Patents

Literature

84results about How to "Prevent external leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

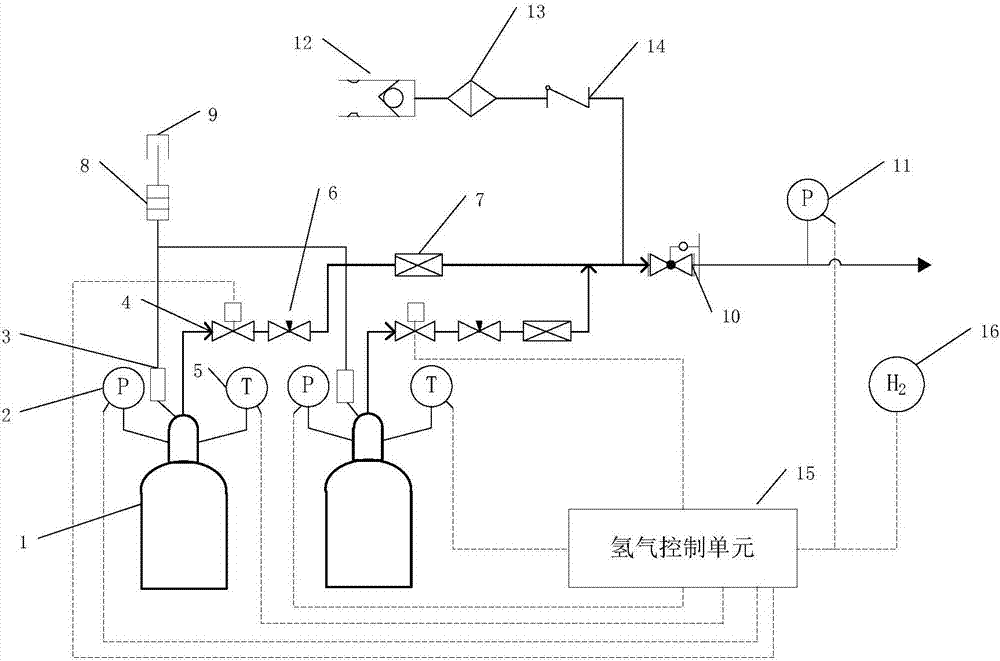

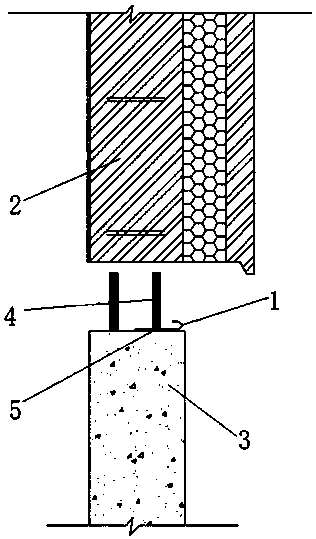

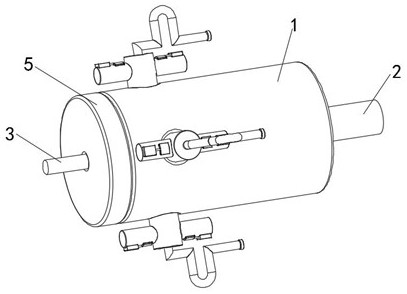

Hydrogen management system of vehicle-mounted fuel cell

PendingCN106876749AAchieve hydrogenation controlRealize hydrogen supply controlFuel cell auxillariesGas cylinderHydrogen storage system

The invention relates to a hydrogen management system of a vehicle-mounted fuel cell. The hydrogen management system comprises a hydrogen control unit (15), and a hydrogen bottle electromagnetic valve (4), a hydrogen bottle pressure sensor (2), a temperature sensor (5) and a hydrogen concentration sensor (16) which are connected with the hydrogen control unit (15) separately; the hydrogen bottle electromagnetic valve (4), the hydrogen bottle pressure sensor (2) and the temperature sensor (5) are connected with a vehicle-mounted high-pressure hydrogen bottle (1) separately; a probe of the hydrogen concentration sensor (16) is arranged in the environment above the high-pressure hydrogen bottle (1); and the hydrogen control unit (15) is in communication connection with a vehicle-mounted fuel cell controller through CAN. Compared with the prior art, the functions of hydrogen adding control, hydrogen supplying control, safety detection and the like of a vehicle-mounted hydrogen storage system can be realized, cable connection between systems is reduced, and signal missing in a signal transmission process and risk of high probability of interference are lowered.

Owner:TONGJI UNIV

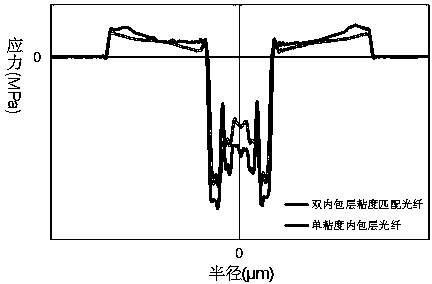

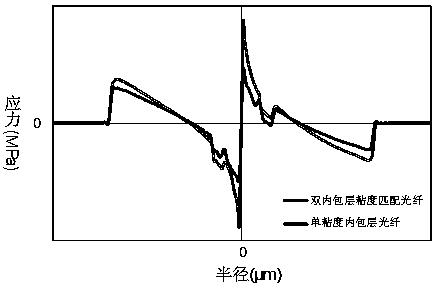

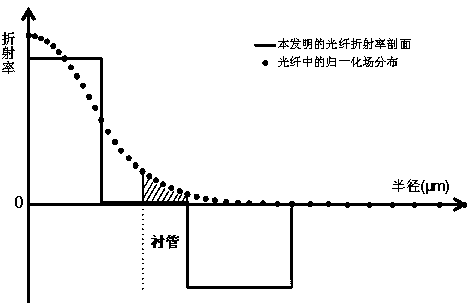

Low-attenuation bending insensitive single mode fiber

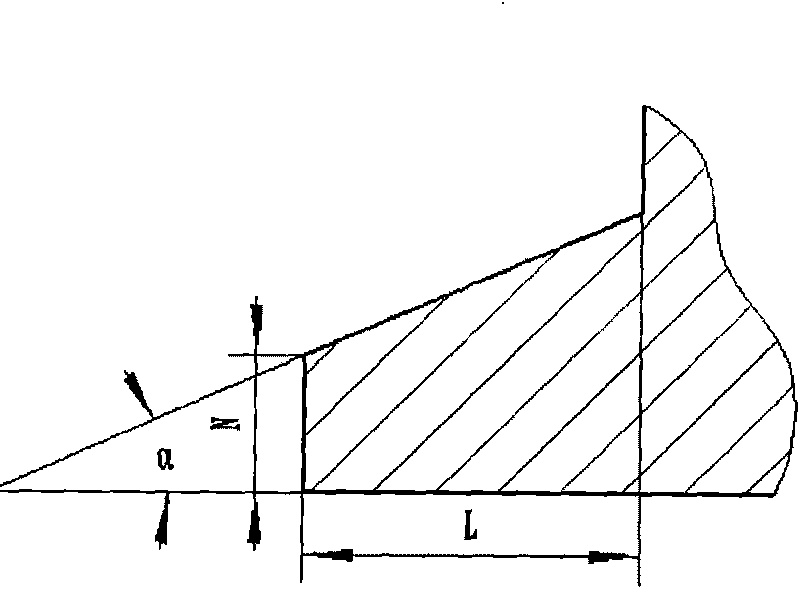

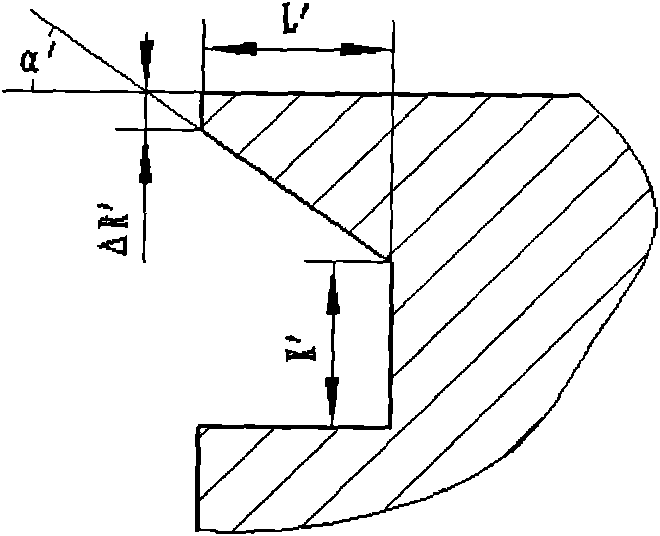

InactiveCN104316994AGood attenuation performanceDelay decayOptical fibre with multilayer core/claddingOptical waveguide light guideUltrasound attenuationMicrometer

The invention relates to a low-attenuation bending insensitive single mode fiber which comprises a core layer and wrapping layers. The low-attenuation bending insensitive single mode fiber is characterized in that the relative refractive index difference delta1 of the core layer ranges from 0.30% to 0.38%, the radius R1 of the core layer ranges from 3.5 micrometers to 4.5 micrometers, the four wrapping layers are arranged outside the core layer, the first wrapping layer is a first inner wrapping layer tightly surrounding the core layer, the relative refractive index difference delta2 of the first wrapping layer ranges from -0.02% to 0.02%, the radius R2 of the first wrapping layer ranges from 6.5 micrometers to 8.5 micrometers, the second wrapping layer is a second inner wrapping layer tightly surrounding the first inner wrapping layer, the relative refractive index difference delta3 of the second wrapping layer ranges from -0.02% to 0.02%, the radius R3 of the second wrapping layer ranges from 8 micrometers to 11 micrometers, the third wrapping layer is a downwards-concave wrapping layer tightly surrounding the second inner wrapping layer, the relative refractive index difference delta4 of the third wrapping layer ranges from -0.5% to -0.2%, the radius R4 of the third wrapping layer ranges from 12 micrometers to 20 micrometers, and the fourth wrapping layer is an outer wrapping layer tightly surrounding the downwards-concave wrapping layer and is a pure quartz glass layer. The low-attenuation bending insensitive single mode fiber can be completely matched with a G.652.D optical fiber, and therefore the low attenuation, the large effective area and the bending resistance can be better unified.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

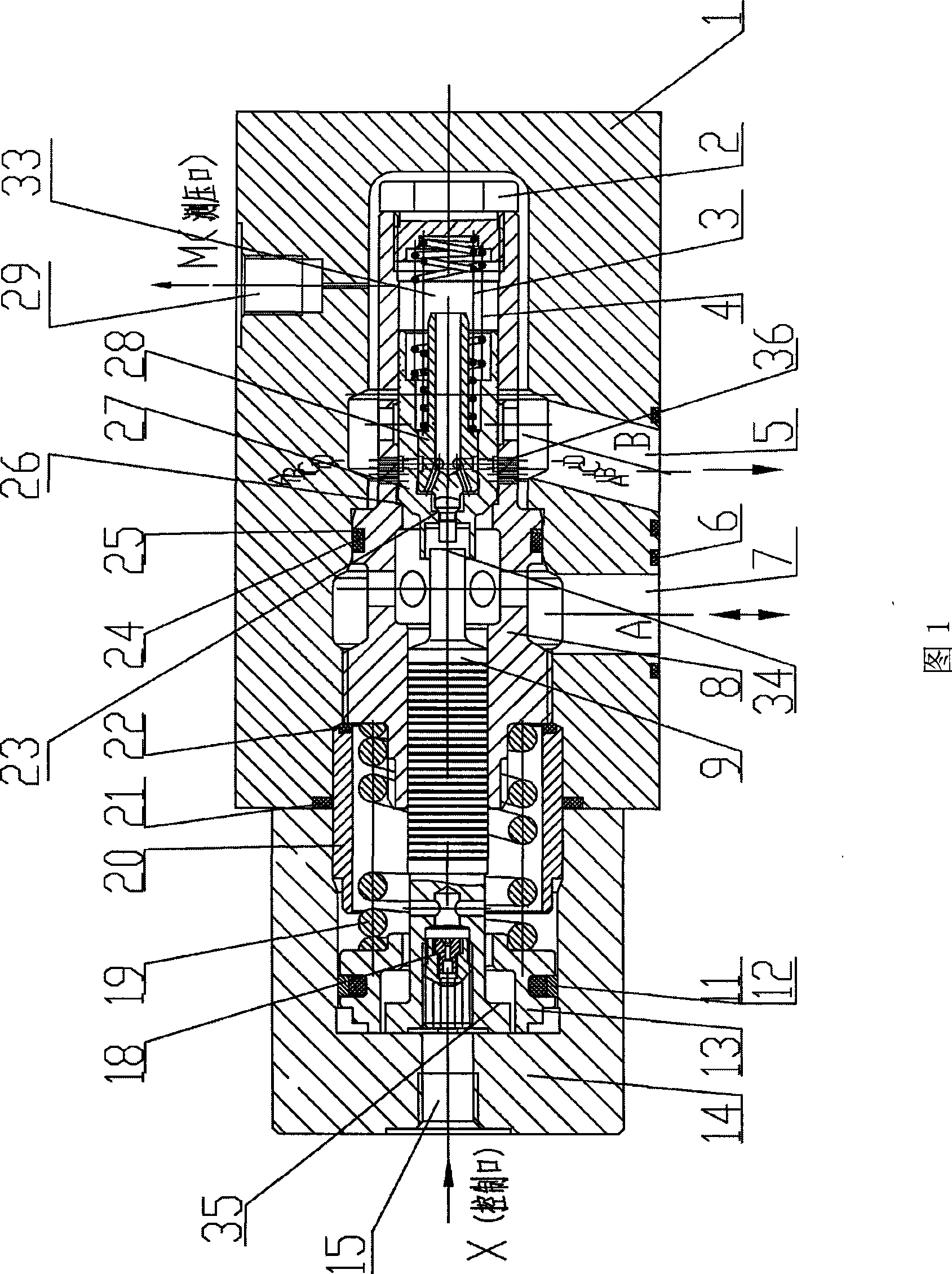

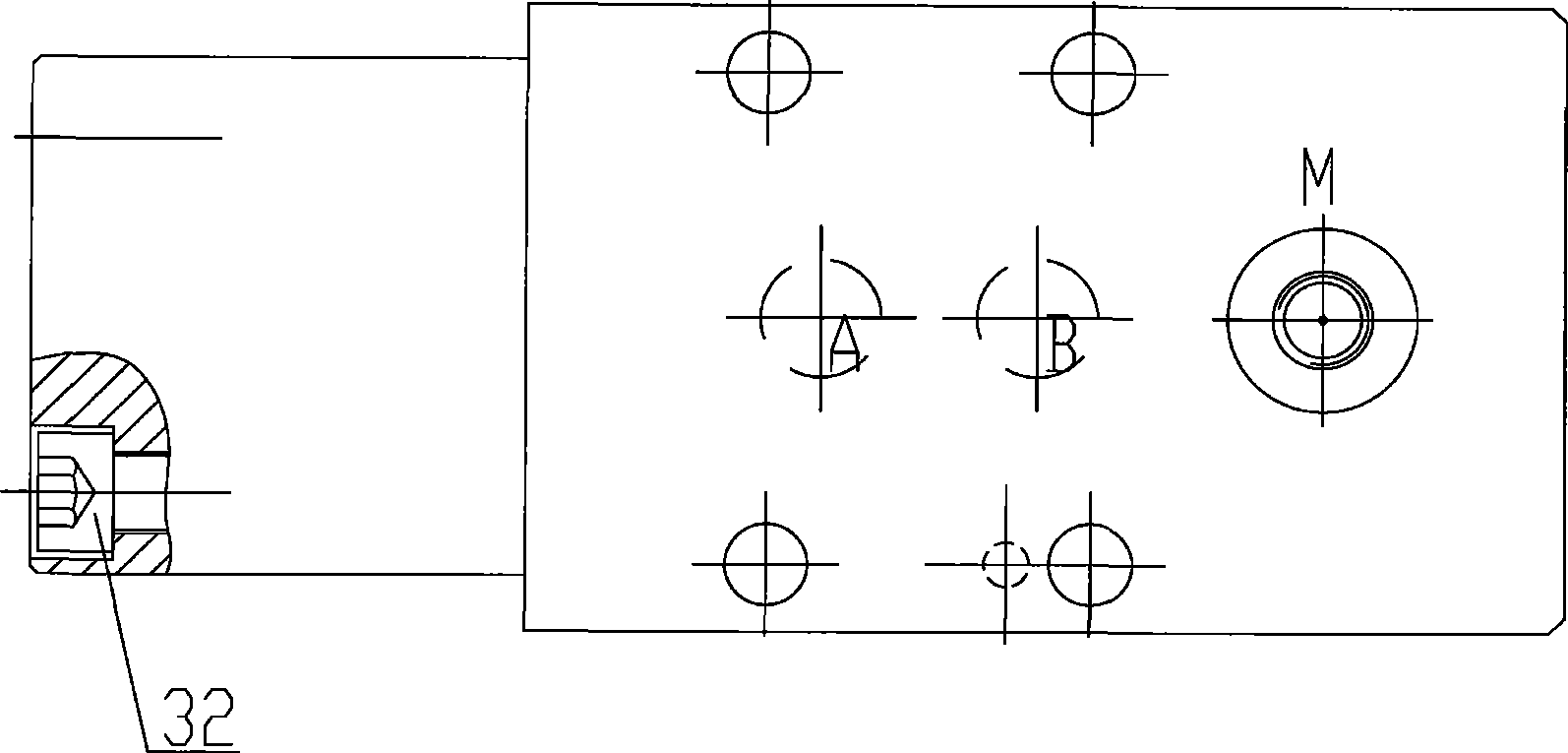

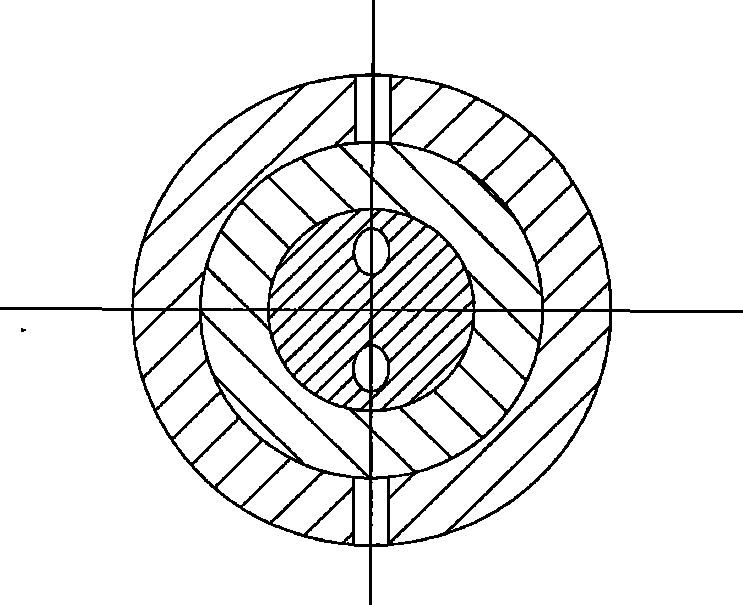

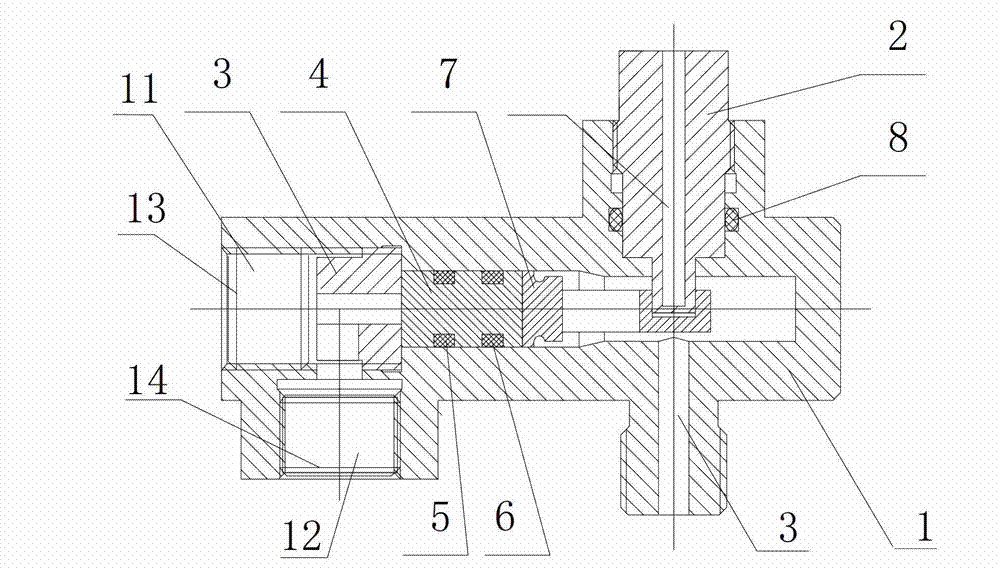

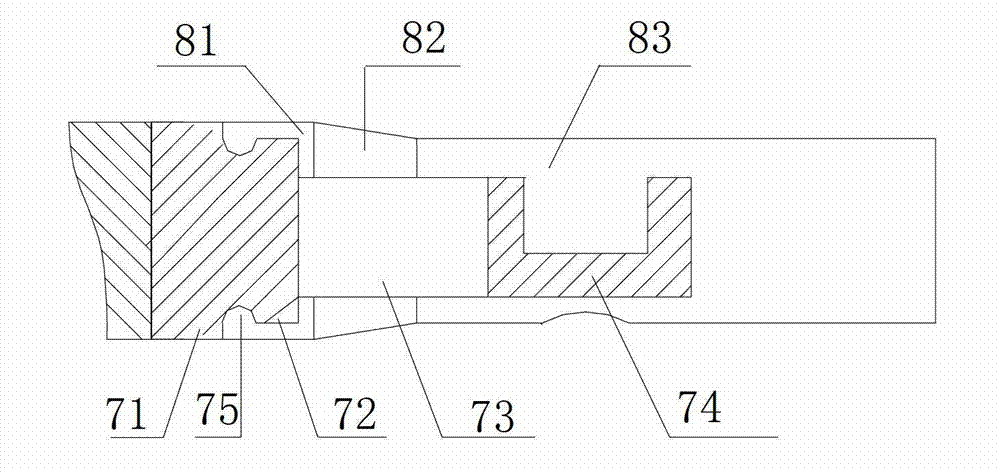

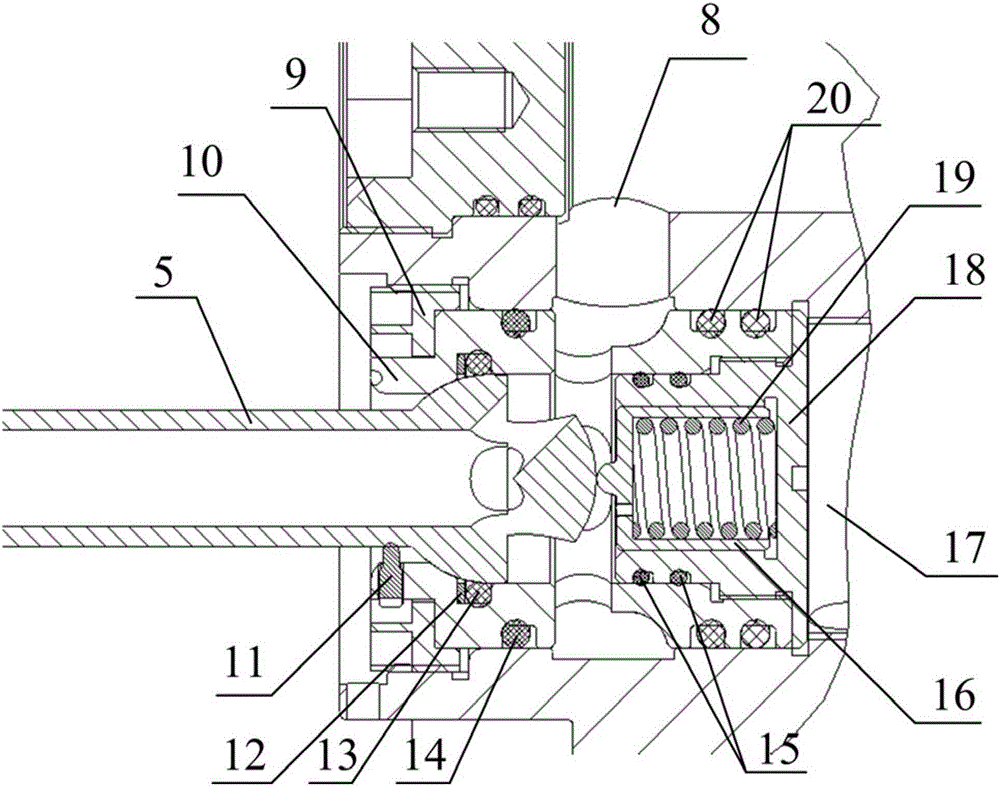

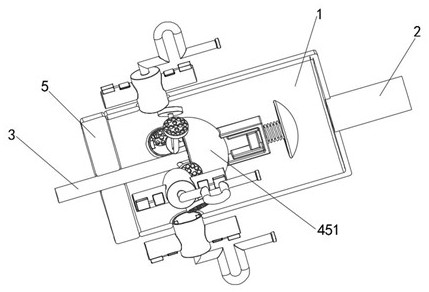

Balance valve

InactiveCN101435446AReduce internal leakagePrevent external leakageServomotor componentsEngineeringPilot valve

The invention provides a balance valve which is used to solve the problems that the prior balance valve has a complex structure, high manufacturing cost and poor sealing performance. The balance valve comprises a valve body; the end part of the valve body is provided with an end cover; the side of the valve body is provided with a first main oil port and a second main oil port; the end face of the end cover is provided with a control port; the valve body is manufactured into a main valve hole along the length direction; a balance valve component and a main valve are sequentially arranged in the main valve hole; the balance valve component comprises a valve sleeve; the valve sleeve is provided with axial through holes; and a cone valve, a pilot valve and springs are sequentially arranged in the valve sleeve. The balance valve is characterized in that the pilot valve is a pilot cone valve; and the number of the springs is two. In the balance valve, the pilot valve and the main valve have a cone valve structure so as to improve the sealing performance of a one way valve; the pilot valve and the main valve are controlled through two springs with different rotating directions, on the premise of reducing no composite force of the springs, the balance valve reduces the force of a single spring, thereby improving the service life of the springs; and the right end of a sleeve is added with a sealing ring so as to improve the sealing performance of a control chamber.

