Blow-off valve for steam explosion adverse working conditions and action mode

A kind of operation and harsh technology, applied in the direction of valve operation/release device, lift valve, valve details, etc., can solve the problems of incompatibility of production practice, affecting production efficiency and output quality, bulky and heavy, etc., to improve efficiency and output quality, adaptability to a wide range of working conditions, and prolong the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

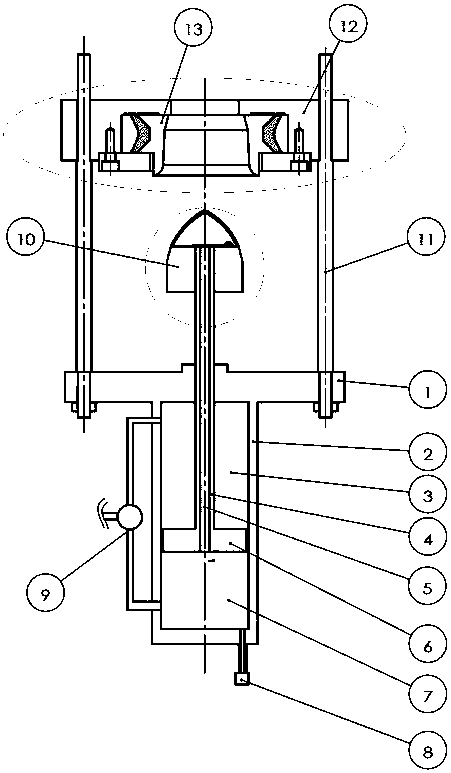

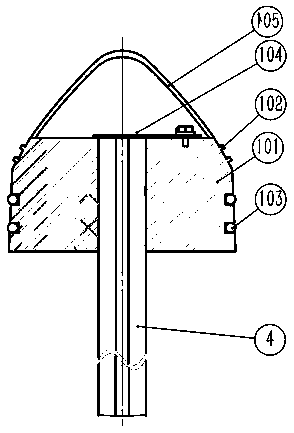

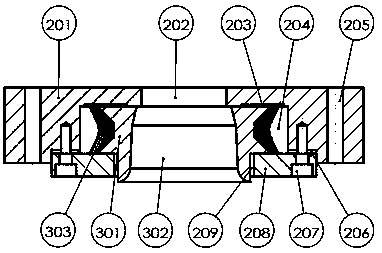

[0028] Example 1, the discharge valve is integrally assembled on the lower end surface of the discharge port at the bottom of the steam explosion tank, and the reversing valve is adjusted to inject pressure steam into the lower air chamber of the valve cylinder (the reversing valve synchronously transfers the gas leakage), the piston of the cylinder pushes the piston rod and the valve core at the rod end to move upward quickly together. At this time, part of the steam ascends through the hollow through hole of the piston rod, and the upper port of the through hole is temporarily caught by the reed in the valve core. Blocked, when the continuously and rapidly upward valve core enters the taper inner diameter of the upper valve seat and is about to contact each other, it is controlled by the buffer at the end of the cylinder stroke to move slowly, and gradually touches the tapered inner diameter of the valve seat gently while moving slowly. Force the valve seat in the valve seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com