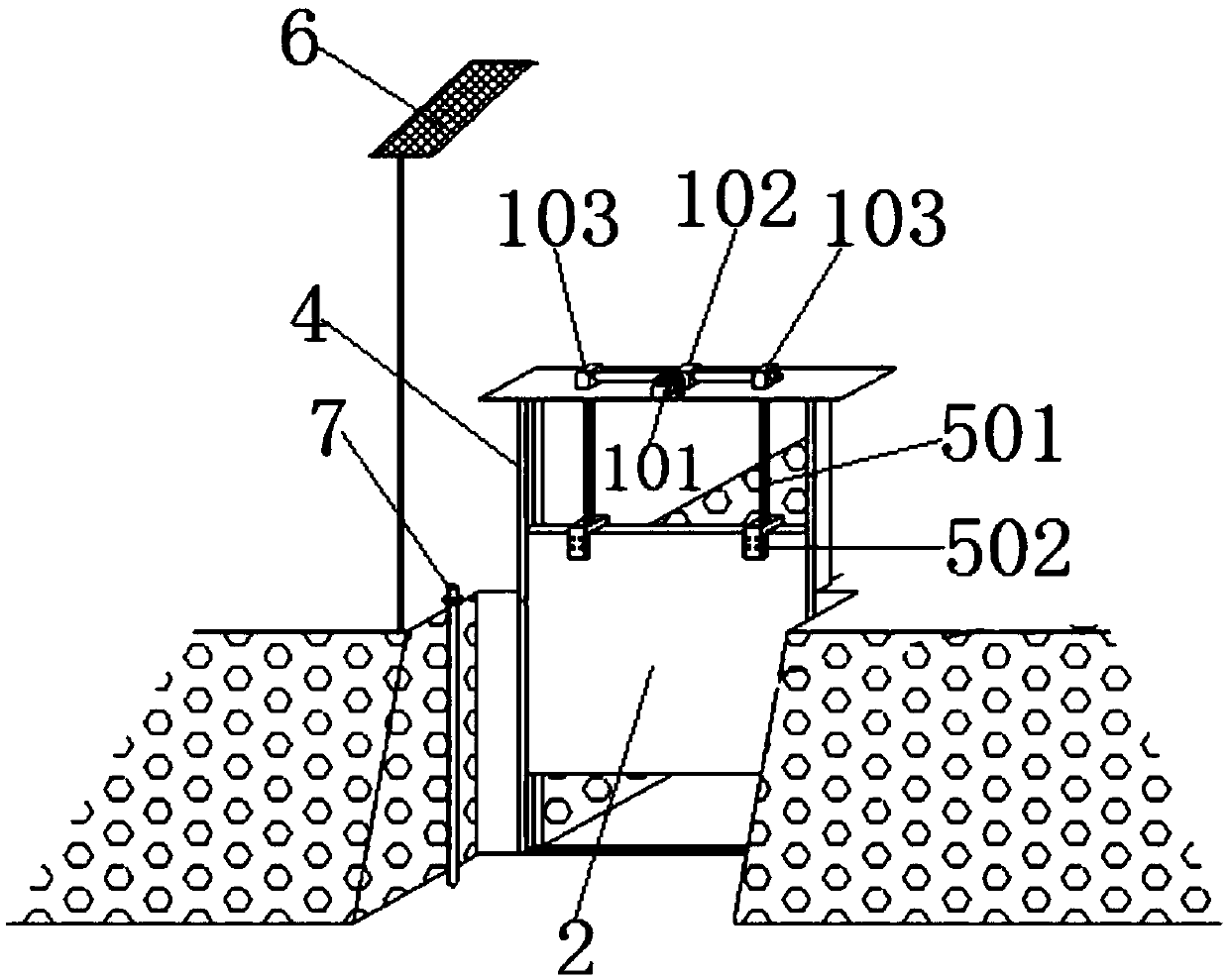

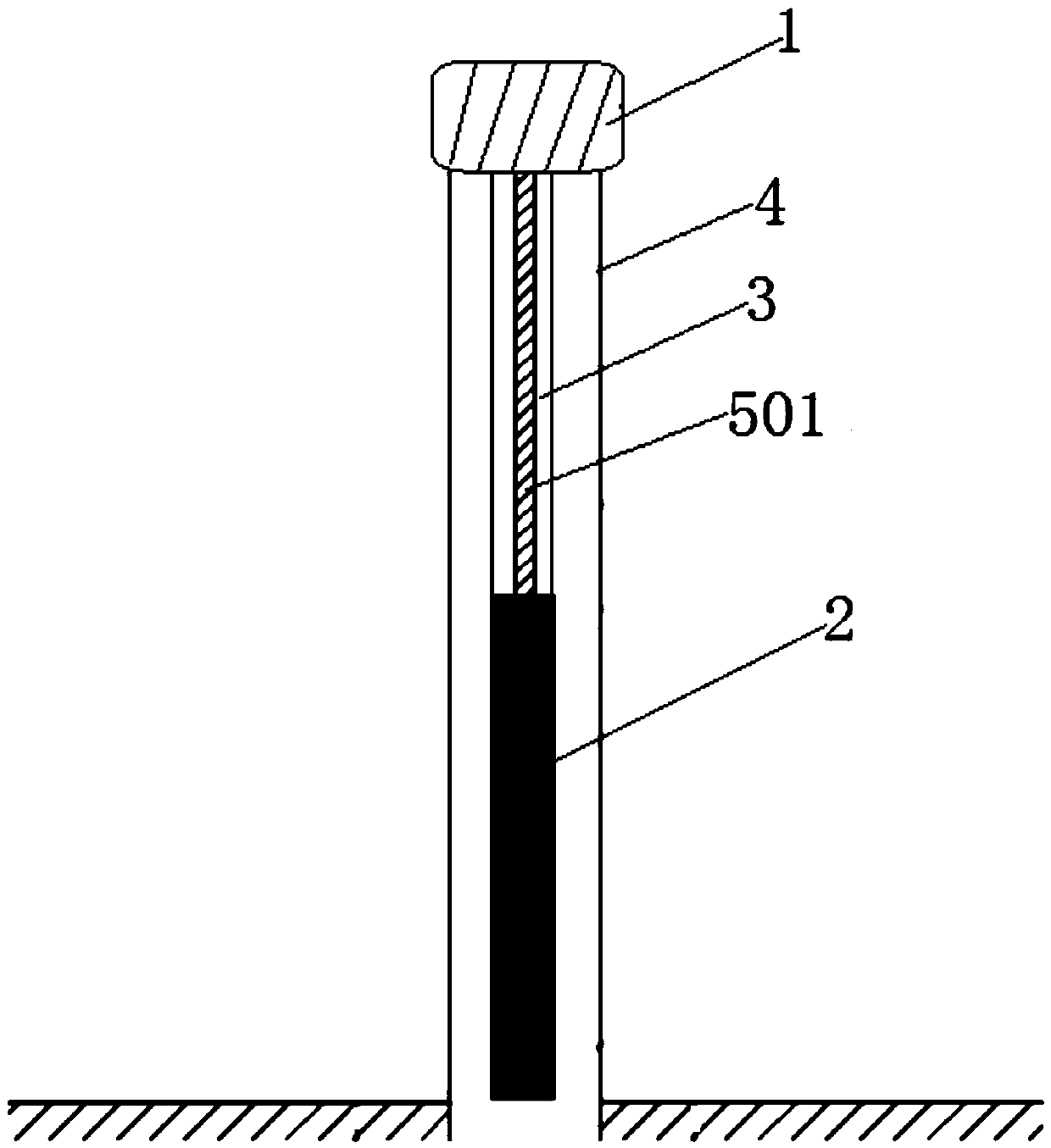

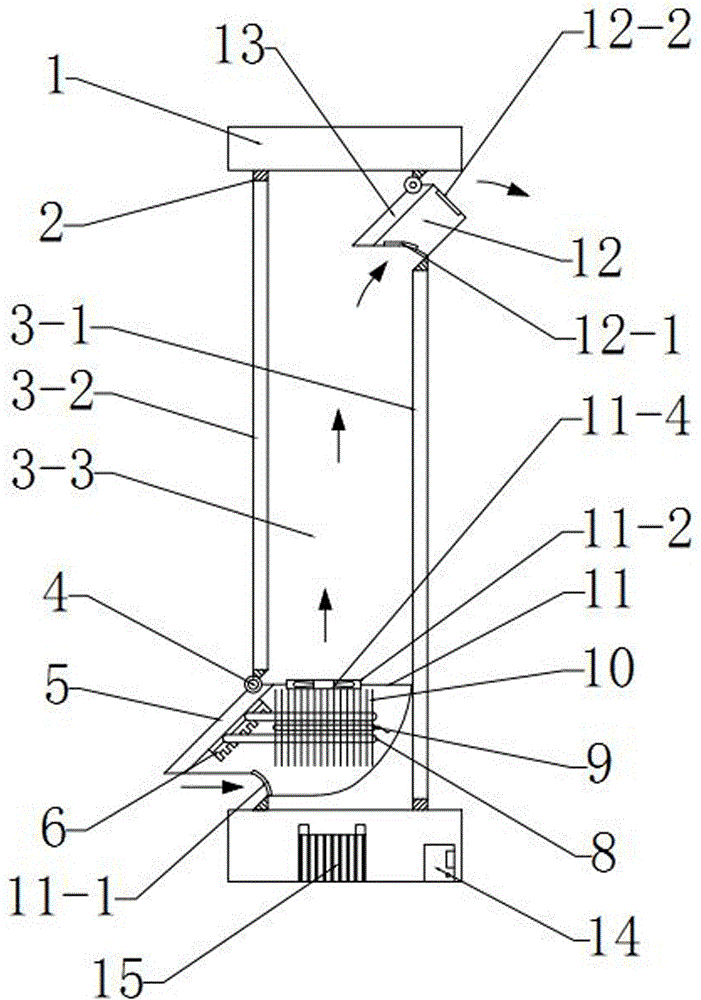

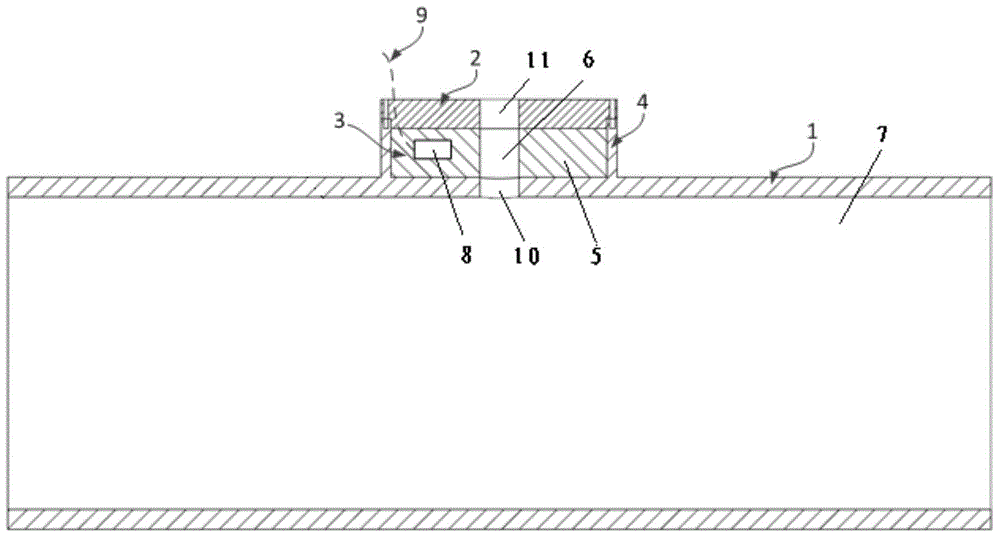

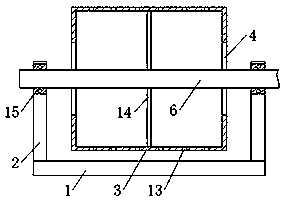

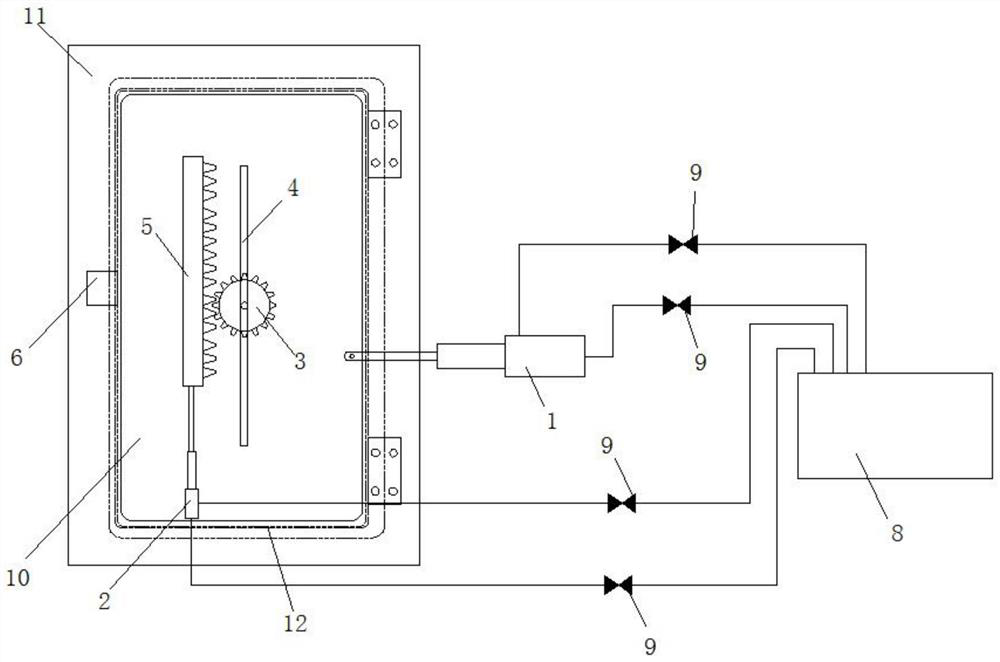

Solar driven gate

The invention discloses a solar driven gate and belongs to the technical field of irrigation. The gate comprises a waterproof control box, a flashboard, flashboard sliding chutes, a door-type gate frame, two driving screws and bearing nuts; a power source, a motor, a synchronizer, a worm gear reducer, and a solar panel electrically connected with the power source are arranged in the waterproof control box; the door-type gate frame is fixed on canal banks on two sides of a canal, and the bottom of the door-type gate frame is flush with the bottom of the canal; the flashboard sliding chutes are fixed on left and right sidewalls of the door-type gate frame and two left and right sides of the flashboard are inserted into the flashboard sliding chutes; the waterproof control box is fixed on the top of the door-type gate frame; the bearing nuts are fixed on the top of the flashboard; upper ends of the driving screws are connected with the worm gear reducer, while lower ends of the driving screws are in threaded connection with the bearing nuts; the solar panel powers the power source and drives the motor to run; the synchronizer synchronously transmits the driving force of the motor to the worm gear reducer and drives the driving screws to rotate in the bearing nuts, thereby putting the flashboard in up-and-down motions in the flashboard sliding chutes. The solar driven gate is low in energy consumption.

Owner:CHINA IRRIGATION & DRAINAGE DEV CENT +3

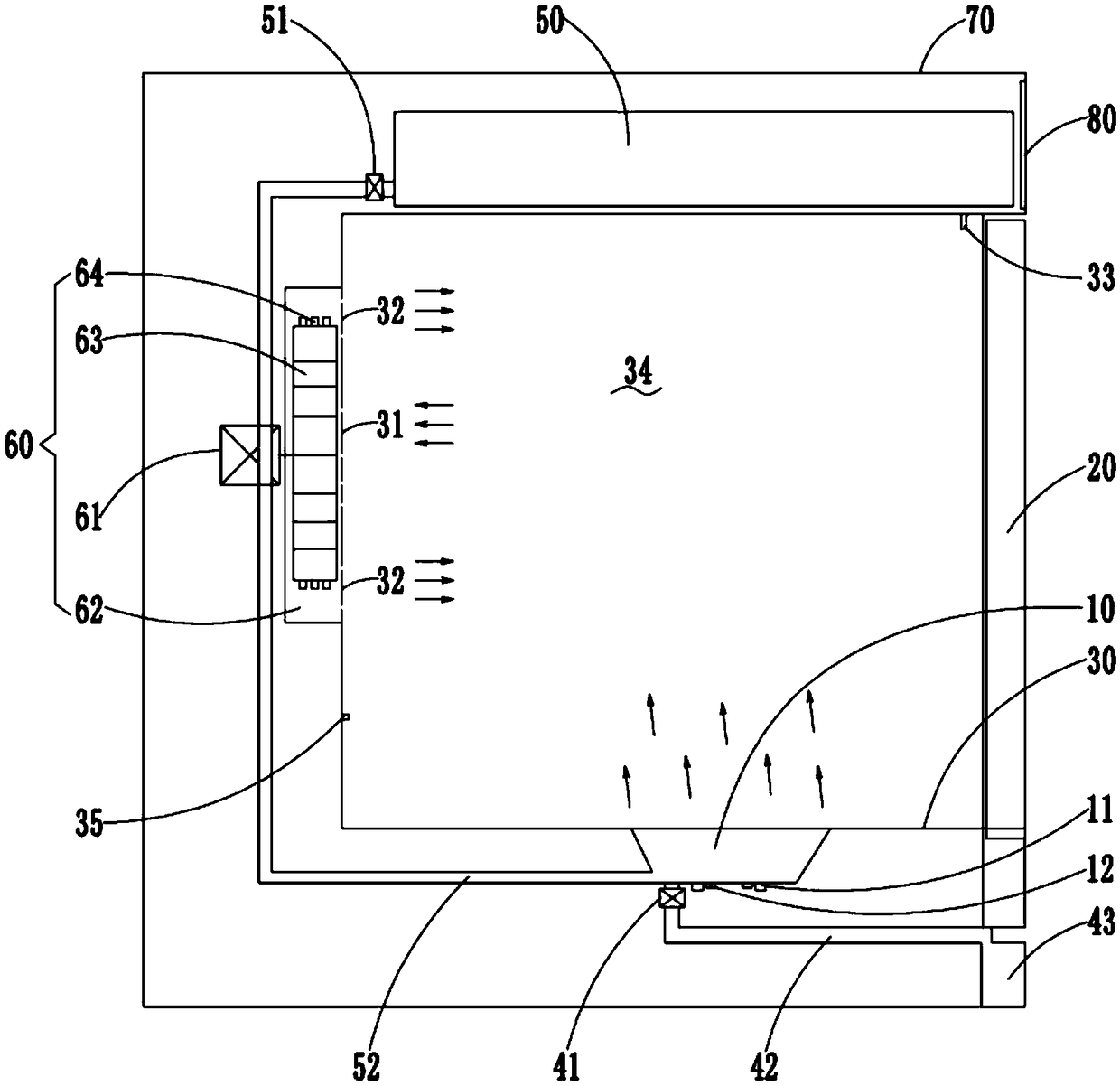

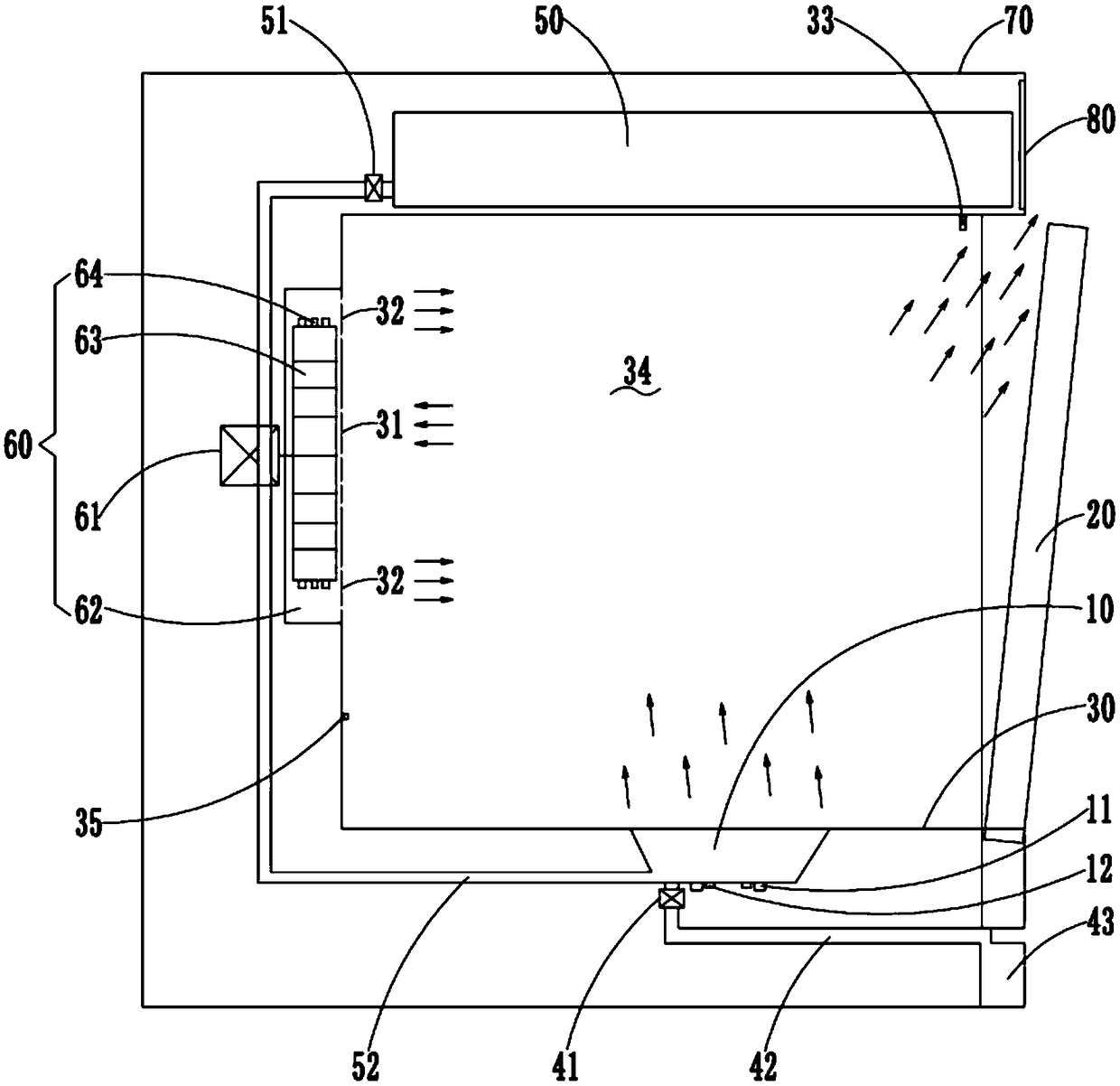

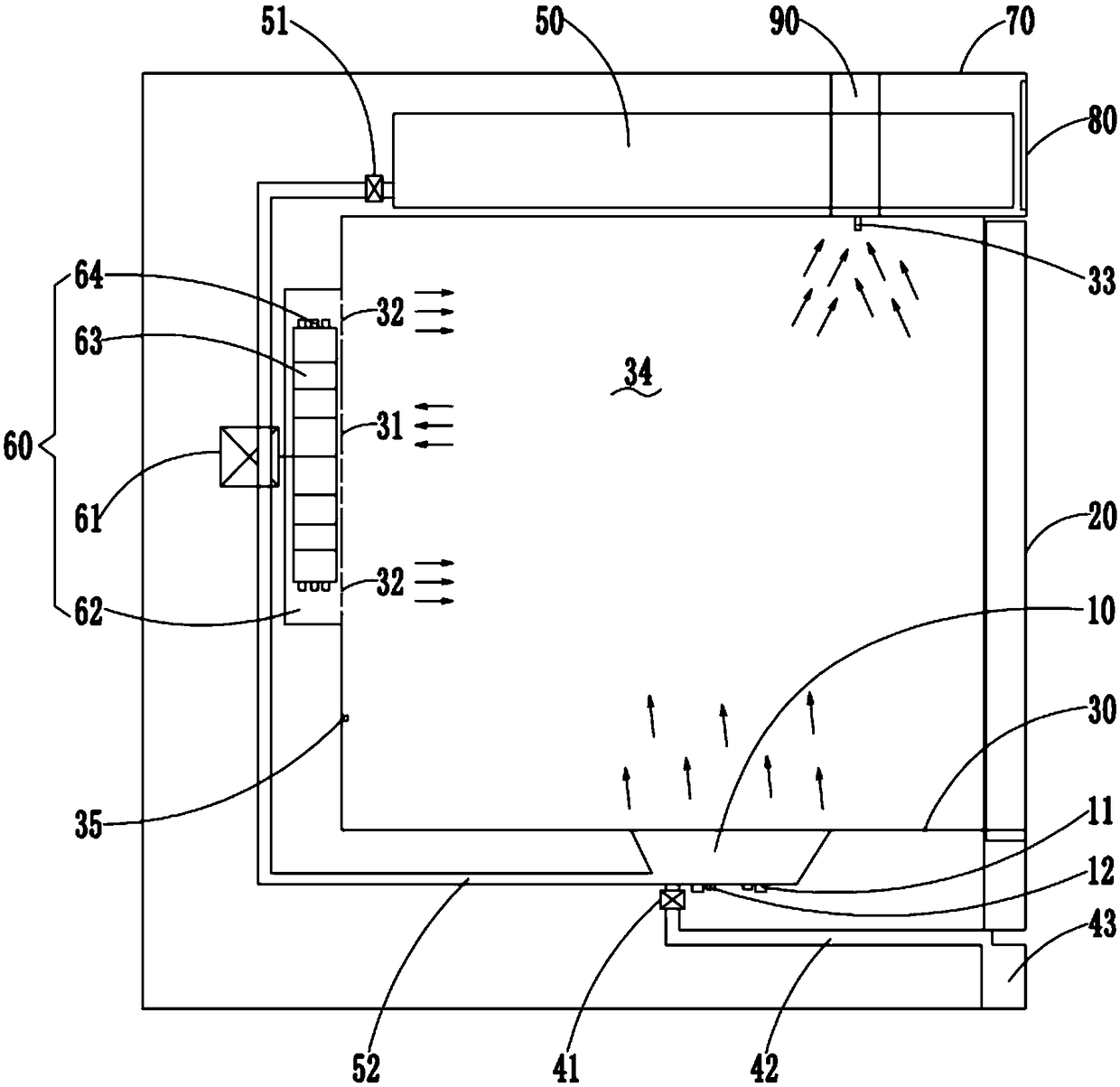

Cooking appliance with steam cooking function and drying control method

PendingCN109008594ATurn on the implementationOpen and closeSteam cooking vesselsVessels with intergral heatingWater dischargeSteam cooking

The invention provides a cooking appliance with a steam cooking function and a drying control method, relates to the technical field of household appliances, and aims to solve the problems that in theprior art, a cooking appliance with the steam cooking function is low in drying efficiency, and more energy is wasted in the drying process. The cooking appliance comprises a shell, a door, a humidity sensor, a steam generator in an inner container, a water discharging pipe, a water supply pipe, a heated air circulation device, an air discharging outlet and a controller, wherein the water discharging pipe and the water supply pipe are communicated with the steam generator; the heated air circulation device is used for cyclically heating air flow in the inner container; the air discharging outlet is used for discharging high-temperature steam in the drying process; the steam generator is provided with heaters, the heaters separately work, and the powers of the heaters are different. The drying control method is used for drying the inner container of the cooking appliance. According to the cooking appliance with the steam cooking function and the drying control method, it is not required that residual water is dried, the drying time is effectively shortened, and less energy is wasted.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