Owner:SHANGHAI LIXIN HYDRAULIC

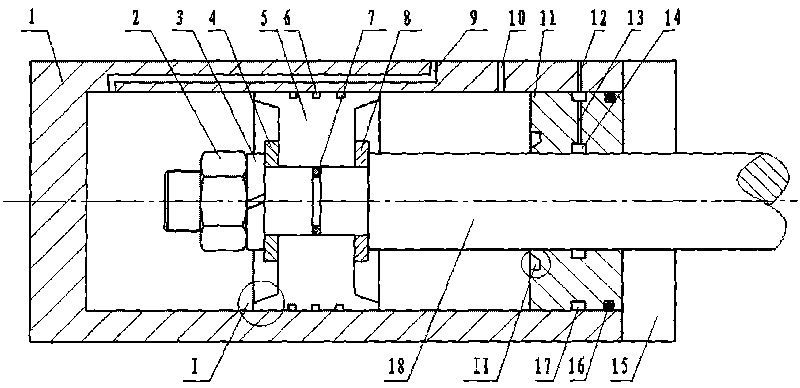

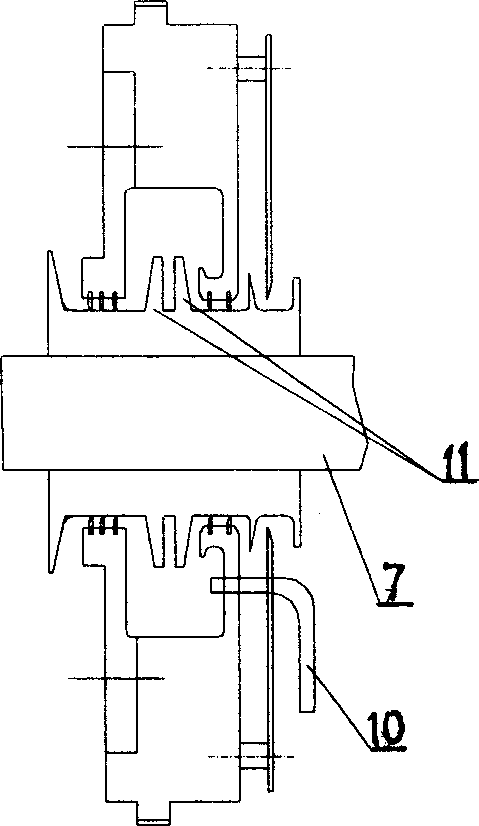

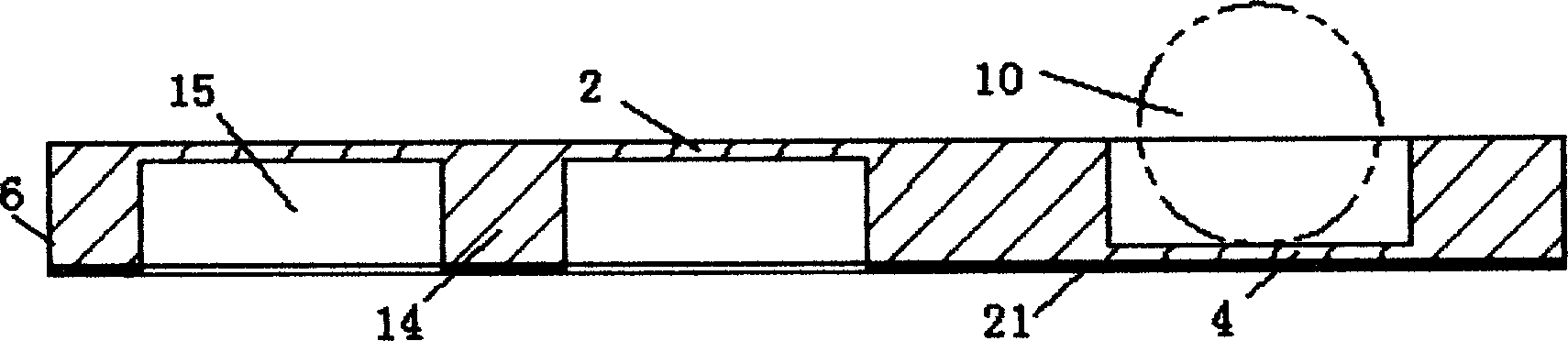

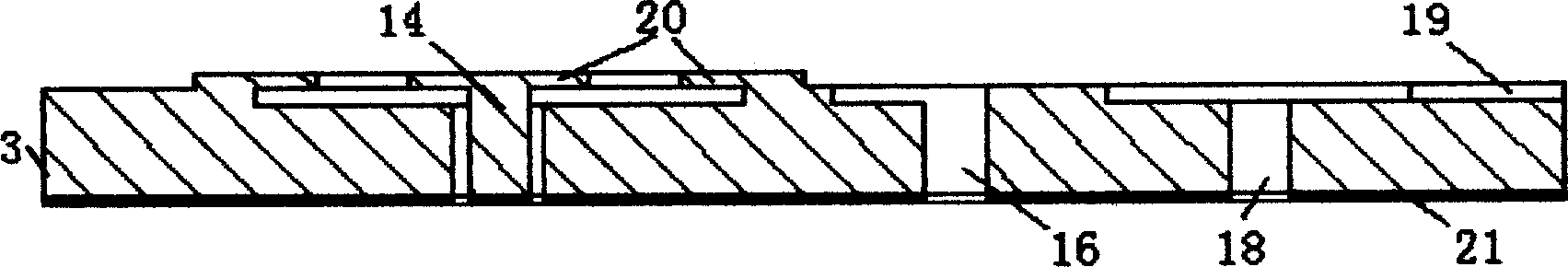

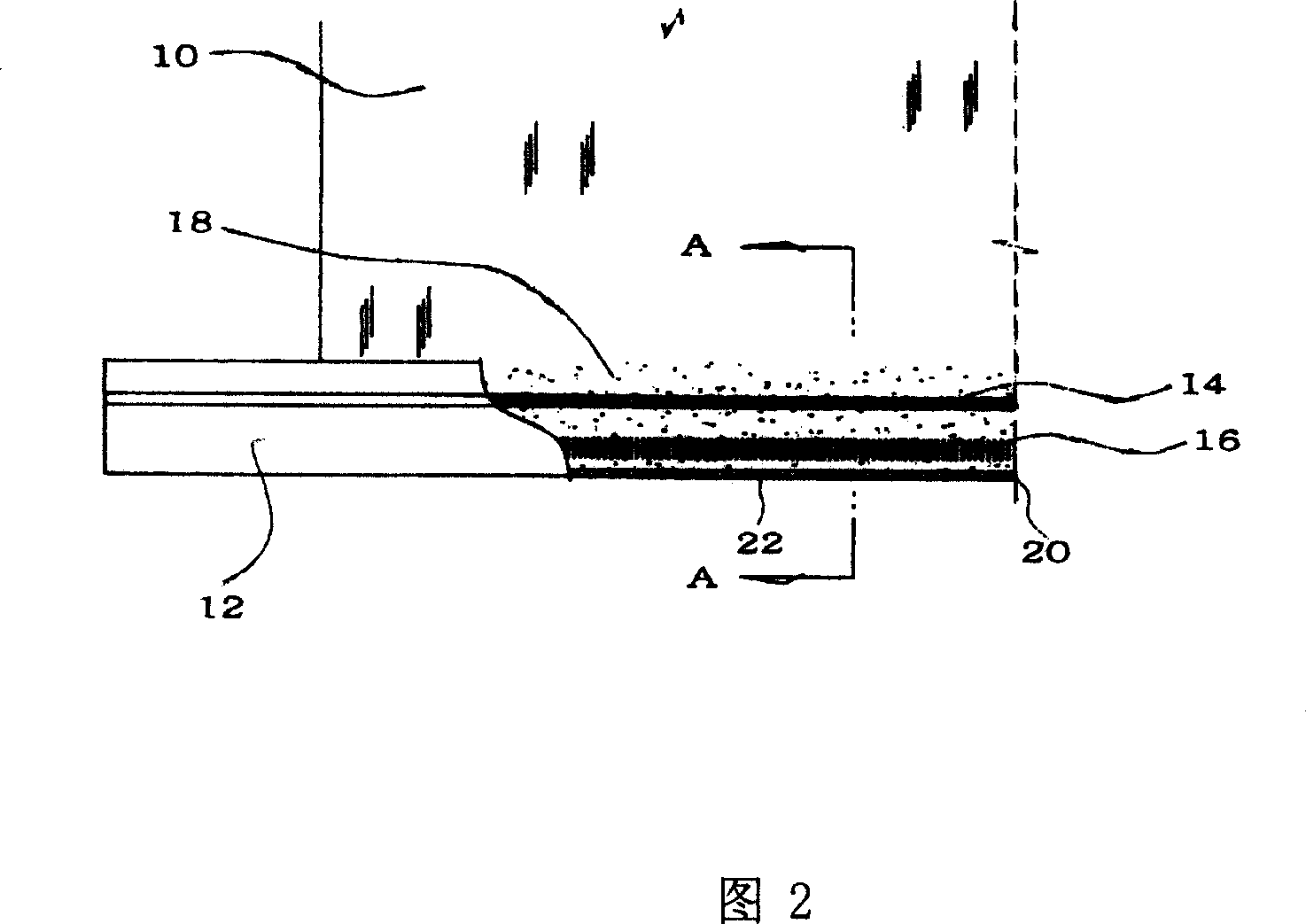

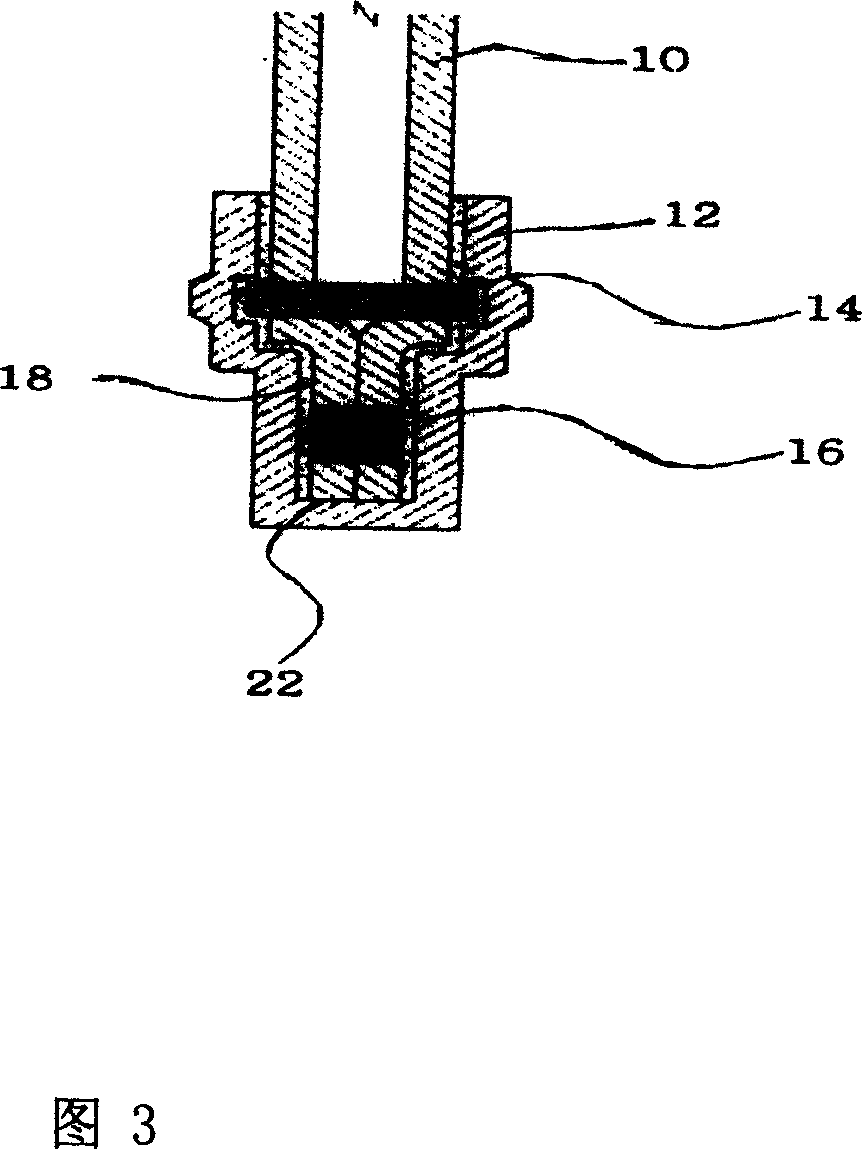

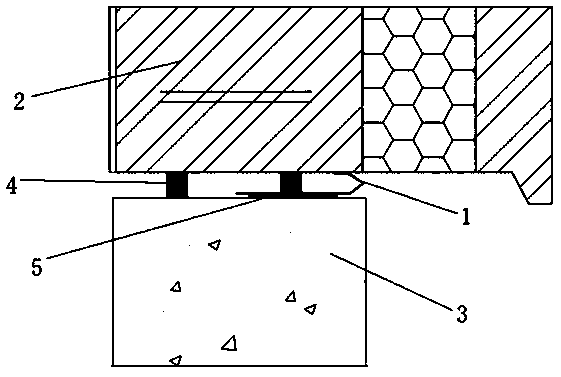

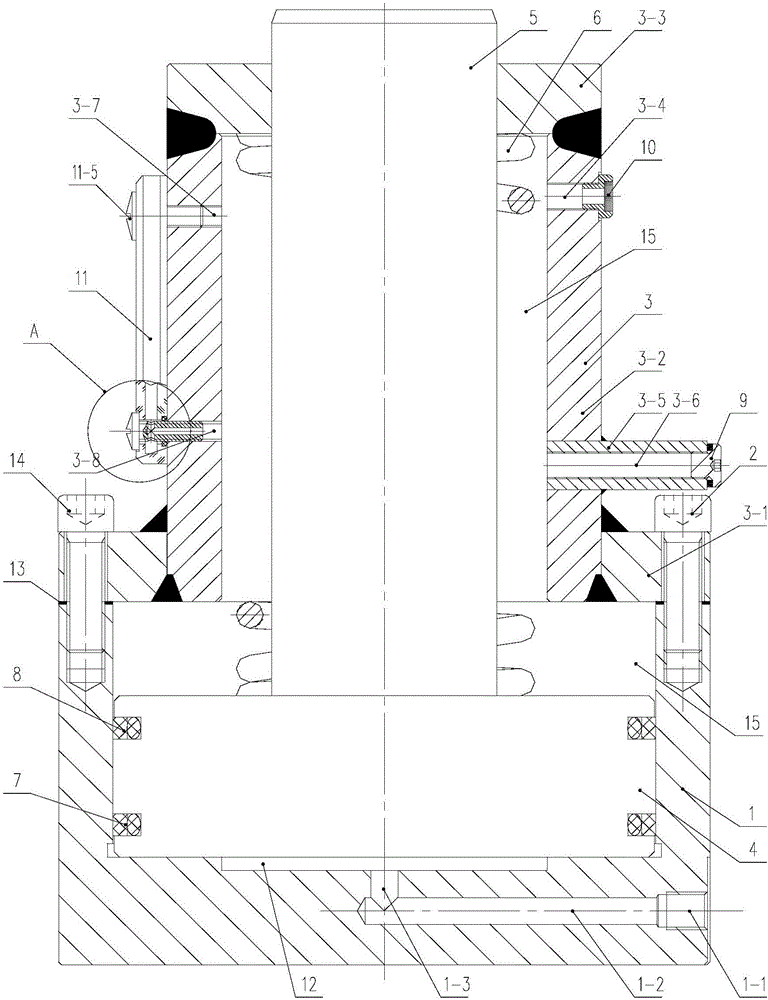

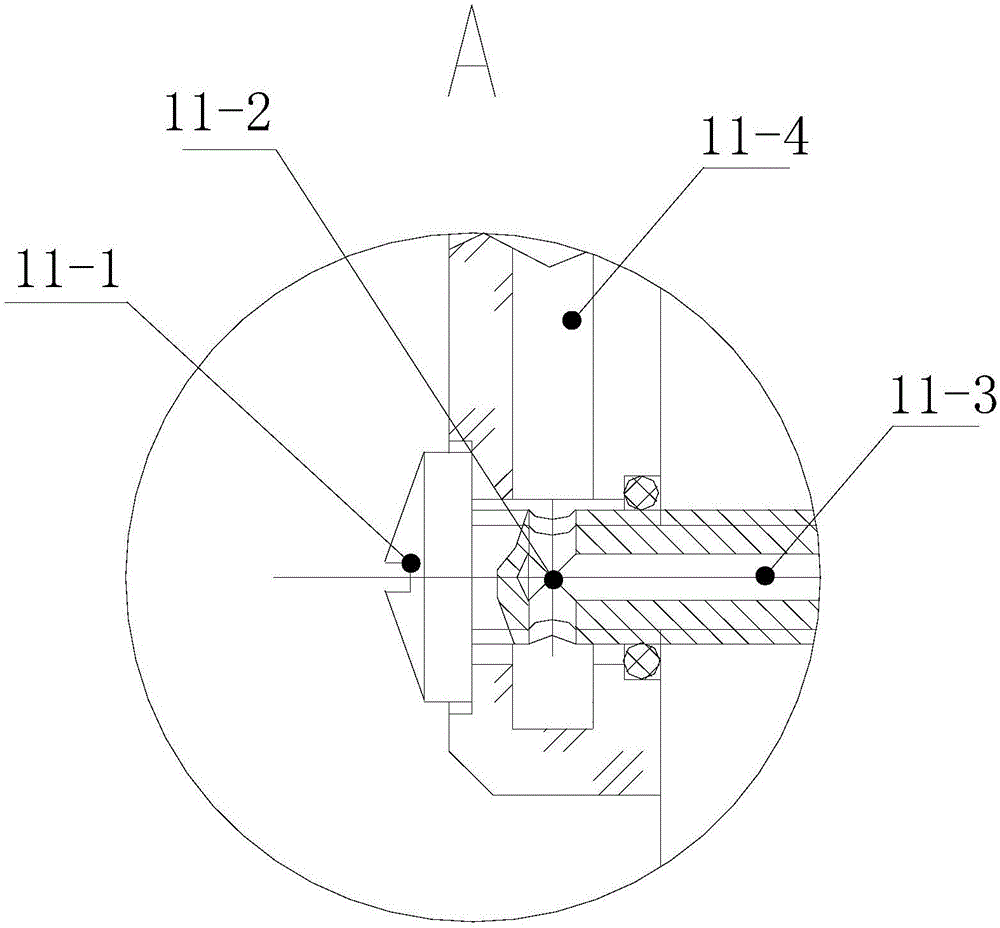

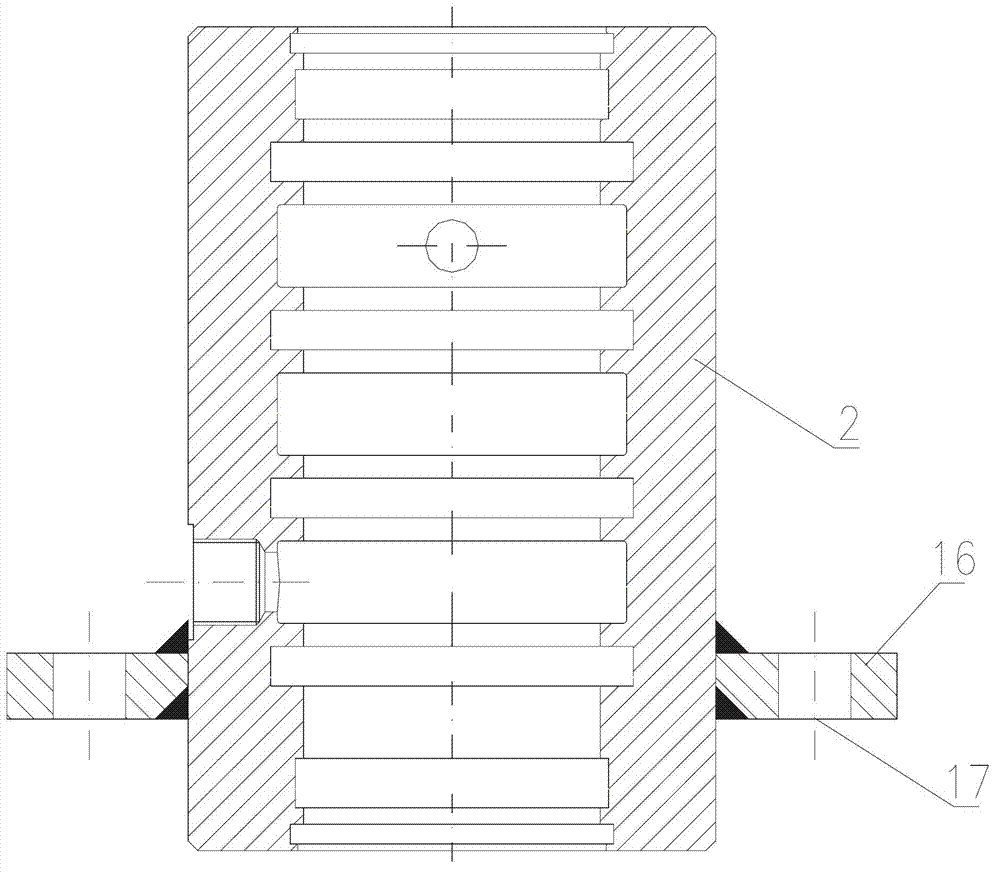

Hydraulic cylinder with clearance sealed type deformed piston

InactiveCN101725588AReduce leakageReduce frictional resistanceFluid-pressure actuatorsHydraulic cylinderPiston rod

The invention particularly relates to a hydraulic cylinder with a clearance sealed type deformed piston, which adopts the following technical scheme that: an excircle of a piston [5] is uniformly and symmetrically provided with 3 to 5 balance slots [6]; a piston rod [18] of the piston [5] is provided with a first seal groove [7]; an annular boss of which the outer diameter is the same as that of the piston [5] is arranged on the end faces of two sides of the piston [5] respectively; an excircle of a guide sleeve [11] is provided with a second seal groove [16]; a first drain pan [14] and a second drain pan [17] are arranged on an inner circle and the excircle of the guide sleeve [11] respectively; the first drain pan [14] is communicated with the second drain pan [17] through a second oil drain channel [13]; the second drain pan [17] is communicated with a first oil drain channel [12] arranged on a cylinder body [1]; and an end face, close to the inner circle, of the inner side of the guide sleeve [11] is provided with am annular groove. The hydraulic cylinder has the characteristics of simple structure, convenient assembly and disassembly and maintenance, long service life, small friction, high frequency response, high reliability, external leakage prevention, and the like.

Owner:WUHAN UNIV OF SCI & TECH

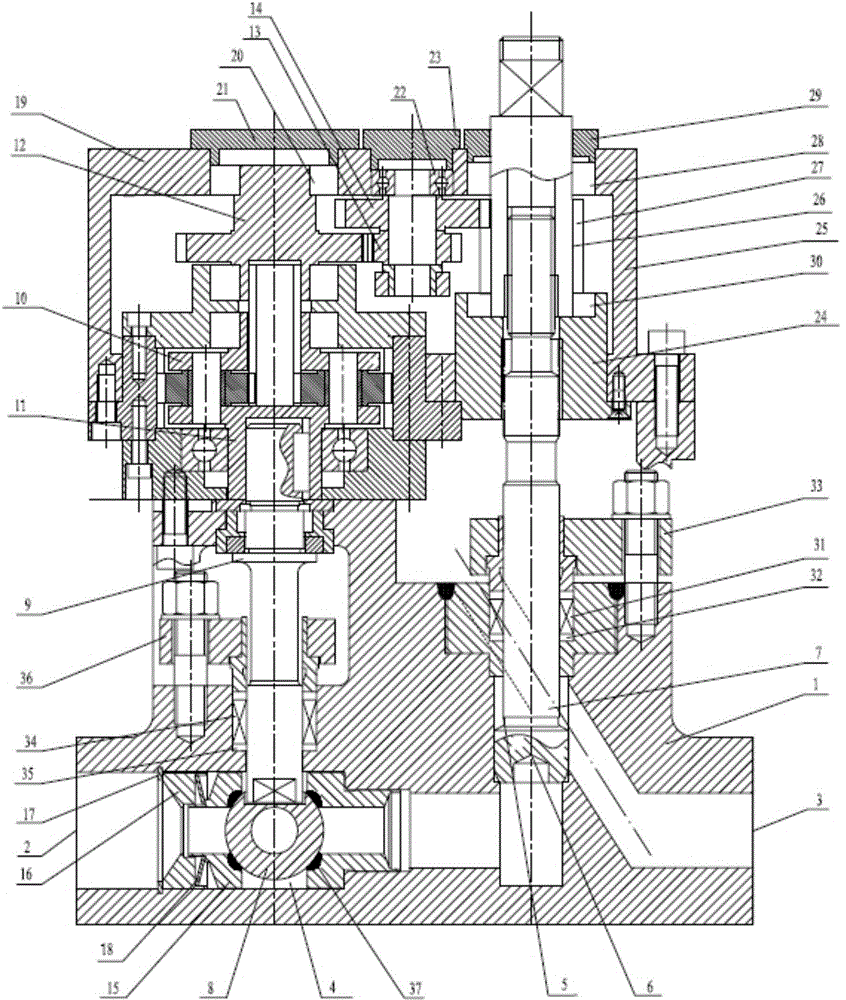

Integrated hydraulically-driven permanent magnet synchronous generator

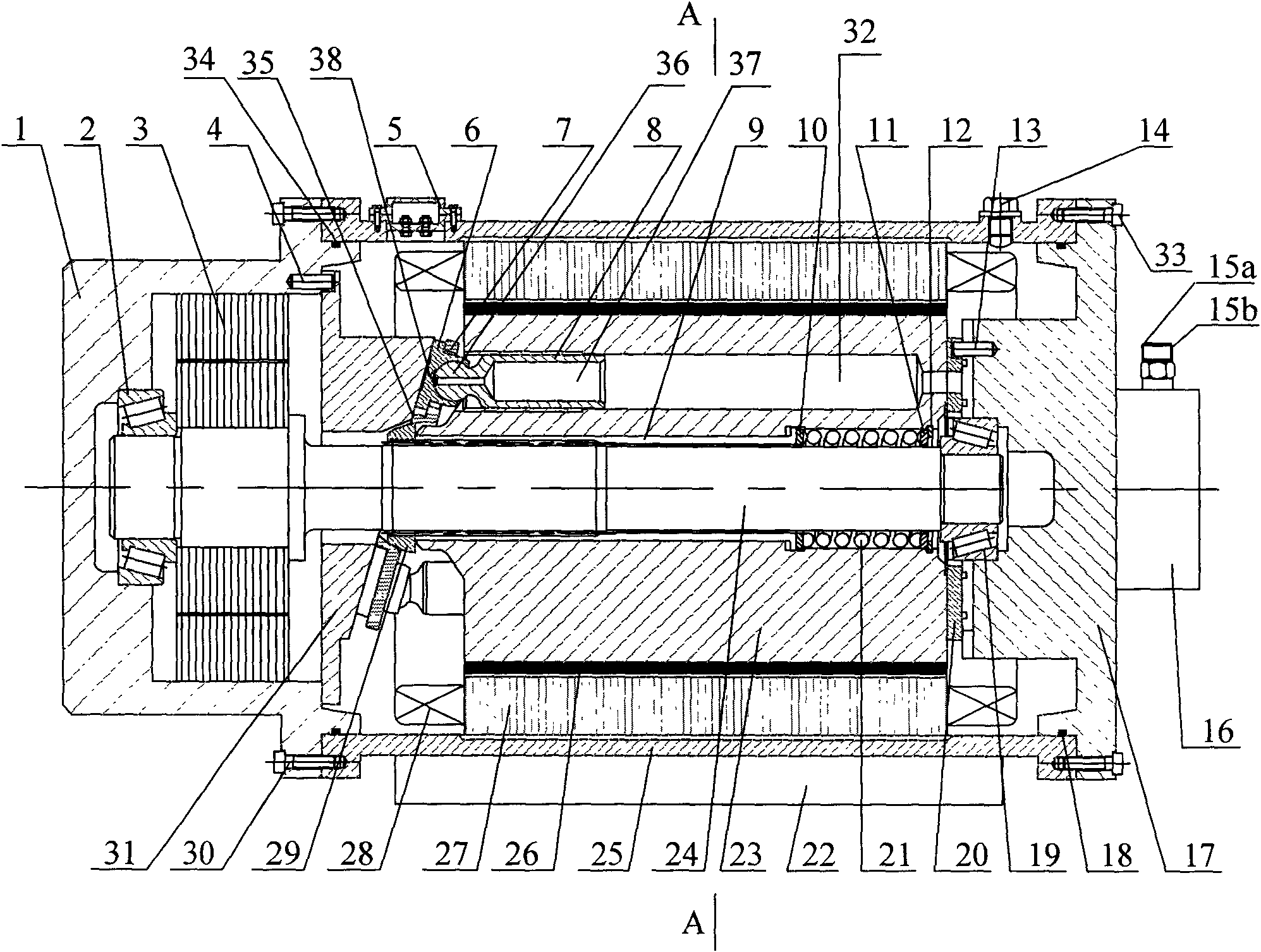

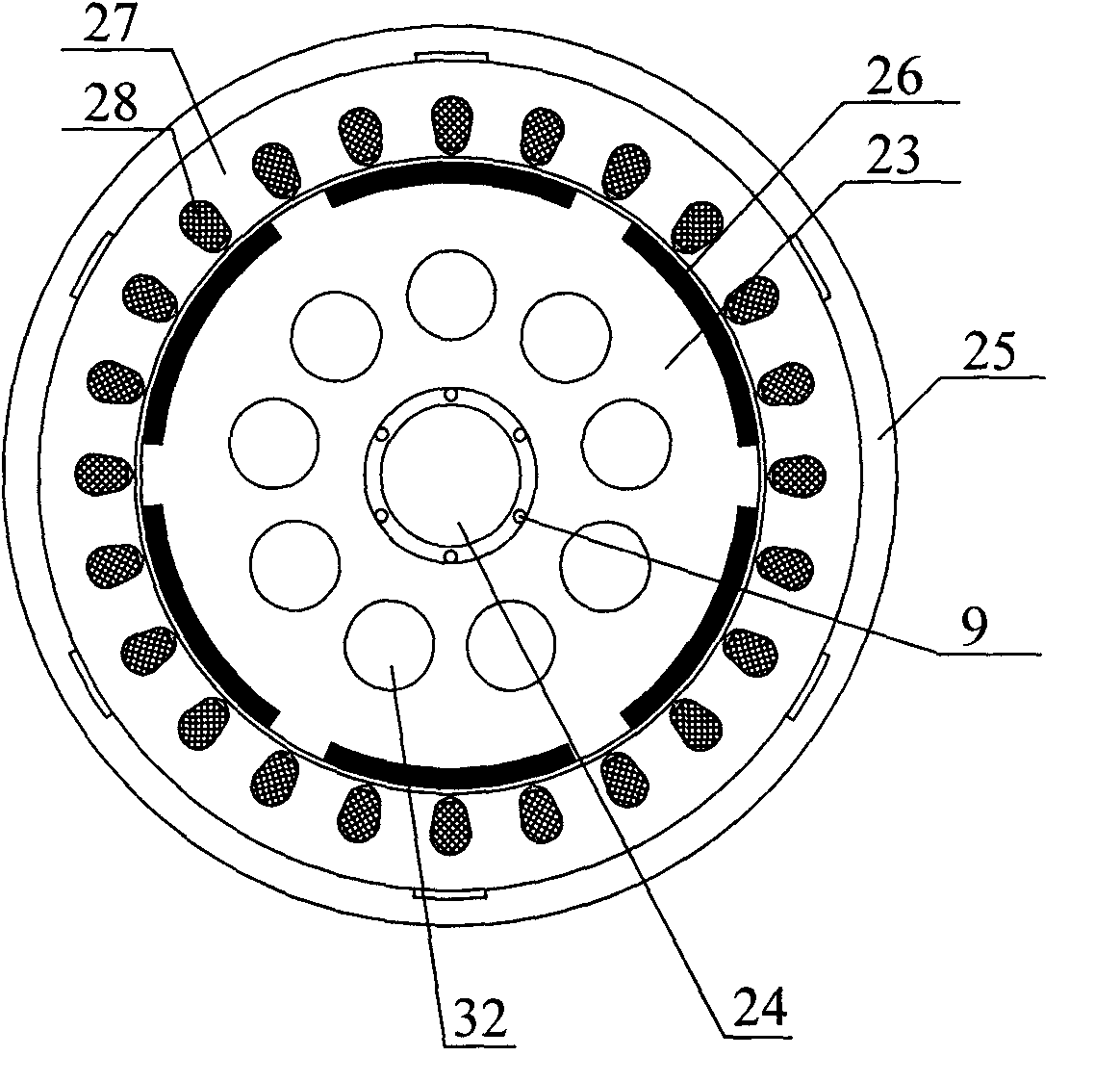

InactiveCN101635484ACompact structureReduce weightMechanical energy handlingStructural associationElectric energyStator

