Patents

Literature

109results about How to "Prevent reverse installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

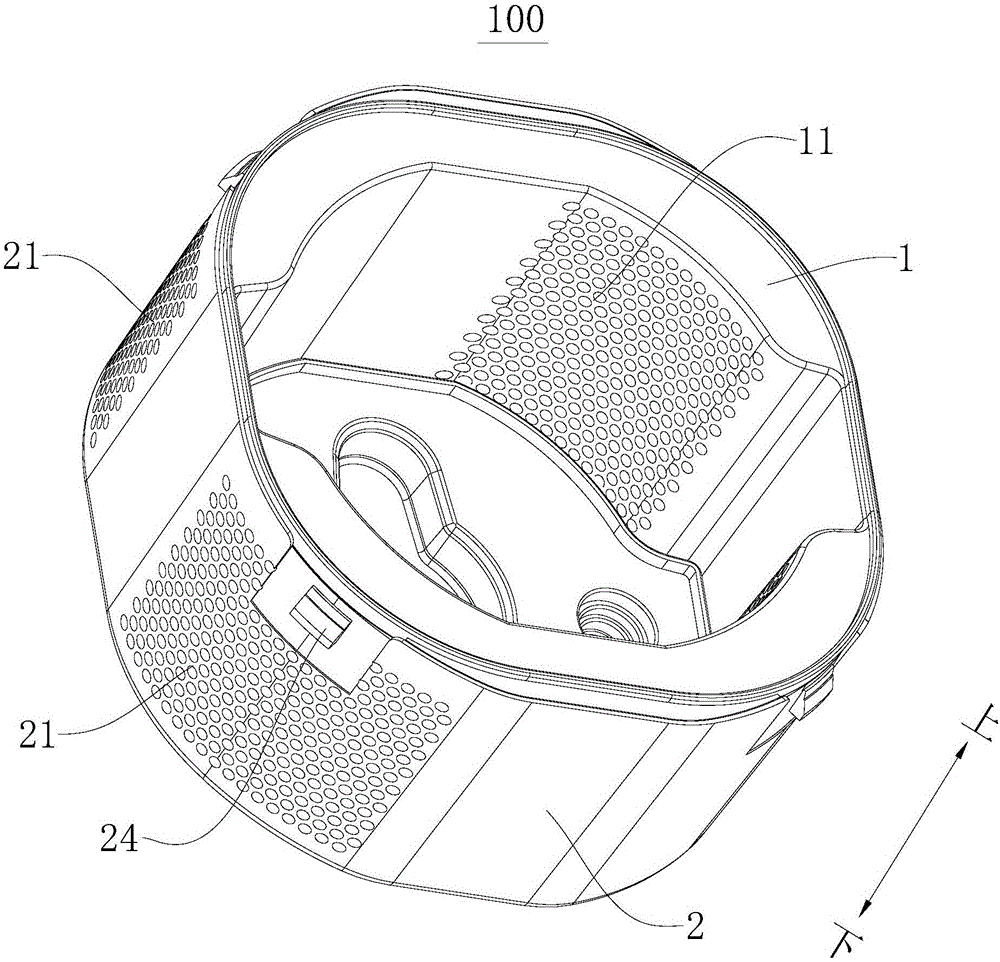

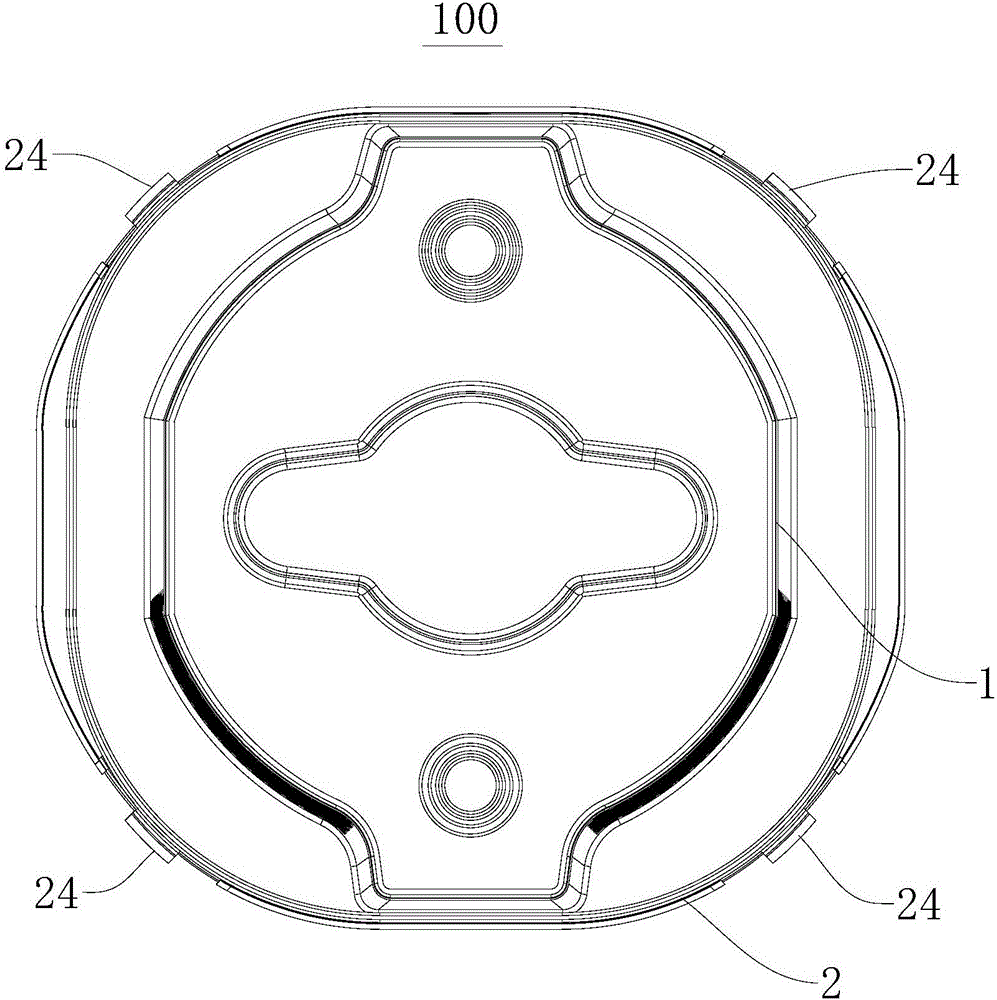

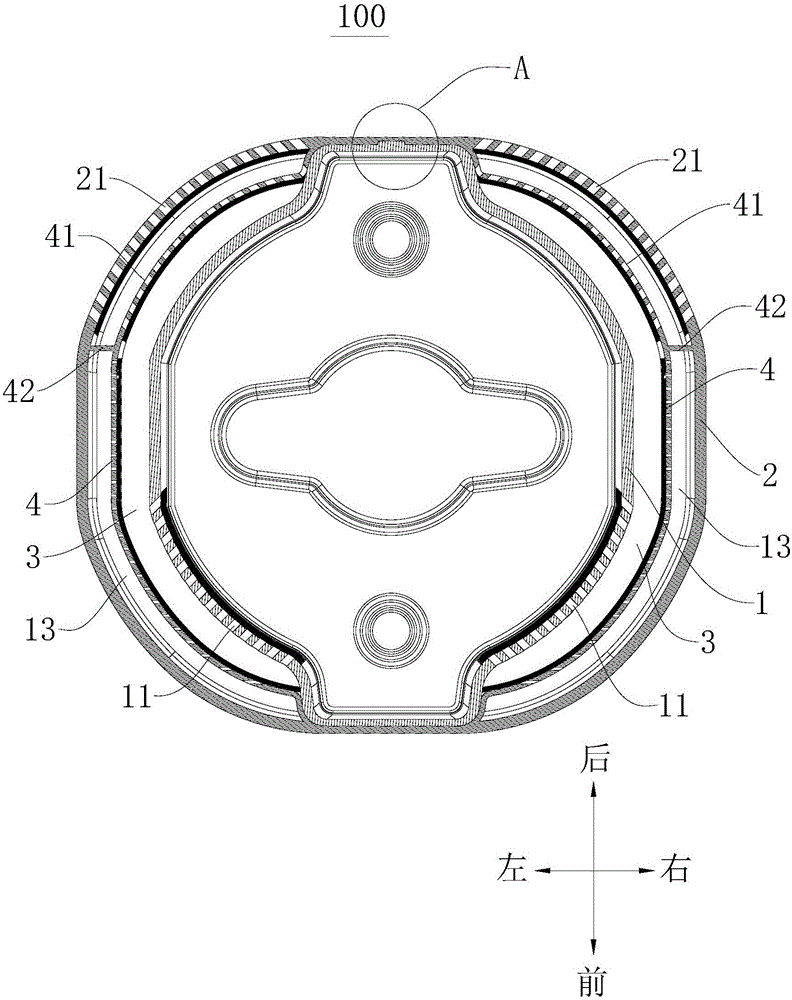

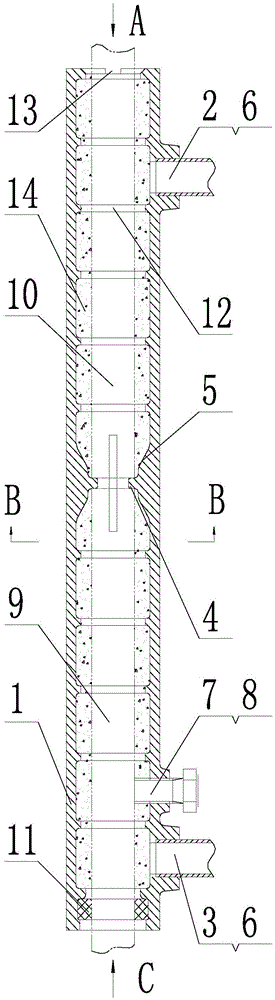

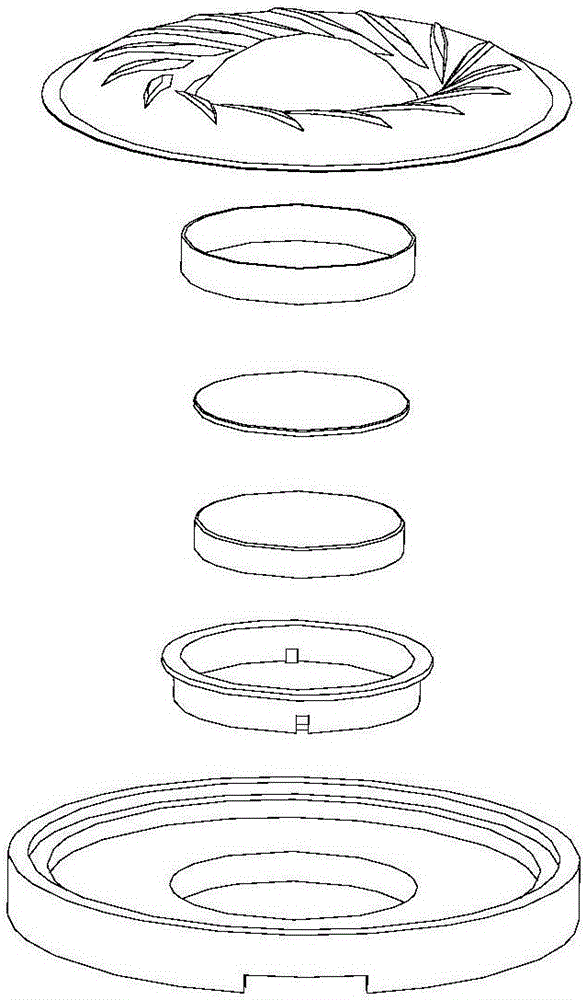

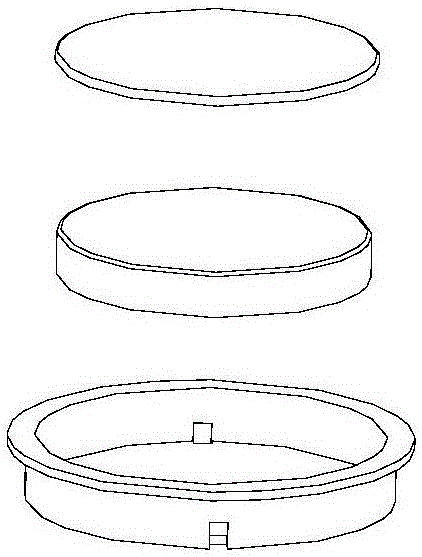

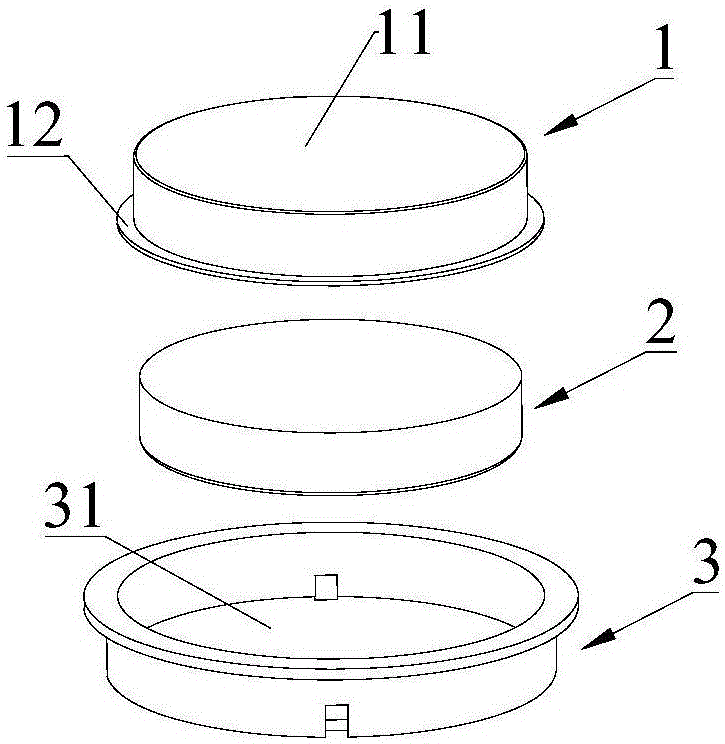

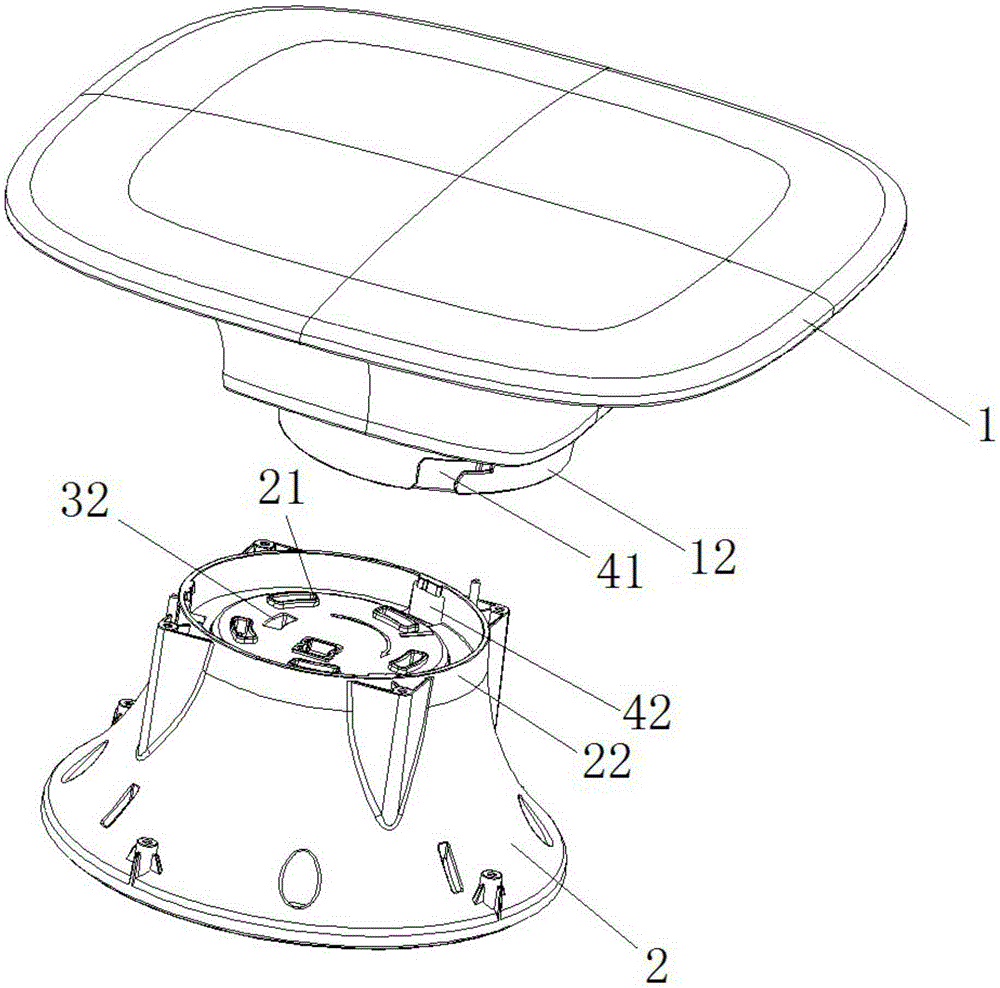

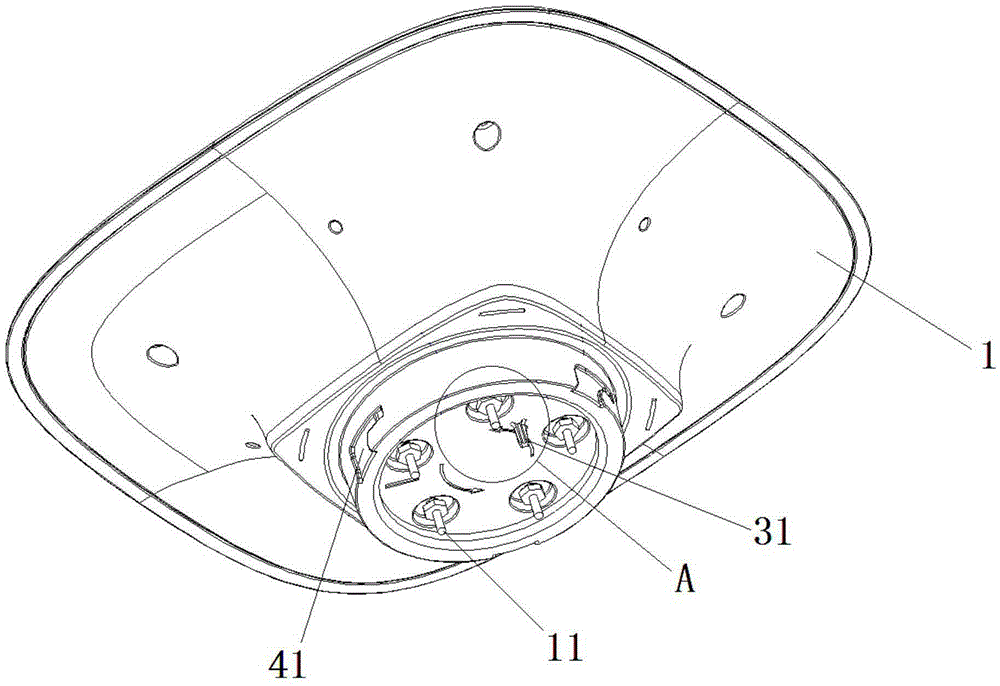

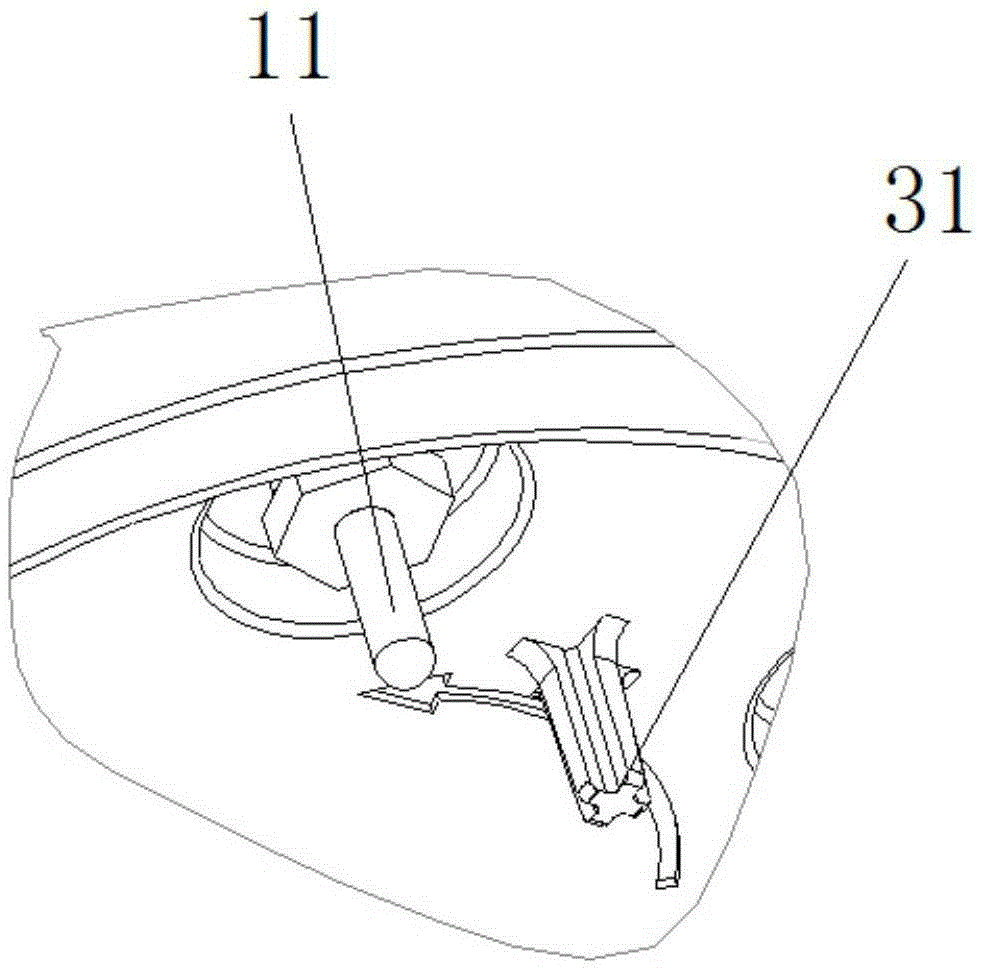

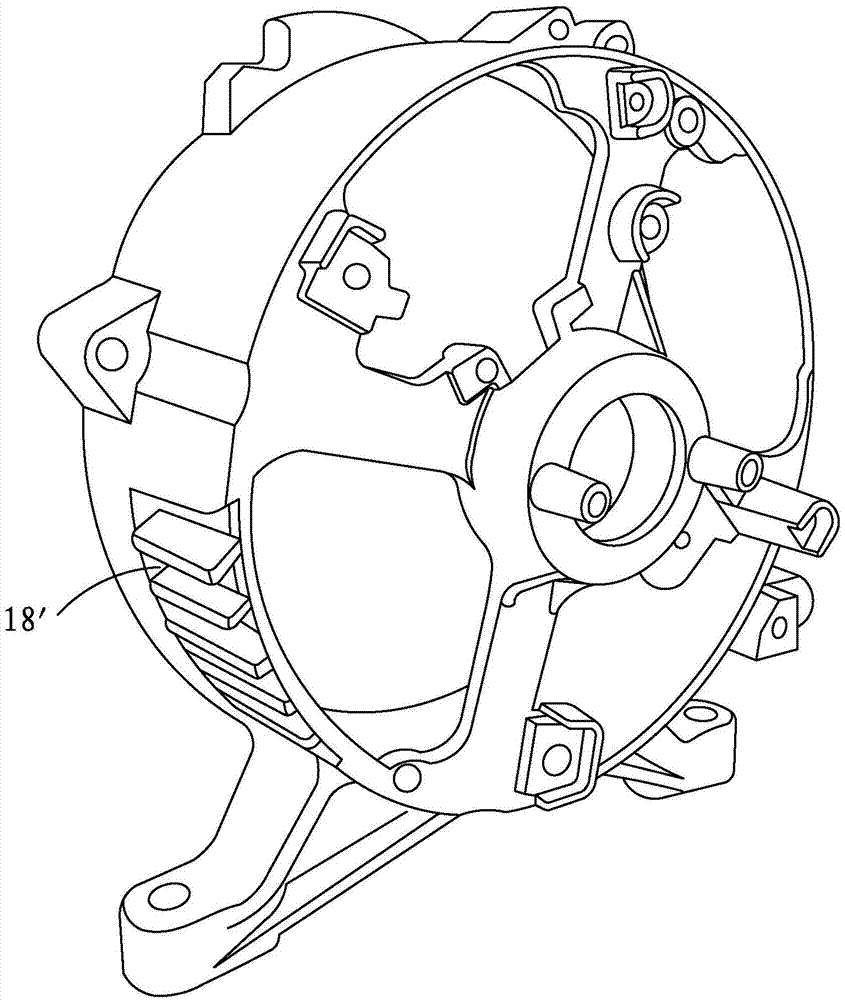

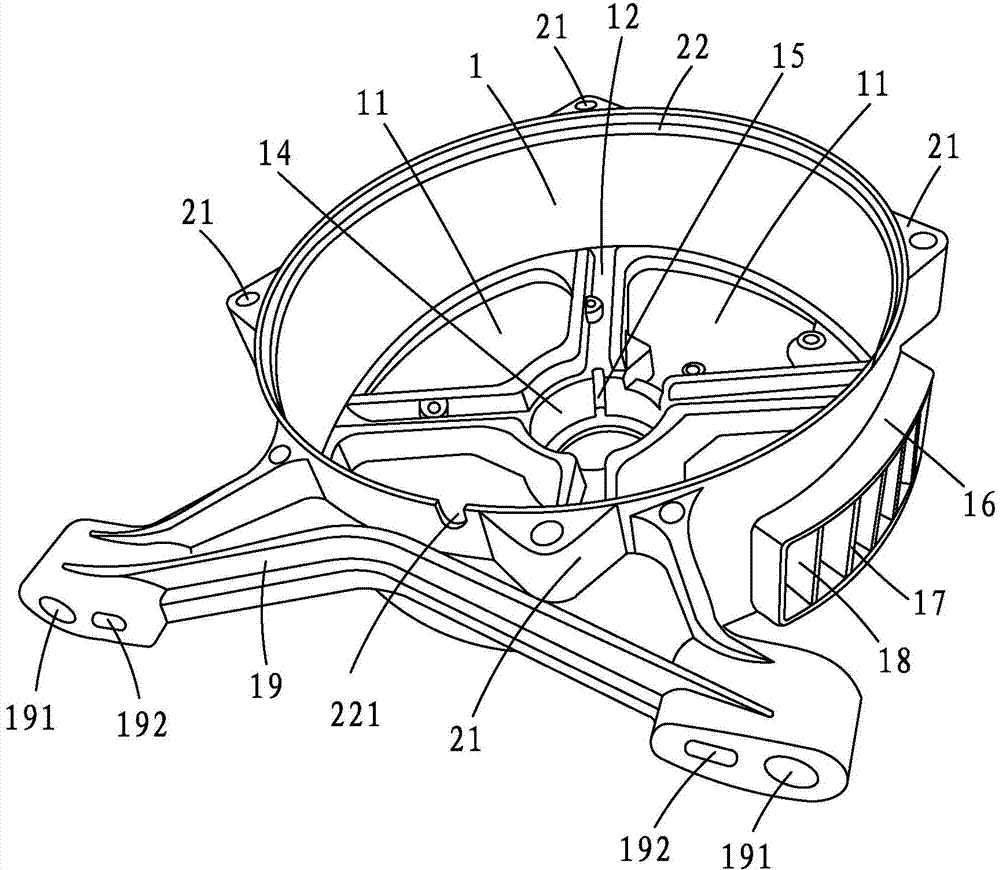

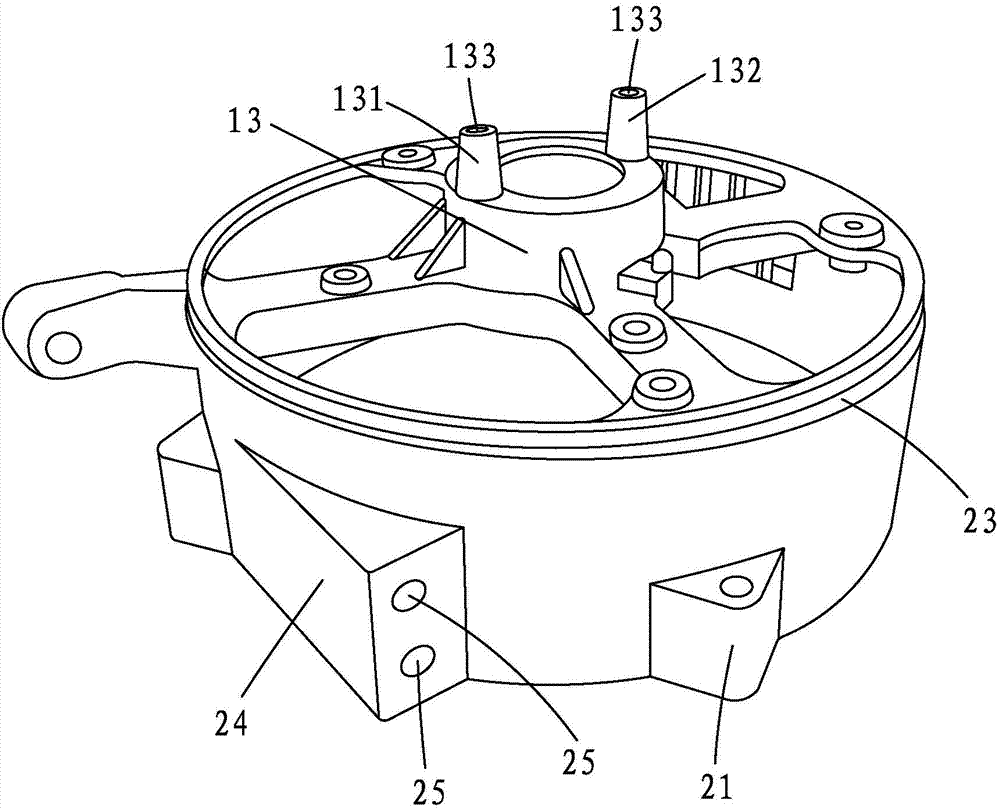

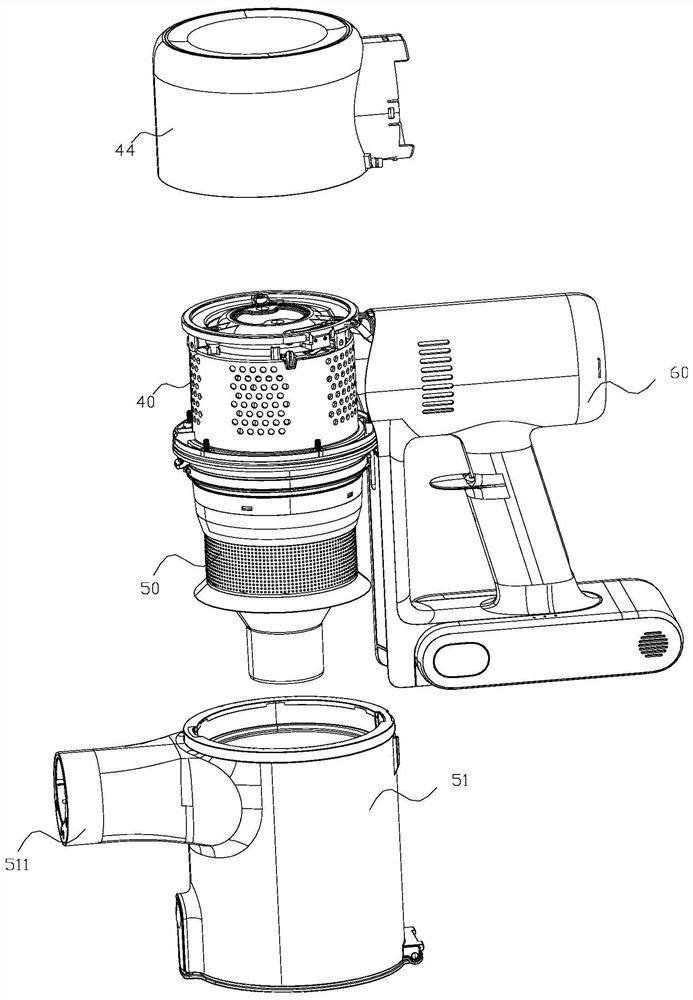

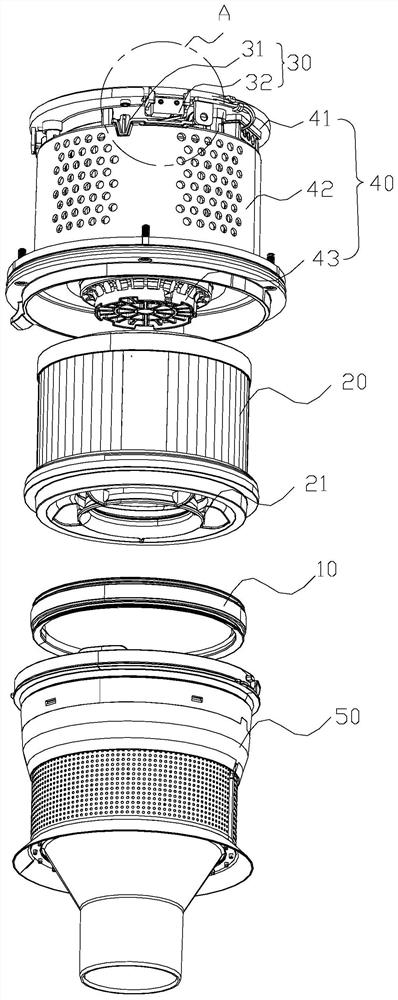

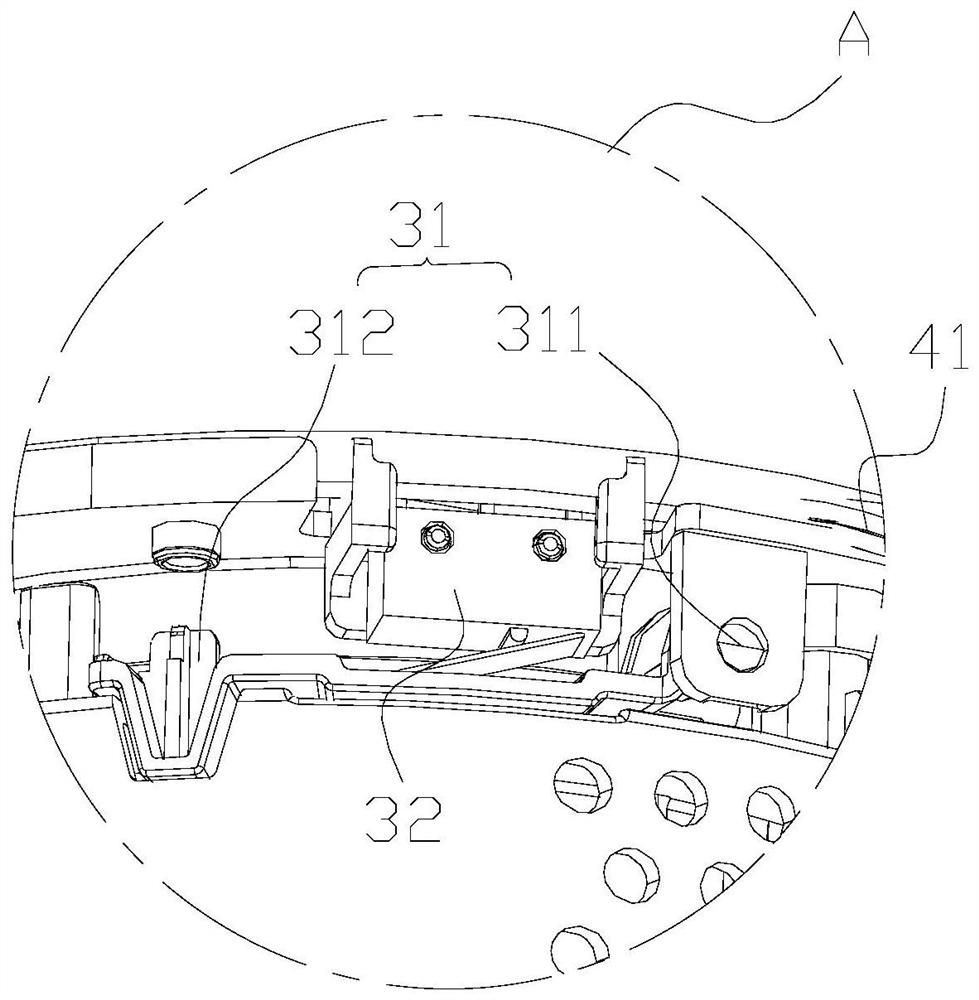