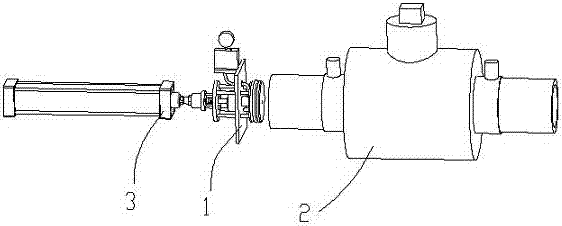

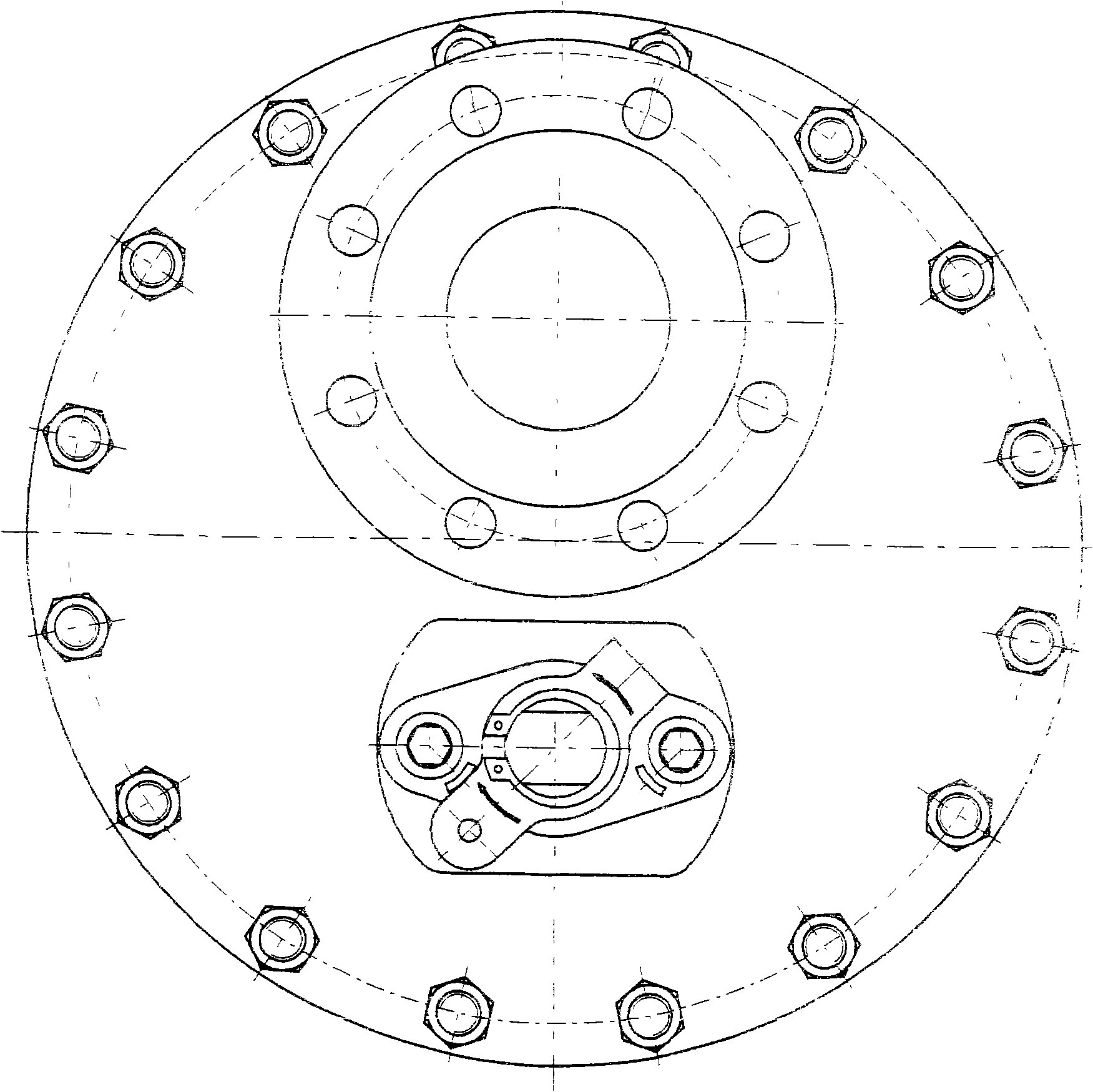

Polyethylene ball valve air tightness detection device

ActiveCN107152993AHigh degree of automationImprove test efficiencyMeasurement of fluid loss/gain rateOvervoltageTest efficiency

The invention relates to a polyethylene ball valve air tightness detection device which comprises a detecting body connected with a driving device. The polyethylene ball valve air tightness detection device is characterized in that the detecting body is provided with two pushing bodies coaxially connected in series; the two pushing bodies are provided with pressure plates in extrusion fit; a sealing body capable of expanding along the radial direction is arranged between the two pressure plates; the two pressure plates and the sealing body constitute a sealing head matching an inner hole of a ball valve to be detected; the sealing head is internally provided with an inflatable channel; one end of the inflatable channel is communicated with an inflatable cylinder; and the inflatable channel is externally connected with a pressure gauge through an air pipe, and the air pipe is provided with an overvoltage protection mechanism. As the detecting body is internally provided with the inflatable cylinder, no external air source is needed. The pushing bodies seal the inner cavity of the valve body in the operation process to realize continuous, quick and automatic inflation, and the pressure value can be read directly from the pressure gauge and is clear at a glance. Water-free test is realized, which helps to protect the environment. The degree of automation is high. The test efficiency is improved. The reusability is high. The labor cost is reduced.

Owner:ZHEJIANG QINGFA PIPE TECH

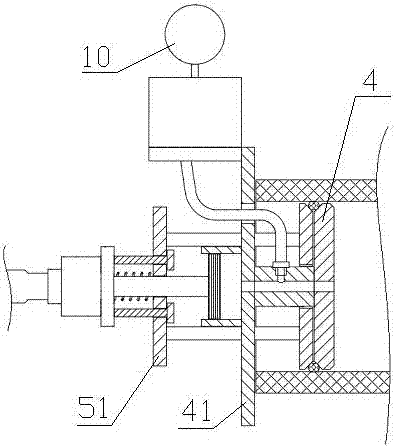

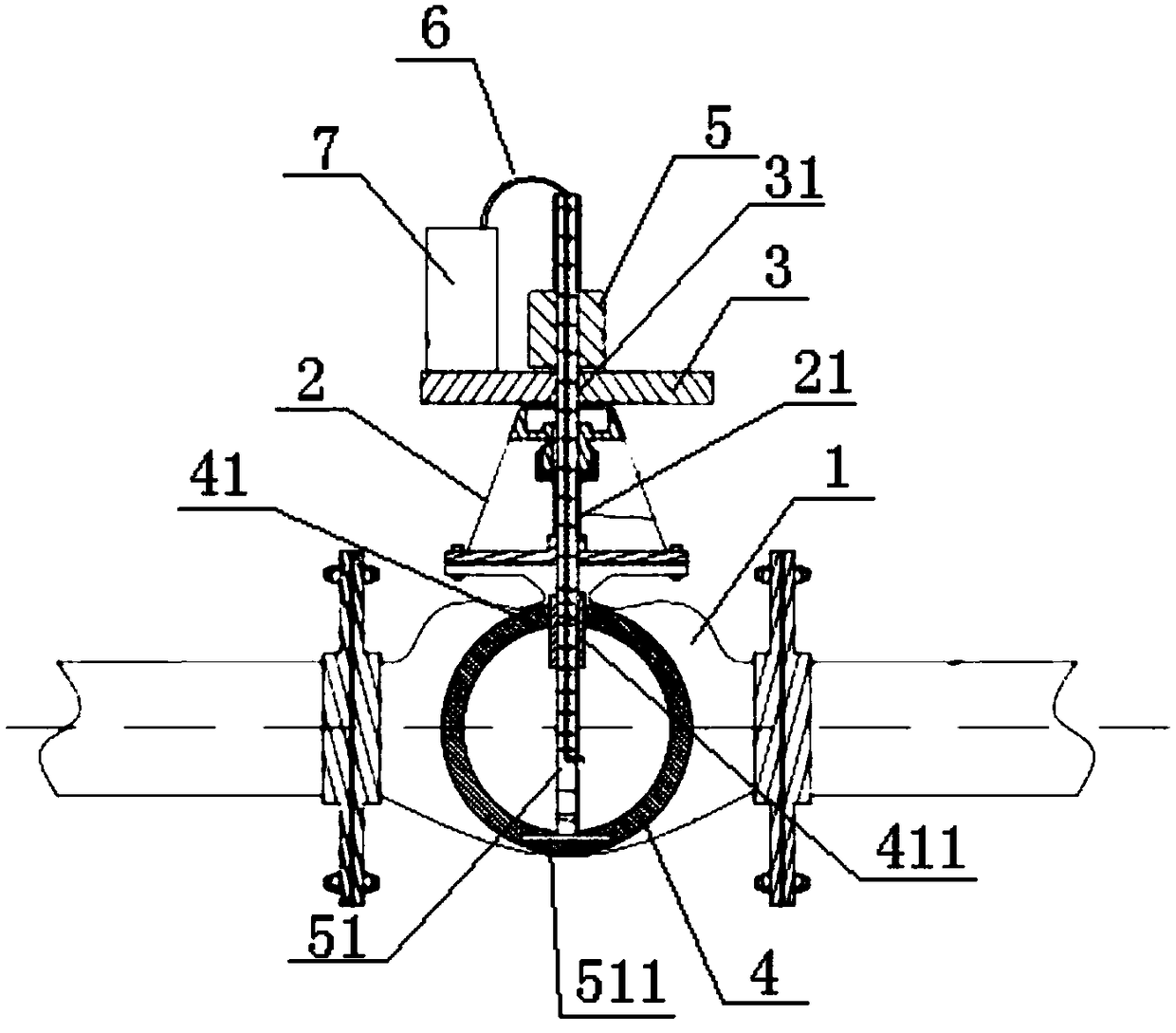

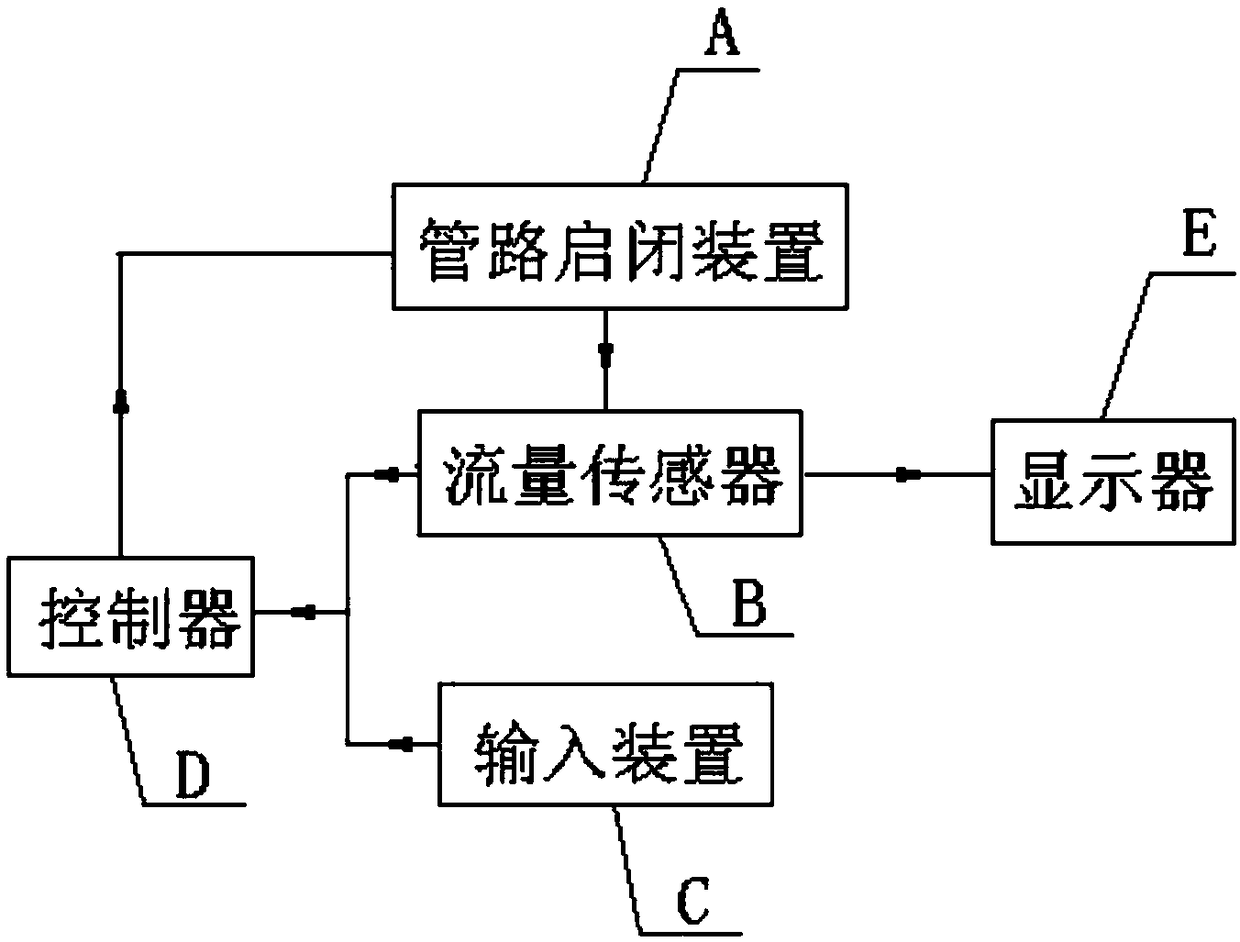

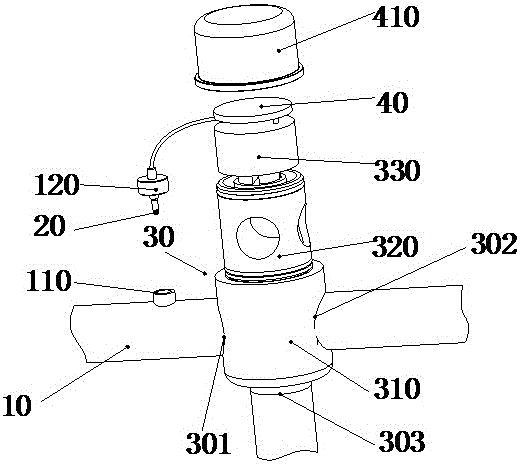

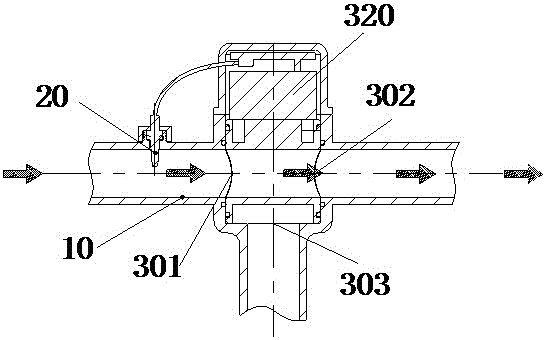

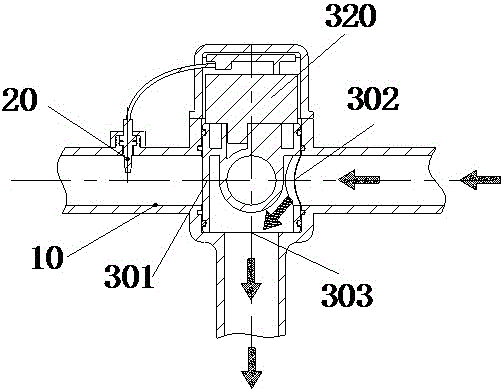

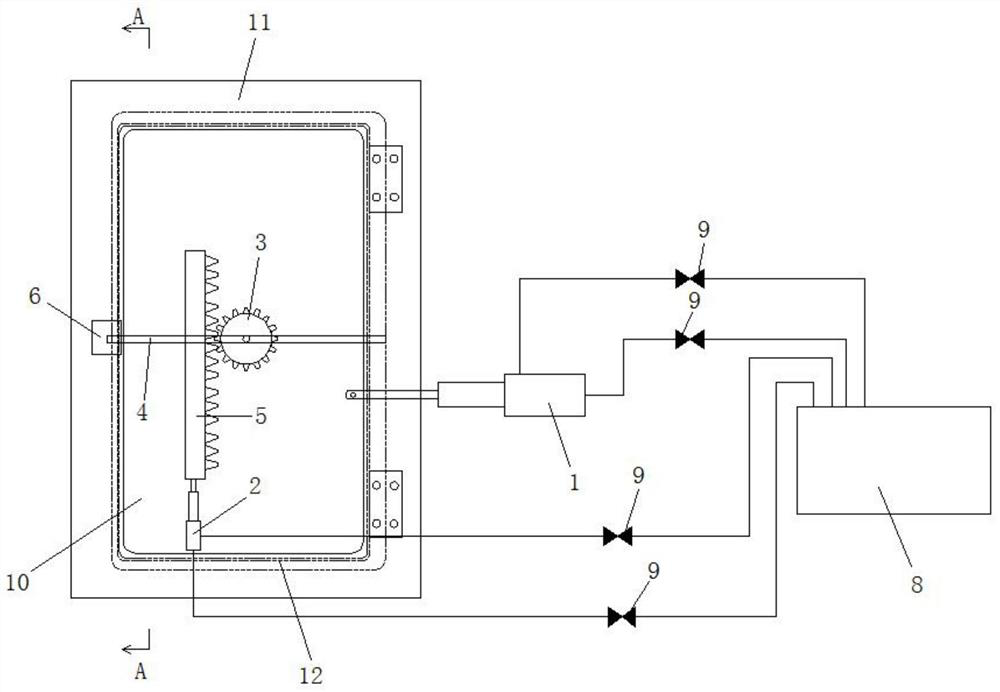

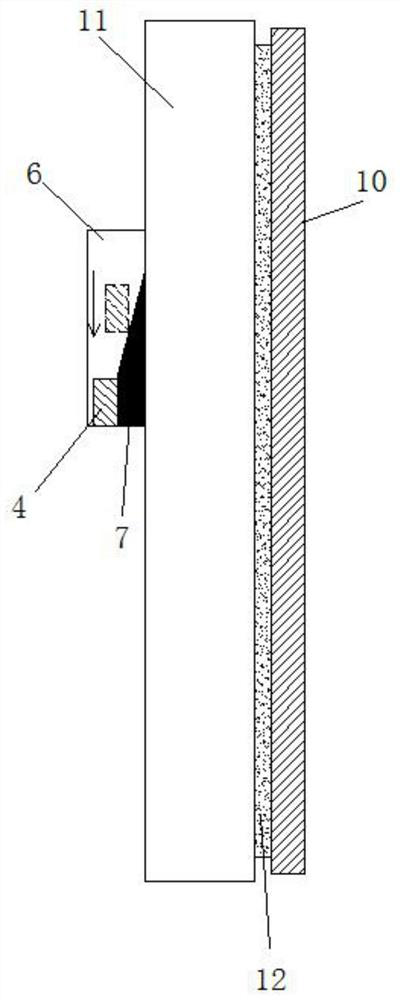

Pipeline switching-on and switching-off device and system

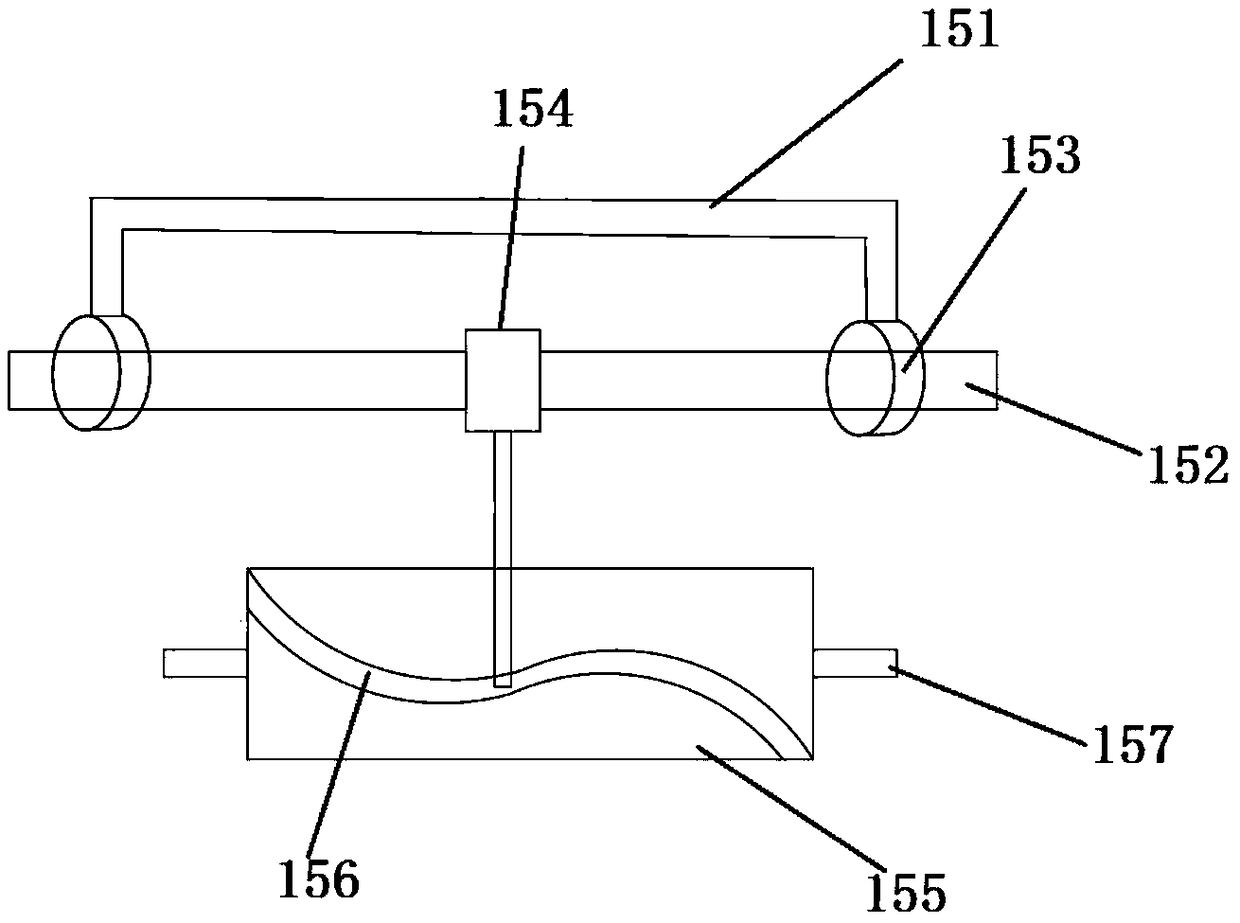

ActiveCN108591528AOpen and closeAchieve closureDiaphragm valvesOperating means/releasing devices for valvesEngineeringAir compressor

The invention discloses a pipeline switching-on and switching-off device and system. According to the switching-on and switching-off device, a valve is switched on and switched off in the manner thatan air bag driven by a lead screw and a hose serves as a valve element of the traditional valve, and the purpose of switching on and switching off a pipeline is achieved. Specifically, an air compressor serves as an air source, the air bag is inflated or the air in the air bag is discharged by controlling air discharging and air feeding of the air compressor, and then switching-off, switching-on and flow adjustment of the pipeline are achieved. To facilitate air inflation and air discharging of the air bag, the pipeline switching-on and switching-off device is further internally provided witha lead screw stepping motor, rapid air inflation and rapid air discharging of the air bag can be realized through match between the lead screw stepping motor and the air compressor, and rapid adjustment of the flow is realized. The air bag serves as the valve element of the valve for the first time, and compared with a previous metal valve element, the air bag valve element has the advantages of being resistant to impurities, capable of realizing stepless adjustment of the flow, long in service life, precise in flow adjustment and the like.