The invention discloses an integrated hydraulically-driven permanent magnet synchronous generator which comprises a motor shell (25), a rotating shaft (24), a cylinder body (23), a permanent magnet (26) and a motor stator (27), wherein the right side of the cylinder body (23) is tightly attached to an oil distribution disk (20), and the left side of the cylinder body (23) is provided with an inclined disk (31); a plunger hole (32) is arranged in the cylinder body (23), a plunger (8) positioned in the plunger hole (32) is rotatably connected with a slide shoe (6), and the slide shoe (6) is tightly attached to the inclined disk (31); an oil inlet (15a) on an oil-pass joint block (16), an oil inlet passage in a right end cover (17) and an oil inlet window on the oil distribution disk (20) are communicated in sequence; and an oil outlet (15b) on the oil-pass joint block (16), an oil outlet passage in the right end cover (17) and an oil outlet window on the oil distribution disk (20) are communicated in sequence. The permanent magnet synchronous generator is used for converting hydraulic energy into electric energy.

Owner:ZHEJIANG UNIV

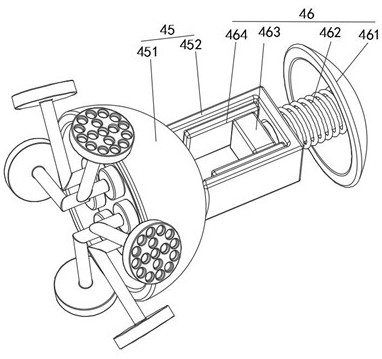

Atomizing head, atomizer and electronic cigarette thereof

ActiveCN105476072APrevent external leakageMedical devicesTobacco devicesInlet channelElectronic cigarette

The invention provides an atomizing head, an atomizer and an electronic cigarette applying the same. The atomizing head comprises a shell provided with a liquid inlet and an inner cavity and an atomizing head base provided with an air inlet channel; the liquid inlet and the air inlet channel are both communicated with the inner cavity, the bottom end of the shell is fixedly connected with the atomizing head base, the air outlet end of the air inlet channel is coated with an elastic part, and the elastic part has a first state of communicating the air inlet channel with the inner cavity and a second state of isolating the air inlet channel from the inner cavity. Due to the fact that the elastic part is arranged, the atomizing head can enable the passage between the air inlet channel and the inner cavity to be communicated with each other or isolated from each other in the use process according to needs, the passage between the air inlet channel and the inner cavity is isolated when the atomizing head is in a non-use state, and the problem that cigarette liquid is leaked outwards from the inner cavity through the air inlet channel is effectively avoided.

Owner:JOYETECH EURO HLDG

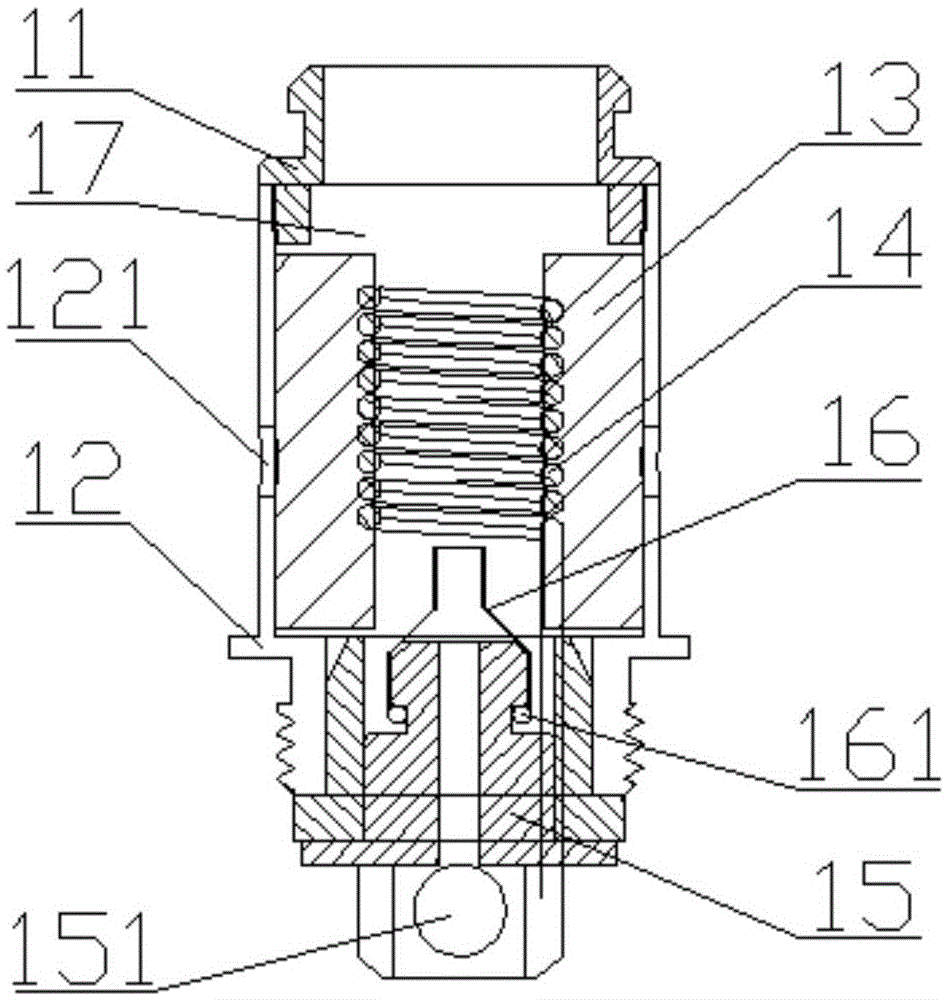

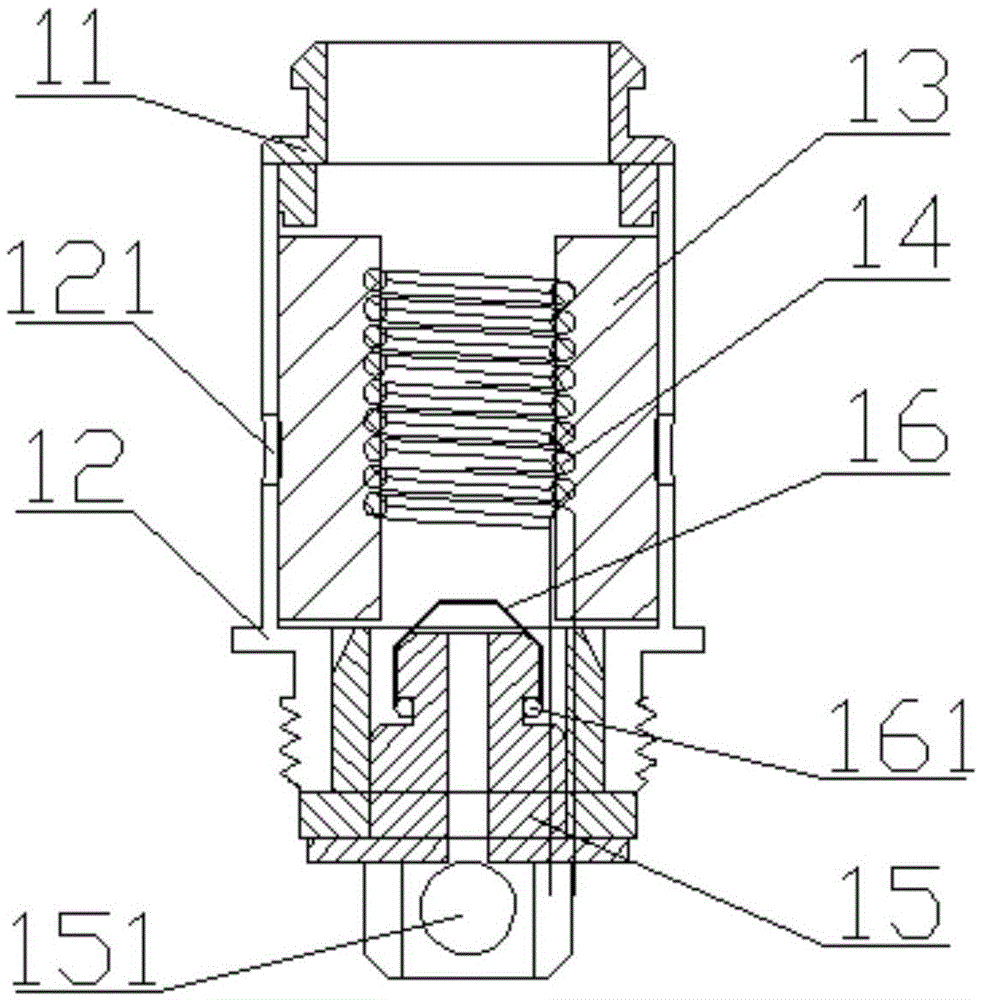

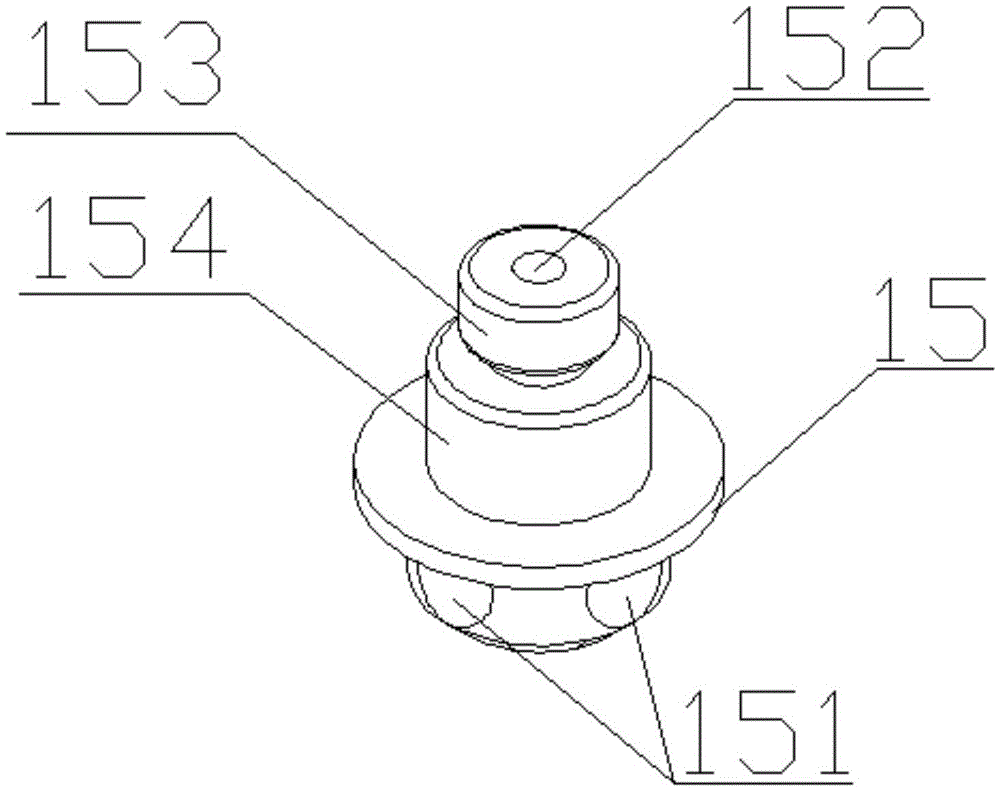

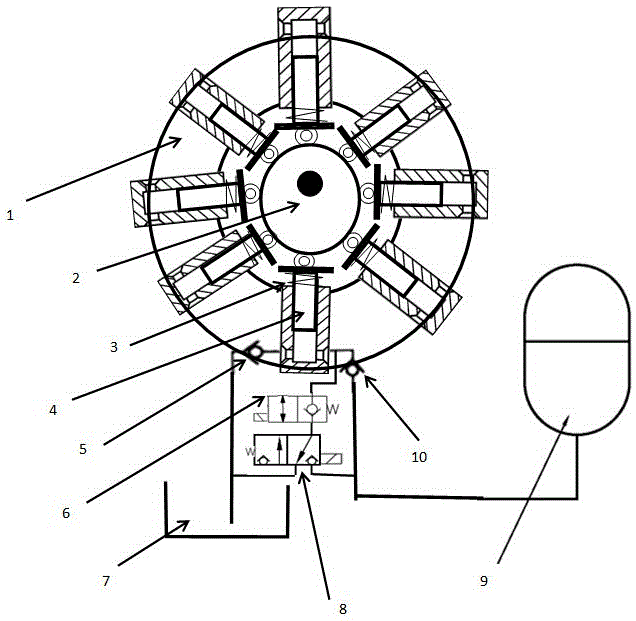

Automobile kinetic energy conversion and recovery device

ActiveCN105059274AImprove efficiencyIncrease energy densityHybrid vehiclesBraking element arrangementsHydraulic motorRadial motion

The invention discloses an automobile kinetic energy conversion and recovery device. The automobile kinetic energy conversion and recovery device is used for storing energy during subway braking and recovering kinetic energy during starting. The automobile kinetic energy conversion and recovery device mainly comprises an eccentric wheel, hydraulic plungers and a corresponding hydraulic loop. During subway braking, the eccentric wheel and an axle rotate synchronously, so that the built-in hydraulic plungers conducts reciprocating radial motion; hydraulic oil is pressed into an energy accumulator through the hydraulic plungers on the basis of the design of the corresponding hydraulic loop, and therefore kinetic energy of the automobile is converted into hydraulic energy to be stored. During subway starting, the device is used as a low-speed large-torque hydraulic motor on the basis of switching control over an electromagnetic valve to push a subway to achieve kinetic energy recovery. According to the automobile kinetic energy conversion and recovery device, the hydraulic mode is utilized for energy storage, braking energy is not converted into electric energy and is just stored as hydraulic energy, and the efficiency is much higher than that of the existing energy storage mode.

Owner:王林翔

Structure for preventing water coming into turbine fuel and fuel leakaging

ActiveCN1888484APrevent external leakageStop the leakEngine sealsPositive displacement pump componentsEngineeringTurbine

In the invention, a miniature pressurized fan is added at the position of the original rotor boss or the slot in the oil baffle of a turbine, a fan and a compressor, or the miniature pressurized fan adopts a shrink fit on the oil scraper ring. The fan can produce two airflows, an airflow flows on the side of the cylinder to stop the steam leaked from the shaft end from being sucked into the bearing box and the other airflow flows to the bearing box in order to prevent the turbine oil from leaking outwards and water from entering into the turbine oil.

Owner:DONGFANG TURBINE CO LTD

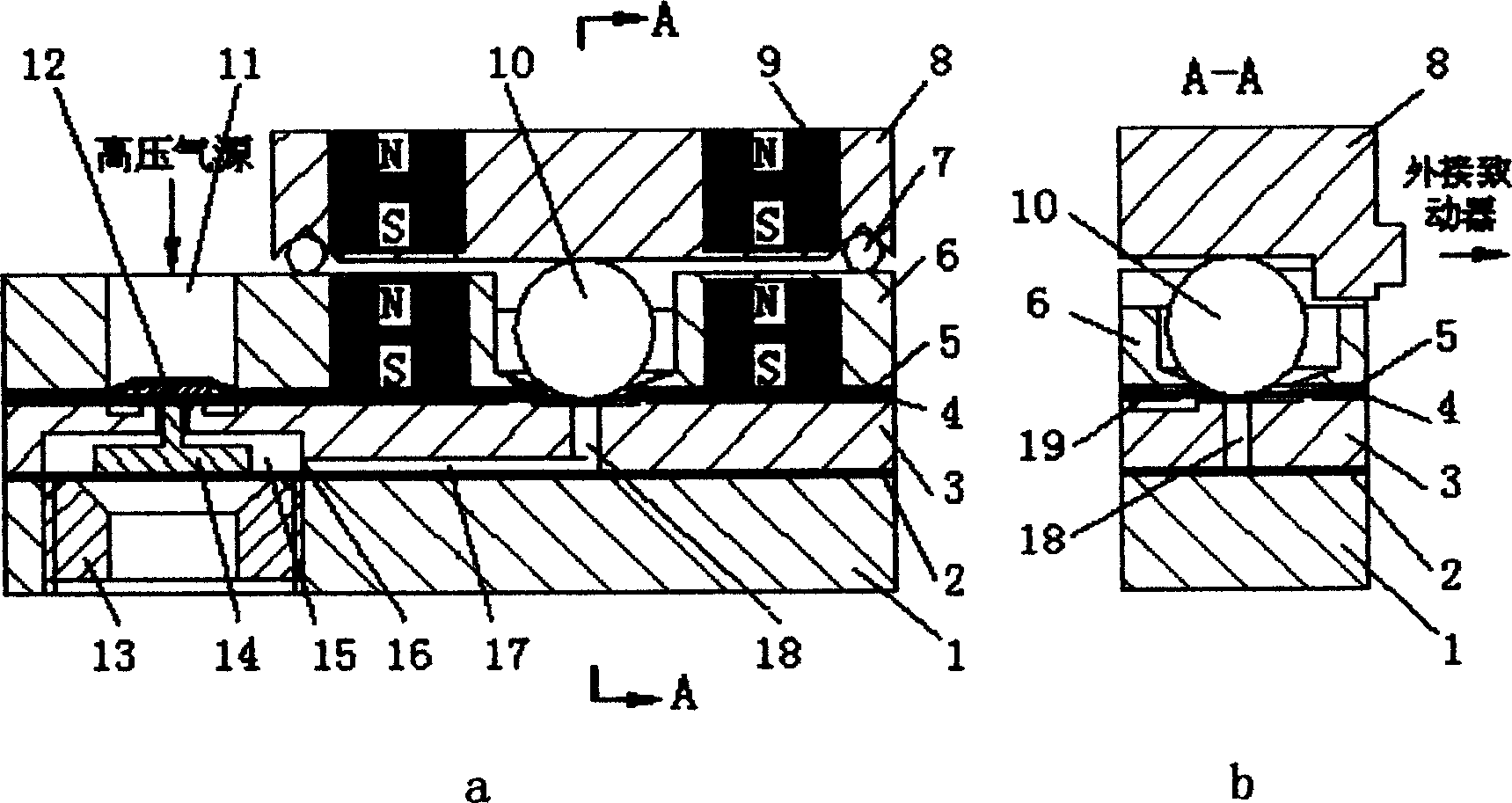

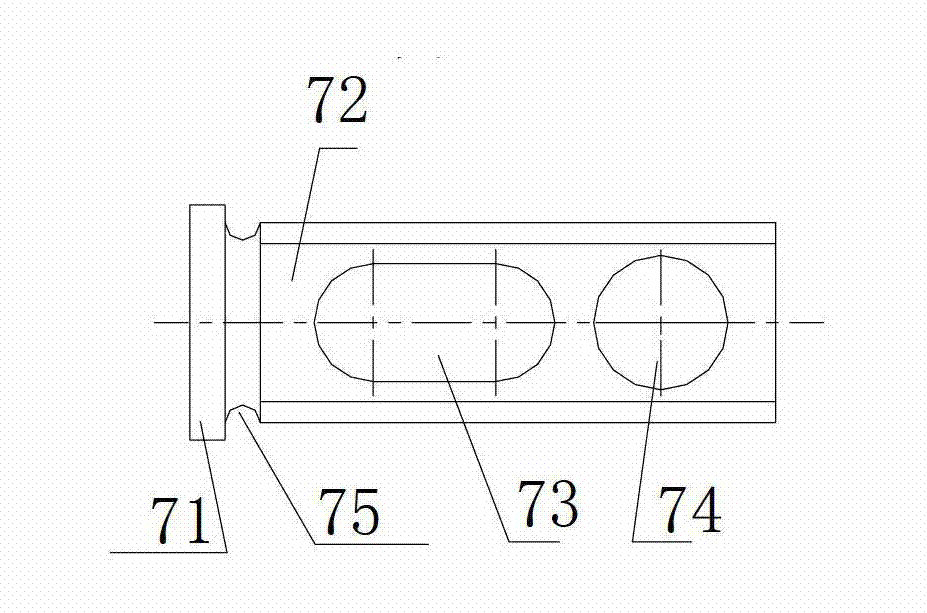

Miniature integral cold air propeller

InactiveCN1486904AReduce vertical sizeSimple structureRocket engine plantsSpacecraft guiding apparatusFluid controlEngineering

The present invention relates to miniature fluid control element in precise machine and astronautics, and is especially miniature integral cold air propeller for satellite posture and position control. The pressure reducer, cut-off valve, shared seat, valve base, valve cap, sealing film and other parts constitute one integral structure, and the miniature planar nozzle is set near the air outlet of the cut-off valve. Elastic film and plate spring are used in the reducing and stabilizing of high pressure air to simplify the structure, machining and installation. Rolling ball valve core is used to raise the control pressure of the cut-off valve, and permanent magnetic suction is used to provide sealing pressing force of the cut-off valve and the restoring force of actuator. The main parts of the pressure reducer and the cut-off valver are in planar structure and integrally designed, and this makes it possible to transplant to planar miniature technique, and integrating the structural parts can omit assembly, reduce size and raise integration degree and control precision.

