Floating sealing structure of thrust shaft rod

A floating seal, thrust shaft technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of unfavorable saving of energy consumption of driving devices, increased operating torque, and large packing pressing force, etc. The effect of routine maintenance, reducing valve operating torque, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

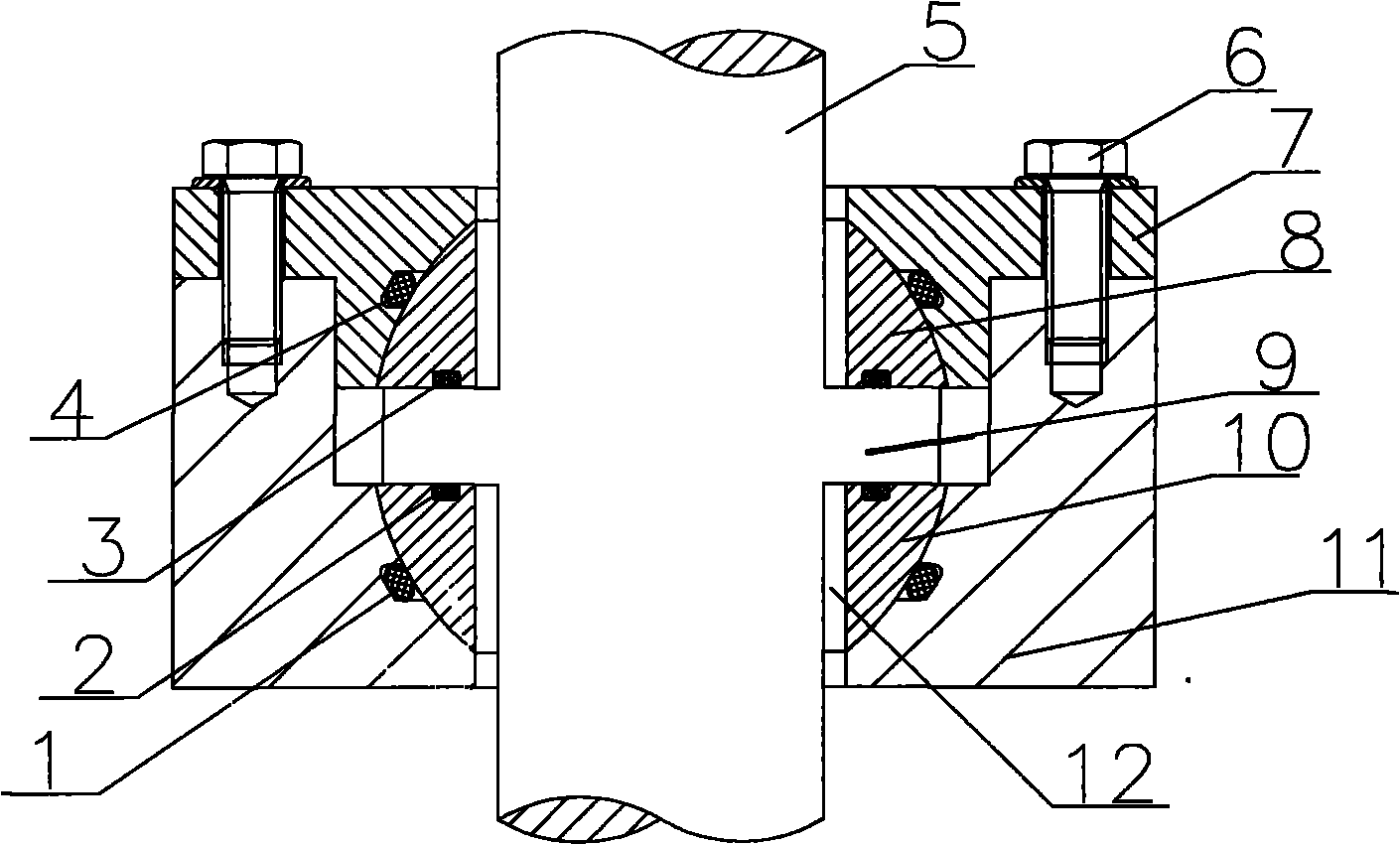

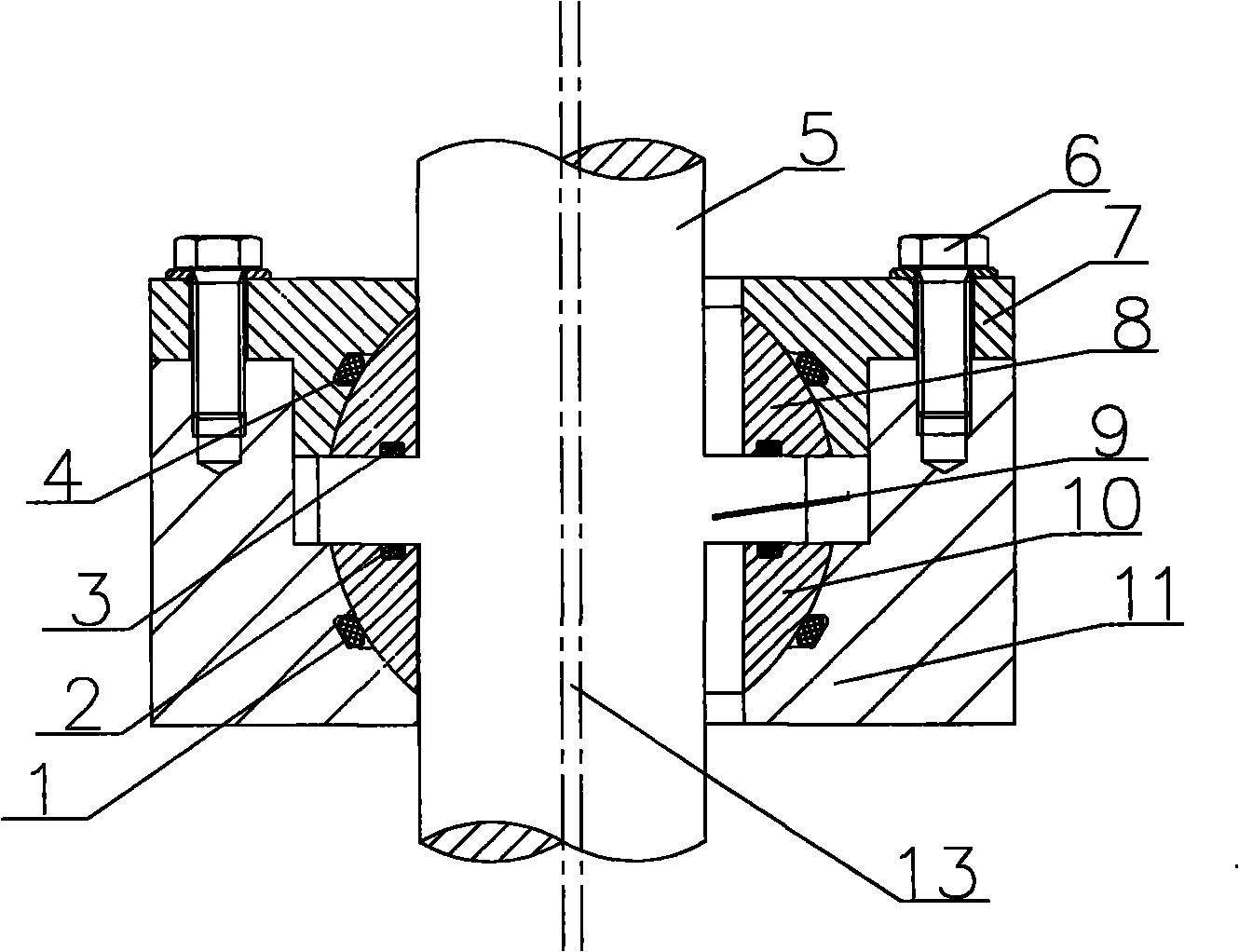

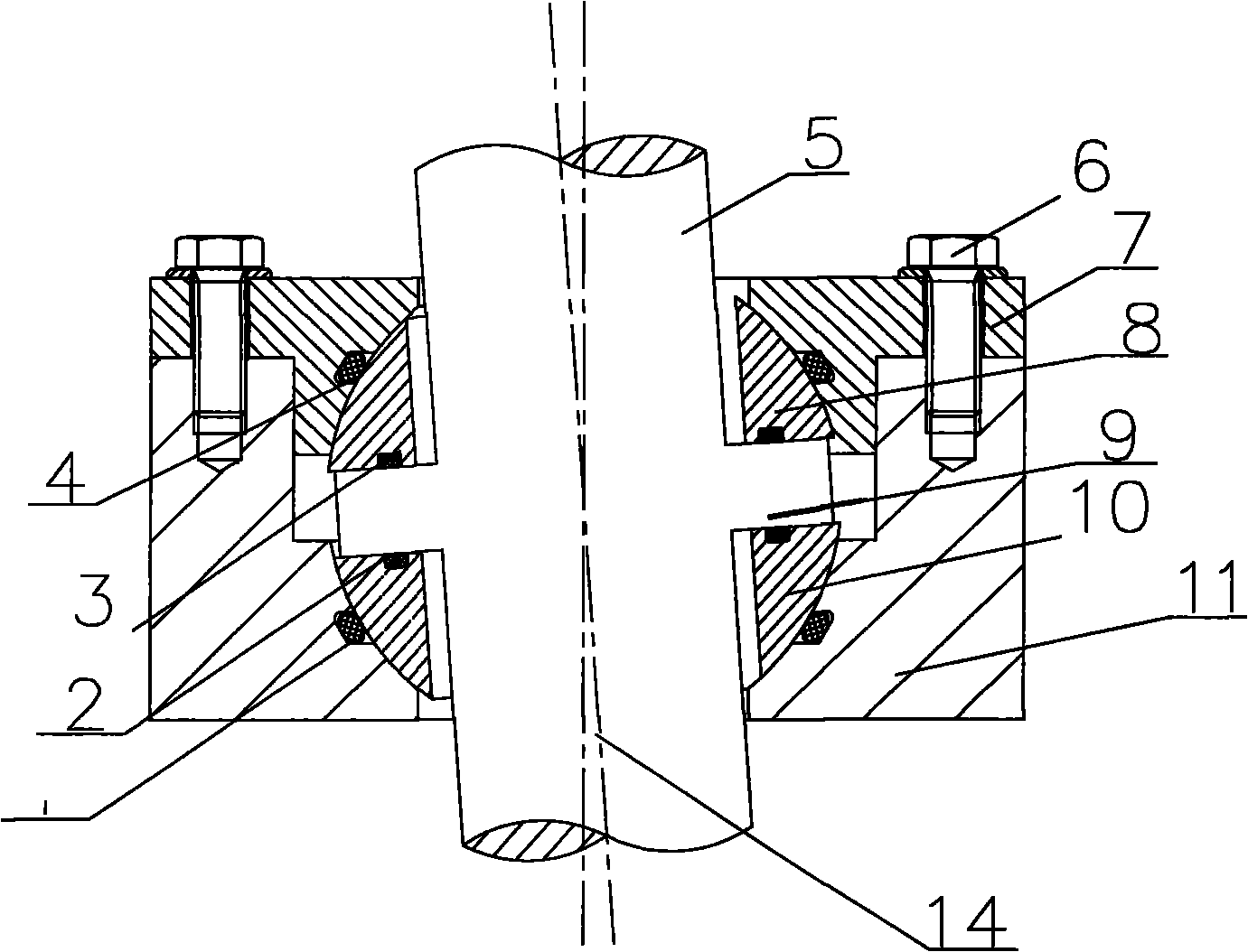

[0020] Such as figure 1 As shown, a floating sealing structure of a thrust shaft includes a first sealing ring 1, a second sealing ring 2, a third sealing ring 3, a fourth sealing ring 4, a shaft 5, bolts 6, a gland 7, The first ball ring 10, the second ball ring 8, and the valve cover 11. The first ball ring 10 and the second ball ring 8 are middle cylindrical holes, and the outer wall surface is a part of the spherical surface. The bottom of the middle hole of the valve cover 11 is a spherical surface, which is matched with the spherical surface of the first ball ring 10, and the upper part is a cylindrical hole. The gland 7 is disc-shaped, the upper flange is fixed on the valve cover 11 with bolts 6 , and the bottom of the middle hole is a spherical surface, which is matched with the spherical surface of the second ball ring 8 . The shaft 5 is a cylindrical rod with a shoulder 9 in the middle, and the shoulder 9 is used to bear the upward and downward axial force when ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com