Patents

Literature

137results about How to "Reduce operating torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

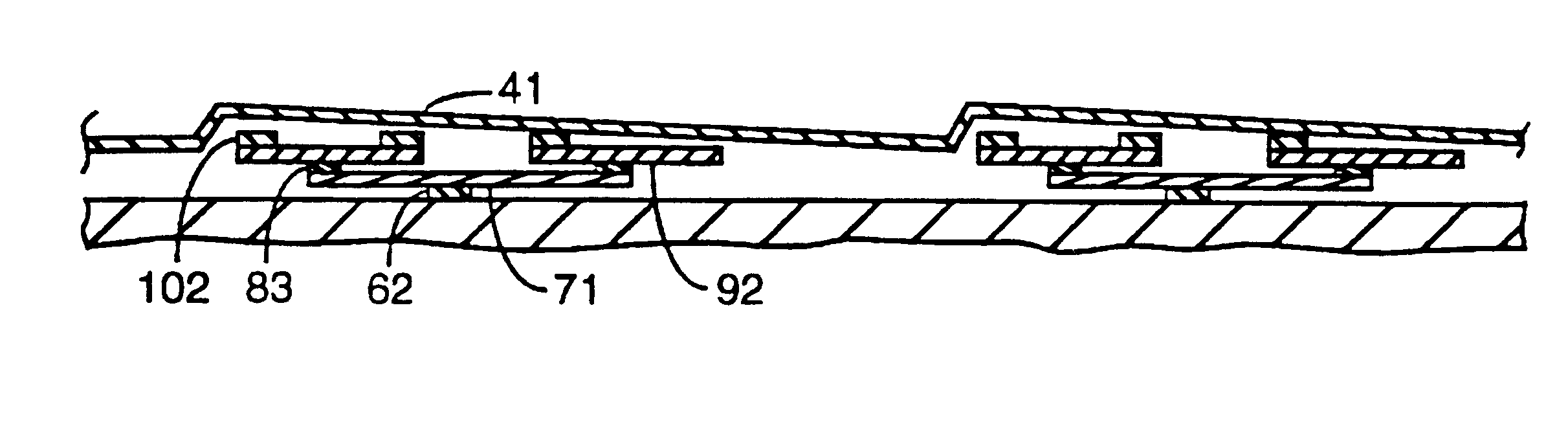

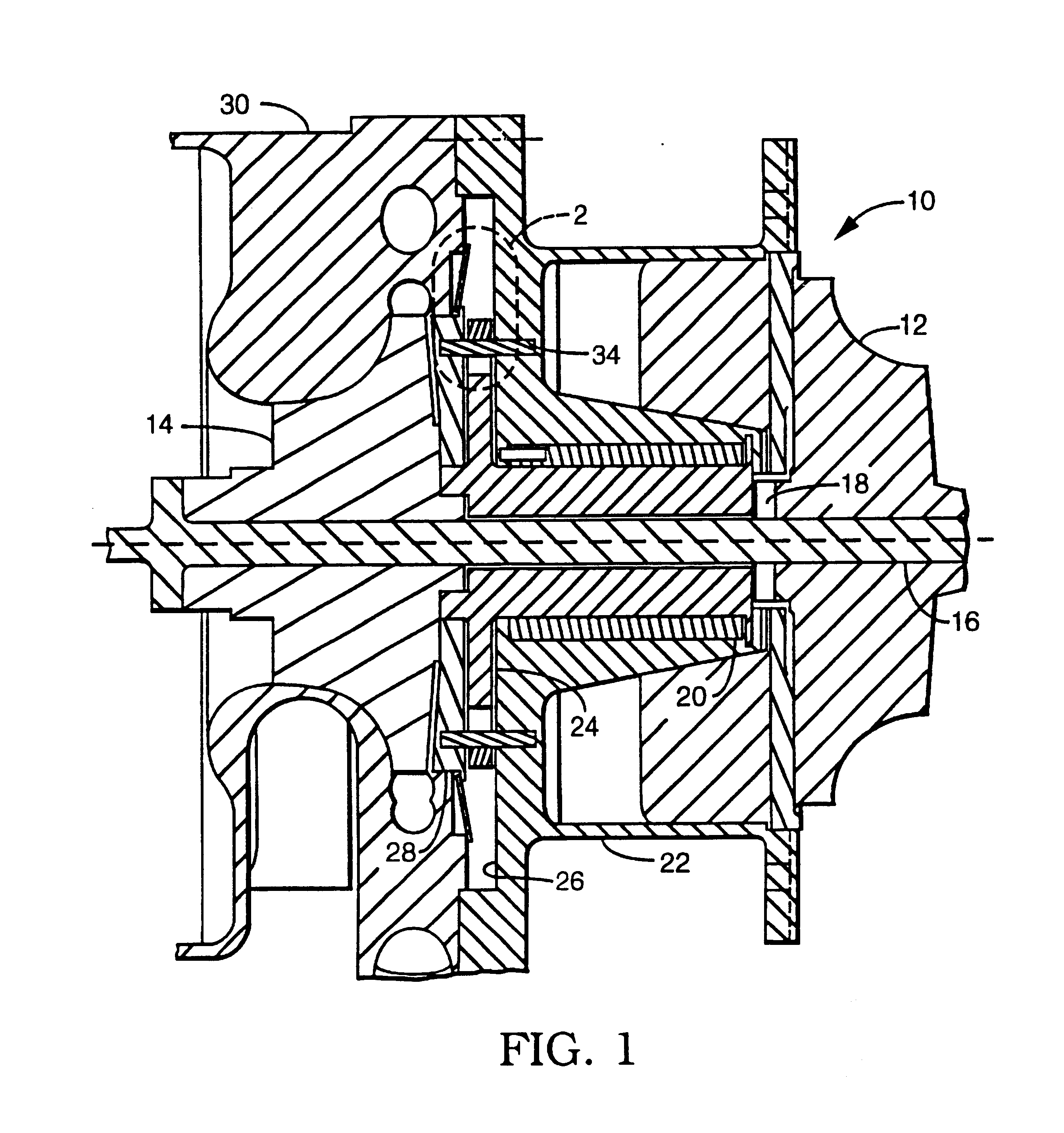

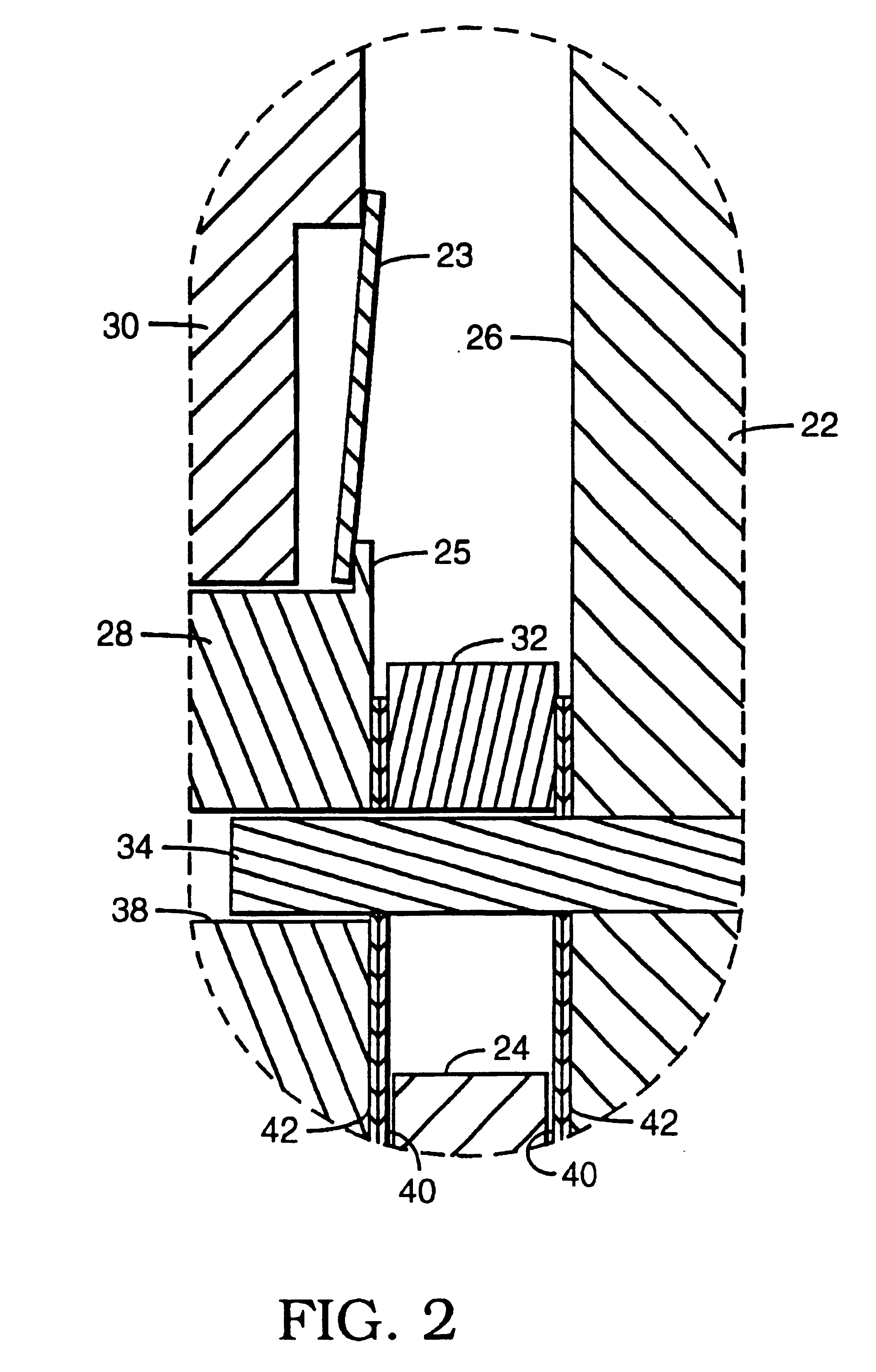

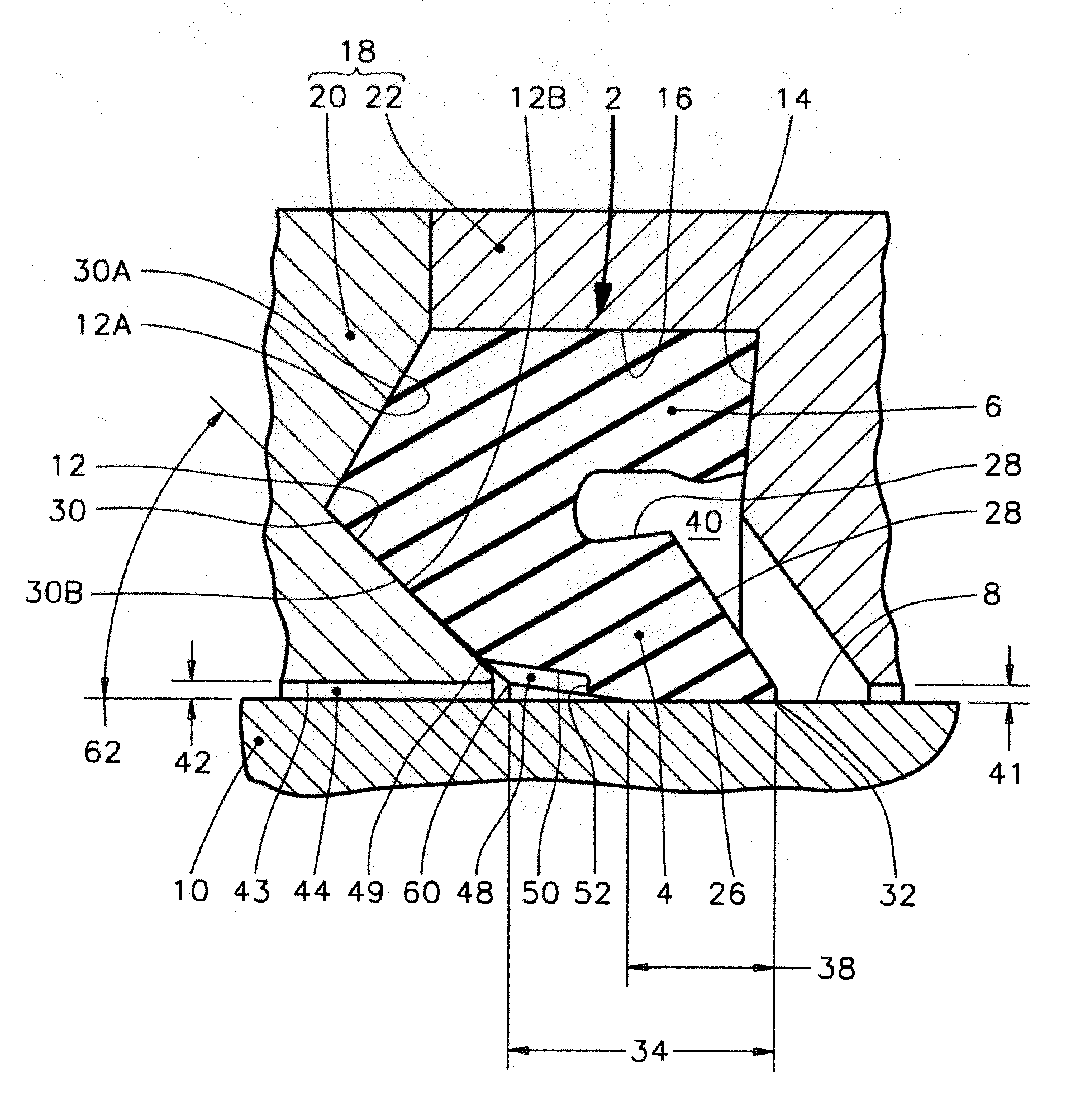

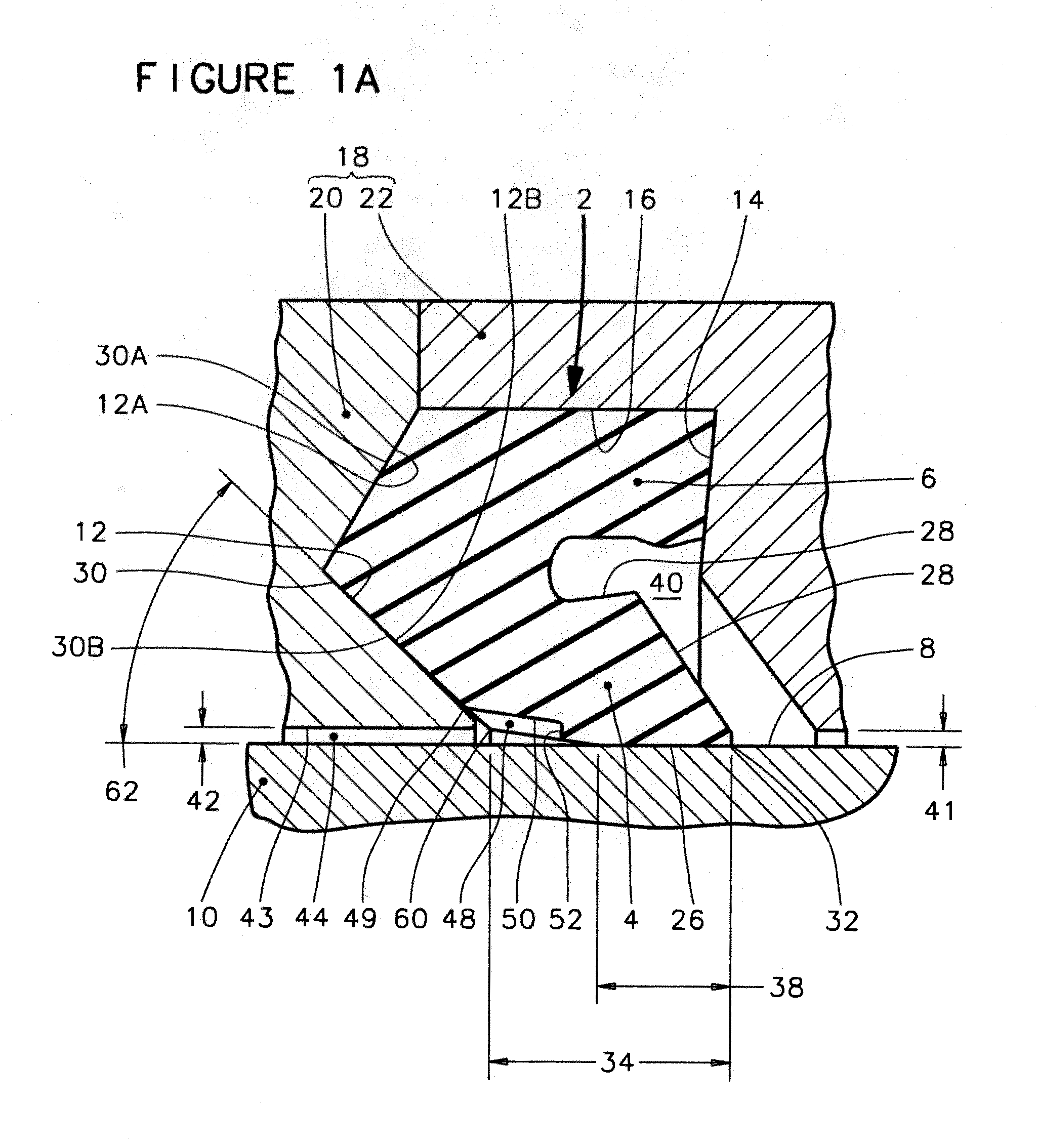

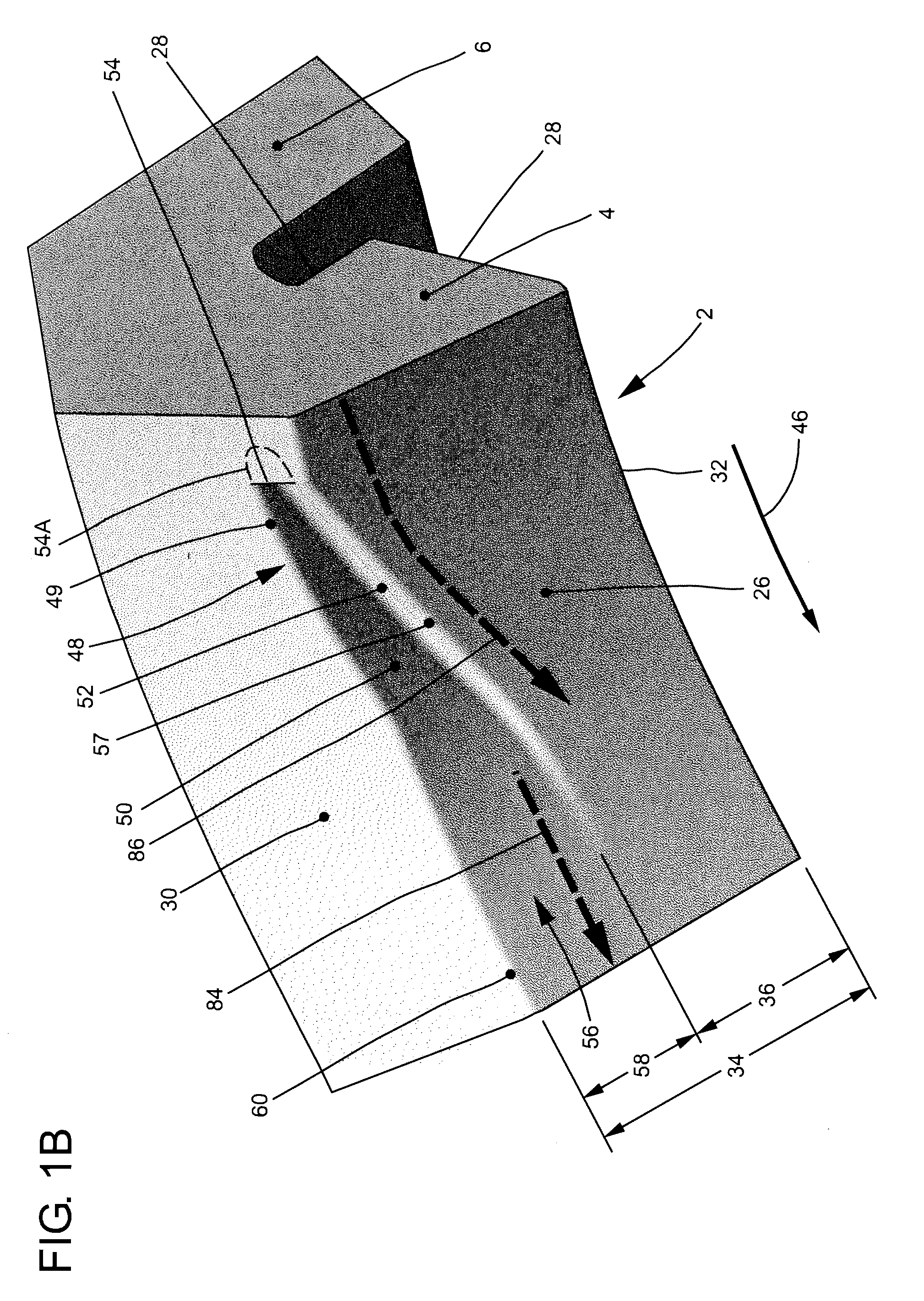

Compliant foil fluid film thrust bearing with a tilting pad underspring

InactiveUSRE38373E1Suppress mutationZero starting torqueShaftsMachines/enginesThrust bearingFluid power

A compliant foil fluid film thrust bearing including a thrust disk (24) rotor, fluid foils (40), spring foils (42), a thrust plate (28), and a housing (22) thrust surface. The non-rotating but compliant fluid foils (42), mounted on the thrust plate (28) and / or housing (22) thrust surface and positioned adjacent to the thrust disk (24), have open faced channels that induce regenerative vortex flow patterns in the process fluid. The multiple spring foils together provide a tilting pad support for the fluid folds but allow them to follow the axial and overturning motion of the thrust disk. The interaction of the tilting pad underspring supports and the circumferential fluid pressure gradients in the process fluid between the fluid foils and the thrust disk rotor assure that the fluid foils will assume hydrodynamically efficient convex shapes on the surfaces adjacent to the rotor regardless of the load applied to the thrust bearing.