Mute motor inner cover, mute motor and dust collector provided with mute motor

InactiveCN106175584AReduce installation stepsSimple structureExhaust-air diffusionSupports/enclosures/casingsControl theoryDust collector

The invention discloses a mute motor inner cover, a mute motor and a dust collector provided with a mute motor. The mute motor inner cover for the dust collector comprises an inner housing defining an accommodating cavity for accommodating a motor body and an outer housing which is an integrally formed part, wherein a first outlet is formed in the side wall of the inner housing, the inner housing is detachably arranged in the outer housing, an airflow channel is defined between the outer housing and the inner housing, a second air outlet is formed in the outer housing, the first air outlet and the second air outlet are respectively communicated with the airflow channel, and a mute cavity is defined in the outer housing, is located between the first air outlet and the second air outlet and is communicated with the first air outlet. According to the mute motor inner cover for the dust collector, the number of parts is decreased, convenience is brought to mounting and dismounting, damage is not likely to occur, and the problem of inverse mounting can be also prevented. In addition, the mute cavity can be defined in the outer housing, and the mute effect of the motor inner cover for the dust collector can be further improved.

Owner:JIANGSU MIDEA CLEANING APPLIANCES

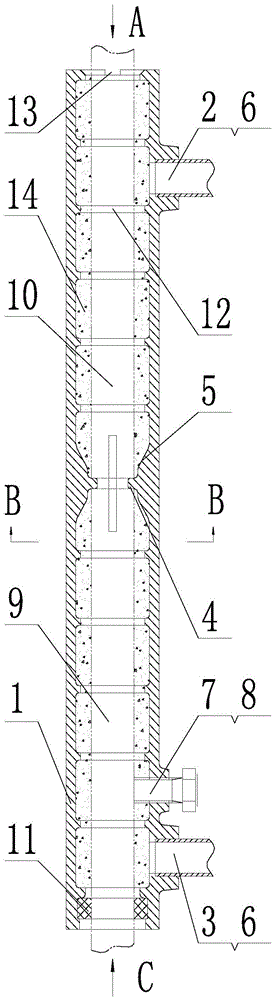

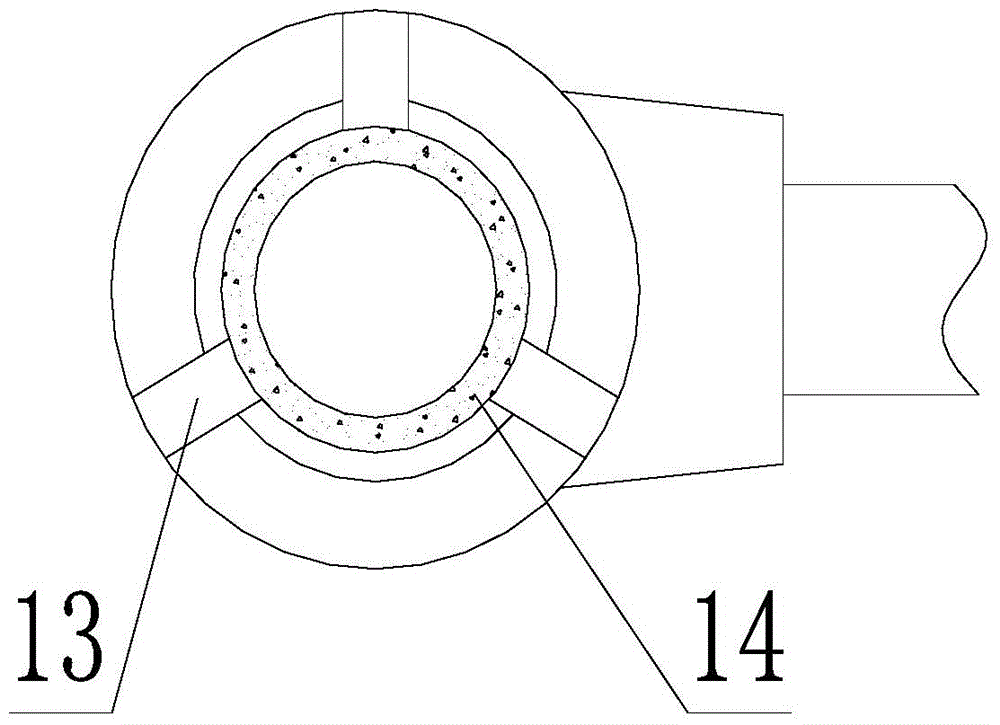

Full-grouting sleeve for connection of construction reinforcing steel bars

