Bidirectional sealing gate valve and using method thereof

A two-way sealing and gate valve technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of large opening and closing torque of the gate, poor bidirectional sealing performance, and unstable movement of the gate, so as to achieve the goal of gate valve opening and closing Fast, small operating torque, smooth up and down movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

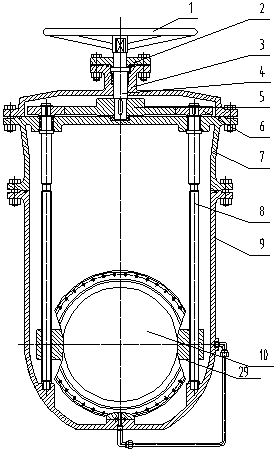

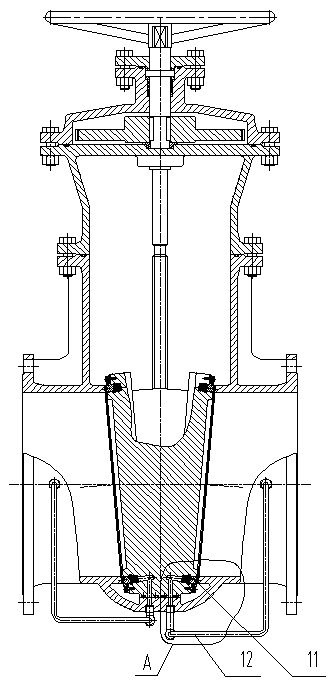

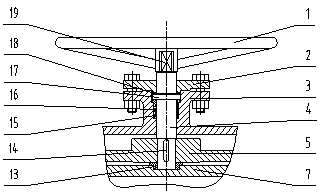

[0027] Embodiment 1: a two-way sealing gate valve, which includes a valve cover 7, a valve shaft 4, a valve body 9, a gate plate 10, a valve seat 11, a valve body sealing surface 25 and a valve seat sealing surface 24, and the valve seat is pressed by the valve seat. The cover 26 is floatingly connected to the gate plate, such as Figure 6 As shown, the side of the valve seat and the side of the seat gland are matched with the concave and convex parts, so that the valve seat can float slightly relative to the gate. For example, the side of the valve seat has a bump, and the side of the valve seat gland has a concave block. An elastic connecting piece is installed between the inner end surface of the valve seat and the gate plate, the elastic connecting piece is a spring, a gear case cover 3 is fixedly connected to the valve cover, and a valve shaft pressure is fixedly connected to the gear case cover. Cover 2, the gear box cover and the valve shaft gland are provided with a th...

Embodiment 2

[0028] Embodiment 2: The difference from Embodiment 1 is that the concave-convex cooperation between the side of the valve seat and the side of the valve seat gland is different. Bolts / screws and other methods are fixed on the gate plate. The elastic connector installed between the inner end surface of the valve seat and the gate plate is a bellows. The cross-sectional shape is triangular.

Embodiment 3

[0029] Embodiment 3: The difference from Embodiment 1 is that the elastic connector installed between the inner end surface of the valve seat and the gate is a diaphragm, and the middle thread of the screw rod is fitted with a connecting plate 29 fixedly connected with the gate, and the thread The cross-sectional shape is rectangular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com