Elastic sluice valve with wedge-shaped sealing face

A gate valve and elastic technology, applied in the field of elastic seat sealing gate valve, can solve the problems of rubber aging, poor sealing of gate valve, elastic fatigue, etc., and achieve the effect of facilitating replacement, reducing and reducing operating torque, and reducing water leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

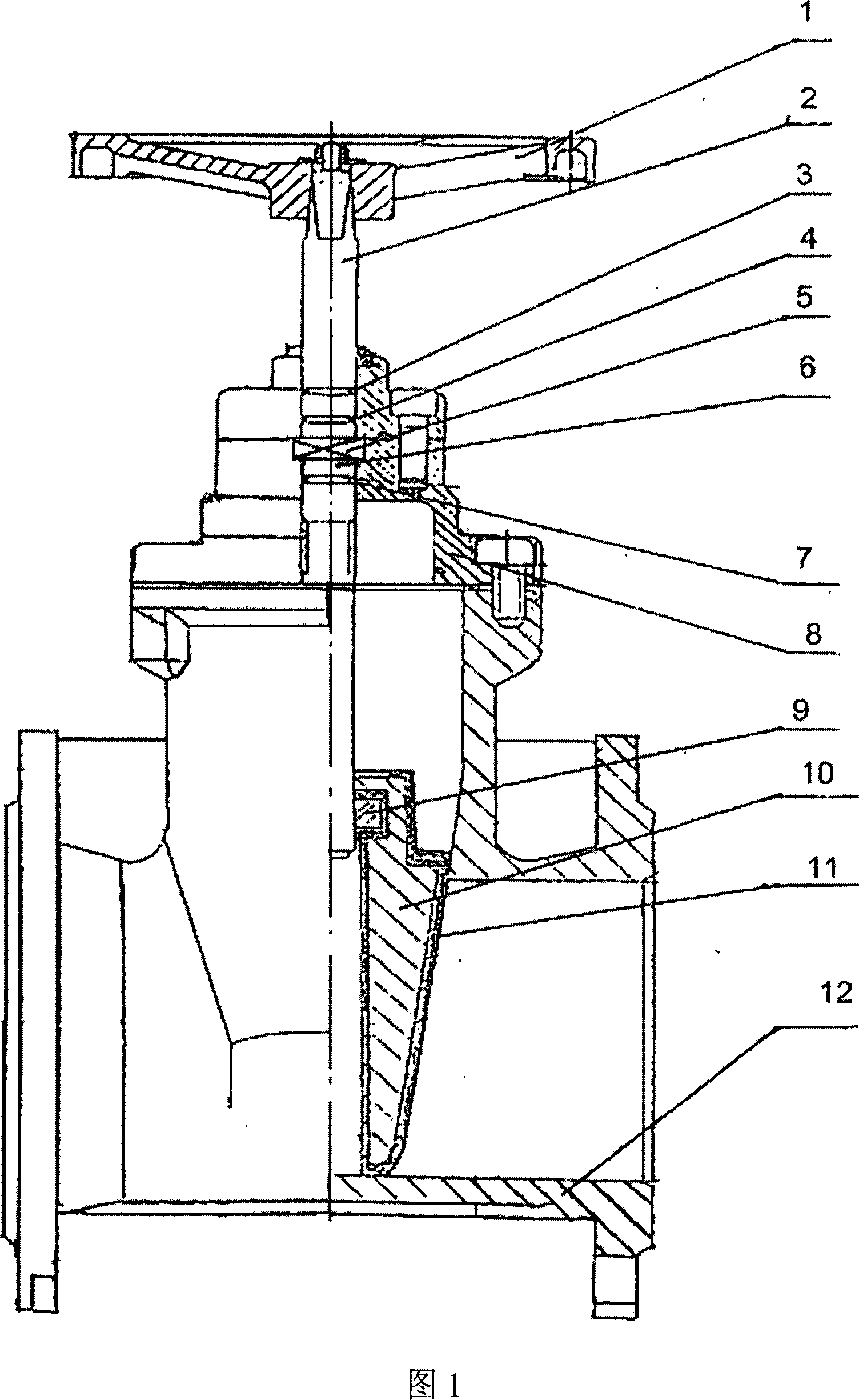

[0012] Resilient seated gate valves are installed on fluid lines. When the gate valve needs to be opened, the operator rotates the handle (1) counterclockwise. When the handle rotates, the valve stem (2) also rotates. The lower part of the valve stem (2) is threaded, and the thread is connected with the square copper nut (9). Copper nut (9) is embedded in the square hole of valve plate (10) spool. When the valve stem (2) rotates, the valve plate (10) is slowly lifted up. When the valve plate (10) is lifted upward, the fluid in the pipeline will flow from the high pressure to the low pressure. When the valve plate (10) is lifted When it is lifted to the highest point, the valve is fully opened, and the fluid in the pipeline can flow through the gate valve unimpeded to achieve the purpose of conveying fluid.

[0013] When the valve is opened, or when the fluid in the low-pressure area is about to reach the predetermined target, the handle (1) can be operated to adjust the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com