Exhaust butterfly valve for auxiliary braking of automobile

An exhaust butterfly valve and automobile auxiliary technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve problems such as difficult to increase reset force, unsmooth reset, reset failure, etc., to achieve high promotion and application value, reduce Effect of small operating torque and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

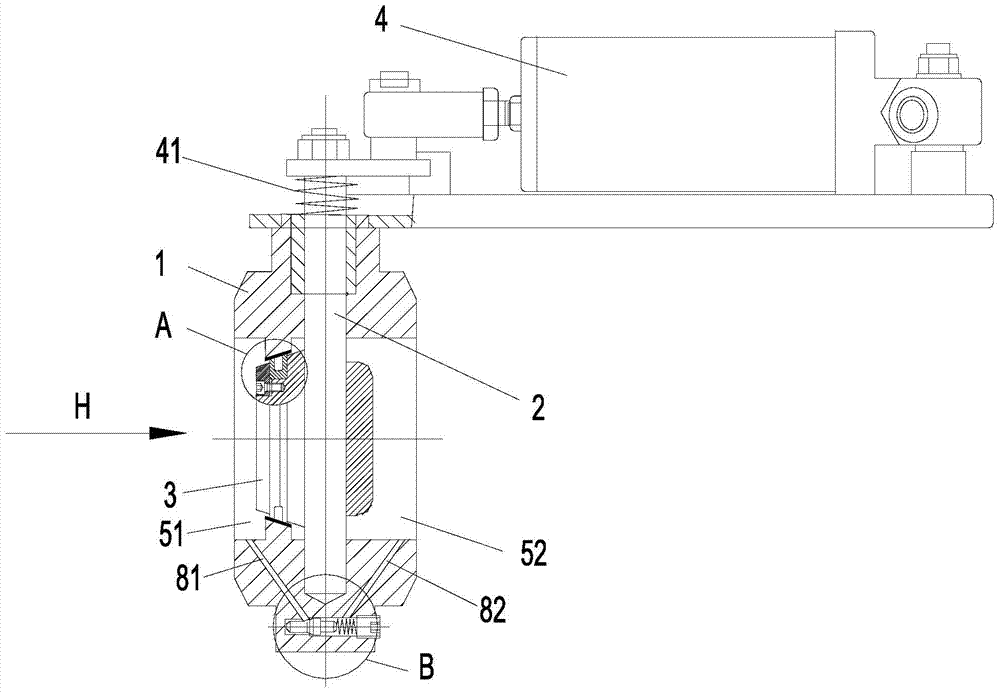

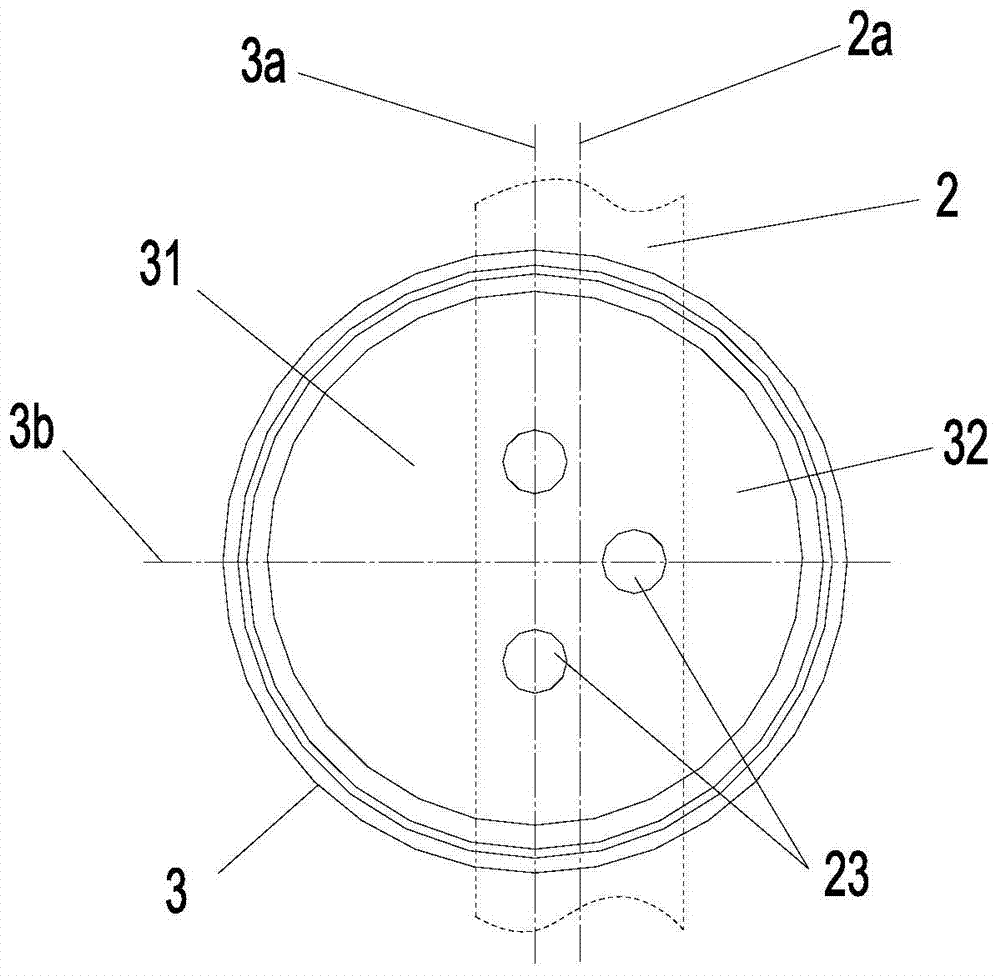

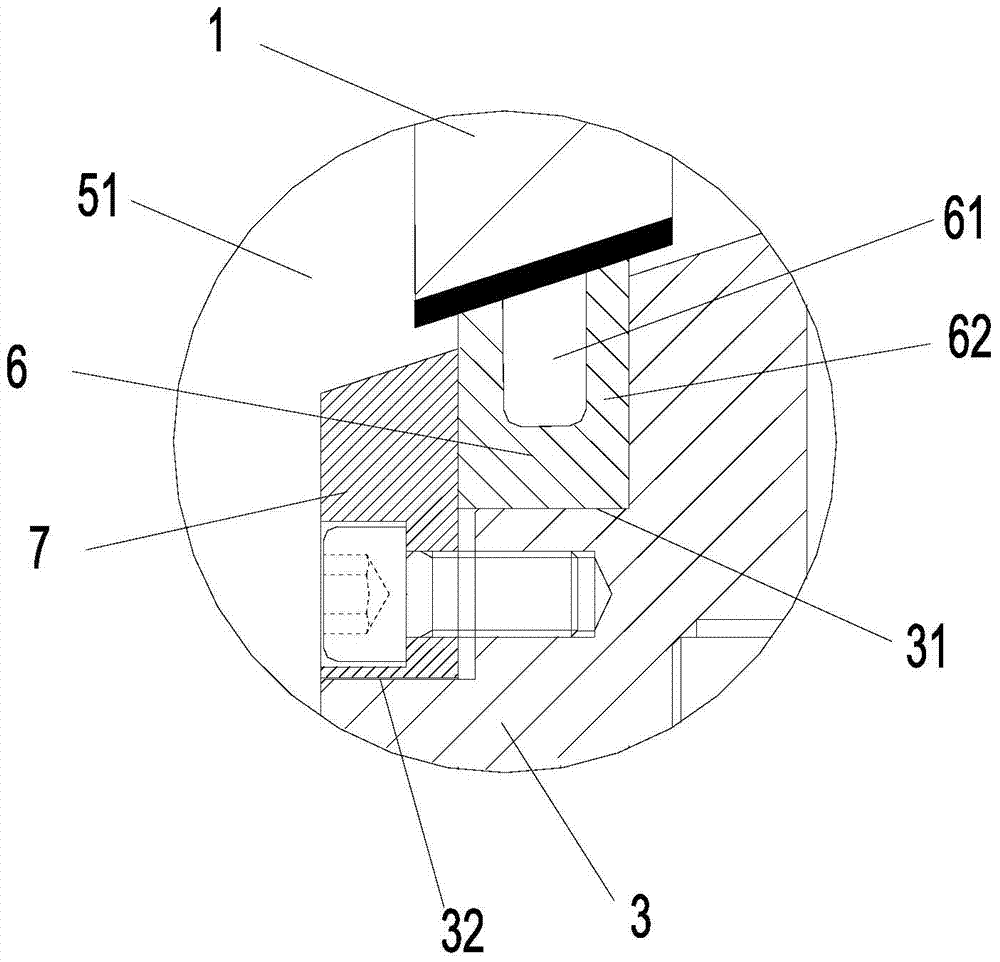

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 H direction view in, image 3 for figure 1 The magnified view at A in the middle, Figure 4 for figure 1 The enlarged view at the B place in the middle is as shown in the figure: the exhaust butterfly valve for automobile auxiliary braking in this embodiment includes a valve body 1, a valve stem 2, a valve plate 3 and a power mechanism 4, and when the valve plate 3 is closed, it will The inner cavity is divided into an air intake chamber 51 and an exhaust chamber 52, the valve plate 3 is connected with the power mechanism 4, and the power mechanism 4 drives the valve plate 3 to rotate on the valve stem 2 as a rotating shaft. When the valve plate 3 is closed, the inner cavity is divided into an air intake chamber 51 and an exhaust chamber 52. The valve plate 3 is left-right and up-down symmetrical, and the axis 2a of the valve stem 2 deviates from the The left and right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com