InactiveCN104358360APrevent reverse installationGuaranteed positioning accuracyBuilding reinforcementsButt jointArchitectural engineering

The invention discloses a full-grouting sleeve for connection of construction reinforcing steel bars, and belongs to the technical field of building projects. A reinforcing steel bar axial-limiting guide stop dog is arranged on the inner wall in the middle of a sleeve main body; guide slopes are arranged between the stop dog and the inner wall of the sleeve main body; a positioning bolt is arranged on the sleeve main body at the prefabricated end; the reinforcing steel bar at the prefabricated end is axially and radially fixed through the positioning bolt; the sleeve main body is molded by one-step casting of spheroidal graphite cast iron, so that the production cost is low; the outer surface of the sleeve main body serves as a roughened surface, so as to ensure the anchoring force between the grouting sleeve and the concrete; a plurality of convex hooping ribs are arranged on the inner wall of the grouting sleeve; an identification gap is formed in the port face of the sleeve main body at the field poured end, so as to prevent the situation that the grouting sleeve is installed reversely; a seal ring is arranged inside the port of the sleeve main body at the prefabricated end. When the grouting sleeve disclosed by the invention is in axial butt joint with the reinforcing steel bar, the precise axial control can be automatically realized, and the radial positioning can be automatically realized, so as to ensure the positioning accuracy between the reinforcing steel bar and the grouting sleeve, and meet the requirements on building construction quality.

