Overflow-preventing garbage can and control method thereof

A control method and trash can technology, which is applied in the field of trash cans, can solve the problems of overflowing trash cans, difficulty in finding them, and low awareness of environmental protection, and achieve the effects of preventing garbage overflow, preventing odor, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

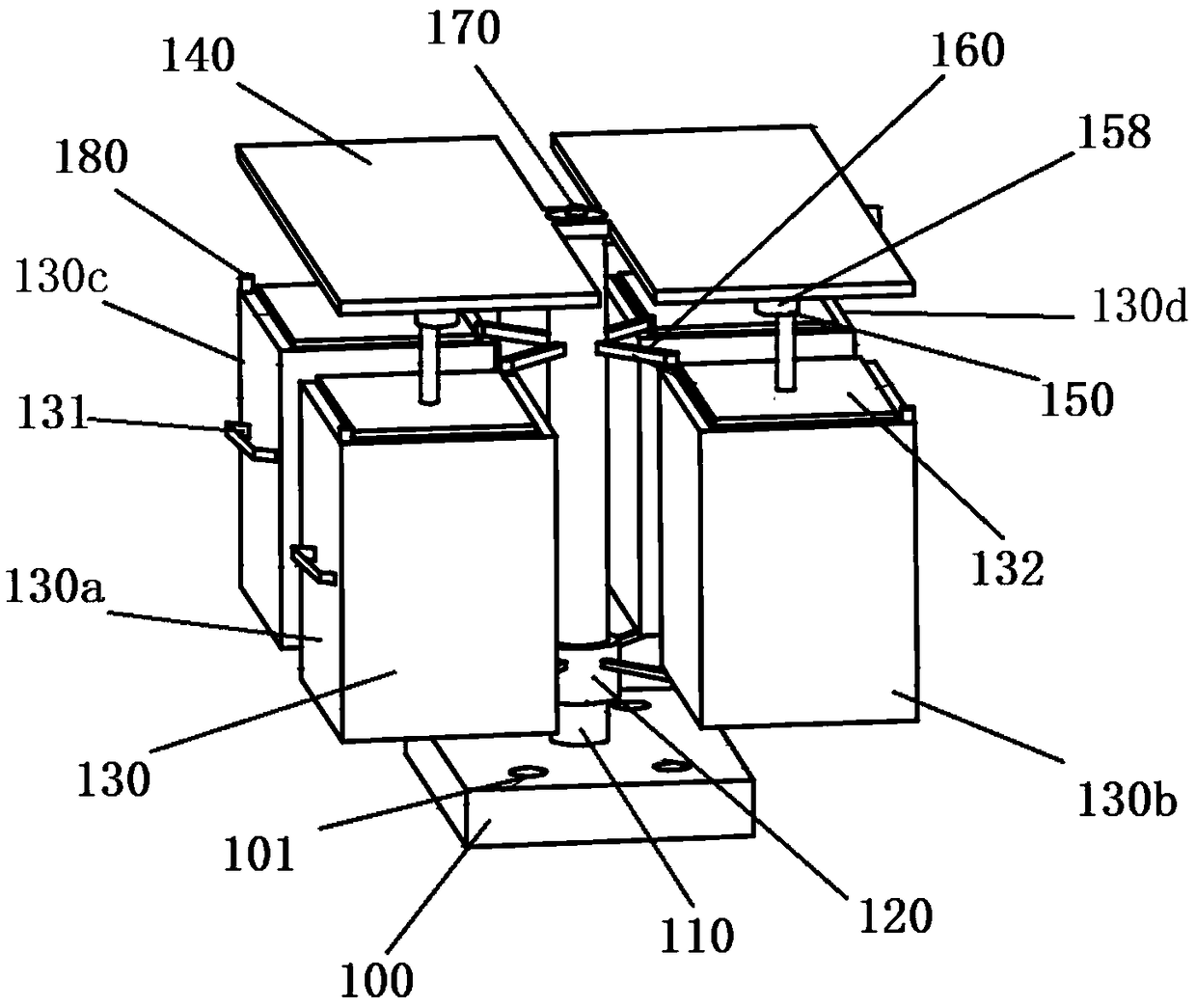

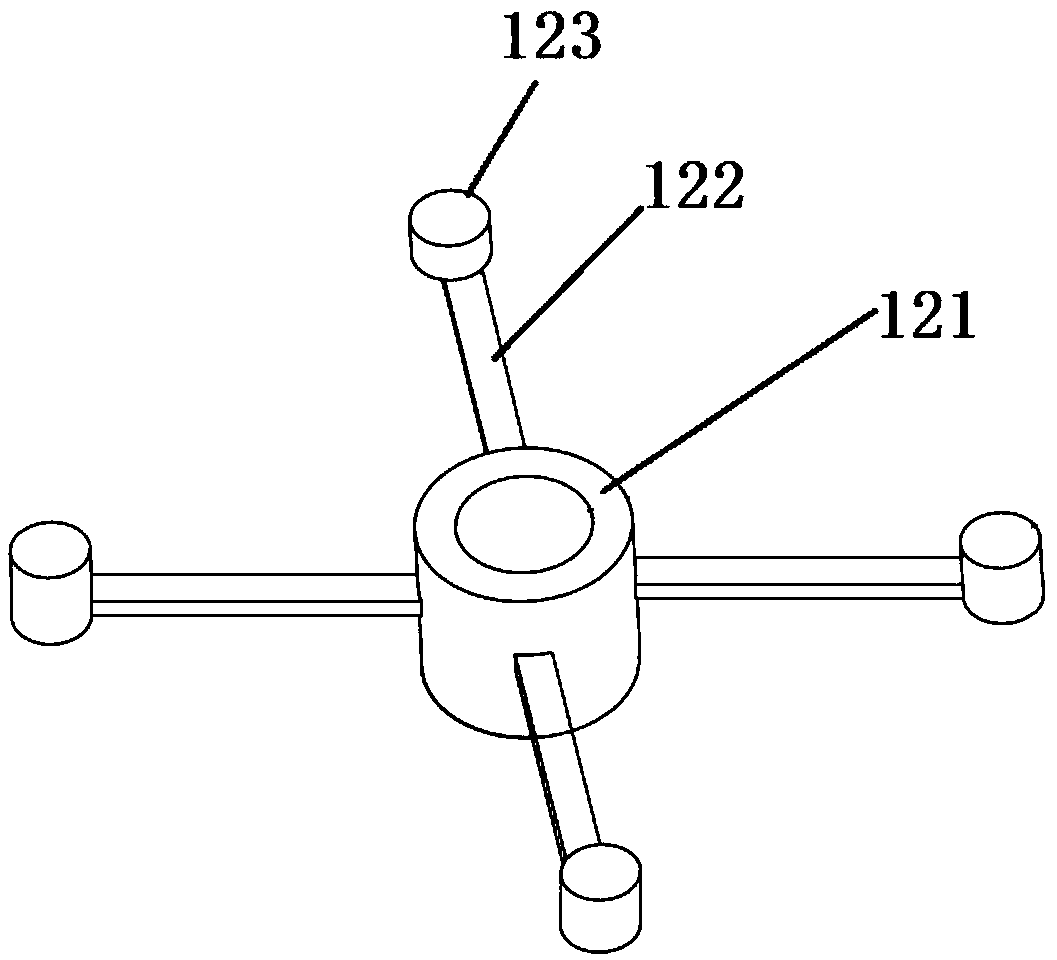

[0056] Such as figure 1 As shown, the anti-spill garbage bin of the present invention includes a fixed bottom plate 100, the center of which has a cylindrical groove on its upper surface. The fixed bottom plate 100 is used for supporting and fixing the trash can as a whole. The fixed floor 100 is provided with a plurality of threaded holes 101, which can form a solid connection with the ground through bolts to fix the dustbin entity. A pillar rotating shaft 110 is matched in the groove, and the lower end of the pillar rotating shaft 110 can rotate in the groove. Four garbage bins 130 are arranged symmetrically above the fixed bottom plate 100 and fixedly connected with the pillar rotating shaft 110 , and a cover plate 132 is arranged above the garbage bins.

