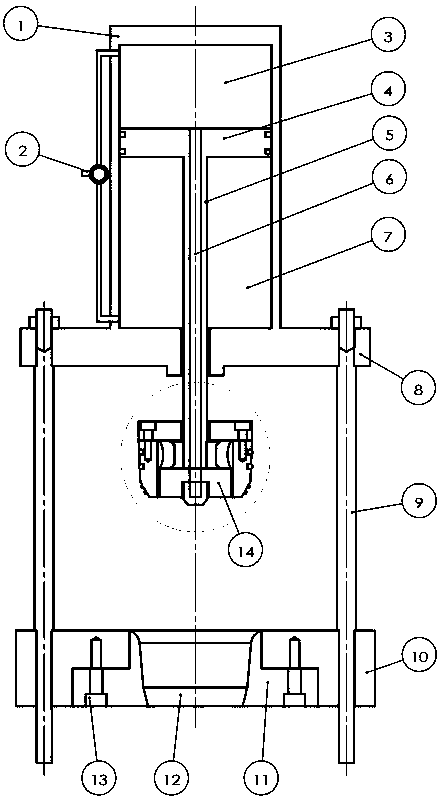

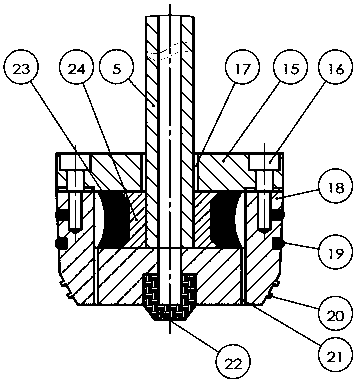

Feeding valve for steam explosion operation and action mode of feeding valve

A technology of feeding valve and operation, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of difficulty in forming steam explosion operation, affecting production efficiency and output quality, and easy damage and maintenance. The effect of improving efficiency and output quality, adaptability to a wide range of working conditions, and reliable sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will be further described in conjunction with specific examples, without limiting the present invention.

[0026] Assemble the feeding valve on the upper end of the steam explosion tank, close the discharge valve at the bottom of the steam explosion tank, and then inject external compressed air into the lower air cavity of the cylinder through the reversing valve, so that the piston drives the piston rod The spool at the rod end quickly moves up to the apex, and then closes the reversing valve to stop the gas injection. At this time, the valve body channel of the feeding valve is completely opened, and the additional conveyor hose runs from the upper side and along the four pillars of the valve. The large-area space between them extends into the inner diameter of the taper of the valve seat, and the plant-like crushed materials are input into the tank, and the conveyor hose returns to the original position after reaching the set value.

[0027] Adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com