Owner:CAPSTONE TURBINE

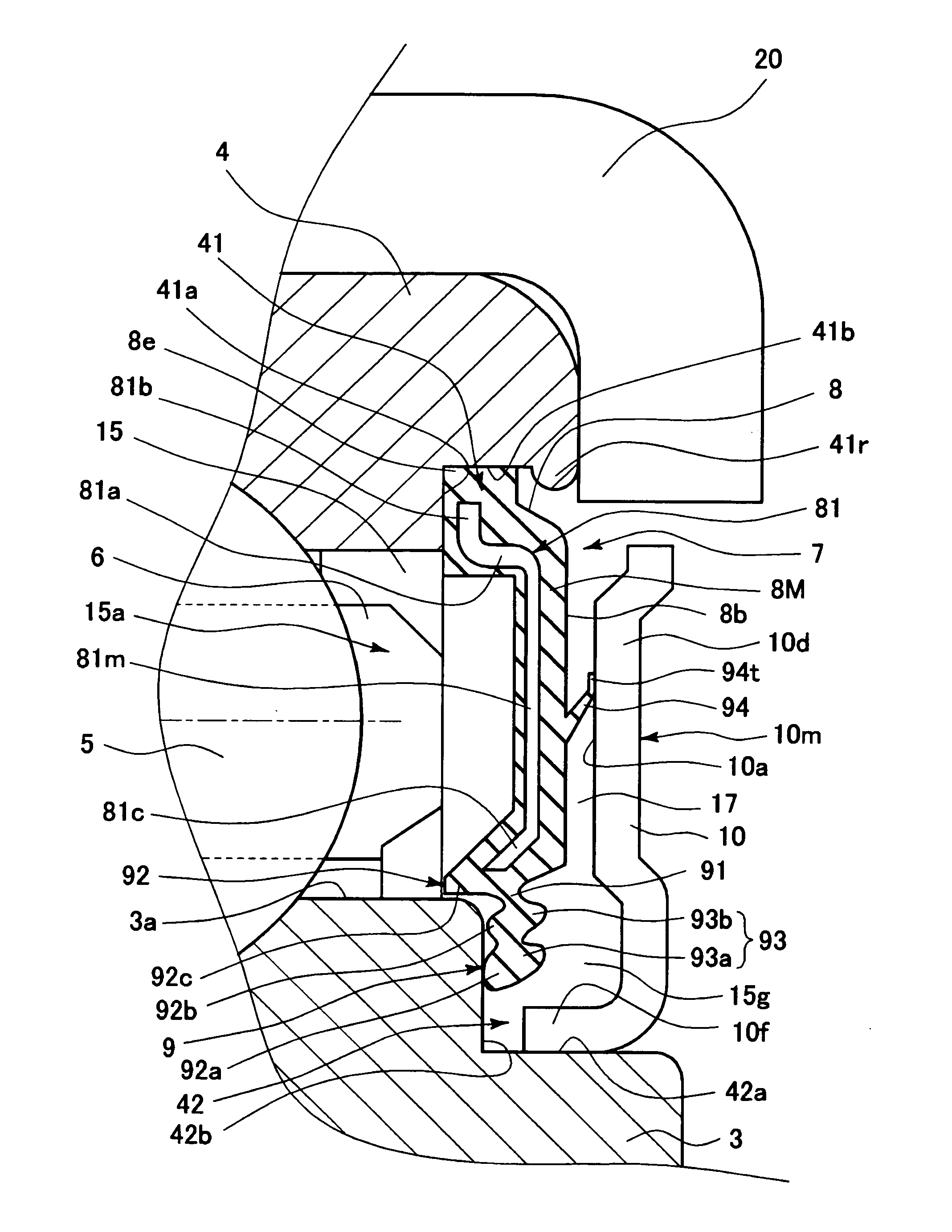

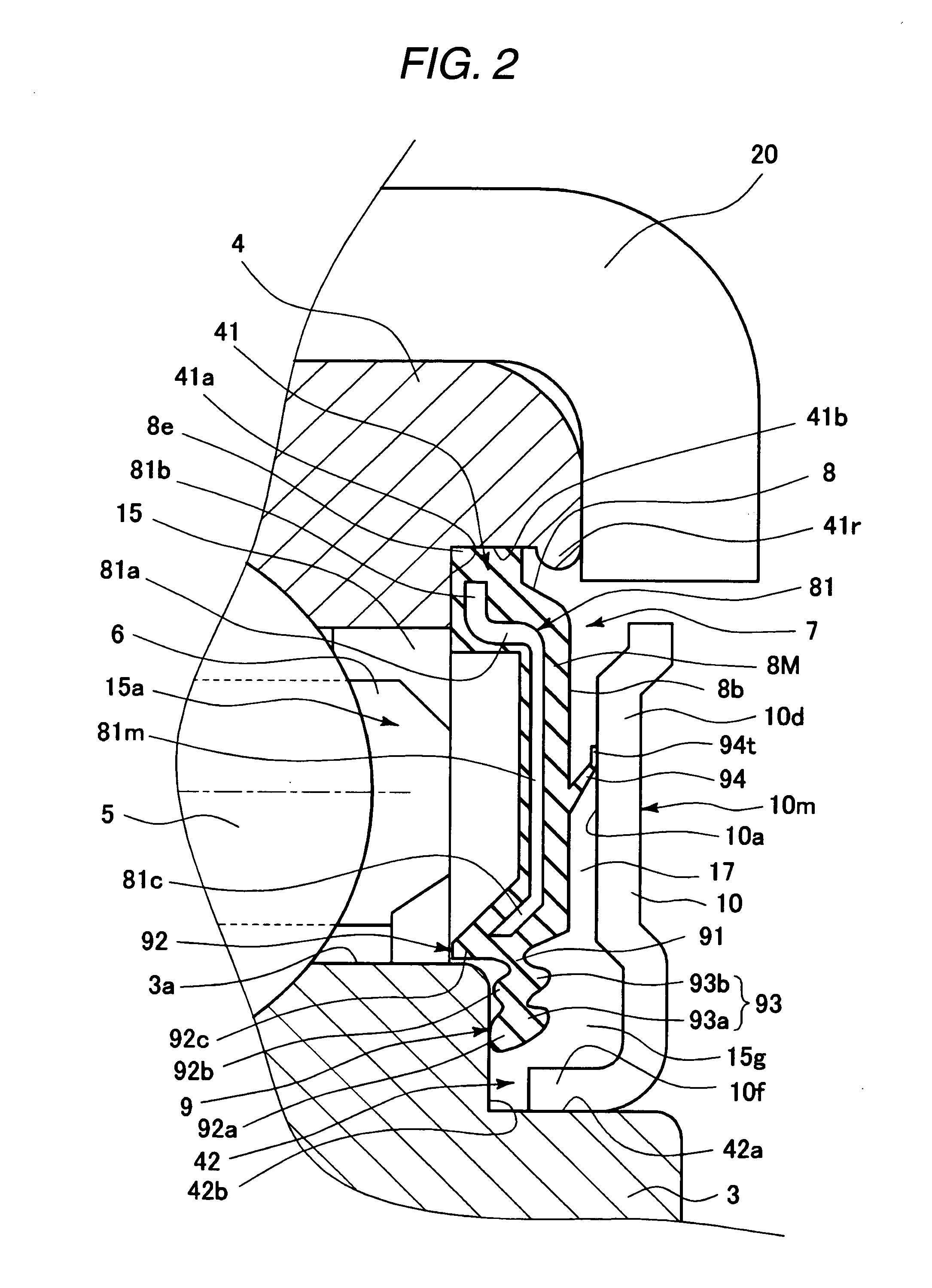

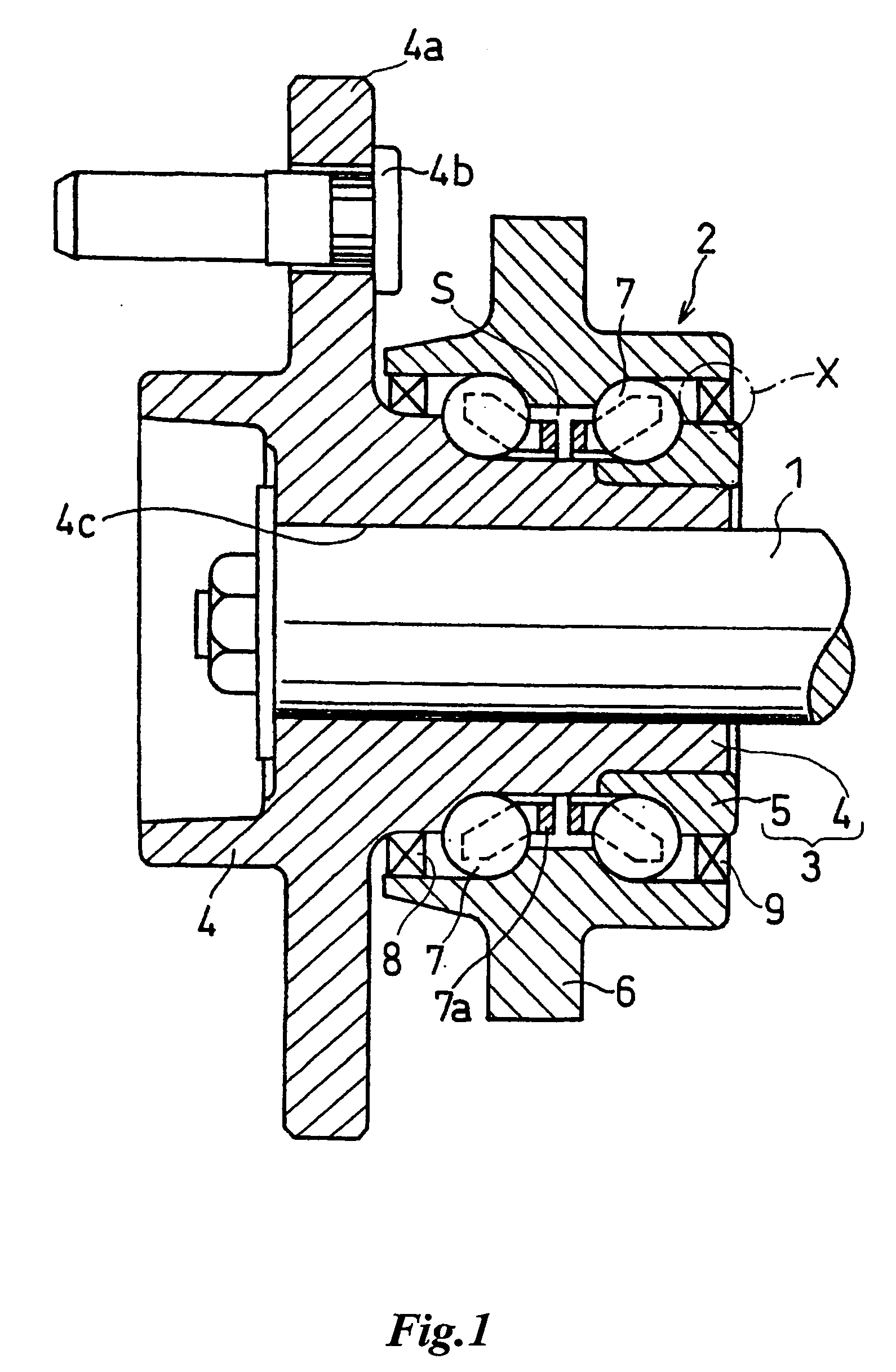

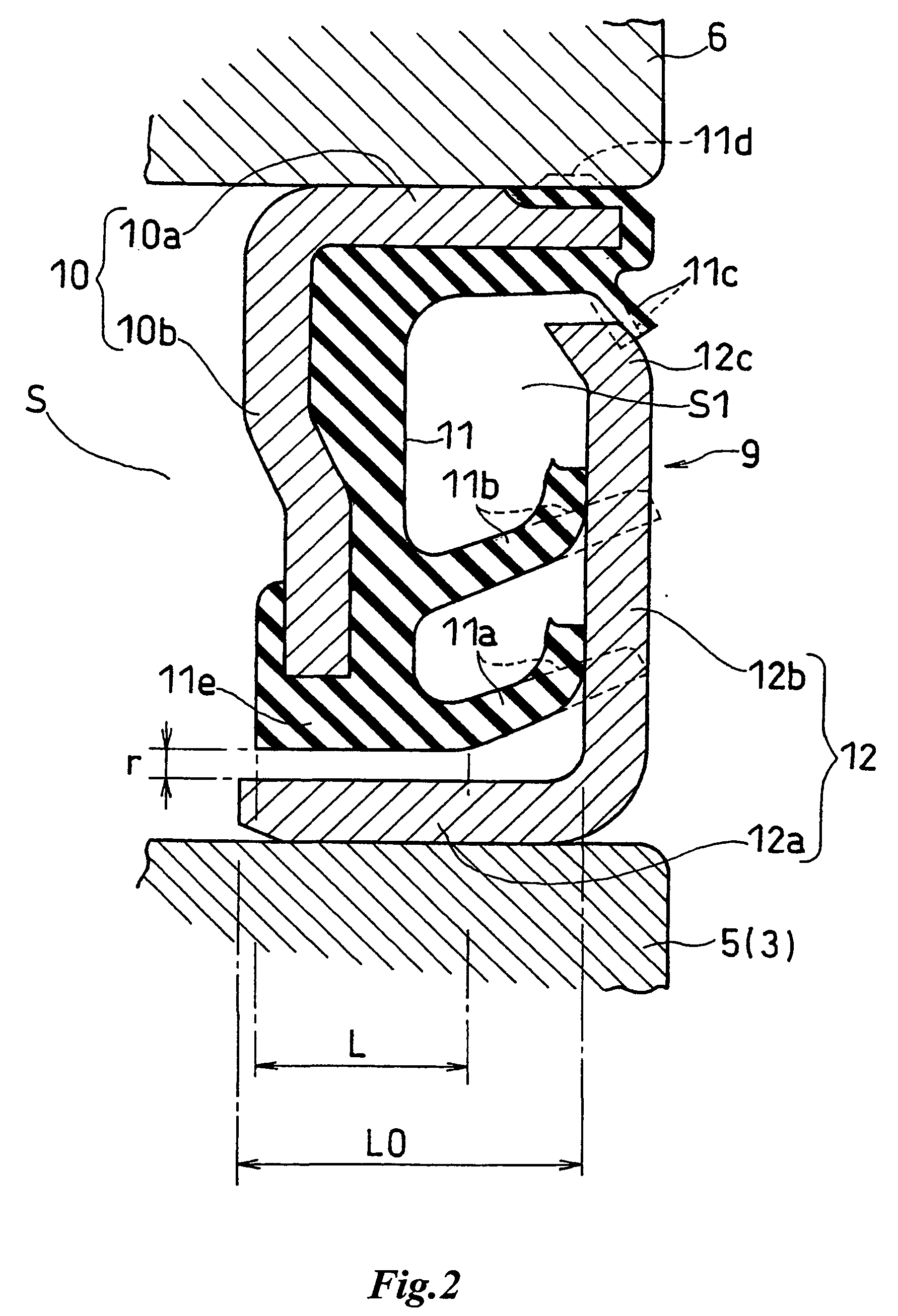

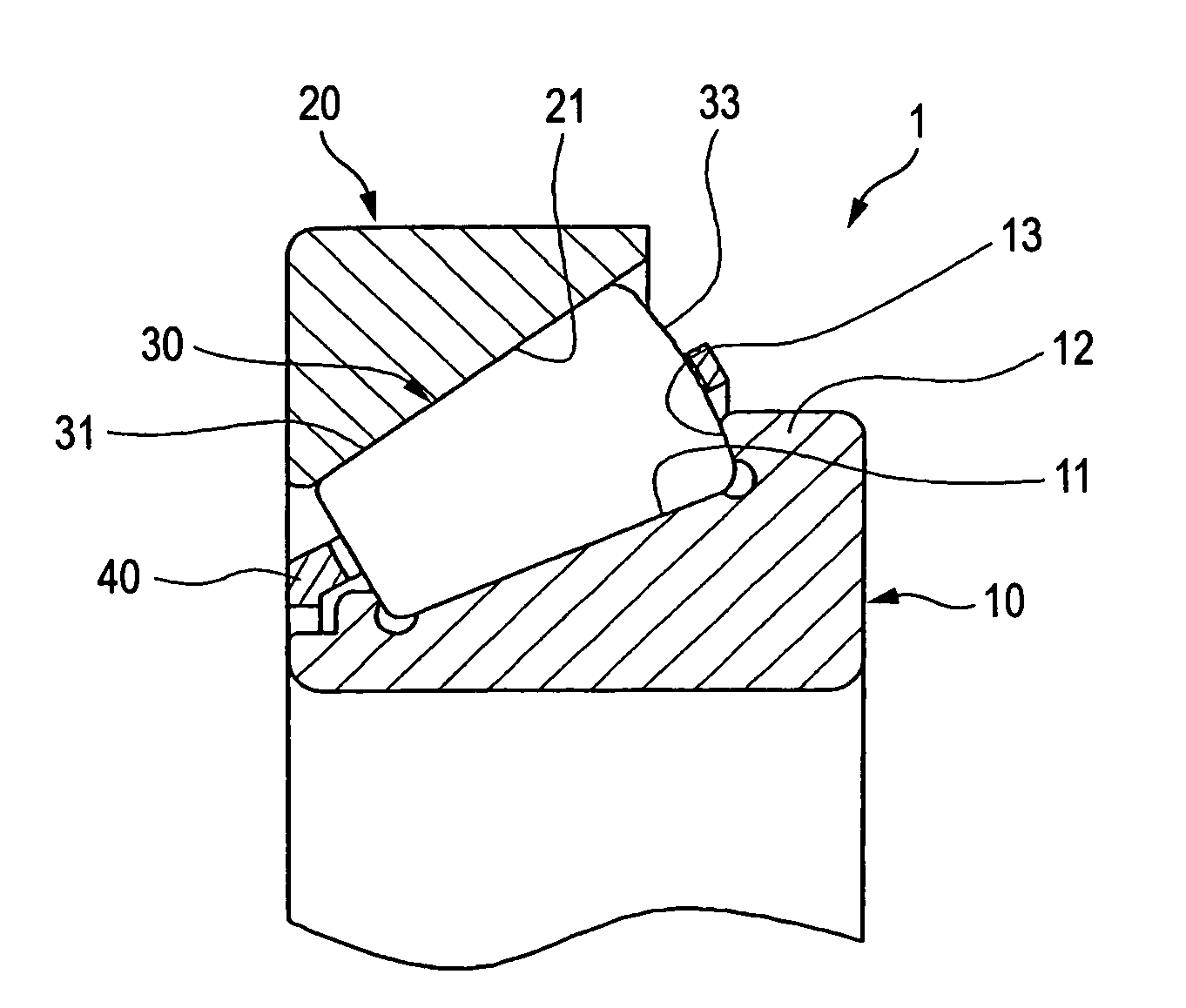

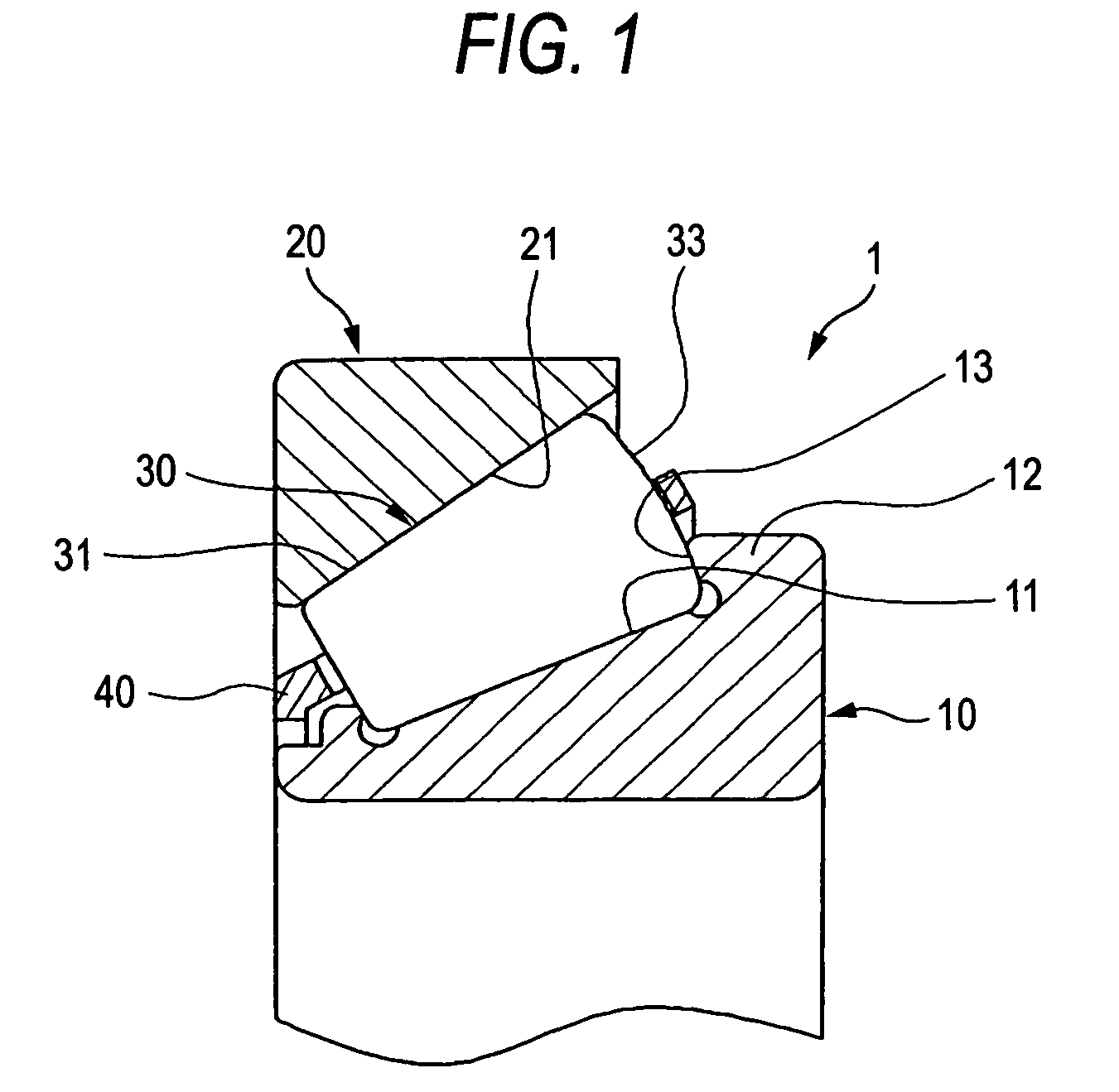

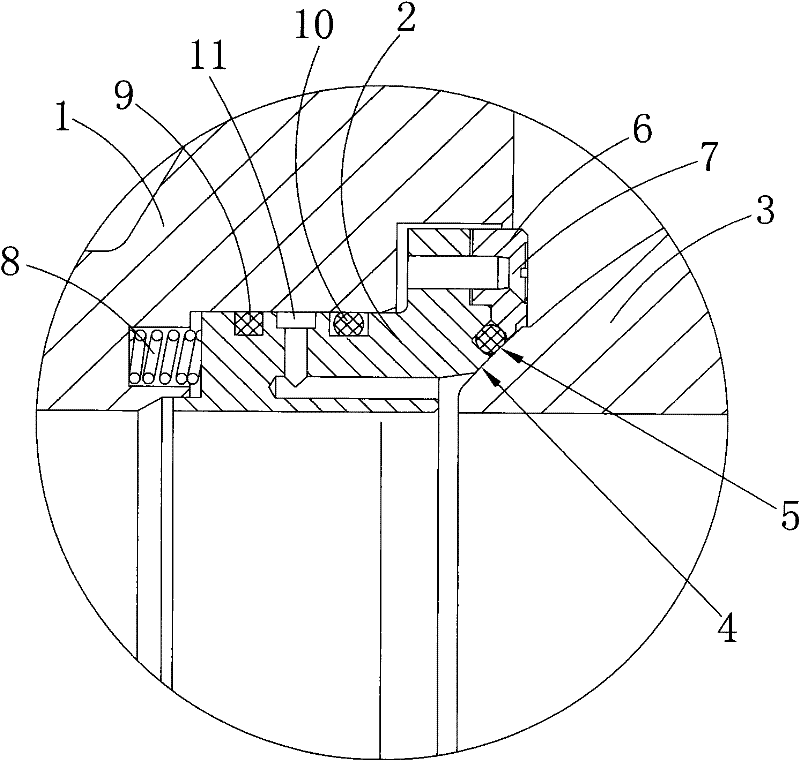

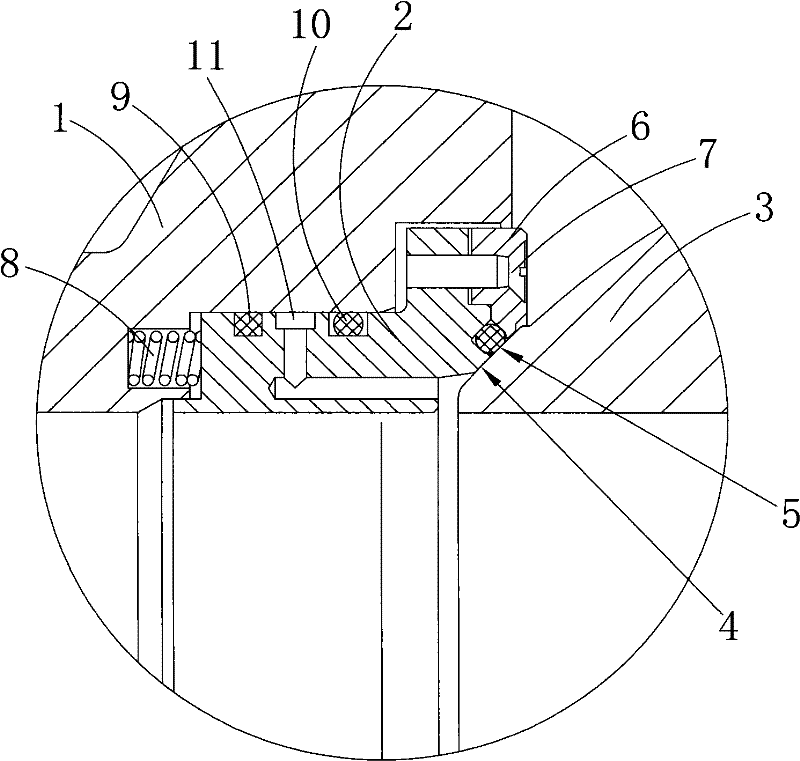

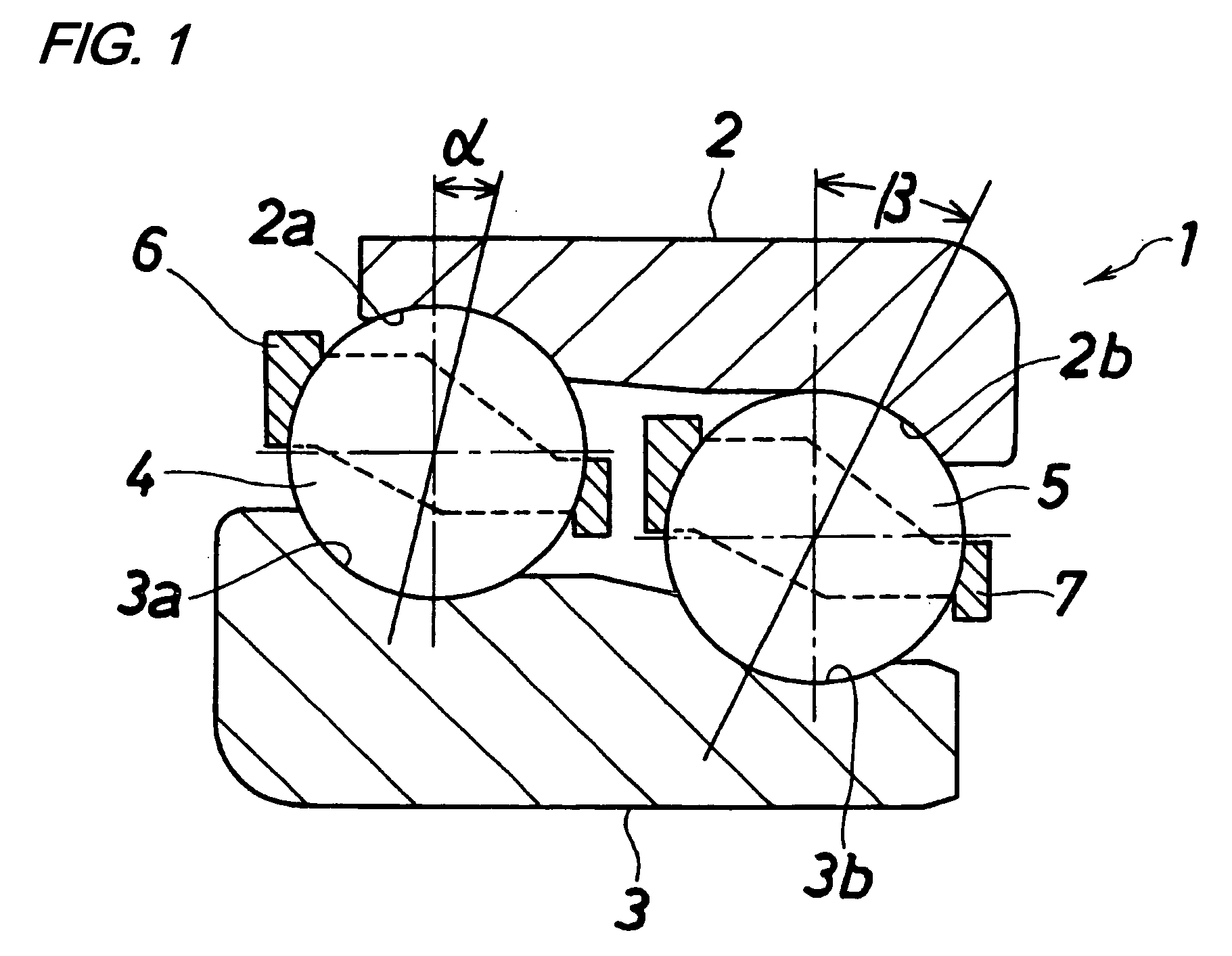

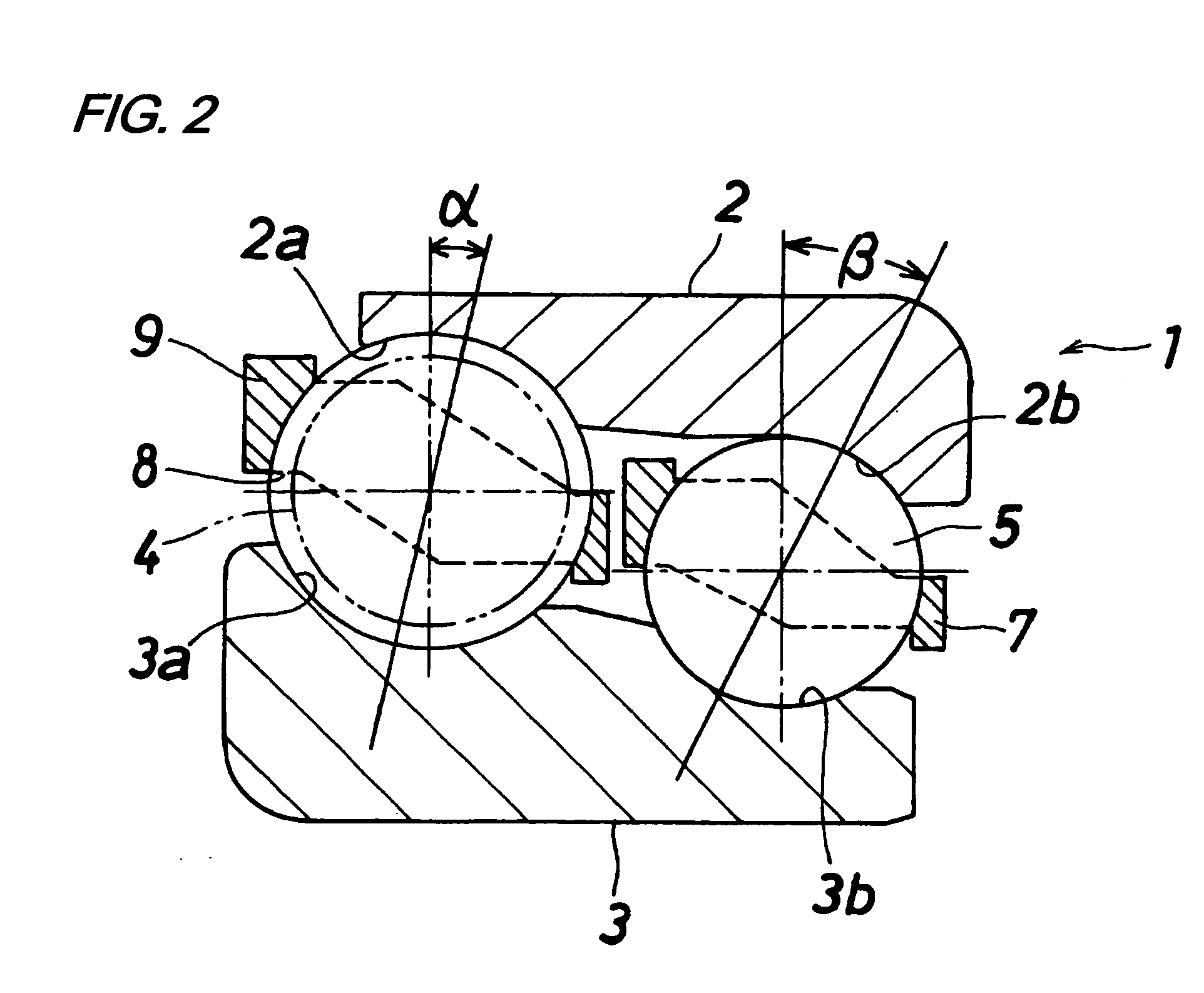

Sealing device for bearing

ActiveUS20090226124A1Improve sealingReduce operating torqueEngine sealsBall bearingsCentrifugal forceSliding contact

In a sealing device for a bearing, a sub-seal lip is configured such that a slide contact surface is formed like an annular band. As the rotation speed of the bearing increases, the width of the slide contact surface is reduced by a centrifugal force. Thus, sliding friction can effectively be minimized. The torque of the bearing can be prevented from increasing at high-speed rotation. Even when the centrifugal force increases somewhat, only reduction in the width of the slide contact surface is caused. Thus, a slide-contacted state can be maintained. Consequently, the problem of floating-up of the sub-seal lip from a slinger is difficult to occur.

Owner:JTEKT CORP

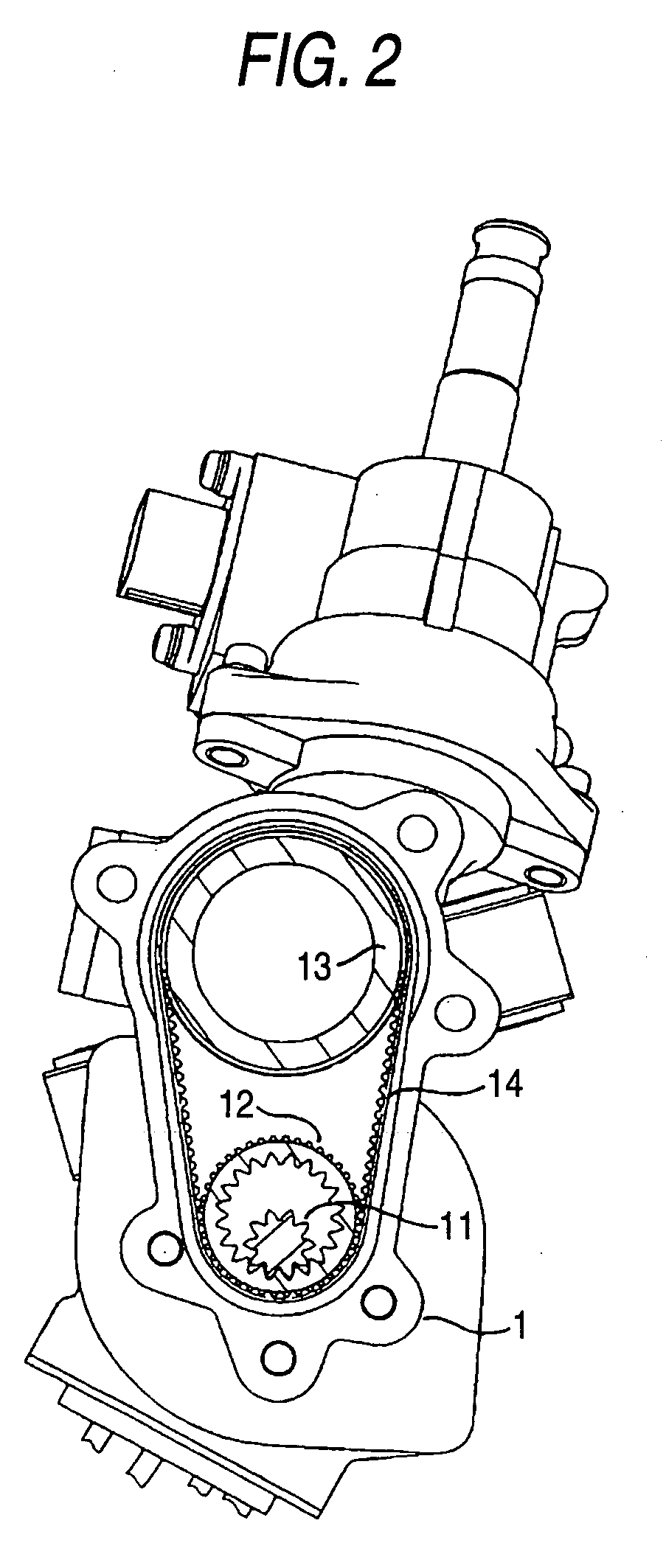

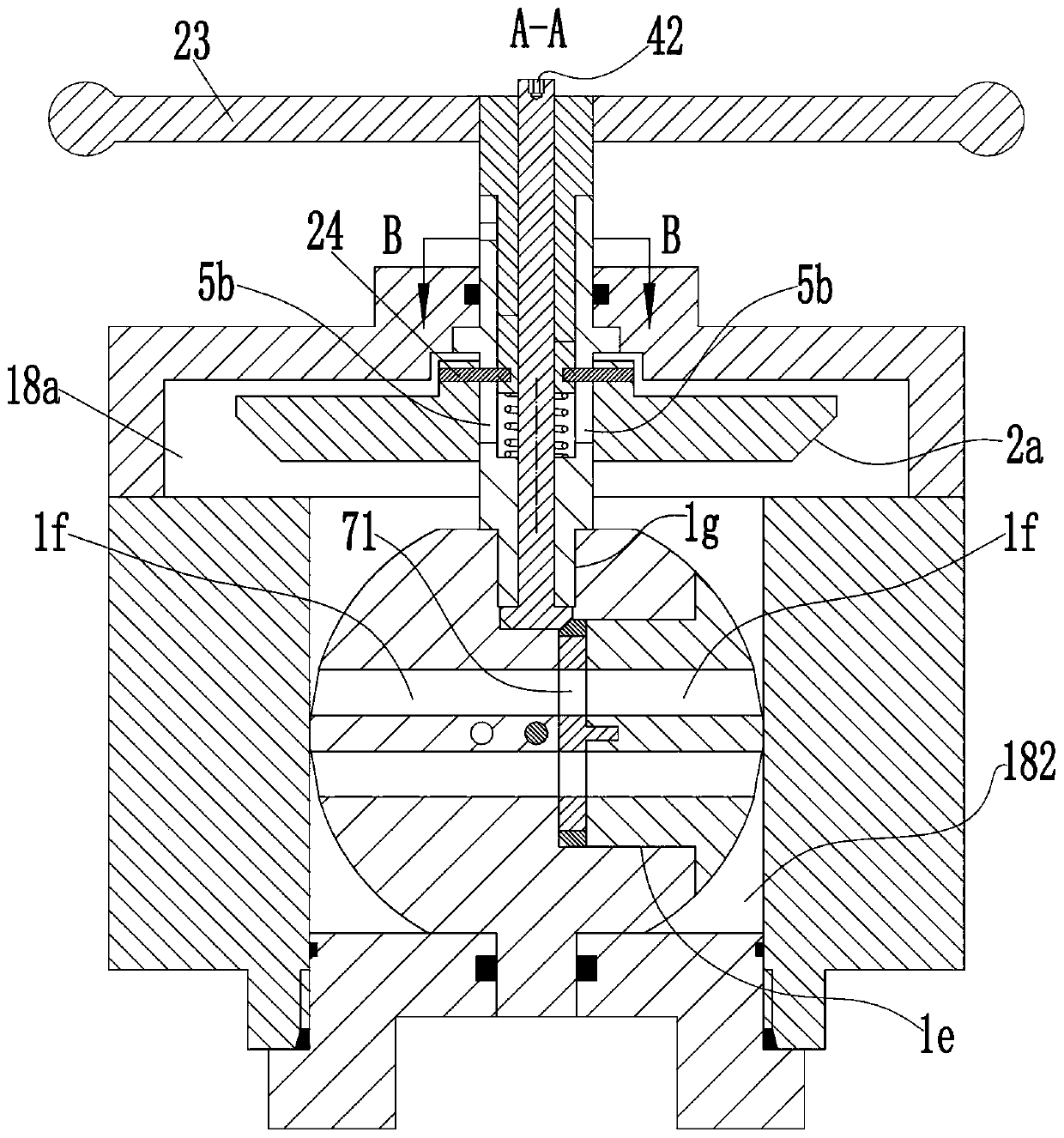

Grinding process of sealing surface of ball valve

The invention relates to a grinding process of a sealing surface of a ball valve. The grinding process comprises the steps of rough grinding, fine grinding, ultrafine grinding, and grinding and cleaning of a valve seat and a sphere, wherein a diamond paste and an engine oil mixture are adopted in the rough grinding, the particle size phi of the selected diamond paste ranges from 40mu m to 10mu m, so that the scratch removal and sphere rounding can be realized; in fine grinding, a diamond paste, kerosene and a microcrystal graphite mixture are adopted, the particle size phi of the selected diamond paste ranges from 7mu m to 5mu m, so that the primary mirror surface effect can be achieved; in the ultrafine grinding, a diamond paste and a microcrystal graphite and kerosene mixture are adopted, the particle size phi of the selected diamond paste is smaller than 5mu m, the rotating speed of the sphere is controlled to be below 5rpm to achieve the mirror surface effect, and finally the kerosene is coated on the sphere and grinding cleaning are performed to achieve a better mirror surface effect. The sphere ground and the sealing surface of the valve seat can achieve the mirror surface effect, the surface roughness can achieve Ra0.02-0.005, the operation torque is low, the service life is long, the valve seat can be adsorbed on the spherical surface of the sphere, and no leakage exists under the trial pressure of low-pressure nitrogen being 0.6Mpa.

Owner:WENZHOU ARTECH MACHINERY TECH CO LTD

Rotary seal with supported inlet

ActiveUS20110140365A1Reduces seal running torqueReduce wearEngine sealsSealing/packingCentrifugal pumpArtificial lift

A hydrodynamically lubricated sealing element for applications where the pressure of a contained fluid can be significantly greater than the pressure of the seal lubricant. The sealing element retains the pressure of the contained fluid and provides hydrodynamic lubricant pumping activity at the dynamic sealing interface to enhance service life. The invention is particularly suitable for oilfield drilling swivel washpipe assemblies, downhole drilling tools, and rotary mining equipment, and for applications such as artificial lift pump stuffing box assemblies and centrifugal pumps where a rotating shaft penetrates a pressurized reservoir that is filled with abrasive-laden liquids, mixtures, or slurries.

Owner:KALSI ENG

Electric power steering apparatus

InactiveUS20070151794A1Durable strength of toothReduce stepsGearingElectrical steeringElectric power steeringSteering wheel

In an electric power steering apparatus, in which an auxiliary steering torque is generated by an electric motor according a steering torque impressed upon a steering wheel transmitted to a rack shaft of a steering mechanism via a power transmission mechanism. The power transmission mechanism has a small diameter external gear, and an outer circumferential face thereof acts as a drive side pulley, a driven side pulley driven by the internal-external gear and a ball screw mechanism driven by the driven side pulley so as to move the rack shaft. A circular support body is concentrically provided at the external gear and an annular support body, which supports the circular support body, is concentrically provided at the internal-external gear so as to be inscribed with the circular support body.