Owner:DALIAN COSCO KHI SHIP ENG

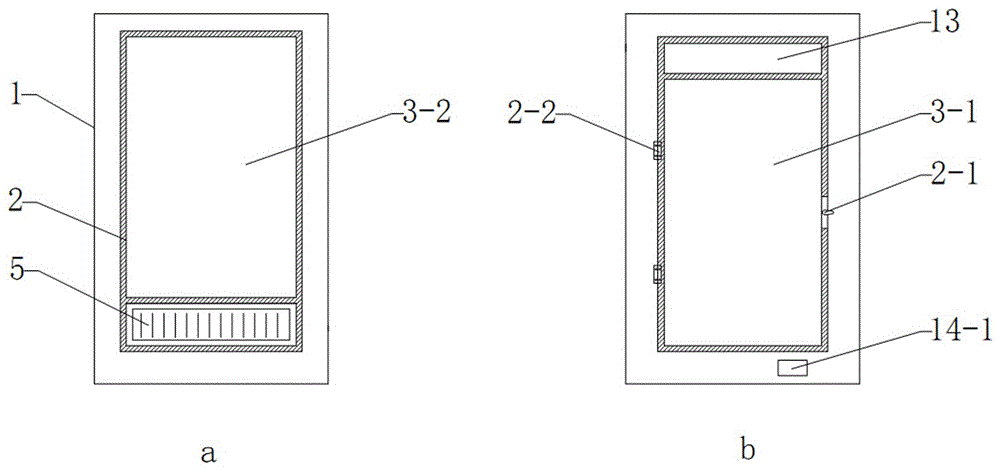

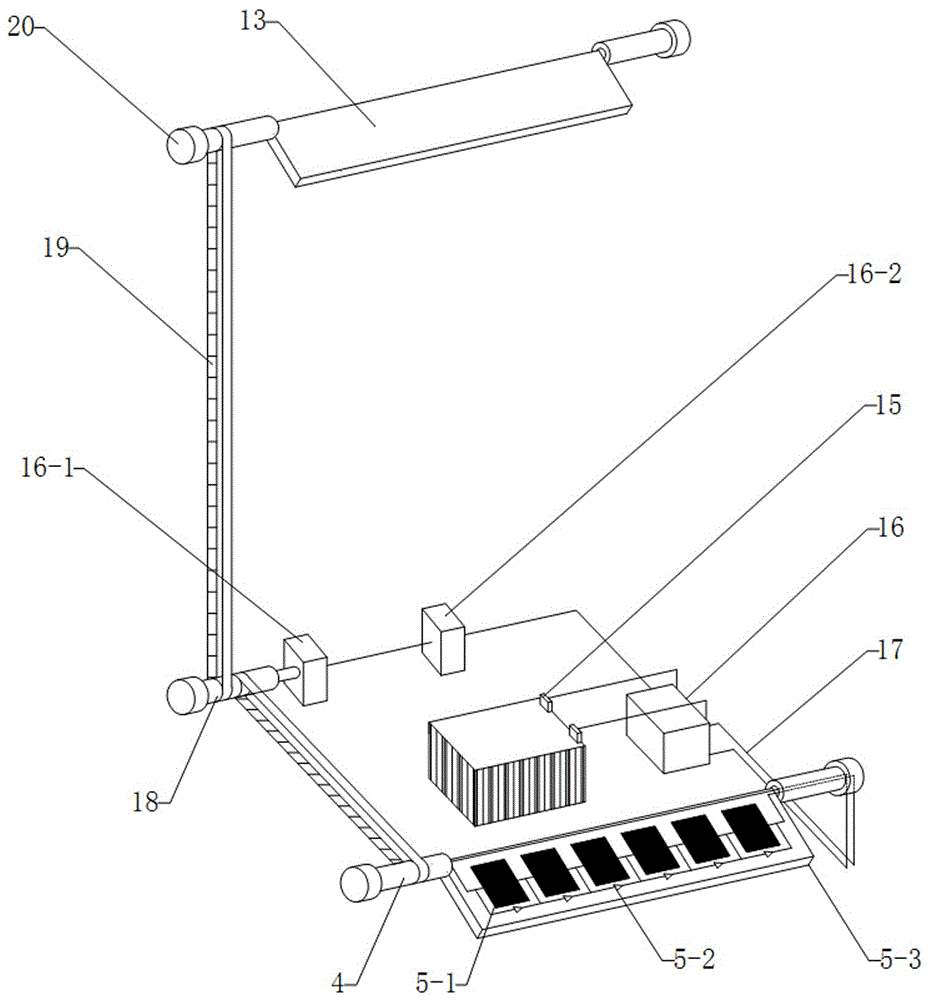

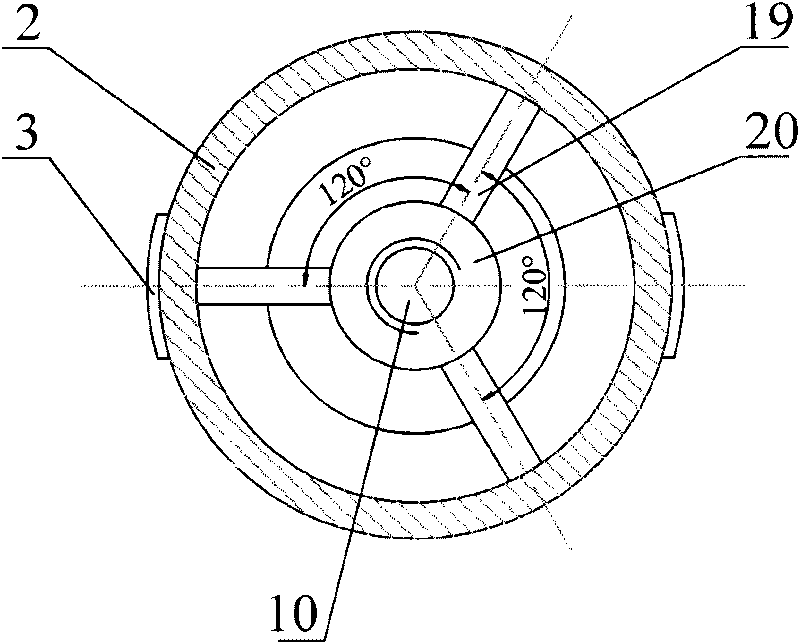

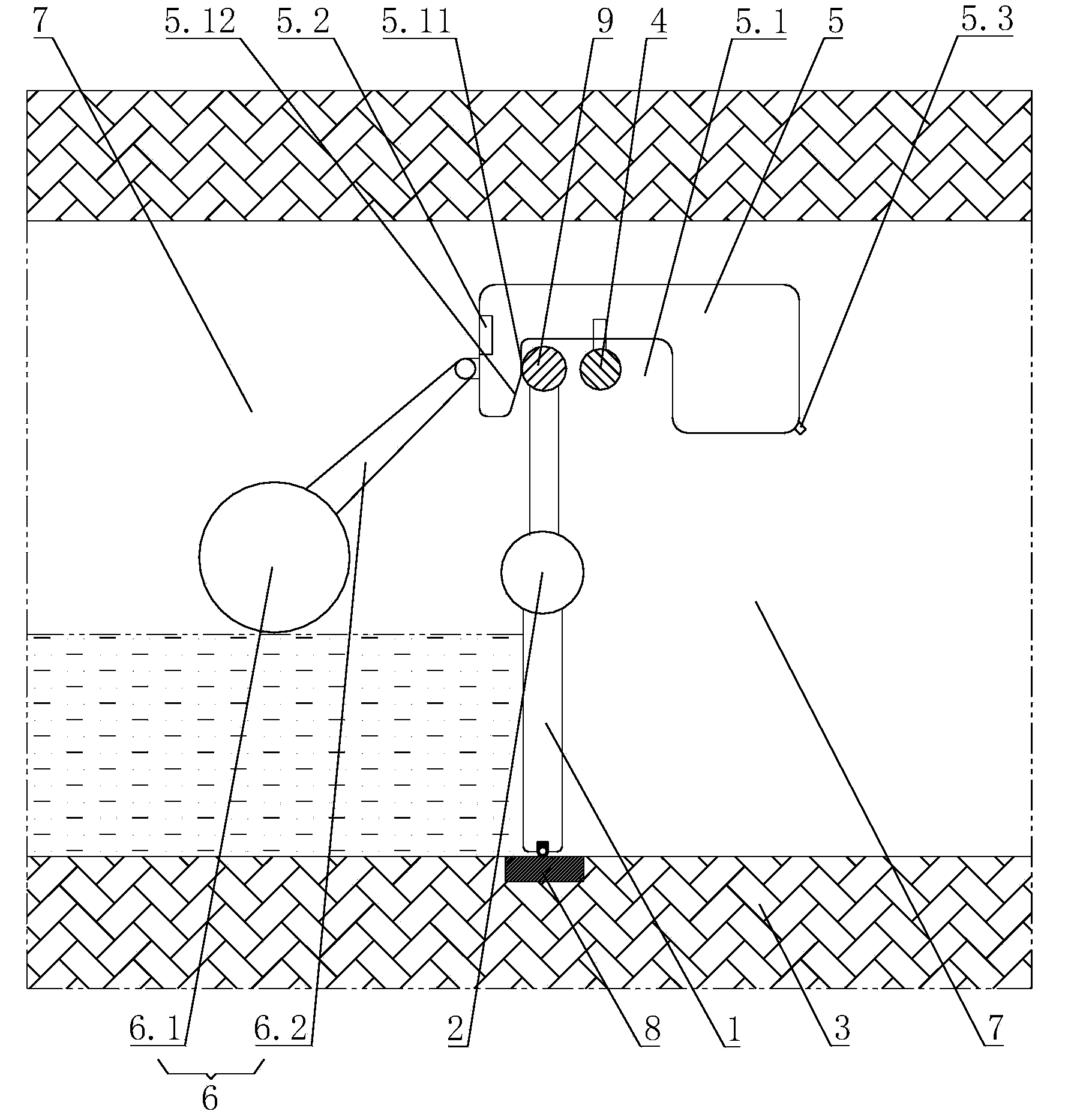

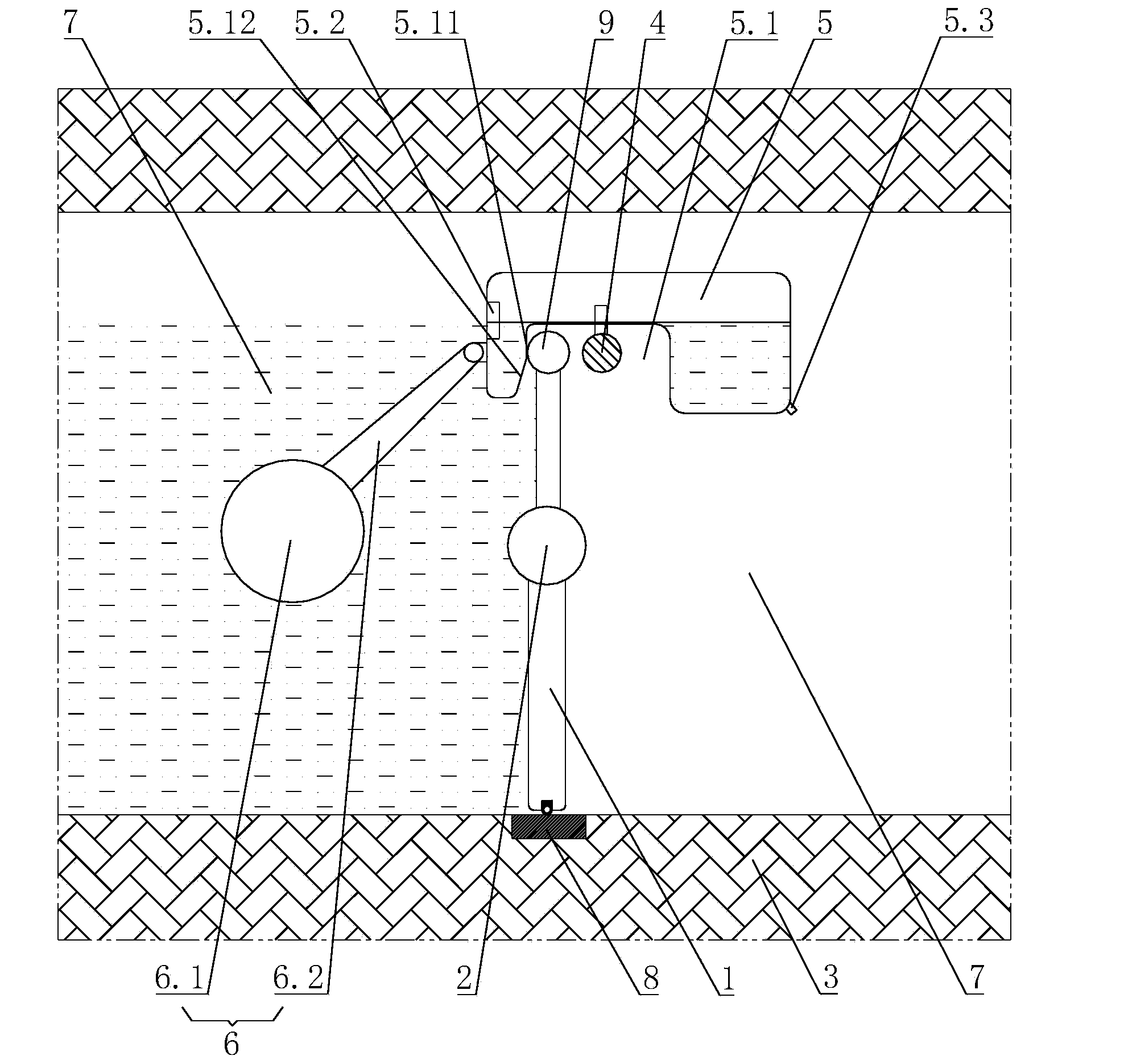

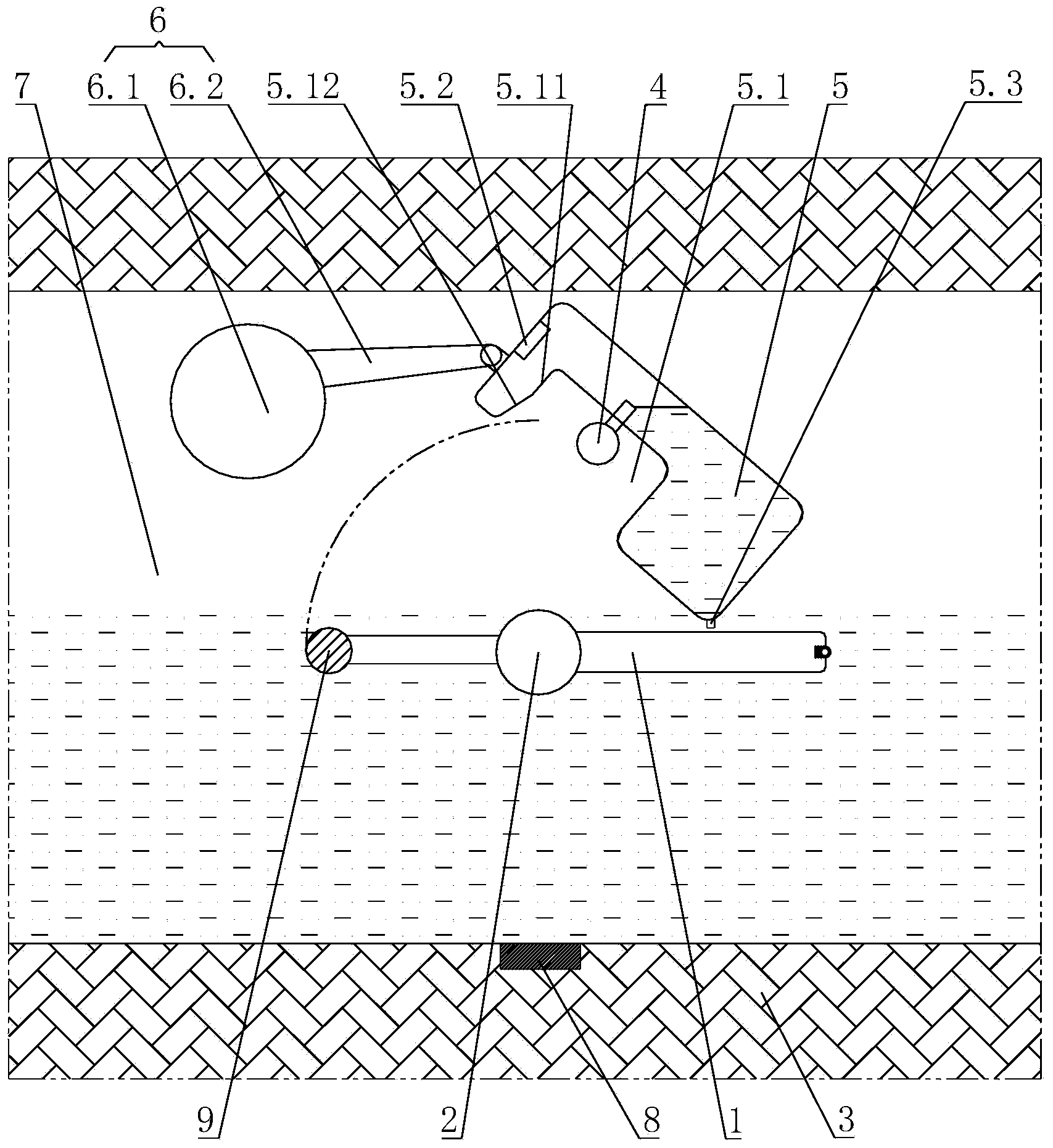

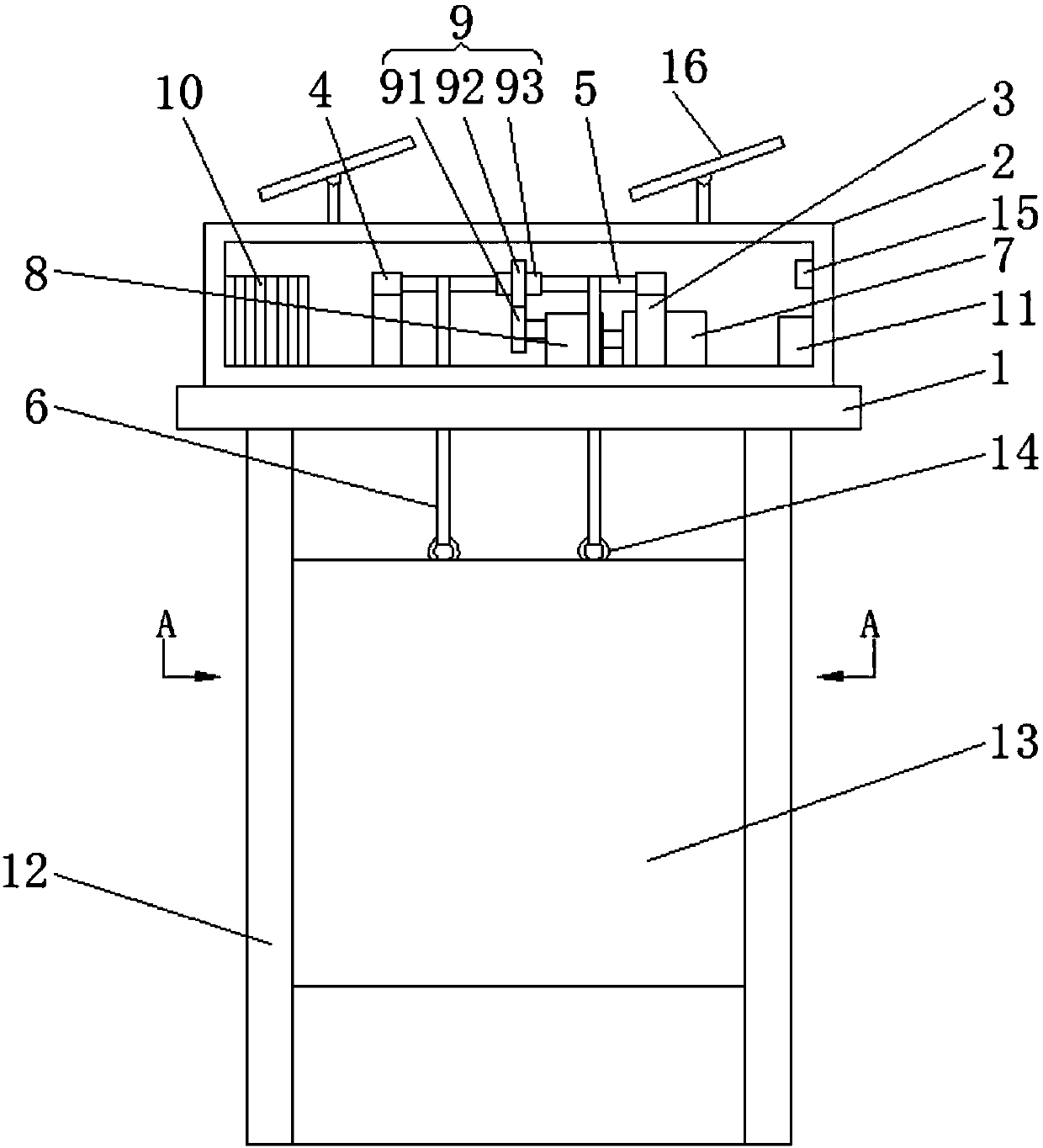

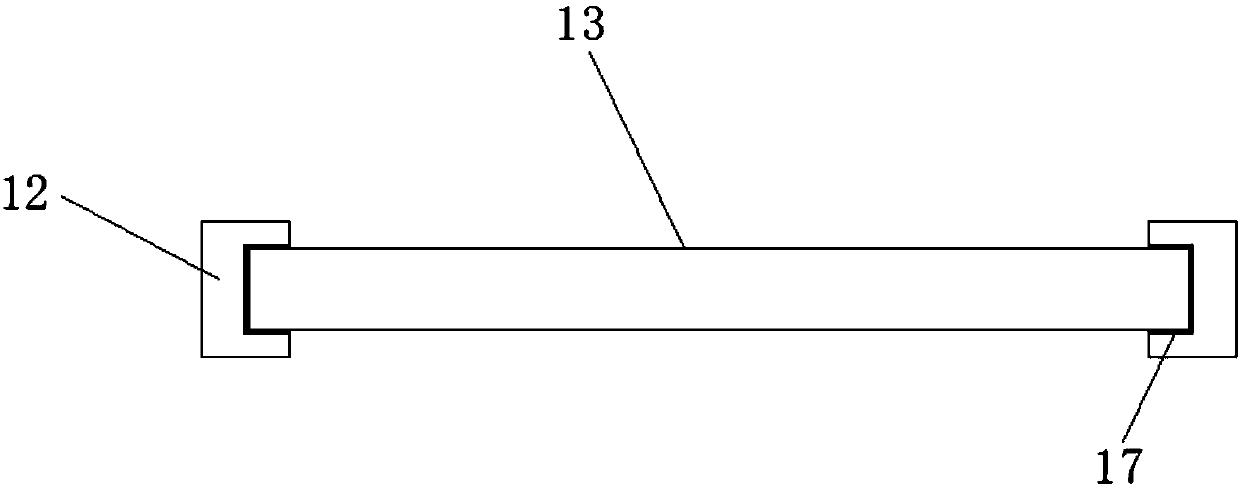

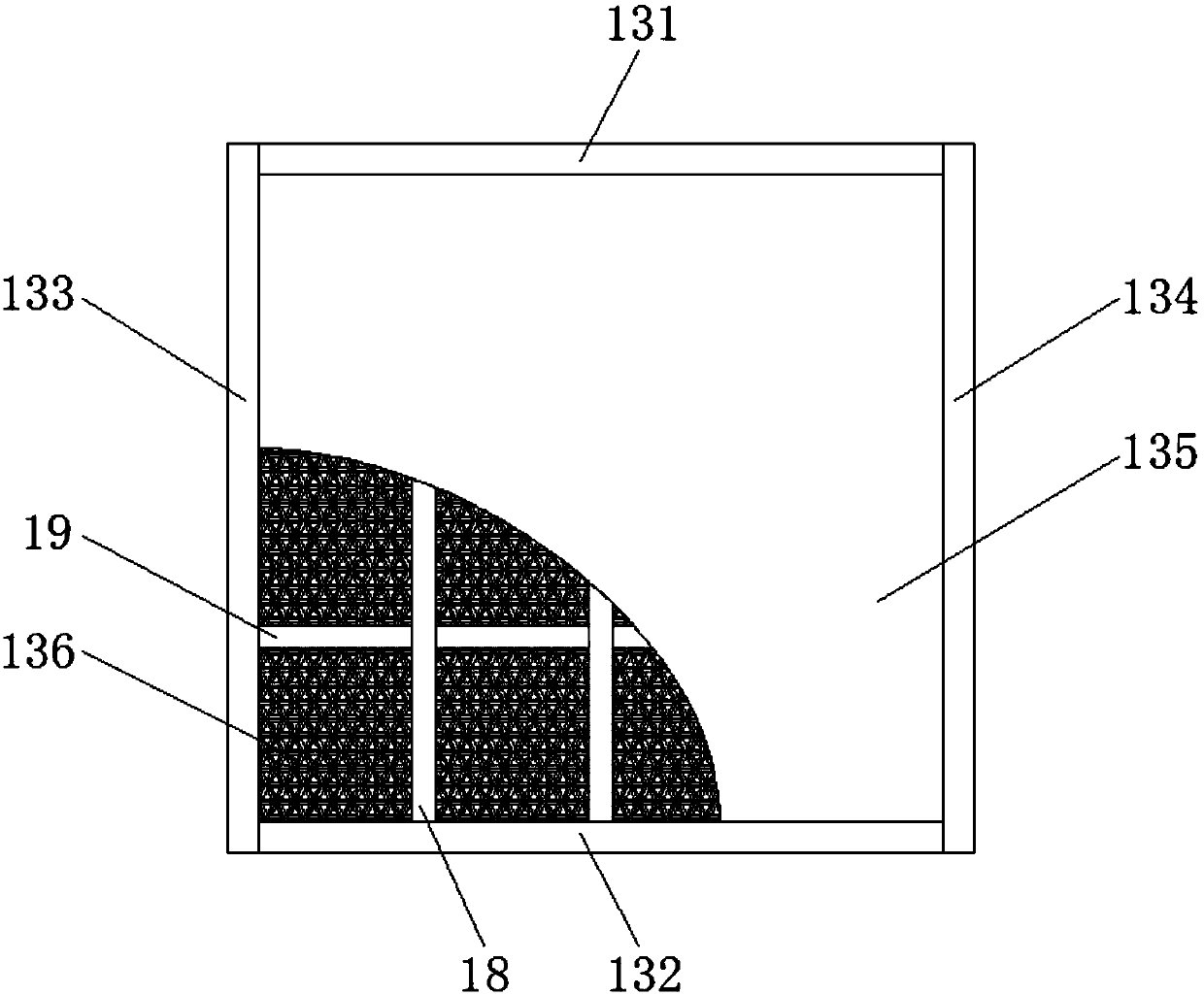

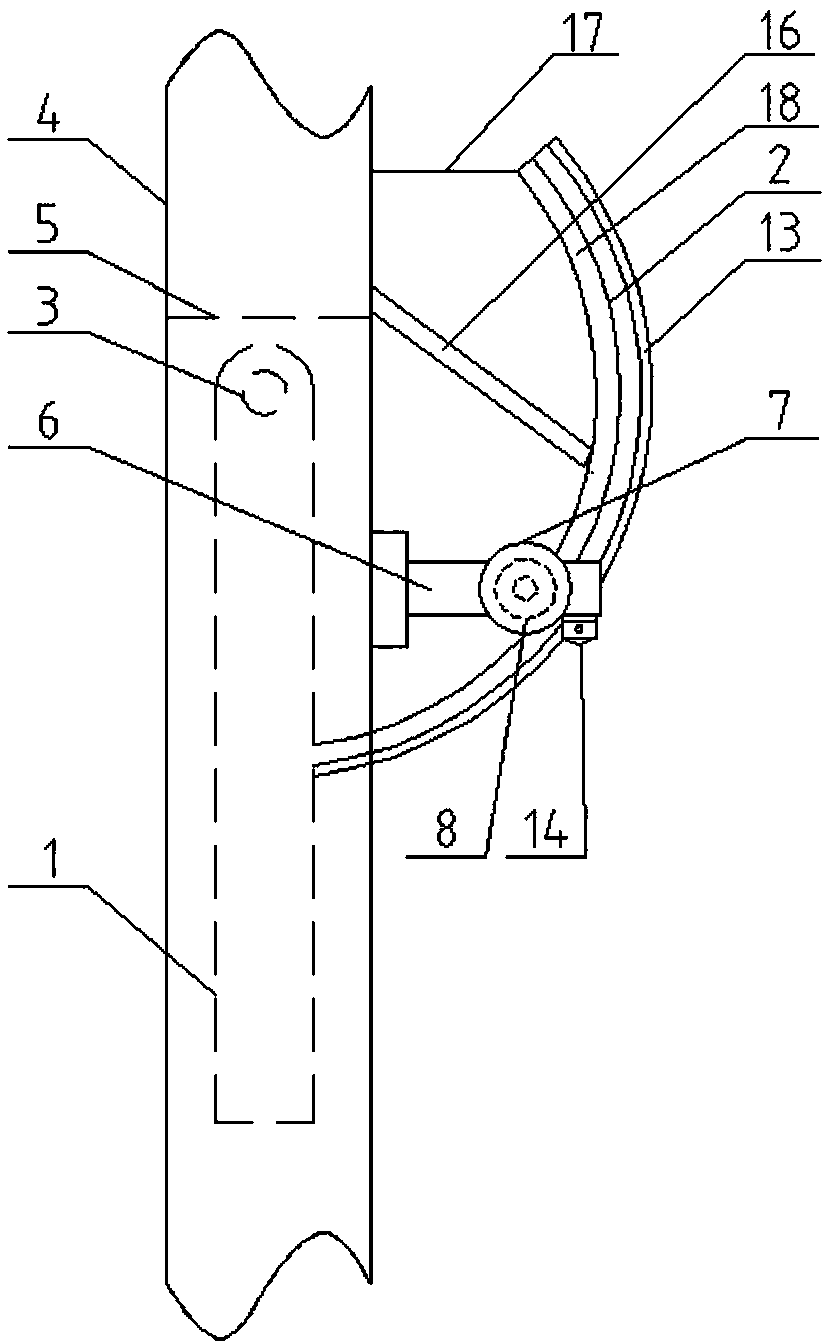

Winter time-controlled type ventilation window of concentrating photovoltaic electric heating coupling ventilation system

ActiveCN106837121AEnergy savingLighten the heating loadBatteries circuit arrangementsDispersed particle filtrationElectric heatingFresh air

The invention discloses a winter time-controlled type ventilation window of a concentrating photovoltaic electric heating coupling ventilation system. The ventilation window comprises a window body assembly, a concentrating photovoltaic cell plate (5), an air port baffle (13), a control device, a driving device, an air inlet heating assembly and a noise reduction filter channel box (12). The window body assembly comprises an integrated window frame (1), a window sash (2) and two pieces of hollow glass on the two sides. A heat preservation and ventilation flow channel (3) is formed between the two pieces of hollow glass. The control device comprises a photovoltaic controller (14) and an accumulator (15). The driving device comprises a servo motor set, synchronous drive shafts (18), a synchronous belt (19), rotating shafts (4) and fixed bearing seats (20). The air inlet heating assembly comprises an air inlet channel box (11) and a phase change heat pipe-electric heat pipe complementary heat sink. The electric energy and waste heat of a photovoltaic cell are fully utilized, and meanwhile timing control over ventilation and fresh air heating is achieved, so that the problem that the ventilation effect of the window is incompatible with the indoor heat preservation effect is solved.

