Low torsion moment ball valve for fuel gas vertical pipe

A low-torque, riser technology, applied in the field of new valve structure research, can solve the problems of poor fire resistance and sealing, large operating torque, misoperation, etc., to prolong the service life, reduce the operating torque, and prevent misoperation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention analyzes the structural defects of traditional ball valves and some problems commonly used in gas risers, and innovatively proposes a low-torque ball valve for gas risers, which has better sealing, fire prevention, portability and durability.

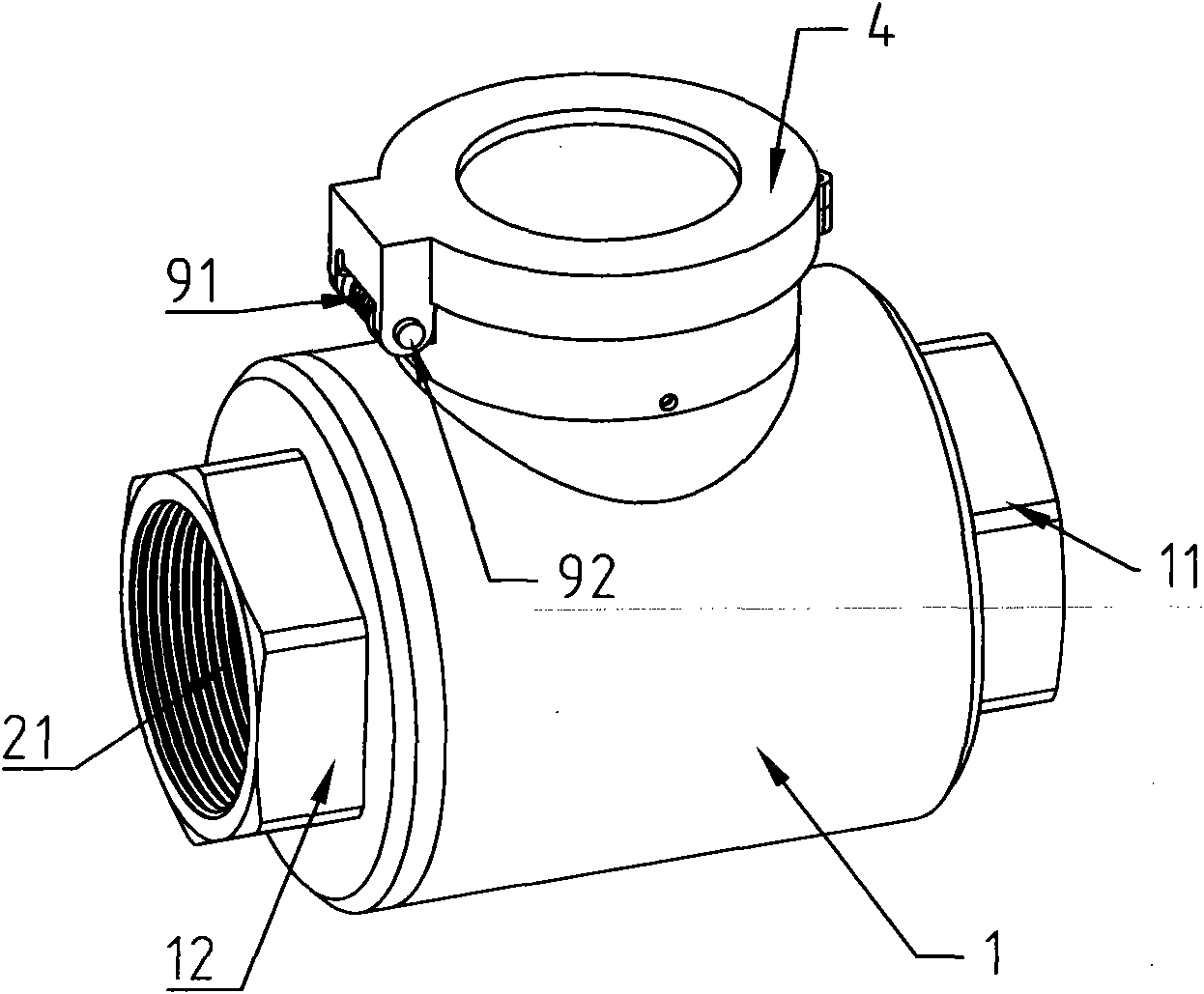

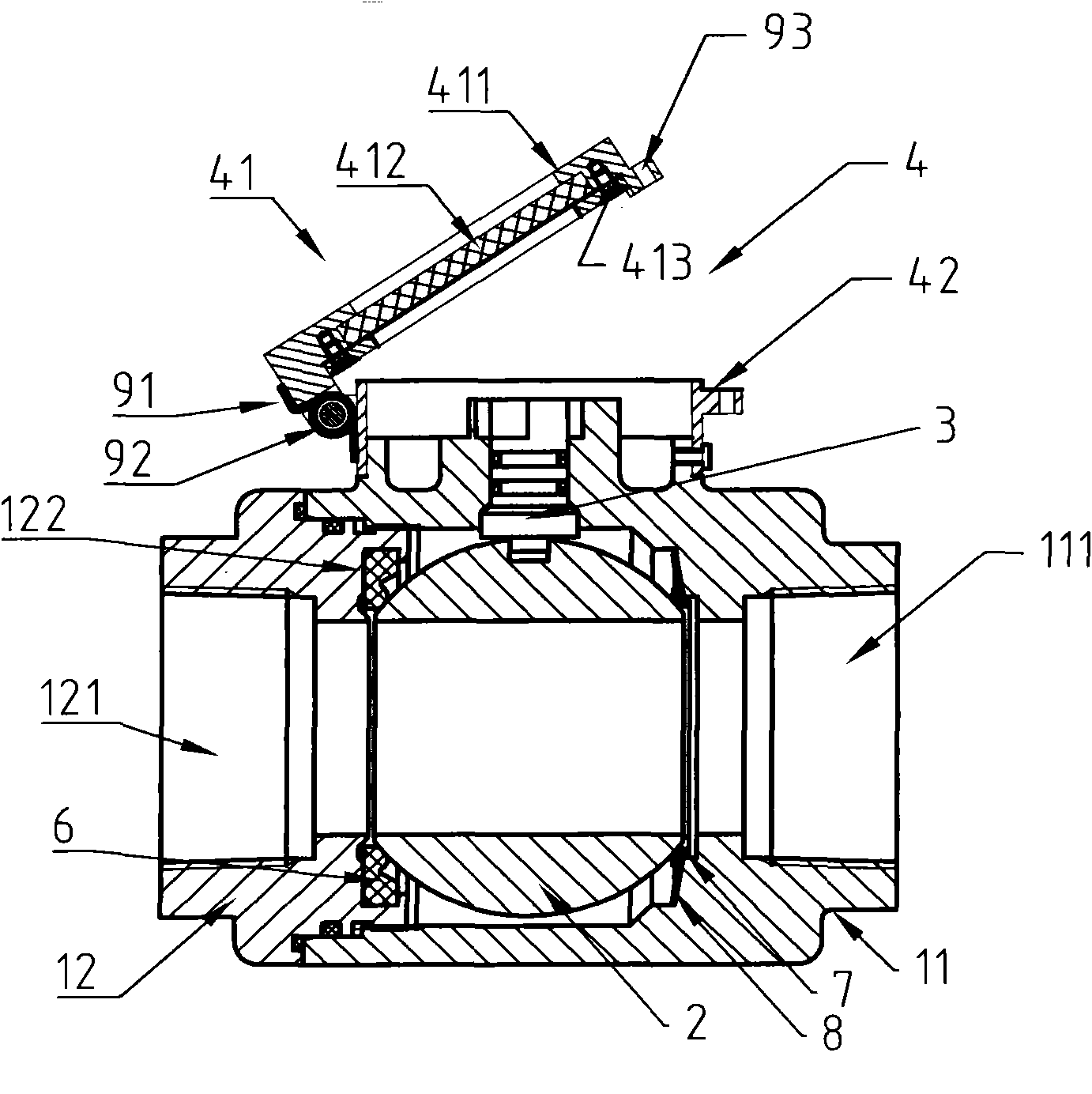

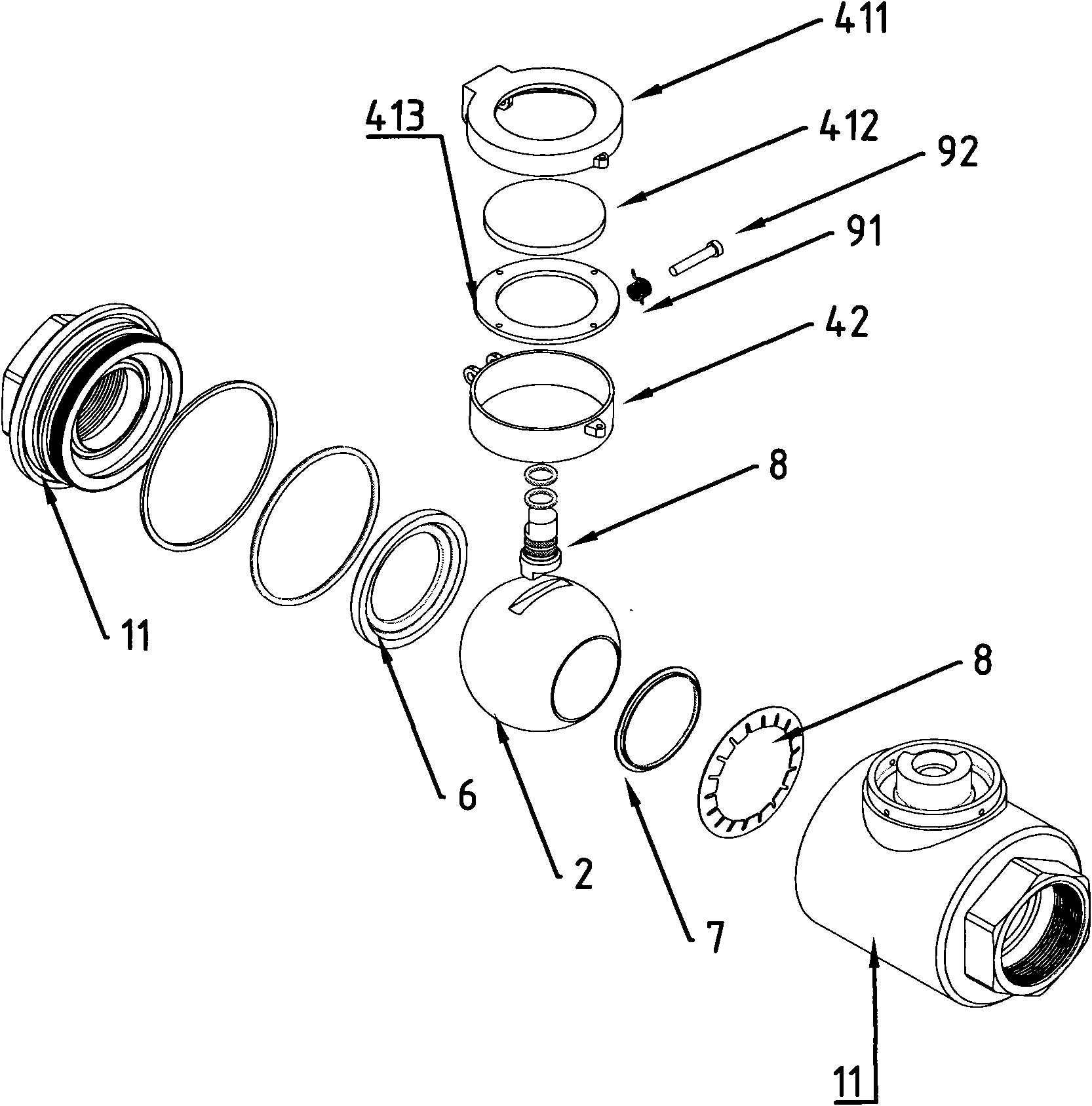

[0023] The gas riser low-torque ball valve is composed of a valve body, a protective cover, a ball, and a valve stem connected to the ball through the valve body in linkage. Such as Figure 1 to Figure 3 As shown: the valve body 1 is a cylindrical body with both ends open and connected by the thread connection of the main valve body 11 and the auxiliary valve body 12, the ball 2 is installed in the inner cavity of the valve body, and the protective cover 4 is facing the valve body. The rod 3 is connected to the valve body 1 in an openable manner; and the inner cavity of the valve is provided with a sealing ring 6 and a retaining ring 7 at the positions in contact with the ball along the through direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com