Owner:NSK LTD

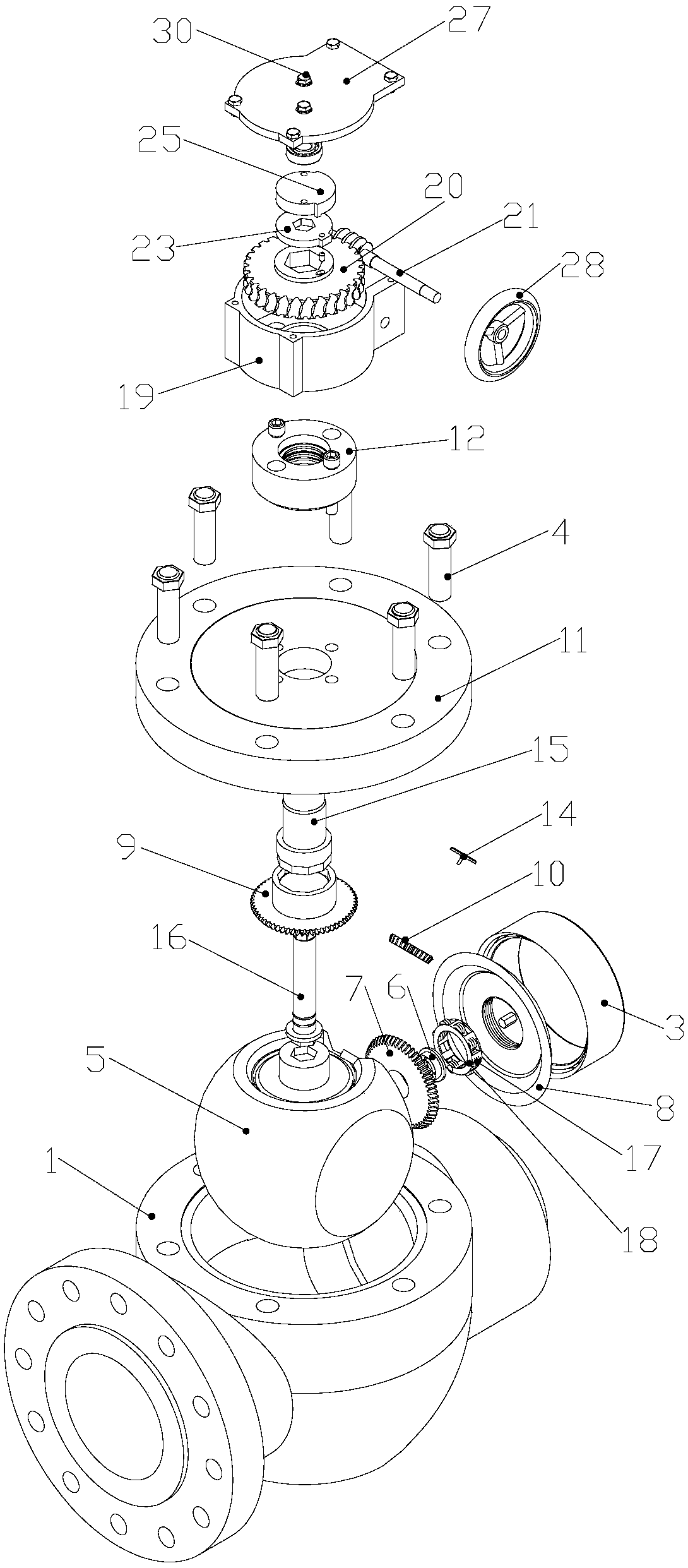

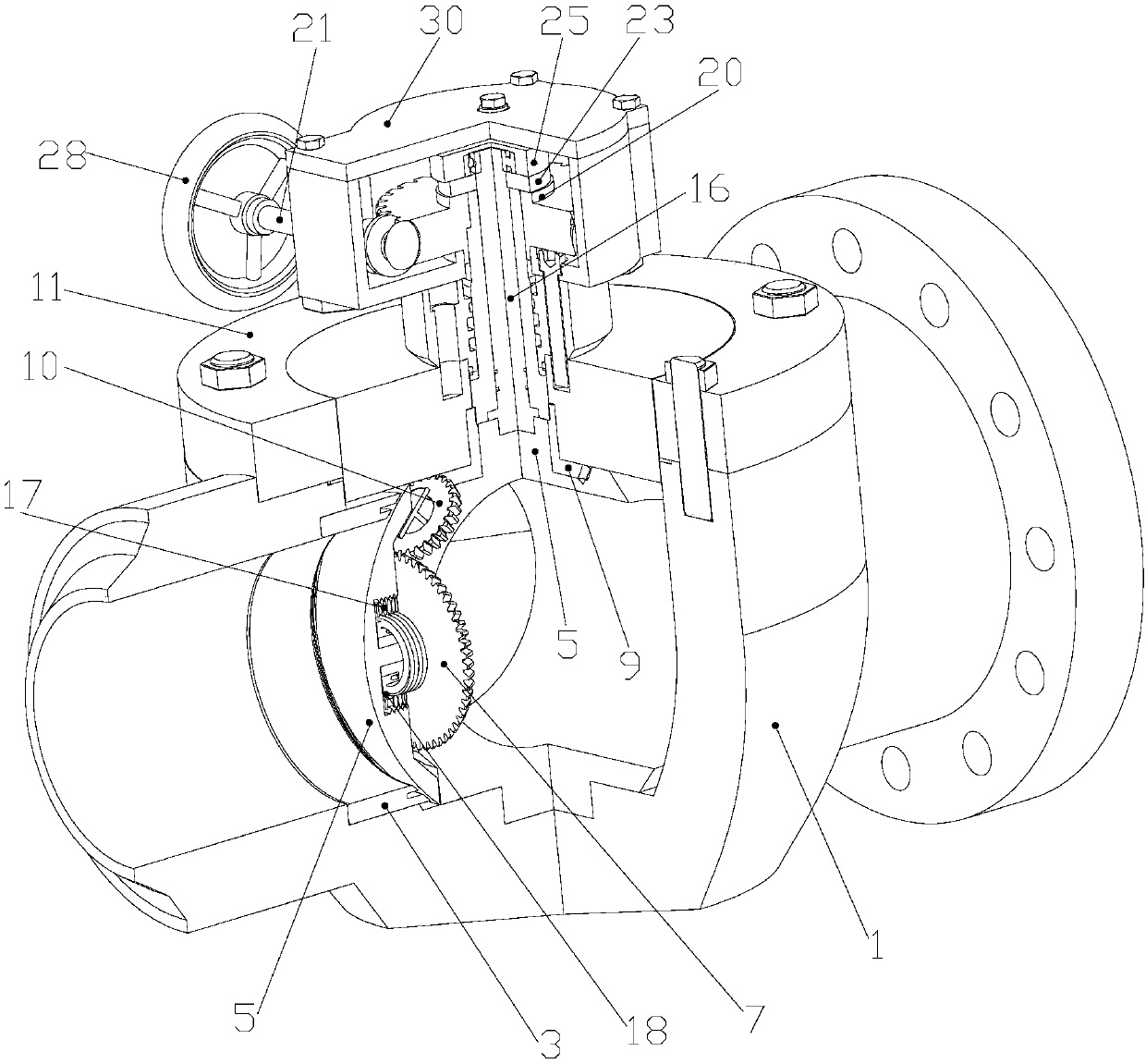

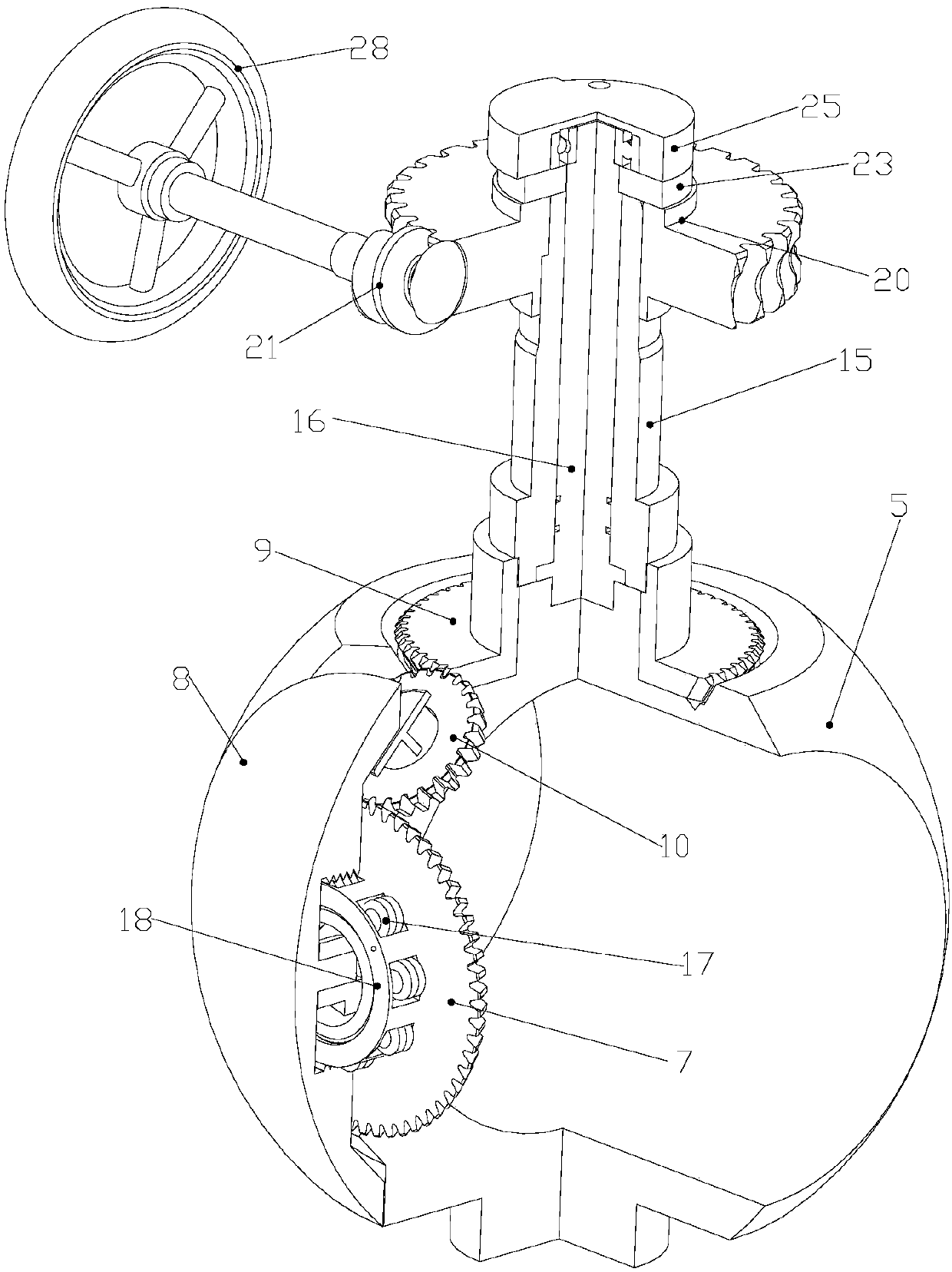

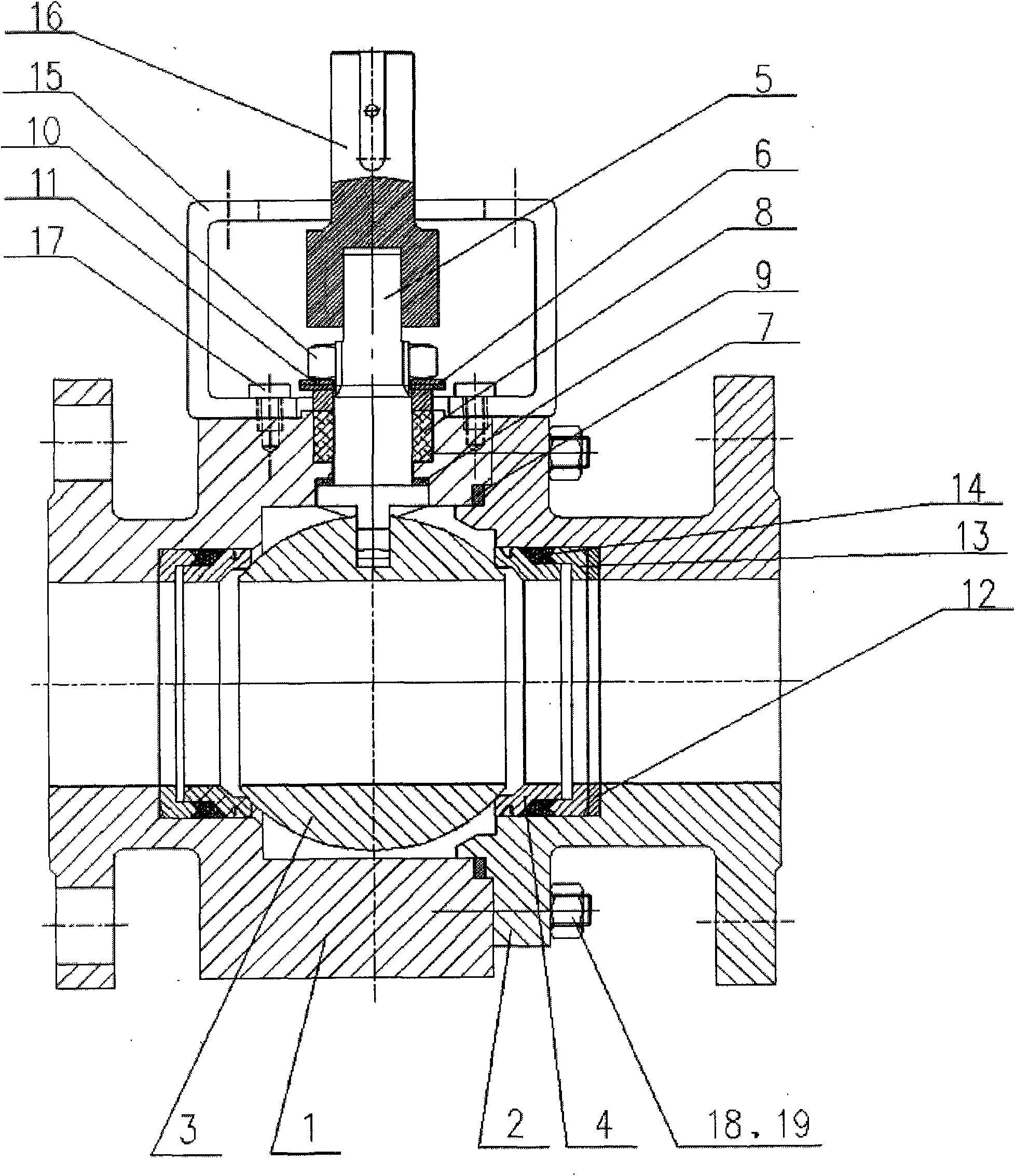

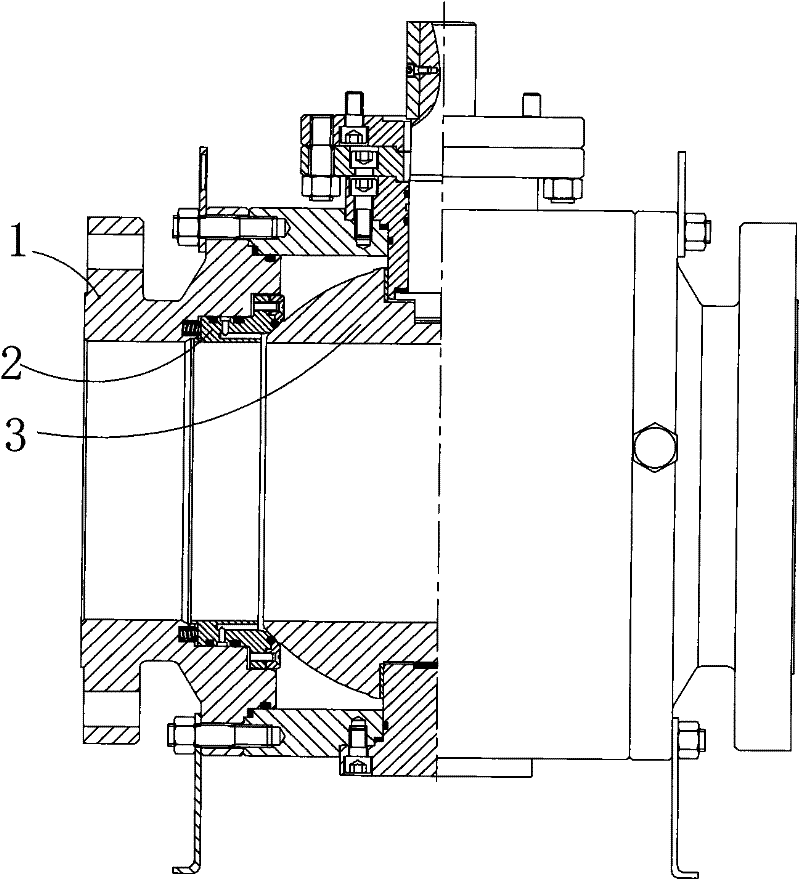

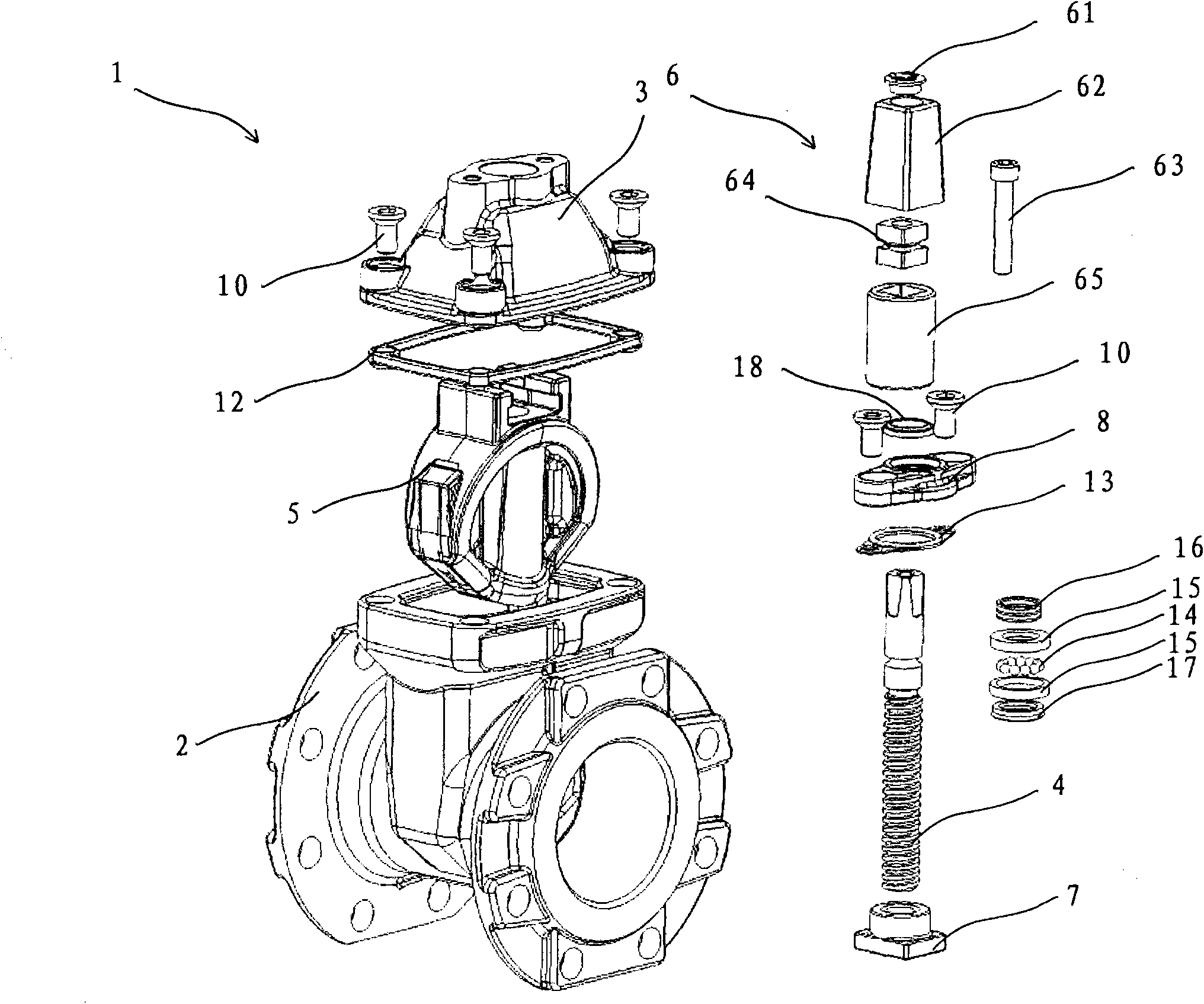

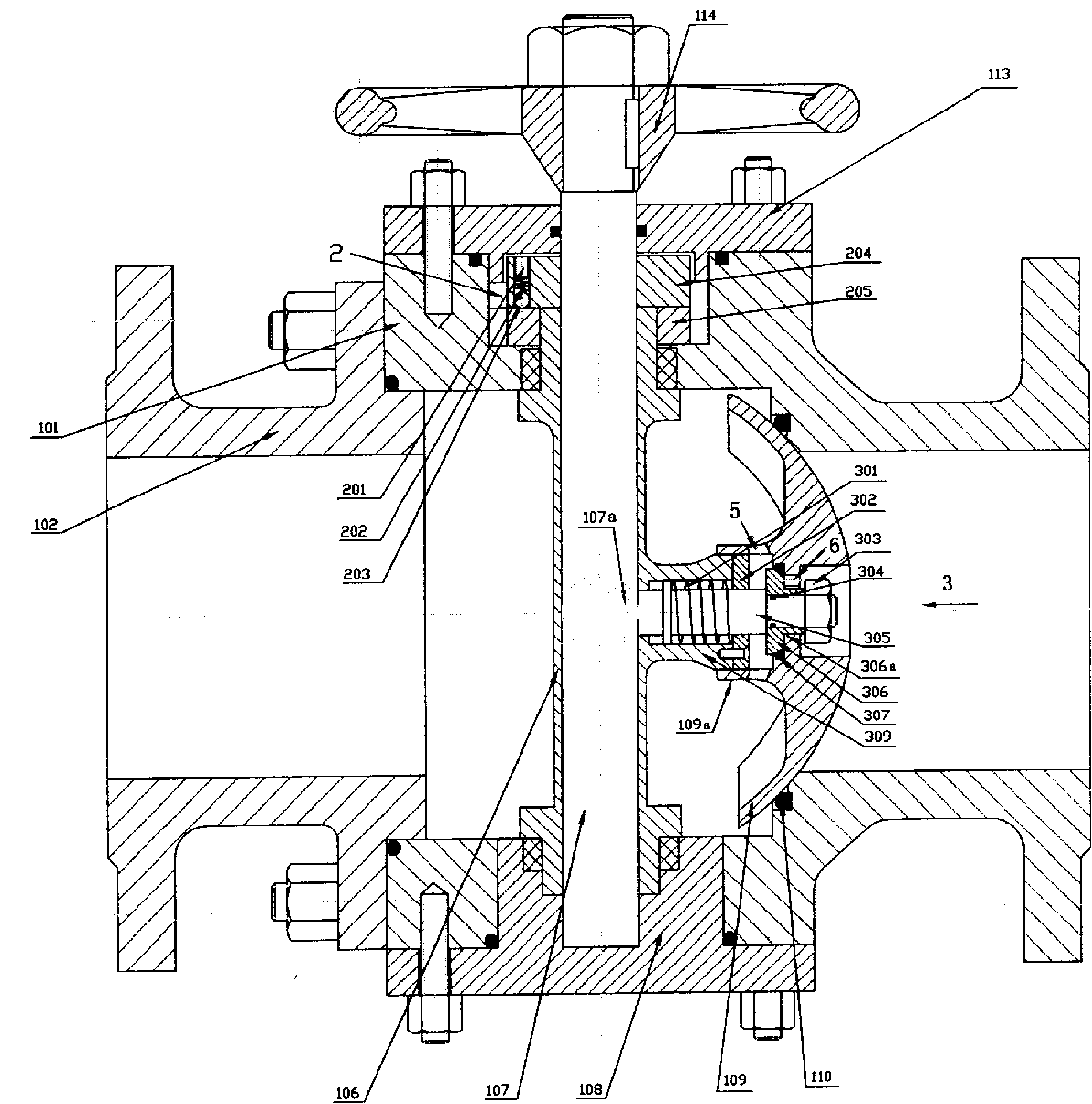

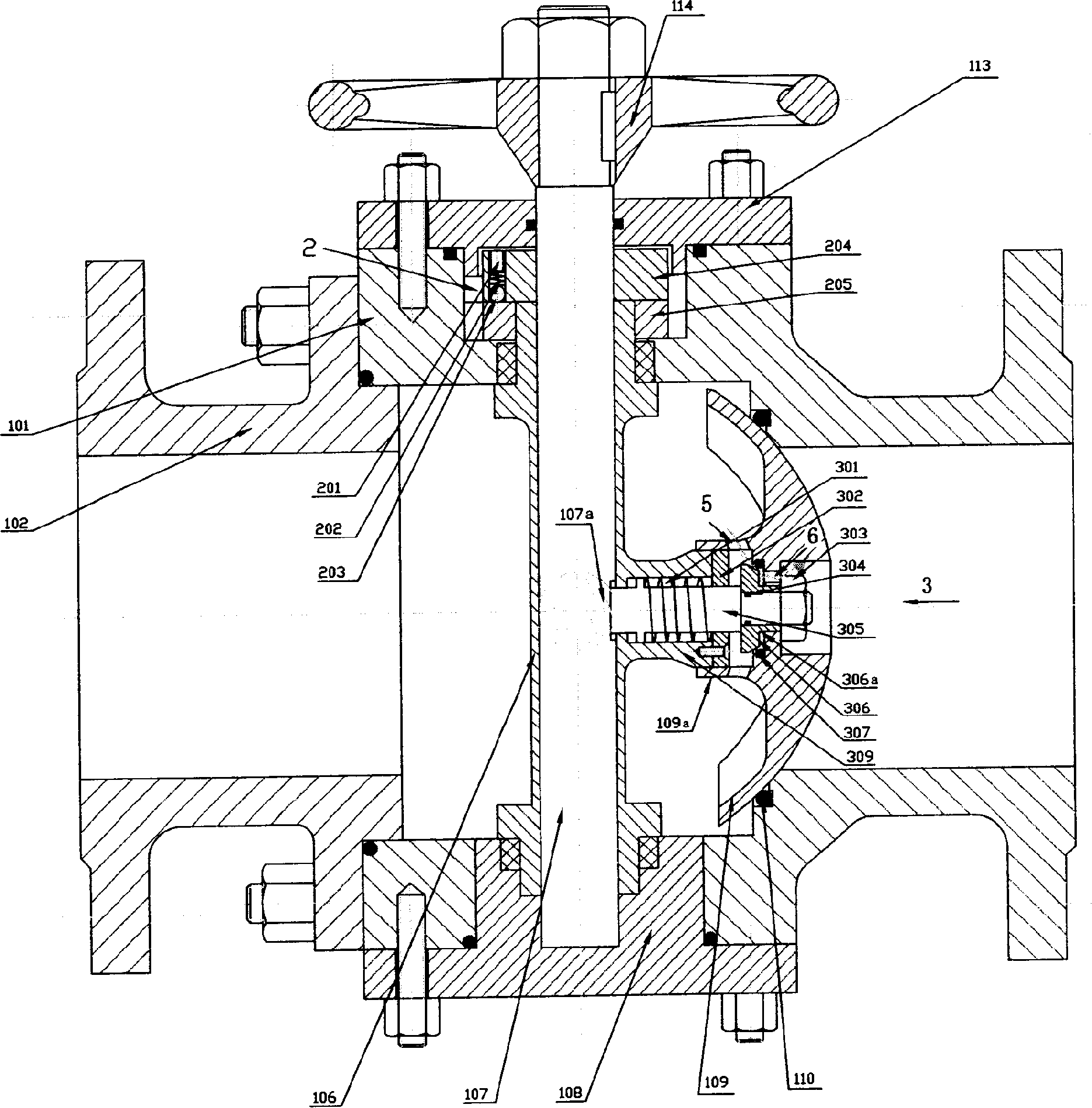

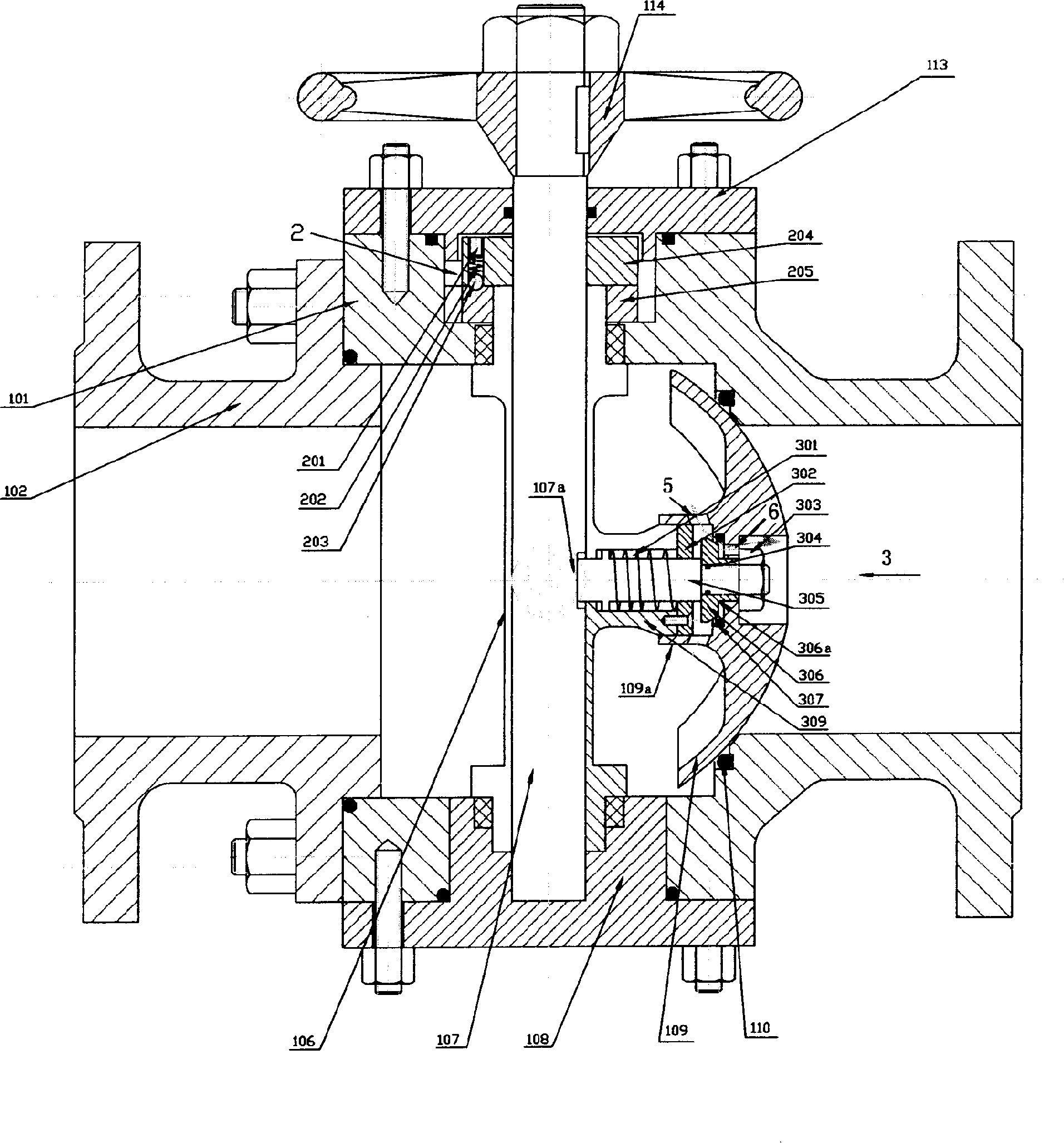

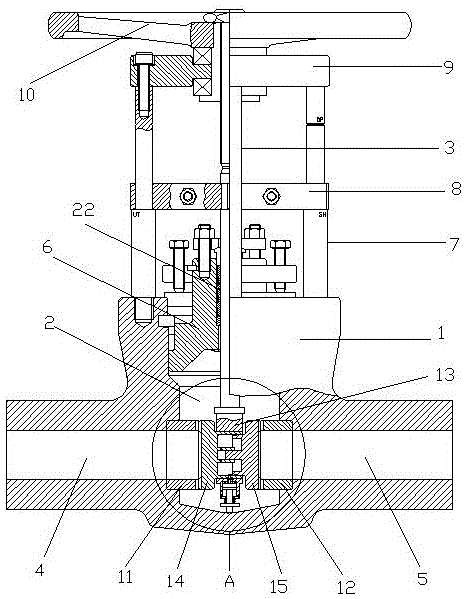

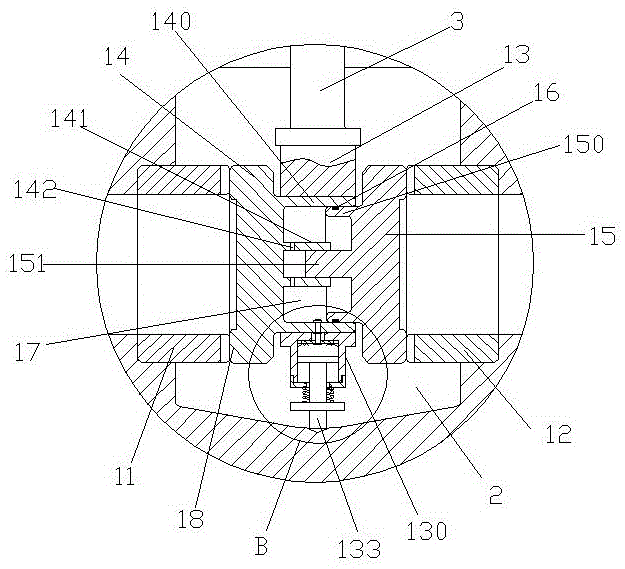

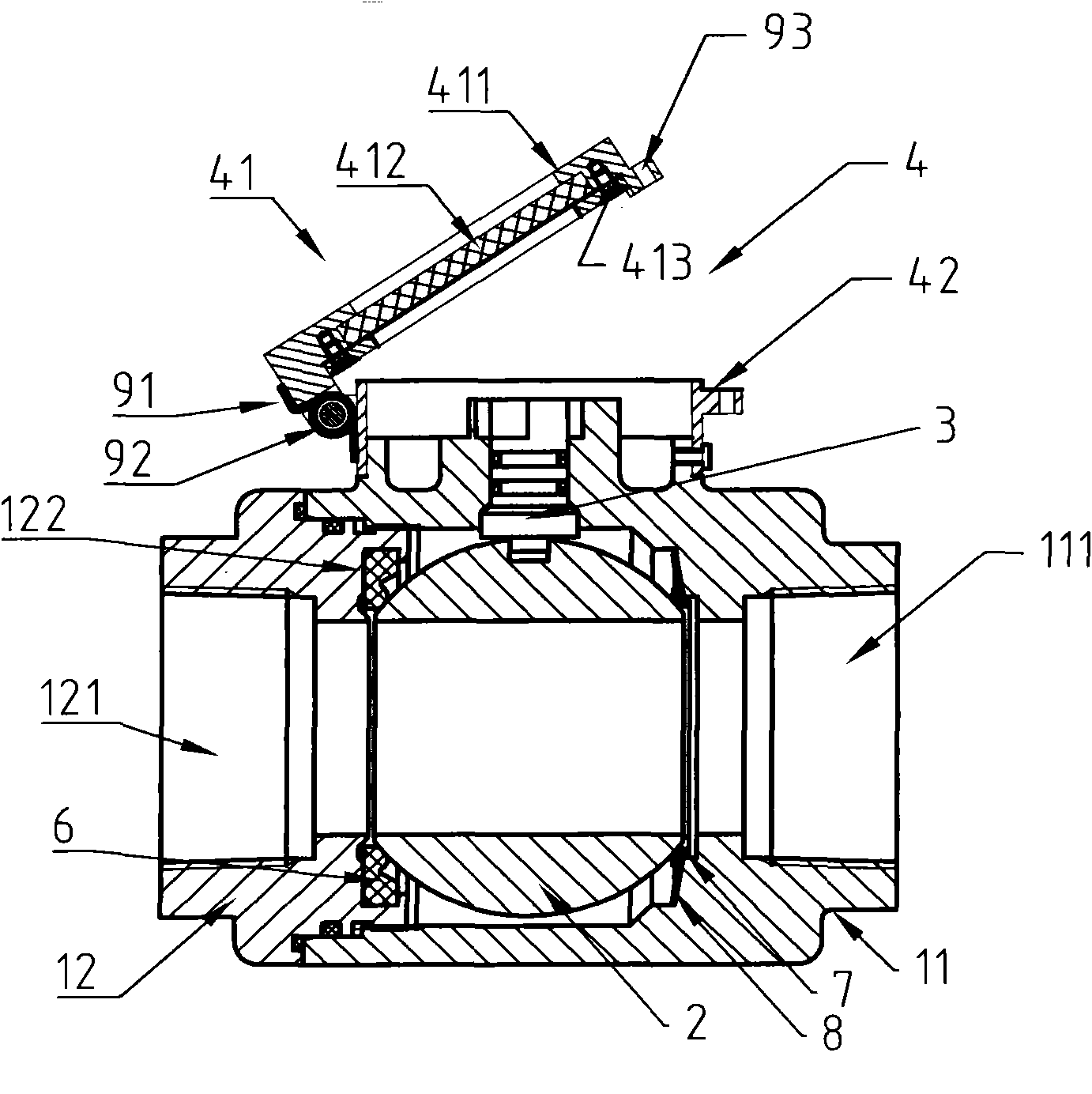

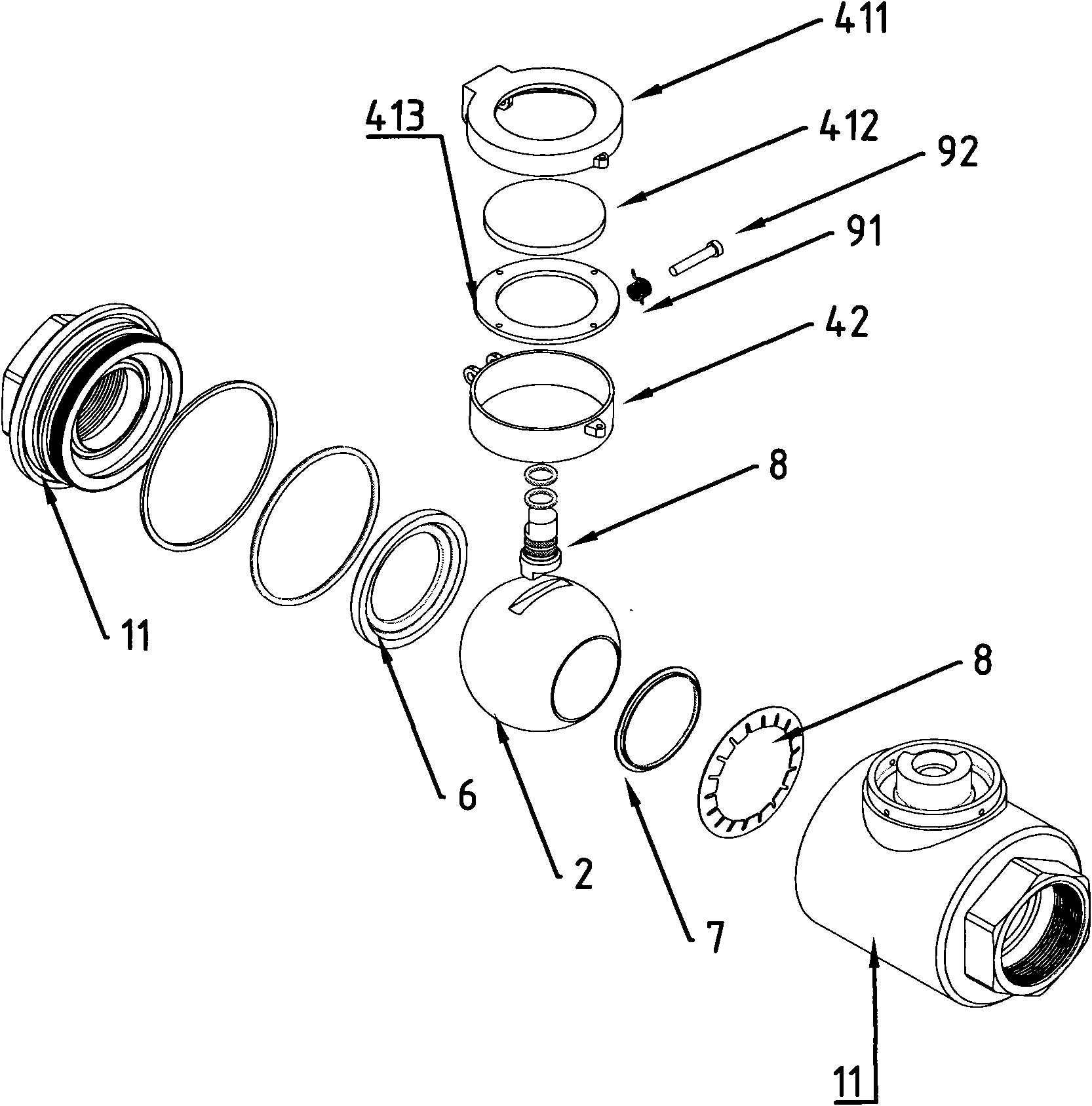

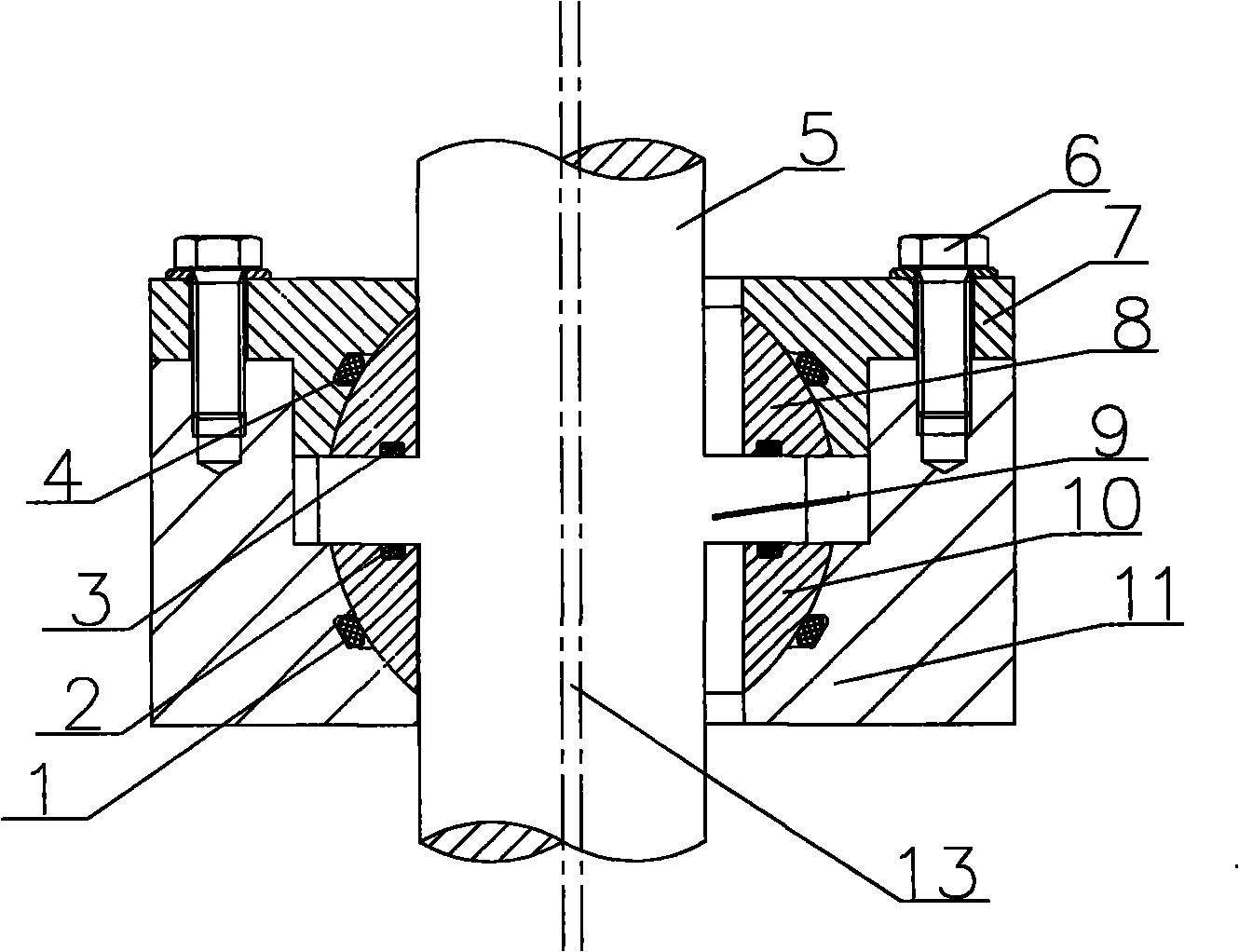

Forced sealing ball valve

PendingCN107763240AReduce frictionReduce operating torquePlug valvesOperating means/releasing devices for valvesEngineeringValve stem

The invention relates to a forced sealing ball valve which comprises a valve body, a valve seat, a valve ball, a valve rod and a valve rod driving device, wherein the valve ball is arranged in the valve body. The valve rod is arranged on the valve ball, and the valve rod driving device is arranged at the upper end of the valve rod. The valve rod comprises an inner valve rod and an outer valve rod,and the valve ball comprises a valve ball base body, a valve clack and a gear transmission assembly, wherein the valve rod drives the valve ball to rotate in a reciprocating mode between an opening position and a closing position under the driving of the valve rod driving device, and the valve clack is jacked up from the valve body base body and is embraced with the valve seat when the valve ballbase body rotates to a closed position. The valve ball valve has the advantages of being simple to operate, safe, reliable and small in friction force.

