Normally closed type guide type gas anti-explosion valve

A pilot-operated, normally closed technology, which is applied in the direction of valve lift, valve details, valve device, etc., can solve the problems that the valve pressure cannot be opened, the valve is not easy to open, etc., and achieves convenient operation and use, simple structure and good sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

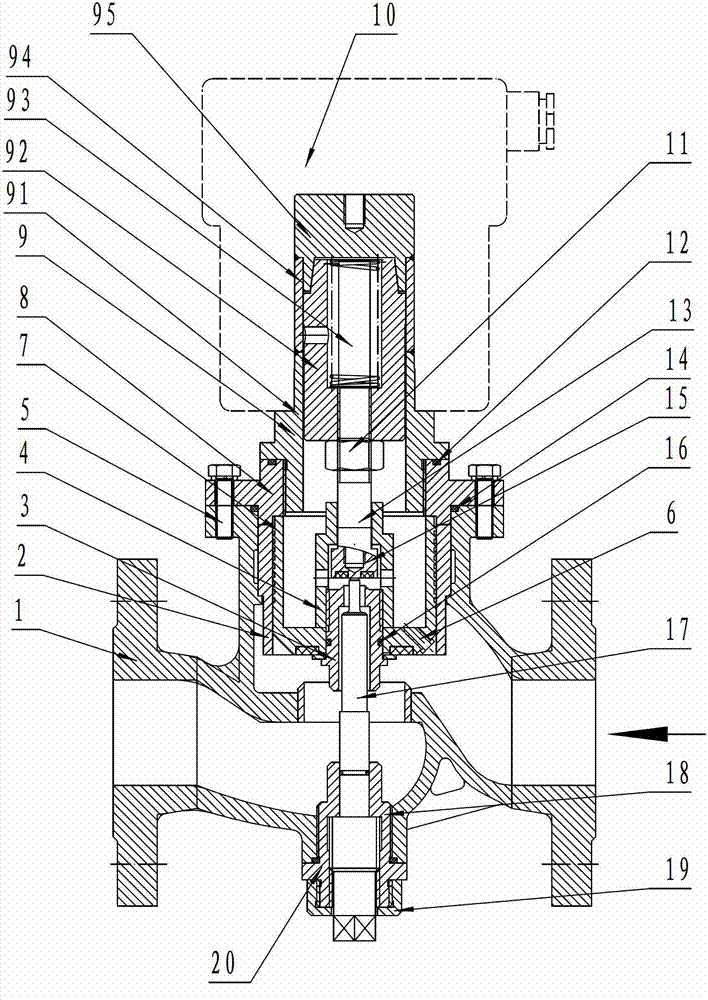

[0017] Embodiment 1, a normally closed pilot-operated gas explosion-proof valve, including a valve body 1, an upper bonnet 8, a valve cup, and an electromagnetic controller, is characterized in that: the valve body and the upper bonnet 8 are connected by fixing bolts 5, and the upper An electromagnetic controller composed of a non-magnetic tube assembly 9 and a solenoid head 10 is threaded on the top of the valve cover. A guide sleeve 2 is installed in the upper opening of the valve body, a valve cup assembly 7 is installed in the guide sleeve, and a valve cup assembly 7 is installed in the center of the valve cup assembly. The upper connecting nut 4 and the lower connecting nut 3 together, the pilot valve assembly 15 is installed in the inner hole of the connecting nut, the moving iron core 92 is installed in the inner hole of the non-magnetic tube, the top of the non-magnetic tube is welded with the static iron core 95, and the center of the valve body A vertical inner hole f...

Embodiment 2

[0018] Embodiment 2, a normally closed pilot-operated gas explosion-proof valve, including a valve body 1, an upper bonnet 8, a valve cup, and an electromagnetic controller, is characterized in that: the valve body and the upper bonnet 8 are connected by fixing bolts 5, and the upper An electromagnetic controller composed of a non-magnetic tube assembly 9 and a solenoid head 10 is threaded on the top of the valve cover. A guide sleeve is installed in the upper opening of the valve body, and a valve cup assembly 7 is installed in the guide sleeve. The upper connecting nut 4 and the lower connecting nut 3, the pilot valve assembly 15 is housed in the inner hole of the connecting nut, the moving iron core 92 is housed in the inner hole of the non-magnetic tube, the top of the non-magnetic tube is welded with the static iron core 95, and the center of the valve body is set There is a vertical bore for mounting the manual assembly 20 . The side corner of the valve cup bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com