Owner:TSINGHUA UNIV

Non-electric explosion propagation type redundancy control electric explosion isolating valve

ActiveCN103032204AImprove opening reliabilityReliable cutRocket engine plantsShock waveIsolation valve

The invention discloses a non-electric explosion propagation type redundancy control chipless high-reliability electric explosion isolating valve. The isolating valve consists of a valve body, an adapter tube nozzle, a baffle ring, a piston, a check ring, an O-shaped rubber ring and a cutter. Before explosion, a medium in a gas cylinder can be separated from a downstream passage by an electric explosion isolating valve sealing position; when a system starting command is received, the non-electric explosion propagation system is exploded to generate high-pressure and high-temperature gas and shock wave; the high-pressure and high-temperature gas and the shock wave are acted on the piston; and the cutter is pushed to cut off a bushing on the sealed position to open the medium and the downstream passage. According to the non-electric explosion propagation type redundancy control electric explosion isolating valve disclosed by the invention, the valve working reliability is improved by a double-explosion device redundant structure design, the phenomenon that metal chips enter the downstream system is avoided by a cutter rear-end single-side positioning structure, the valve miniaturization is realized, and the system reliability is improved. Meanwhile, the system power load is reduced by the non-electric explosion propagation system, and the valve opening synchronism is improved.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

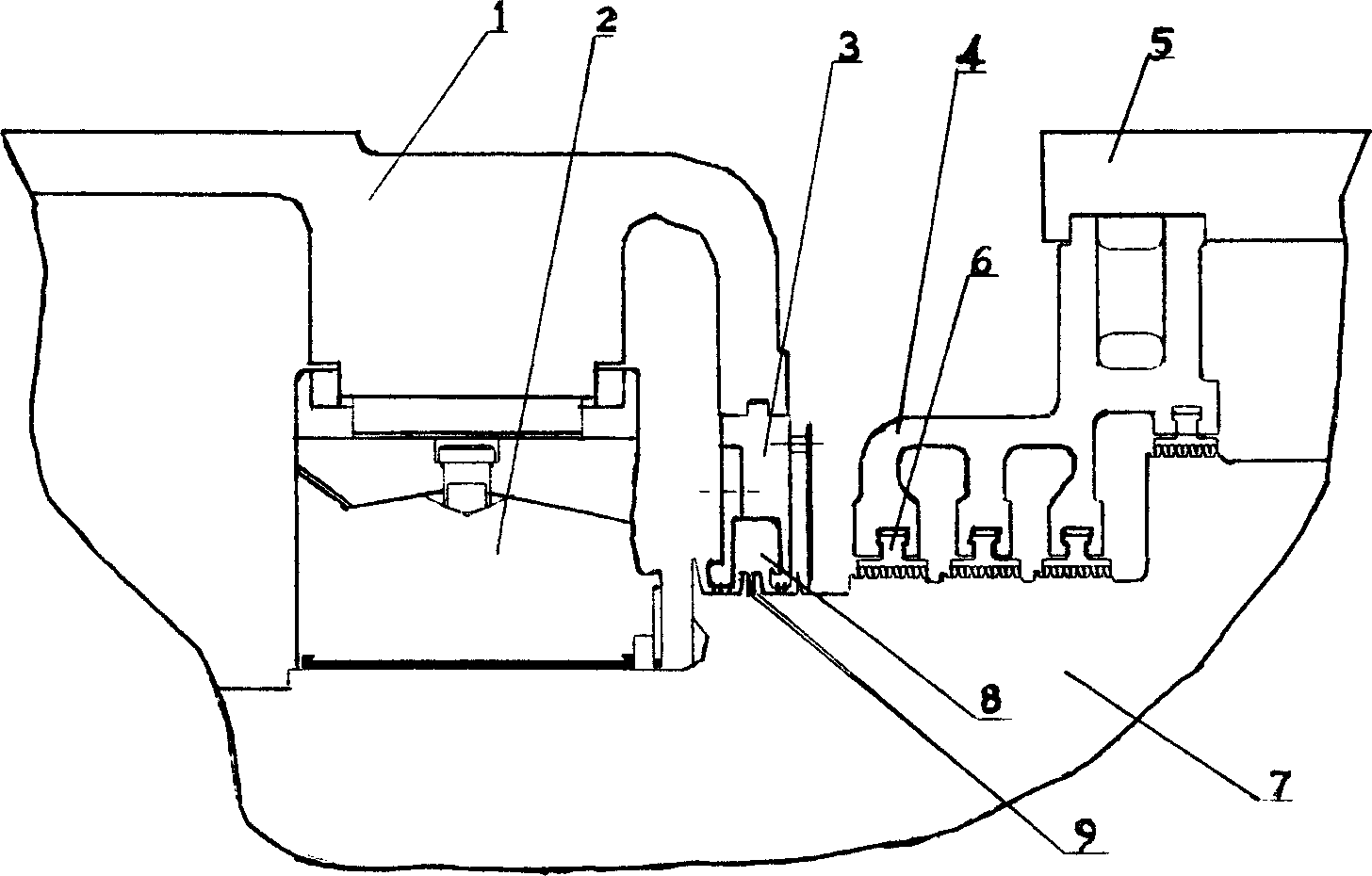

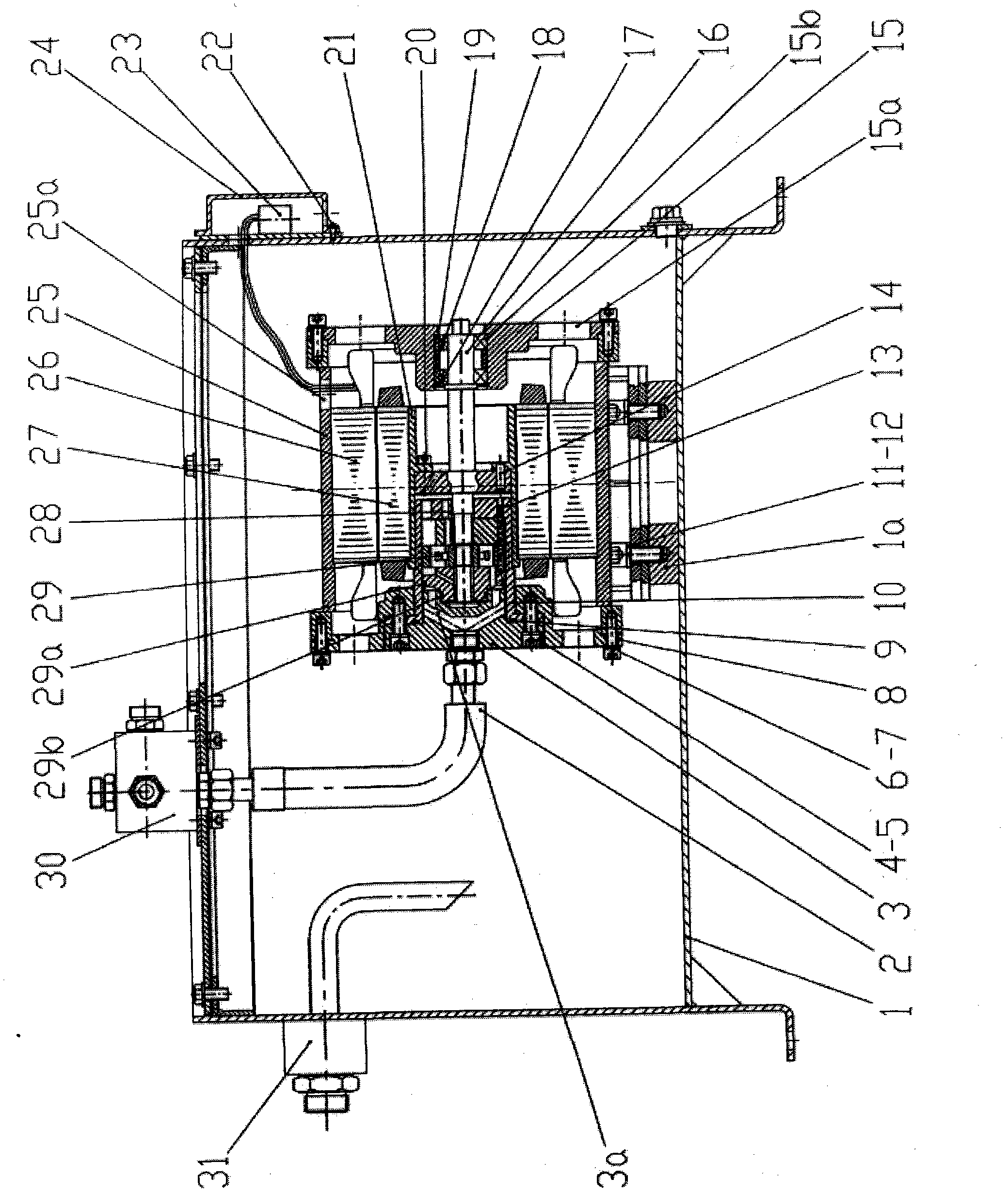

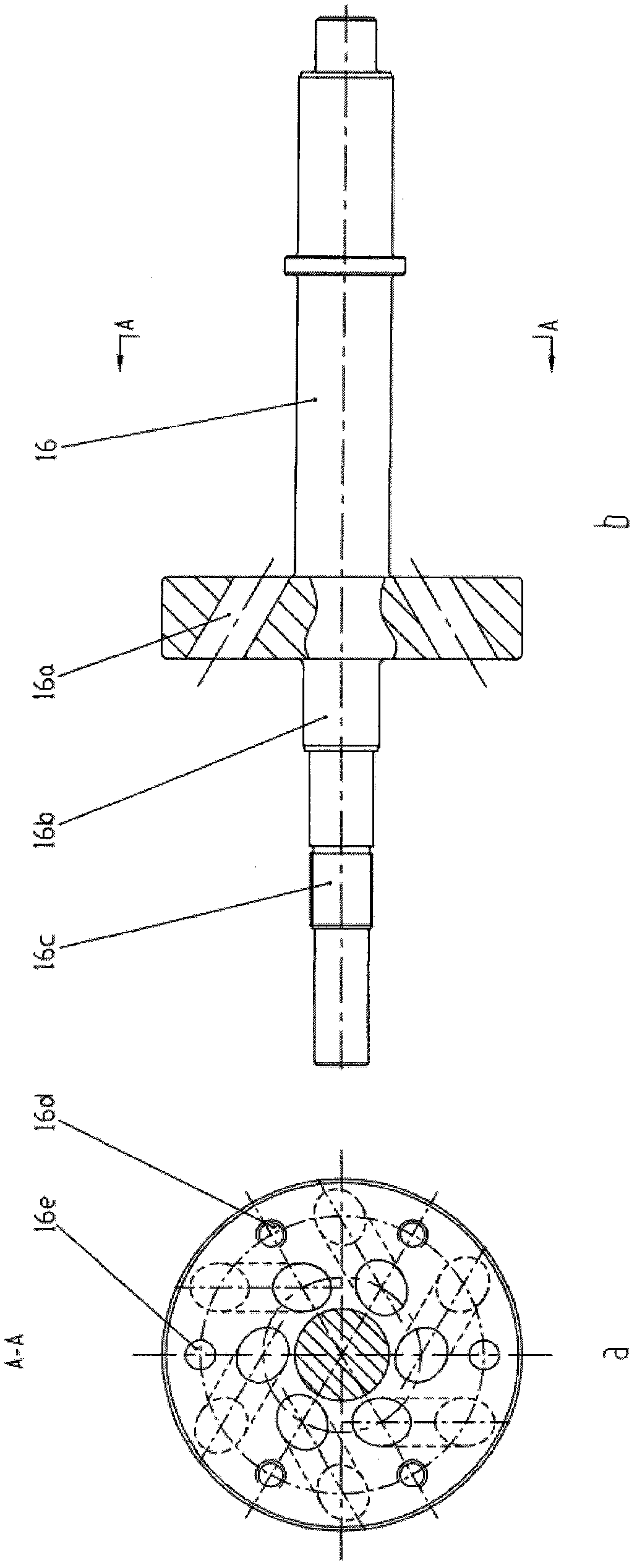

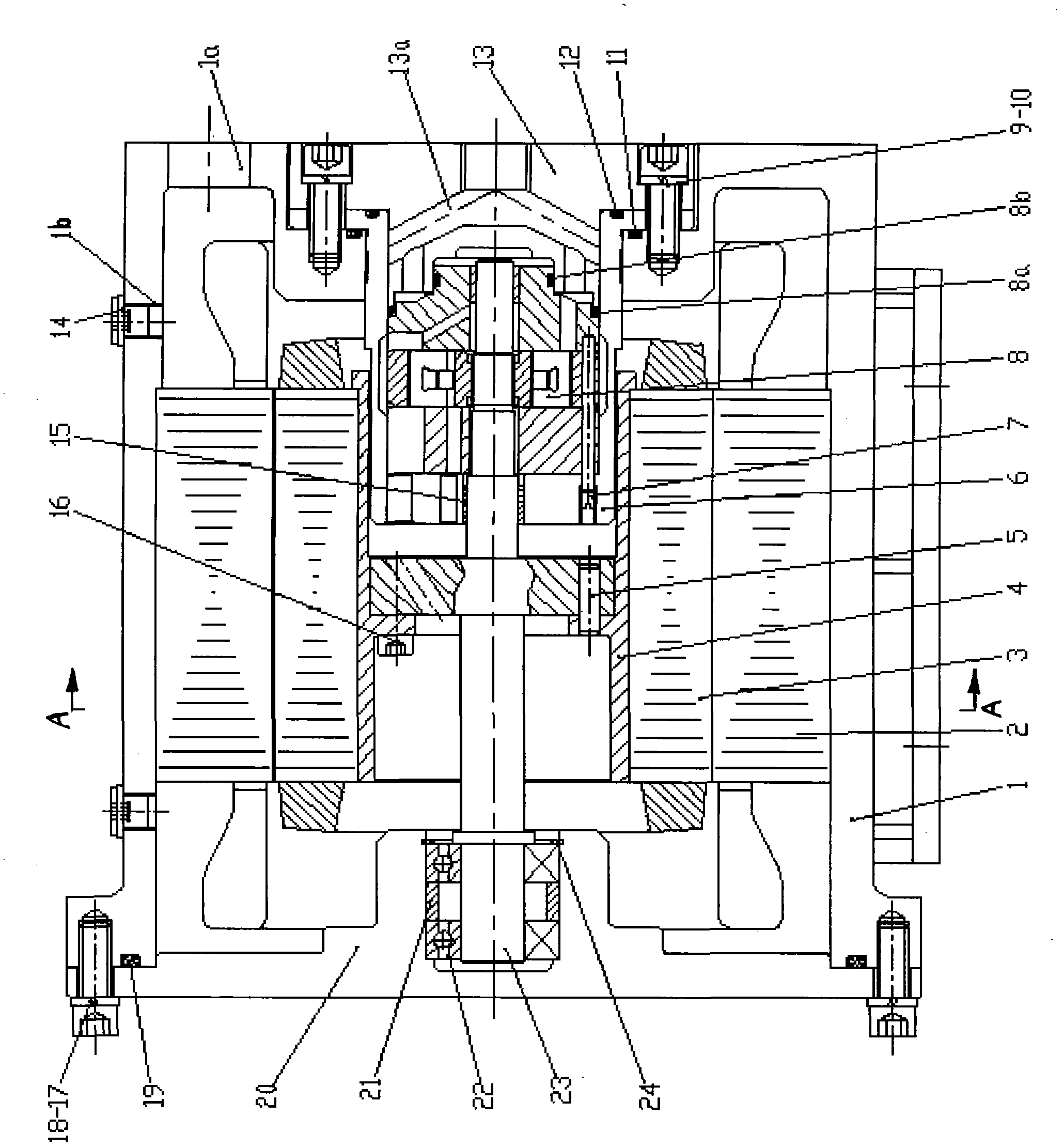

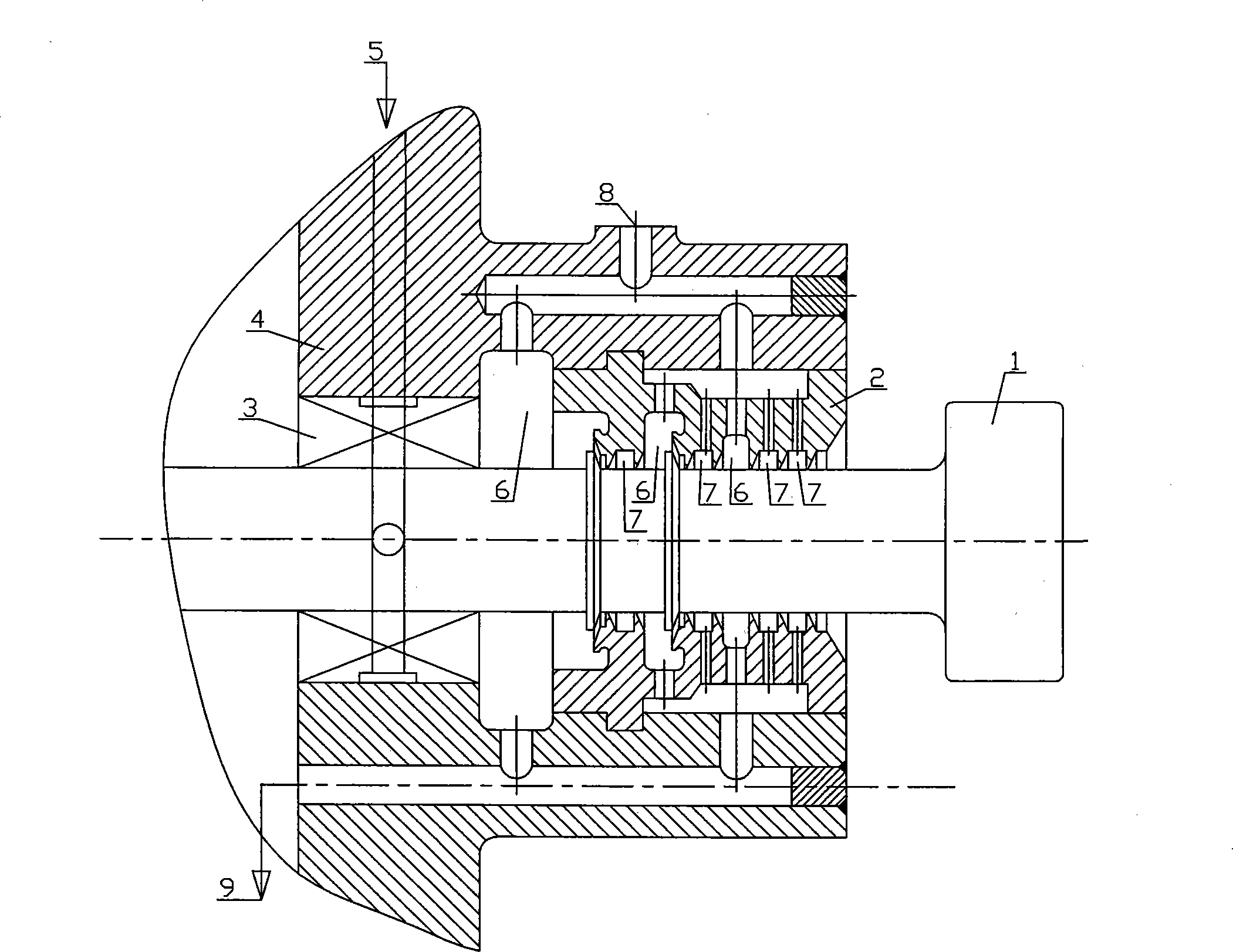

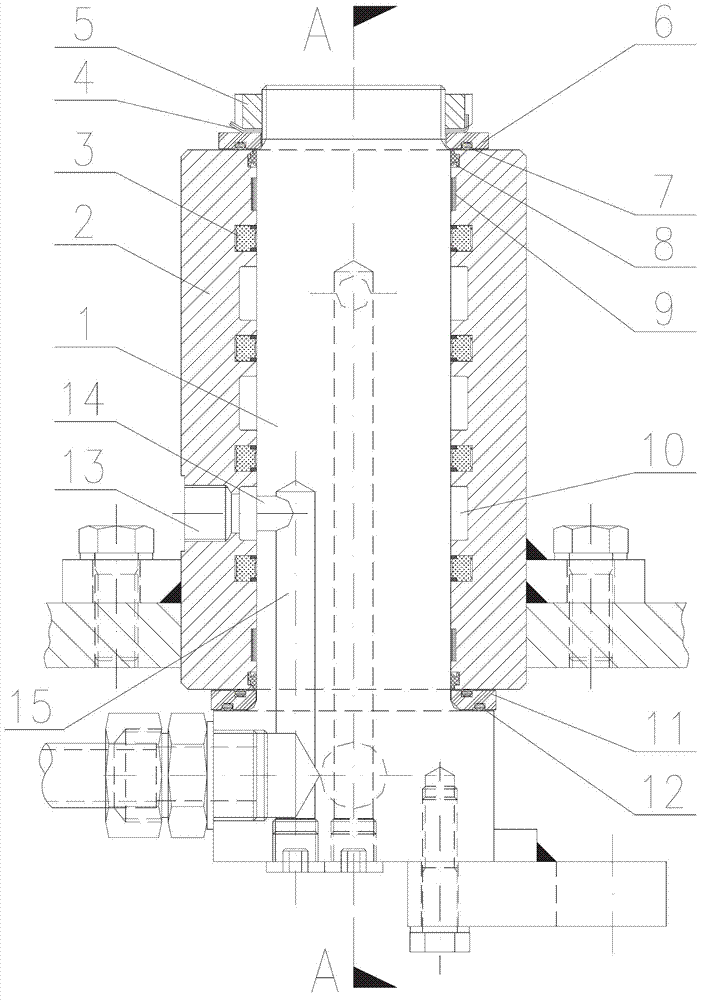

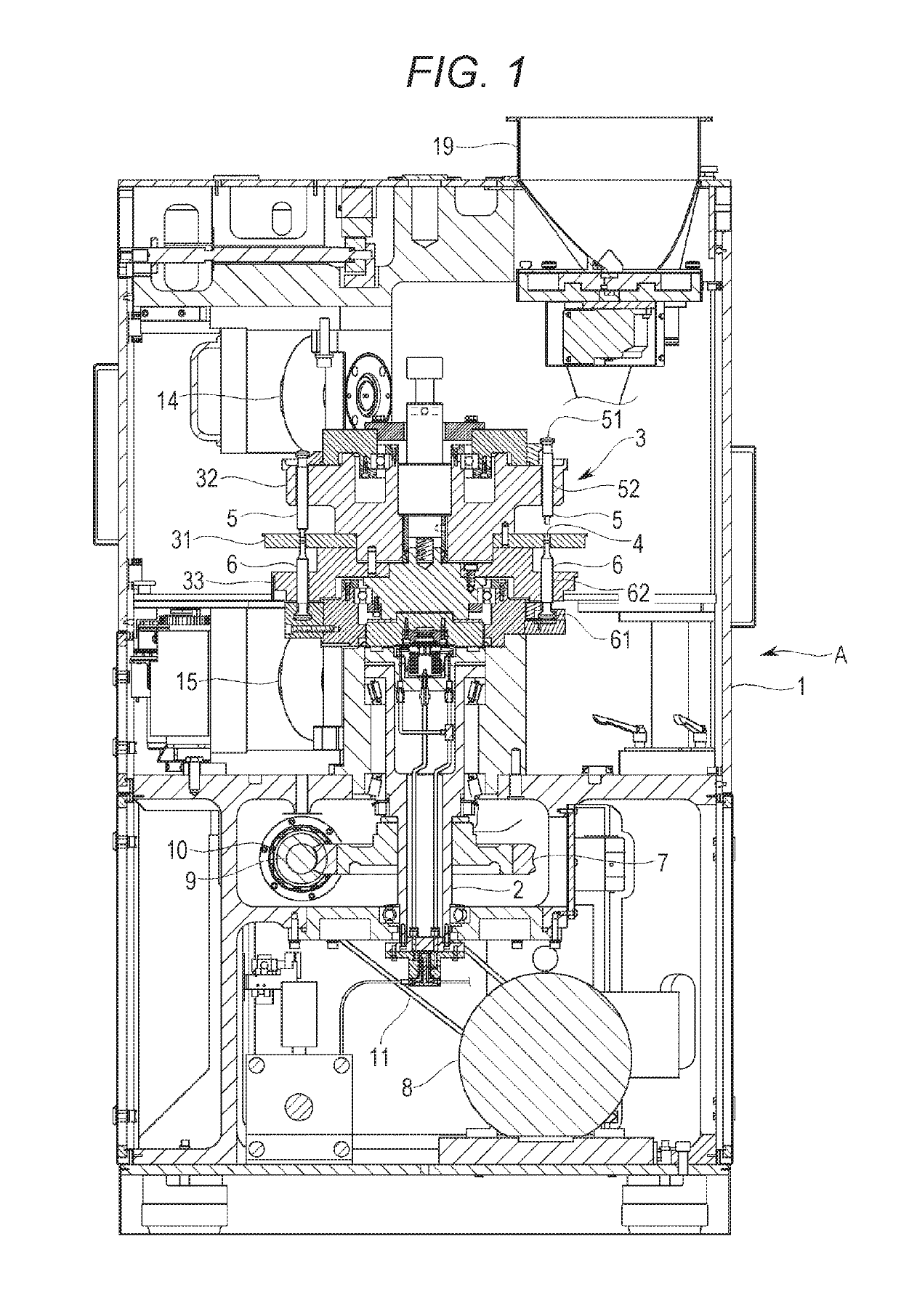

Integrated motor vane pump hydraulic power unit

InactiveCN102628464ACompact structureReduce volumeFluid-pressure actuator componentsHydraulic pumpHigh pressure

The invention relates to an integrated motor vane pump hydraulic power unit. In the integrated motor vane pump hydraulic power unit, a motor rotor (27) is connected with a rotor sleeve (21) and a main shaft (16) through a pin (14) and a screw (20), so as to form a rotor body; the rotor body is supported on a pump rear cover (15) and a pump core seat (10) through a sliding bearing (28) in the pump core seat (10) and two groups of rolling bearings (19) in the pump rear cover (15); a vane pump (29) is connected with the main shaft (16) through a spline (16c); the vane pump (29) is arranged in the pump core seat (10) through an oil outlet gland (3), a screw (4), a gasket (5) and a pump front cover (8); a motor stator (26) is pressed in a motor base (25); the pump front cover (8) and the pump rear cover (15) are fixed on the motor base (25); the motor base (25) is fixed on a support (1a) in a box body (1); an oil outlet of a hydraulic pump (29) is communicated with an inner runner (3a) of the oil outlet gland (3); and the oil outlet gland is connected with an oil path block (30) on the box body (1) through a high-pressure oil pipe (2).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

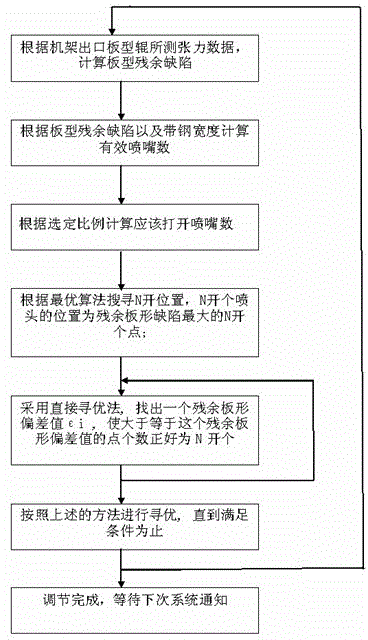

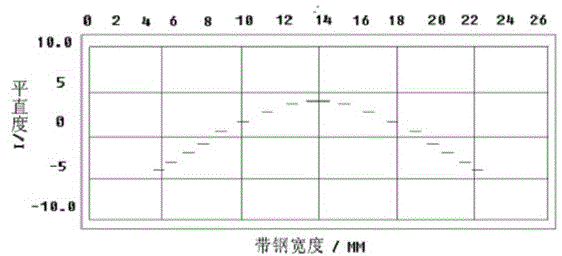

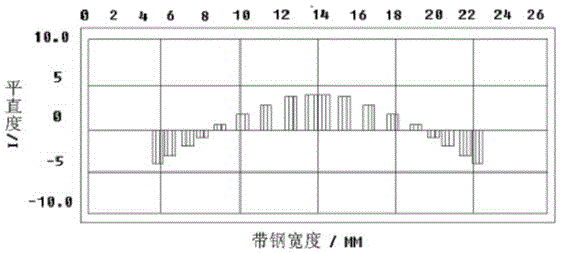

Emulsion fine cooling system control method and control device

ActiveCN104874614AReduce resistanceAvoid damageTemperature control deviceWork cooling devicesEmulsionShape deviation

The invention relates to an emulsion fine cooling system control method. The emulsion fine cooling system control method is characterized by comprising the following steps that the plate-shaped residual defect is calculated in dependence on steel strip contact tension data detected by a frame outlet plate-shaped roller; 2) the valid nozzle number is calculated in dependence on the plate-shaped residual defect and the steel strip width, N (valid)=B / 52, wherein B is the steel strip width (mm), and the distance between any two adjacent nozzles is 52mm; 3) the number N (open) of nozzles which need to be opened is calculated in dependence on a selected proportion, N (open) = N (valid)*K1, K1 is the selected open proportion, and is generally selected to be 50%, and the K1 can be reset as needed; 4) the positions of the N (open) nozzles are searched in dependence on the optimal algorithm, the positions of the N (open) nozzles are N (open) points where the plate-shaped residual defect is maximal; 5) through a direct optimum seeking method, a residual plate-shaped deviation value [epsilon]I is found out, and the number of points which are smaller than or equal to the residual plate-shaped deviation value is just equal to N (open); and 6) the optimum seeking is carried out through the above way until the condition is satisfied.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