Owner:ZIBO VOTAISI PETROCHEM EQUIP CO LTD

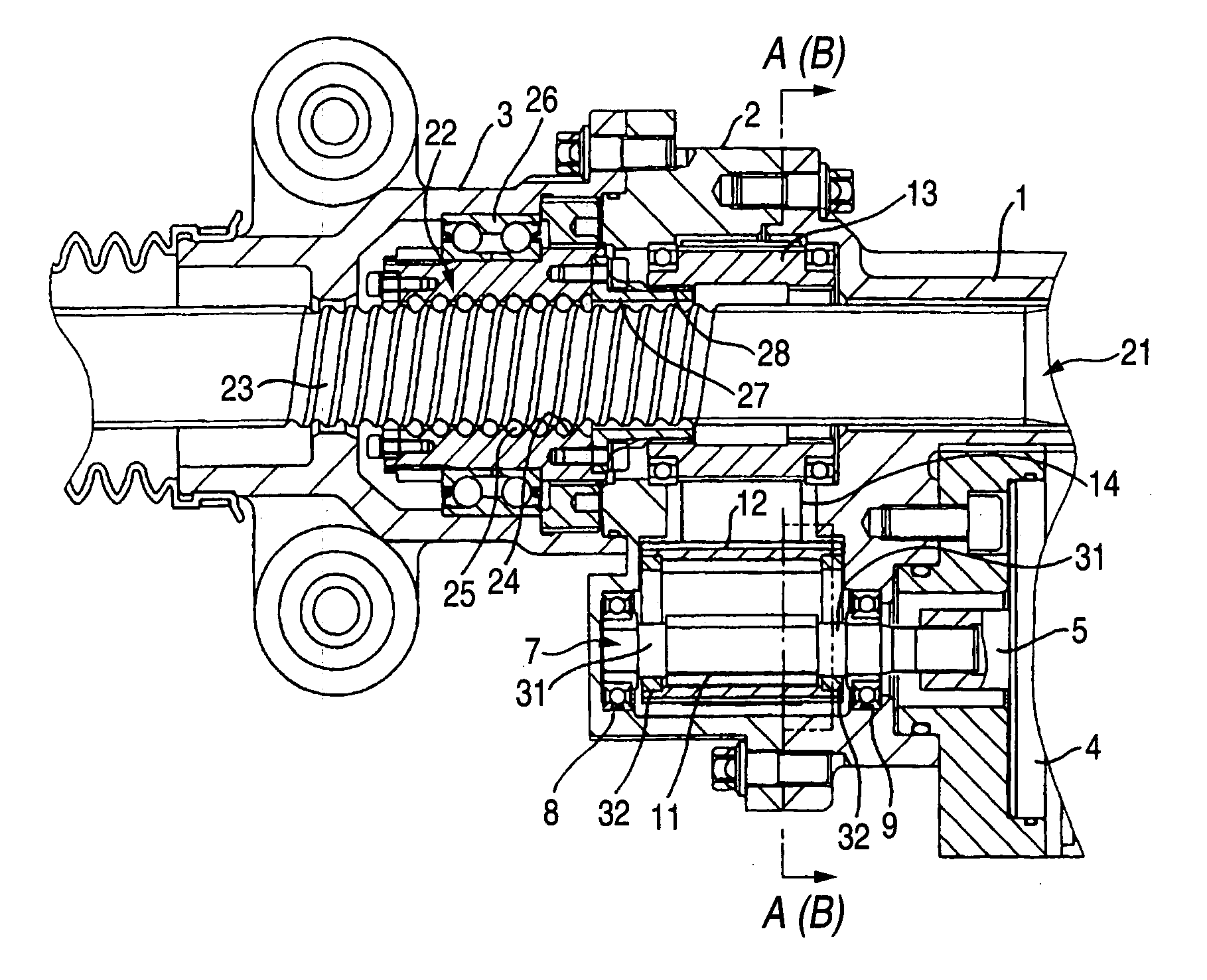

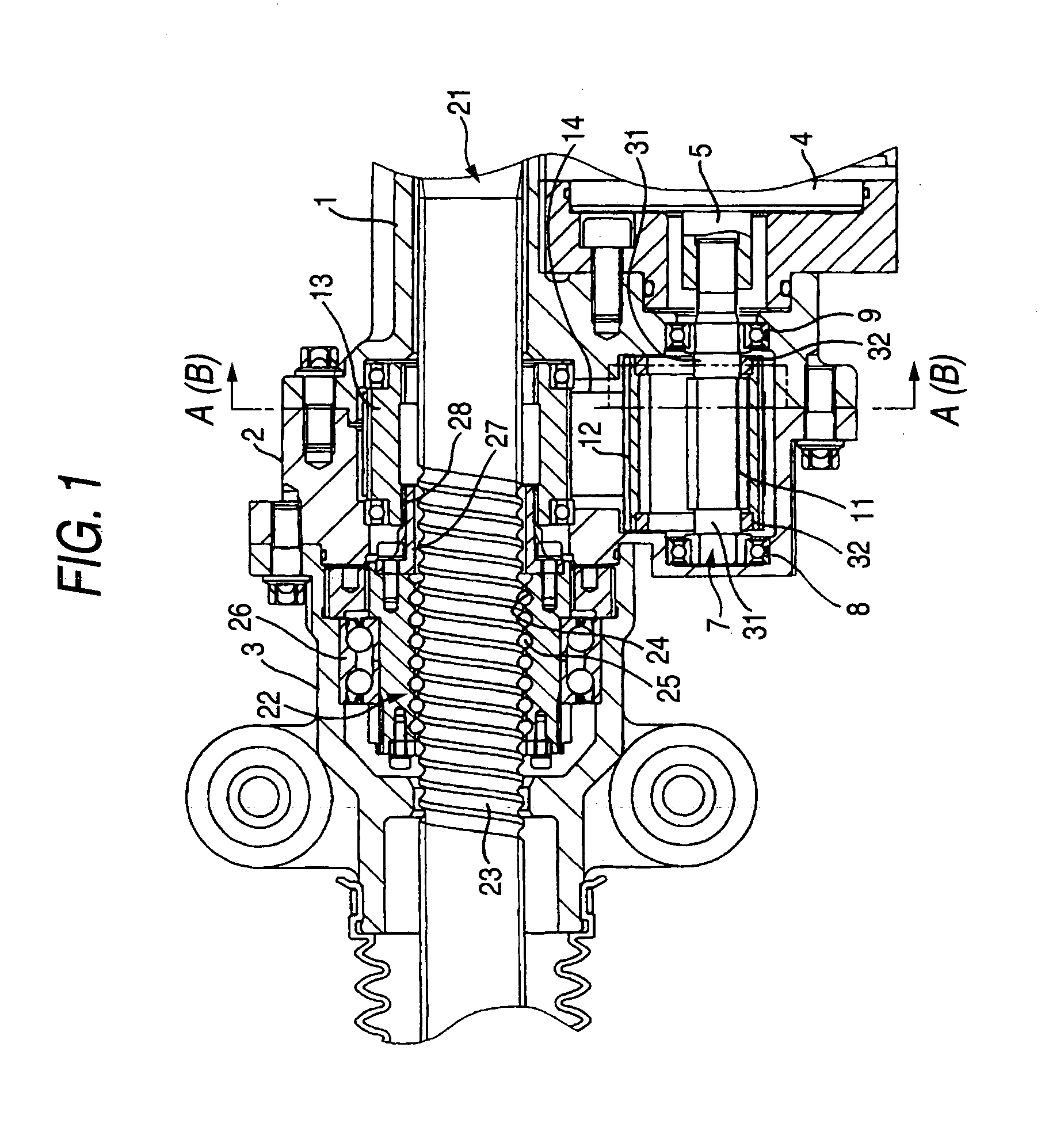

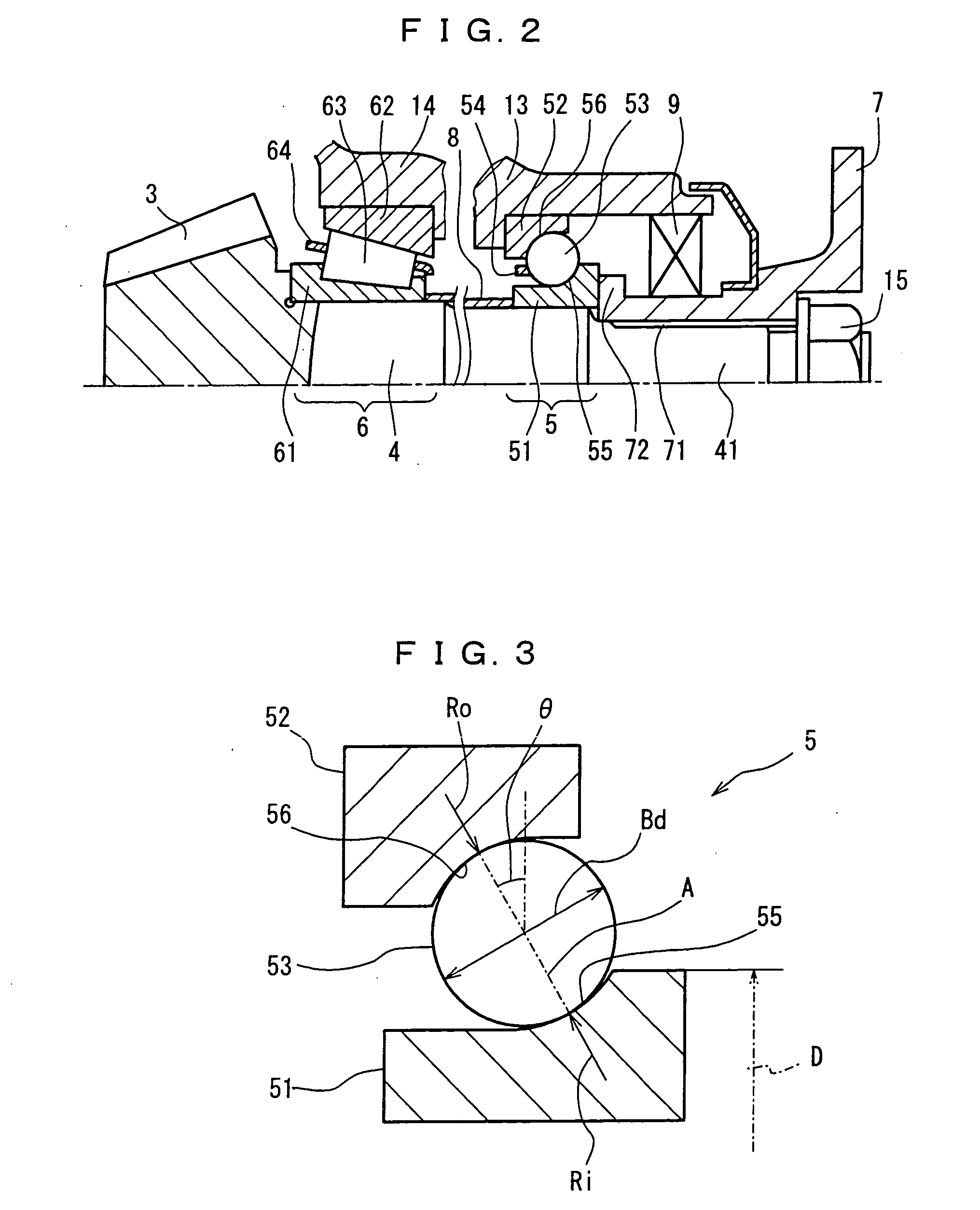

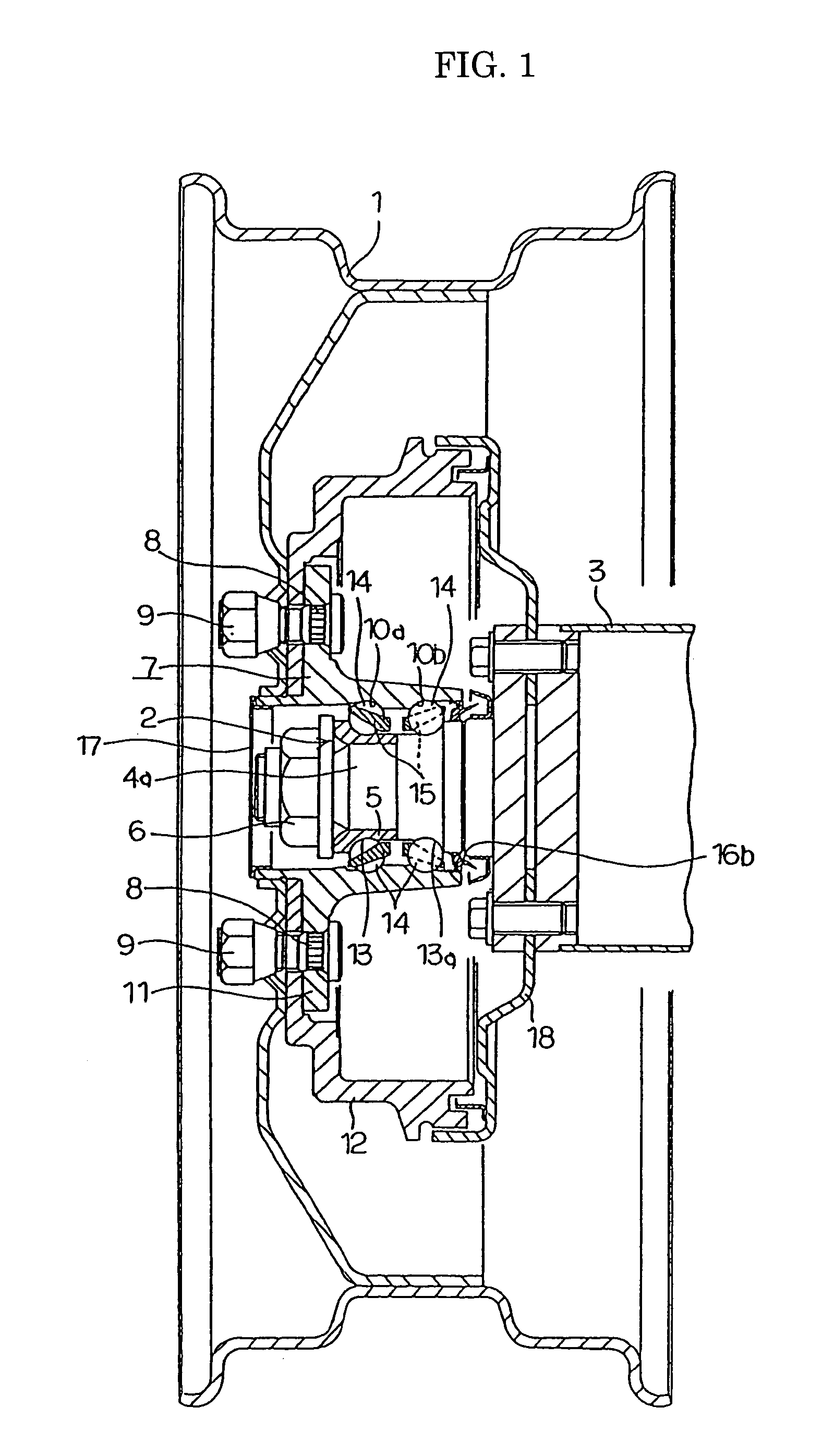

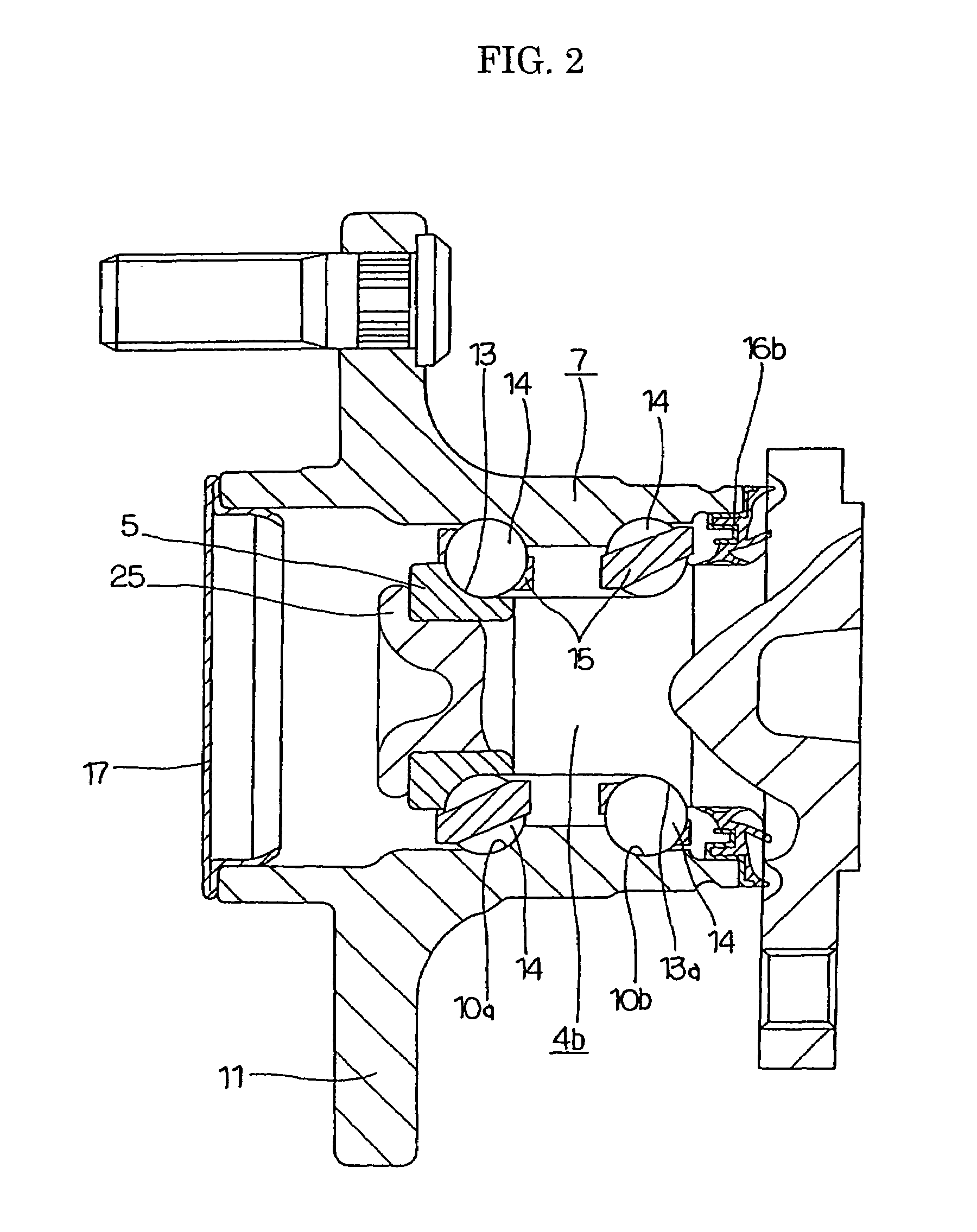

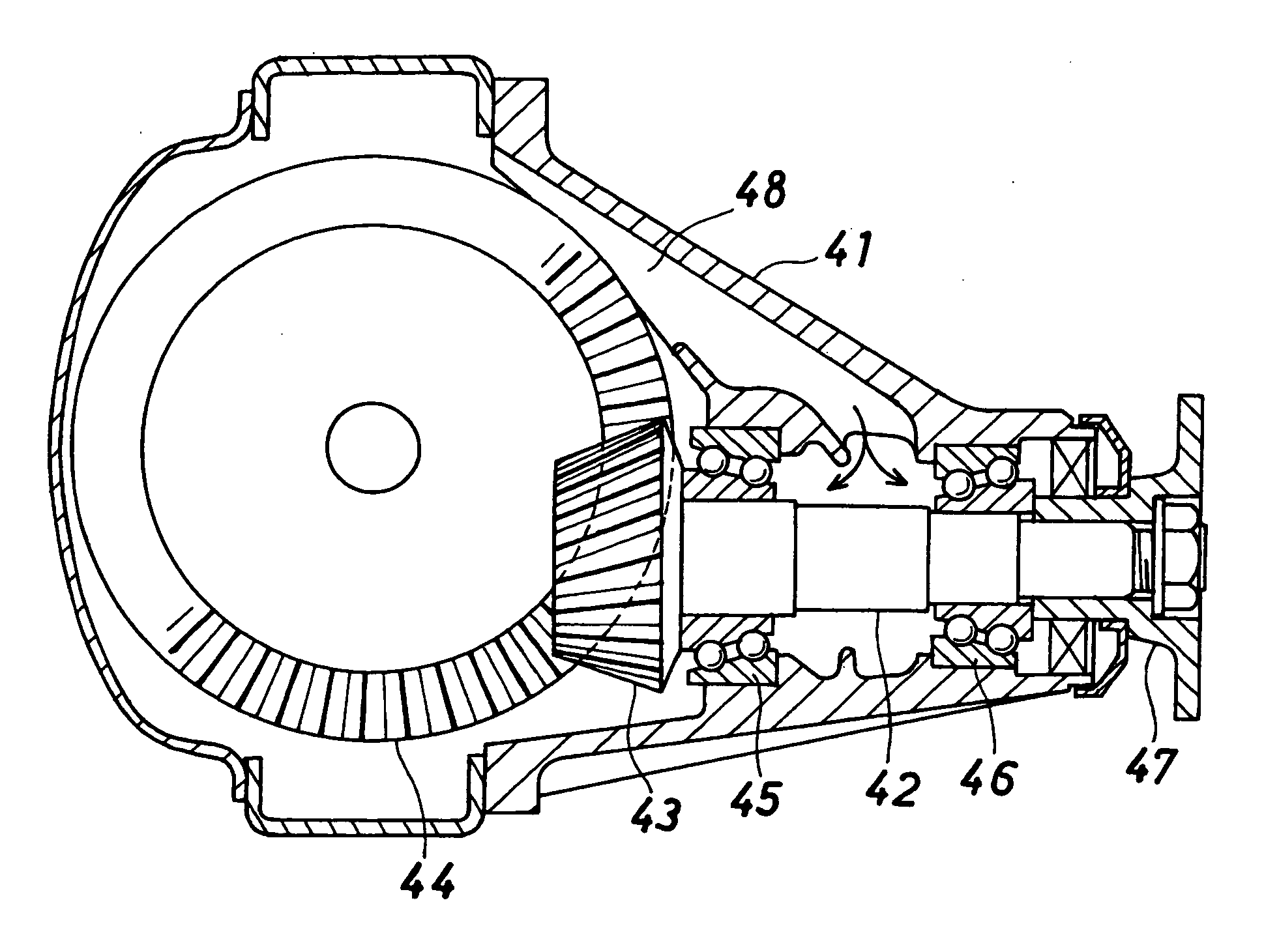

Bearing apparatus for supporting pinion shaft

InactiveUS20070104403A1Improve carrying capacityLarge contact angleShaftsBall bearingsBall bearingRolling-element bearing

A bearing apparatus for supporting a pinion shaft comprises a pair of rolling bearings which rotatably support a pinion shaft to a case and are arranged side by side in a shaft direction between a pinion gear arranged at one end of the pinion shaft, and a companion flange attached outside the other end thereof. The rolling bearing on a companion flange side comprises an angular ball bearing, and a radius of curvature Ri of an inner ring raceway, a radius of curvature Ro of an outer ring raceway, and a ball diameter Bd of the rolling bearing may satisfy a relationship given by equations of Ri<Ro, 0.502×Bd≦Ri≦0.512×Bd, and 0.510×Bd≦Ro≦0.520×Bd.