Owner:NORTHEAST GASOLINEEUM UNIV

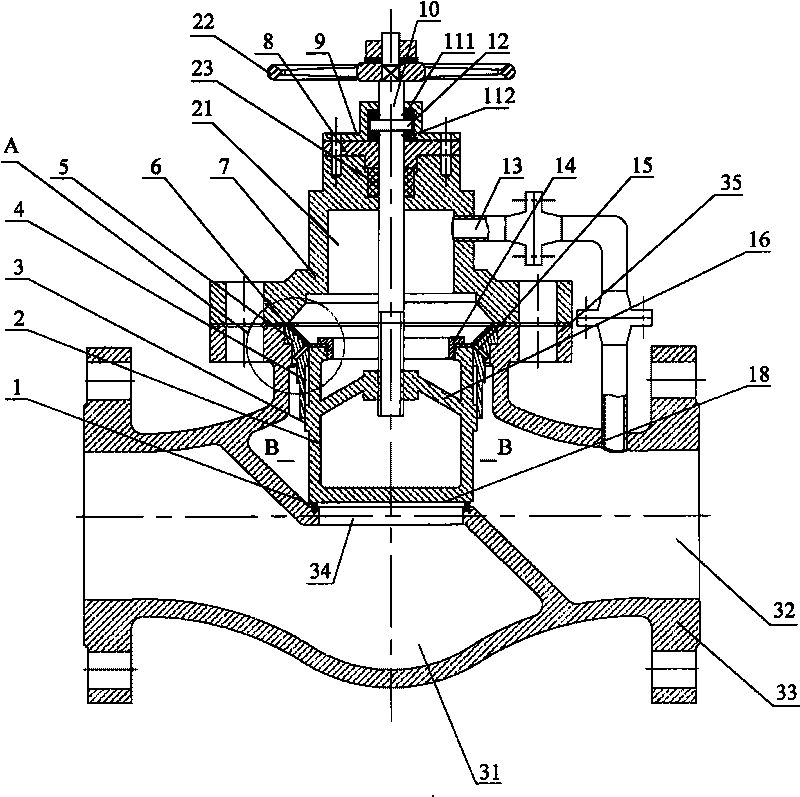

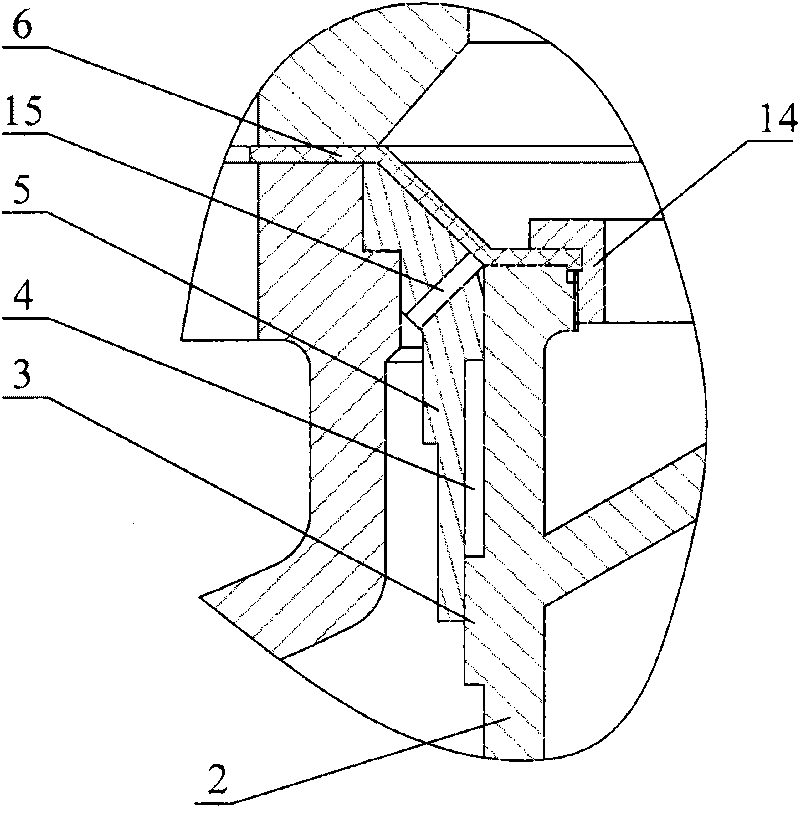

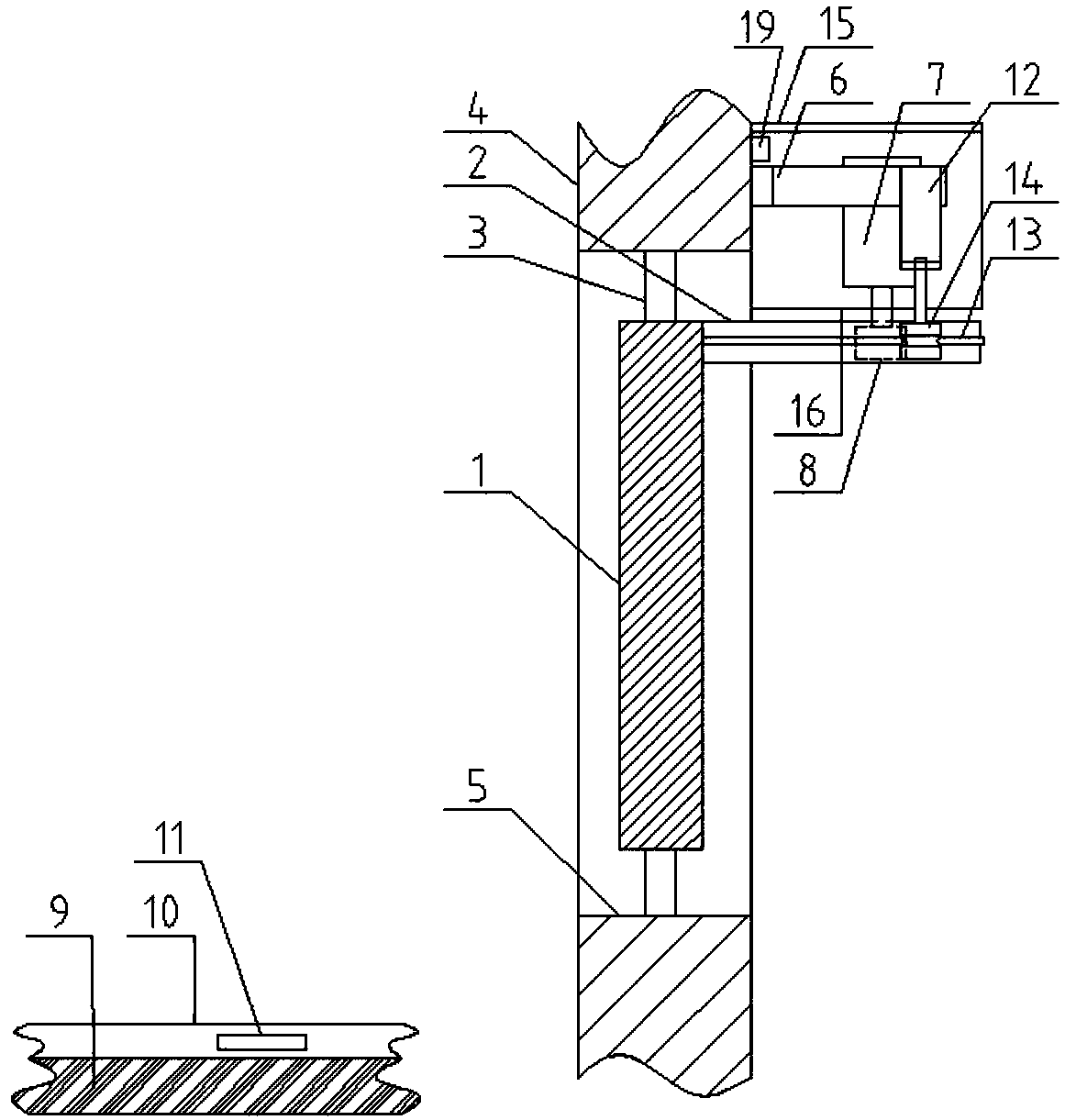

Self-balancing stop valve with piston type valve core and hidden rod

The invention discloses a self-balancing stop valve with a piston type valve core and a hidden rod, which comprises a valve cover (7) and a valve body (33) provided with a front valve cavity (31) and a rear valve cavity (32), wherein a passage (34) is formed between the front valve cavity (31) and the rear valve cavity (32). Guide sleeves (5) in vertical sealed sliding connection and the piston type valve core (2) in which a cavity is formed are arranged in the rear valve cavity (32); the bottom surface (18) of the piston type valve core (2) is used for blocking the passage (34); the guide sleeves (5) are hermetically and fixedly connected with the valve body (33); a lifting component is connected with the piston type valve core (2); the valve cover (7) is hermetically connected with the valve body (33); the inner surfaces of the piston type valve core (2), the guide sleeve (5) and the valve cover (7) encircle an upper chamber (21); and the upper chamber (21) is communicated with the rear valve cavity (32) through a guide pipe component (13). The self-balancing stop valve has the characteristic of remarkable energy-saving effect.

Owner:ZHEJIANG UNIV

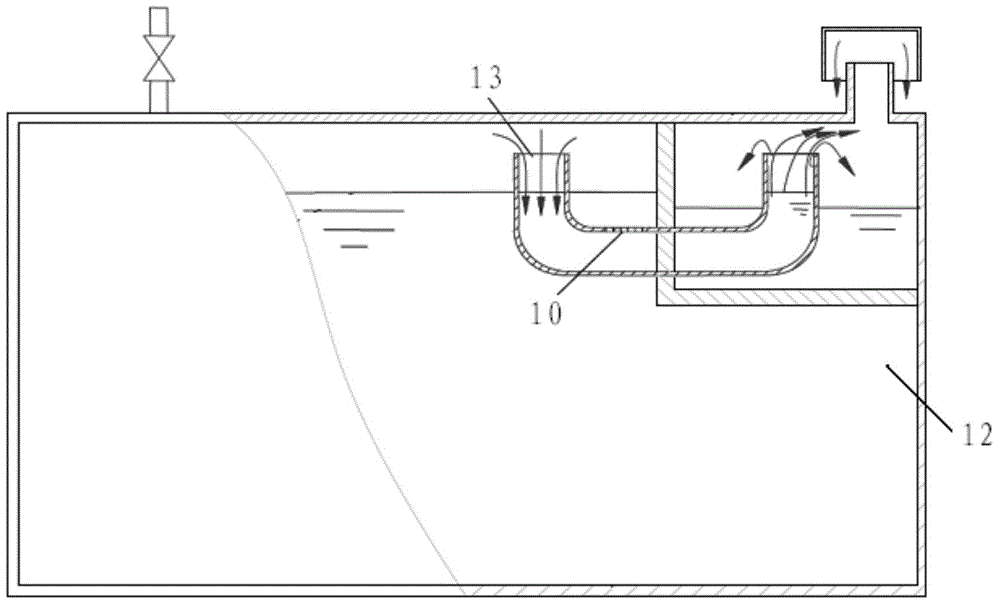

Eccentric water tank type hydraulic self flushing intercepting and accumulating door

The invention discloses an eccentric water tank type hydraulic self flushing intercepting and accumulating door, which comprises a door plate, wherein a rotating shaft is arranged at the upper part of the door plate, the two ends of the rotating shaft extend into a base body of a water discharge pipeline, the gravity of the part, positioned under the rotating shaft, of the door plate is greater than the gravity of the part positioned above the rotating shaft, a connecting shaft is arranged at the downstream of the door plate, the two ends of the connecting shaft extend into the base body of the water discharge pipeline, an eccentric water tank is rotationally connected onto the connecting shaft, the bottom of the eccentric water tank is provided with a clamp groove, the clamp groove is arranged parallel to the connecting shaft, and in addition, the clamp groove deviates towards the upper steam of the door plate; the top of the door plate can be clamped in the clamp groove, one end of the eccentric water tank is positioned at the upper stream of the door plate, and in addition, a weight balancing element is fixedly connected onto the side wall of the end; one end, positioned at the upper stream of the door plate, of the eccentric water tank is provided with a water inlet, and one end, positioned at the downstream of the door plate, of the eccentric water tank is provided with a water outlet. The water flow in the water discharge pipeline is used as driving force, the opening and the closing of the intercepting and accumulating door can be realized without other external force effects, the structure is simple, the installation is easy, and meanwhile, the transformation on the existing water discharge pipeline is easy.

Owner:WUHAN SHENGYU DRAINING SYST

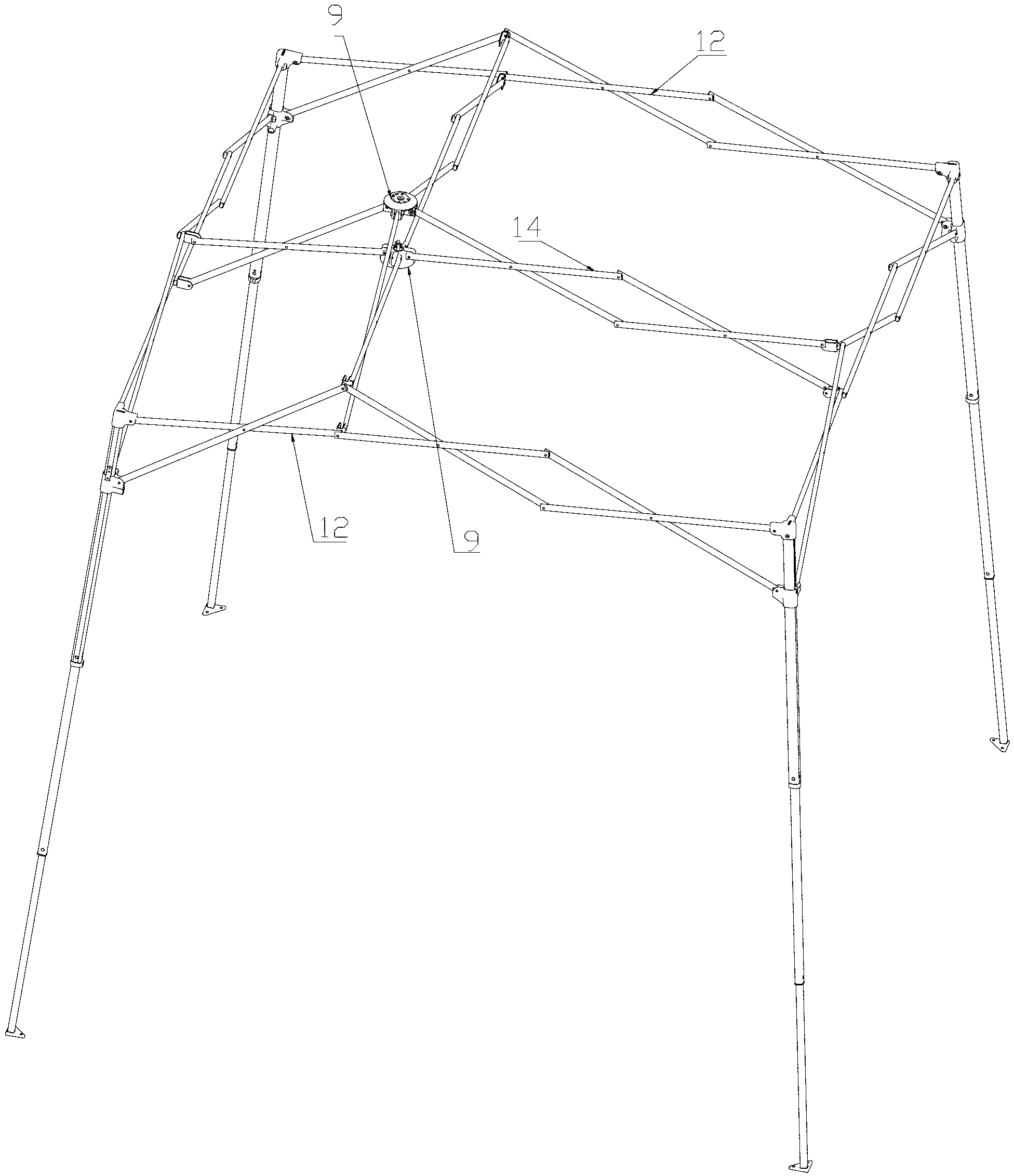

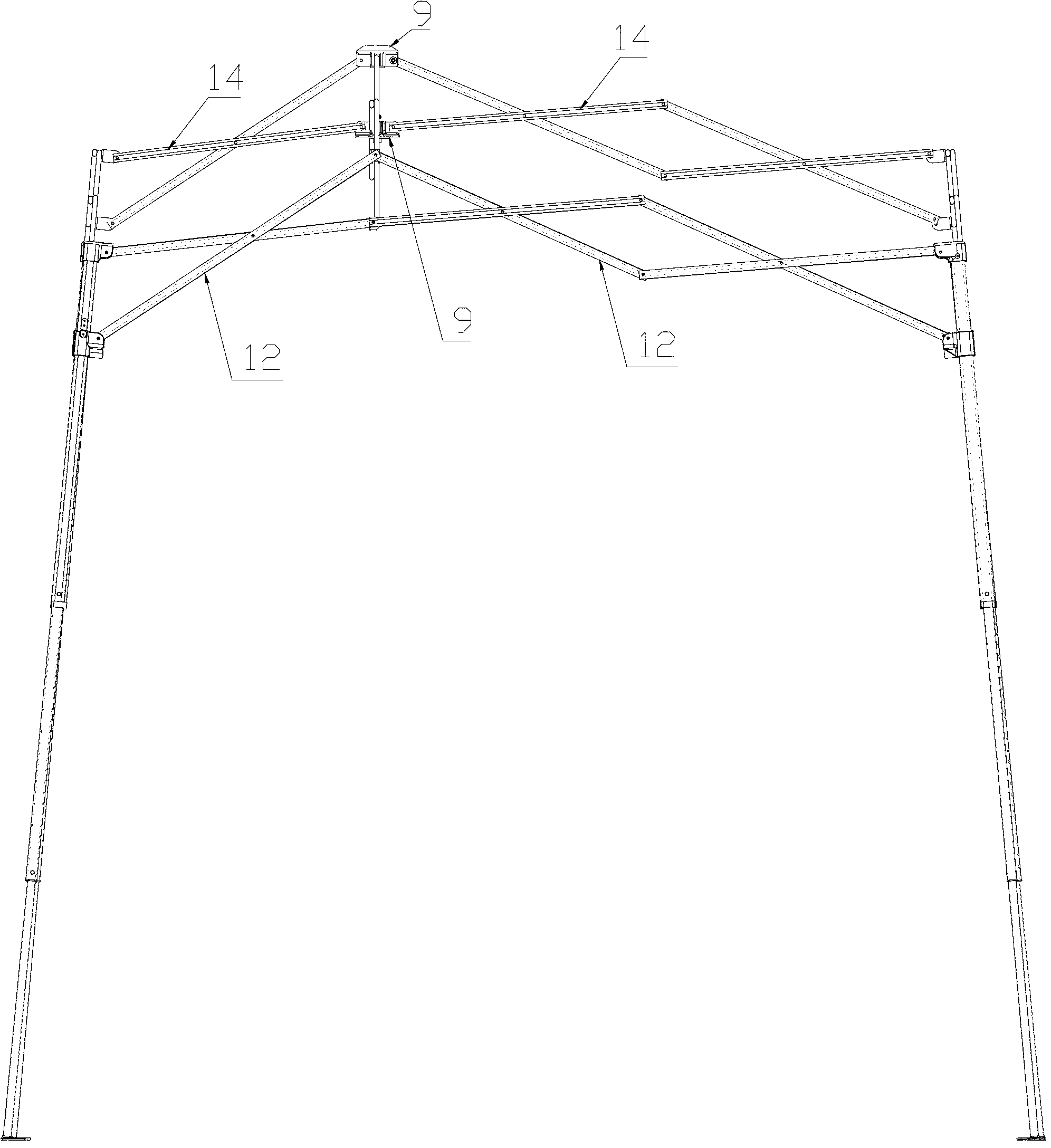

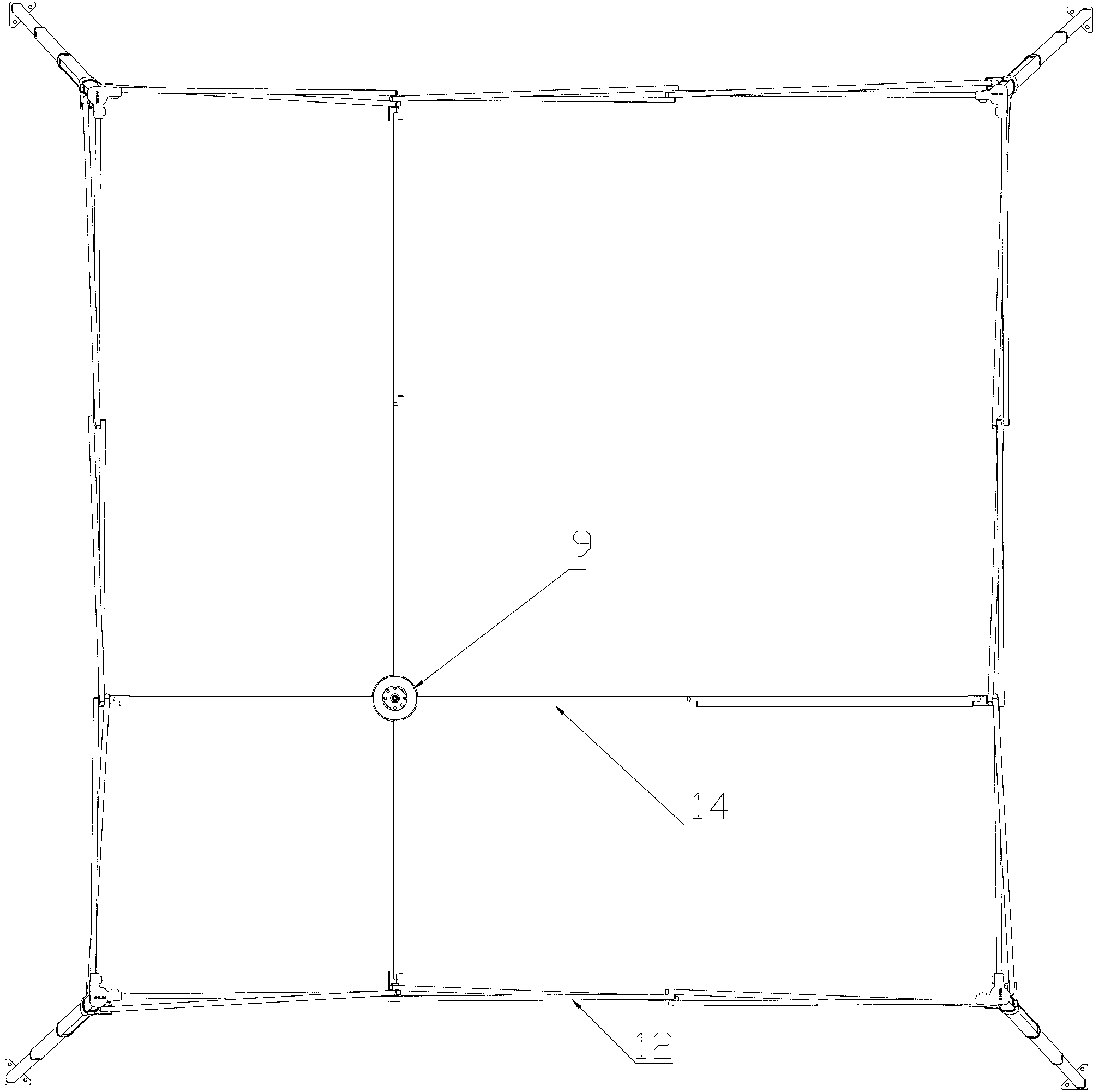

Outdoor tent with multi-section extensible legs

InactiveCN103216138ARealize automatic opening and closingOpen and closeTents/canopiesEngineeringSteel belt

The invention relates to the technical field of tents, in particular to an outdoor tent with multi-section extensible legs. The outdoor tent with the multi-section extensible legs is mainly composed of a plurality of tubes sleeved from inside to outside. The tops of the tubes are respectively sleeved by tube plugs. The plurality of tubes are arranged to be a first level tube to an Nth level tube from inside to outside. N is equal to or larger than 2 and is a natural number. A sliding block is arranged on an outer wall of the Nth level tube. A gasket is arranged between any two adjacent tubes. The upper end of each gasket is fixed at the bottom in the tube, located on the outer layer, of the two adjacent tubes. One end of a steel belt is fixed on the top of an outer wall at one side of an N-1th level tube. The other end of the steel belt extends upwards along an inner wall at one side of the Nth level tube, winds the top of the Nth level tube, is located outside the outer wall at the other side of the Nth level tube and fixed on the sliding block. Compared with the prior art, stretching and contraction of each level tube are controlled by the steel belt or a steel wire and extensible stroke larger than 1:1 can be achieved.

