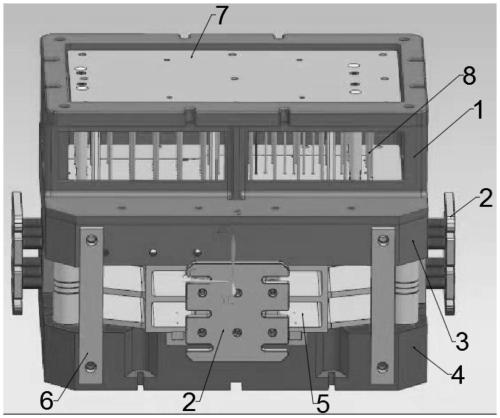

Radiator case for maglev train and casting method thereof

A technology for maglev trains and radiators, which is applied in the directions of chassis/case/cabinet/drawer parts, locomotives, electric vehicles, etc., can solve the problems of unsatisfactory and difficult casting and molding of radiator cases for maglev trains, and achieves the pass rate The effect of improving, good density and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

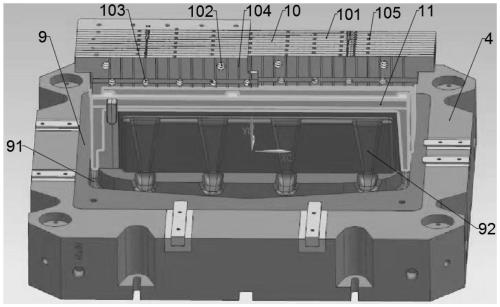

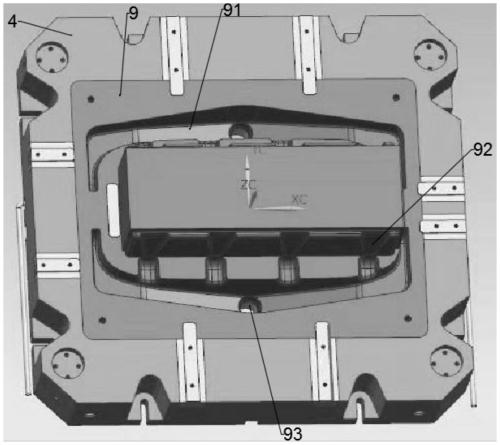

Embodiment 1

[0025] Embodiment 1: A radiator case 11 for a maglev train. After the mold is installed, the oxide layer on the inner wall surface of the mold cavity is removed by sand blasting. The mold is heated to 185° C., and the mold is sprayed with thermal insulation coating. The coating adopts metal type G-395 After spraying, heat it up to 225°C again, and spray the paint again, so that the paint is evenly distributed on the surface of the mold. The thickness of the paint is 0.18mm, and the mold is heated again to 380°C. Use temperature measuring equipment to check to ensure that the temperature is uniform and the temperature is suitable. The heating tube is energized to heat the blade 101 of the upper mold, and the heating temperature is 380°C; close the mold and prepare to start casting. It is best to move the mold a few times, and set the travel switch and product parameters of the low-pressure casting machine. This product is molded and casted in three stages. , the time of the firs...

Embodiment 2

[0026]Embodiment 2: A radiator case 11 for a maglev train. After the mold is installed, the oxide layer on the inner wall surface of the mold cavity is removed by sand blasting. The mold is heated to 170° C., and the mold is sprayed with thermal insulation coating. The coating adopts metal type G-395 After spraying, heat it up to 230°C again, and spray the paint again, so that the paint is evenly distributed on the surface of the mold. The thickness of the paint is 0.15mm, and the mold is heated again to 350°C. Use temperature measuring equipment to ensure that the temperature is uniform and the temperature is suitable. The heating tube is energized to heat the blade 101 of the upper mold, and the heating temperature is 350°C; close the mold and prepare to start casting. It is best to move the mold a few times, and set the travel switch and product parameters of the low-pressure casting machine. This product is molded and casted in three stages. , the time of the first stage is...

Embodiment 3

[0027] Embodiment 3: A radiator case 11 for a maglev train. After the mold is installed, the oxide layer on the inner wall surface of the mold cavity is removed by sand blasting. The mold is heated to 200° C., and the mold is sprayed with thermal insulation coating. The coating adopts metal type G-395 After spraying, heat it up to 200°C again, and spray the paint again, so that the paint is evenly distributed on the surface of the mold. The thickness of the paint is 0.2mm, and the mold is heated again to 370°C. Use temperature measuring equipment to check to ensure that the temperature is uniform and the temperature is suitable. The heating tube is energized to heat the blade 101 of the upper mold, and the heating temperature is 370°C; close the mold and prepare to start casting. It is best to move the mold a few times in idling, and set the travel switch and product parameters of the low-pressure casting machine. This product is molded and casted in three stages. , the time of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com