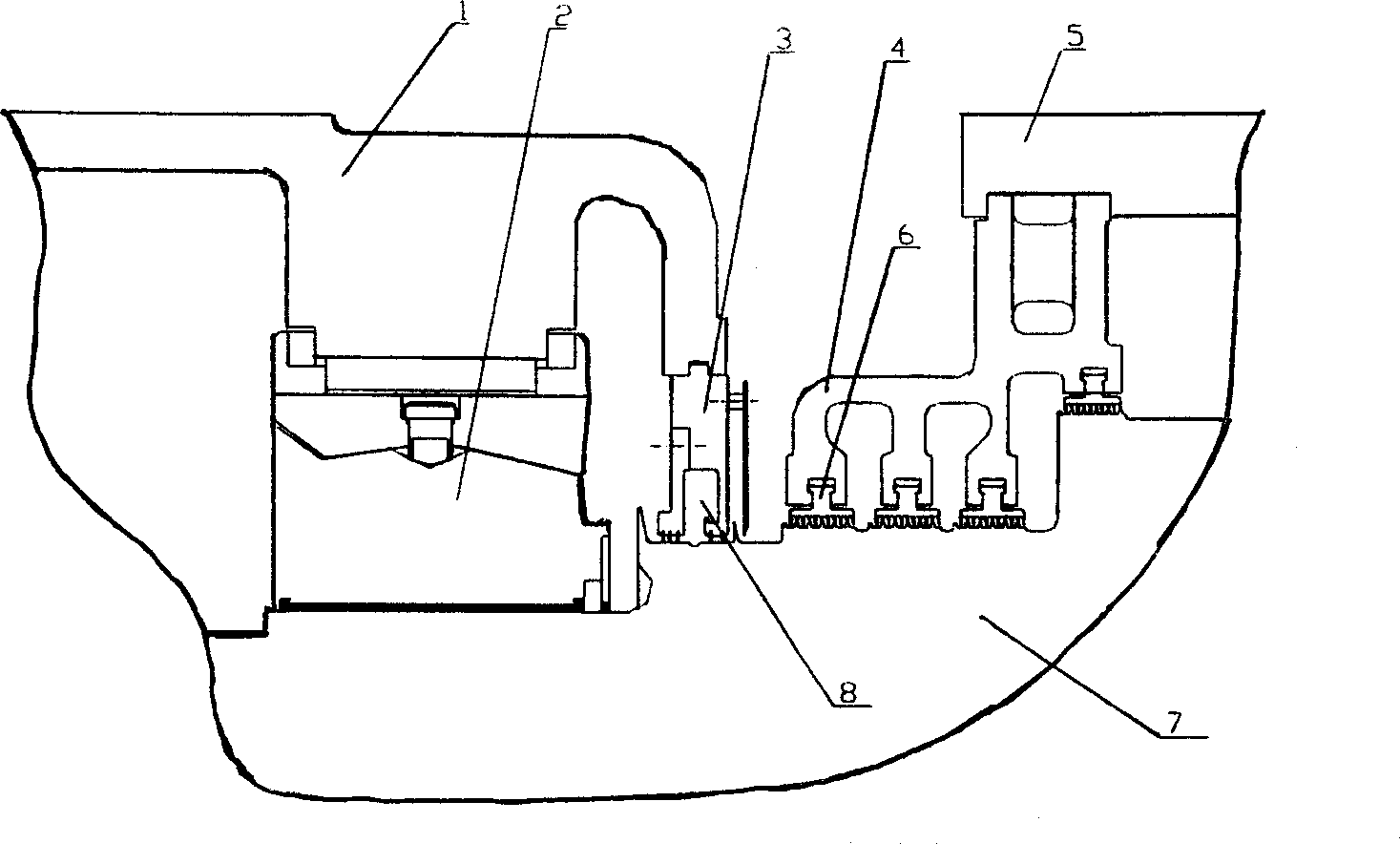

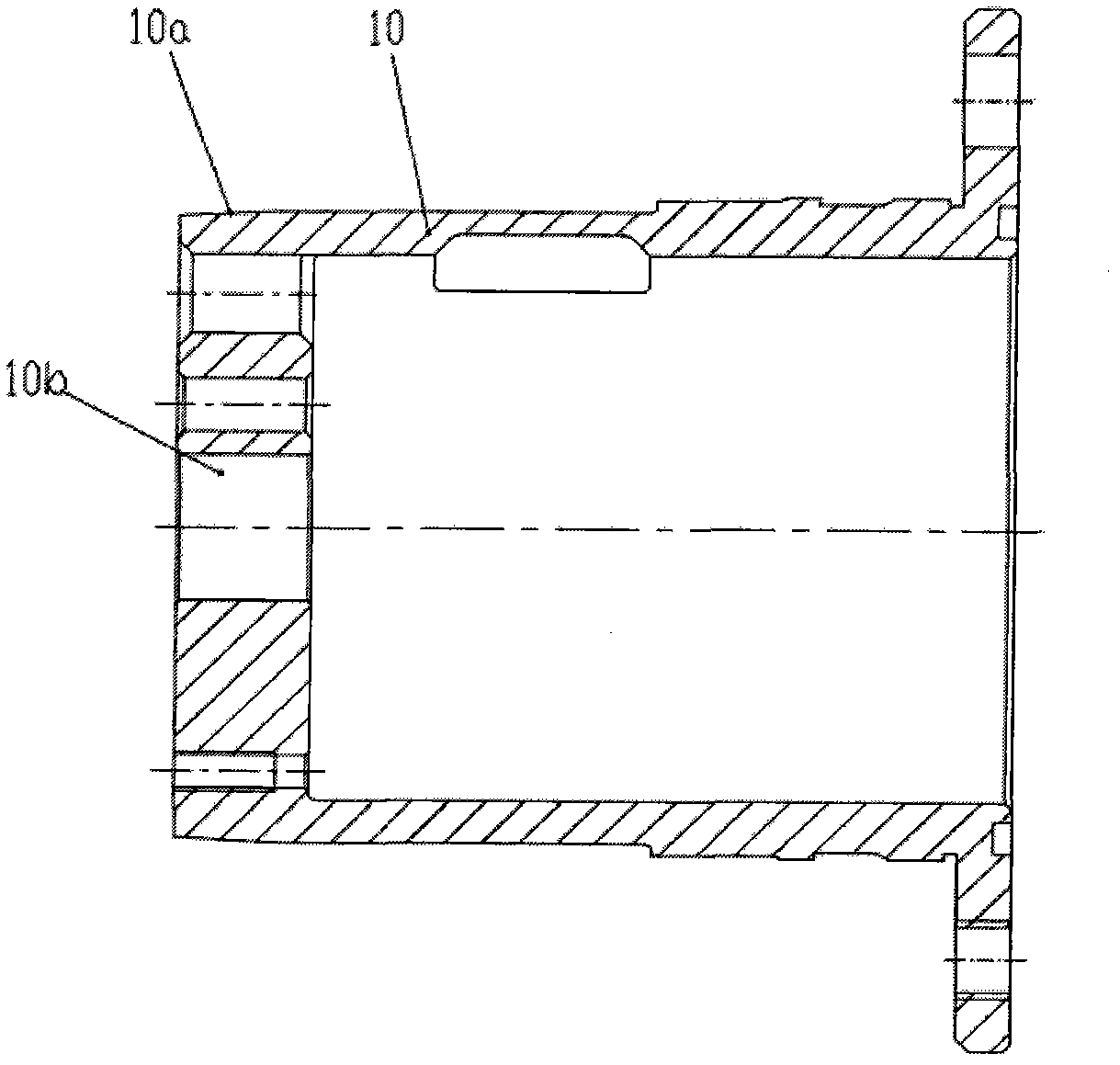

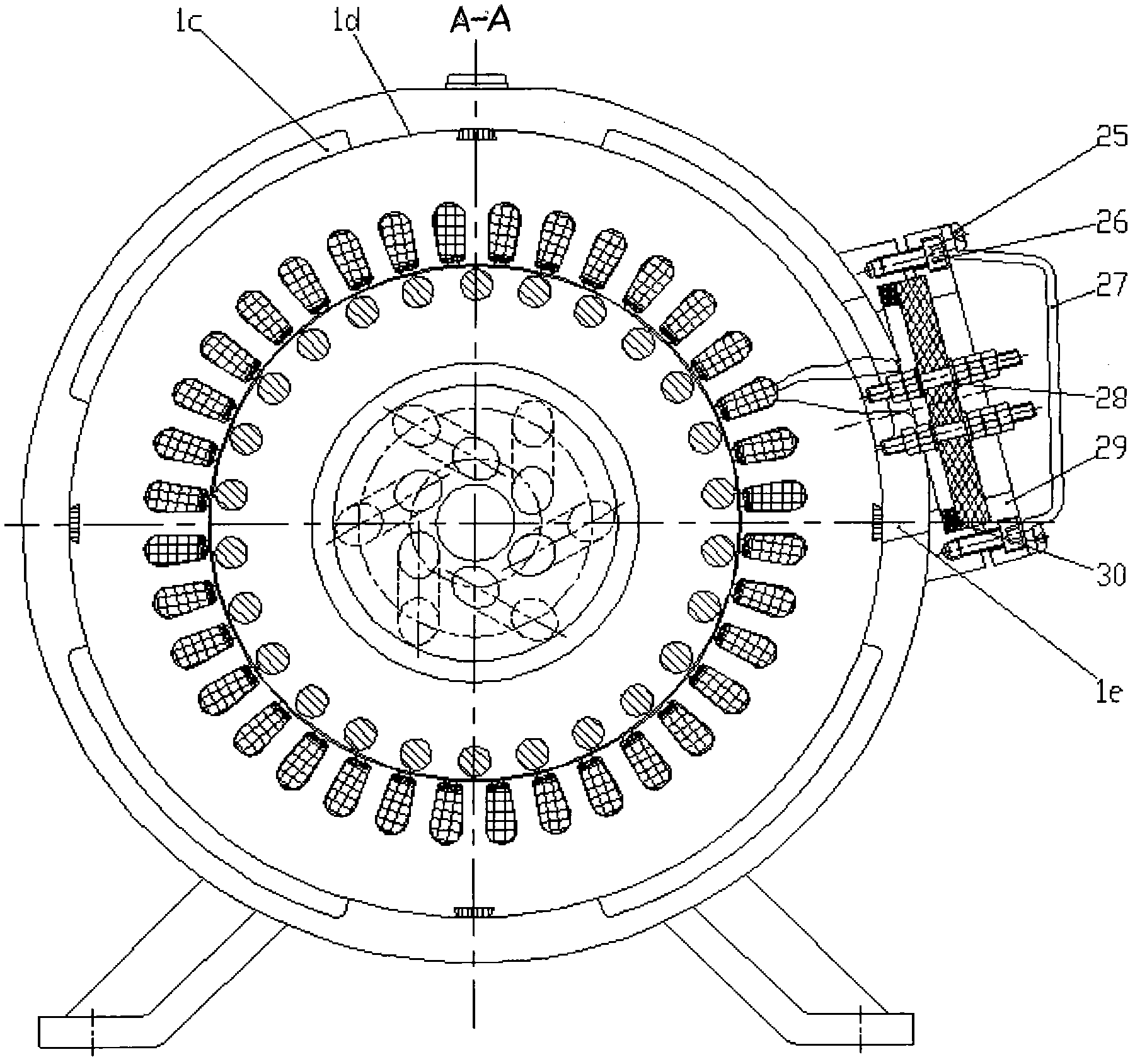

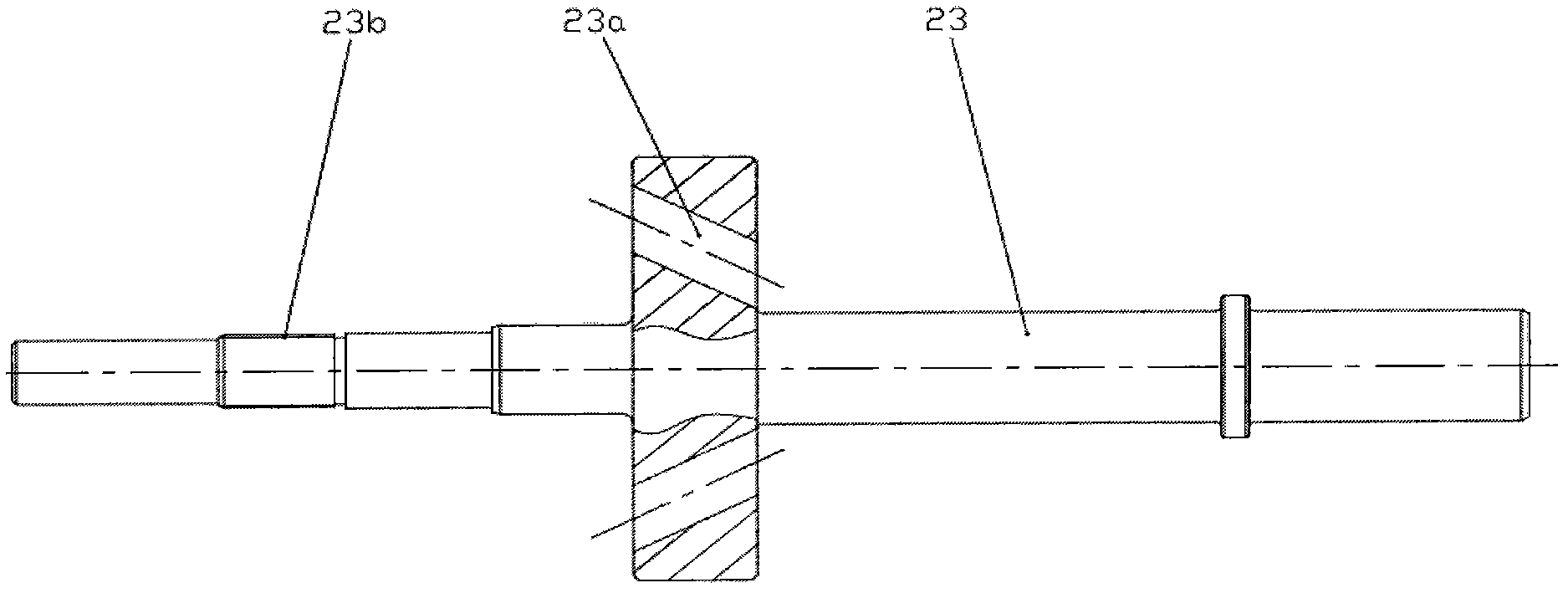

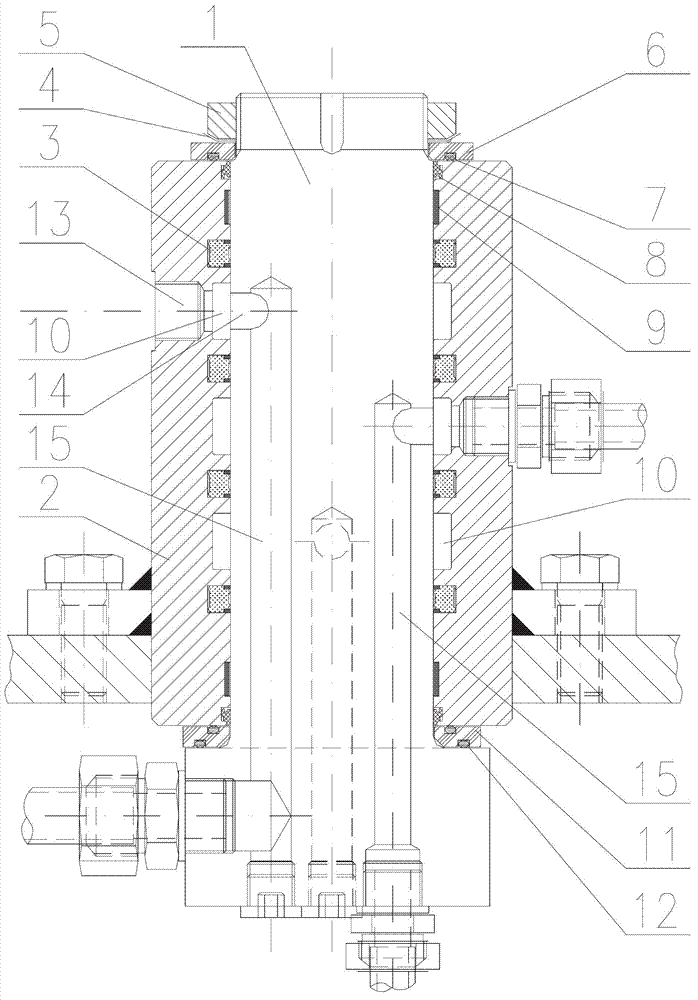

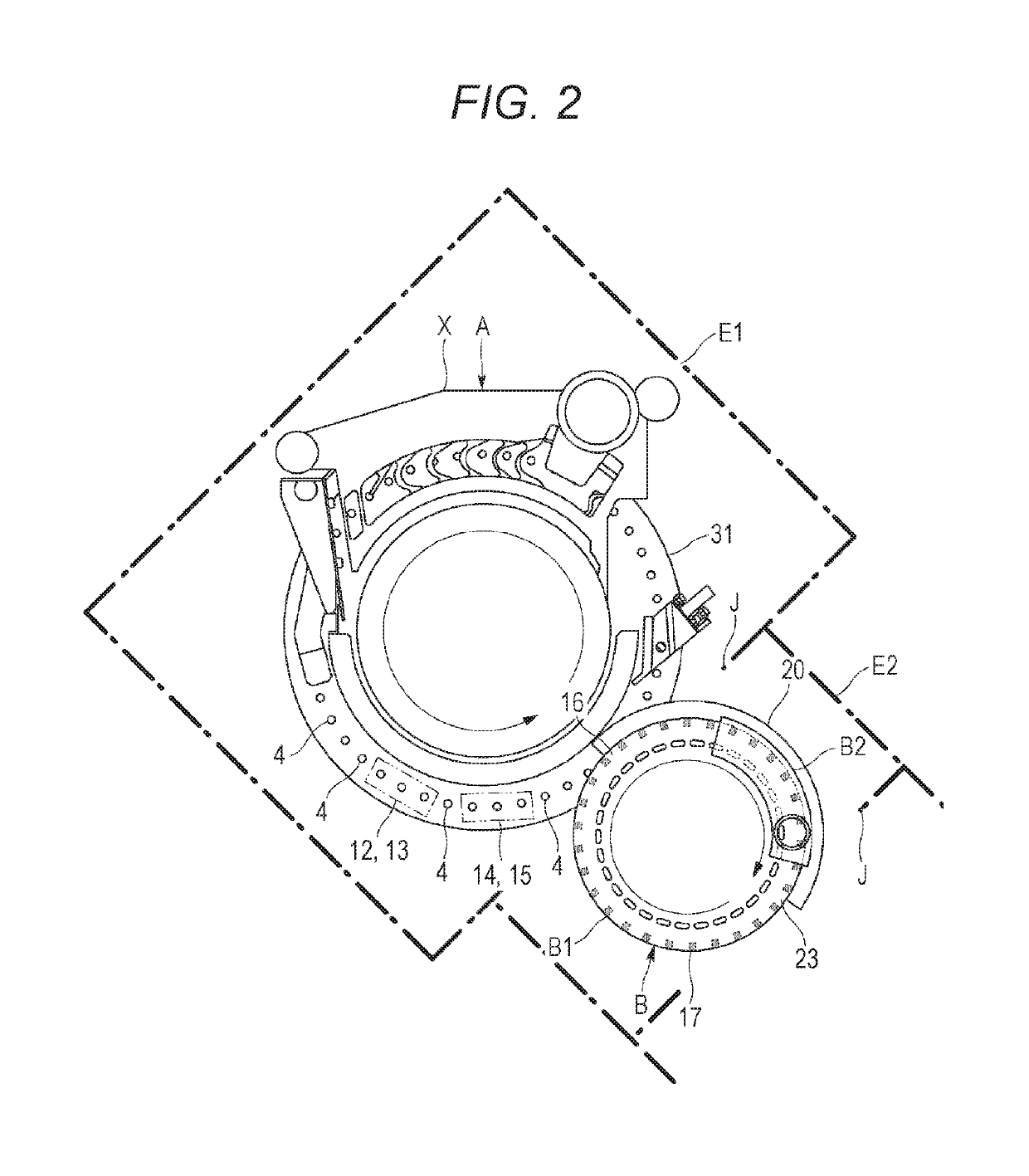

Hydraulic power unit including centrifugal pump and vane pump in motor

InactiveCN102628435ASimple structureCompact structurePump installationsPositive-displacement liquid enginesCentrifugal pumpPower unit

The invention provides a hydraulic power unit including a centrifugal pump and a vane pump in a motor. A motor rotor (3) is connected with a rotor sleeve (4) and a spindle (23) to form a rotor body, and is supported on an end cover (20) and a pump core seat (6) by a sliding bearing (15) in the pump core seat (6) and two groups of rolling bearings (22) in the end cover (20); the vane pump (8) is connected with a spindle (23) by a spline (23b), mounted in the pump core seat (6), and fixed on a stand (1) by an oil outlet press cover (13); a motor stator (2) is pressed on a boss (1d) within the stand (1); the end cover (20) and a sealing ring (19) are fixed on the stand (1); an oil outlet of the vane pump (8) is communicated with a runner (13a) of the oil outlet press cover (13) so as to output high pressure oil; power is supplied to the motor in the hydraulic power unit by a wiring terminal (28); and the wiring terminal (28) and a sealing ring (30) are fixed on the stand (1) by a bolt (26) and a press cover (29).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Labyrinth type oil seal structure with holes for high speed axis

InactiveCN101251193AWeaken the phenomenon of "adsorption blockage"Prevent external leakageEngine sealsGearboxesAtmospheric airFuel tank

The invention relates to an oil sealing structure for an output end of a main axis in a speed-increasing gear box of a high-speed fan, in particular to the oil sealing structure which is used to prevent the lubricating oil on the output end of the main axis from leaking out, belonging to the mechanical structure technical field, wherein a labyrinth type oil sealing piece is provided with a plurality of grooves, forming a labyrinth type oil sealing structure together with the output axis; the structure comprises interstage space and intertooth space and is characterized in that upper parts and lower parts of the interstage space and the intertooth space are provided with pressure equalizing holes(communicated with the atmosphere) and oil return holes(return to an oil tank) respectively. When a great amount of oil needs to be supplied, in the invention, enough intertooth space and pressure equalizing holes on the upper parts can weaken the 'adsorbing retardation' phenomenon caused by the viscosity of the lubricating oil, which makes the lubricating oil quickly pass through oil return holes on the lower parts and return to the oil tank, therefore the leaking-out of the lubricating oil is effectively avoided.

Owner:无锡金露通用机械有限公司

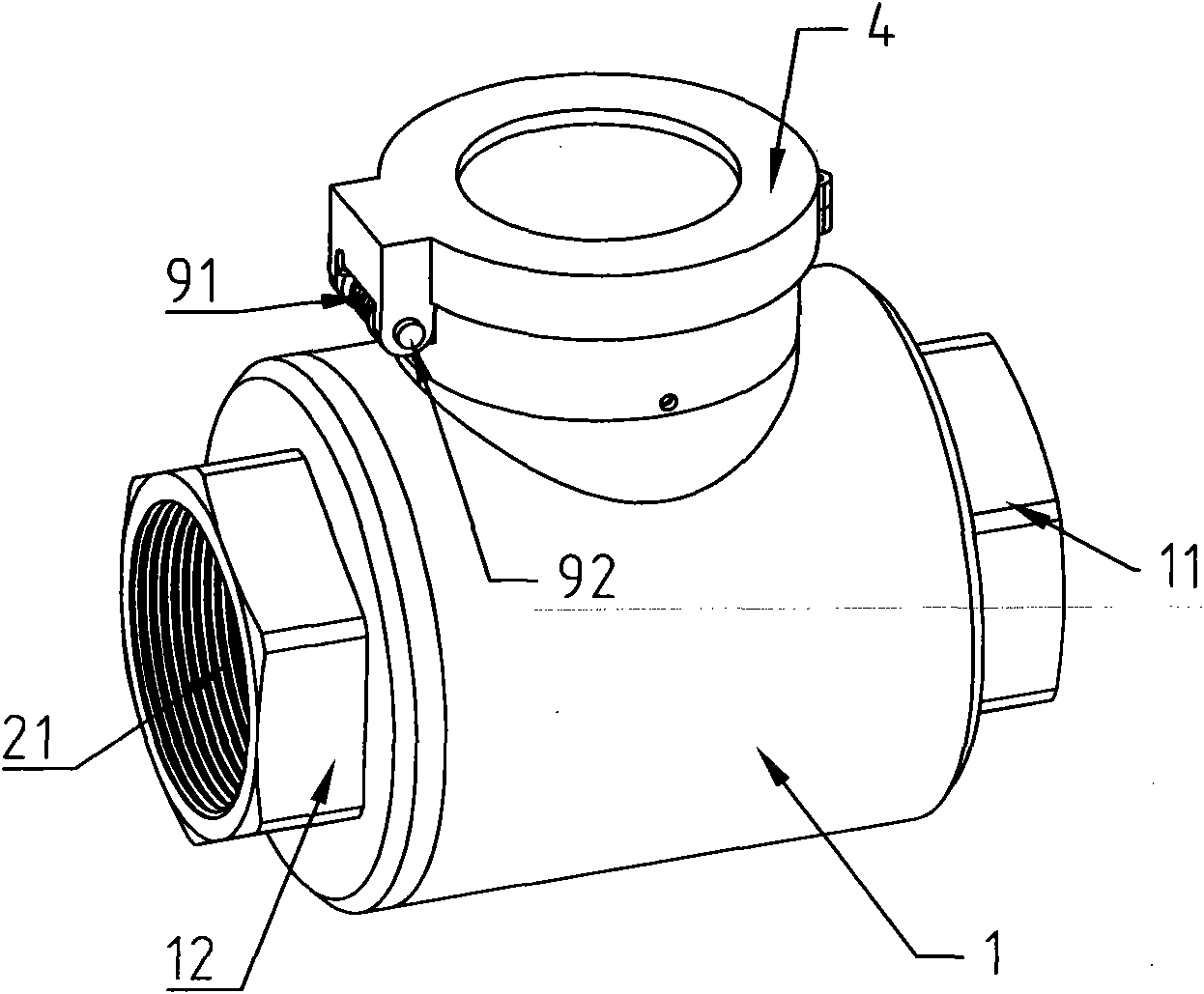

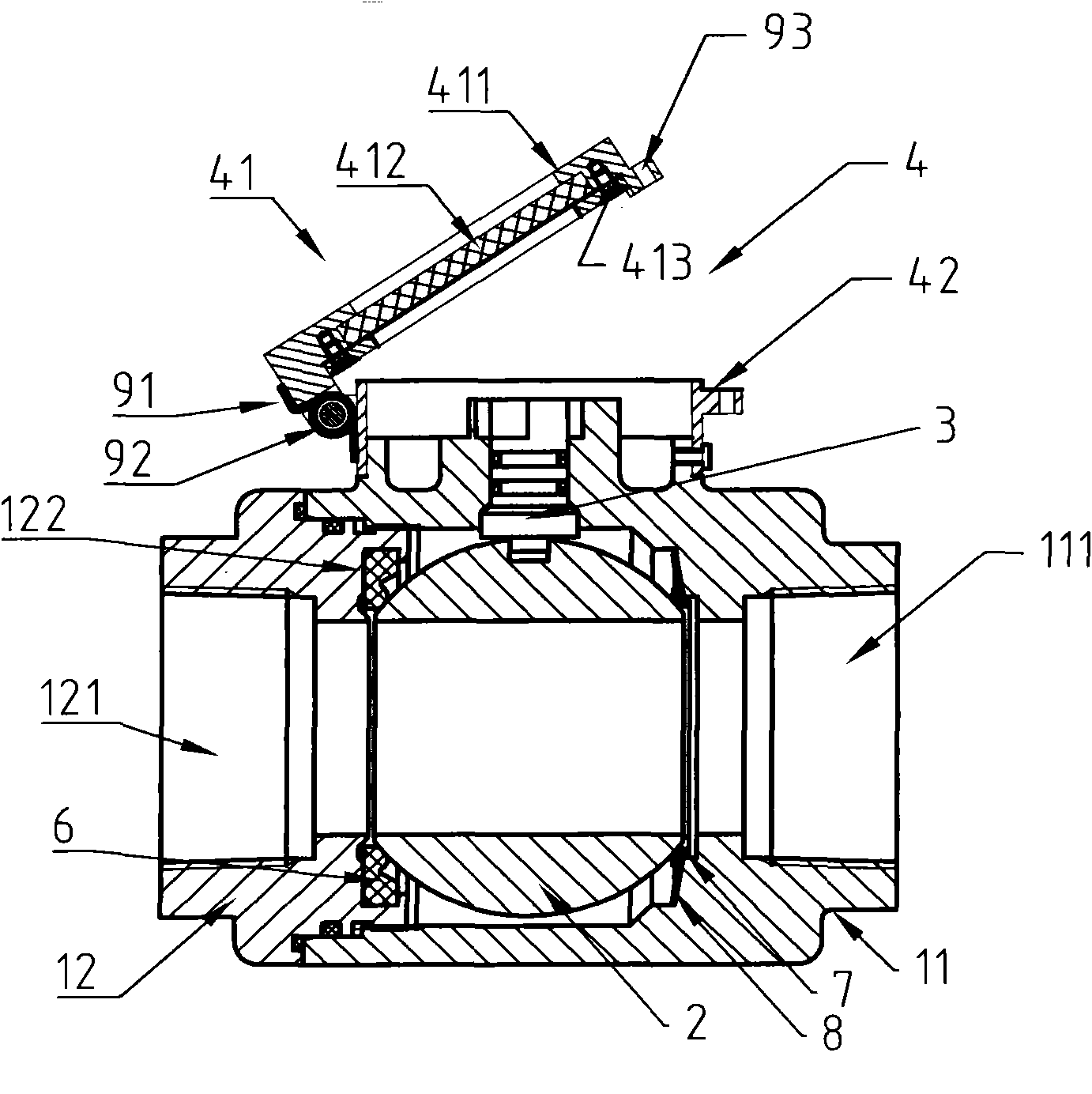

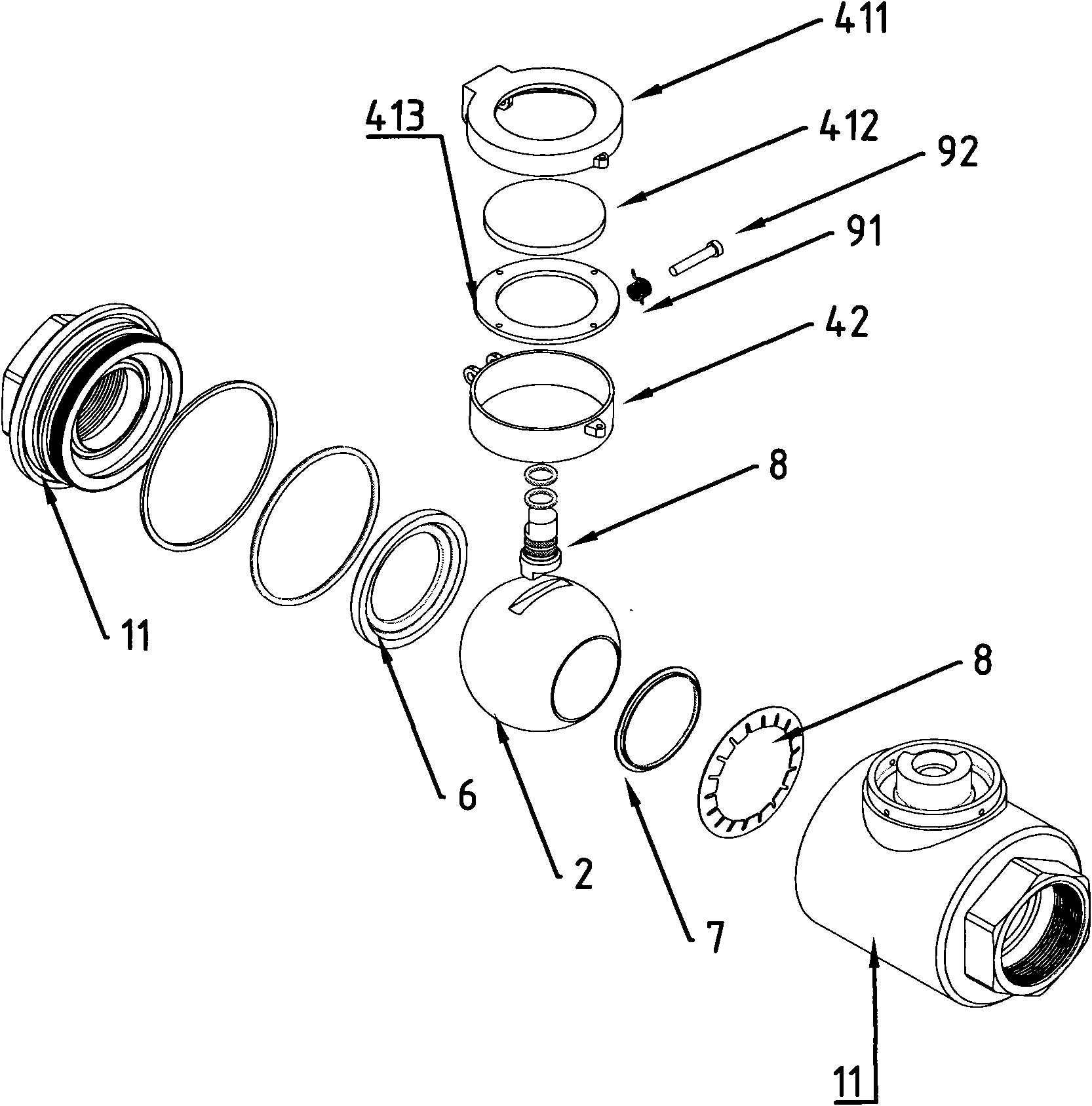

Combined valve

InactiveCN104482253ASolve bad working conditionsSolve the requestSpindle sealingsPlug valvesEngineeringVALVE PORT