Owner:WITH U E COMMERCE SHANGHAI CO LTD

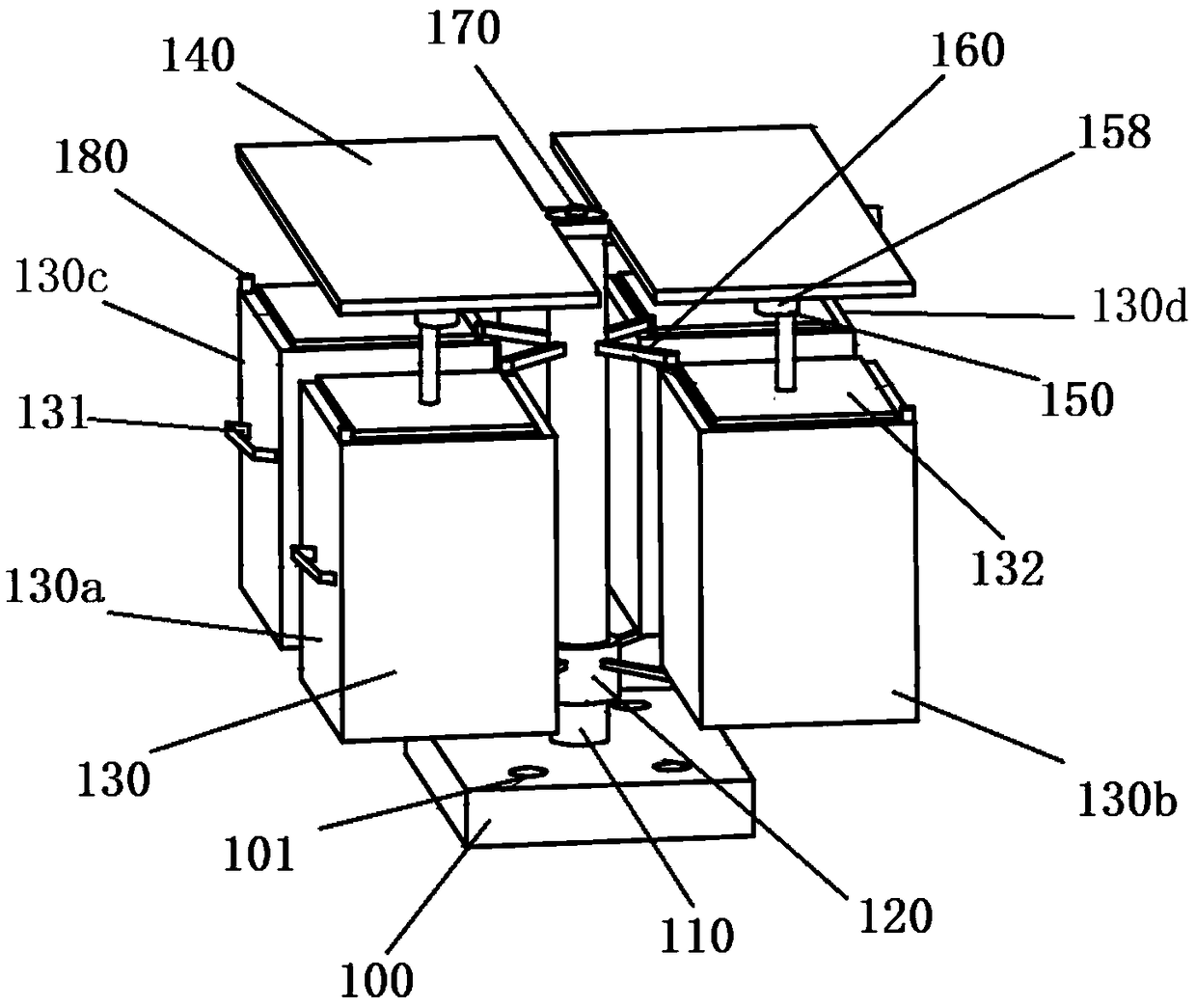

Overflow-preventing garbage can and control method thereof

PendingCN109368095APrevent spillageImprove work efficiencyRefuse receptaclesRefuse cleaningDrive shaftEngineering

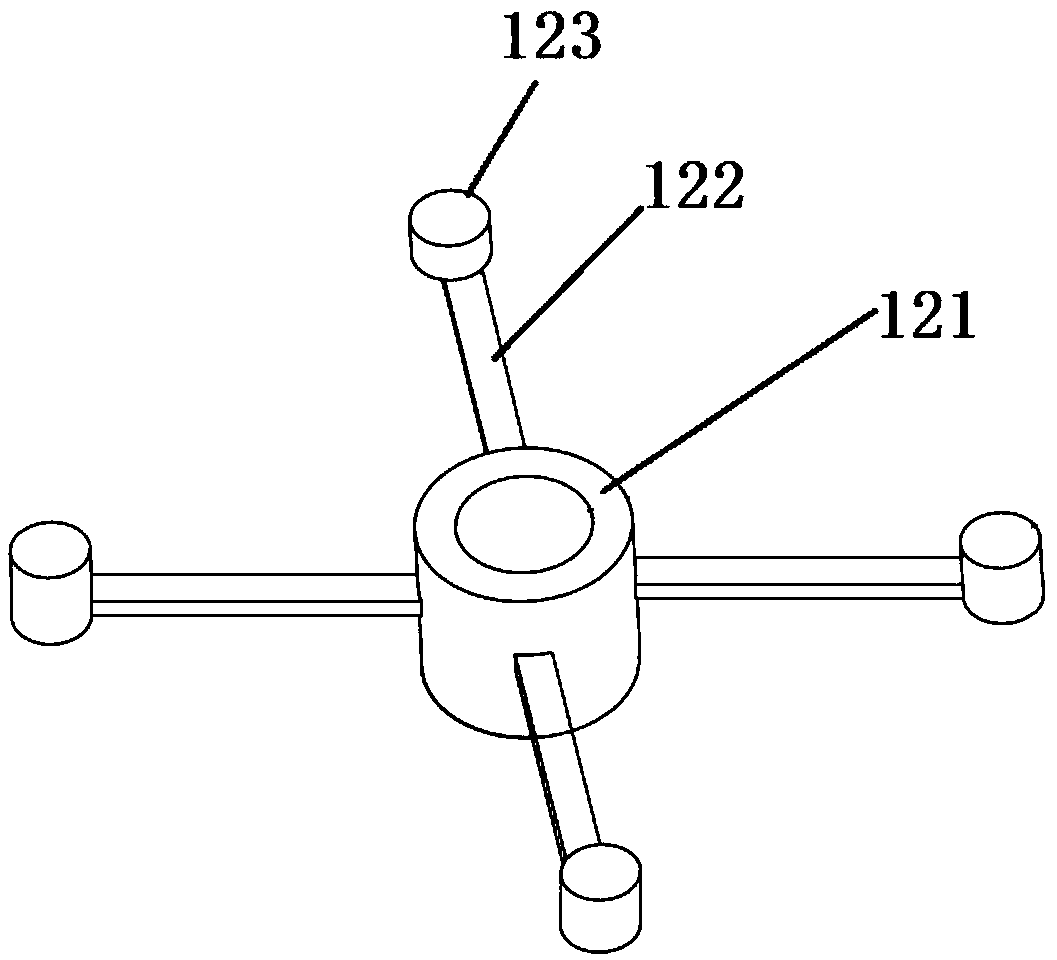

The invention discloses an overflow-preventing garbage can which comprises a fixed bottom plate, a supporting column rotary shaft, four garbage can bodies, a top cover, a supporting arm, a telescopicrod, a cylindrical cam machine, a track walking needle and a motor, wherein a groove is formed in the center of the fixed bottom plate; one end of the supporting column rotary shaft is perpendicularlyand rotatably arranged in the groove; the four garbage can bodies are symmetrically arranged above the fixed bottom plate and are fixedly connected to the supporting column rotary shaft, and a coverplate is arranged on the garbage can bodies; the top cover is arranged on the garbage can bodies and is fixedly connected to the supporting column rotary shaft; the supporting arm is perpendicularly arranged at the lower end of the top cover, and supporting rings are arranged at two ends of the supporting arm; one end of the telescopic rod is fixedly connected to the cover plate and the telescopicrod slidably penetrates the supporting rings successively; the cylindrical cam machine is arranged next to the telescopic rod, transmission shafts are arranged at two ends, and an annular groove is formed in the surface; one end of the track walking needle is fixed to the telescopic rod while the other end of the track walking needle is arranged in the annular groove; and the motor is fixedly mounted below the top cover, and the power output shaft of the motor is connected to one ends of the transmission shafts. The function of opening and closing and compressing the garbage can bodies by means of a telescopic shaft, so that garbage is prevented from overflowing.

Owner:JILIN UNIV

Three-way valve

InactiveCN102705567AOpen and closeQuick opening and closingSpindle sealingsOperating means/releasing devices for valvesLinear motionPlaying card

The invention belongs to the field of environment-friendly equipment and discloses a three-way valve. The three-way valve comprises a valve body and a valve switch control device, wherein the valve switch control device comprises silicon rubber sealing rings on the inner side of a valve port, a valve plate, a valve rod, a cylinder seat, a piston rod, a cylinder with two-way buffer and a sealed connecting part; the cylinder seat is fixed on a valve body on an opposite side of a valve port to be controlled; the cylinder on the cylinder seat is connected with one end of the valve rod through the piston rod in the cylinder seat; the valve rod is positioned at the other end in the valve body and is connected with one side of the valve plate which is positioned inside the valve body; and the sealed connecting part is positioned on a part of the valve rod which penetrates through the valve body. By the three-way valve, the switch control device has a playing card type structure; the valve plate is controlled to be contacted with the silicon rubber sealing rings, so that opening and closing of the valve are realized; and moreover, the valve plate is in linear motion, and the three-way valve is rapidly opened and closed and low in leakage rate and long in service life.

Owner:JIANGSU DAXIN ENVIRONMENTAL SCI & TECH

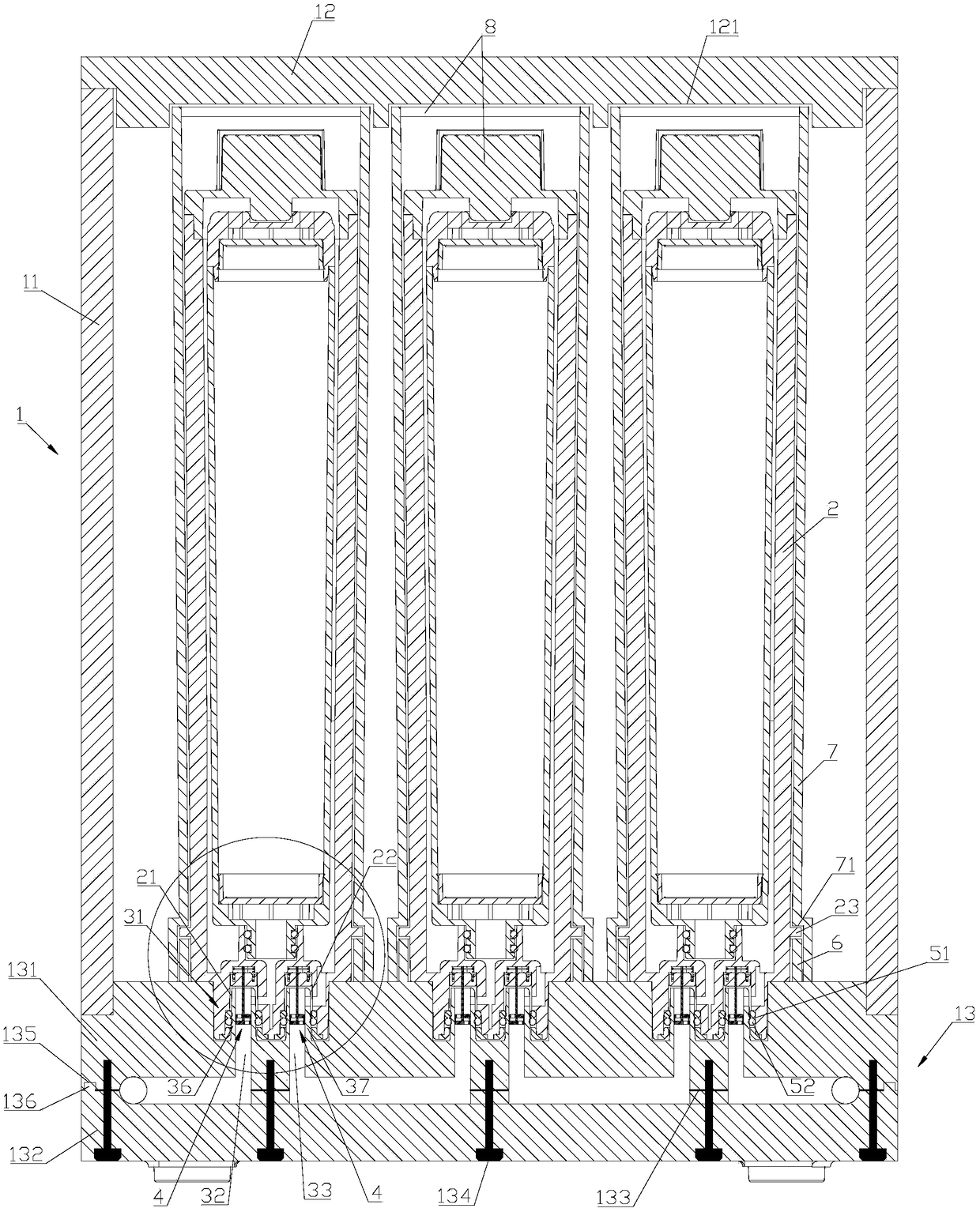

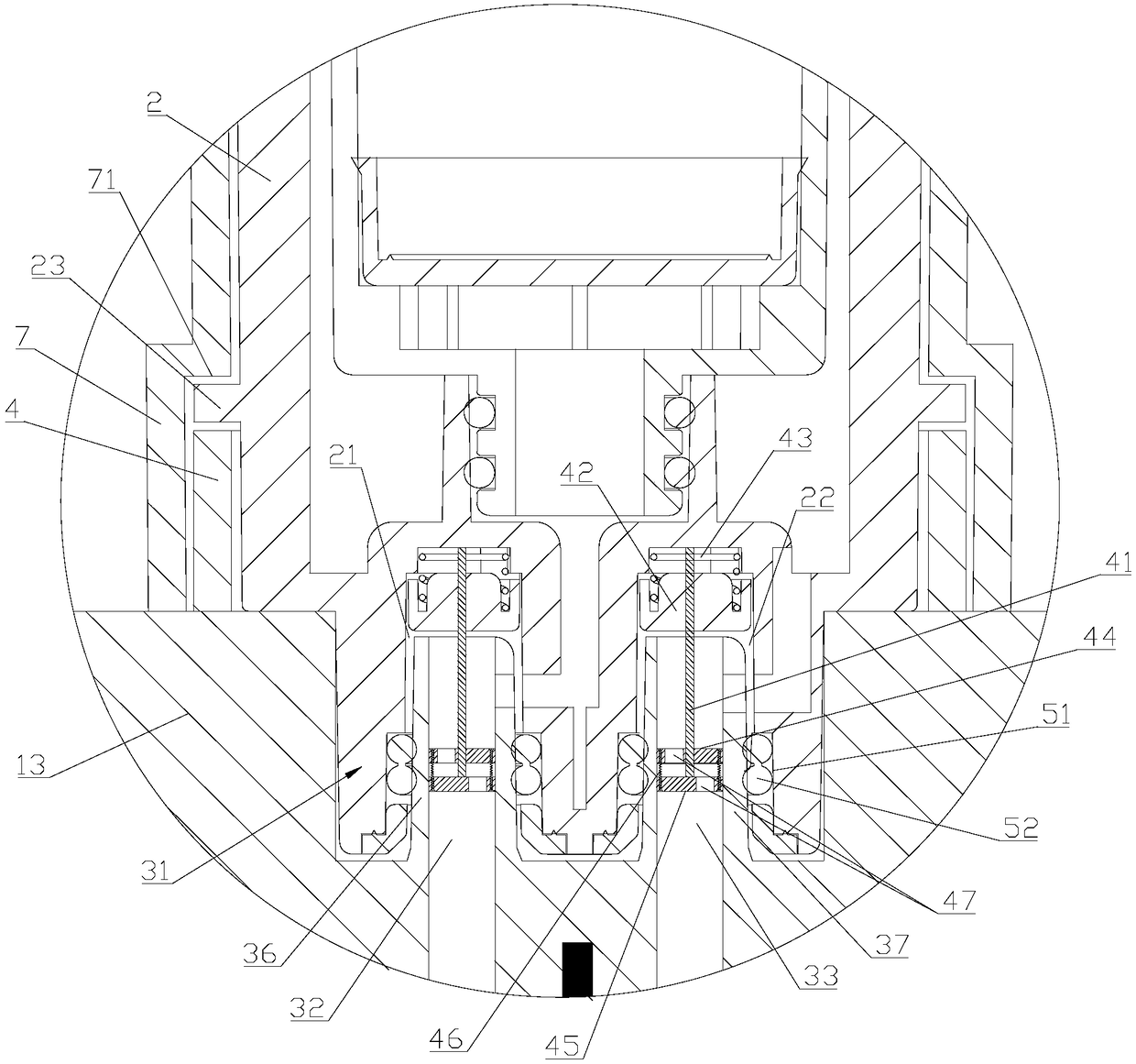

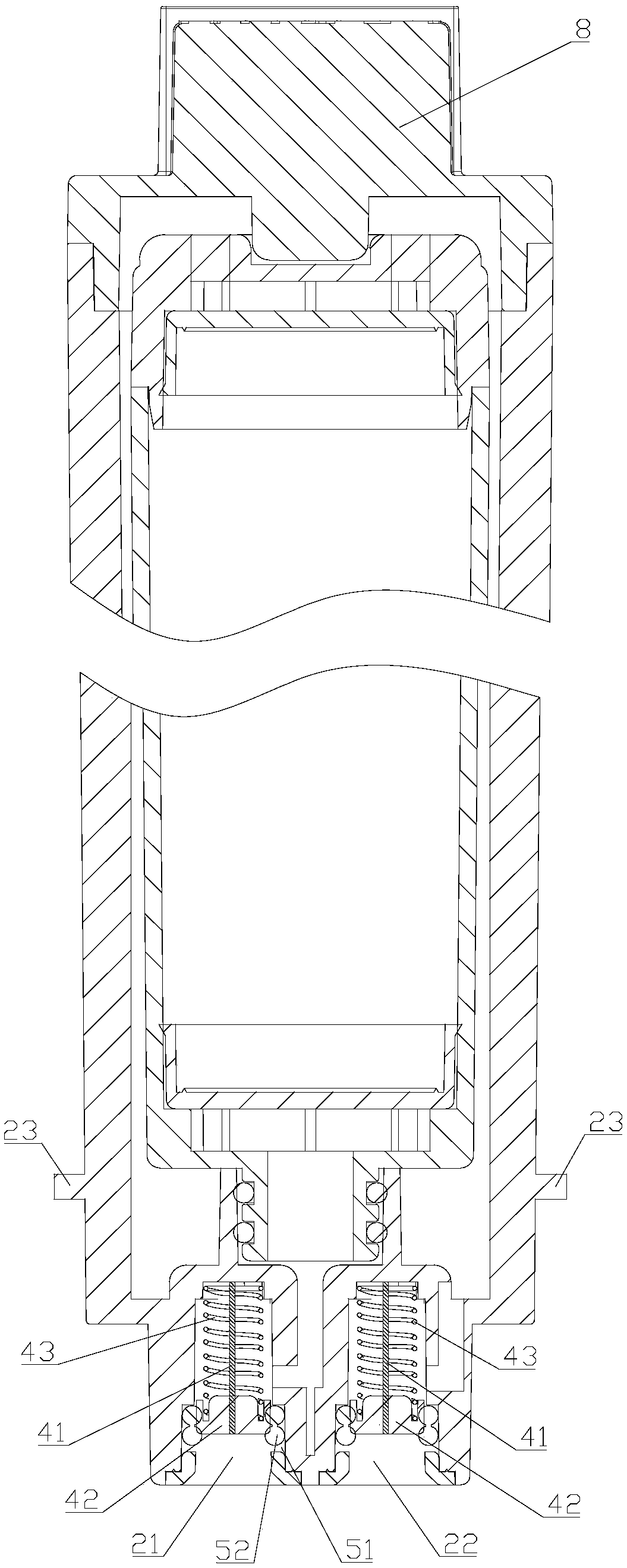

Multistage water purifier capable of conveniently replacing filter elements

ActiveCN109110840AGood sealing effectSimple structureTreatment involving filtrationStationary filtering element filtersFilter elementPurified water

The invention discloses a multistage water purifier capable of conveniently replacing filter elements. The multistage water purifier comprises a machine body and filter element cylinders, wherein insertion holes, a raw water inlet and a purified water outlet are formed in a base of the machine body; each filter element cylinder is inserted in each insertion hole; a water inlet column and a water outlet column are arranged in each insertion hole; a filter element water inlet hole and a filter element water outlet hole are formed in the lower end of each filter element cylinder; water locking components are arranged in the water inlet columns, the filter element water inlet holes, the water outlet columns and the filter element water outlet holes; when the water inlet columns and the water outlet columns are respectively inserted into the filter element water inlet holes and the filter element water outlet holes, two groups of water locking components are opened, so that a water channelis penetrated, and all the filter element cylinders are connected in series on the water channel. The multistage water purifier is capable of preventing the residual water from flowing out when replacing the filter elements and is also capable of preventing the inflow water and the outflow water of the filter elements from mixing during purifying water and preventing the water from leaking from filter element joints at the same time.

Owner:吴联星

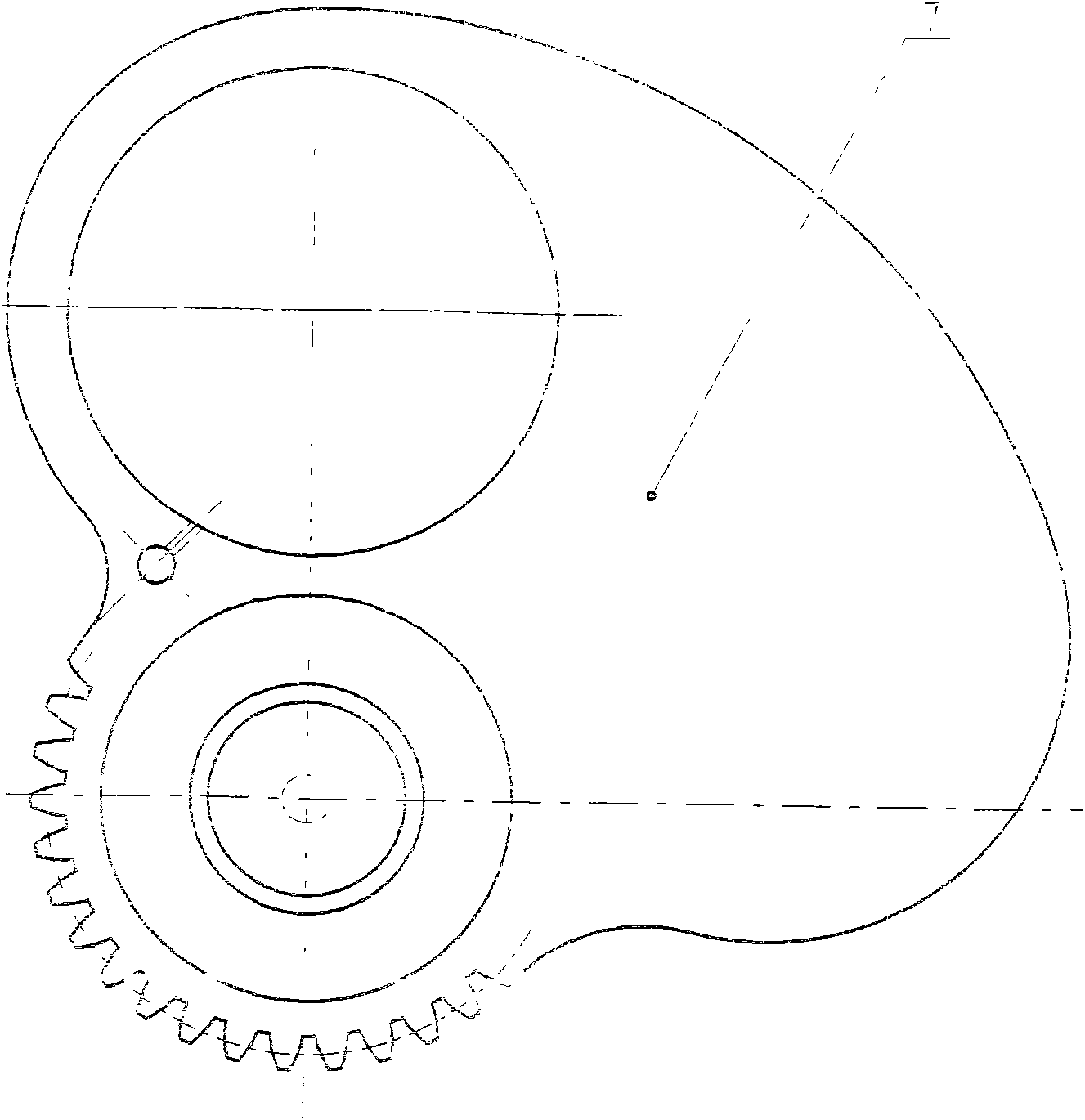

Rotary cutting valve

InactiveCN101943272AOpen and closeQuick opening and closingOperating means/releasing devices for valvesSlide valveGear wheelEngineering

The invention discloses a rotary cutting valve. A left valve body, an intermediate body and a right valve body form a housing; a handle, a valve rod, a gland cover, the right valve body and the left valve body are connected; the valve rod is inserted into the positioning hole of the left valve body; a fixing shaft passes through a splint and a valve clack on the two sides; the two ends of the fixing shaft are inserted into the positioning holes of the left and right valve bodies; the right valve body, a right valve seat, the valve clack, a left valve seat, a cylindrical compression spring and the left valve body are connected; the splint and the valve clack are connected; a hexagonal bolt, a belleville spring and a hexagonal nut serve as fasteners which is a structure floating with the position of the valve clack; the outer circles of the left and right valve seats and the left and right valve bodies and the splint are sealed by O-shaped sealing rings; the valve rod and the valve clack transversely rotate around a gear pair; the splint is a semicircular plate of which the upper part is provided with a medium channel hole, the lower part is provided with a fixing shaft hole and the two sides are provided with blind plates; the valve clack is a sector plate of which the upper part is provided with a medium channel hole, the right side is provided with a blind plate and the lower part is provided with a fixing shaft hole; the outer side of the shaft hole is provided with a semicircular gear; and the valve rod is also provided with a semicircular gear. The valve can ensure that deposit or scale is not generated in the inner cavity.

Owner:江苏江恒阀业有限公司

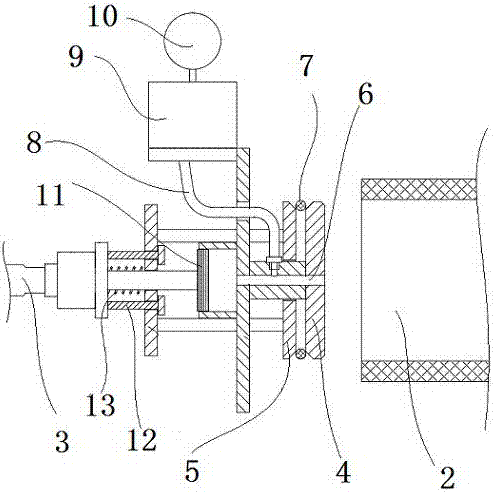

Low temperature protector and working method thereof

ActiveCN106369217ASimple structureOpen and closeOperating means/releasing devices for valvesMultiple way valvesFrost crackWater pipe

The invention provides a low temperature protector and a working method thereof. The low temperature protector comprises a water inlet pipeline for providing a water source for a water-requiring device. A temperature sensor and a water path switching device for achieving switching of the water source are arranged between the water inlet pipeline and the water-requiring device. The water path switching device comprises a water inlet communicating with the water inlet pipeline, a water outlet for discharging the water source, and a drainage opening for achieving drainage in the switching device. A switching valve is arranged in the water path switching device, the temperature sensor is connected with the switching valve through a control module, and when the temperature is lower than a preset value, water current switching is achieved, and water is prevented from being supplied to the water-requiring device. The low temperature protector is simple in structure, the temperature sensor is utilized for feeding back the water temperature so that water feeding can be started or stopped, and the situations that at the extremely low temperature in winter, water in a water pipe or a water purification product or the water-requiring device is frozen, consequently, frost cracking of the water pipe or the water purification product is caused, and unnecessary economic losses are caused are avoided.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

Gate for water conservancy project

The invention discloses a gate for a water conservancy project. The gate comprises a supporting plate, a control box is arranged on the upper side of the supporting plate, and supporting columns are arranged on the inner side of a bottom plate of the control box; a winding and unwinding roller is arranged between bearing blocks, a motor and a speed reducer are fixedly installed on the inner side of the bottom plate of the control box through a mounting base, an output shaft of the speed reducer is in transmission connection with the winding and unwinding roller through a transmission device, and a PLC is correspondingly and electrically connected with the motor and a storage battery through wires; and a gate frame is arranged on the lower side of the supporting plate, a gate plate is arranged in the gate frame, lifting rings are arranged at the upper end of the gate plate, and the lifting rings are fixedly connected with the lower ends of lifting ropes. According to the gate, solar energy can be converted into electric energy, so that the electric energy is saved, meanwhile, opening and closing of the gate can be realized in a wireless mode after mains supply is cut off, the mass of the gate is reduced while the overall strength of the gate is not reduced, meanwhile, the corrosion resistance of the gate is improved, remote control can be realized, and the operation is simple and convenient.

