Three-way valve

A three-way valve and valve body technology, applied in the field of three-way valves, can solve problems such as difficulty in meeting the sealing requirements of regenerative incinerators, inconvenient replacement of sealing rings, and leakage of harmful gases, so as to reduce equipment maintenance costs and improve sealing effects Good, to ensure the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

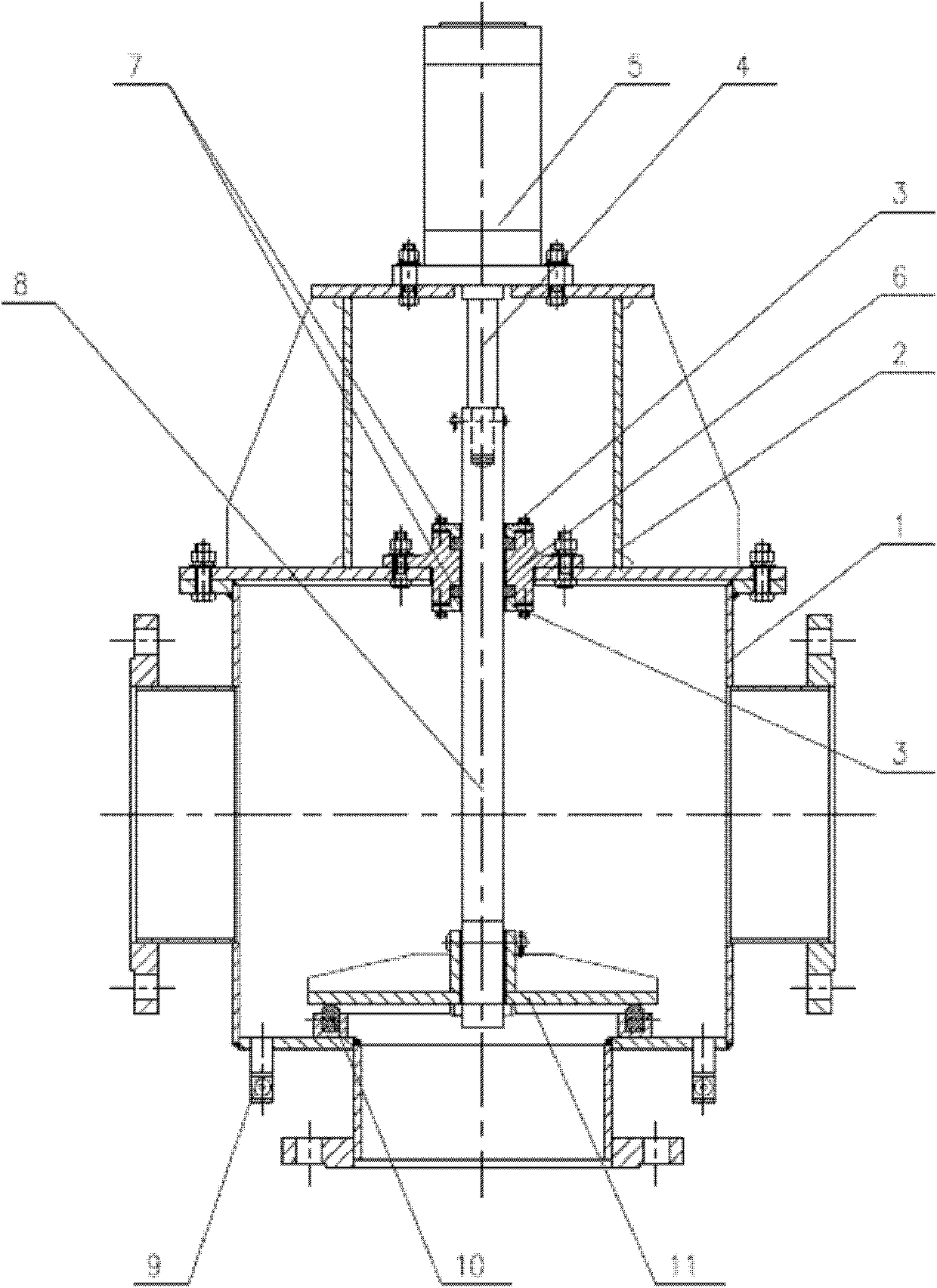

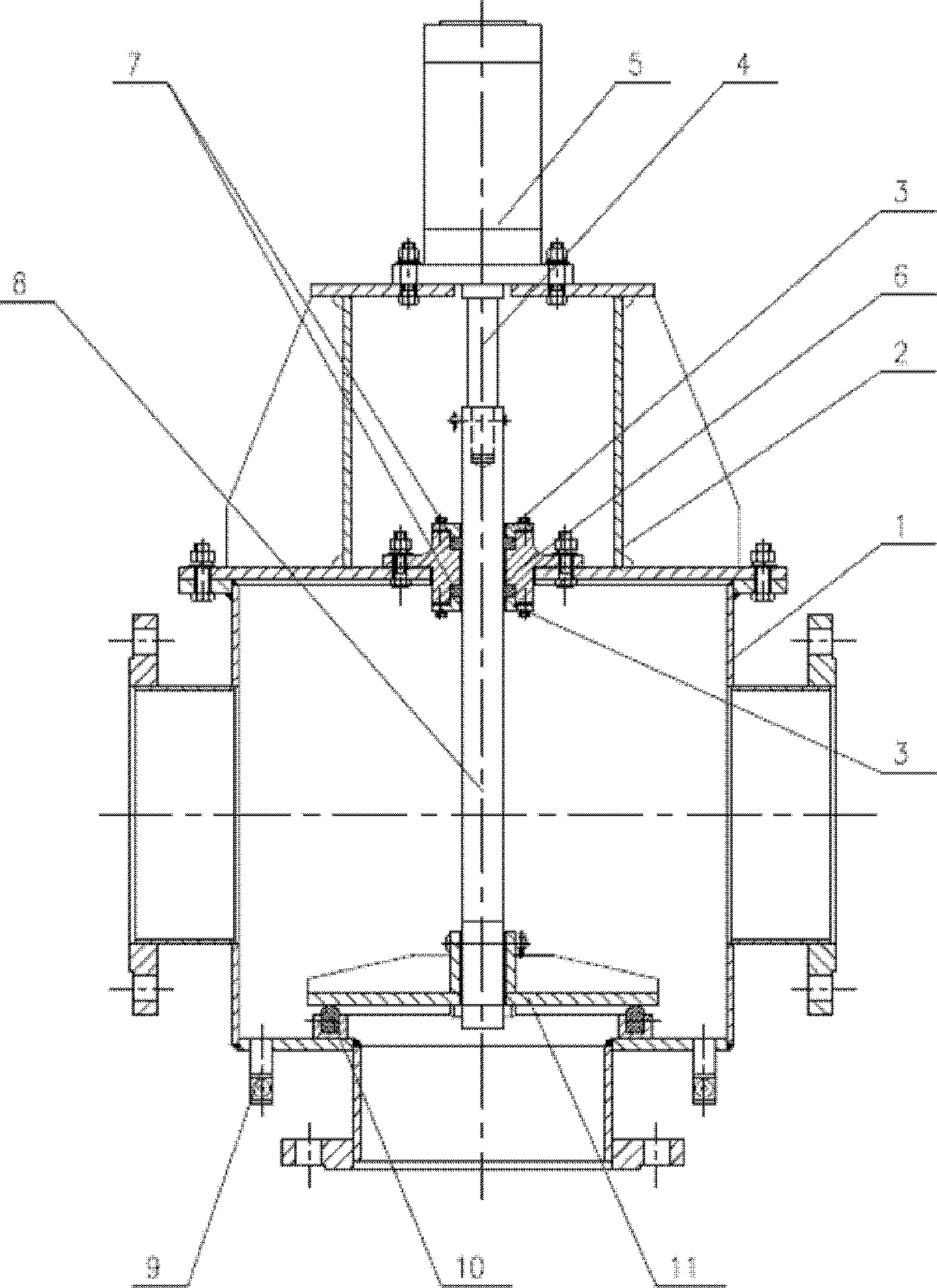

[0025] A three-way valve (such as figure 1 shown), including the valve body 1 and the valve switch control device. The valve switch control device includes a silicon rubber sealing ring 10 inside the valve port, a valve plate 11, a valve stem 8 made of stainless steel SUS304, a cylinder seat 2, a cylinder 5 with two-way buffer, a piston rod 4, and a sealing connection part; the cylinder The seat 2 is fixed on the valve body 1 on the opposite side of the valve port, the cylinder 5 above the cylinder seat 2 is connected to one end of the valve stem 8 through the piston rod 4 in the cylinder seat 2, and the other end of the valve stem 8 is located in the valve body 1 and One side of the valve plate 11 is connected, and when the valve is closed, the valve plate 11 presses on the silicone rubber sealing ring 10 inside the valve port to realize the sealing of the valve port; the sealing connection part is located at the part where the valve stem 8 passes through the valve body 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com