The invention provides a combined valve. The combined valve can be free of leakage for a long time under severe working conditions. The combined valve comprises a combined valve body, wherein a medium inlet and a ball valve cavity communicated with the medium inlet are formed in one side of the combined valve body, a medium outlet and a stop valve cavity communicated with the medium outlet are formed in the other side of the combined valve body, the ball valve cavity is communicated with the stop valve cavity, a stop valve element arranged in the stop valve cavity a is connected with stop valve rod, a handle is connected to one end of the stop valve rod, a ball valve ball body arranged in the ball valve cavity is connected with a ball valve rod, the ball valve rod is connected with an output shaft at one end of a speed reduction mechanism, the other end of the speed reduction mechanism is connected with a driving gear for driving the speed reduction mechanism to rotate, the driving gear is meshed with a transition gear, and the stop valve rod drives the transition gear to rotate. The combined valve is integrally designed, has few leakage points, and is more reliable in pipeline installation, and more convenient to operate.

Owner:BEIJING OTE CONTROL VALVE

Low torsion moment ball valve for fuel gas vertical pipe

InactiveCN102155552AReduce frictionReduce operating torquePlug valvesOperating means/releasing devices for valvesSpecial designEngineering

The invention discloses a low torsion moment ball valve for a fuel gas vertical pipe, which is a ball valve with novel sealing structure; a valve body is connected by a screw thread so as to reduce the weight of the valve; a sealing ring is arranged in a sealing groove on the valve body so that the sealing ring does not fall off at any state, the reliability of the valve is ensured, the torsion of the valve opening and closing is reduced, simultaneously a slotting disk spring is used for providing the pre-pressure of the valve, and a specially designed sealing ring greatly reduces an operating torsion; and after the sealing ring is burned at high temperature, the slotting disk spring pushes a sphere so that the sphere is contacted with an auxiliary valve body so as to form a metal hard seal which avoids the internal leakage of the valve and has the fire prevention function. In addition, a special designed valve opening mechanism prevents the possibility of incorrect operations.

Owner:SUZHOU GAS EQUIP & VALVES MFG

Composite plastic woven bag for fine powder product

The invention relates to a composite plastic packaging pouch of powder product. Wherein, its bottom edge is treated with ultrasonic wave to form adhesive part; the upper part of adhesive part is stitched via stitch wire; the sealing paper via fused material or coated with liquid adhesive, or packed with emulsion coats the adhesive part and stitch wire. The inventive adhesive part can avoid powder leakage.

Owner:TIANJIN SHINIL INDAL

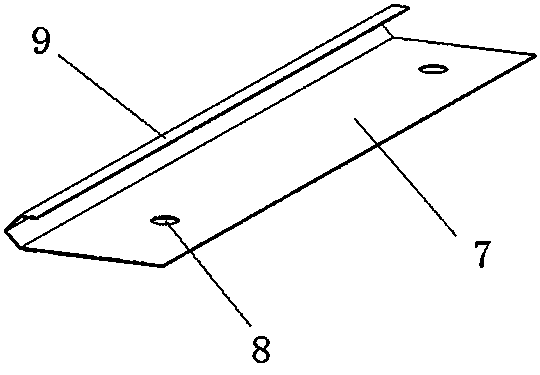

Construction tool and construction method for sealing seam of transfer layer of prefabricated building

The invention discloses a construction tool and a construction method for sealing a seam of a transfer layer of a prefabricated building. The construction tool is a steel formwork gasket as a whole and includes a fixing part with fixing holes and a deformation part which is located at one side of the fixing part and is bent upwards. The fixing part is horizontally fixed to a cast-in-situ structurebearing wall, and the deformation part is bent upwards by 45 degrees, 135 degrees in sequence and finally is bent 180 degrees in parallel with the fixing part in the horizontal direction. The construction tool has the leak-proof function for controlling leakage of concrete slurry during grouting and seam sealing, the forming function for controlling seam sealing and accelerating forming, and thefunction for controlling a sleeve grouting port of a prefabricated exterior wall board not to be blocked by the concrete slurry. The construction tool acts on the transfer layer of a prefabricated concrete building, an upper prefabricated exterior wall board is hoisted and dropped to enable a seam sealing tool to deform, a firm sealing seam shape is formed, slurry leakage of the outer side in thegrouting process is effectively avoided, the connection quality of the steel bar sleeve grouting and the use safety of the prefabricated building are effectively ensured.

Owner:吉林建筑科技学院

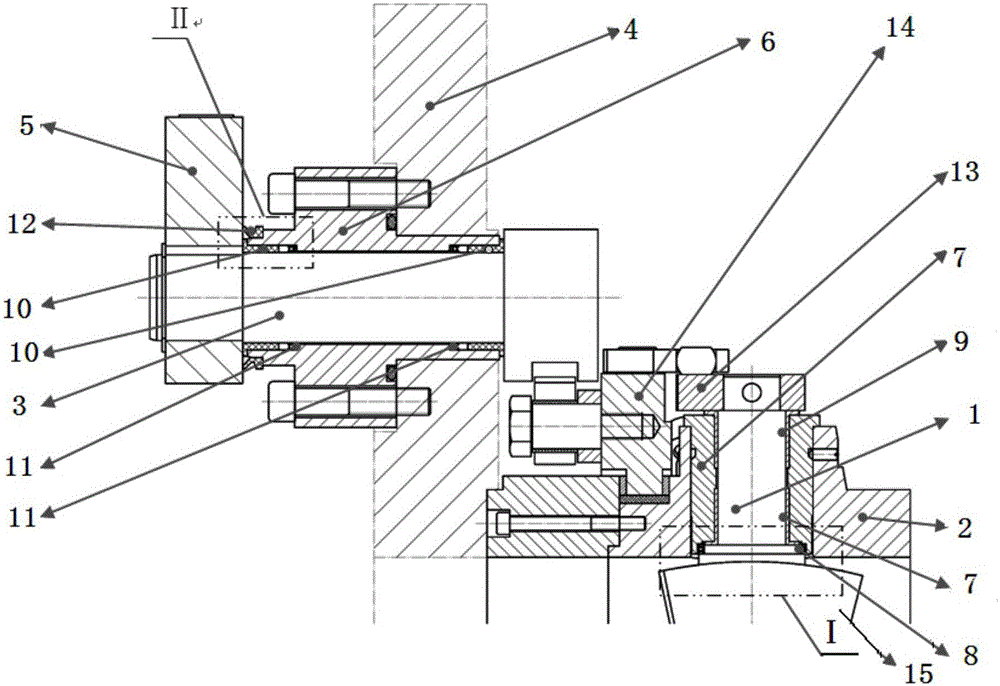

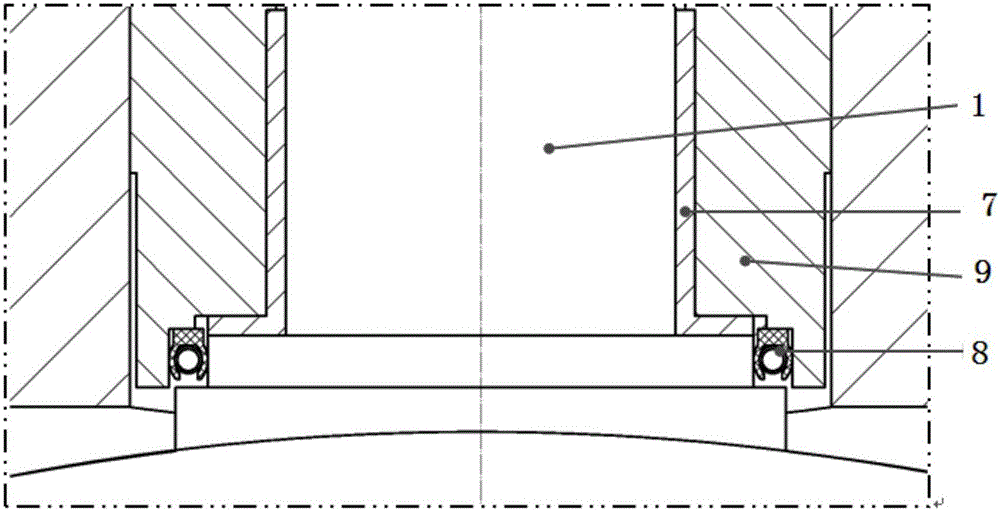

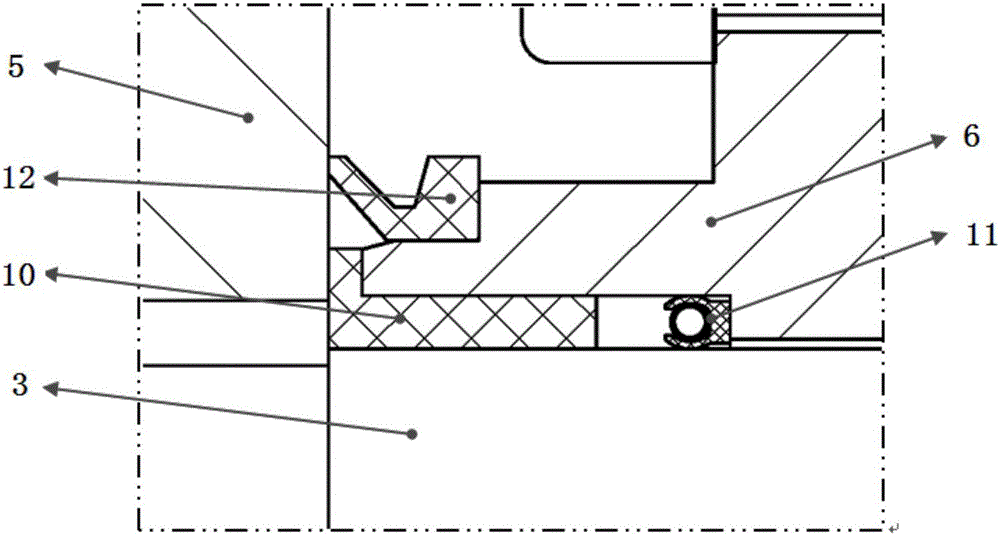

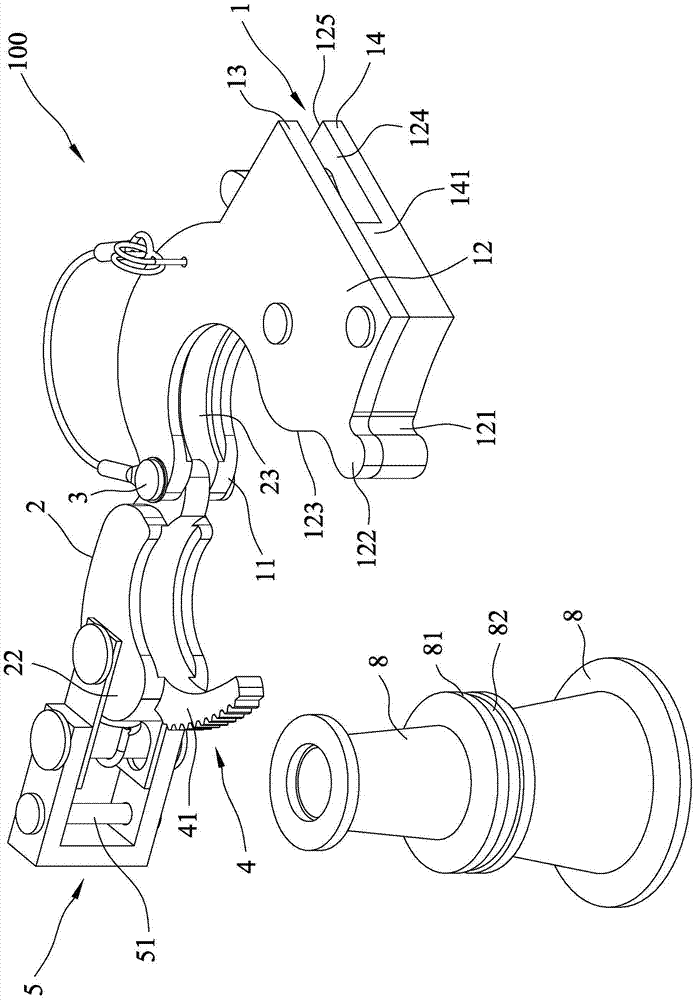

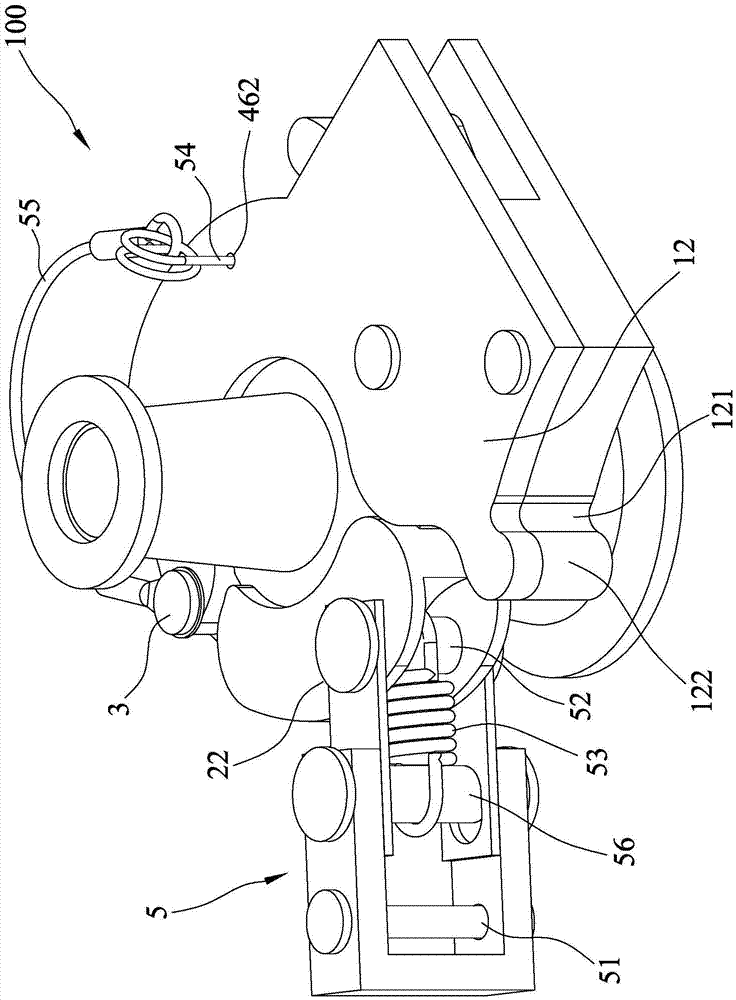

Booster compressor inlet guide vane adjusting device and method

ActiveCN105927588AOvercoming frictional resistancePrevent high pressure gas from leaking outsidePump componentsPumpsCentrifugal compressorEngineering

The invention discloses a booster compressor inlet guide vane adjusting device and method and belongs to the technical field of centrifugal compressors. The booster compressor inlet guide vane adjusting device comprises a drive handle, a drive handle transmission mechanism connected with the drive handle, an installing plate connected with the drive handle transmission mechanism, a drive handle transmission seal mechanism connected with the drive handle transmission mechanism, a guide vane rotating mechanism connected with a guide vane shell, an adjusting ring with one end connected with the drive handle transmission mechanism and the other end connected with the guide vane rotating mechanism, a guide vane rotating seal mechanism connected with the guide vane rotating mechanism, and a guide vane connected with the guide vane rotating mechanism. The booster compressor inlet guide vane adjusting device and method can effectively overcome friction resistance generated by the high-pressure difference, outward leakage of high-pressure gas is prevented, and safety and reliability of a compressor are improved.