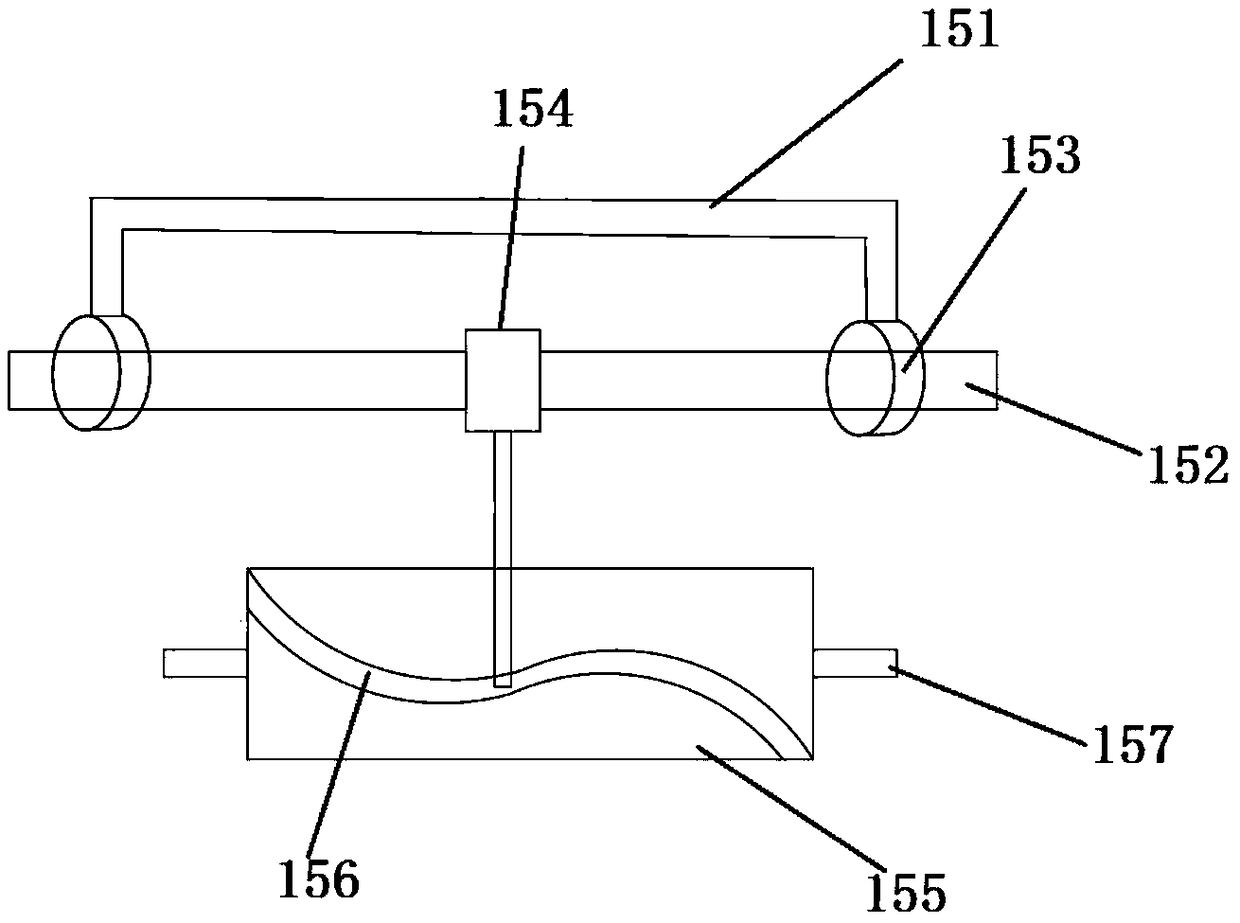

[0057] A top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com