Owner:陈家龙

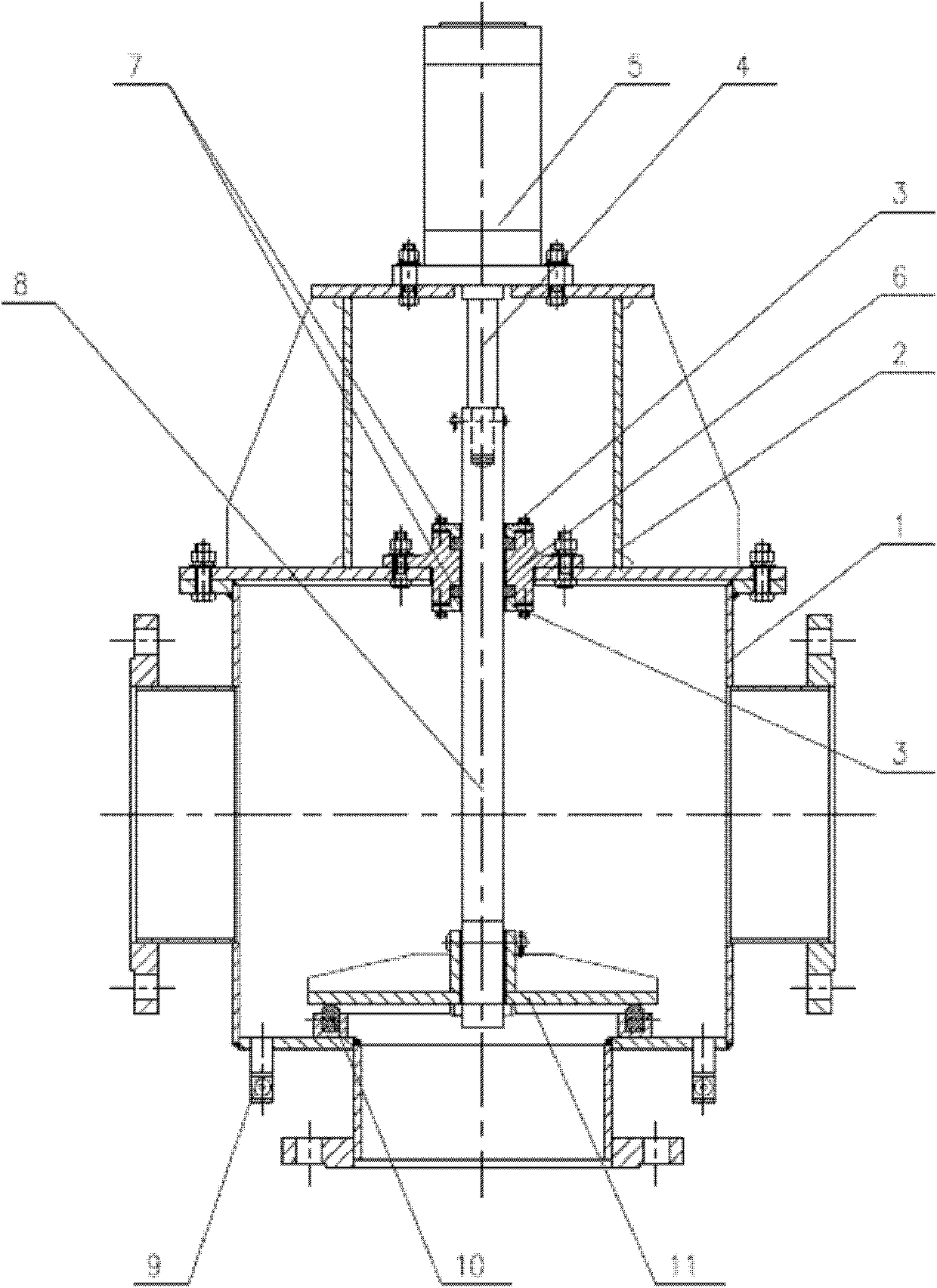

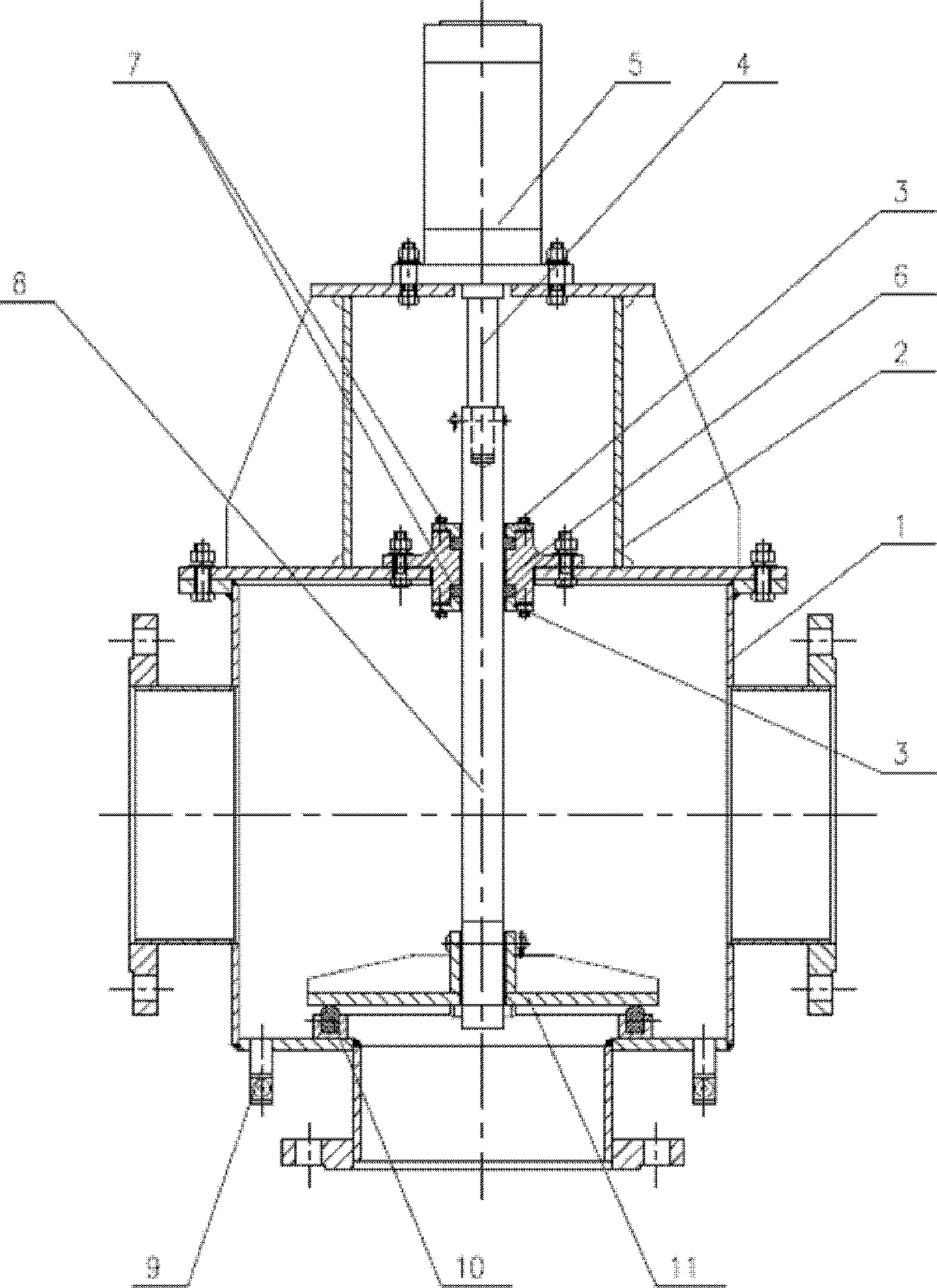

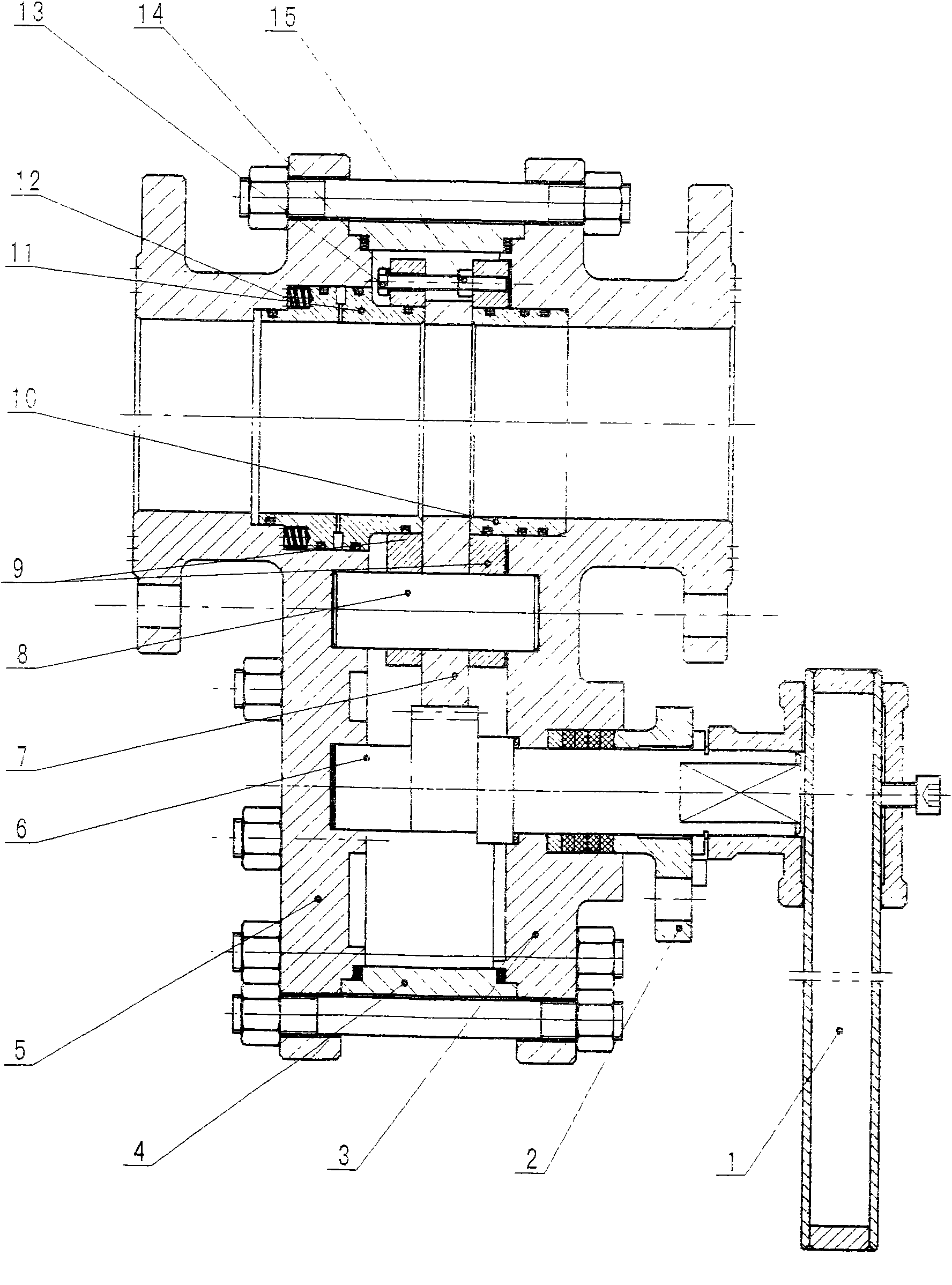

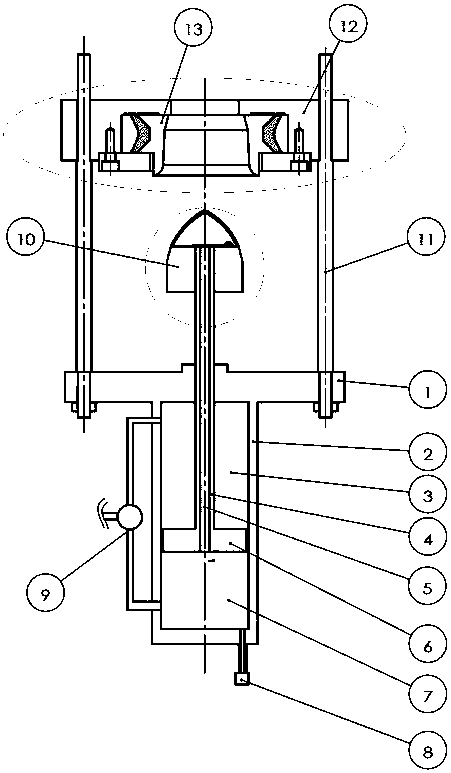

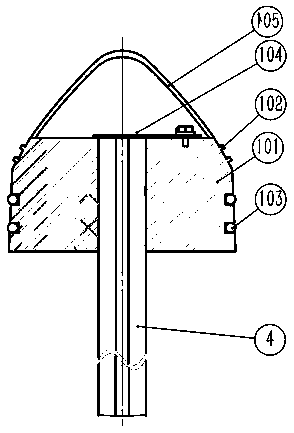

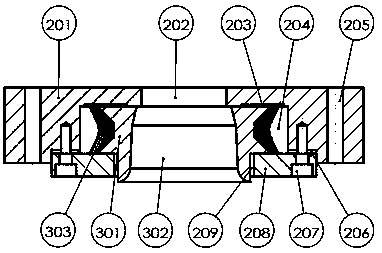

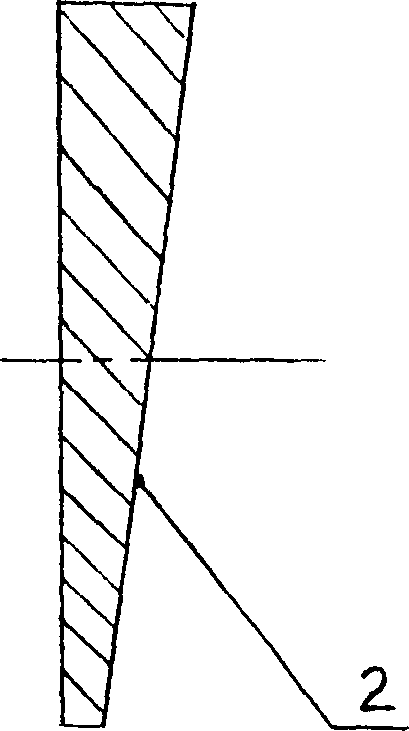

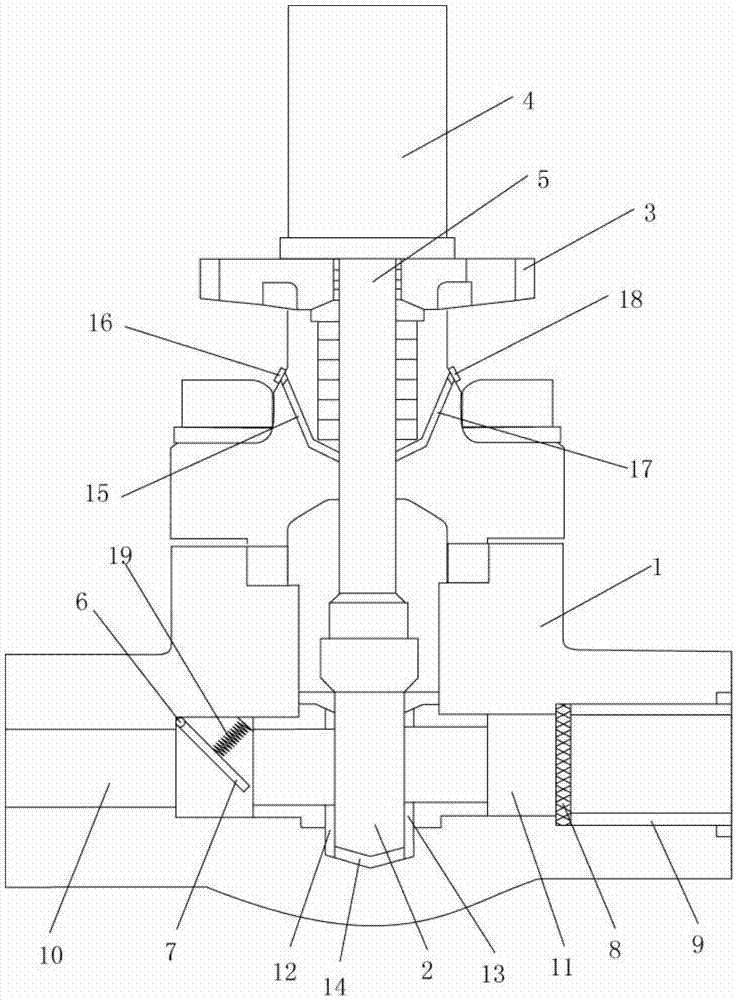

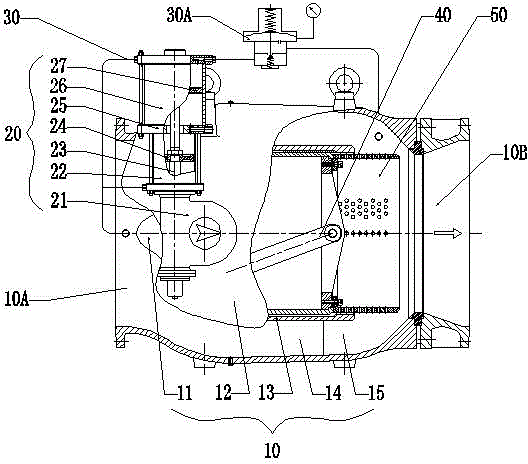

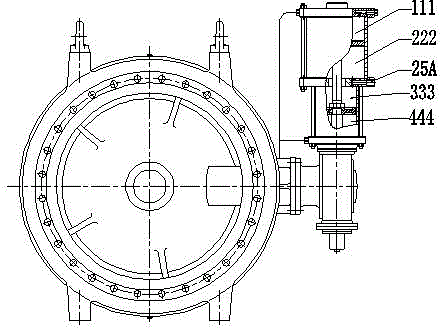

Blow-off valve for steam explosion adverse working conditions and action mode

InactiveCN108105396AThe opening and closing speed is fast, flexible and stableImprove efficiencyOperating means/releasing devices for valvesLift valveMode of actionEngineering

The invention discloses a blow-off valve for steam explosion adverse working conditions and an action mode. The valve is of a main structure, a lower cylinder, an upper valve body, an upper valve carrier and four middle supporting columns form the main structure, and the valve is assembled on the lower end surface of a discharging port of a steam explosion tank. The valve is provided with a 'tapered plug type starting and stopping mechanism', a free body construction' and a 'pressure balancing mode', has characteristics of gas, solid and liquid substances and can blast and control biomass materials under the adverse working conditions of high temperature and pressure and polymorphism mixing, steam explosion efficiency is remarkably improved, the blow-off valve has the advantages of wide application range, good sealing performance, rapidness and stability in operation, simplicity, convenience and easiness in maintenance and long service life, and the valve can be widely used for intermittent pressure tanks and provides an ideal device section type for industrial application.

Owner:李肥生

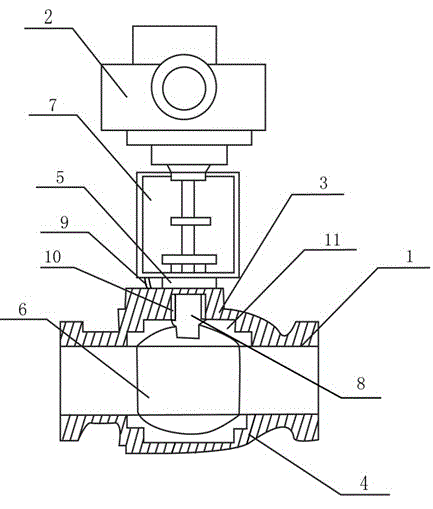

Passive temperature control fluid path on-off switch

ActiveCN103953746ARealize on-offOpen and closeDiaphragm valvesOperating means/releasing devices for valvesTemperature controlThermal deformation

The invention provides a passive temperature control fluid path on-off switch. The on-off switch is arranged on a fluid pipeline pipe wall, and a through-flow hole is formed in the fluid pipeline pipe wall. The on-off switch comprises a cylindrical side wall and an end cover, wherein the cylindrical side wall is fixed on the fluid pipeline pipe wall, the end cover is buckled on the top end of the cylindrical side wall, a limiting space is formed among the cylindrical side wall, the end cover and the fluid pipeline pipe wall and is filled with thermal deformation filler, a heater is arranged in the thermal deformation filler, a central through hole is formed in the end cover, a cut-off hole is formed in the thermal deformation filler, and the cut-off hole in the thermal deformation filler, the central through hole in the end cover and the through-flow hole in the fluid pipeline pipe wall form a fluid path. According to the passive temperature control fluid path on-off switch provided by the invention, switching between on and off of the fluid path is realized by utilizing the opening and the closing of the cut-off hole; realization of the switching between on and off does not need outside interference, so that the switch has the passive characteristic; the reliability is high, the structure is simple, and routing inspection and daily maintenance are not needed.

Owner:CHINA NUCLEAR POWER ENG CO LTD

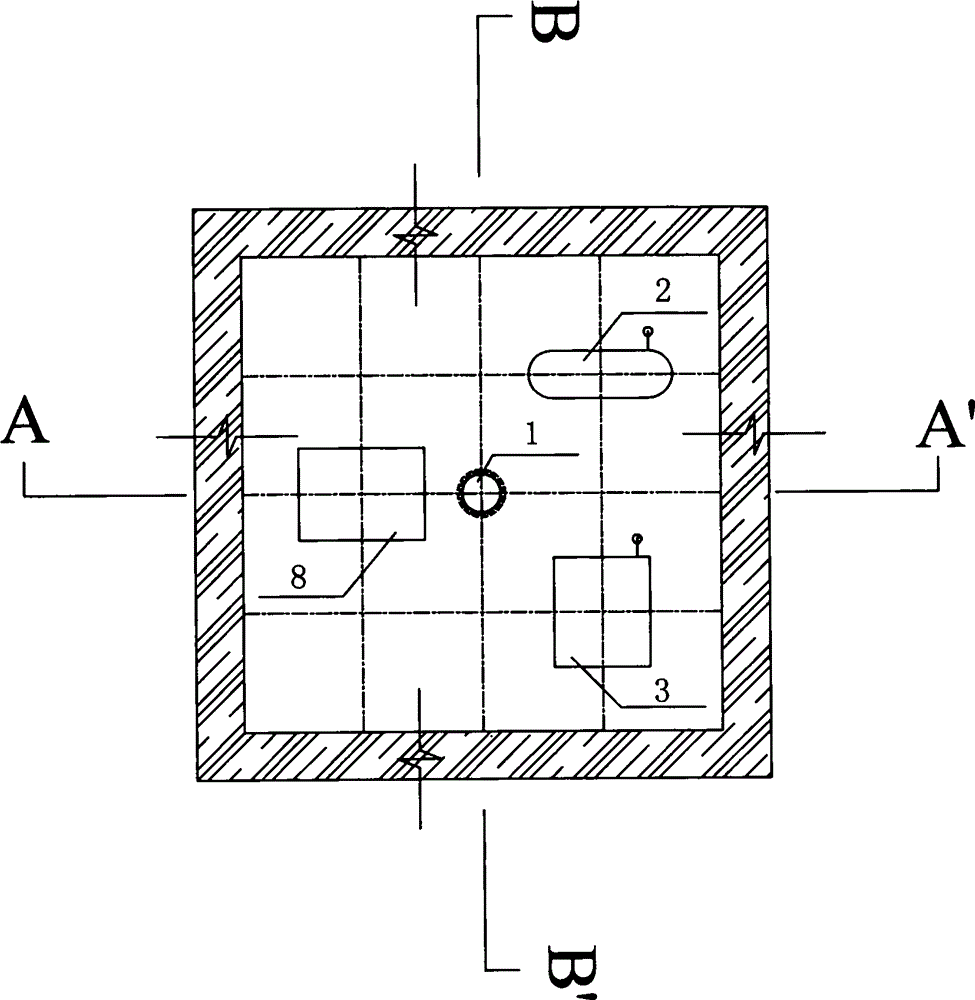

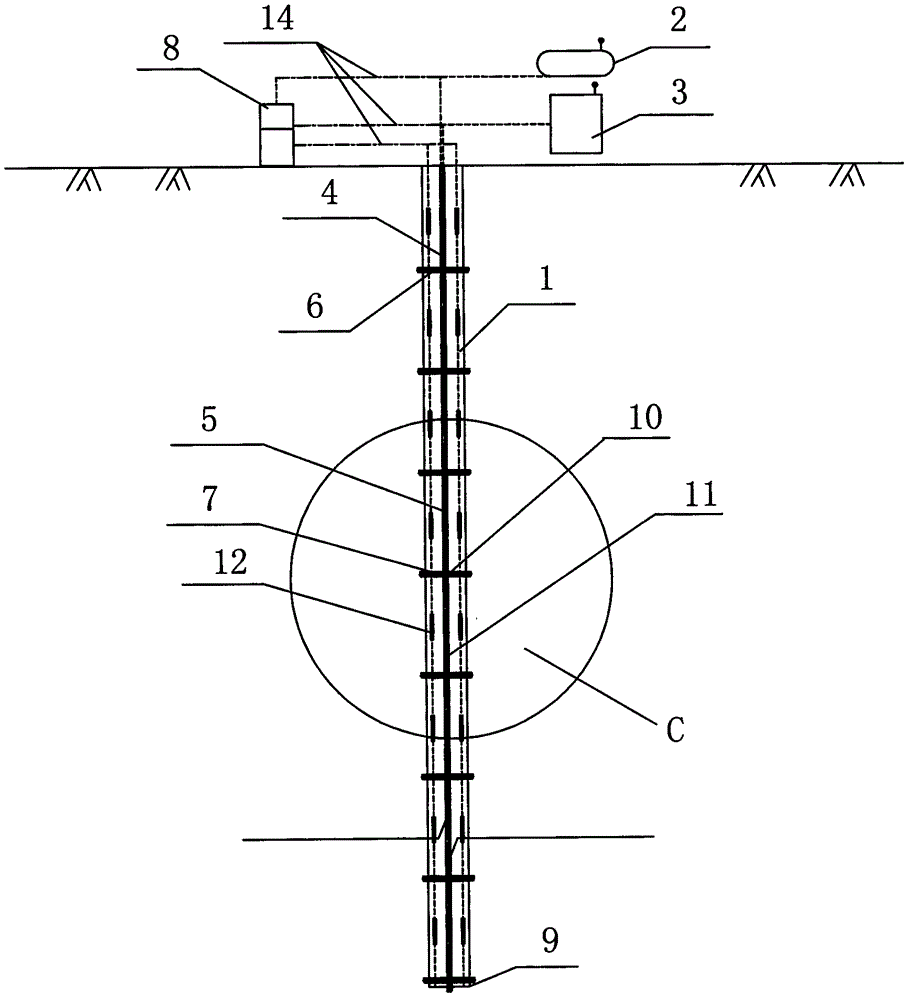

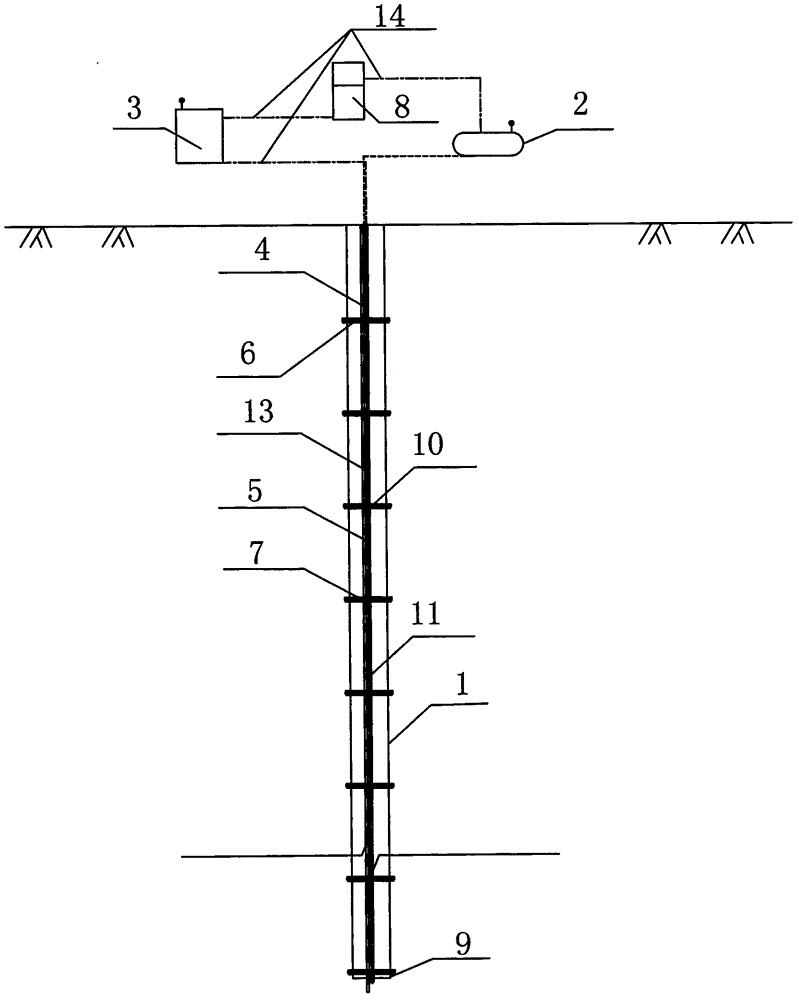

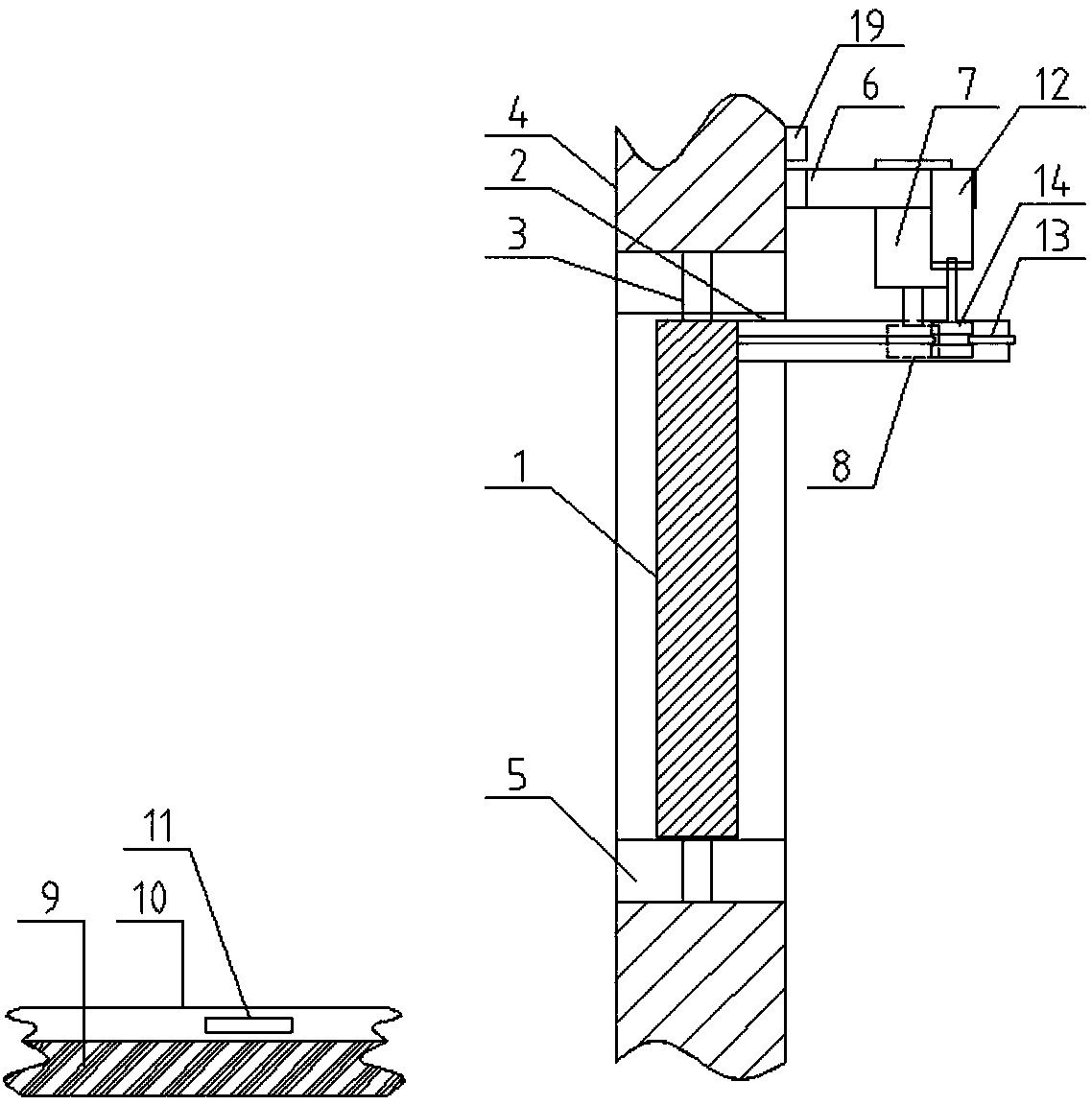

Device for regulating and controlling contact and interaction between pile and earth