Owner:SHENYANG TURBO MASCH CORP

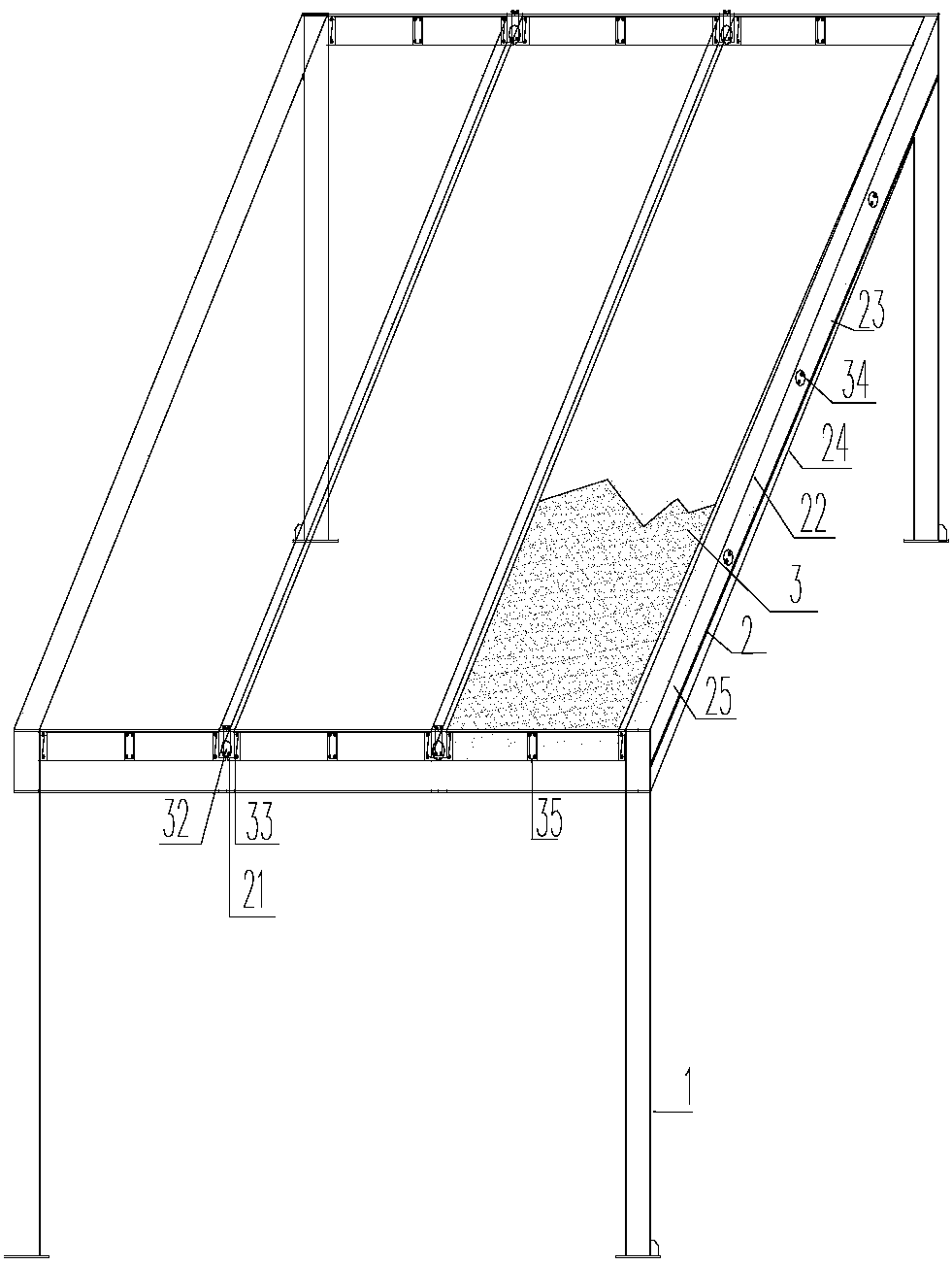

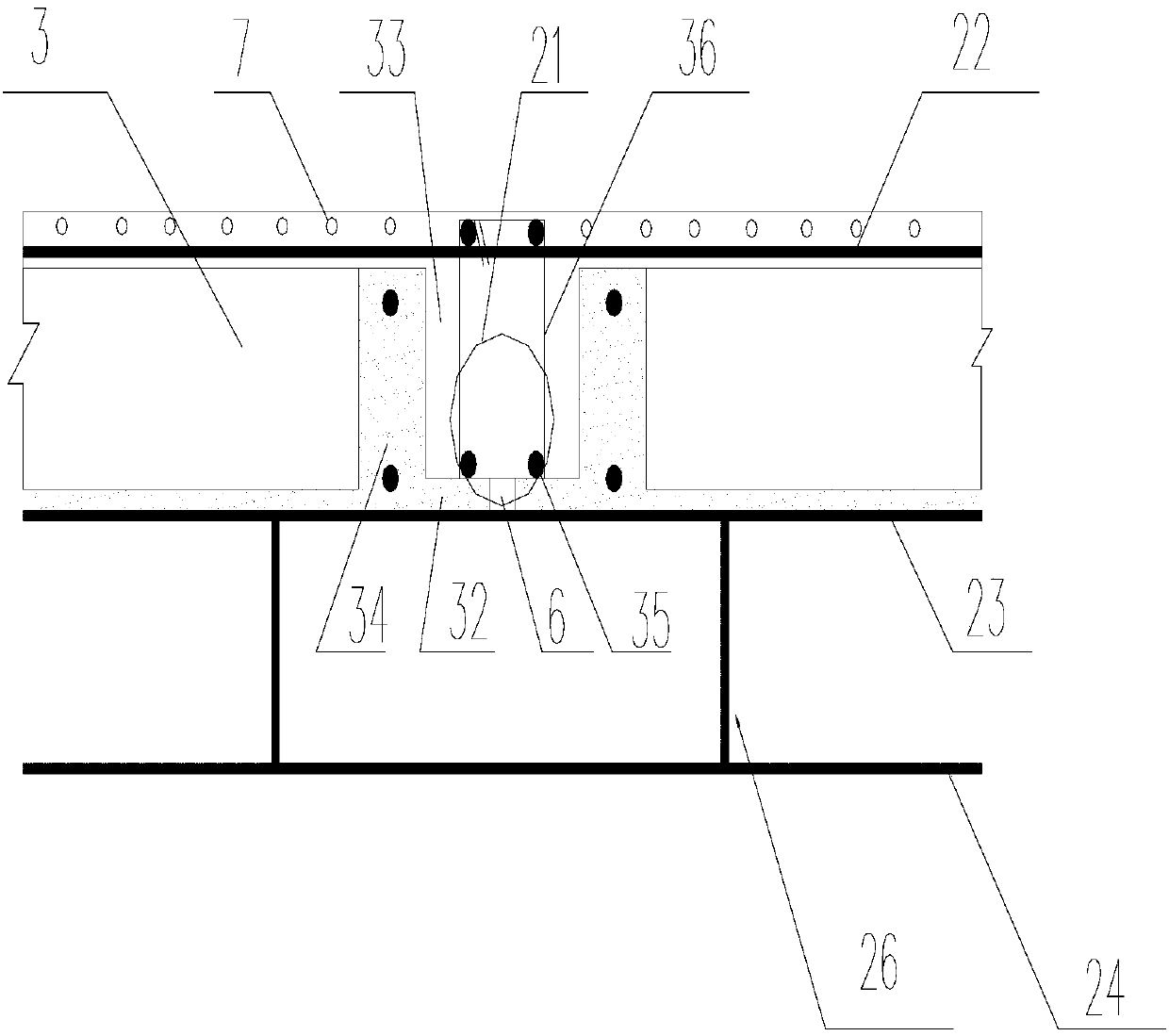

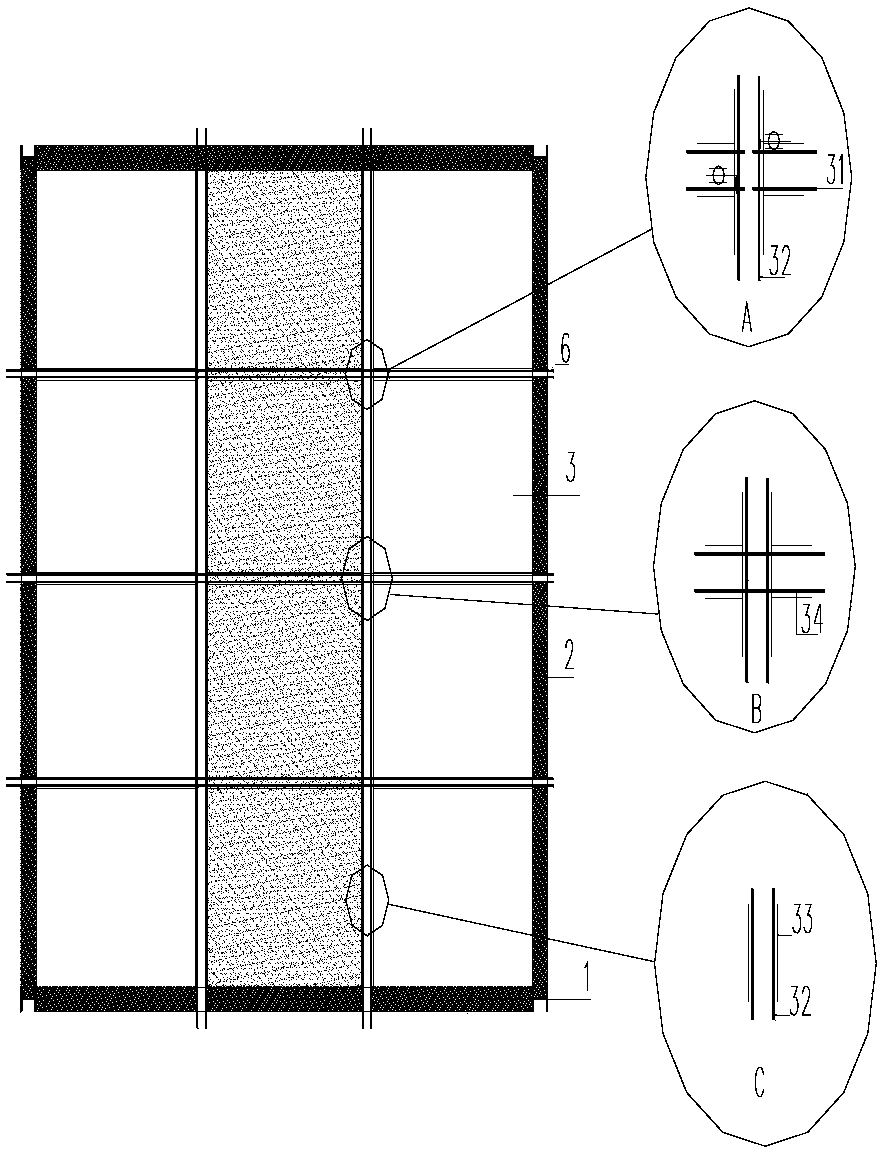

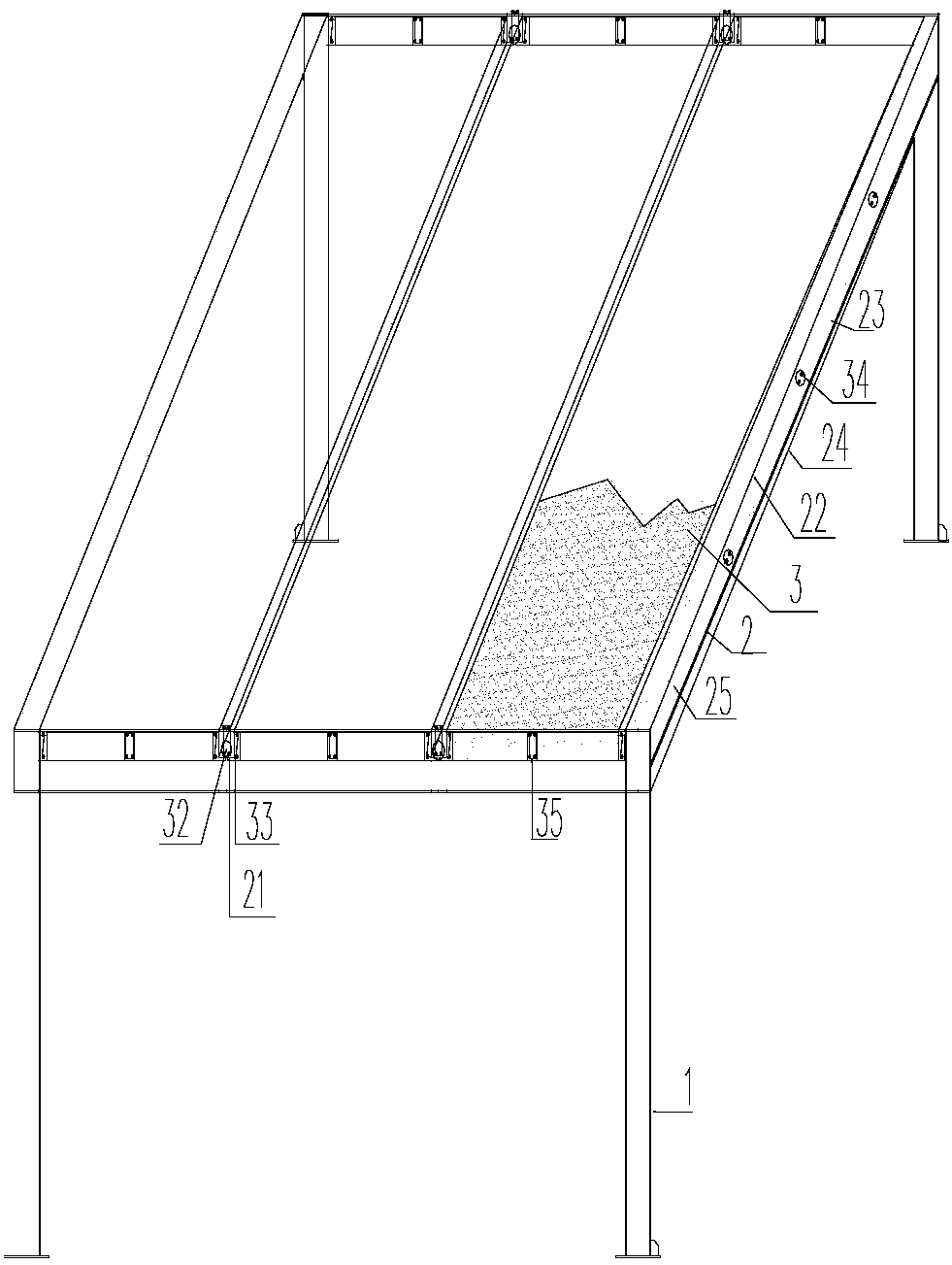

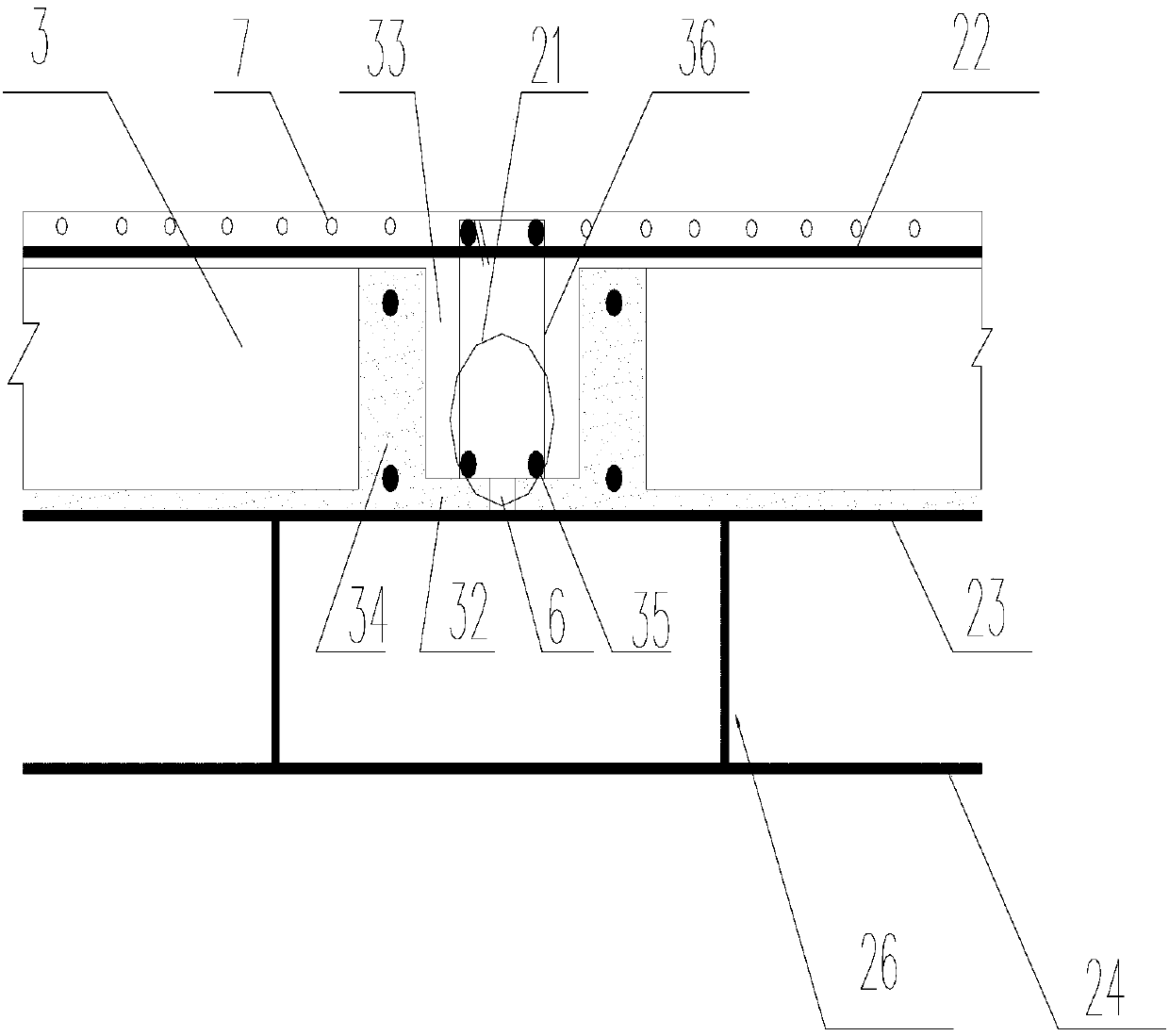

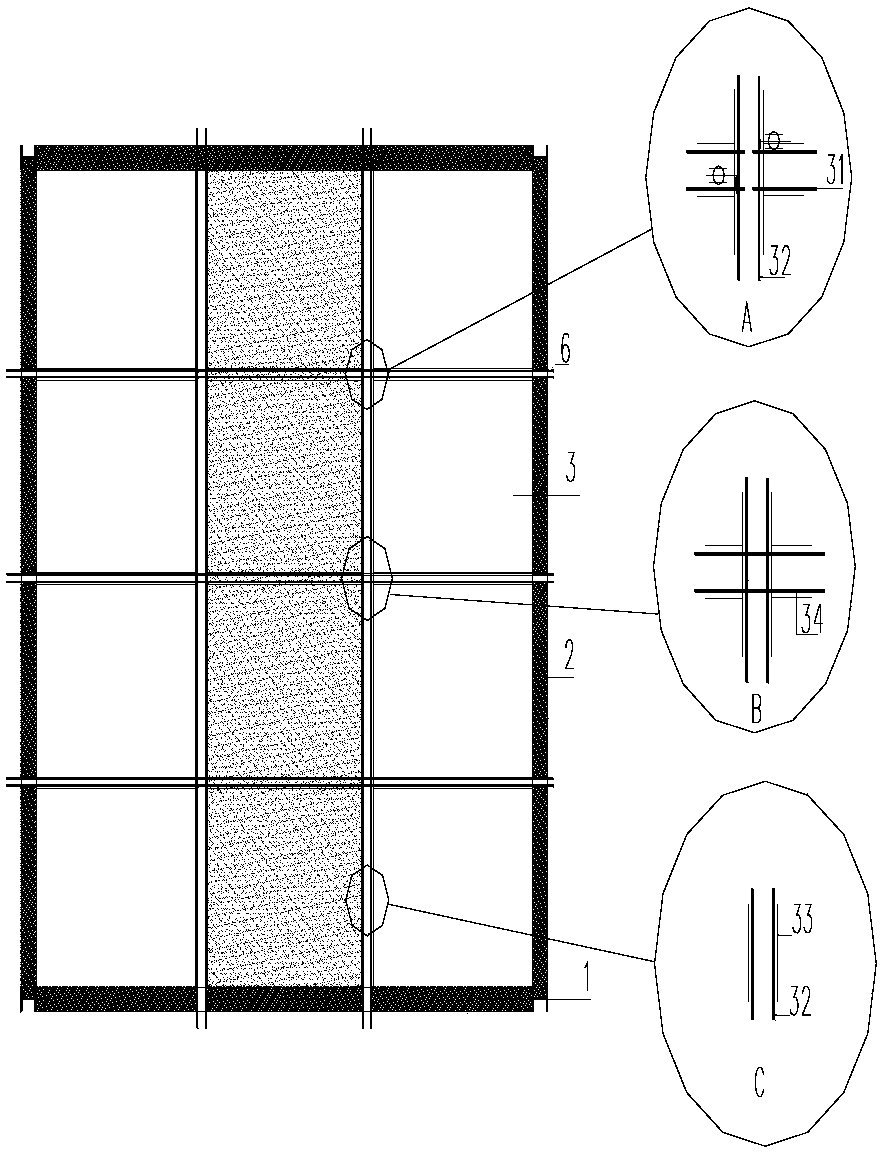

Steel structure fabricated cavity floor slab

The invention provides a steel structure fabricated cavity floor slab. The steel structure fabricated cavity floor slab comprises a sectional steel column, a steel beam being in the shape like a Chinese character 'wang', cavity plate members and joint seams. The steel structure fabricated cavity floor slab is characterized in that the steel beam being in the shape like the Chinese character 'wang'is composed of an upper flange plate, a middle flange plate or a supporting plate, a lower flange plate and a web plate; the widths of steel beam flange plates being in the shape like a Chinese character 'wang' are not equal; each cavity plate member is composed of a reinforced concrete longitudinal rib beam, a reinforced concrete transverse rib beam, a ribbed steel wire mesh and a concrete mortar lower flange plate containing a metal mesh; the ribbed steel wire mesh is an expanded ribbed steel wire mesh or a fish-scale ribbed steel wire mesh; a mesh body of the ribbed steel wire mesh is a ribbed metal mesh, and the ribbed steel wire mesh is internally provided with a cold-drawn mesh supporting body or a foamed cement block supporting body; the cavity plate members are mounted on horizontal planes of the middle flange plate of the steel beam being in the shape like the Chinese character 'wang' or upper sections of supporting plates; the joint seams of the cavity plate members do not penetrate through the cavity plate members; and the height of the transverse reinforced concrete rib beam at the two ends of each cavity plate member is less than the heights of other transverse reinforced concrete rib beams.

Owner:HUNAN BDF ENERGY SAVING TECH +1

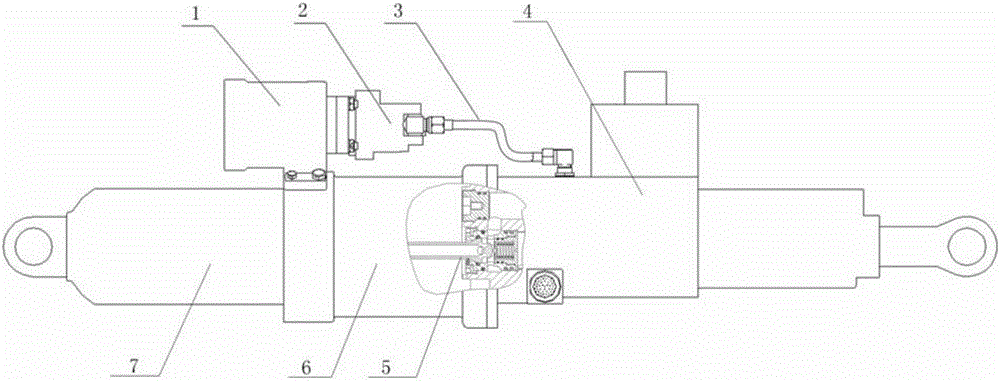

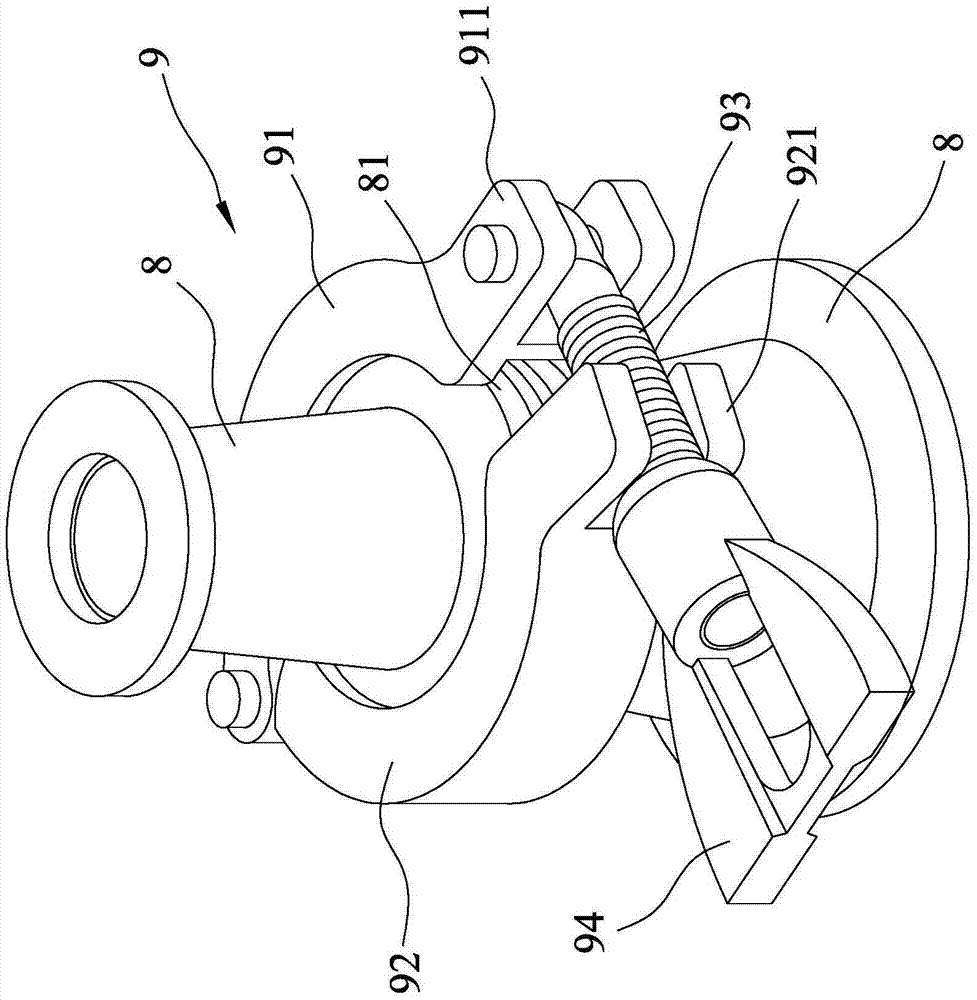

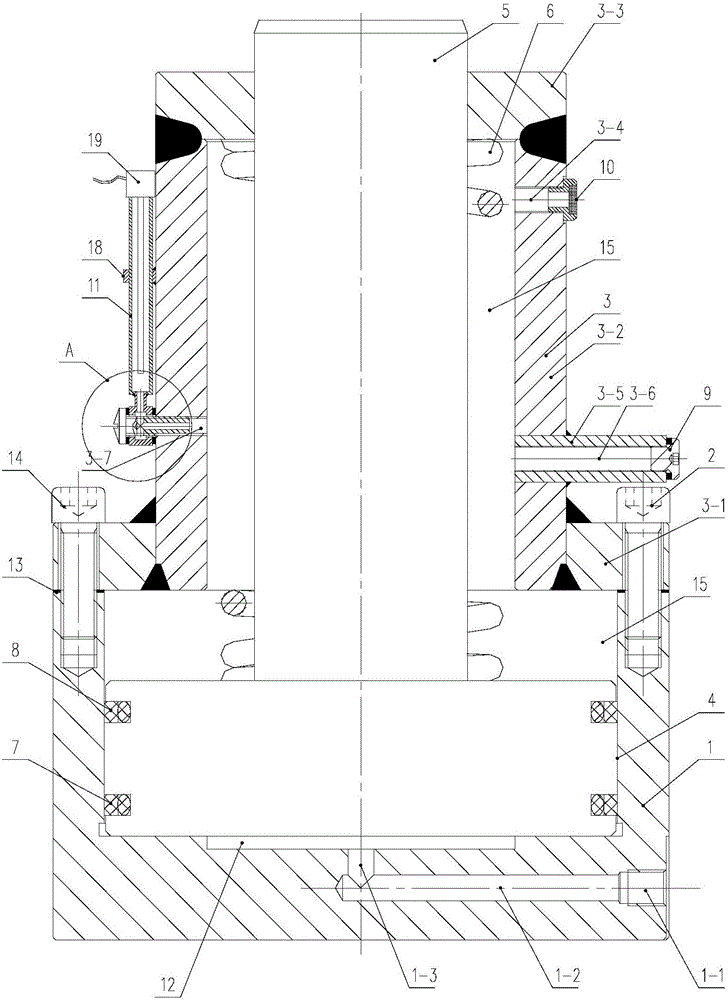

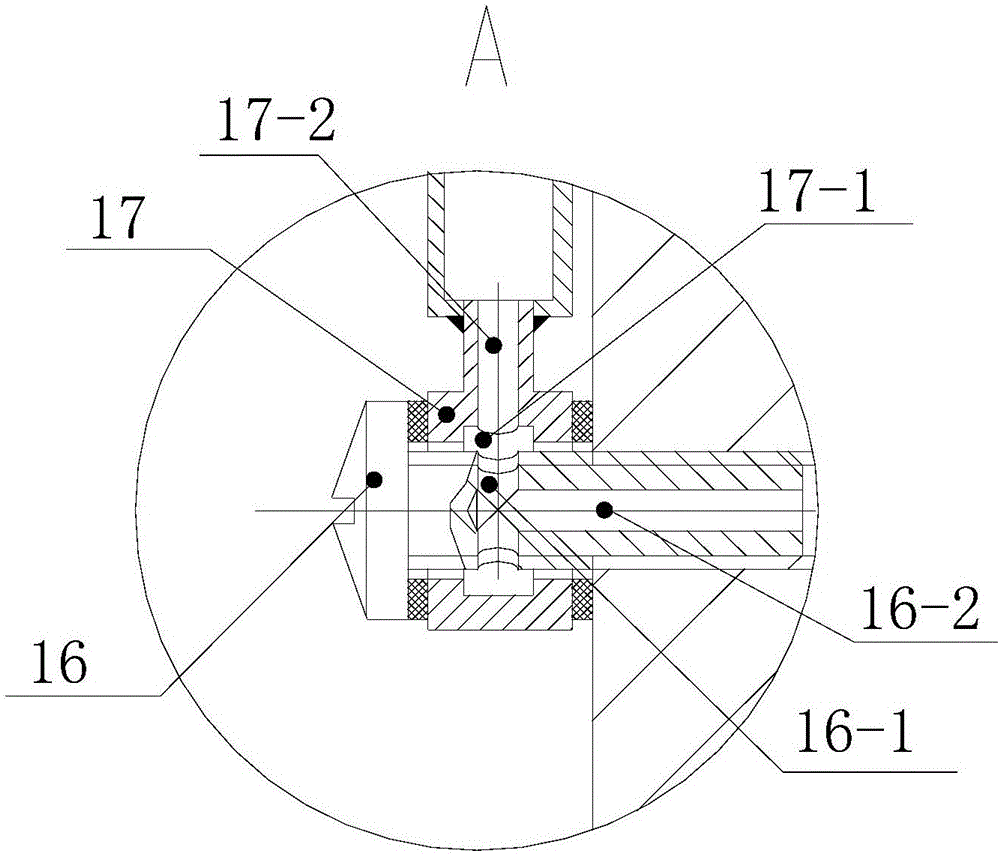

Floating oil passing pipe supporting structure for integrated type hydraulic servo mechanism

ActiveCN105179382AEliminate the influence of different axesAvoid stuck phenomenonFluid-pressure actuator componentsAxial forcePipe support

The invention discloses a floating oil passing pipe supporting structure for an integrated type hydraulic servo mechanism. The floating oil passing pipe supporting structure comprises an oil passing pipe (5), a supporting seat (10), a spring seat (18), a spring guiding sleeve (16) and a spring (19). One end of the oil passing pipe (5) is a ball head, and the supporting seat (10) is provided with a ball socket structure. The supporting seat (10) is connected with the oil passing pipe (5) through a spherical hinge so that the oil passing pipe can have certain rotating flexibility. The oil passing pipe (5) is axially supported through the spring (19). The top end of the ball head of the oil passing pipe (5) is in contact with a semispherical protruding point at one end of the spring guiding sleeve (16). The spring guiding sleeve (16) slides in a blind hole in the spring seat (18). The spring (19) is located in a blind hole of the spring guiding sleeve (16). The spring guiding sleeve (16) exerts axial force on the oil passing pipe (15) so that the ball head and the ball socket can be tightly pressed and sealed. The spring seat (18), the spring guiding sleeve (16) and the supporting seat (10) are coaxial. According to the floating oil passing pipe supporting structure, dual-redundancy sealing is adopted, and sealing is reliable.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

Empty cavity board member used for assembled steel structure

InactiveCN107620415AEasy inflowReduce year-round maintenanceFloorsFire proofingReinforced concreteRebar

The invention provides an empty cavity board member used for an assembled steel structure. The empty cavity board member comprises a reinforced concrete longitudinal rib beam, a reinforced concrete transverse rib beam, a ribbed steel network, a surface exposed steel bar, a hanging ring, a lower flange plate and a two-end-head concrete downward concave part. The lower bottom surface of at least oneedge of longitudinal rib beam concrete in the reinforced concrete longitudinal rib beam concrete is provided with an L-shaped concrete bulge. A lower steel bar of the reinforced concrete transverse rib beam steel bar is exposed. The ribbed steel network is an expansive ribbed steel network or a scale ribbed steel network. A network body of the ribbed steel network is a ribbed metal net. The ribbed steel network is internally provided with a cold-dial net supporting body or a foamed cement block supporting body. The lower flange plate is composed of a metal net and concrete mortar. The two-end-head concrete downward concave part makes the height of a transverse reinforced concrete rib beam be lower than the heights of other transverse reinforced concrete rib beams.

Owner:HUNAN BDF ENERGY SAVING TECH +1

Single-action hydraulic cylinder with internal leakage display function

ActiveCN106762947APrevent oil leakagePrevent external leakageFluid-pressure actuator testingCylinder blockEngineering

The invention discloses a single-action hydraulic cylinder with an inner leakage display function. The single-action hydraulic cylinder with the inner leakage display function comprises a cylinder body, a first screw, a second screw, an upper end cap, a piston, a piston rod, a spring, a first piston seal, a second piston seal, a plug, an air filter, an oil pointer, a sealing gasket and the like. According to the single-action hydraulic cylinder with the inner leakage display function, and the oil pointer and the plug are installed on the side face of a non-working chamber of the single-action hydraulic cylinder, and thus when trace leakage happens to the sealed piston of the single action hydraulic cylinder, the internal leakage condition of the single action hydraulic cylinder can be controlled by observing the liquid level of the oil pointer. If the liquid level exceeds a certain position, by unscrewing the plug and releasing the oil in the non-working chamber of the single-action hydraulic cylinder, oil leakage caused when the liquid level in the non-working chamber of the hydraulic cylinder is up to a certain extent can be avoided. The single-action hydraulic cylinder with the inner leakage display function is simple in structure, reliable in operation, and capable of providing the internal leakage condition of the single-action hydraulic cylinder and preventing oil leakage, thereby having a wide application prospect.

