Revolution conveying device

A technology of conveying device and conveying trough is applied in the field of fluid transmission, which can solve the problems of increased cost and inconvenient maintenance, and achieves the effects of reliable connection, prevention of leakage and simplification of system structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

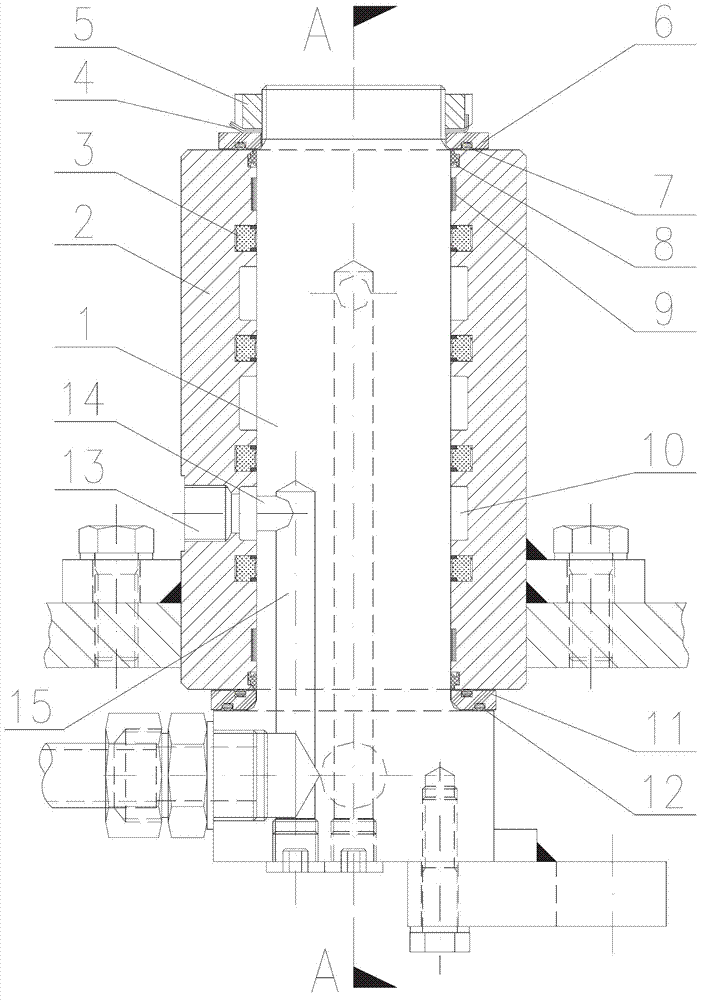

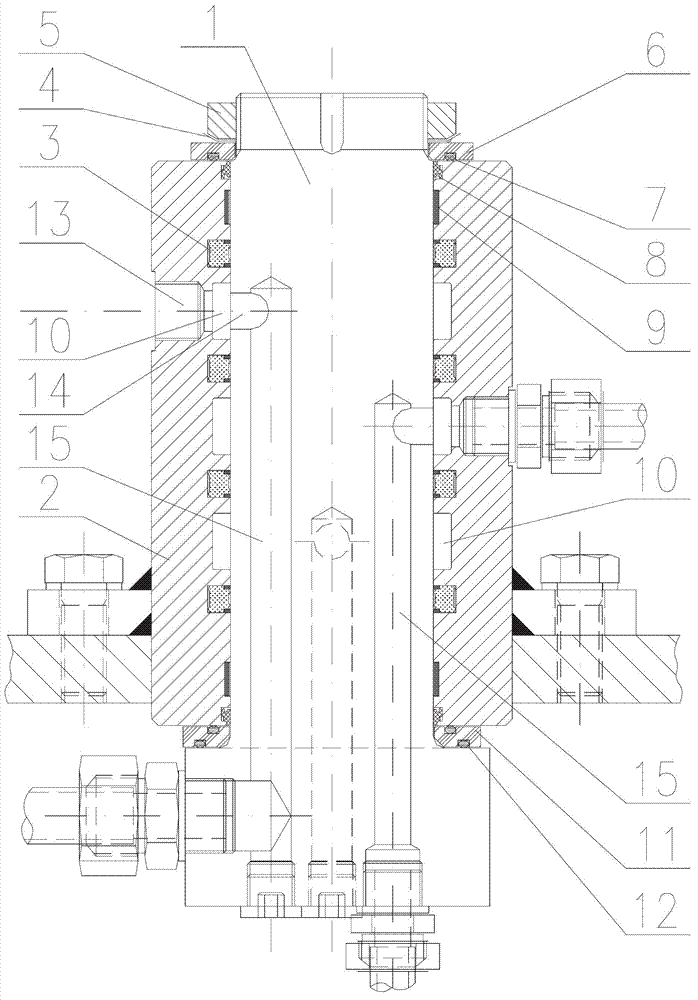

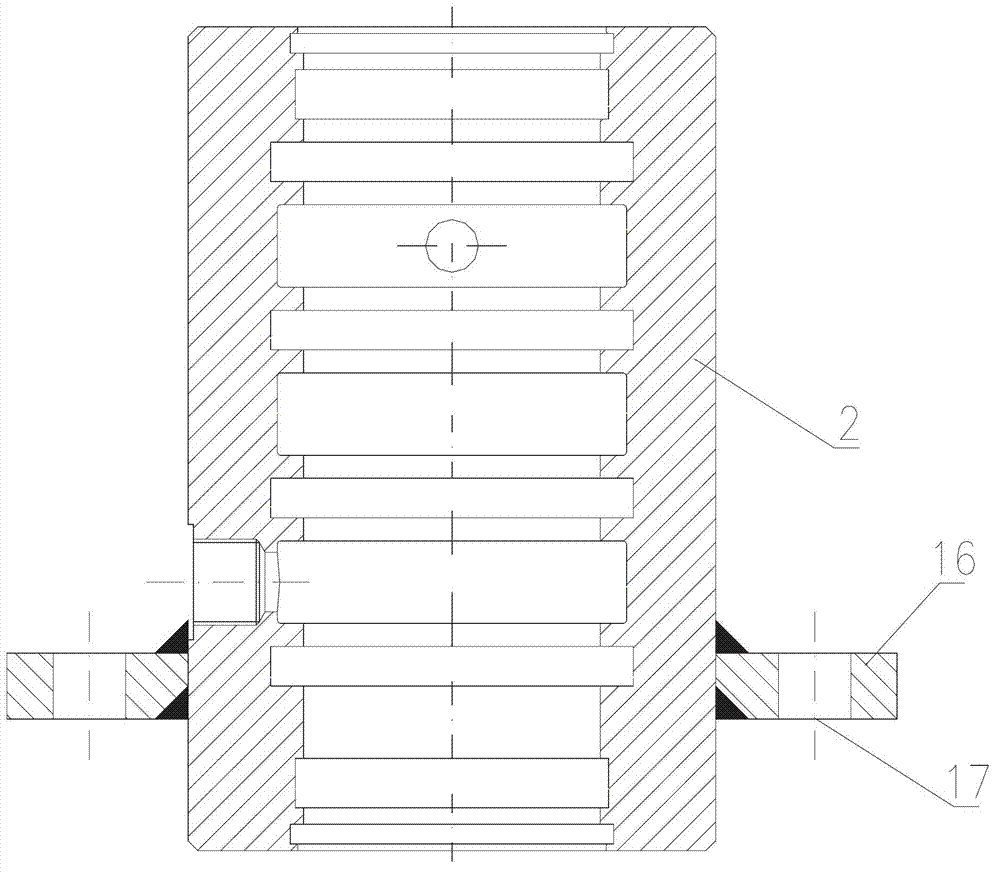

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] like figure 1 , 2 As shown, the mandrel 1 and the slip ring body 2 of the rotary conveying device of the present invention are respectively fixed on the fixing mechanism of the mechanical equipment and the slewing mechanism rotating around the fixing piece through bolts and welding, etc., the lower end surface of the slip ring body 2 and the There is a lower copper washer 11 between the mandrel 1, and an annular groove 12 is processed on the upper and lower end surfaces of the lower copper washer 11 to store the sealing ring, so that the lower end surface of the slip ring body 2 and the mandrel 1 form an end face seal to prevent hydraulic oil from leaking. External leakage; the inner circumference of the slip ring body 2 is separated from the sealing groove, and the rotary seal 3 is embedded in the sealing groove, and there is an annular conveying groove 10 bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com