Owner:JTEKT CORP

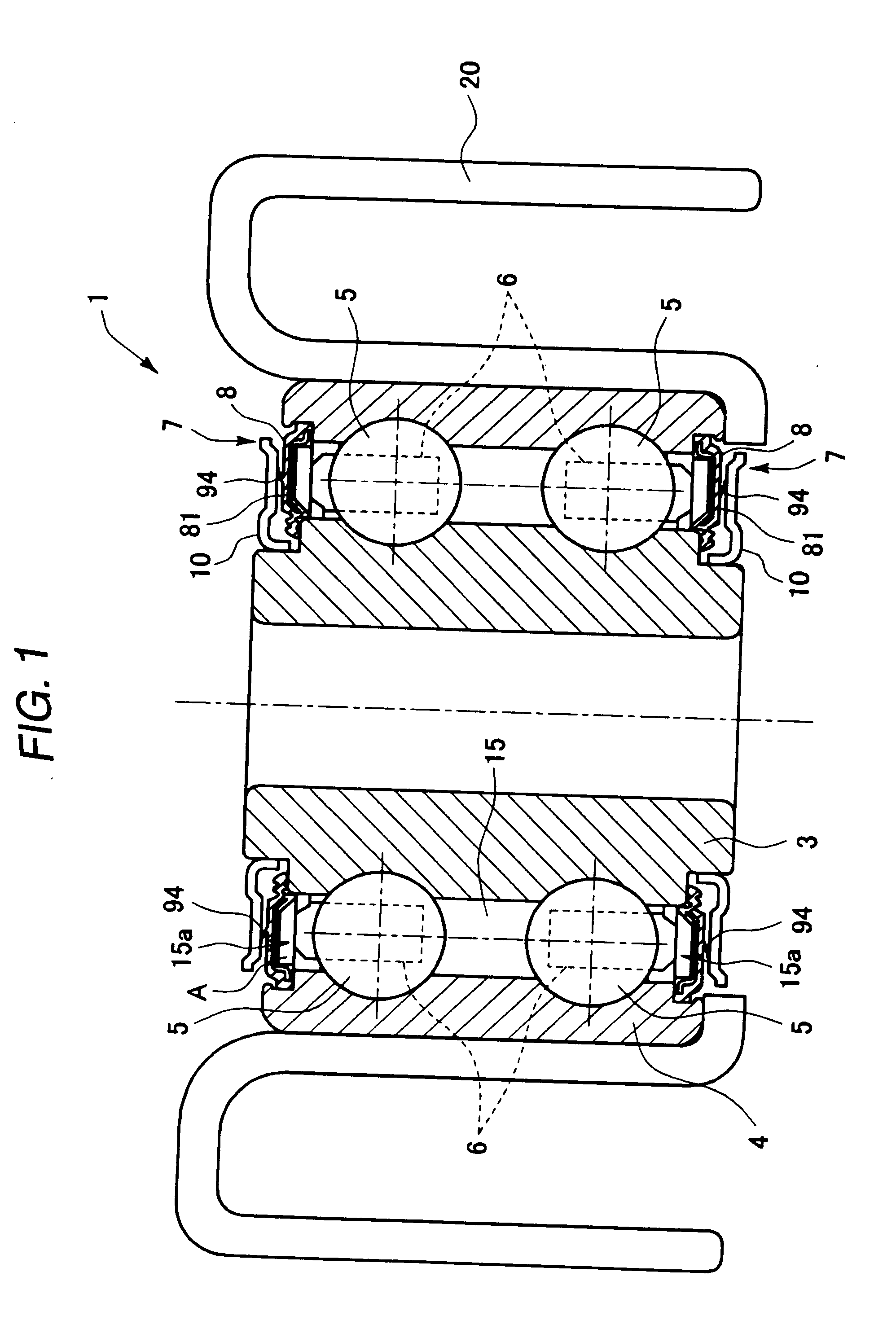

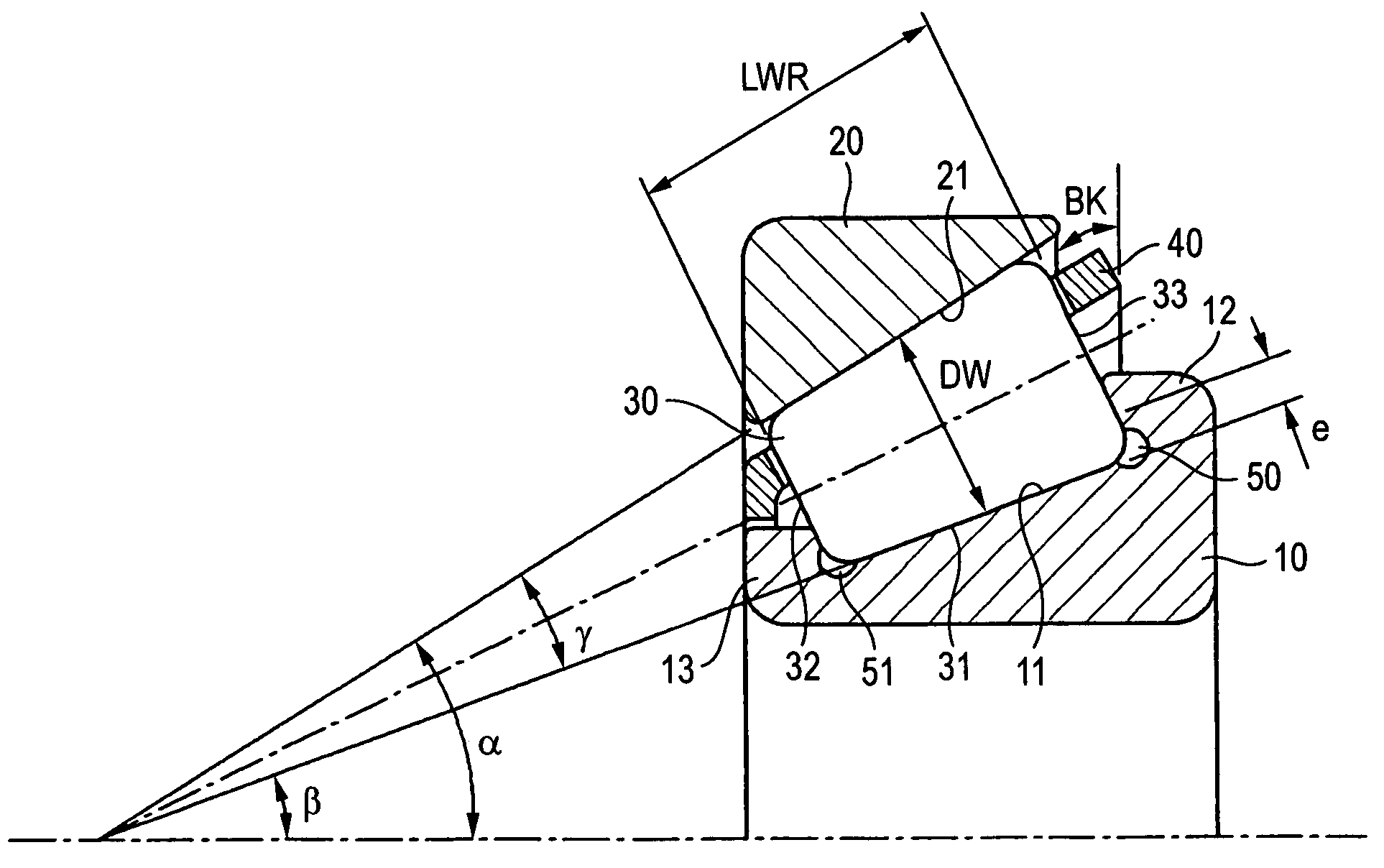

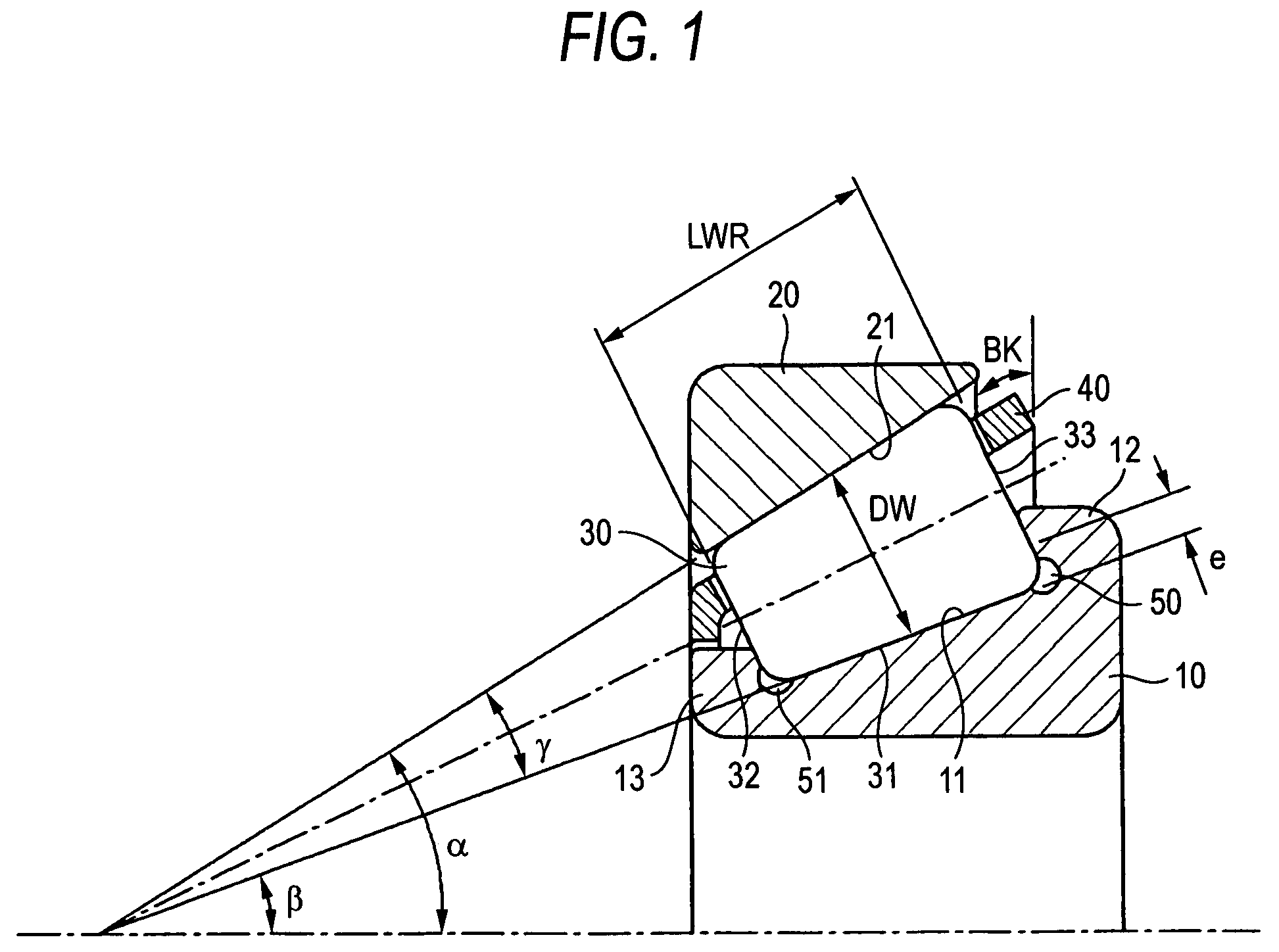

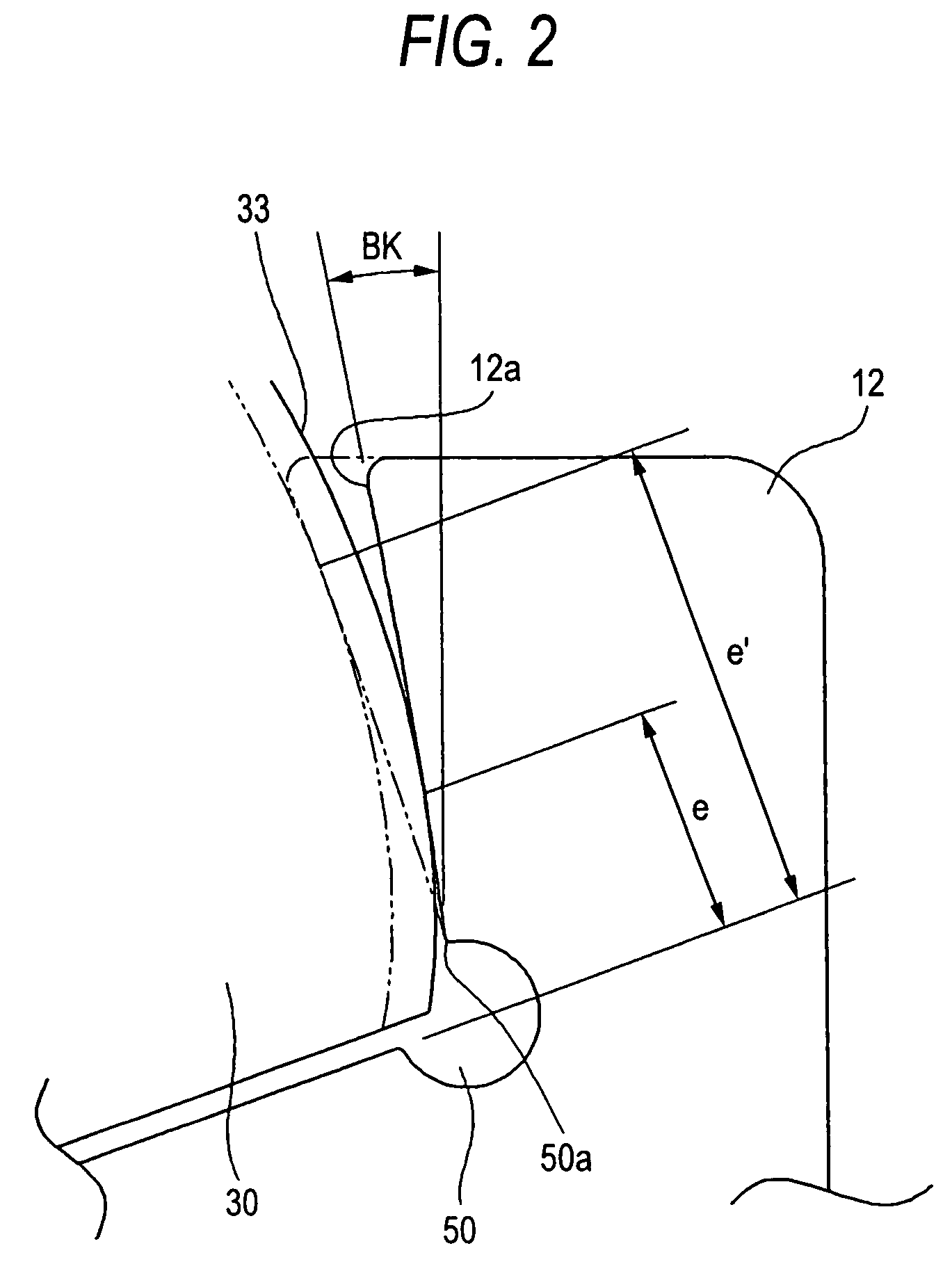

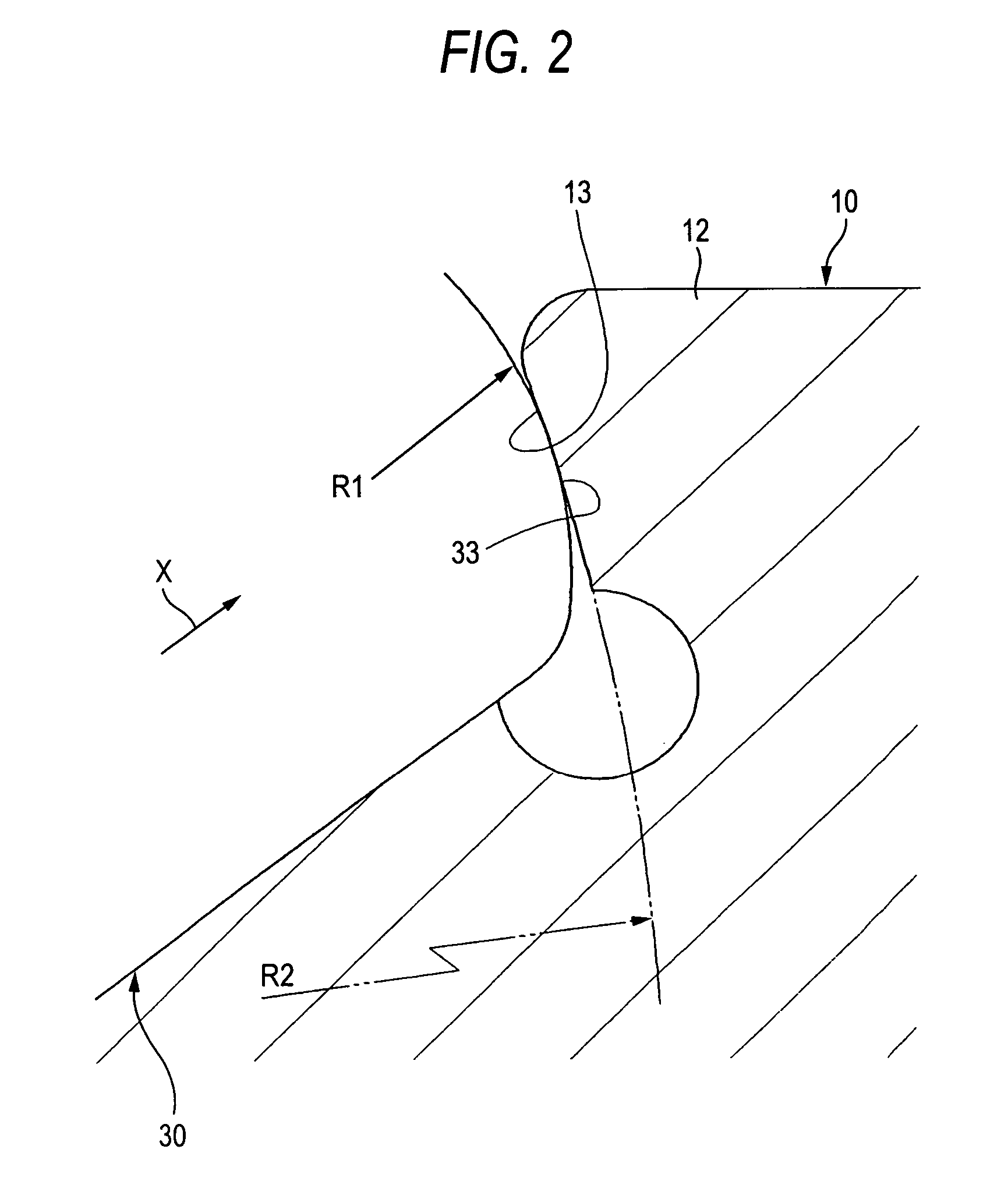

Tapered roller bearing, tapered roller bearing apparatus, and automotive pinion shaft supporting apparatus utilizing same tapered roller bearing apparatus

In a tapered roller bearing, LWR / DW is in the range of 1.1 to 1.7 where LWR represents a roller effective length of tapered rollers and DW represents a roller mean diameter of tapered rollers. RCO / LRO is 30 to 150, and RCI / LRI is 50 to 260 where RCO represents a crowning radius of an outer ring, LRO represents a raceway length of the outer ring, RCI represents a crowning radius of an inner ring and LRI represents a raceway length of the inner ring. The following expressions are satisfied: 20°≦α≦30°, and α−0.87γ−0.334≦BK≦α−0.87γ−0.167, where α represents a raceway angle of the outer ring, γ represents a roller angle of the tapered rollers, and BK represents a rib angle of a large rib portion of the inner ring.

Owner:JTEKT CORP

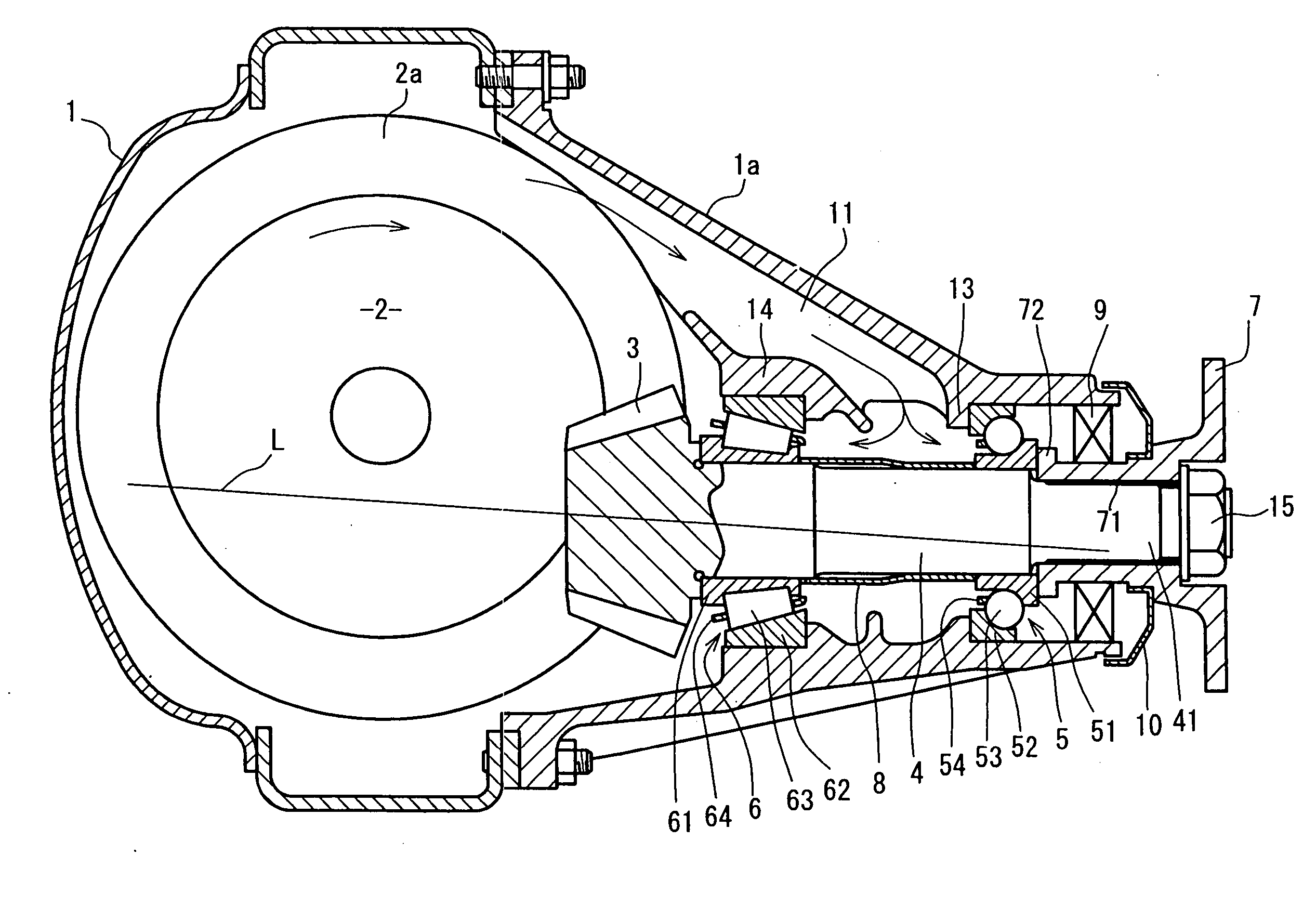

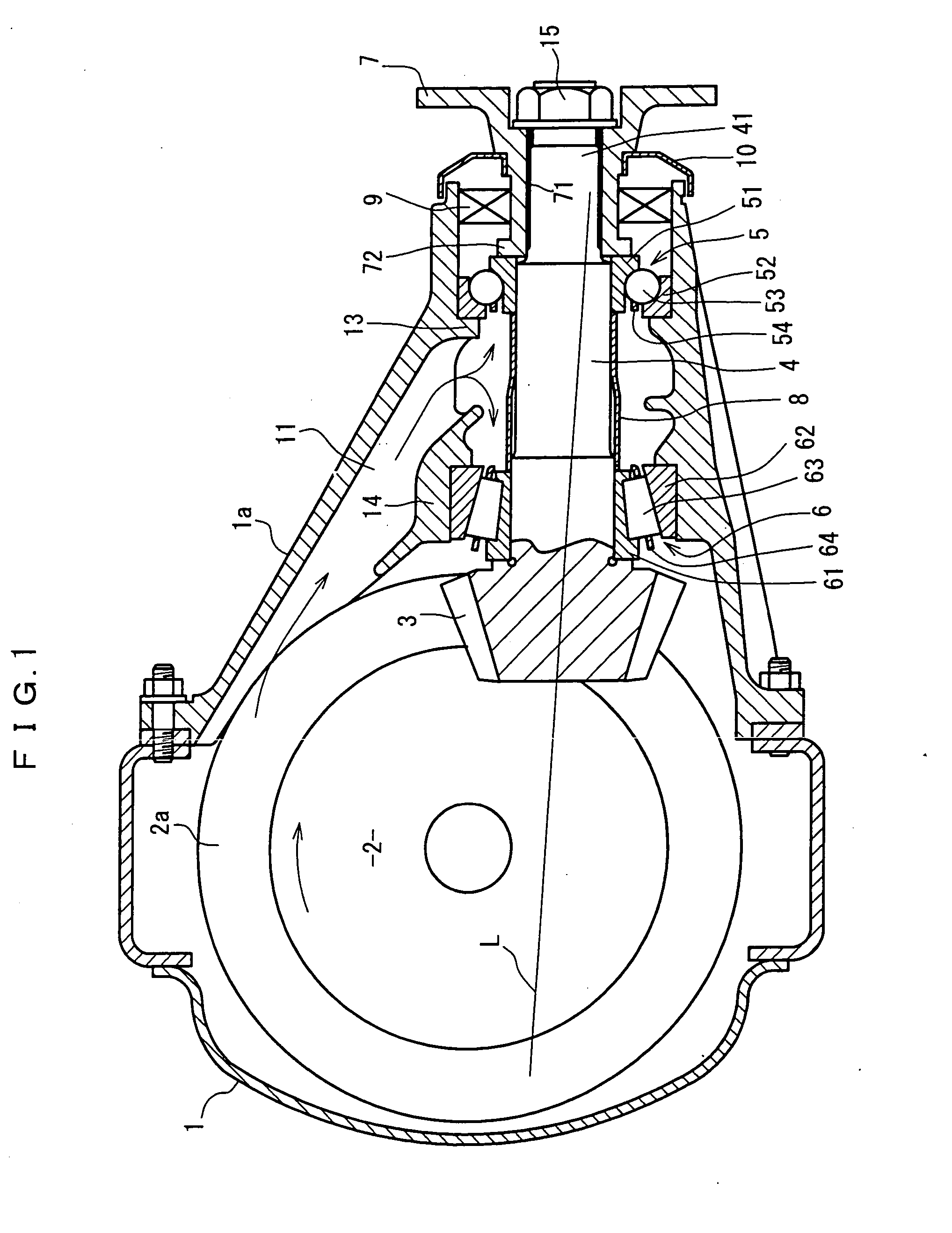

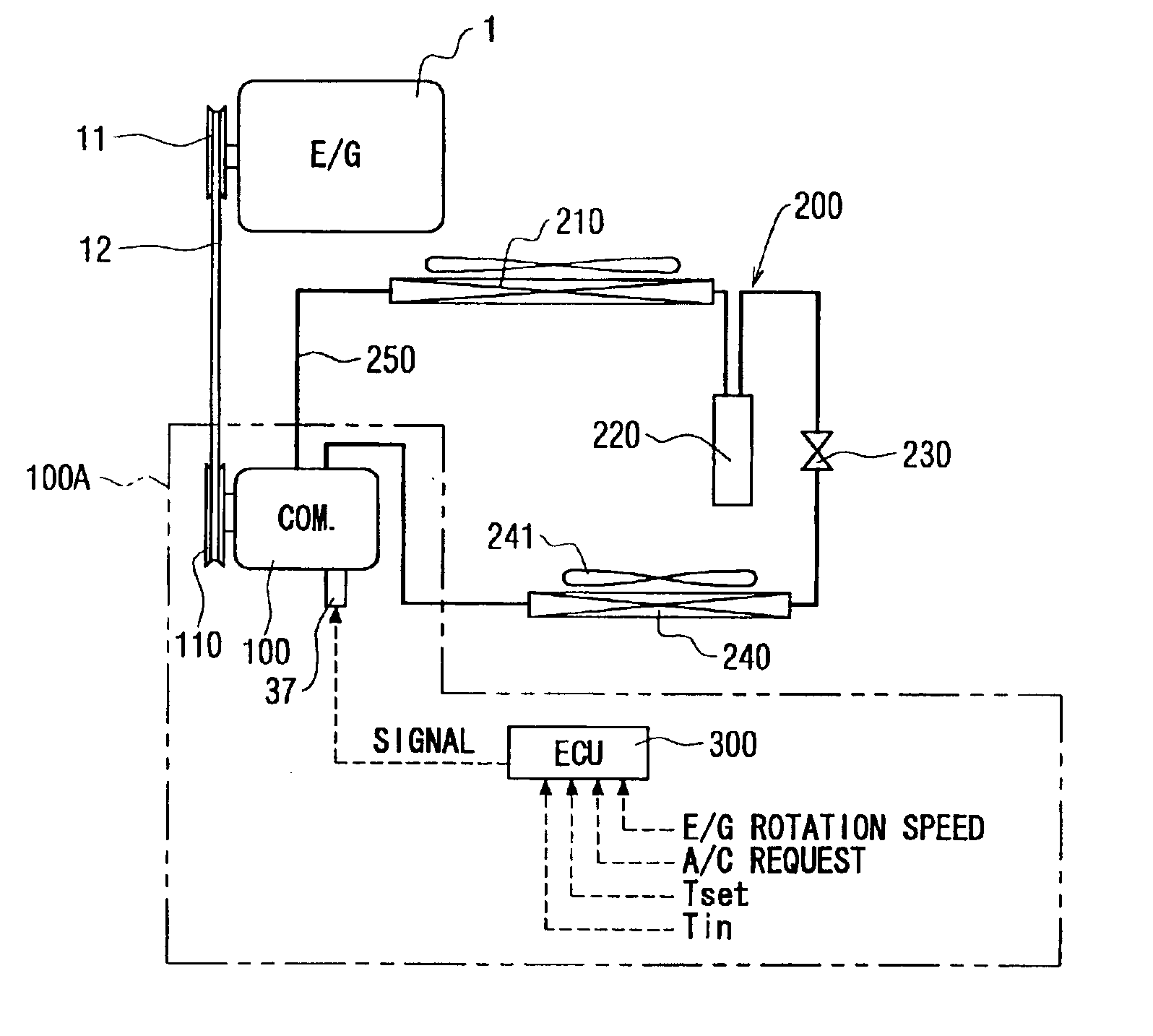

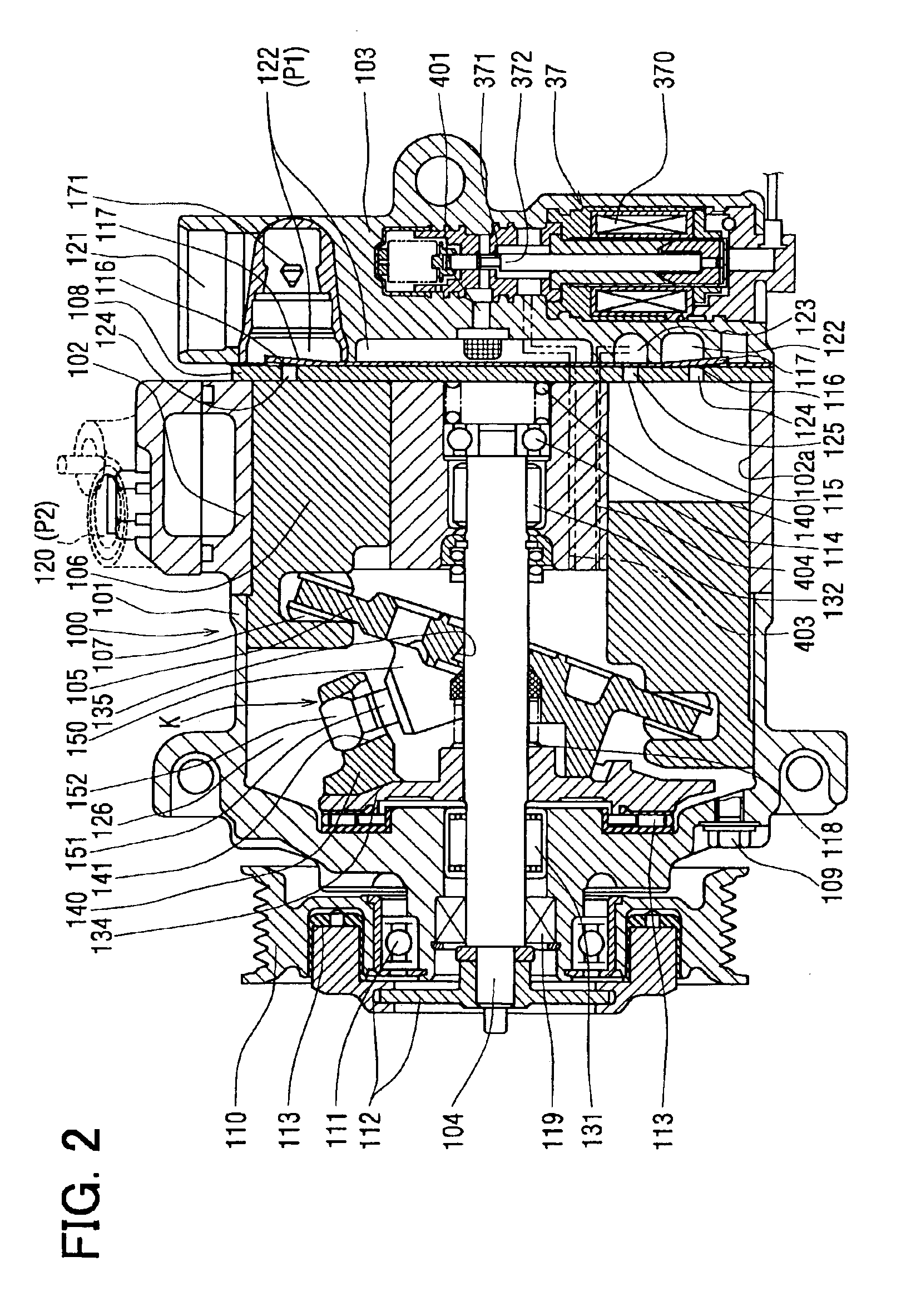

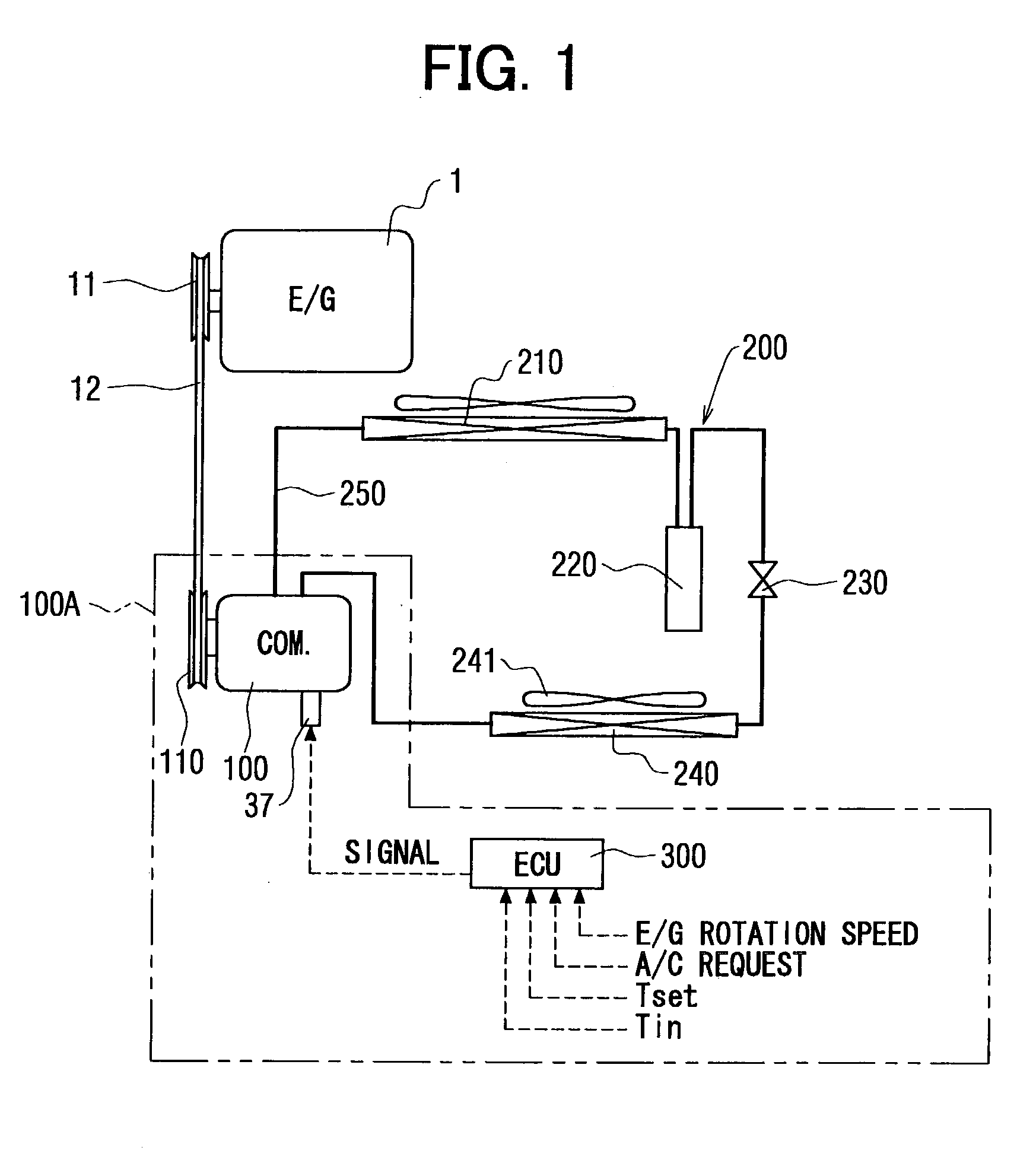

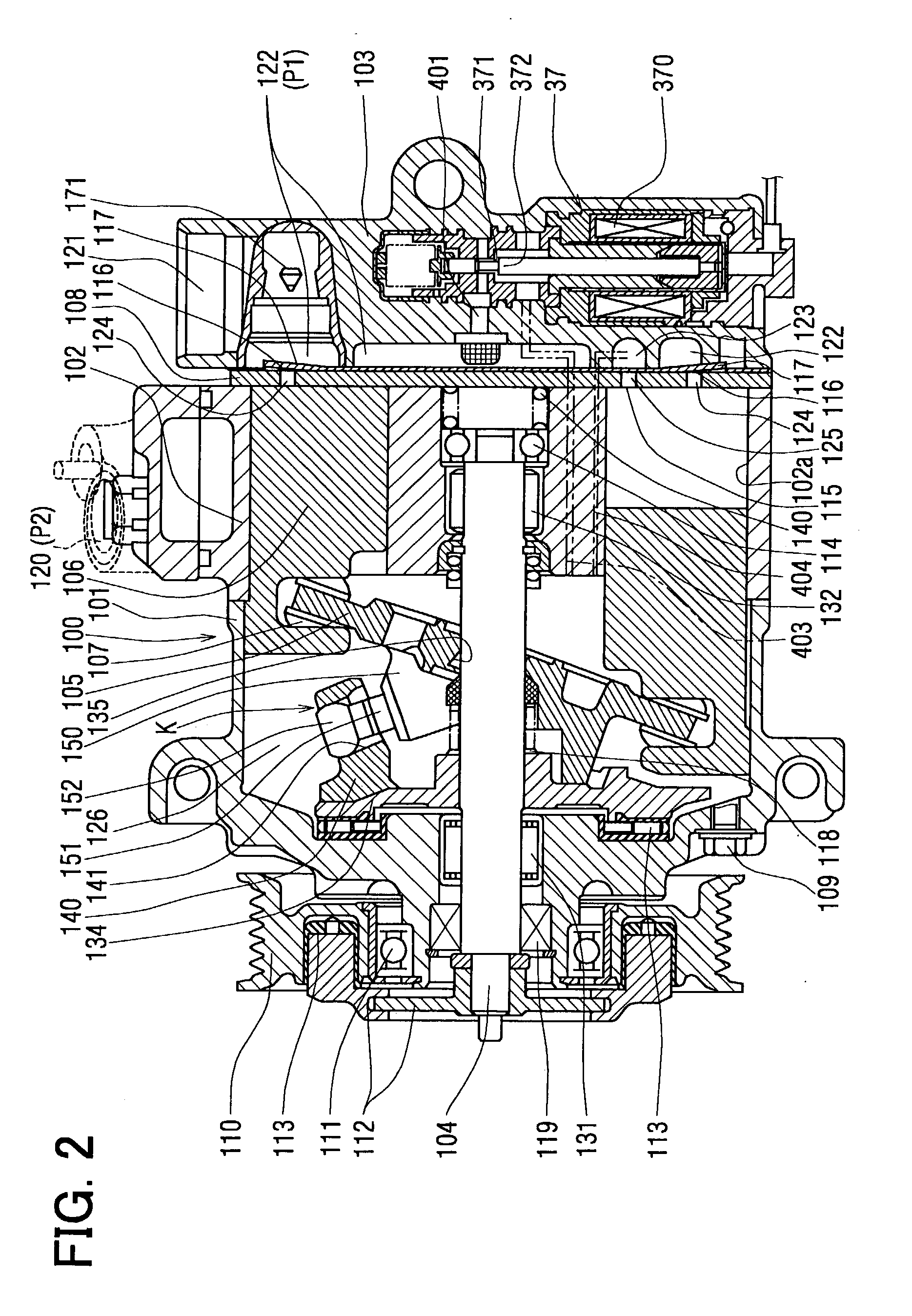

Compressor device and control method for the same

InactiveUS6848262B2Reduce operating torquePreventing engine stallAir-treating devicesFluid parameterControl theoryControl unit

Owner:DENSO CORP

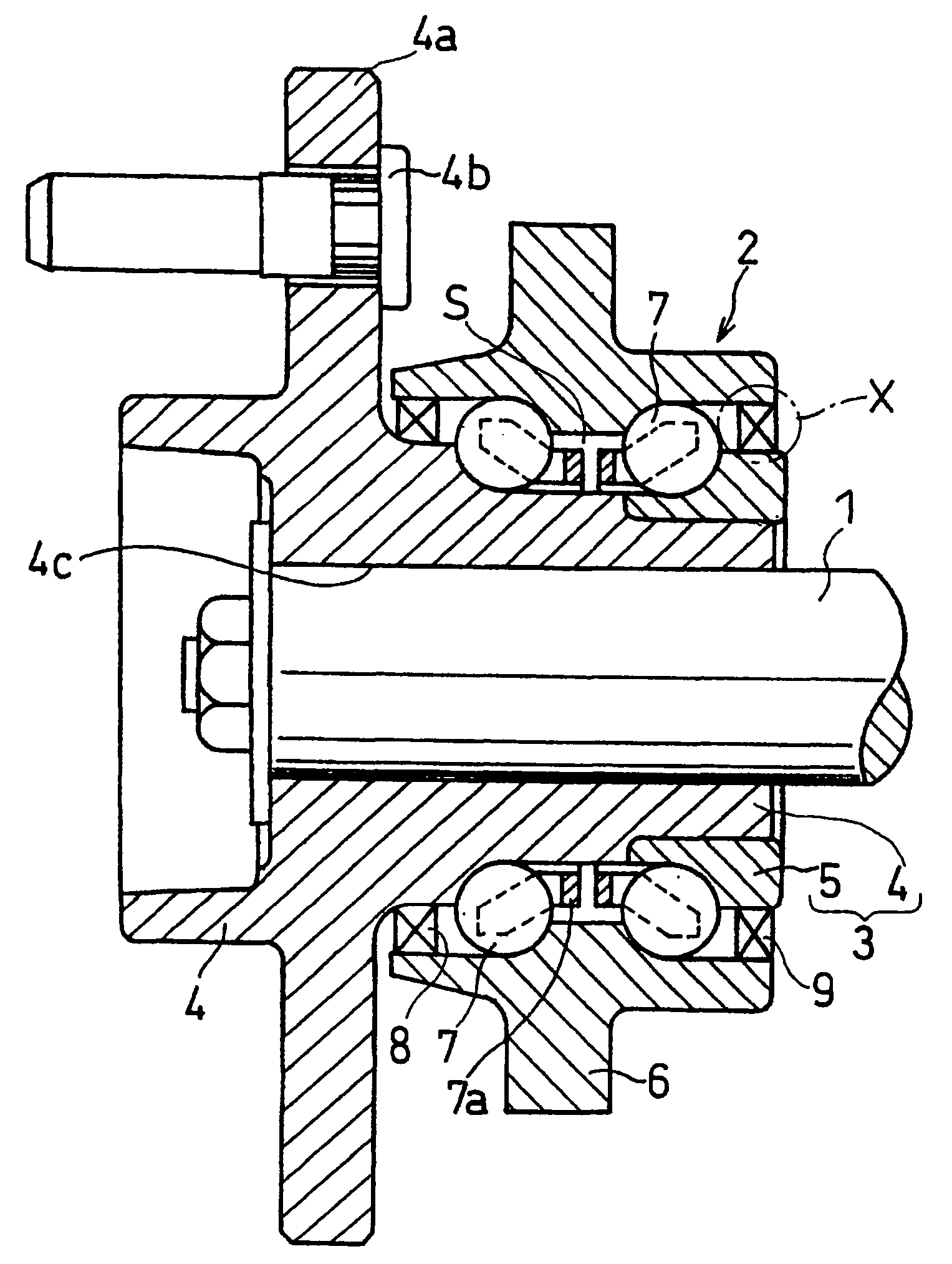

Sealing device

InactiveUS20070090604A1Prevent leakageContribute to energy efficiencyEngine sealsRolling contact bearingsEngineeringFlange

A sealing device for sealing a space between two members relatively rotating in concentricity, comprising: a slinger fixedly fitted into one of the members, a core member fixedly fitted into the other of the members, and an elastic seal member attached to the core member, the elastic seal member having a seal lip elastically and slidably contacting with the slinger. The slinger has a fitting cylindrical portion to be fitted into the one member and a flange portion extending from the fitting cylindrical portion in its radial direction, whereas the seal lip has a base portion fixed to the core member and constitutes an axial lip elastically and slidably contacting with the inner surface of the flange portion of the slinger. The peripheral surface of the fitting cylindrical portion of the slinger and the corresponding peripheral surface of the base portion of the elastic seal member closely face each other with substantially constant space along the axial direction of the slinger, thereby constituting labyrinth construction between them.