Owner:SHENYANG JIANZHU UNIVERSITY

Air purifier

InactiveCN105169826AThere will be no phenomenon that is not filteredImprove filtration efficiencyDispersed particle filtrationFire rescueAir purifiersEnvironmental engineering

The invention relates to an air purifier, which comprises a purifying main body, one side of the purifying main body is provided with an air inlet, a filter and a fan are arranged sequentially along an air flow path in the purifying main body, and the entire purifying main body is covered by the filter; the purifying main body is provided with an air passage at a position corresponding to the fan; the air passage is communicated with an air outlet formed in one side of the purifying main body; a flow guide plate for air flow is arranged at one side of the fan, the flow guide plate is divided by ribs, and the ribs are in contact with the filter. The air purifier is small in size and lightweight, and therefore is convenient to carry, the air supply and filtering power is high, active air supply is adopted, breathing resistance is low, and the air purifier is comfortable.

Owner:BROAD A Q TECH

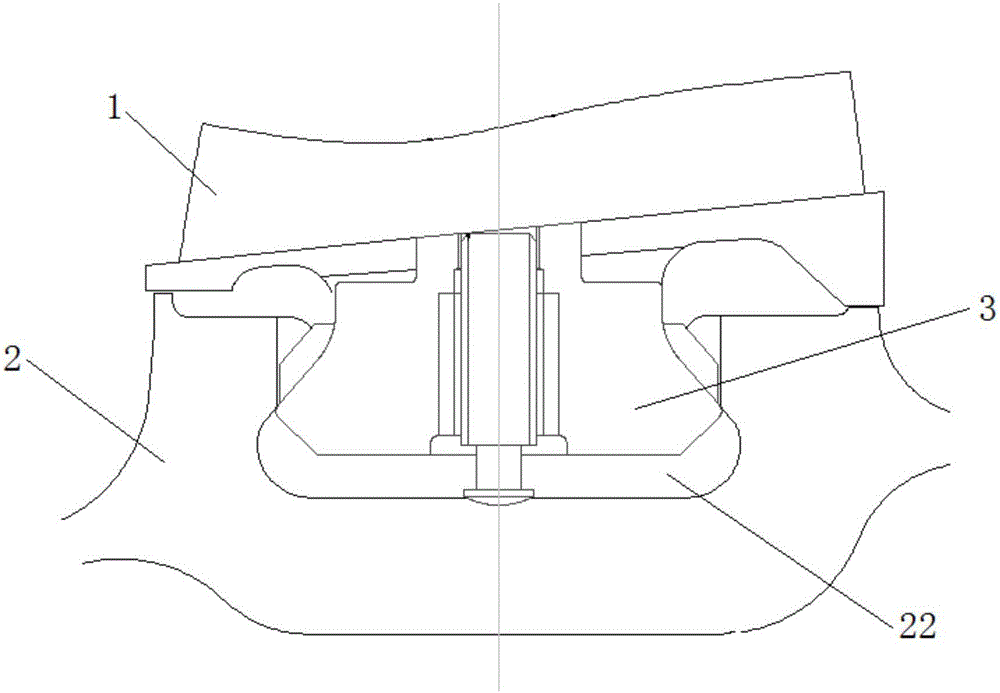

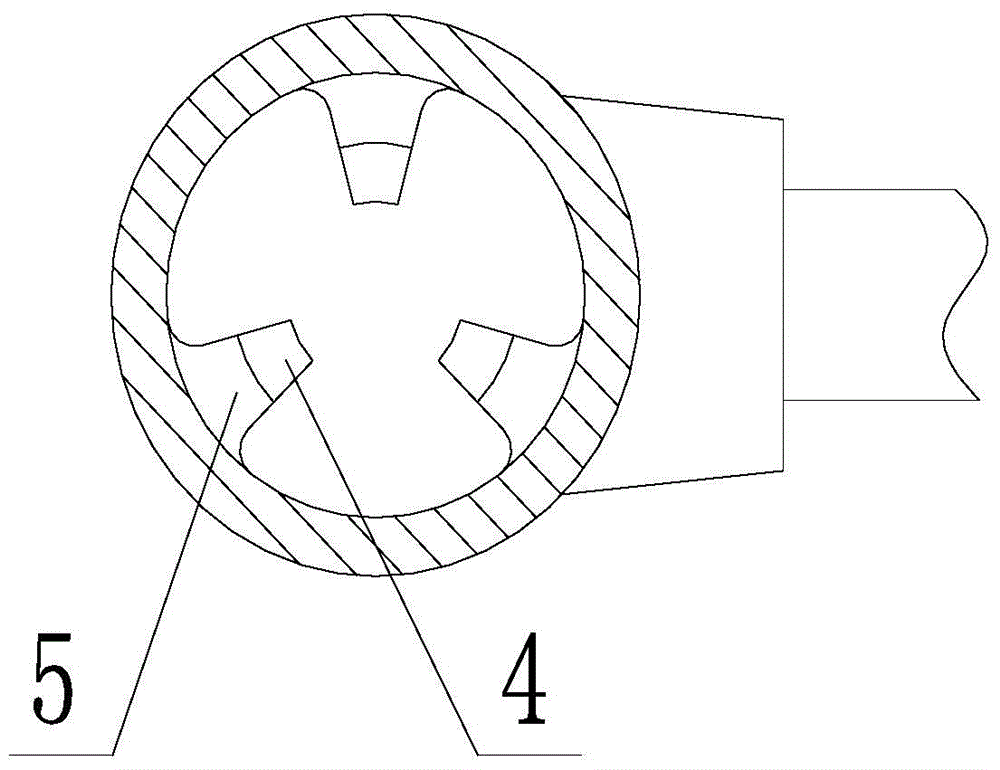

Rotor vane locking structure

ActiveCN106014490APrecise positioningPrevent reverse installationBlade accessoriesMachines/enginesMechanical engineeringEngineering

Owner:AECC SHENYANG ENGINE RES INST

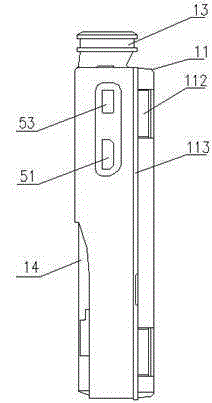

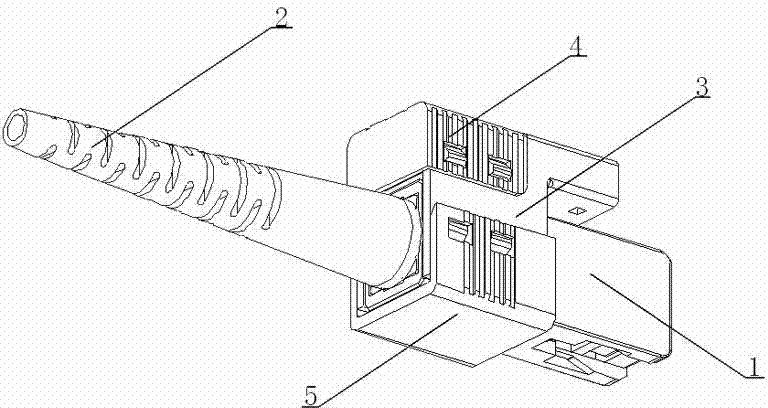

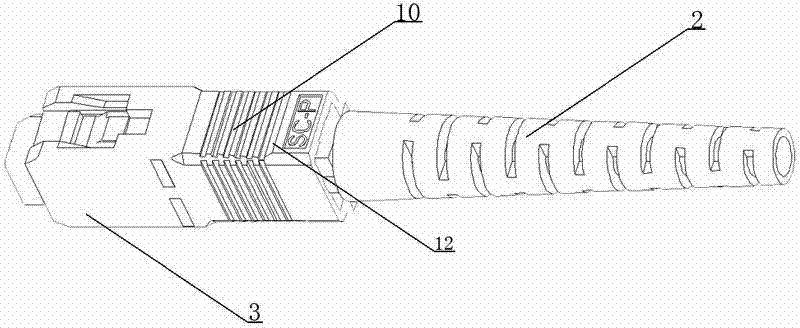

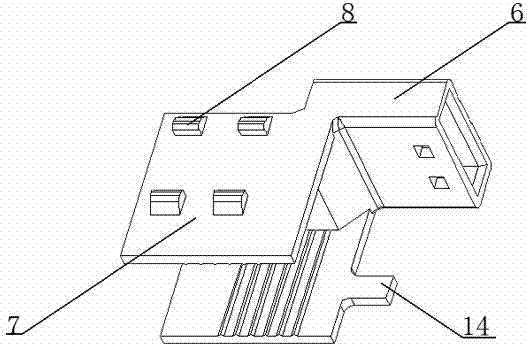

Intelligent optical fiber connector

ActiveCN103901553AWith anti-loosening engagement structureWith anti-loosening effectCoupling light guidesOptical fiber connectorMechanical engineering