InactiveCN104631452AEngineering safety and controllabilityReduce negative frictionBulkheads/pilesJoint workingStructural engineering

The invention discloses a device for regulating and controlling contact and interaction between a pile and earth. The device comprises a negative pressure pump, a grouting pump and a pile body embedded in a selected region. The device is structurally characterized in that a main negative pressure pipeline and a main grouting pipeline are arranged in the pile body or on the surface of the pile body, wherein the main negative pressure pipeline is connected with the negative pressure pump, and the main grouting pipeline is connected with the grouting pump; the device is further provided with a plurality of branch negative pressure pipelines distributed at intervals and a plurality of branch grouting pipelines distributed at intervals, wherein the branch negative pressure pipelines are communicated with the main negative pressure pipeline, and the branch grouting pipelines are communicated with the main grouting pipeline; a valve can be arranged in each branch grouting pipeline, and a plug can be arranged in the main grouting pipeline; deformation sensors and stress sensors can be further arranged in the pile body, wherein the deformation sensors and the stress sensors are connected with a monitoring station. The device has the advantages that opening and closing of the contact surface between the pile and the earth can be flexibly controlled, the stress condition of the end of the pile can be effectively controlled, stress and deformation of the pile body can be flexibly adjusted, and the device can effectively cooperate with the pile and the earth to work together.

Owner:刘林松

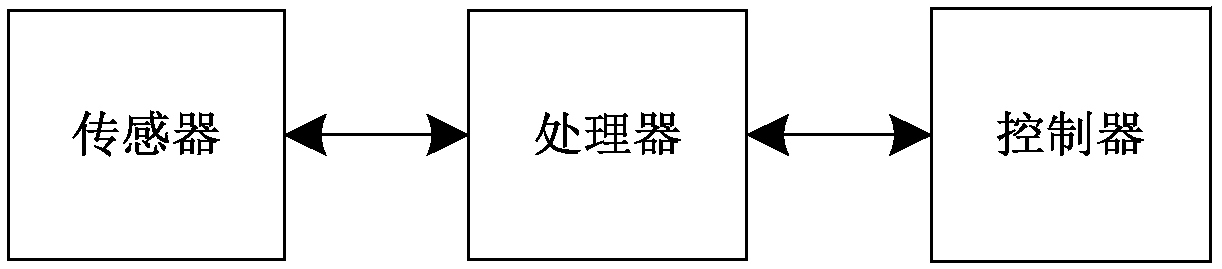

Intelligent window control device

InactiveCN107893601AAvoid damageRealize intelligencePower-operated mechanismAutomatic controlComputer science

The invention provides an intelligent window control device which comprises a sensor, a processor and a controller; the sensor is used for acquiring humidity in an environment and sending a humidity numerical value to the processor; the processor is used for comparing the humidity numerical value with a preset humidity numerical value, and sending a window state acquisition instruction to the controller if the humidity numerical value is greater than or equal to the preset humidity numerical value; the controller acquires current state information of a window according to the window state acquisition instruction and feeding the current state information back to the processor; the processor is also used for sending a control instruction to the controller according to the state information;and the controller is also used for automatically controlling the window to be opened or closed according to the control instruction. The intelligent window control device can automatically control the window to be closed when the humidity is high and when in the rainy days by acquiring environment humidity data, the situation that rainwater enters a room to cause damage to a wood floor or furniture is avoided, and intellectualization can be realized essentially.

Owner:莫宝兰

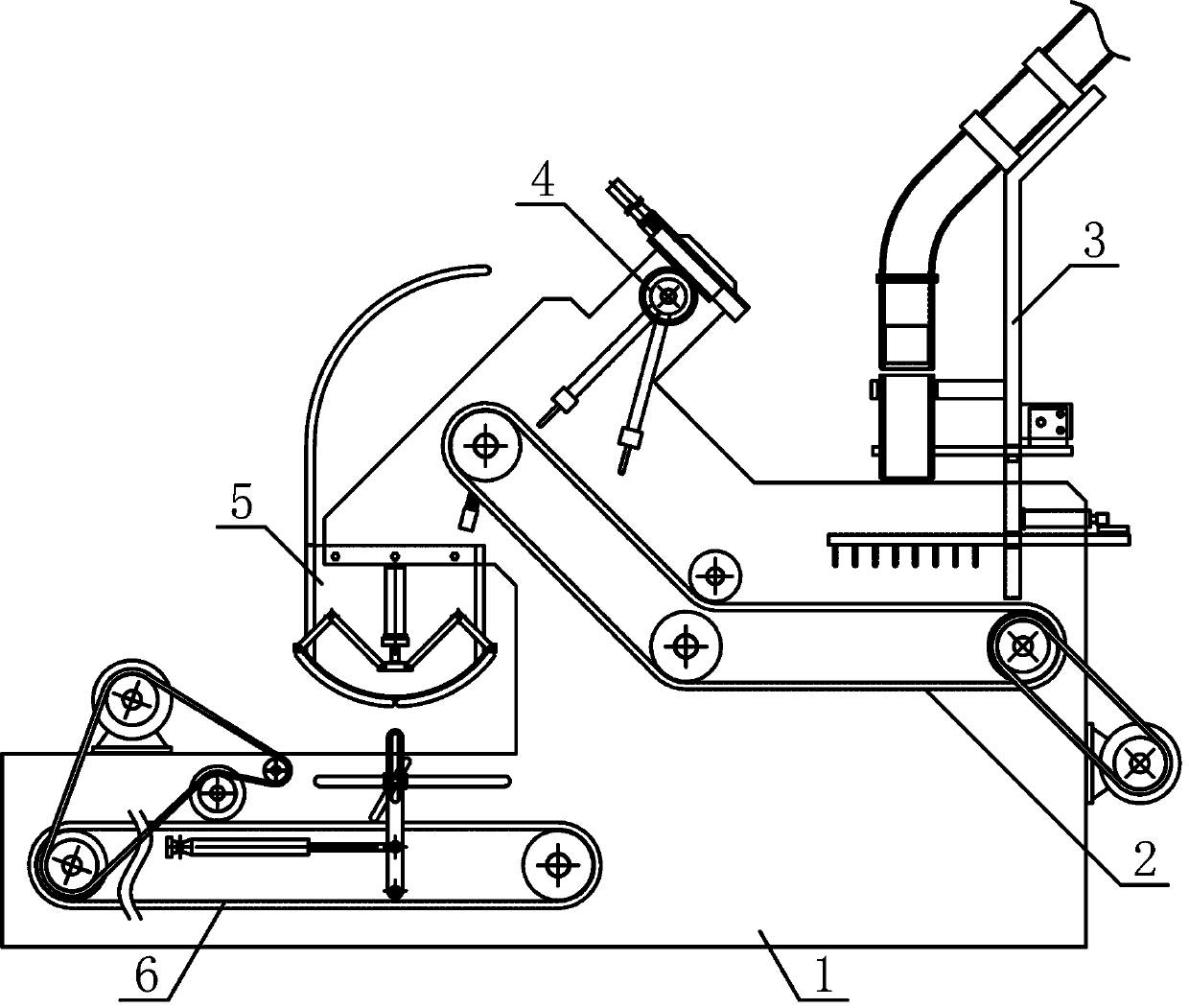

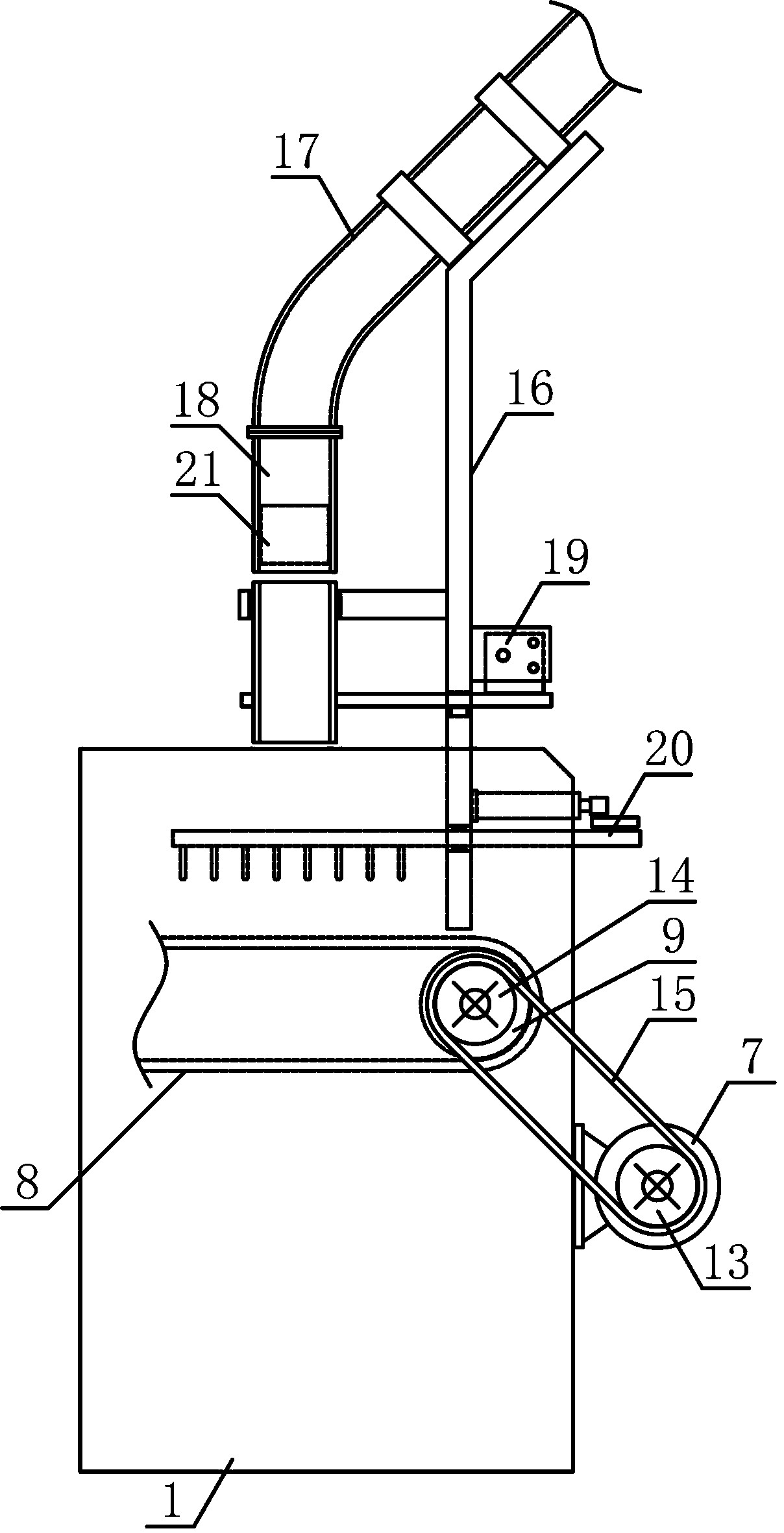

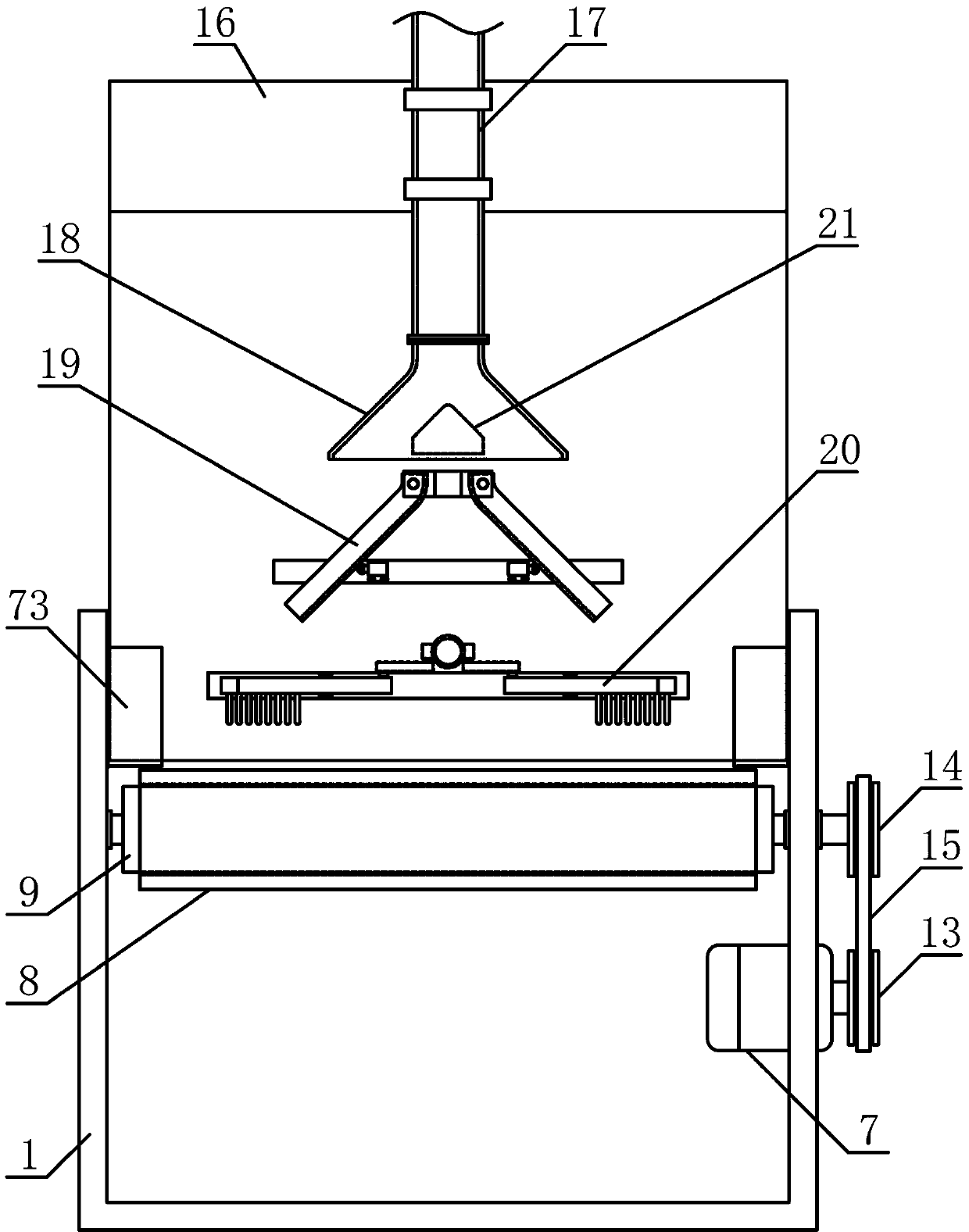

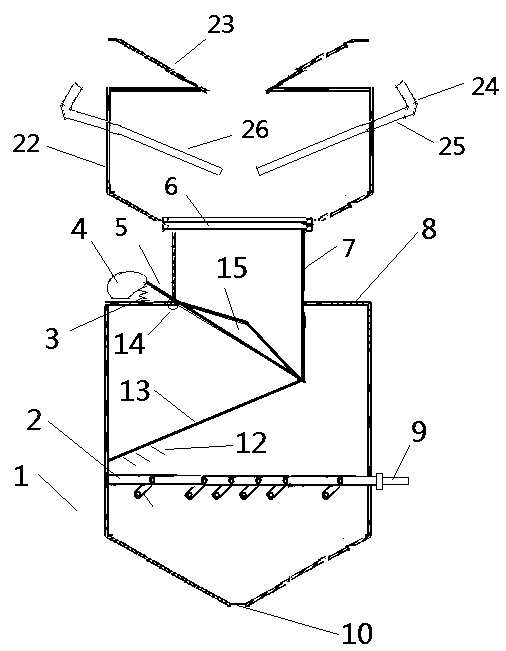

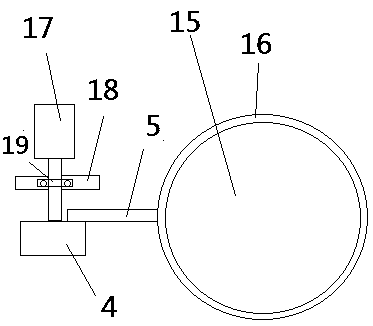

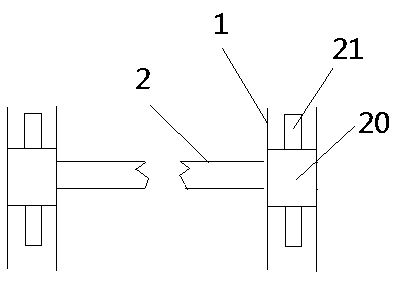

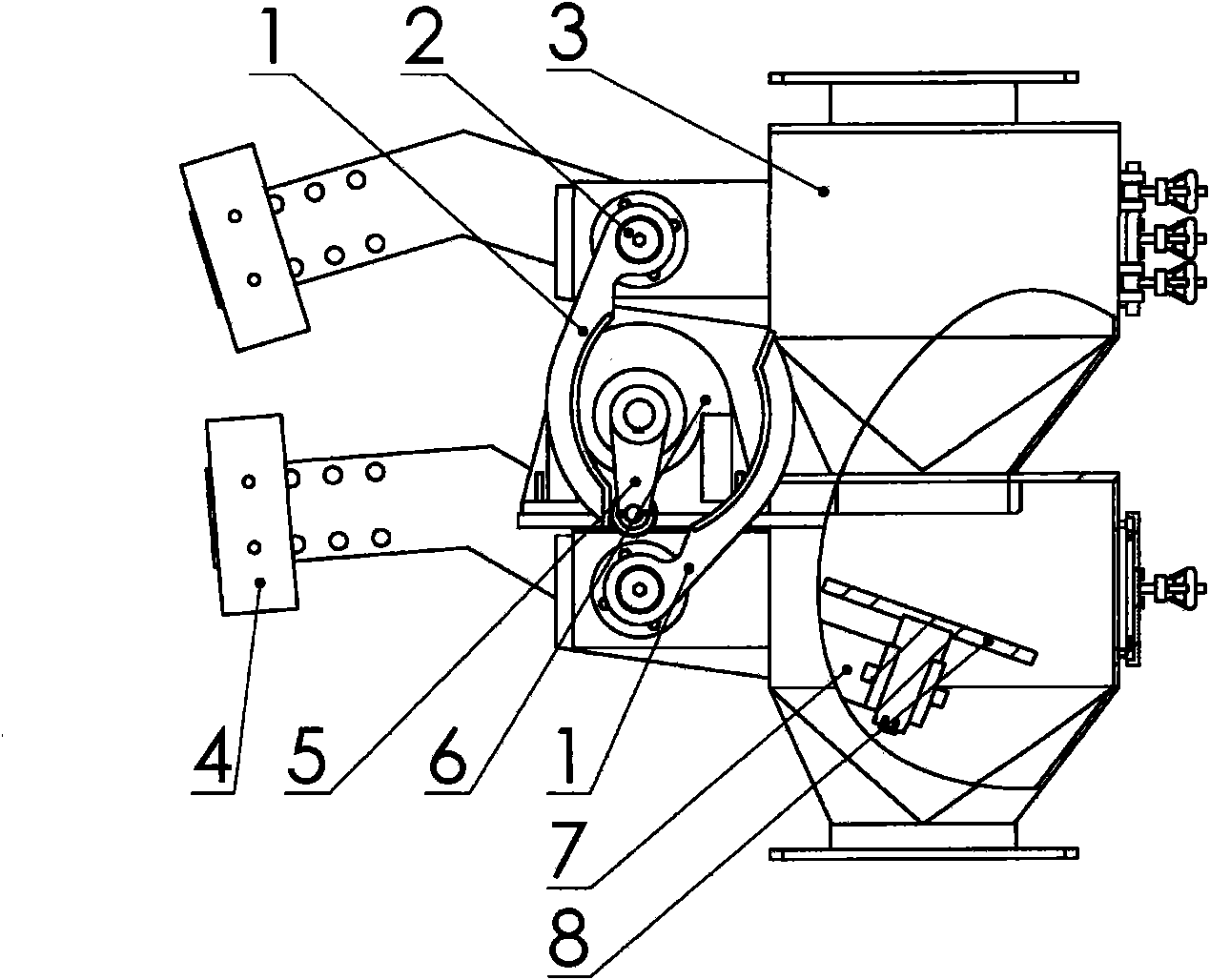

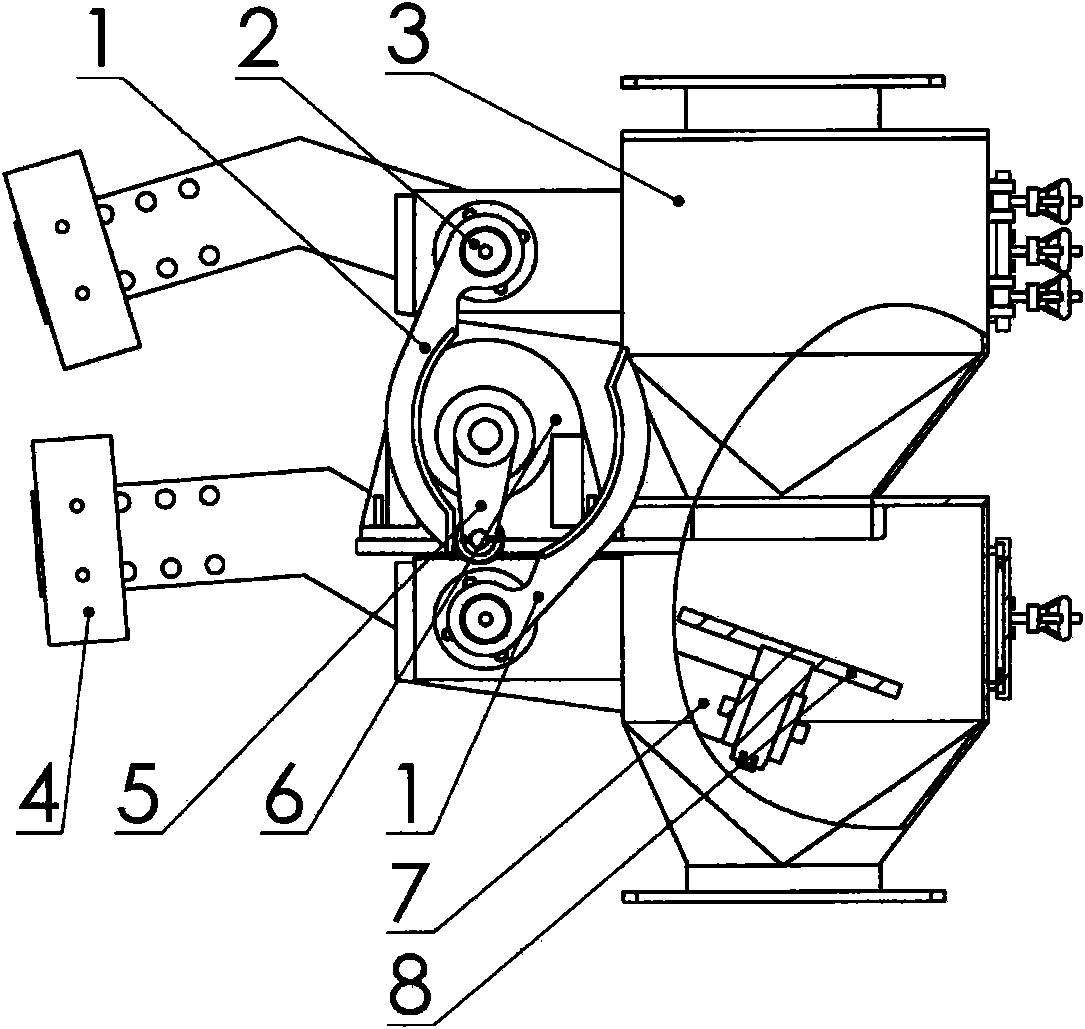

Wool spinning raw material guiding and flat spreading device used for wool top processing

PendingCN110093689AFully efficient marathonThe thickness of the material is uniformFibre feedersMechanical equipmentGuide tube

The invention discloses a wool spinning raw material guiding and flat spreading device used for wool top processing, and belongs to the field of textile processing mechanical equipment. A fallen material dispersion mechanism and a material pulling and conveying mechanism of the device are fixedly arranged at wool spinning material guiding brackets on the two sides over a conveying and feeding mechanism respectively, a quantitative blanking mechanism is horizontally and fixedly arranged at the wool spinning material guiding bracket on one side below the conveying and feeding mechanism, and a material flat pushing and spreading mechanism is fixedly arranged at the wool spinning material guiding bracket on the lower side of the quantitative blanking mechanism horizontally; a wide opening material falling pipe is vertically communicated with and arranged at the lower side of a material conveying pipe, material blocking rotation plates are symmetrically arranged on the two sides below a material containing hopper, and a reciprocating pushing plate is obliquely arranged at the wool spinning material conveying bracket on the lower side of the material containing hopper. The device is reasonable in structural design, wool spinning raw materials can be quickly and conveniently guided to and scattered at a material conveying belt for being conveyed, the wool spinning raw materials can beefficiently and uniformly spread and guided for being conveyed in sequence, the automation degree of production processing is high, and the requirements of processing use are met.