Owner:UCHIYAMA MFG

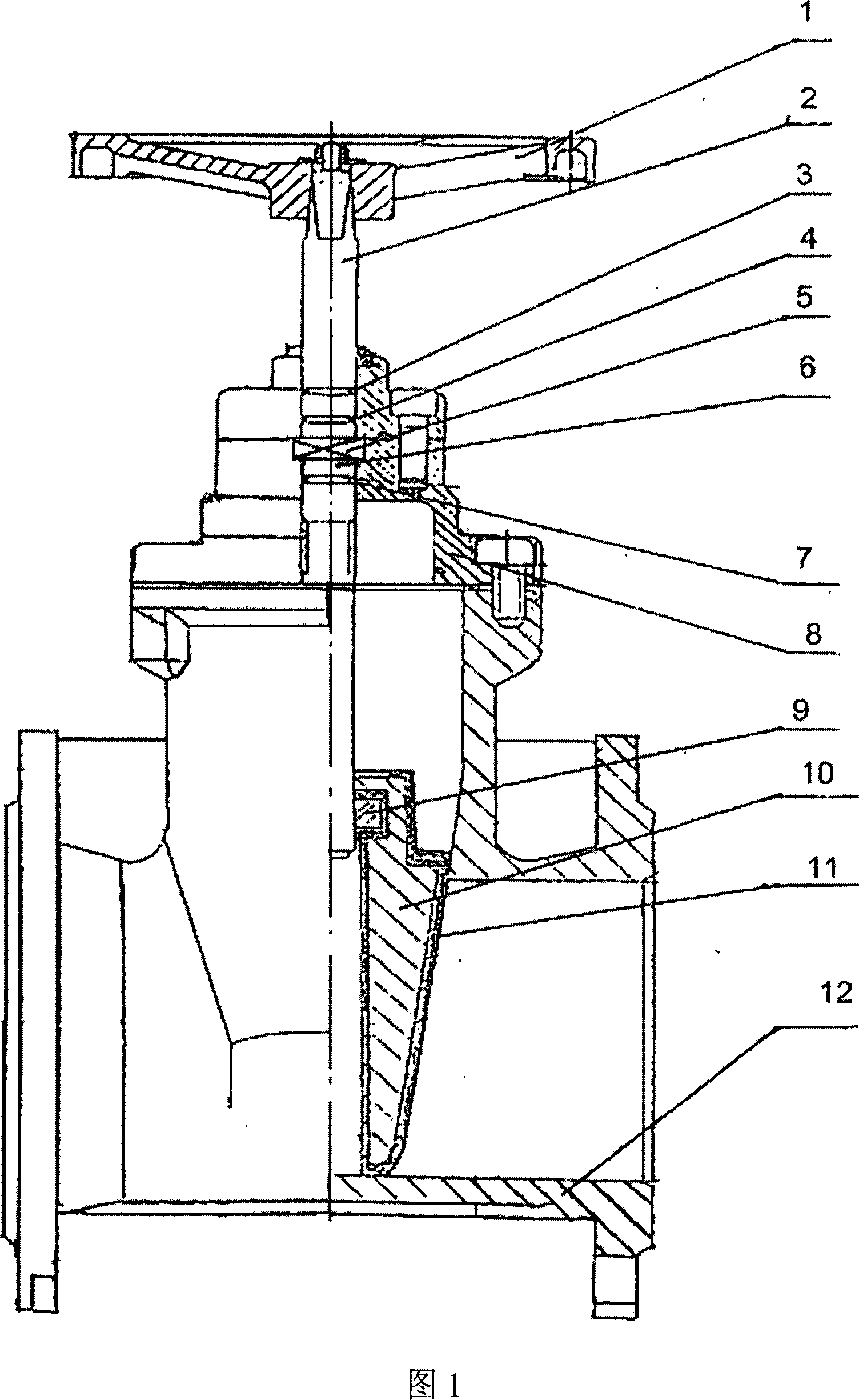

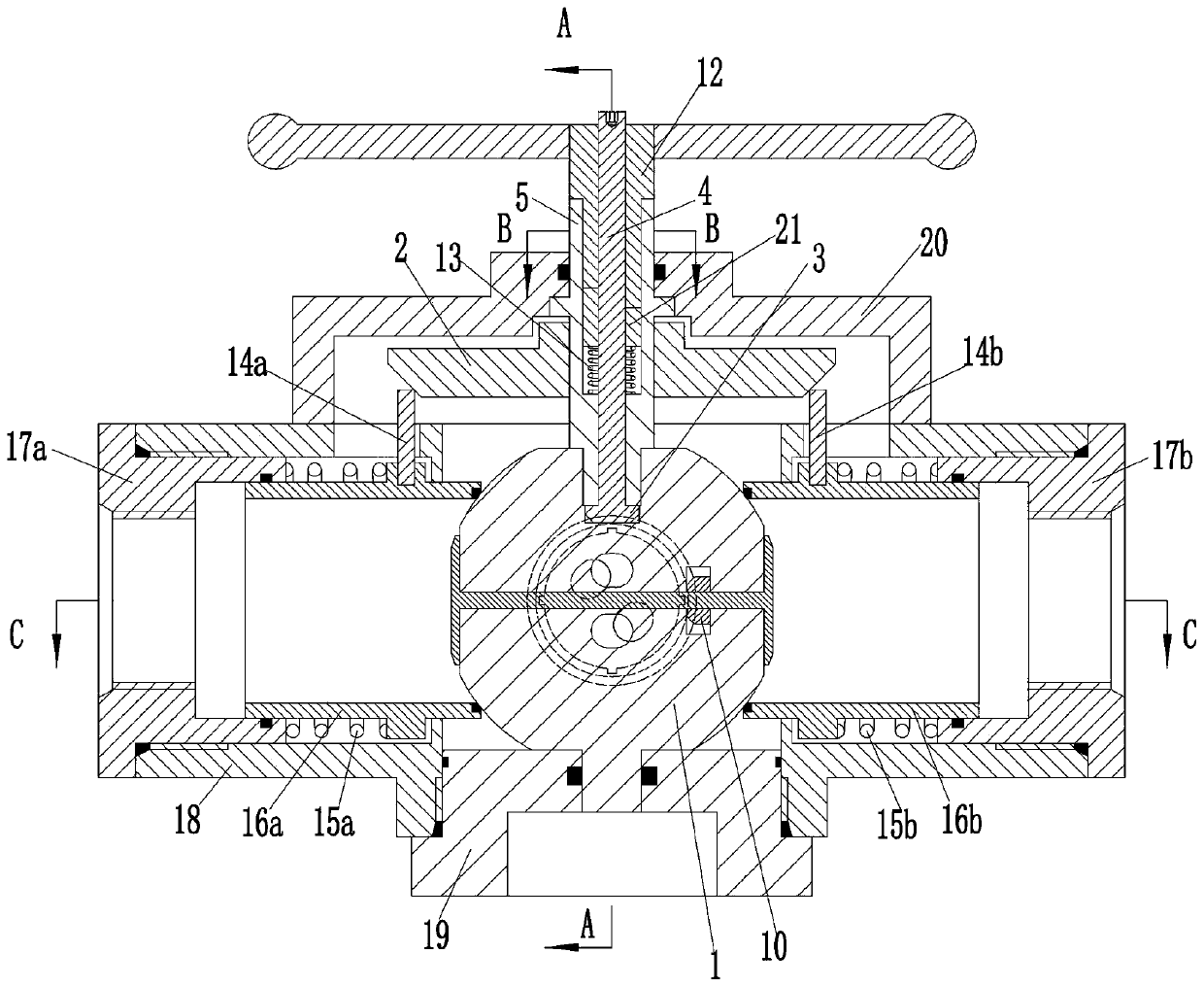

Metal hard seal ball valve

The invention discloses a metal hard seal ball valve, which comprises a valve body, a valve cover, a valve ball, valve seats, a valve rod, a bracket and a drive device, wherein the valve body and the valve cover are connected to form a cavity, the valve ball provided with a through hole is positioned in the cavity, the upper end of the valve ball is connected with the valve rod, two sides of the valve ball are provided with the valve seats respectively, the bracket is fixedly connected with the valve body through bolts, the drive device is connected with a valve rod shaft through the bracket, the valve seats are made of a metal material, and a sealing gasket, a pressure ring and a belleville spring are arranged between the valve base and the valve body in turn. The metal hard seal ball valve adopts a metal-metal dual sealing mode between the valve body and the valve seats, between the valve cover and the valve seats, and between the valve seats and the valve ball to greatly improve the sealability, and can be applied to a working condition at a temperature of more than 500 DEG C; besides, by spraying a hard alloy or a hardened material on the surfaces of the valve seats and the valve ball, the metal hard seal ball valve has necessary precision and hardness for sealing, and the specially manufactured elastic valve seats and the belleville spring have quite low operating torques.

Owner:KUSN WEISA VALVE

Tapered roller bearing and automotive pinion shaft supporting apparatus utilizing same tapered roller bearing

ActiveUS7874737B2Reduce operating torqueRolling viscous resistanceRolling contact bearingsShaftsSurface roughnessEngineering

A tapered roller bearing according to the invention is such that when an arithmetical mean roughness as a surface roughness of a large end face of a tapered roller is σ1 and an arithmetical mean roughness as a surface roughness of a large rib surface of an inner ring is σ2, σ1 is 0.04 μm or larger, anda composite roughness that is expressed by a square root of a sum of a squared value of σ1 and a squared value of σ2 is 0.17 μm or smaller. Raceway surfaces of an outer ring and the inner ring and a rolling contact surface of the tapered roller are crowned, and a total crowning amount is set to 50 μm or larger, an outer ring crowning rate is set to 40% or larger, and a roller crowning rate is set to 20% or smaller.

Owner:JTEKT CORP

Soft and hard double seal fixed ball valve

InactiveCN102278491AAvoid damageMeet the sealing requirements of "zero leakage"Plug valvesRubber materialEngineering

The invention discloses a soft and hard double-seal fixed ball valve, which comprises a valve body, a valve seat and a spherical valve core. It is made of metal, and the valve seat has a hard sealing surface. The hard sealing surface is the surface of the valve seat in contact with the spherical valve core. The shape of the hard sealing surface is consistent with the arc surface of the corresponding spherical valve core. The hard sealing surface is the same as the spherical valve core. The contact of the core constitutes the primary hard seal, and the first O-ring of rubber material is fixed on the valve seat, and the contact between the first O-ring and the spherical valve core forms the secondary soft seal. The hard double seal combination sealing structure makes the sealing performance of the ball valve more reliable and basically meets the "zero leakage" sealing requirement. The outer surface of the first O-ring made of rubber has a polytetrafluoroethylene layer, which not only ensures the elasticity and toughness of the sealing surface, It also reduces friction, improves wear resistance, and increases the opening and closing times of the ball valve to more than ten times.

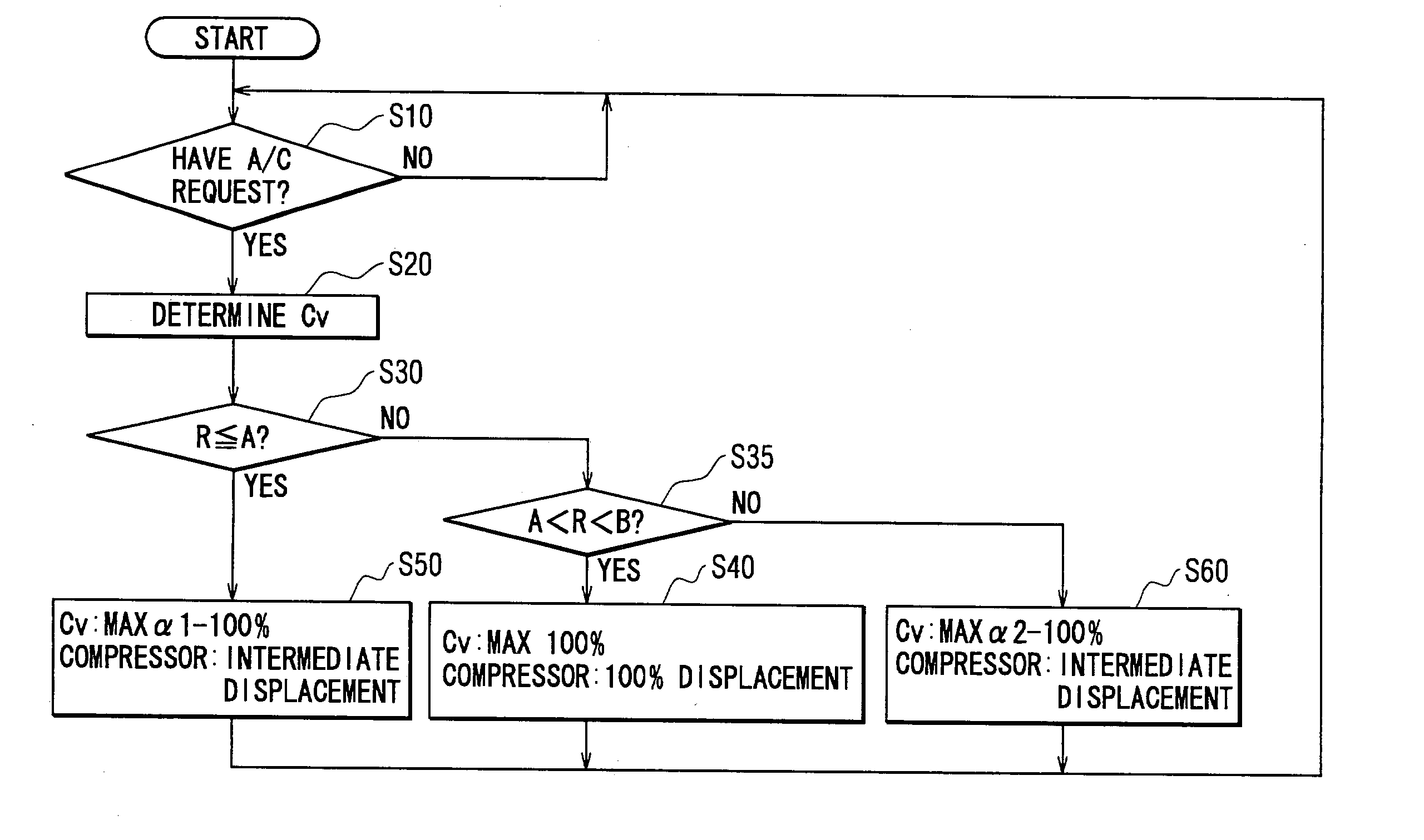

Compressor device and control method for the same

InactiveUS20030226368A1Reduce operating torquePreventing engine stallAir-treating devicesFluid parameterControl theoryControl unit

A compressor device for a refrigerant cycle includes a compressor and a control unit. The compressor is provided with a displacement changing mechanism for changing its displacement. The control unit changes a current value supplied to the displacement changing mechanism, thereby relatively changing the displacement of the compressor. In the compressor device, when a rotational speed of a vehicle engine is lower than a predetermined rotational speed, the control unit controls an upper limit of the current value between a first predetermined value and a maximum value. Accordingly, a displacement specification of the compressor device can be normalized for vehicle engines having different power outputs, while engine stall can be prevented.

Owner:DENSO CORP

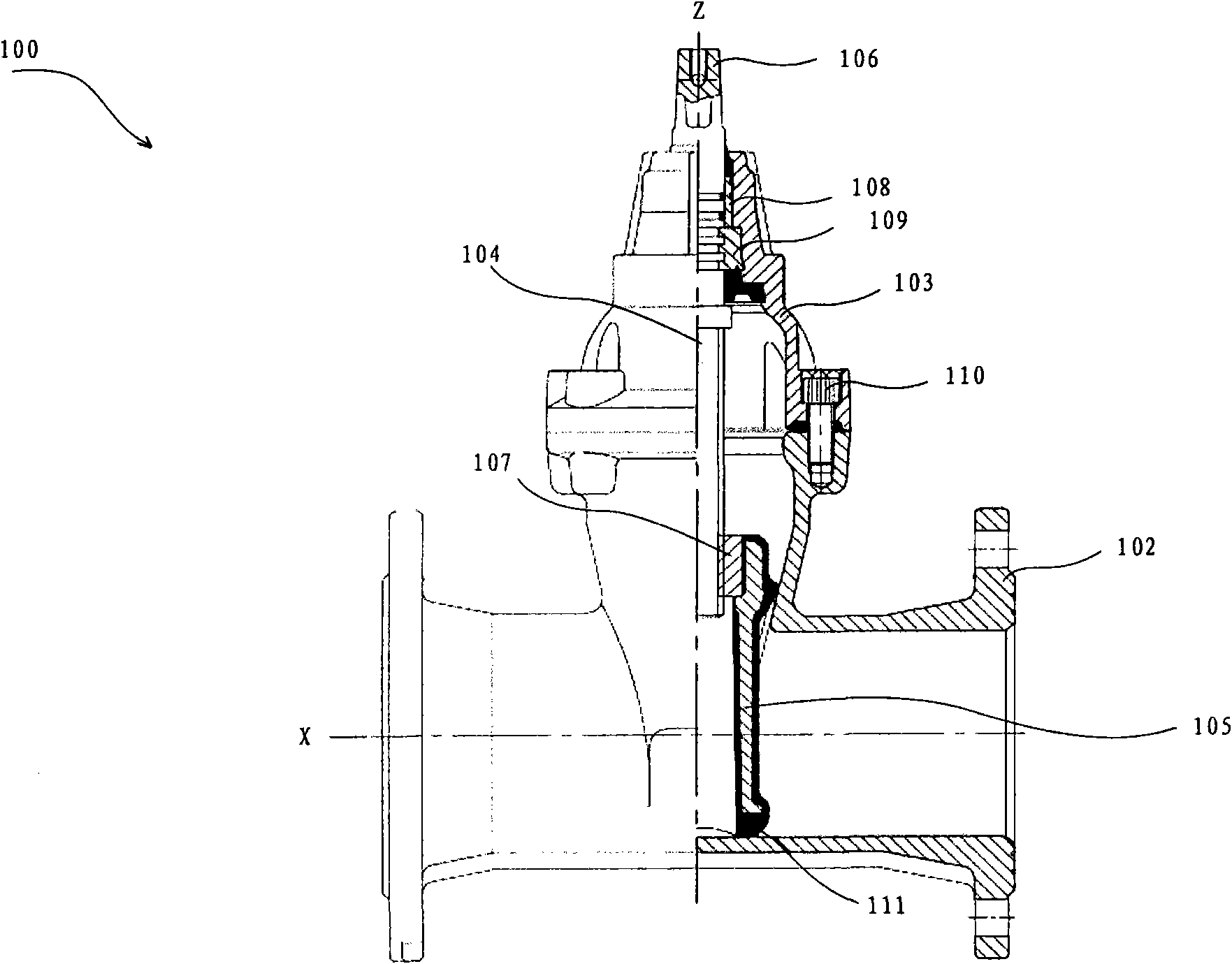

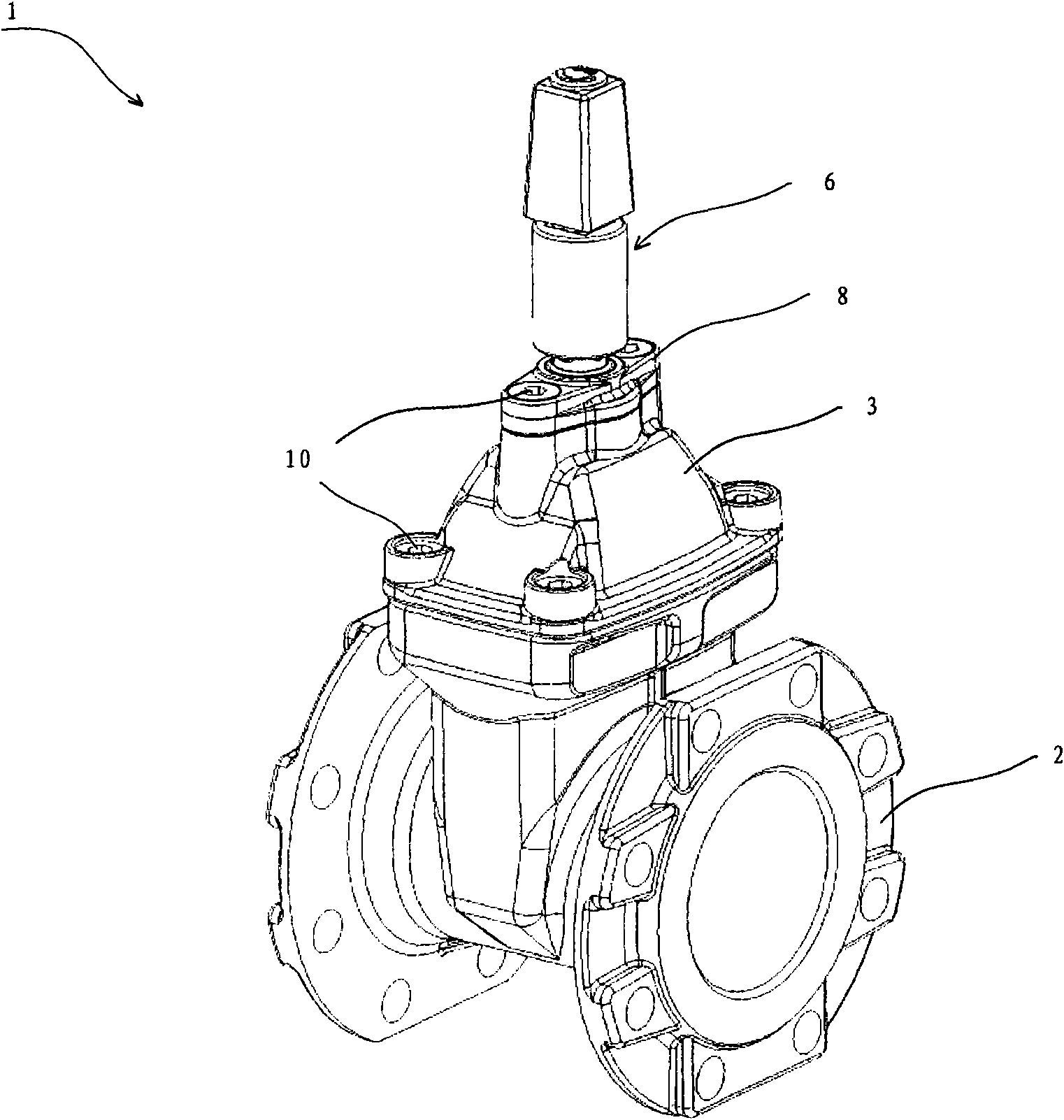

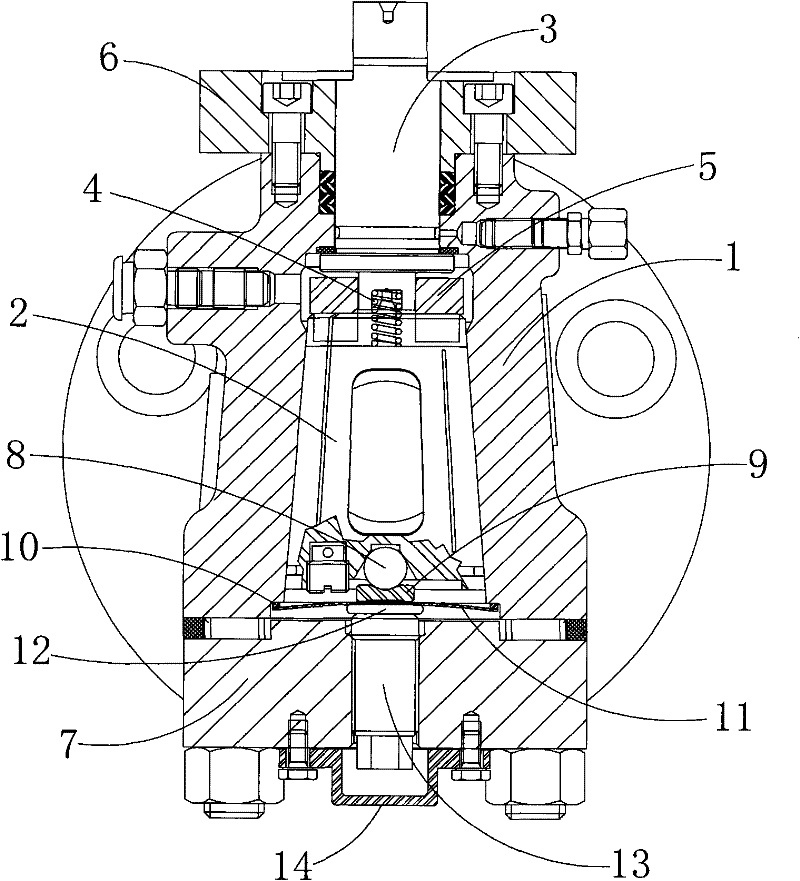

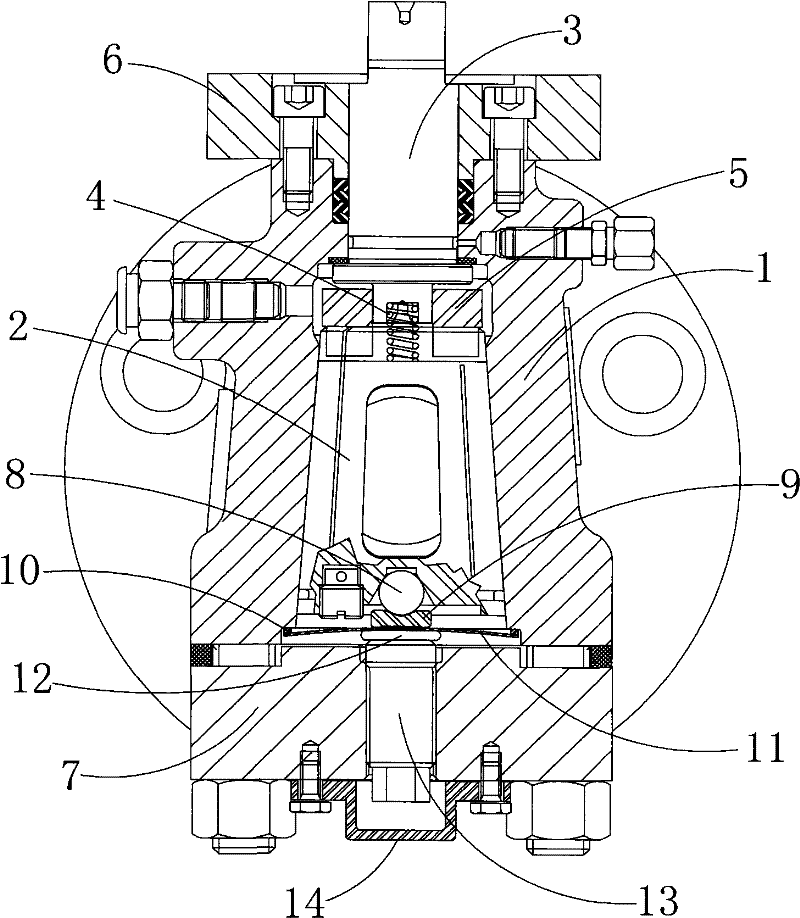

Non-rising stem gate valve

InactiveCN102109044AReduce operating torqueExtend your lifeSpindle sealingsOperating means/releasing devices for valvesEngineeringValve stem

The invention provides a non-rising stem gate valve. The gate valve comprises a valve body, and a valve cover, a valve stem, a valve flap and a transmission device which are connected to the valve body, wherein the upper end of the valve stem is connected with the transmission device, and the lower end of the valve stem is connected with the valve flap; and the valve stem is relatively rotatably supported on the valve cover through a rolling bearing. The gate valve comprises an ultra-large torque safe transmission device which can effectively protect parts in the valve when operating torque is overlarge; a guide shoe is used for accurately positioning the valve flap in the rubber coating process, and rubber coating thickness is uniform; and the gate valve has small operating torque and long service life, and is reliably sealed and easy to assemble.

Owner:PENTAIR SHANGHAI PIPELINE

Spring Balanced Plug Valve

InactiveCN102278495AReduce operating torqueAdjust the force at the right timePlug valvesValve housingsPlug valveValve stem

The invention discloses a spring balanced cock valve, which comprises a valve body, a cock and a valve stem. The cock is an upside-down tapered valve plug. There is an elastic part, the upper end of the elastic part elastically touches the lower end of the valve stem, and the lower end of the elastic part elastically touches the upper end of the cock, the elastic part is in a compressed state, and the upward force of the elastic part pushes the valve stem to the valve body, so that the stepped surface of the valve stem and the thrust pad Close contact, so as to play a good sealing effect; the downward force of the elastic member pushes the cock down, so that when the sealing surface of the cock and the valve body are closely matched with each other, there is a certain small gap, so that the sealing Grease enters the gap to play a good sealing role, and at the same time, reduces the operating torque of the valve, and the elastic member timely adjusts the force on the valve stem and cock to achieve dynamic balance and avoid the occurrence of jamming.

Owner:WOTAI VALVE KUSN

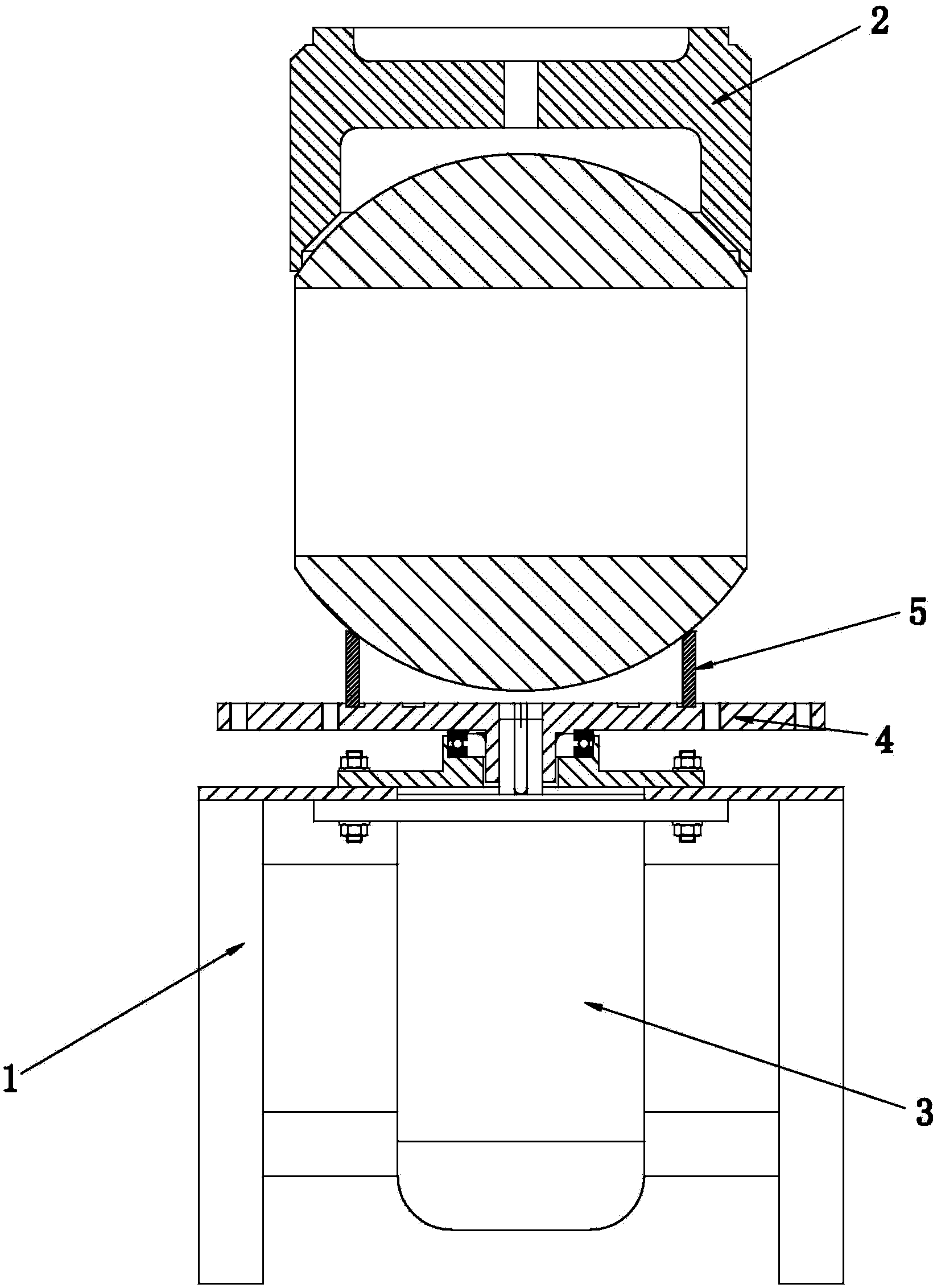

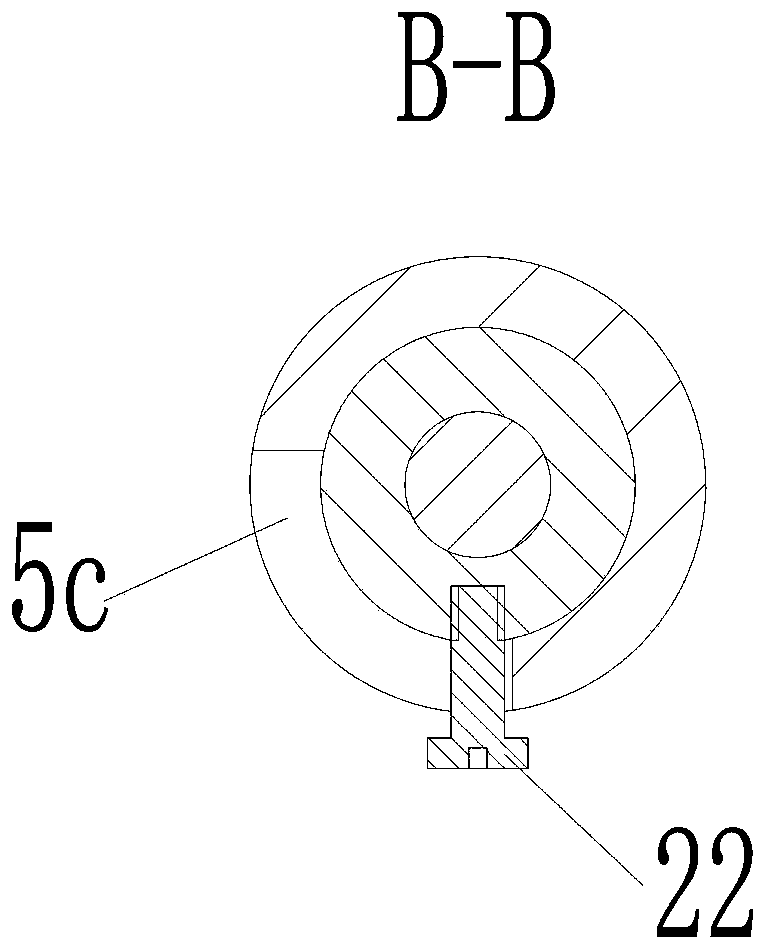

Wheel supporting rolling bearing unit

InactiveUS7287909B2Running torque can be sufficientlyReduce operating torqueHubsBall bearingsRolling resistance

Owner:NSK LTD

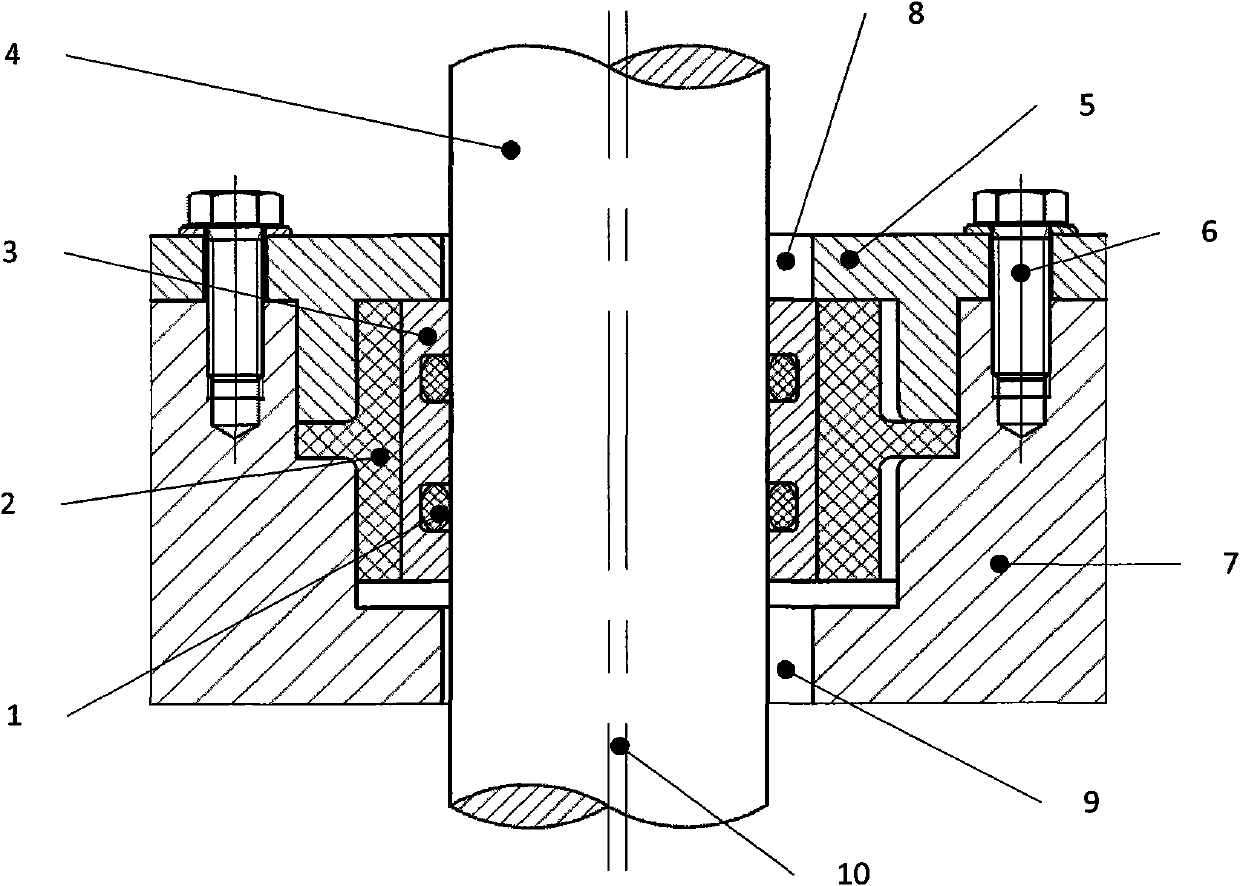

Floating shaft lever sealing structure

InactiveCN102022540AReduce operating torqueFree from routine maintenanceEngine sealsEngineeringMechanical engineering

Owner:SHANGHAI KARON VALVES MACHINERY +1

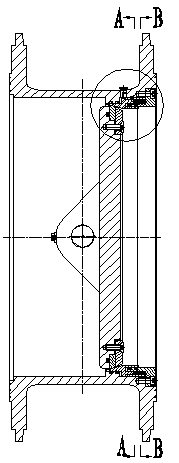

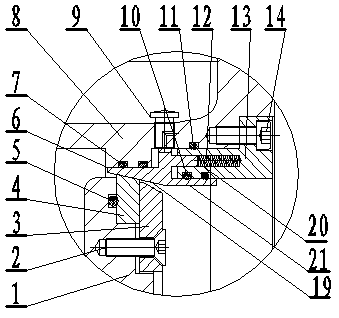

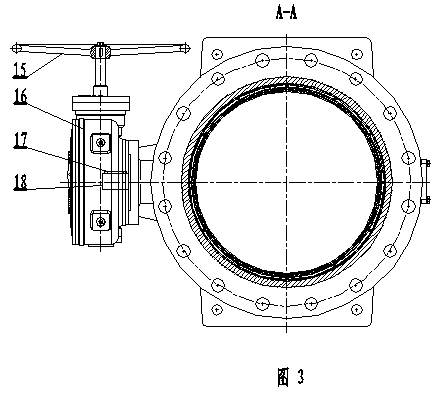

Two-way hard sealing butterfly valve with movable valve seat

The invention discloses a two-way hard sealing butterfly valve with a movable valve seat. The two-way hard sealing butterfly valve comprises a valve body, the valve seat, a butterfly plate, a hand wheel, a worm gear case, a key and a valve shaft. The butterfly plate is fixedly connected with a press plate through a press plate screw. A butterfly plate seal ring is arranged between the press plate and the butterfly plate. The valve seat is arranged between the butterfly plate seal ring and the valve body. The valve seat comprises a horizontally reversely extended clamping part and a support arm part. The matching part between the clamping part and the top of the butterfly plate seal ring is a slope. The support arm part comprises a first support arm and a second support arm, wherein the first support arm and the second support arm are arranged in parallel in a spaced mode. The inner side wall of the valve body is fixedly connected with a pressing sleeve which extends horizontally to the support arm part. The tail end of the pressing sleeve is provided with a groove. A compressed spring set which is arranged horizontally is arranged in the groove. The tail end of the first support arm is arranged in the groove in a matching mode and makes contact with the compressed spring set. The two-way hard sealing butterfly valve has the advantages that the valve seat is horizontally positioned at many positions, and therefore the valve seat will not tilt in the moving process; as a plurality of O-type rings are arranged, the compressed spring set operates in a clean environment, and service life is long; the compressed spring set composed of a plurality of compressed springs is adopted, so that production cost is lowered; an exhaust cap and the movable valve seat allow the operation torque of the butterfly plate to be low.

