Downflow valve of water tank in toilet sealed up by rotary startstop ceramic ring in mode

A technology of rotary opening and closing, ceramic ring, applied in flushing equipment with water tanks, water supply devices, buildings, etc., can solve the problems of easy water leakage, short life, high force and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The working principle and working conditions of the present invention will be described in detail below with reference to the drawings.

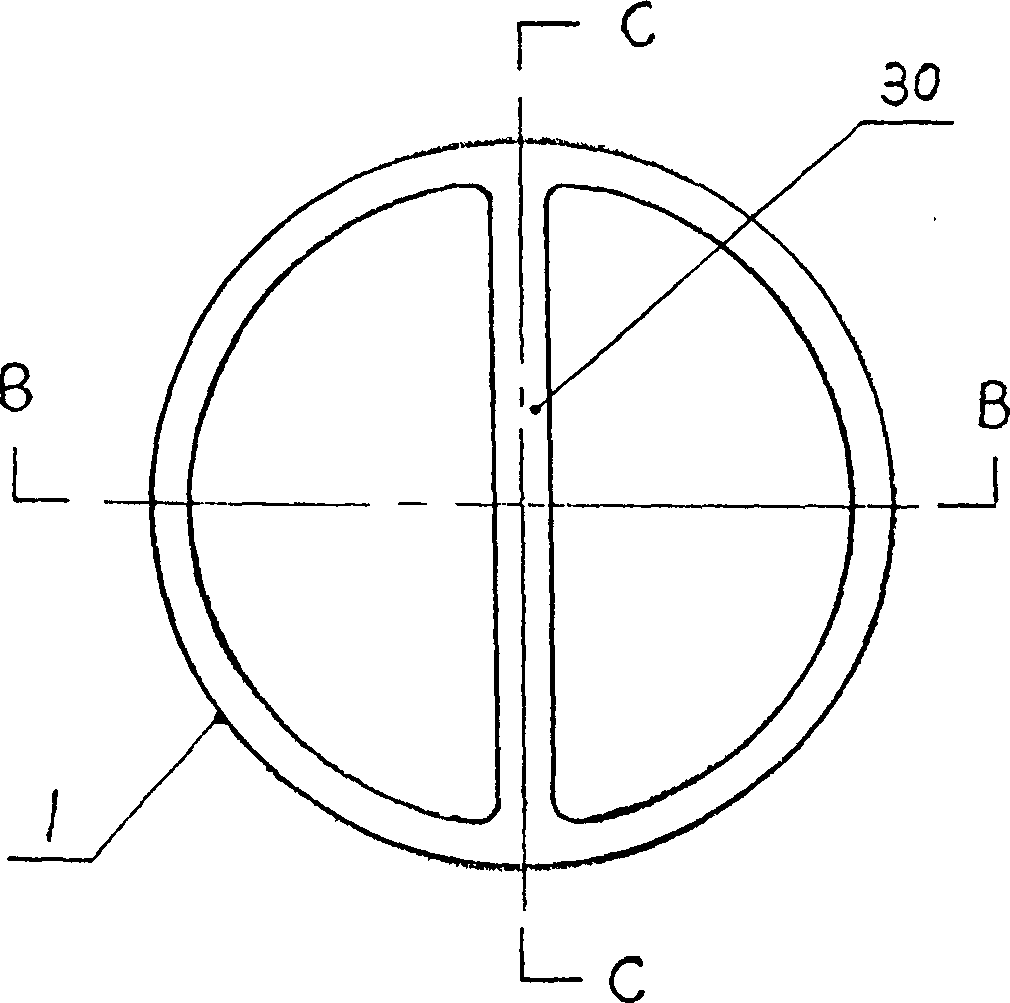

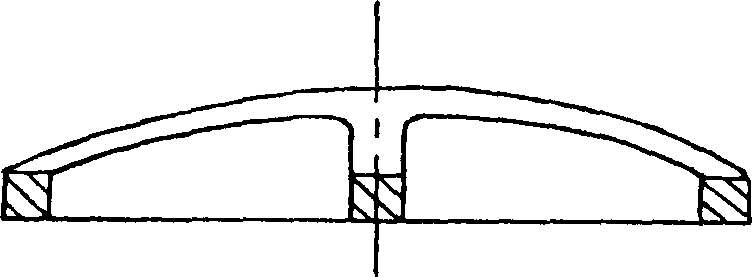

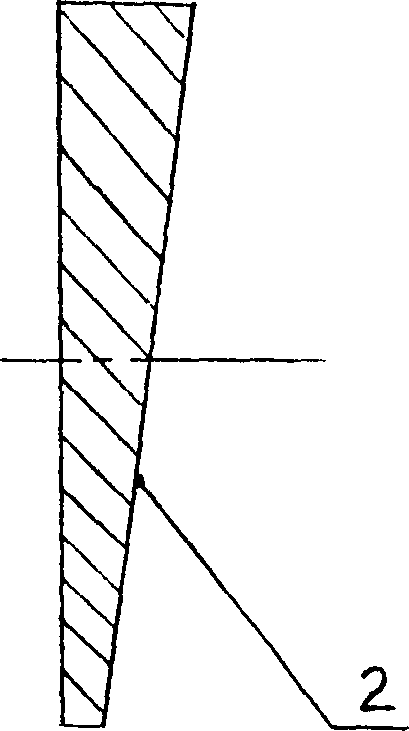

[0014] The ceramic ring 1 has a rib 30 on its diameter. The top of the ceramic ring 1 is cut along the rib 30 into a bevel, and the bevel is ground and polished as the sealing surface 2. Take two ceramic rings 1, one of which is called static ring 3. Its bottom 4 is installed on the plastic base 24 above the round drain 5 of the drain valve. The other is called the moving ring 6, and its bottom 4 is mounted on the open end 8 of the plastic dome 7 with a certain depth 33. The installation method of this embodiment is: the bottom 4 of the stationary ring 3 and the base 24 and the bottom 4 of the moving ring 6 and the open end 8 of the dome 7 are glued together to ensure that the joint does not leak water. An arm 9 extends from the dome 7 and is sleeved on the inclined shaft 10 of the base 24. The inclined shaft 10 is perpendicular to the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com