Owner:浙江秋黎服饰有限公司

Downflow valve of water tank in toilet sealed up by rotary startstop ceramic ring in mode

Owner:浙江帅博卫浴科技有限公司

Hydraulic cast steel sluice valve

InactiveCN106895167APrevent retrogradeImprove sealingOperating means/releasing devices for valvesCheck valvesHydraulic cylinderVALVE PORT

The invention belongs to the field of valves and particularly relates to a hydraulic cast steel sluice valve. The hydraulic cast steel sluice valve is characterized in that a first sealing ring is installed on the position, making contact with a valve body, of one side of a flashboard, a second ring is installed on the position, making contact with the valve body, of the other side of the flashboard, and a third sealing ring is installed on the position, making contact with the valve body, of the bottom of the flashboard; a valve cover is fixed at the top of the valve body, and a hydraulic cylinder is fixed to the valve cover; one end of a valve rod is connected with the hydraulic cylinder, and the other end of the valve rod is connected with the upper end of the flashboard; a first oil filling port leading towards the valve rod is formed in one side of the valve body, and a second oil filling port leading towards the valve rod is formed in the other side of the valve body; the upper end of a non-return plate is installed on a rotary shaft, one end of a spring is connected with the middle of the non-return plate, and the other end of the spring is fixed to the inner wall, corresponding to the non-return plate, of a fluid inlet; and a filter net is fixed to the interior of a fluid outlet and pressed through a pressing sleeve.

Owner:TIANJIN NIUWEI VALVE TECH DEV

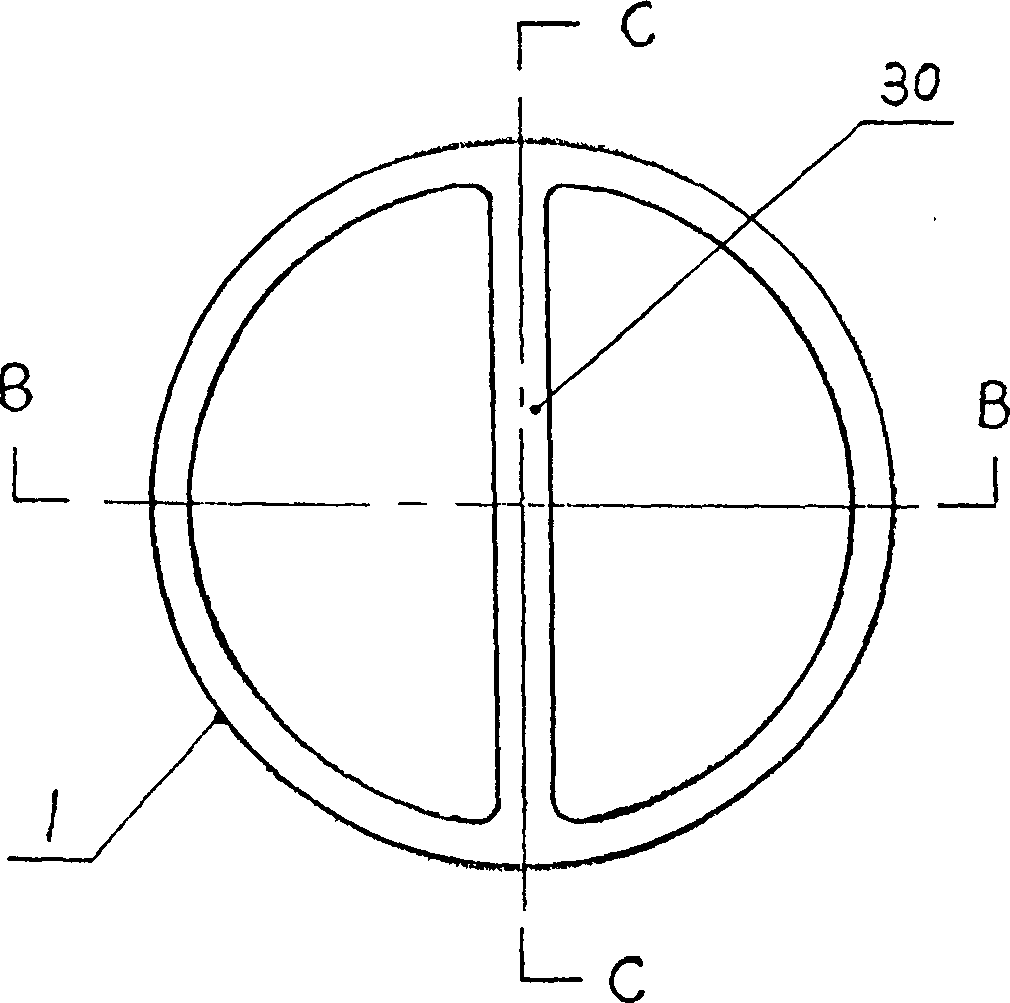

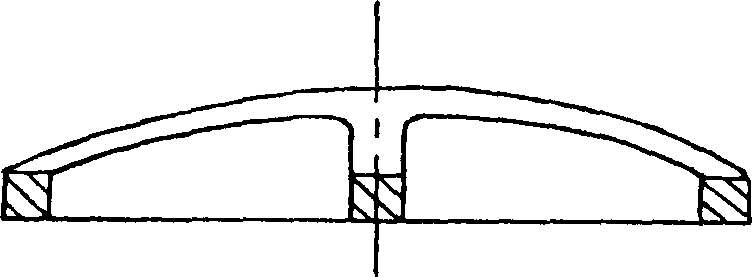

Double-layer combination flap valve

The invention relates to a double-layer combination flap valve which includes a first falling valve and a second falling valve. The first falling valve is located on the upper layer, the second falling valve is located on the lower layer, the first falling valve comprises an upper layer barrel body, a funnel, bends, levers and left and right flapping plates, the bends can control the levels to rotate, thus the left and right flapping plates are driven to rotate, and then the first falling valve is opened or closed; and the funnel is arranged on the upper portion of the upper layer barrel bodyfor receiving materials conveniently, the second falling valve comprises a lower layer barrel body, a partition plate, a spring, a wheel disc, a supporting rod, a flange, a straight barrel, a barrel shoulder, an air cylinder, a discharging port, a blade plate, comb teeth, telescopic rods, a fulcrum, a conical disc, a damping ring, a servo motor, a support, a hoop, rotating rings and bulges, the lower portion of the upper layer barrel body contracts, and the first falling valve and the second falling valve are mutually connected by an end port formed by contraction through the flange.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

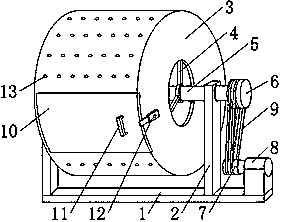

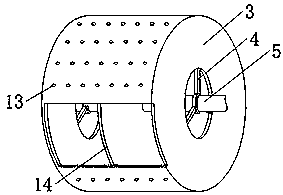

Drum-type polishing machine for bamboo chopstick production

PendingCN108747794AEasy loading and unloadingEasy to useEdge grinding machinesPolishing machinesAgricultural engineeringEngineering

The invention discloses a drum-type polishing machine for bamboo chopstick production. The drum-type polishing machine for bamboo chopstick production comprises a bottom plate, a drum, a rotating rod,a drum plate and a separation plate. Round openings are formed in the left and right end faces of the drum, the rotating rod penetrates through the drum and fixedly connected to the position of the axis of the drum through a support and the separation plate, and the rotating rod is rotatably connected with a drum frame at the left and right ends of the drum through bearings. The lower end of thedrum frame is welded and fixed to the upper surface of the bottom plate, a driven belt pulley is arranged at the right end of the rotating rod, a driving belt pulley is connected with a motor througha rotating shaft of a motor, the driving belt pulley is connected with the driven belt pulley through a belt, and a drum plate is arranged at the notch of the drum wall of the drum. The drum-type polishing machine for bamboo chopstick production is reasonable in design, bamboo chopsticks can rotate in the drum through the design of the drum, and burrs on the chopsticks can be worn off through therotation and friction between the chopsticks, use is convenient, and the polishing effect is good.

Owner:湖南奇宏林业股份有限公司

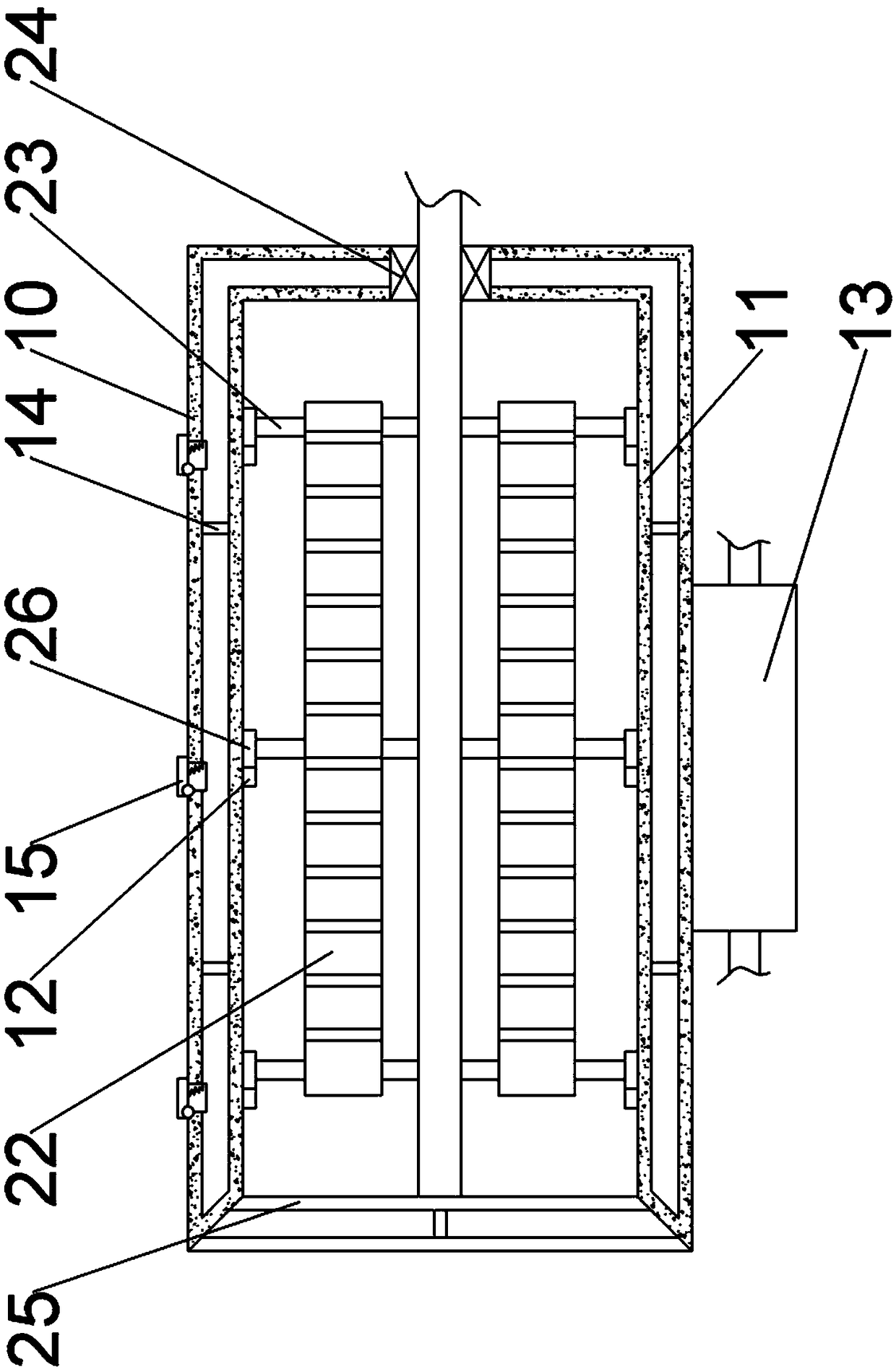

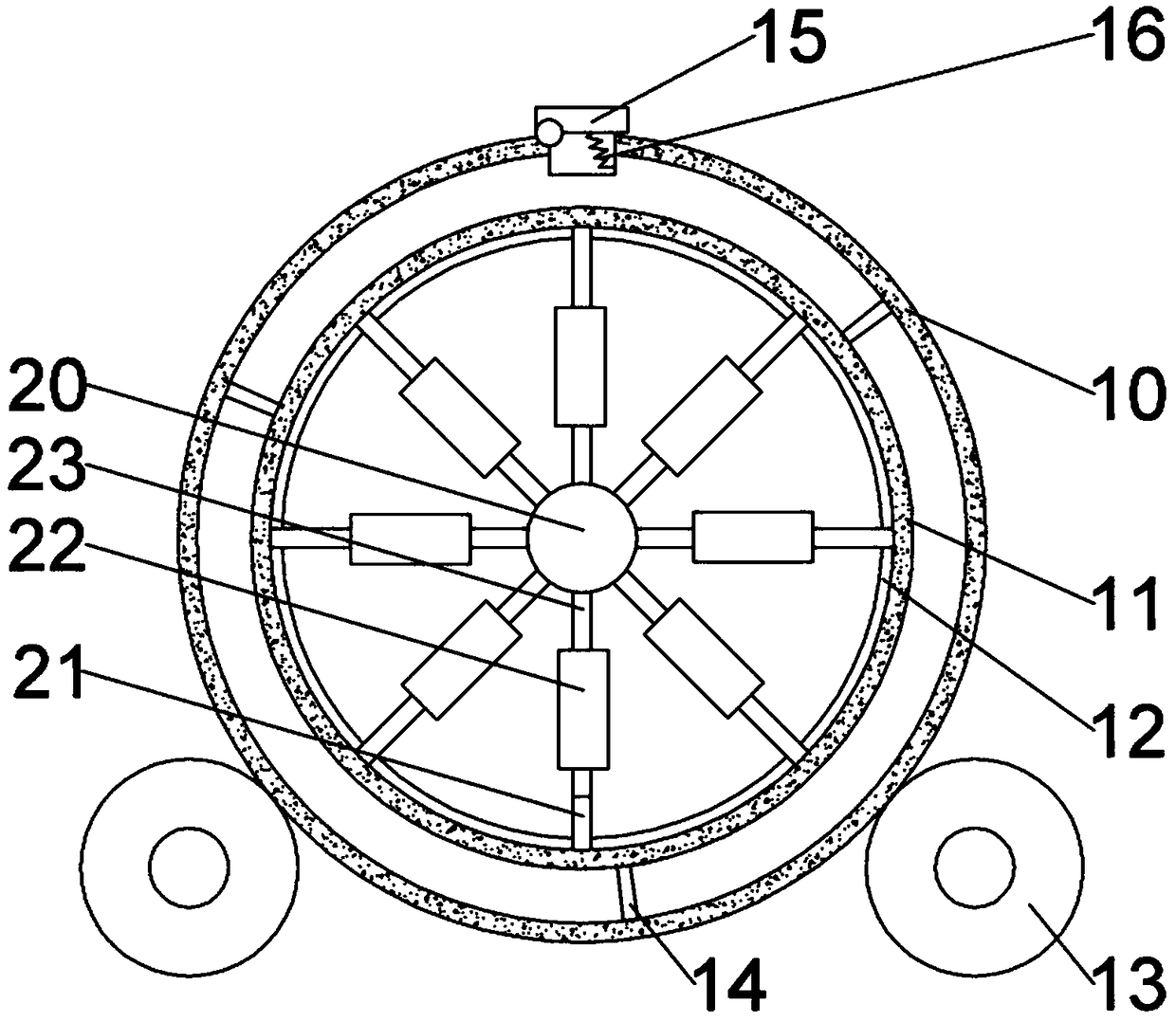

Green tea fixation equipment

InactiveCN108740112AGood killing effectAvoid mixingPre-extraction tea treatmentTransmission beltPulp and paper industry

The invention discloses green tea fixation equipment. The green tea fixation equipment comprises a machine frame and a transmission belt which is arranged in the axial direction of a cylinder body, wherein the cylinder body which is horizontally arranged and a friction roller for driving the cylinder body to rotate are rotatably connected to the machine frame; the cylinder body comprises an innerlayer in the shape of a sieving cylinder and an outer layer; the outer layer and the inner layer are arranged at intervals; an RO membrane is arranged on the outer wall of the inner layer; one end ofthe cylinder body is opened, and a sealing cover is arranged at the opened end of the cylinder body; an air delivery pipe is rotatably connected to the other end of the cylinder body; a plurality of stirring units and a plurality of air outlets are arranged / formed on / in the air delivery pipe in the axial direction; each stirring unit comprises a plurality of stirring rods which are uniformly distributed on the air delivery pipe in the circumferential direction and an end surface gear fixed on the inner wall of the inner layer; one ends of the stirring rods are rotatably connected with the airdelivery pipe, and each driven gear which is meshed with the corresponding end surface gear is fixed to the other end of the corresponding stirring rod. The invention aims to provide the green tea fixation equipment being good in fixation effect on tea leaves.

Owner:贵州省余庆县香茗茶业有限责任公司

Automatic electric ball valve

The invention provides an automatic electric ball valve. The automatic electric ball valve comprises a valve body and a motor located on the valve body, an upper end cover and a lower end cover are arranged on the upper side and the lower side outside the valve body, and a valve rod and a valve core are arranged in the valve body. The automatic electric ball valve is characterized in that a transmission assembly is arranged between the motor and the valve body and connected with the valve rod, a monitor is arranged at the connecting position of the valve core and the valve rod, and a wire is arranged on the monitor and connected with the transmission assembly. As the transmission assembly is arranged, mechanical energy of the motor can be converted into kinetic energy to drive the valve rod to operate so that the valve core can be opened or closed; the monitor monitors the operation condition of the valve core and can transmit signals to the transmission assembly in time, the transmission assembly reversely rotates to drive the valve core to rotate in a bi-directional mode, the valve core is prevented from being stuck, the whole process is completed by means of automatic operation of the valve, and therefore the automation degree is high.

Owner:TIANJIN TIANFEI HIGH TECH VALVE

Swinging-rod device for double-layer ash-discharging valve

InactiveCN102418808ARealize the function of opening and closingSimple structureOperating means/releasing devices for valvesLift valveReducerRocker arm

The invention discloses a swinging-rod device for a double-layer ash-discharging valve. The swinging-rod device comprises a swinging rod, a shaft, a valve body, a heavy hammer, a roller arm, a speed reducer, a rocking arm and a valve plate, wherein the speed reducer is connected with the roller arm, the roller arm is connected with the swinging rod, the swinging rod is in a structure with a circular-arc surface, the swinging rod is connected with the shaft, the shaft is connected with the rocking arm, the rocking arm is connected with the valve plate, and the heavy hammer is connected with the shaft through a heavy-hammer handle. Through the swinging-rod device for the double-layer ash-discharging valve, the opening and closing functions of the valve plate can be effectively and reliably realized, and the swinging-rod device has a simple structure and low cost.

Owner:扬州市聚鑫机械有限公司

Energy-saving protecting device applicable to opening and closing of window of historical building

PendingCN108533116AGuaranteed stabilityPower stabilityWing fastenersPower-operated mechanismSash windowLocking mechanism

The invention discloses an energy-saving protecting device applicable to opening and closing of a window of a historical building. The device comprises an arc-shaped rack which is arranged at the outer side of a rotating shaft of a window sash, an opening and closing mechanism which is arranged on a wall body at the rotating shaft of the window sash, a locking mechanism which is arranged on the wall body and fits the opening and closing mechanism, a power supplying mechanism which is arranged on a floor of the historical building, and a control mechanism which is arranged on the wall body andis used for controlling the opening and closing mechanism, the locking mechanism and the power supplying mechanism. With the adoption of the device, a wooden window of the historical building can be automatically regularly opened and closed, and the opening state can be locked; and in addition, power can be automatically generated as a visitor walks in the building, so that the independent power supply demand is met, and the energy is greatly saved.

Owner:NANYANG INST OF TECH

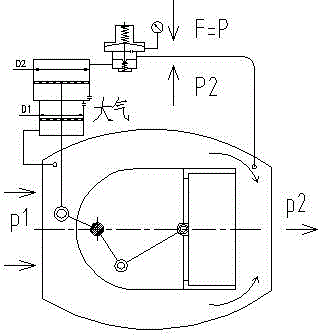

High-circulating easily regulated pilot-operated type piston valve

InactiveCN104806513AImprove liquidityEasy to adjustOperating means/releasing devices for valvesPositive displacement pump componentsEngineeringHigh pressure

The invention discloses a high-circulating easily regulated pilot-operated type piston valve. A valve body comprises an outer shell and an inner shell, wherein a shuttle-type gradient curved cone structure is adopted at one end of the inner shell close to an inlet of the valve body; an annular channel is formed between the outer shell and the inner shell; the outer shell is connected with the inner shell through a streamline type guide plate; an adjusting drum is mounted between the inlet and outlet in the valve body; the adjusting drum is connected with one end of a crank-link mechanism; the other end of the crank-link mechanism is connected with a piston mechanism located on the outer side of the valve body. The high-circulating easily regulated pilot-operated type piston valve can adapt to a high-pressure-difference current-adjusting and pressure adjusting working condition and has the advantages of small flow resistance, excellent adjusting property, small size and light weight.

Owner:CHANGSHA XINQIXIANG AUTOMATION TECH

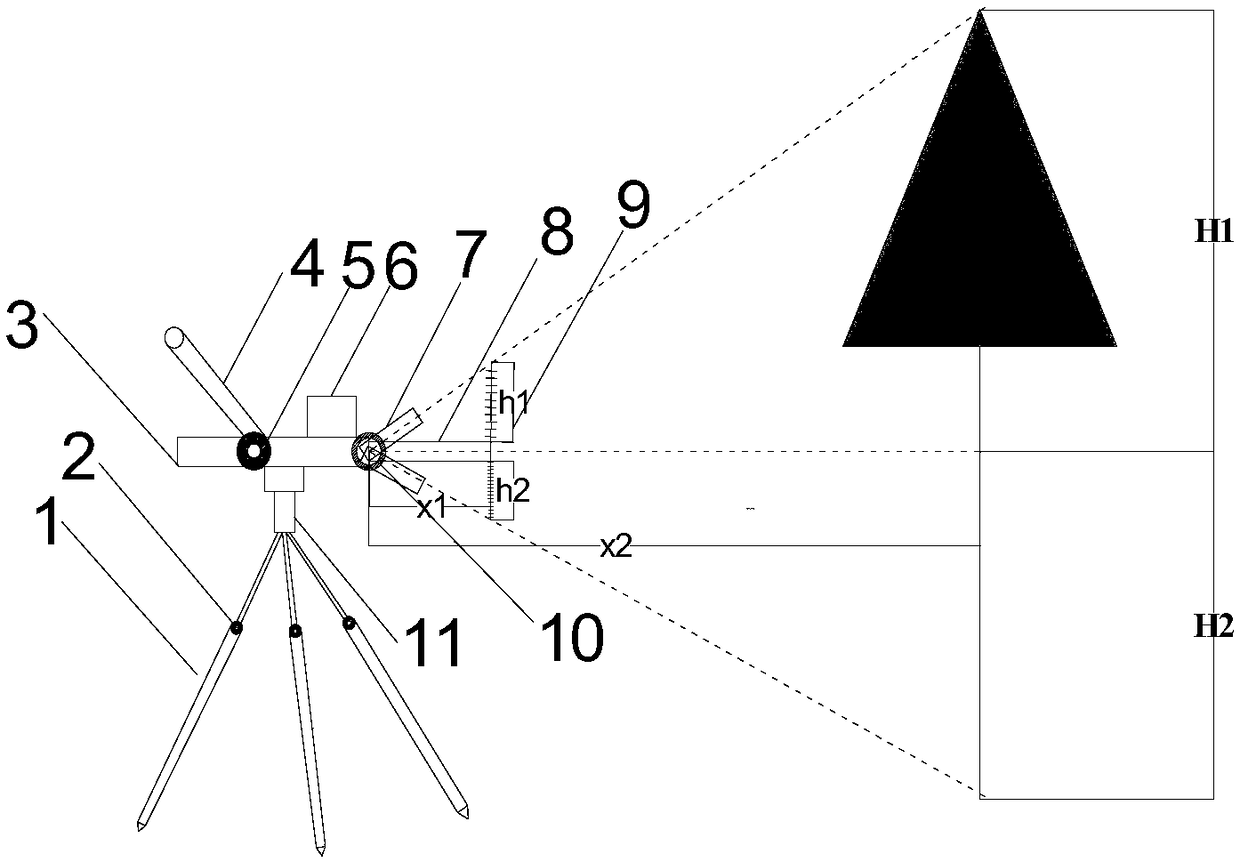

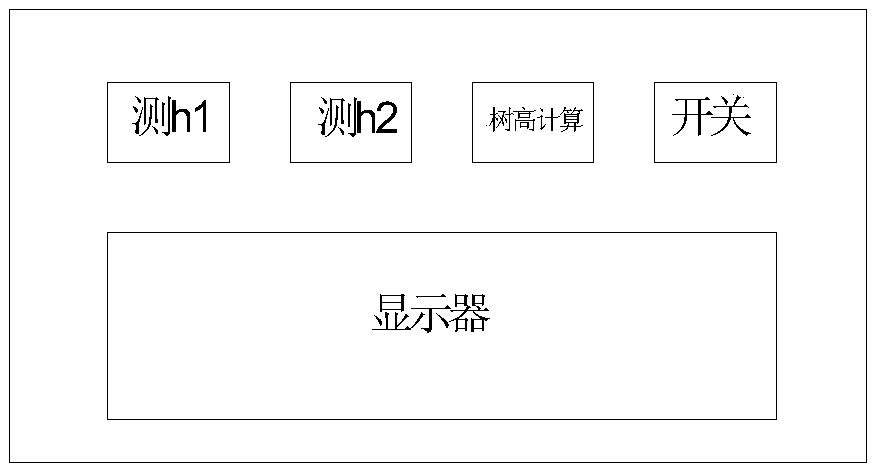

Tree height measuring device and measuring method thereof

InactiveCN108645346AReduce precisionSimple structureUsing optical meansMeasurement deviceControl table

The invention discloses a tree height measuring device and a measuring method thereof. The tree height measuring device comprises a foldable telescopic base, and a telescopic rotary knob capable of adjusting the height of the foldable telescopic base. A horizontal control table is connected to the foldable telescopic base through a rotary table, a sighting telescope is installed on the horizontalcontrol table, the focal length of the sighting telescope can be adjusted by a sighting telescope rotary knob, and a control and display device is installed on the horizontal control table. A rotatable laser sight is installed at the front end of the horizontal control table, the sighting telescope rotary knob controls rotation of the laser sight, and a diastimeter is installed at the front end ofthe horizontal control table. A movable telescopic vertical ruler is installed on the diastimeter. By means of the device, the rigid tree height can be precisely measured, the influence of natural conditions is small, and the device is high in operability, good in stability and high in measuring efficiency.

Owner:HOHAI UNIV

Automatic opening and closing device for air-tight door

PendingCN111852240AOpen and closeEnsure safetyNon-mechanical controlsWing fastenersHydraulic cylinderGear wheel

The invention discloses an automatic opening and closing device for an air-tight door. The automatic opening and closing device comprises a first hydraulic driving assembly, and a locking mechanism, wherein a hydraulic cylinder of the first hydraulic driving assembly is connected with a fixed object, a piston rod of the first hydraulic driving assembly is connected with the air-tight door, and thefirst hydraulic driving assembly is used for driving the air-tight door to move so as to achieve opening and closing of the air-tight door; and the locking mechanism comprises a second hydraulic driving assembly and a rotary locking assembly, and the rotary locking assembly comprises a gear disc, a cross rod and a rack. The automatic opening and closing device for the air-tight door can achieve automatic remote control, is safe and reliable, improves safety and reliability, and achieves remote automatic operation; and the automatic opening and closing device for the air-tight door achieves remote opening and closing of the pump room air-tight door, fills the industry blank, and greatly improves safety and reliability.

Owner:山东能源集团鲁西矿业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com