Owner:ANHUI TONGDU FLOW TECH

Valve

InactiveCN1654866ADifferential pressure decompressionReduce pressure differencePlug valvesOperating means/releasing devices for valvesEngineeringCam

This invention relates to a valve, which comprises main valve with upper and down holes, valve petal, valve bar and handle wheel fixed or electric device and assistant structure. It is characterized by the following: the said valve bar comprises main axis and assistant axis; the valve bar main axis is located with one bias wheel and one guiding valve with hole on one side of the assistant axis; the guiding valve is located with one guiding valve. Due to the guiding valve, the whole valve shall not contact with sealed ring during rotation process to avoid friction force.

Owner:金庆明

Double row ball bearing and differential gear device

InactiveUS7909515B2Low-torque designLower contact angleShaftsBall bearingsBall bearingStructural engineering

Owner:JTEKT CORP

Self-sealing gate valve structure

ActiveCN105065700ANo stuck phenomenonWith sealing compensation performanceOperating means/releasing devices for valvesSlide valveGate valveValve seat

The invention relates to the technical field of valves, and discloses a self-sealing gate valve structure. The self-sealing gate valve structure comprises a valve body, a valve cavity and a valve rod, wherein a left valve seat and a right valve seat which are coaxial are arranged at the inner ends of a left passage and a right passage respectively; a gate seat fixed with the valve rod is arranged between the left valve seat and the right valve seat; a left gate and a right gate are respectively arranged on the two sides of the gate seat; the inner end of the left gate extends to form an outer connecting sleeve; the inner end of the right gate extends to form an inner connecting sleeve; the inner connecting sleeve and the outer connecting sleeve are connected in a sliding manner; the outer connecting sleeve is in clearance fit with a connection hole in the gate seat; and a closed liquid storage cavity is formed between the inner connecting sleeve and the outer connecting sleeve and filled with oil. The self-sealing gate valve structure has the benefits of being good in sealing effect, small in operation torque and anti-locking.

Owner:OUQIU VALVE CO LTD

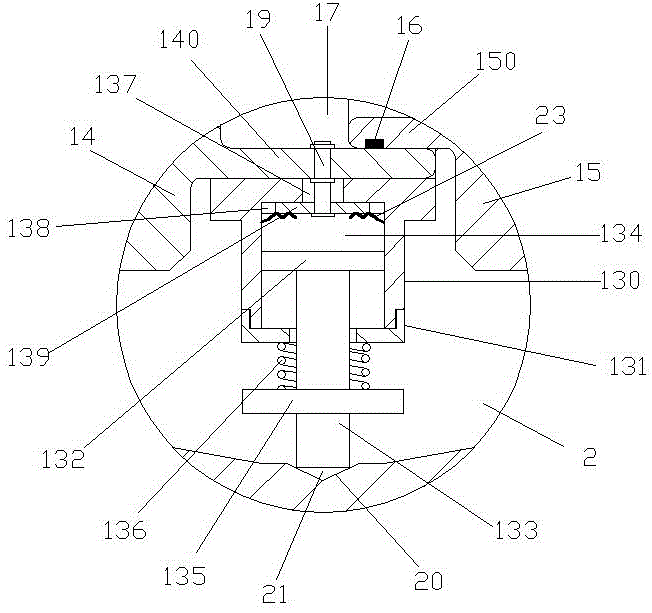

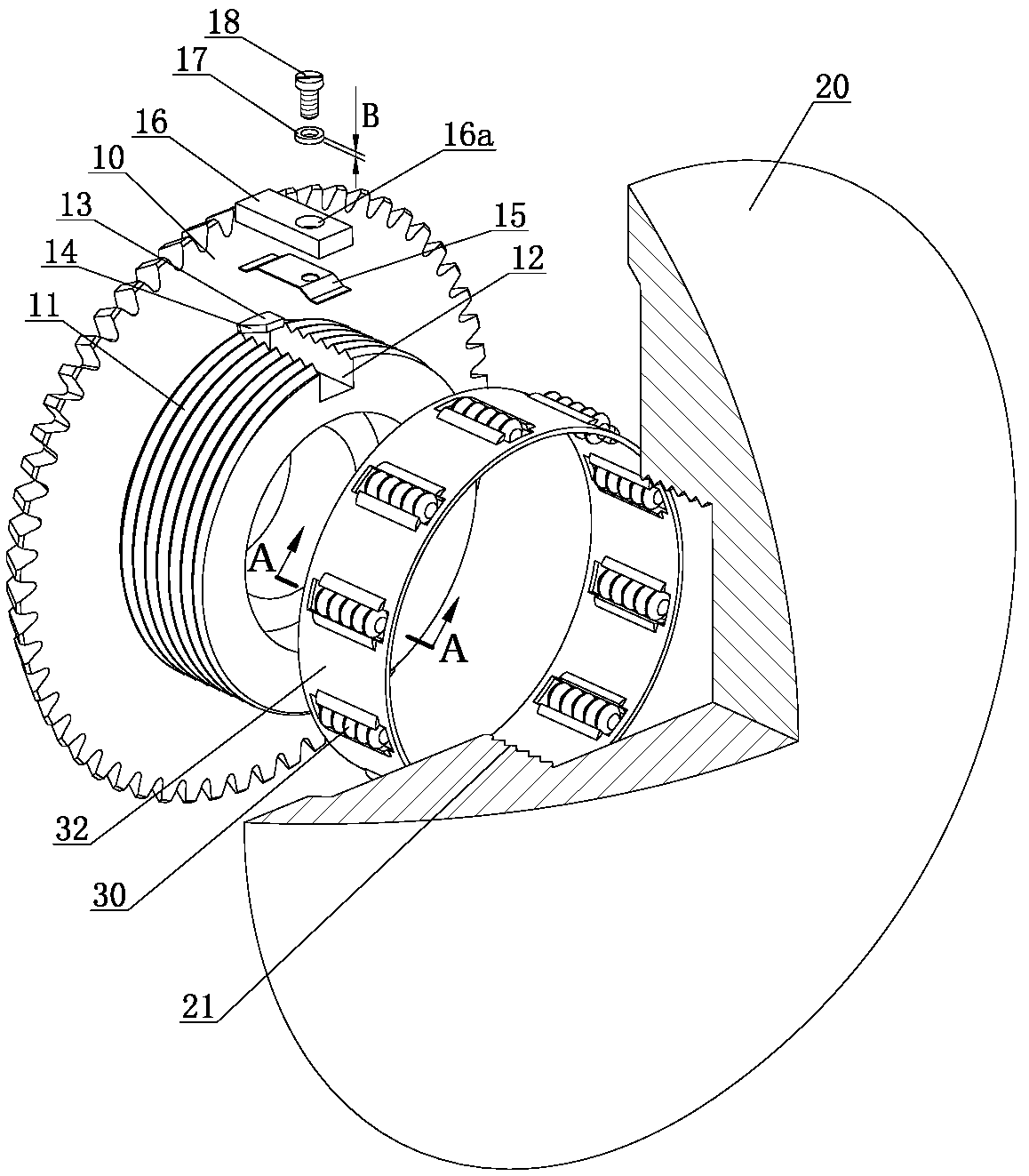

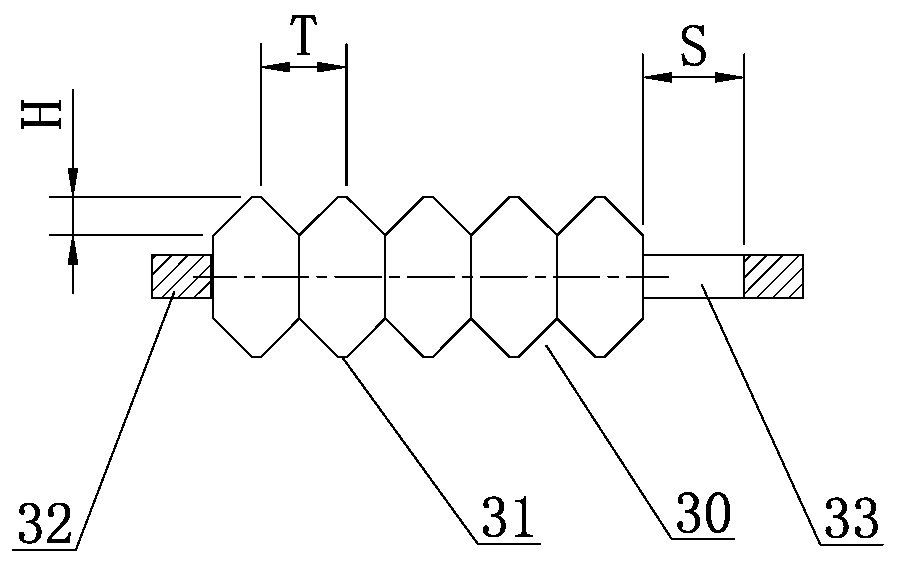

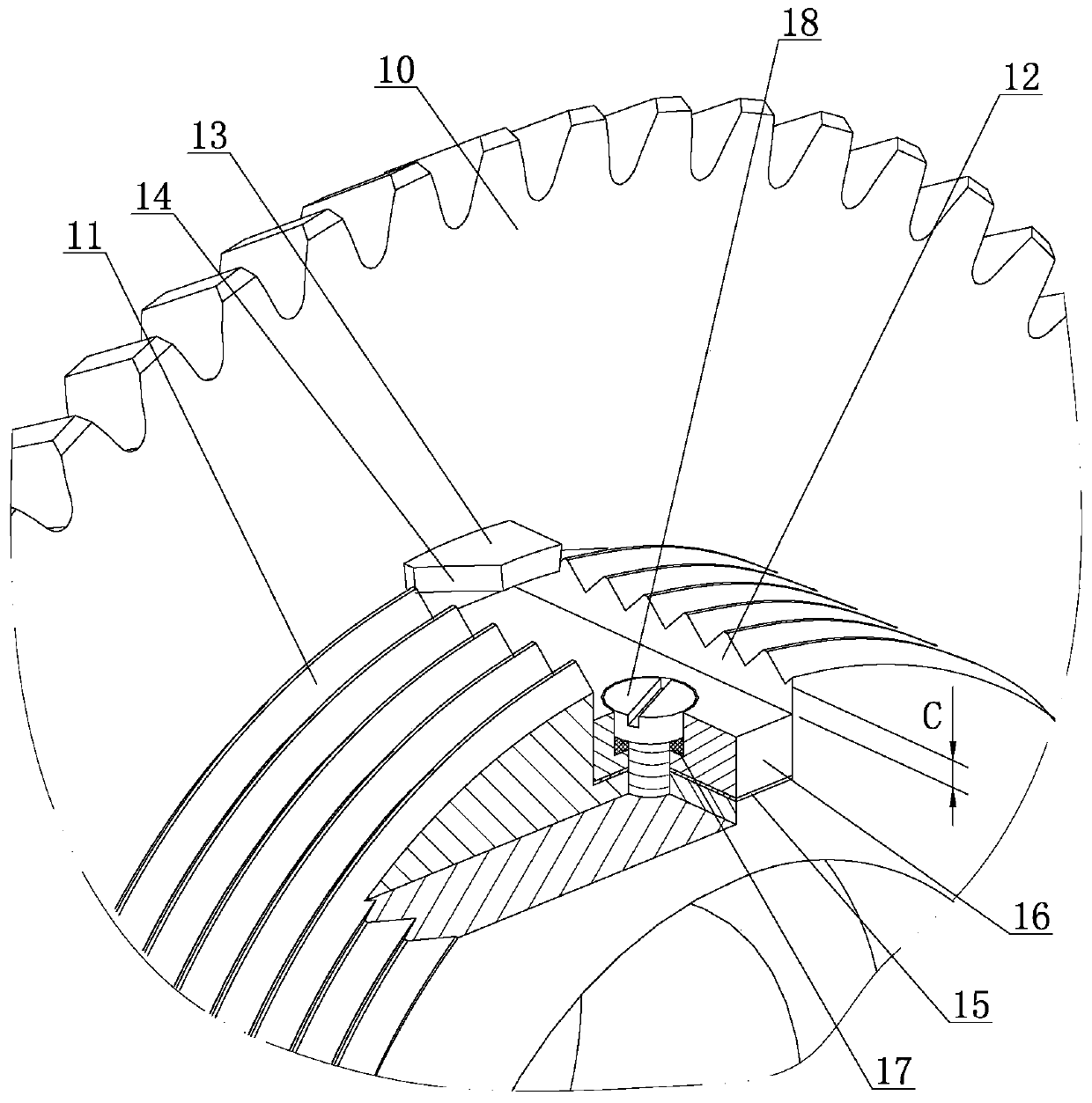

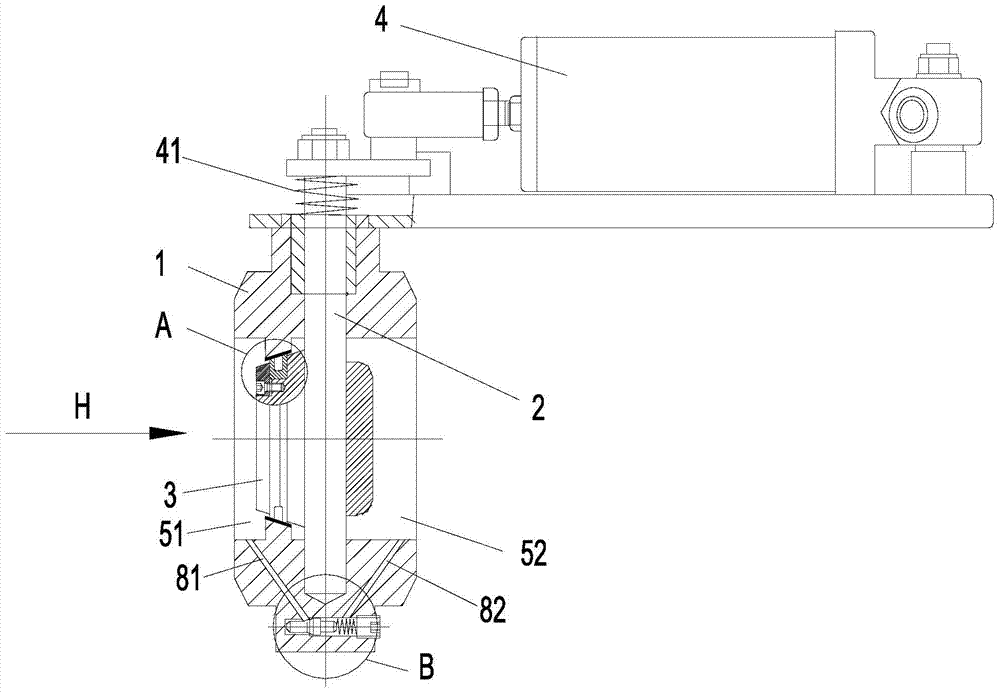

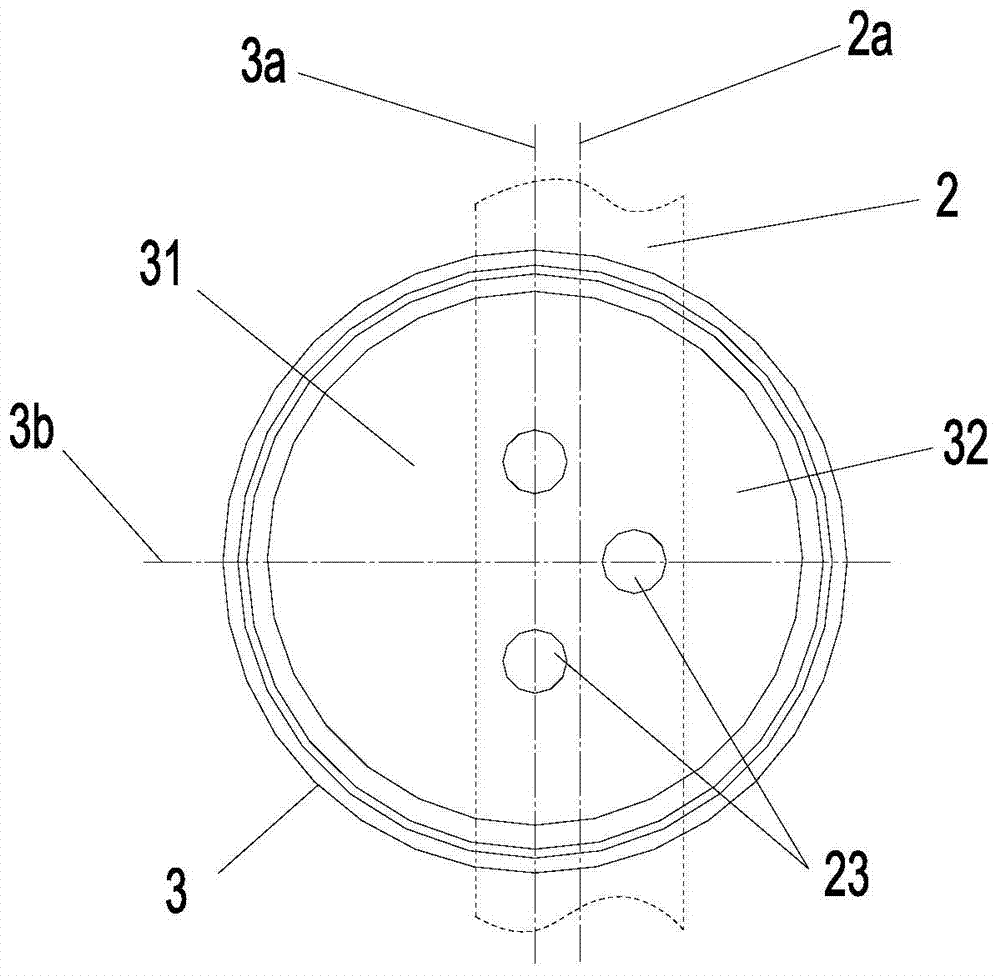

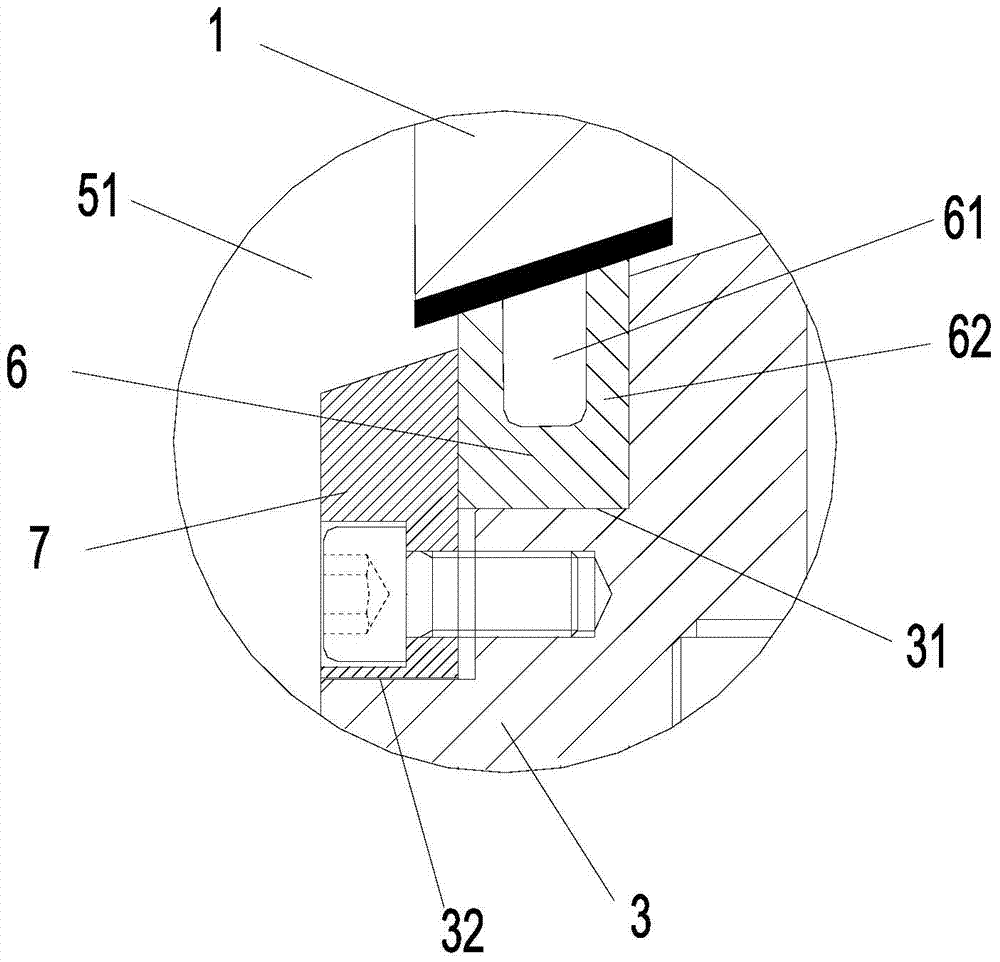

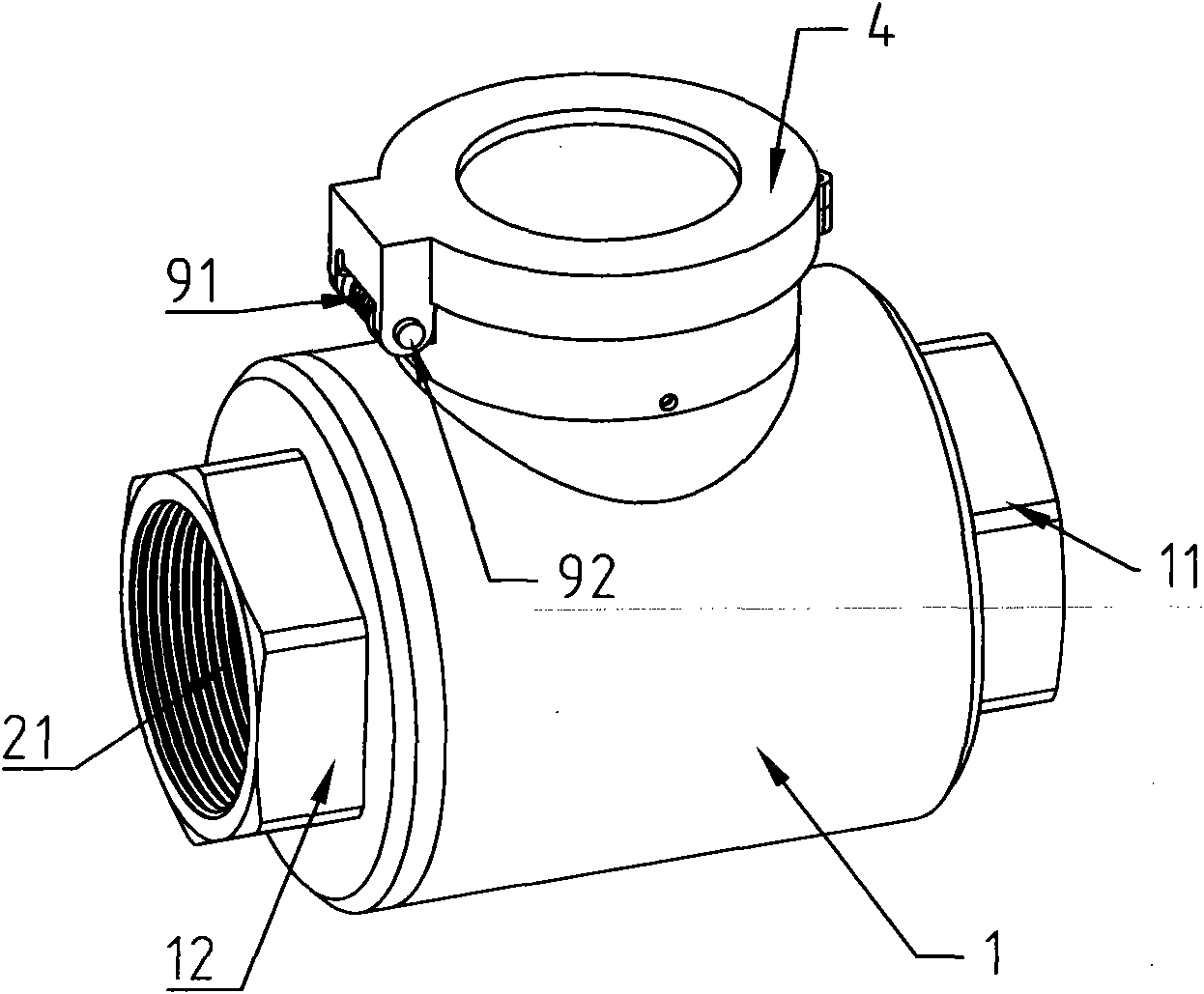

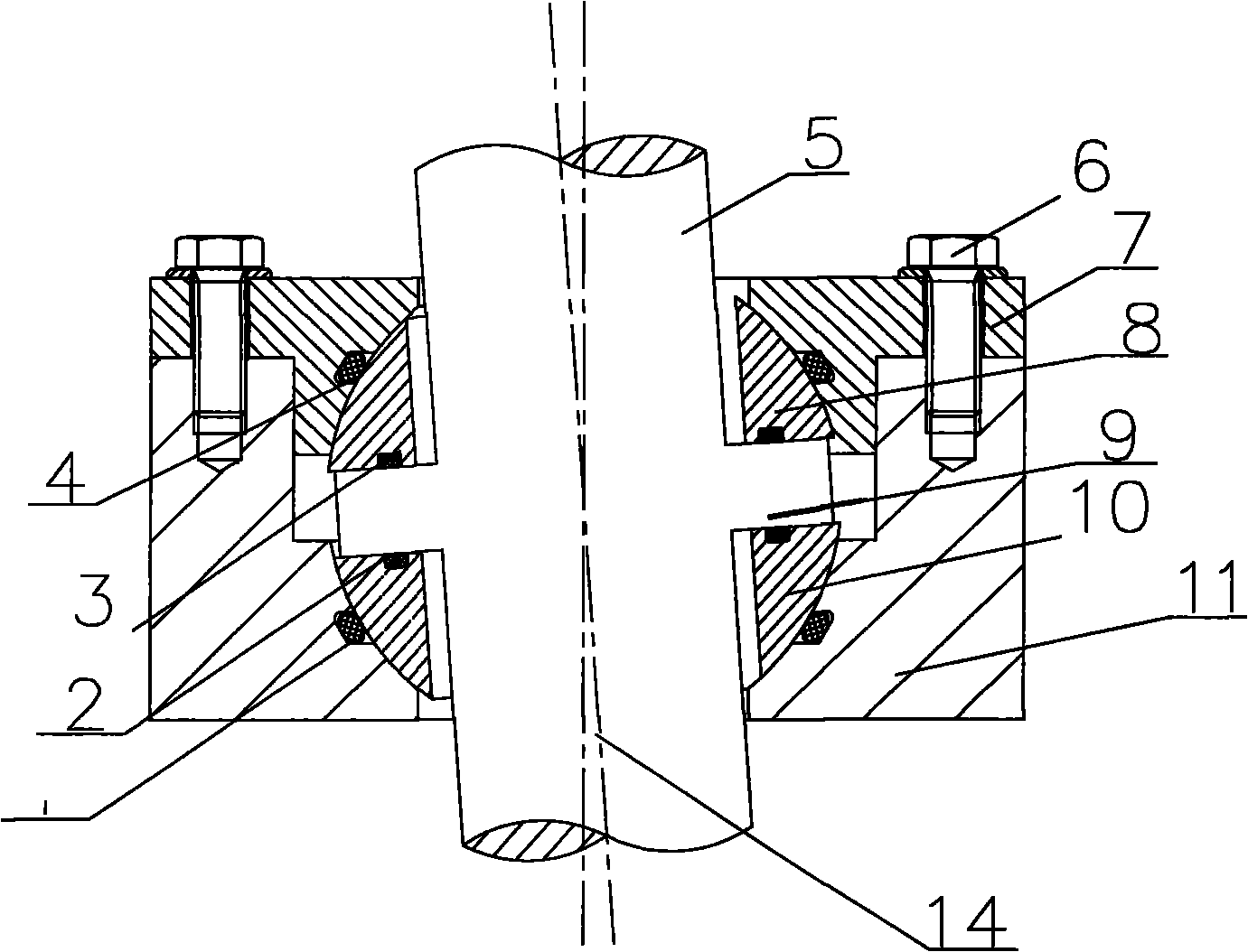

Planet pin roller spiral device, manufacturing method and forced seal ball valve

The invention relates to a planet pin roller spiral device, a manufacturing method and a forced seal ball valve. The planet pin roller spiral device comprises a stud component provided with a stud anda screw hole component provided with a screw hole. A plurality of planet pin rollers are arranged between the stud and the screw hole and arranged between the stud and the screw hole through a retainer. A thread rail replacing groove is formed in the stud in the axial direction, and a top protrusion is arranged at the end of the thread rail replacing groove. An assembling method comprises the steps that a filling-in block is pressed on a leaf spring through a fastening screw via a hot melting gasket, and the leaf spring is compressed towards the bottom face of the thread rail replacing groove; and after the screw hole component is screwed in place, the thread rail replacing groove and the top protrusion part of the stud component are heated, and the filling-in block is elevated under theaction of the leaf spring. The planet pin roller spiral device, the manufacturing method and the forced seal ball valve have the beneficial effects that the friction force in the thread drive processcan be obviously reduced, the operation torque during valve opening and closing is reduced, and the working life of the forced seal ball valve is prolonged.

Owner:ZIBO VOTAISI PETROCHEM EQUIP CO LTD

Exhaust butterfly valve for auxiliary braking of automobile

ActiveCN103615326AReduce operating torqueReduce energy lossEngine controllersMachines/enginesDifferential pressureExhaust brake

The invention discloses an exhaust butterfly valve for auxiliary braking of an automobile. The exhaust butterfly valve for auxiliary braking of the automobile comprises a valve body, a valve rod, a valve plate and a power mechanism, wherein the valve plate is fixedly arranged in an inner cavity of the valve body through the valve rod, the valve plate is connected with the power mechanism, the power mechanism drives the valve plate to overturn in the inner cavity by using the valve rod as a rotary axis, when the valve plate is closed, the inner cavity is divided into a gas inlet cavity and an exhaust cavity by the valve plate, the valve plate is in bilateral symmetry and longitudinal symmetry, the axis of the valve rod deviates from the bilateral symmetry axis of the valve plate so that one surface, facing the gas inlet cavity, of the valve plate can be divided into a pressure surface I and a pressure surface II by the longitudinal plane of the axis, and the pressure surface I and the pressure surface II are different in size. According to the exhaust butterfly valve for auxiliary braking of the automobile, due to the fact that the valve plate and the valve rod are eccentrically installed, the surface, facing the gas inlet cavity, of the valve plate is divided into the pressure surface I and the pressure surface II, the pressure surface I and the pressure surface II are different in size, reset force of the exhaust butterfly valve in the process of removing exhaust braking is increased through the pressure difference between the two pressure surfaces, operating torque can be reduced when the valve plate is open, the energy loss of an engine is reduced, flexibility of opening of the valve plate is ensured, and normal operation of the exhaust braking function of the engine is ensured.

Owner:DFSK MOTOR LTD CHONGQING BRANCH CO

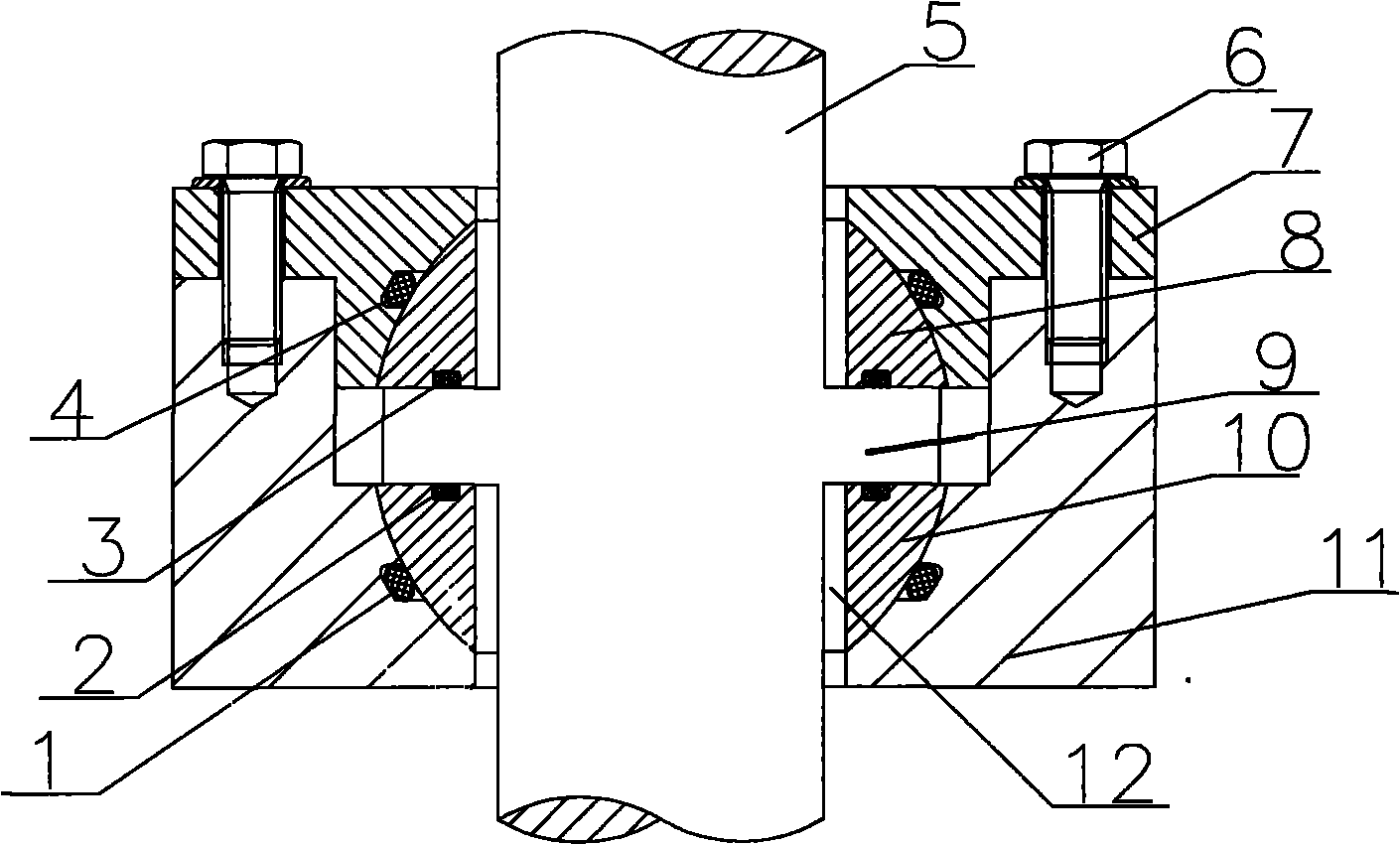

Low torsion moment ball valve for fuel gas vertical pipe

InactiveCN102155552AReduce frictionReduce operating torquePlug valvesOperating means/releasing devices for valvesSpecial designEngineering

The invention discloses a low torsion moment ball valve for a fuel gas vertical pipe, which is a ball valve with novel sealing structure; a valve body is connected by a screw thread so as to reduce the weight of the valve; a sealing ring is arranged in a sealing groove on the valve body so that the sealing ring does not fall off at any state, the reliability of the valve is ensured, the torsion of the valve opening and closing is reduced, simultaneously a slotting disk spring is used for providing the pre-pressure of the valve, and a specially designed sealing ring greatly reduces an operating torsion; and after the sealing ring is burned at high temperature, the slotting disk spring pushes a sphere so that the sphere is contacted with an auxiliary valve body so as to form a metal hard seal which avoids the internal leakage of the valve and has the fire prevention function. In addition, a special designed valve opening mechanism prevents the possibility of incorrect operations.

Owner:SUZHOU GAS EQUIP & VALVES MFG

Elastic sluice valve with wedge-shaped sealing face

The invention belongs to the valve technological area. In detail it is an elastic-seated sealing gate valve, comprising valve body, valve board, valve bar, valve cover, handle and fastener. O-shaped sealing ring, O-shaped sealing ring, thrust bearing, nylon ring and O-shaped sealing ring. On the valve core of valve board a rectangle hole is set, embedded by rectangle copper nut for connecting valve bar and valve board. Inner and outer of valve core of valve board are coated with rubber and the bottom of valve body is flat. The leakage phenomena is decreased widely in the invention meanwhile operation torque is decreased and reduced by adding thrust bearing and nylon ring. There is no groove at the bottom of the valve body so that the sundries are not filled up to hinder the valve door close. The connector between nut and valve board is designed in embedded style so that damaged parts is replaced expediently in repairing.