The invention relates to an intelligent optical fiber connector. The intelligent optical fiber connector comprises an SC shell, a cable protection casing pipe, a connector hood, an upper fastening cap and a lower fastening cap, wherein the SC shell is connected with one end of the cable protection casing pipe in a clamped mode, the connector hood is connected with the SC shell through a U-shaped clamping base in a clamped mode, the upper fastening cap and the lower fastening cap are connected with the connector hood in a clamped mode through clamping holes of the upper fastening cap and clamping holes of the lower fastening cap, anti-looseness meshing structures are arranged between the SC shell and the U-shaped clamping base and between the SC shell and the lower fastening cap, and an anti-misassembly and anti-forward-creep structure is arranged between the U-shaped clamping base and the SC shell. According to the optical fiber connector, a certain anti-looseness and anti-pull-off effect can be achieved between an intelligent device and the SC shell, and the intelligent device can be prevented from being assembled reversely and will not creep forwards after being assembled.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

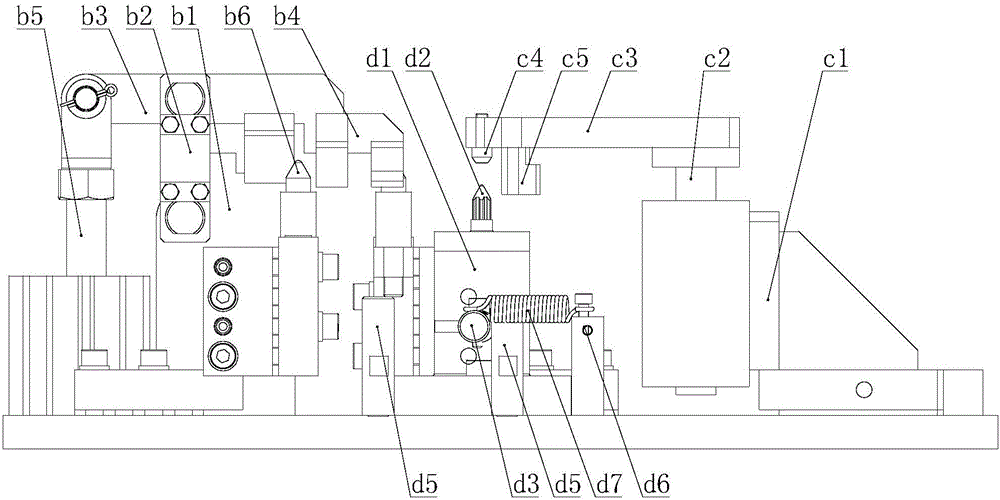

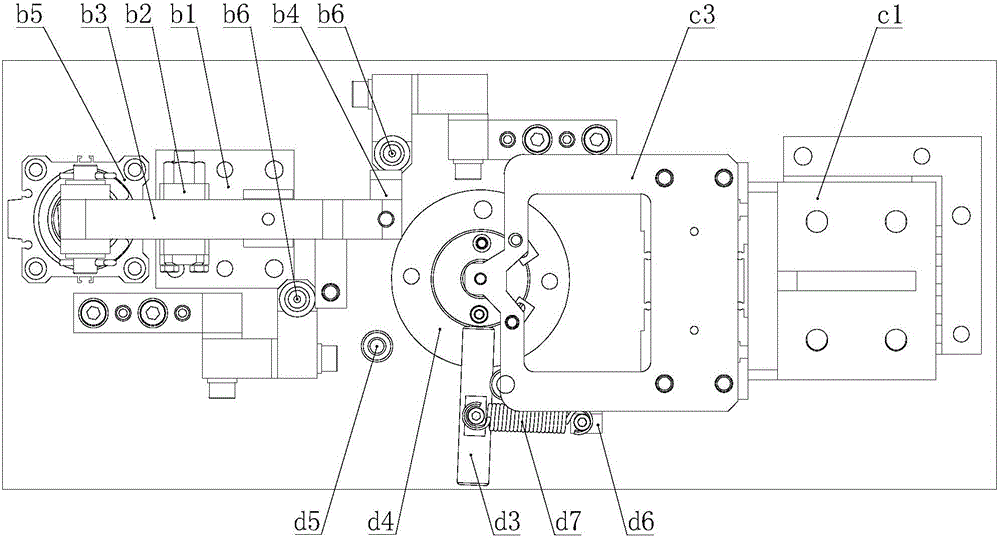

Welding fixture for automobile seat angle adjuster

ActiveCN105773036ASmooth liftPlay a guiding roleWelding/cutting auxillary devicesAuxillary welding devicesEngineeringScrap

The invention discloses a welding fixture for an automobile seat angle adjuster. The welding fixture comprises a base, wherein a connecting plate clamp and a core part clamp are oppositely arranged on the base; an analogue unlocking mechanism is arranged between the connecting plate clamp and the core part clamp; and a clamping part of the core part clamp is positioned above the analogue unlocking mechanism. According to the welding fixture for the automobile seat angle adjuster, disclosed by the invention, analogue unlocking for core parts can be performed before welding, so that unlocking directions of the core parts of the angle adjuster can be judged and verified, the core parts at the left side and the right side of the angle adjuster are prevented from being reversely mounted, the error correction is timely performed, the scrap rate is reduced, and the quality of products is reduced.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