Owner:SHANGHAI SSOEC MARINE ENG CO LTD

Revolution conveying device

The invention relates to a revolution conveying device and belongs to the technical field of fluid conveying devices. The revolution conveying device comprises a core shaft, slip ring members and rotation seals, the slip ring members are sleeved on the outer circumferential surface of a valve core, the rotation seals are located between the valve core and the slip ring members, conveying grooves are arranged between the valve core and the slip ring members and located between each two rotation seals, and connection holes which are communicated with the conveying grooves are opened on the slip ring members corresponding to the conveying grooves; and conveying channels are arranged in the core shaft, one ends of the conveying channels are connectedwith conveying channels to be connected, and the other ends of the conveying channels are communicated with the conveying grooves. Due to the conveying grooves, the conveying channels on the core shaft are communicated with the corresponding connection holes on the slip ring members in 360 degree directions. An external connection pipeline between a fixing mechanism and a revolution mechanism is omitted, phenomena of torsional damage and obstructed conveying of the connection pipeline in the process of rotation of the revolution mechanism are completely prevented, and advantages of system structure simplification and reliable connection are achieved.

Owner:JIANGSU WEIHE MARINE EQUIP

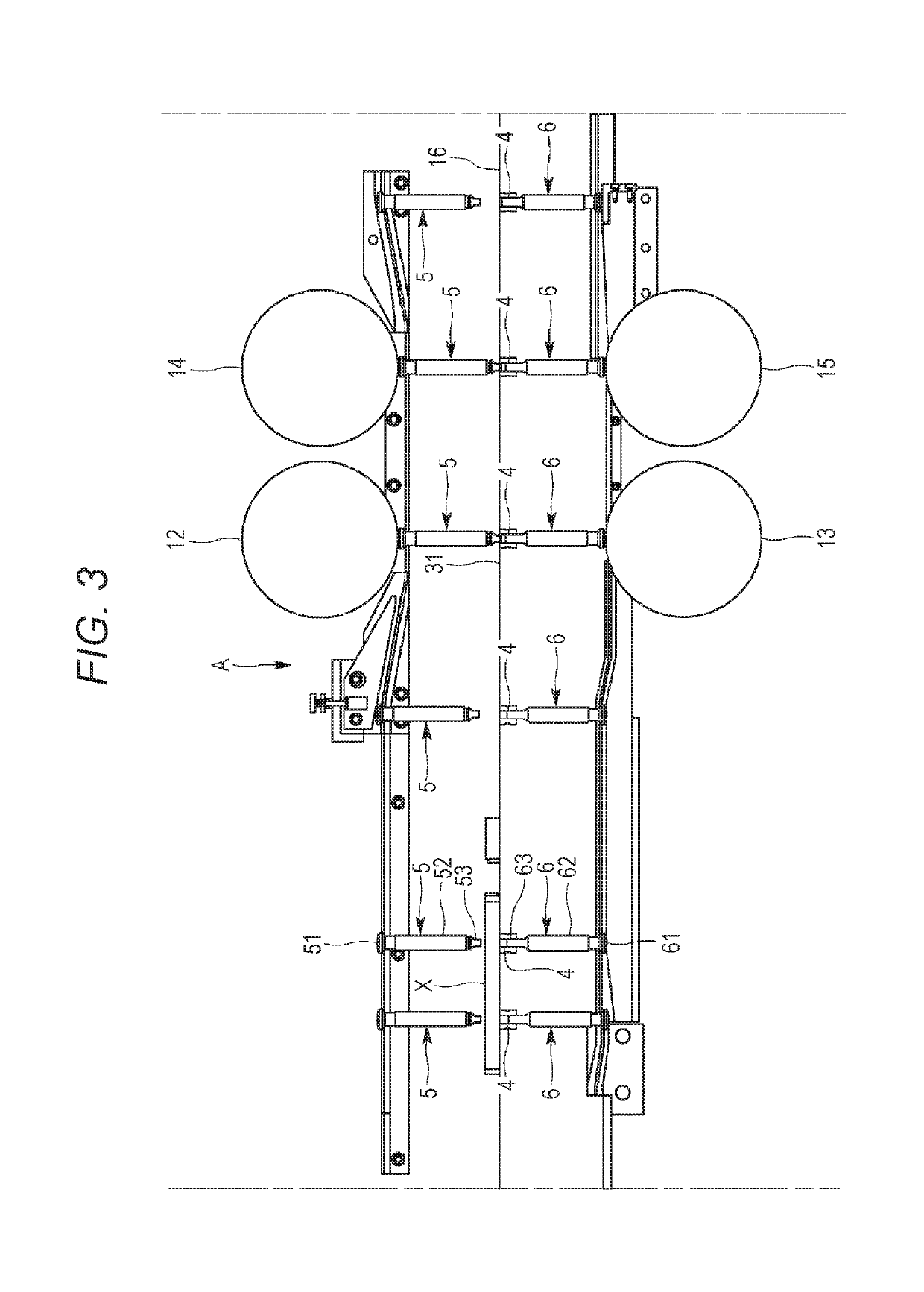

Molded product processing system

ActiveUS20190105863A1Avoid pollutionPrevent leakageConveyor partsShaping pressProduct processingShell molding

A molded product processing system is configured to apply a post process to a molded product molded by a compression-molding machine. The system includes modules each including a conveying mechanism configured to convey a plurality of molded products P kept aligned, and a processing mechanism confronting a travel route of the molded products conveyed by the conveying mechanism and configured to apply a predetermined post process to each of the conveyed molded products, in which upstream one of the modules and downstream one of the modules are connected to allow the molded products having gone through certain processing at the upstream one of the modules to be delivered to the downstream one of the modules and be subjected to a different predetermined processing at one of the modules.

Owner:KIKUSUI SEISAKUSHO LTD

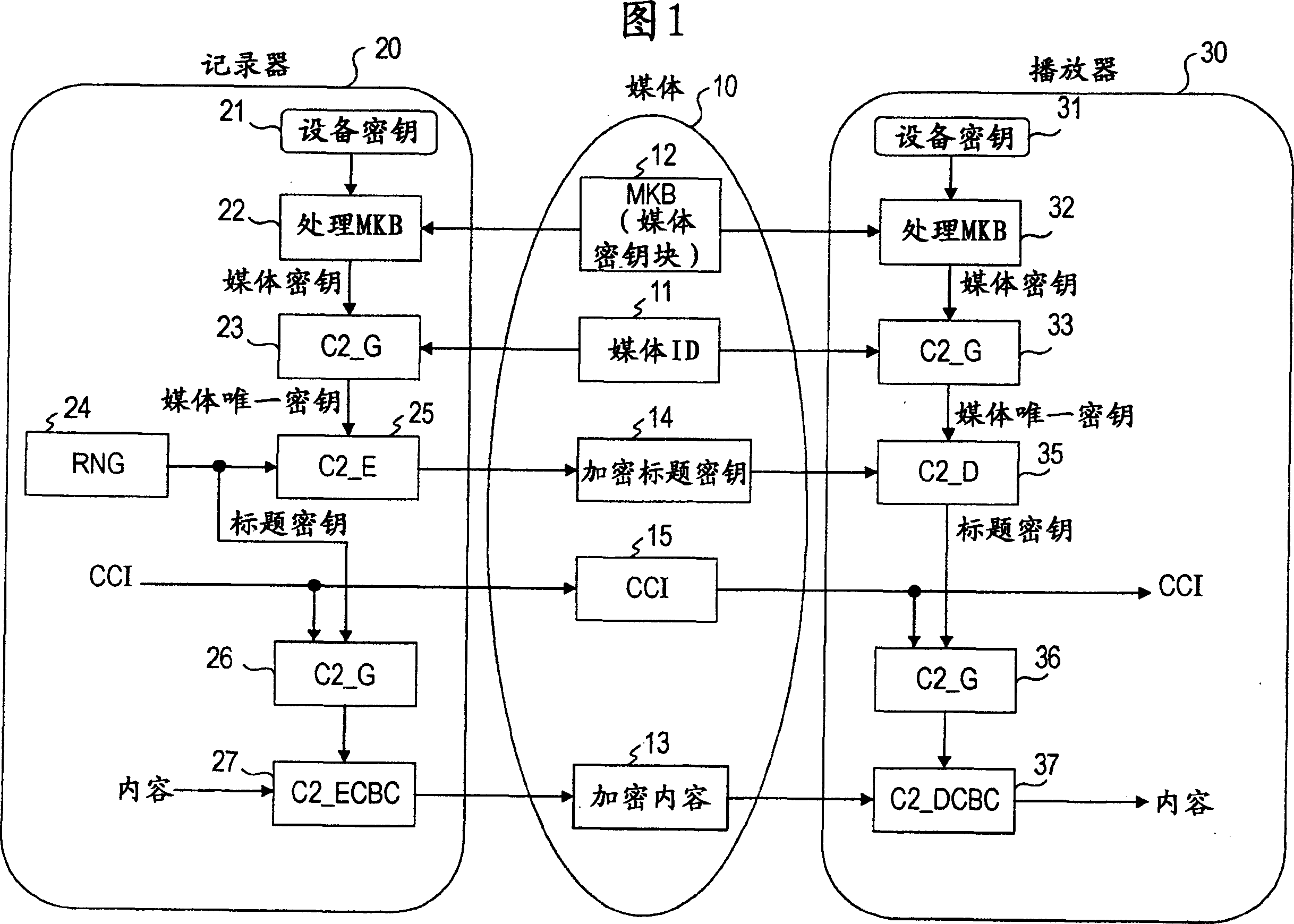

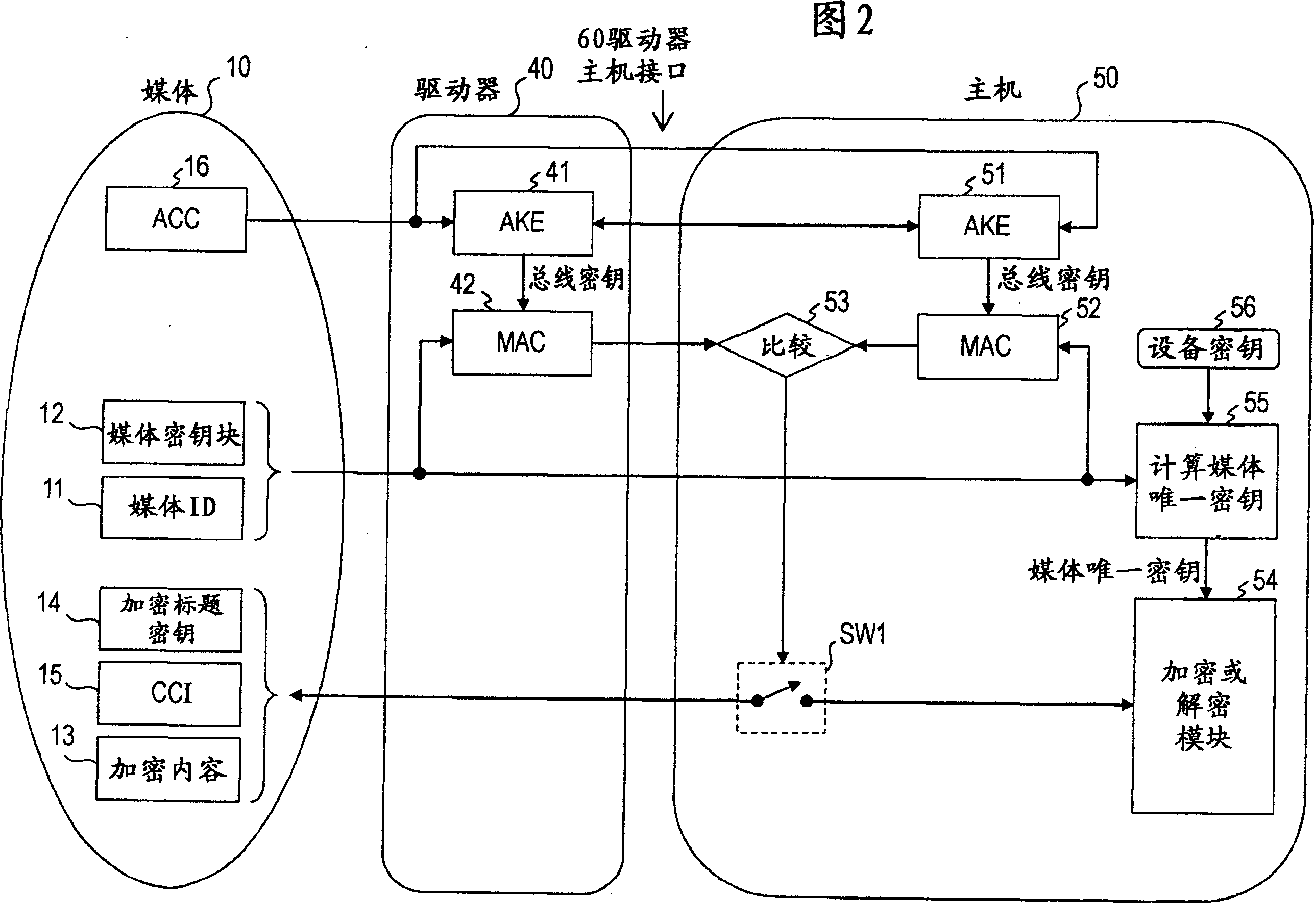

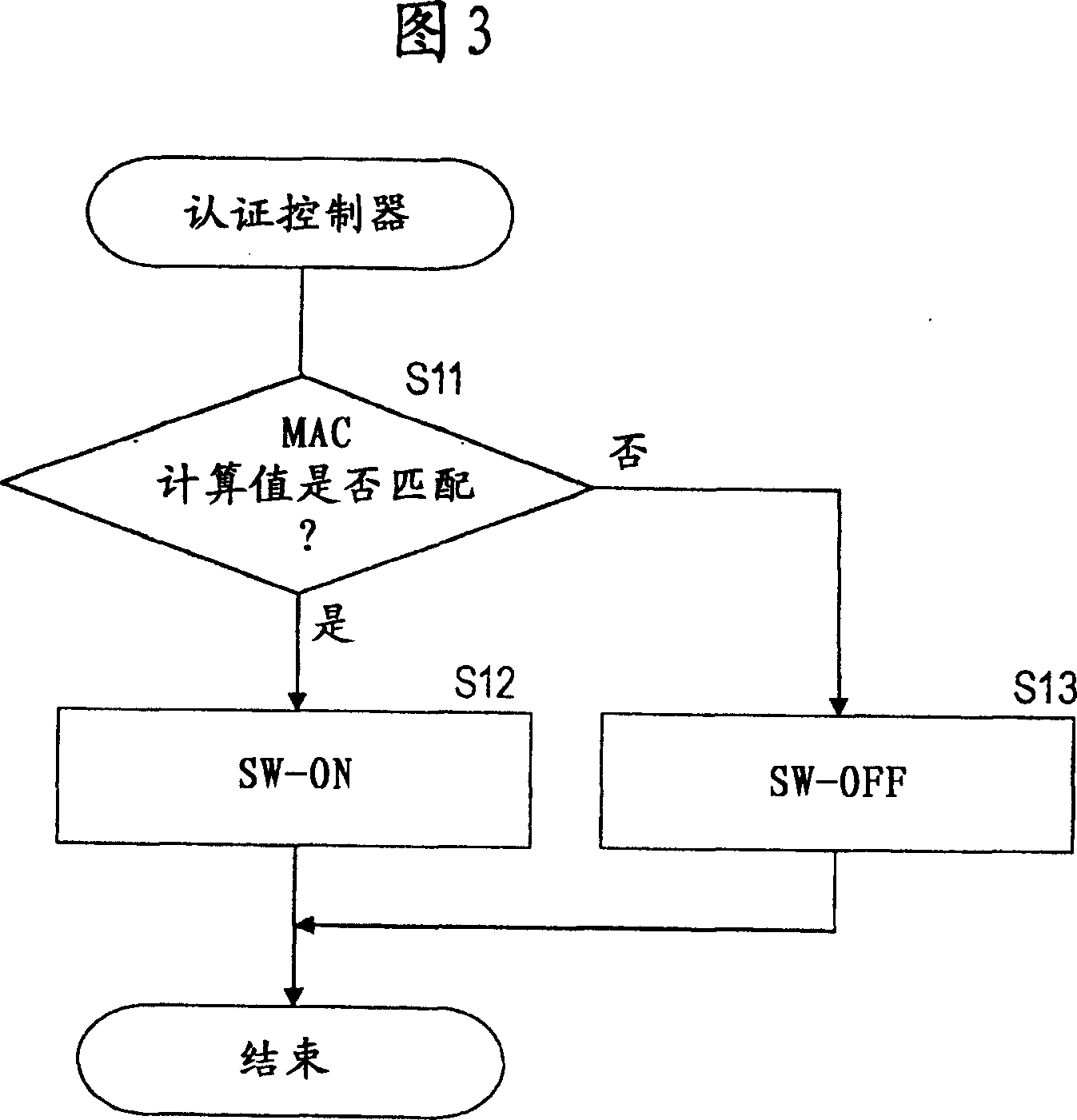

Information processing device, information processing method, and computer program

InactiveCN1977249APrevent external leakageReduces the possibility of external leakageTelevision system detailsRecording carrier detailsInformation processingComputer hardware

A structure for preventing information leakage and content false processing during content utilization involving data transfer between different devices. During content reproduction or recording involving data transfer between different device such as a drive and a host, a medium ID (disk ID) used for encrypting or decrypting a content is read out of a medium, and the drive checks if the medium ID is recorded according to a header code preset for the authenticated medium. If it is confirmed that the medium is an authenticated one, the drive encrypts the medium ID and output it to a host. With this, leakage to the outside of a medium ID and reproduction or recording of a content using a false medium can be prevented.

Owner:SONY CORP

Energy-saving and environment-friendly furnace flue gas treatment device

PendingCN114028915AIncrease profitIncrease contact timeDispersed particle separationThermodynamicsFlue gas

The invention discloses an energy-saving and environment-friendly furnace flue gas treatment device which comprises a barrel; a gas inlet pipe is fixedly connected to the right side of the barrel; a spraying device comprises a transition chamber, an electromagnetic valve, a spraying pipe, a spraying block, a dispersion assembly and a detection device; the transition chamber is connected to the right side of the water inlet pipe; the electromagnetic valve is fixedly connected to the left side of the transition chamber; the spraying pipe is connected to the left side of the electromagnetic valve; the spraying block is fixedly connected to the end, away from the electromagnetic valve, of the spraying pipe; the dispersion assembly is fixedly installed on the right side of the transition chamber through a cylindrical rod; and the detection device is arranged on the dispersion assembly. According to the energy-saving and environment-friendly furnace flue gas treatment device, the purpose of reasonably adapting to water flow sprayed outwards according to the introduction amount of furnace flue gas is achieved through the matching effect of the stress rod, the shifting block, the slide rheostat and the electromagnetic valve, so that water resources are reasonably utilized, the water resources are further saved, and the purposes of energy conservation and environment protection are achieved.

Owner:武蔷薇

Retaining ring

ActiveCN107237946AImprove conveniencePrevent external leakageFlanged jointsRetaining ringEngineering

A retaining ring comprises a first half retaining part, a second half retaining part and a packing unit. The first half retaining part and the second half retaining part are pivoted. The first half retaining part comprises a first positioning end. The second half retaining part comprises a second positioning end capable of being opened and closed relative to the first positioning end. The packing unit comprises a rack arranged at one of the first positioning end and the second positioning end, a tooth part which is located in another of the first positioning end and the second positioning end and can be engaged with the rack, and a control element set used for limiting unidirectional rotation of the tooth part. The design that the rack is arranged at one of the first positioning end and the second positioning end and can be engaged with the tooth part located in another of the first positioning end and the second positioning end is adopted, and thus a mounting operator can complete mounting operation easily without other auxiliary tools.

Owner:林峻梅

Single-action hydraulic cylinder with inner leakage display function

ActiveCN106762946AGrasp the situation of internal leakage in timePrevent external leakageFluid-pressure actuator testingHydraulic cylinderAir filter

The invention discloses a single-action hydraulic cylinder with an inner leakage display function. The single-action hydraulic cylinder comprises a cylinder body, a first screw, a second screw, an upper end cap, a piston, a piton rod, a spring, a fist piston seal, a second piston seal, a plug, an air purifier, an oil pipe, a sealing gasket, a hollow screw, a hinge connector, an oil pipe bracket, a liquid level sensor and the like. According to the single-action hydraulic cylinder with the inner leakage display function, the liquid level sensor is mounted on the side face of a nonworking cavity of the single-action hydraulic cylinder and senses the liquid level position, liquid level position data are transmitted to peripheral equipment for display and alarm, and the inner leakage condition of the single-action hydraulic cylinder is mastered in time; and if the liquid level is higher than a certain position, oil in the nonworking cavity of the hydraulic cylinder is released through the oil pipe, and oil outer leakage is prevented. The single-action hydraulic cylinder is simple in structure and reliable in work, the inner leakage condition of the single-action hydraulic cylinder can be mastered, oil outer leakage is prevented, and the single-action hydraulic cylinder has wide application prospects.

Owner:SHANGHAI SSOEC MARINE ENG CO LTD

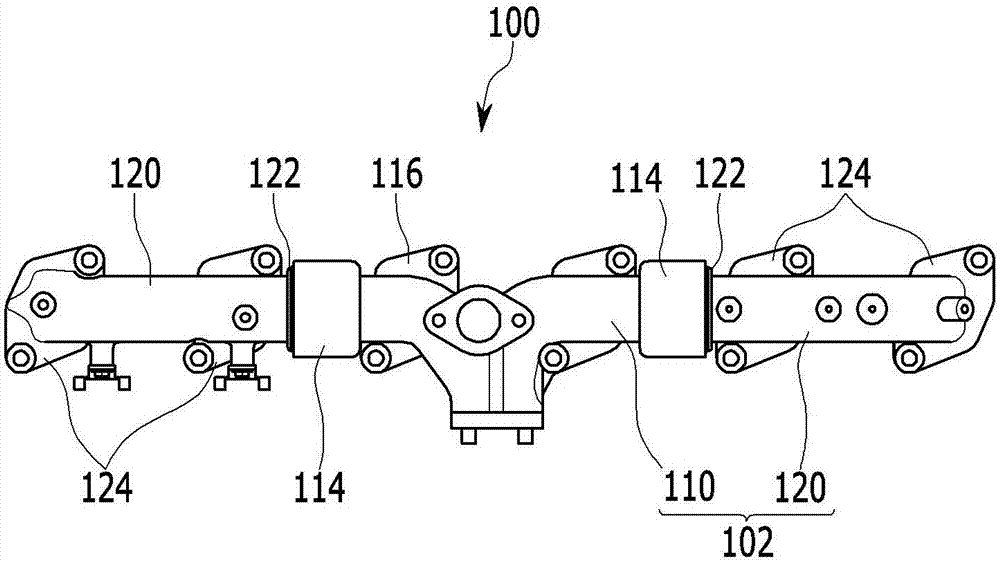

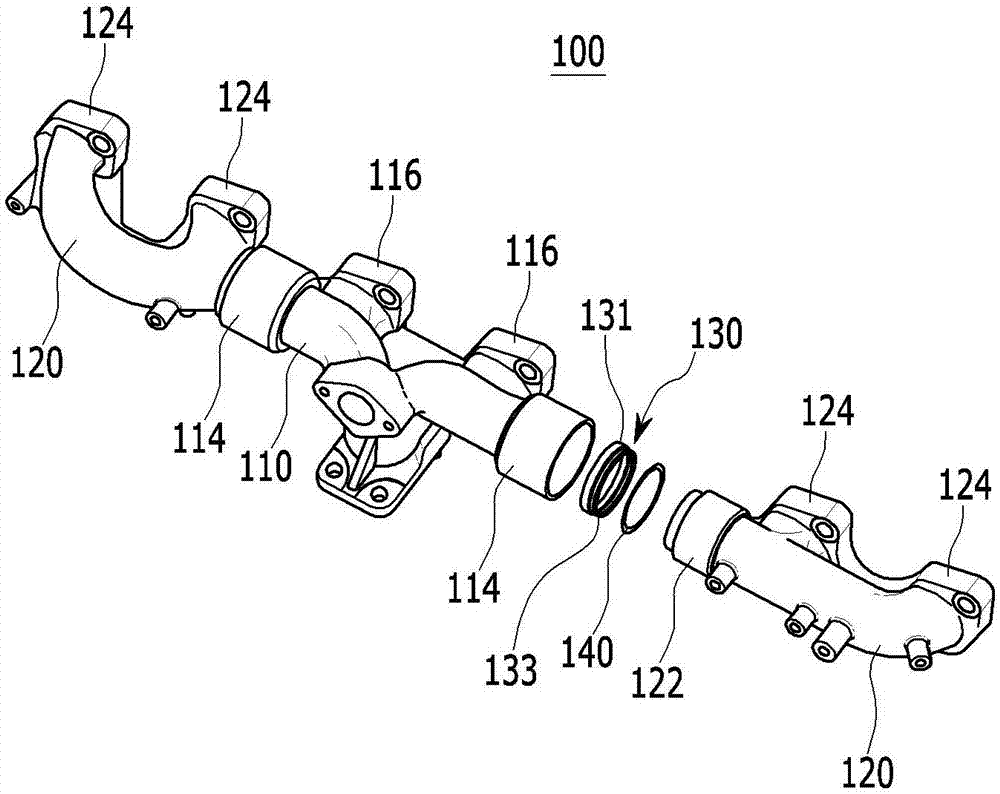

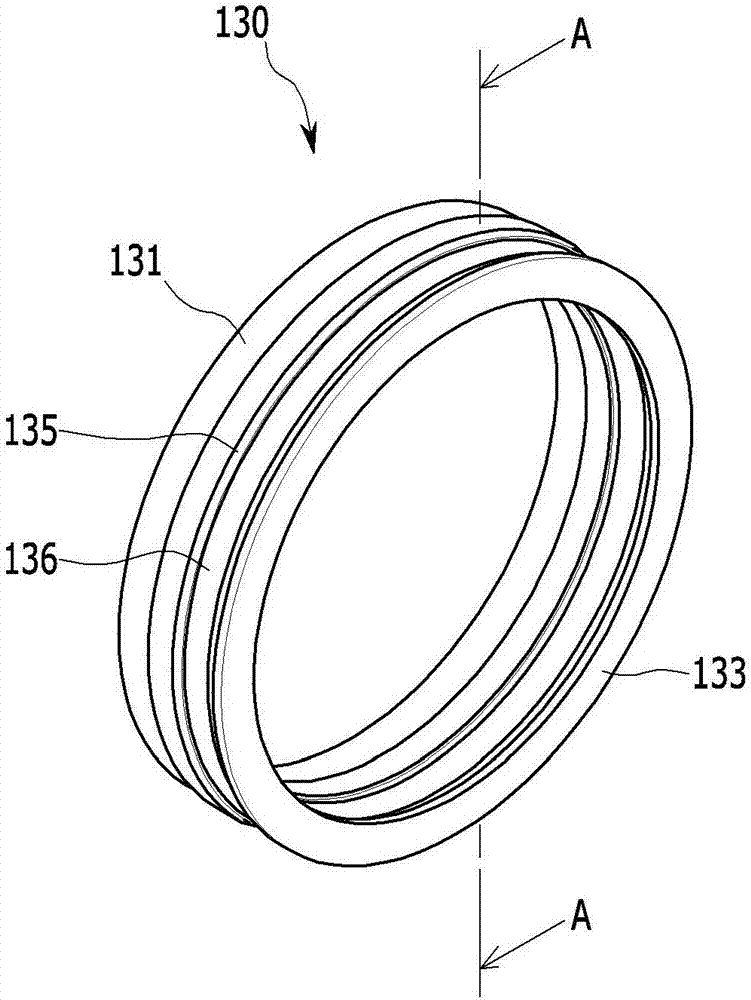

Sealing Device For Exhaust Manifold

ActiveCN107269373APrevent leakagePrevent external leakageSleeve/socket jointsEngine sealsEngineeringMechanical engineering

A sealing device for an exhaust manifold includes a main pipe having a connection portion including a mounting groove formed at an interior circumferential surface; a sub pipe having a protruding portion at one end portion, the sub pipe being coupled to the main pipe in a state in which the protruding portion is inserted into the connection portion; a valve mounted at the mounting groove within the connection portion; and a gasket interposed between the protruding portion and the valve within the connection portion.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com