Owner:SHANGHAI FENGTONG VALVE MFG

Floating sealing structure of thrust shaft rod

InactiveCN102032345AWith pressure self-sealing effectReduce operating torqueEngine sealsEngineeringFlange

The invention relates to a floating sealing structure of a thrust shaft rod. The structure comprises a first sealing ring, a second sealing ring, a third sealing ring, a fourth sealing ring, a shaft rod, a bolt, gland, a first ball ring, a second ball ring and a valve cover, wherein the first ball ring and the second ball ring are central cylindrical holes; the bottom of the middle hole of the valve core is a spherical surface matched and connected with the spherical surface of the first ball ring; the upper part of the valve cover is provided with a cylindrical hole; the gland is disc-shaped, an upper flange of the gland is fixed on the valve core through the bolt, and the hollow bottom of the gland is a spherical surface matched and connected with the spherical surface of the second ball ring; and the shaft rod is a cylindrical rod, the middle of which is provided with a shaft shoulder, and the shaft shoulder of the shaft rod is clamped between the first ball ring and the second ball ring. Compared with the prior art, the floating sealing structure has the advantages of good sealing property, long service life and the like.

Owner:SHANGHAI KARON VALVES MACHINERY +1

Ball valve

PendingCN111442110AReduce frictionReduce wearPlug valvesOperating means/releasing devices for valvesLeft valvePhysics

The invention discloses a ball valve. The ball valve comprises a valve body; a channel and a mounting hole are formed in the valve body; an upper end cover is mounted at the upper end of the mountinghole of the valve body; a lower end cover is mounted at the lower end of the mounting hole of the valve body; the lower end cover is rotatably connected with a ball core; the upper end cover is rotatably connected with a valve rod; a mounting cavity is formed between the upper end and the lower end of the valve body; a pushing plate is mounted in the mounting cavity; a left valve seat component isarranged in the valve body; the left valve seat component comprises a left screw sleeve; the interior of the left valve seat component is in sliding connection with a left valve seat cylinder; a leftconvex shoulder is arranged on the outer side wall of the left valve seat cylinder; a left limiting groove is formed in the valve body; a left convex rod is fixedly mounted on the left convex shoulder; a left first spring is arranged between the left screw sleeve and the left convex shoulder; a first tangent plane is formed on the side surface of the ball core; a first shaft hole and a pressure relieving hole are formed in the ball core; the interior of the first shaft hole is rotatably connected with a shaft rod; a first rotating plate is arranged at one end of the shaft rod; the ball valveis not worn in opening and closing processes; and moreover, the torque is small when the ball valve is opened and closed.

Owner:陈少同

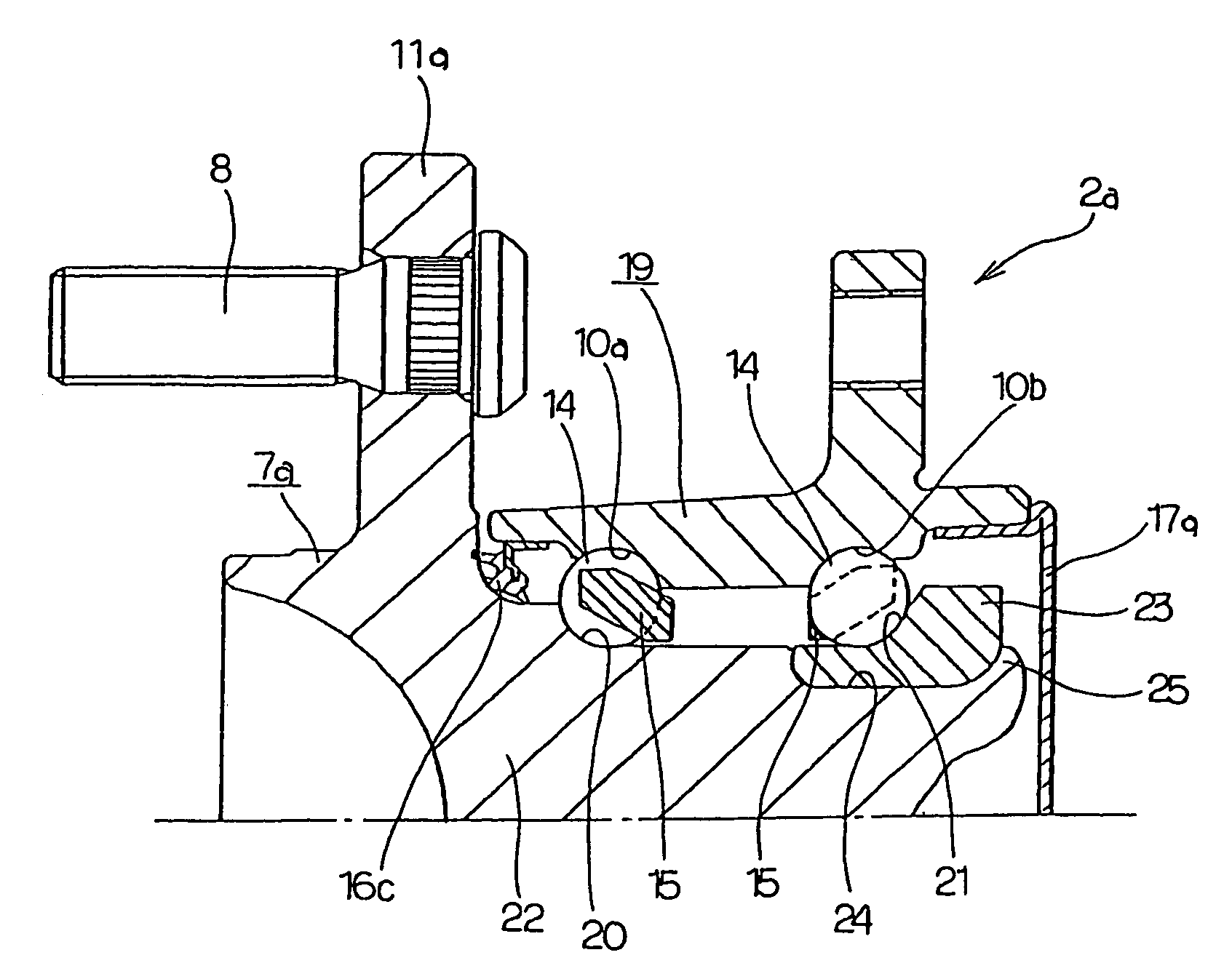

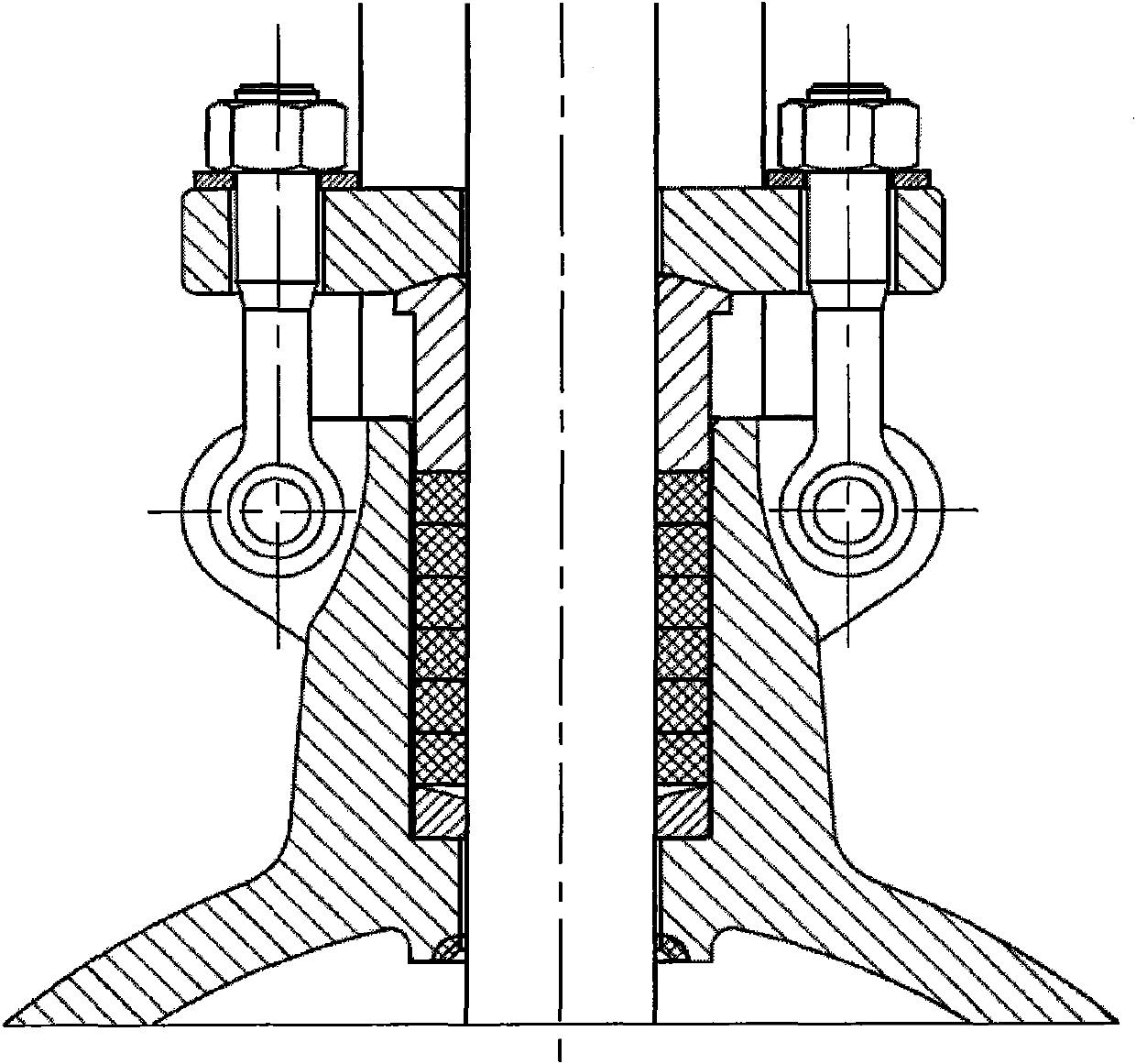

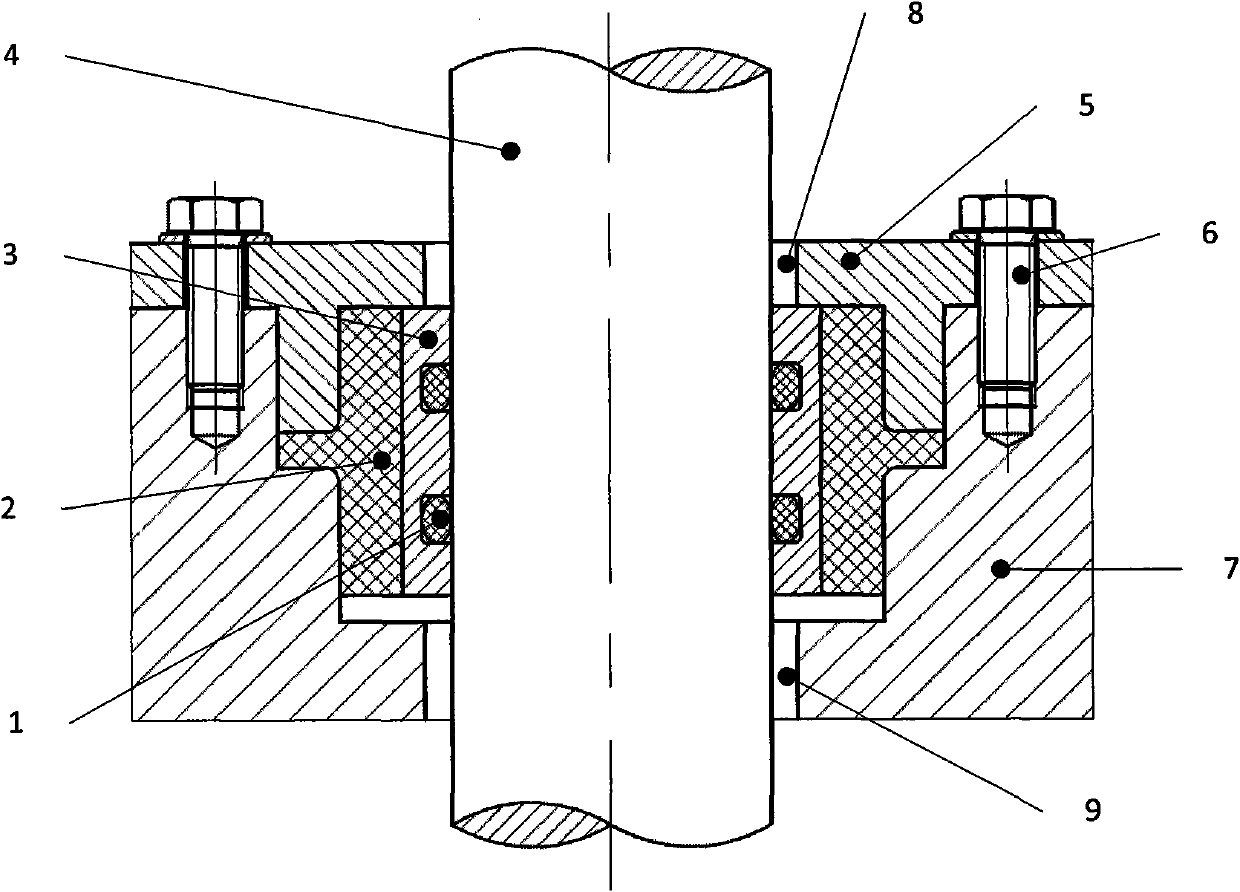

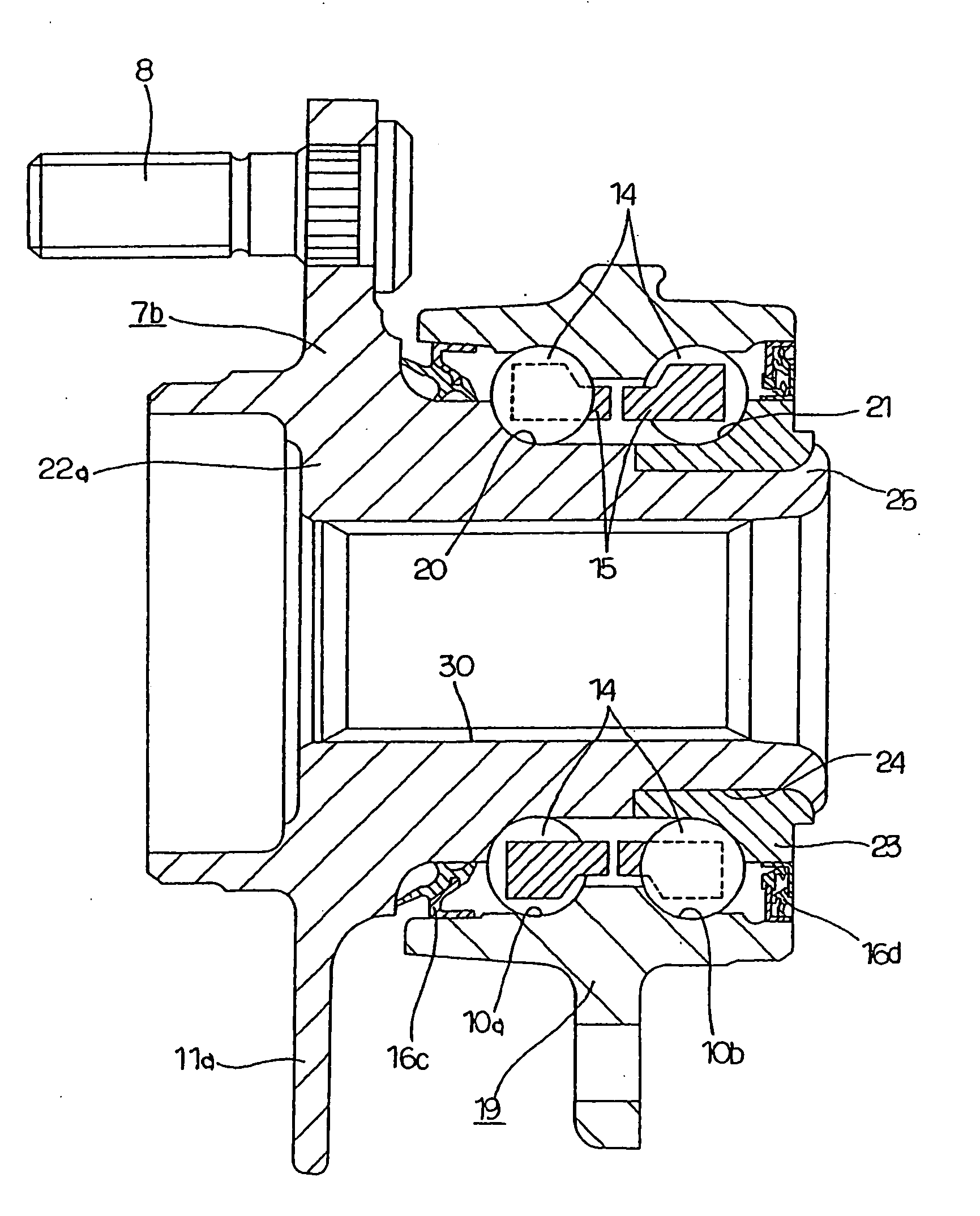

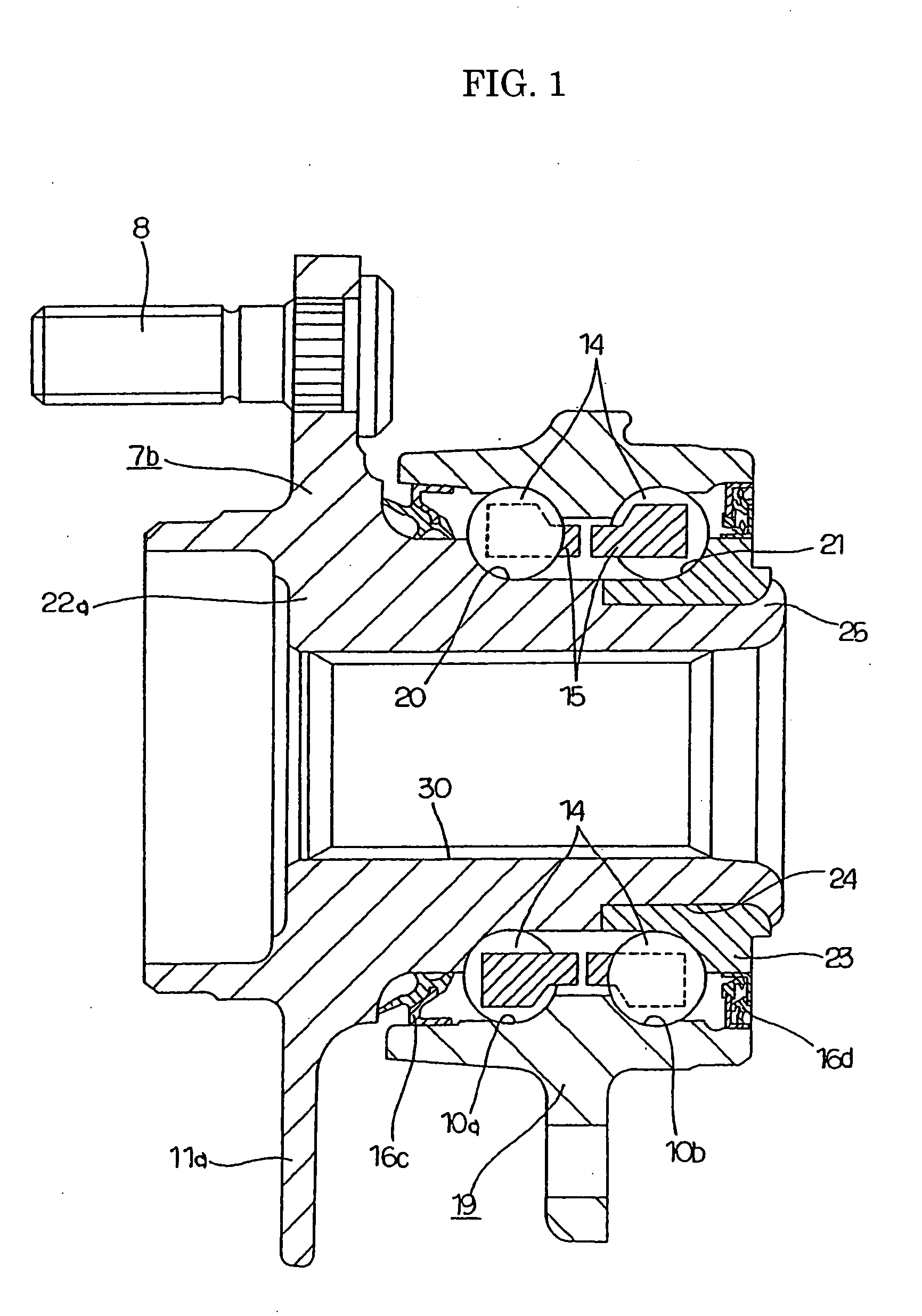

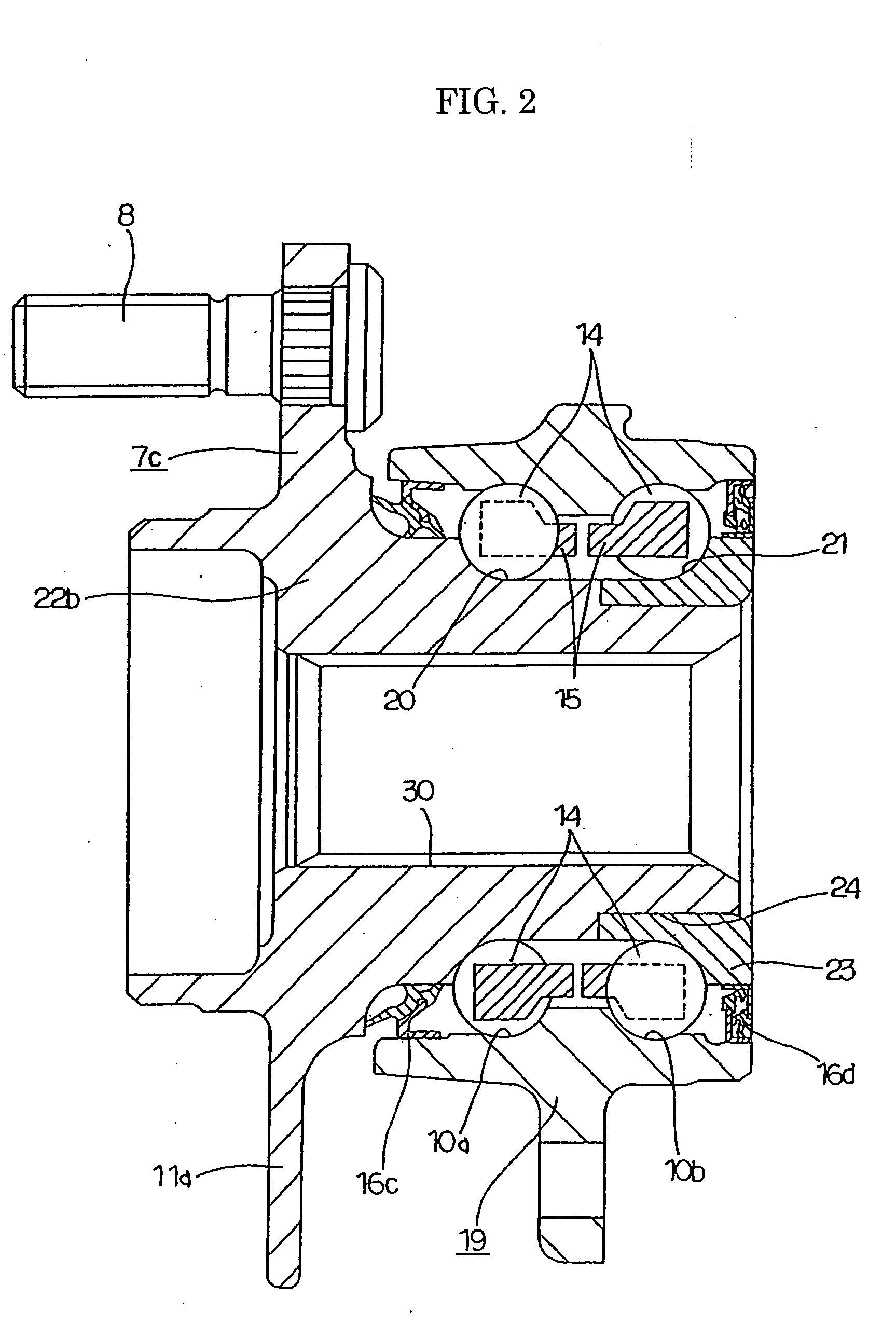

Rolling bearing unit for supporting wheel

InactiveUS20060165331A1Reduce operating torqueOverall controllabilityRolling contact bearingsHubsRolling resistanceEngineering

In a wheel supporting rolling bearing unit, both end openings of a space in which balls 14, 14 are provided are sealed with seal rings 16c, 16d each having two to three seal lips. A rolling resistance that changes based on a preload is regulated in a range of 0.15 to 0.45 N·m, and a total running resistance of both seal rings 16c, 16d based on a friction between the seal lips and counter surfaces is regulated in a range of 0.06 to 0.4 N·m.

Owner:NSK LTD

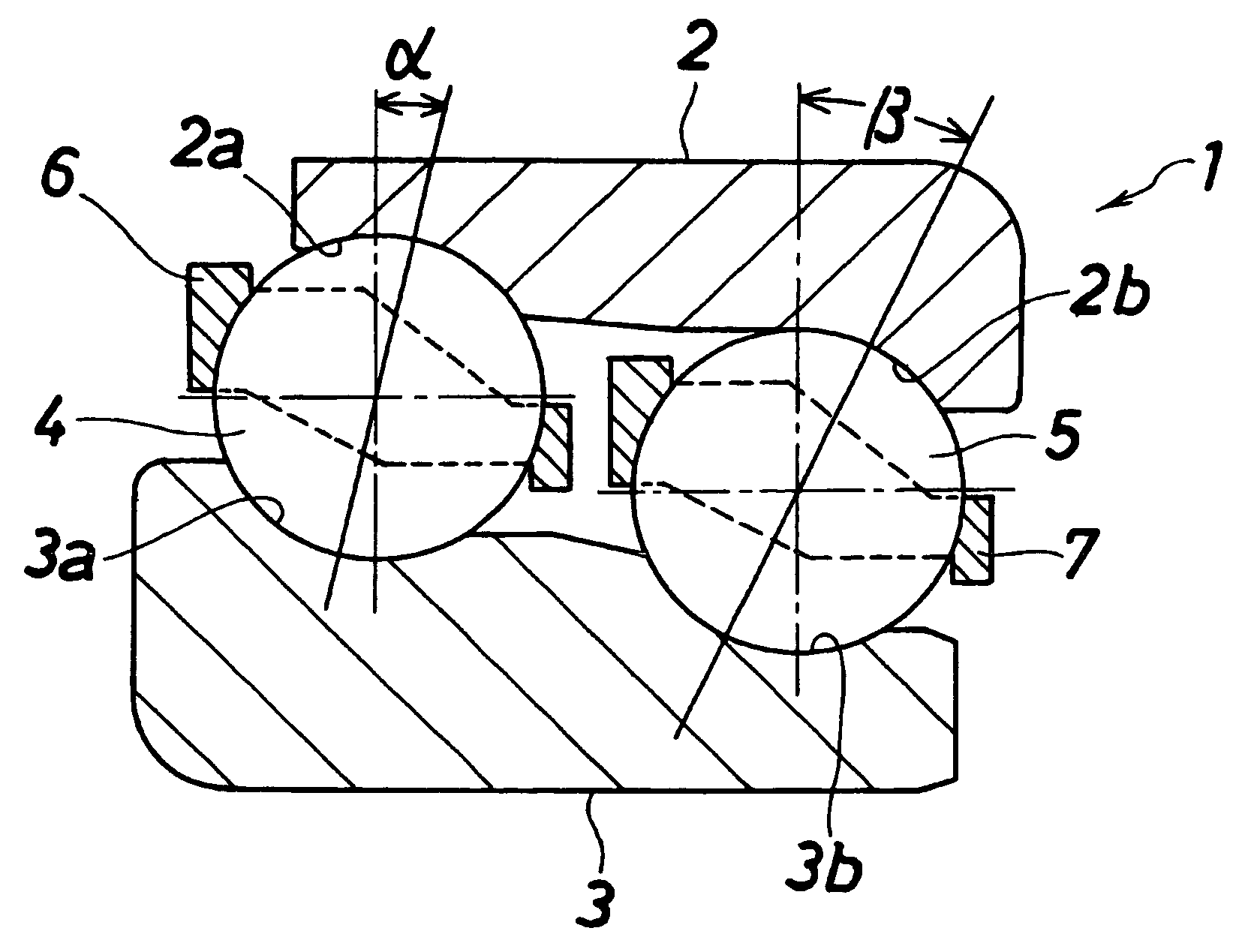

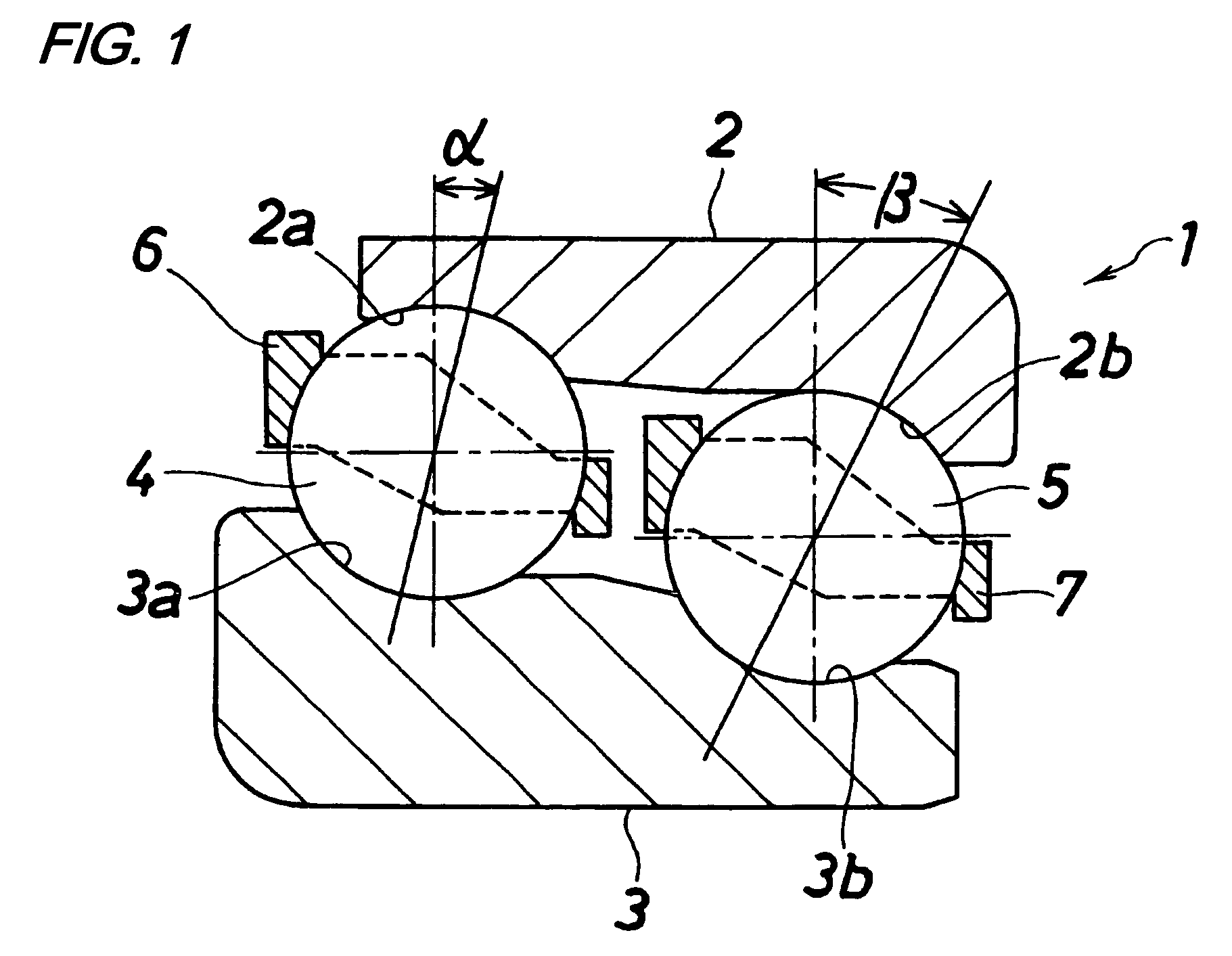

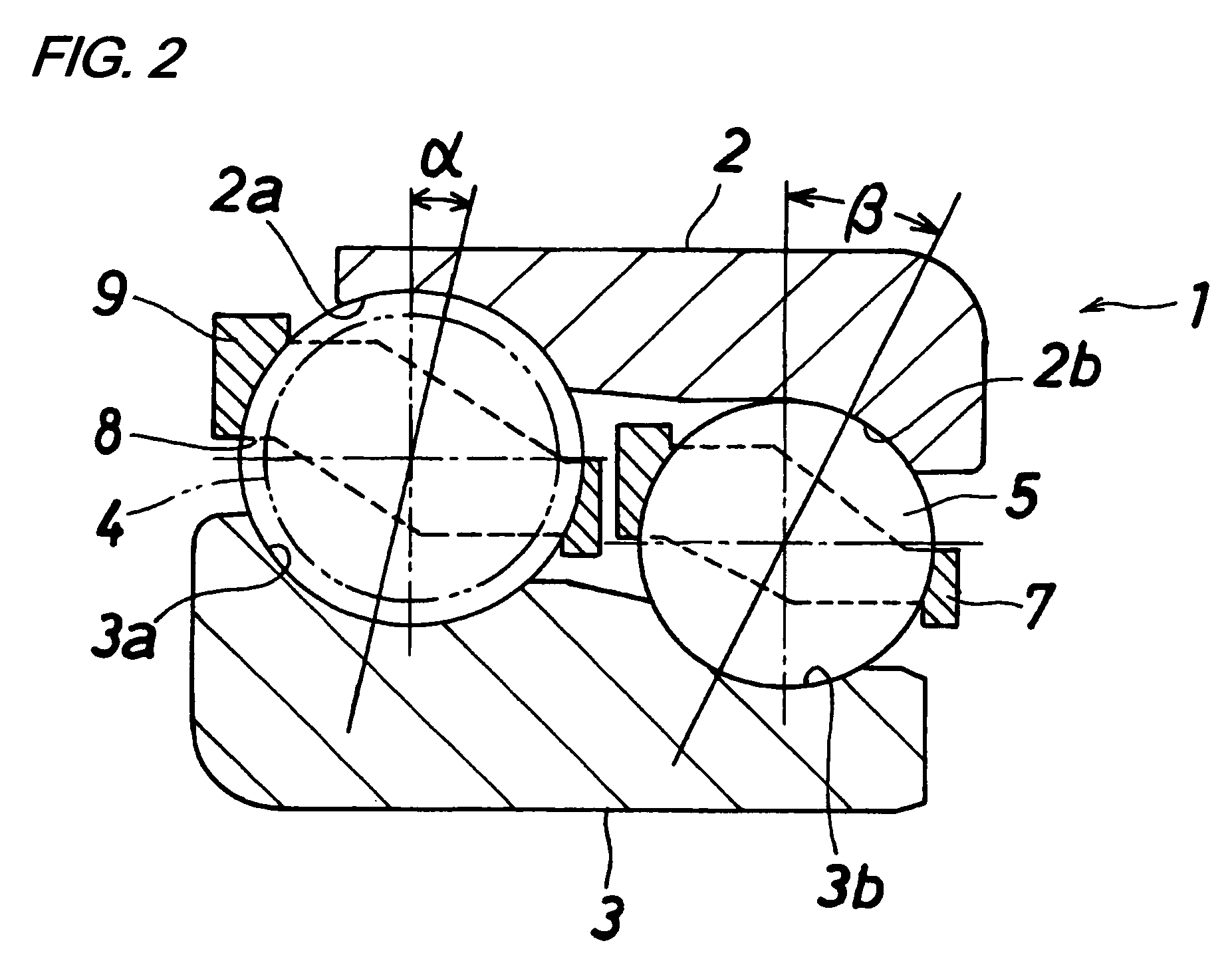

Double row ball bearing and differential gear device

InactiveUS20080240639A1Low-torque designLower contact angleRolling contact bearingsShaftsBall bearingStructural engineering

The difference between a revolution period of larger diameter-side balls and a revolution period of smaller diameter-side balls is smaller as compared with a conventional bearing. The relation, (β−10)≦α<β, is established, where α(°) represents a contact angle of the larger diameter-side ball, and β(°) represents a contact angle of the smaller diameter-side ball.

Owner:JTEKT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com