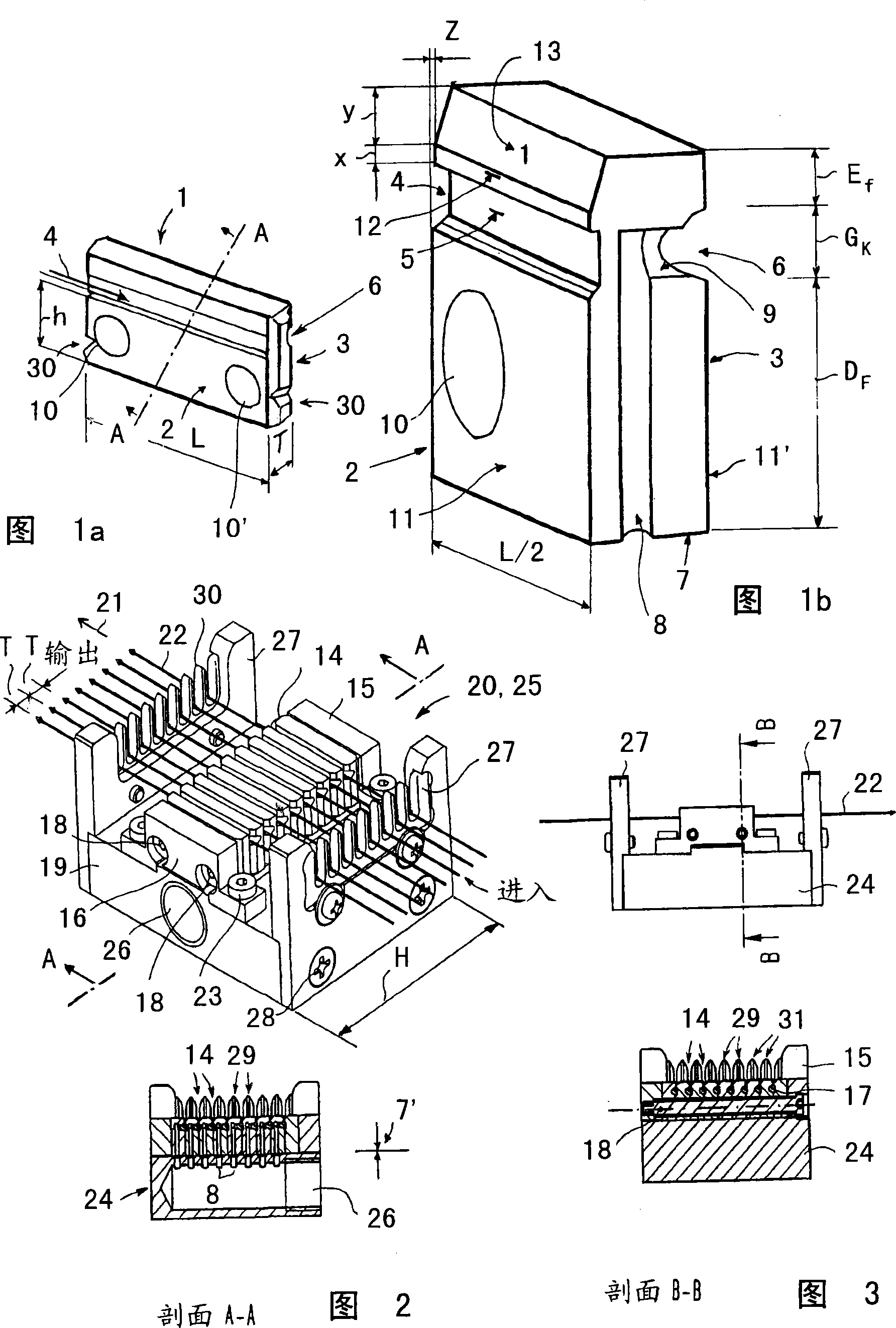

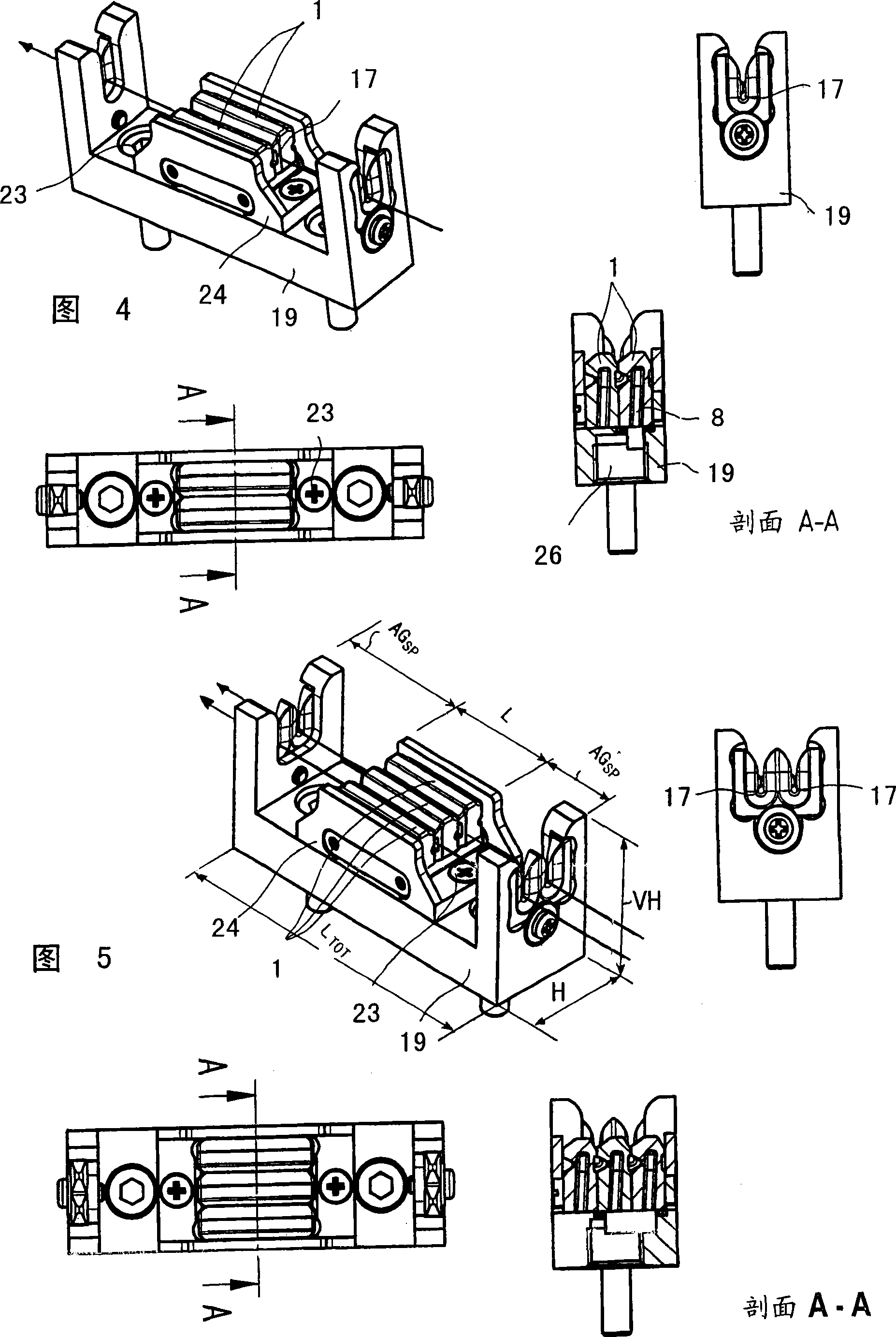

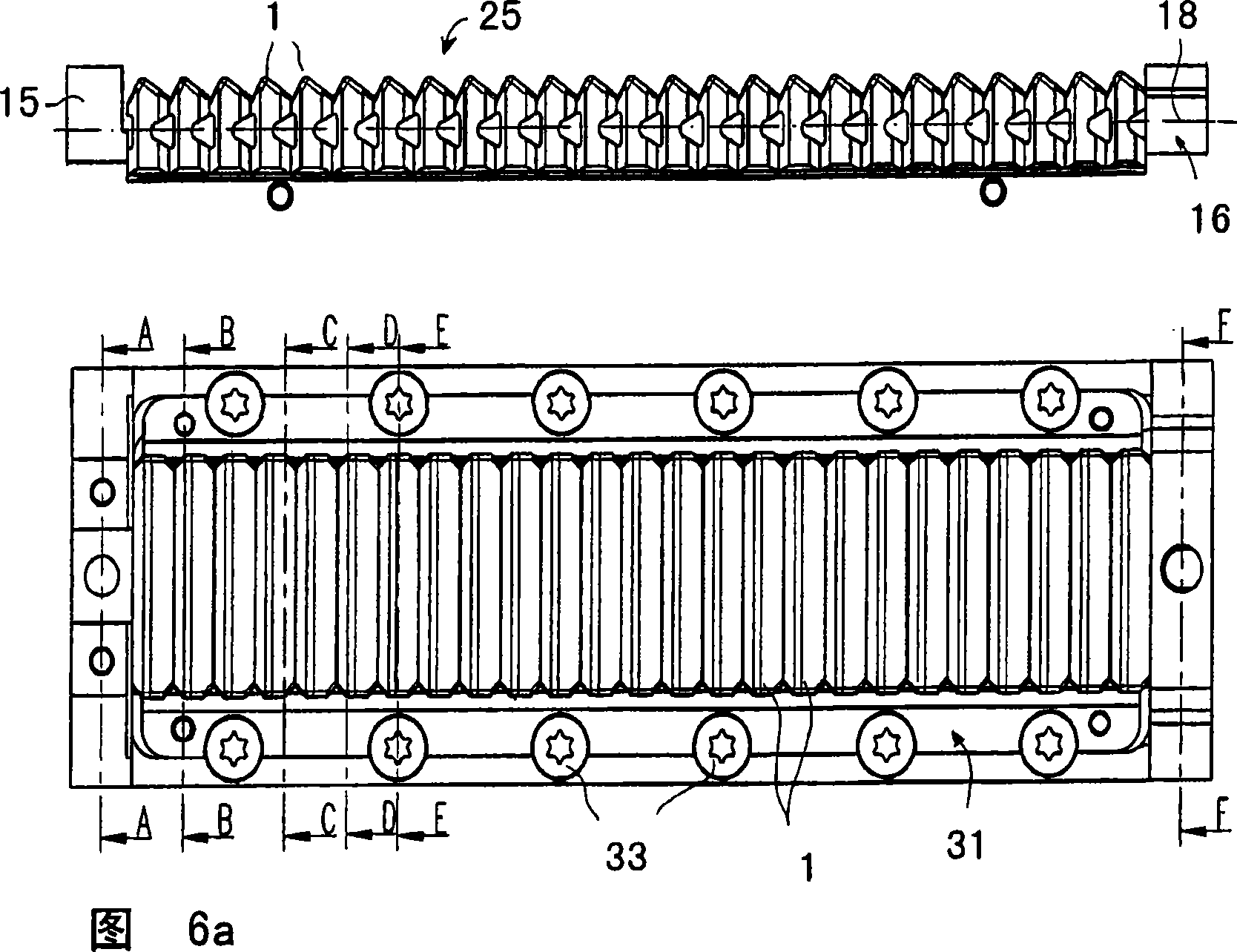

Device and method for treating filament yarn and fancy knotted, migrated, and false-twist yarn

ActiveCN1977075ADurability doubledPrevent flow awayTextiles and paperStructural engineeringMechanics

The invention relates to a device for treating filament yarn by means of air nozzles comprising at least two injector / cover plates that can be clamped together, and at least one air supply channel. Said injector / cover plates form a yarn treatment chamber in the assembled state. According to the invention, the yarn treatment chamber is formed between the injector / cover plates that can be clamped together, in the longitudinal direction of the plates, and the air nozzle is embodied as an open nozzle comprising a threading slit and an individual air supply channel for the yarn channel in the injector / cover plates. The invention has two decisive advantages. The shape of the injector / cover plates is limited to the inherent core functions, namely a yarn channel formed in the plates, the threading slit, and the individual air supply channel for the yarn channel in the plate. The miniaturisation of the injector / cover plates significantly simplifies the production problems.

Owner:HEBERLEIN & CO AG

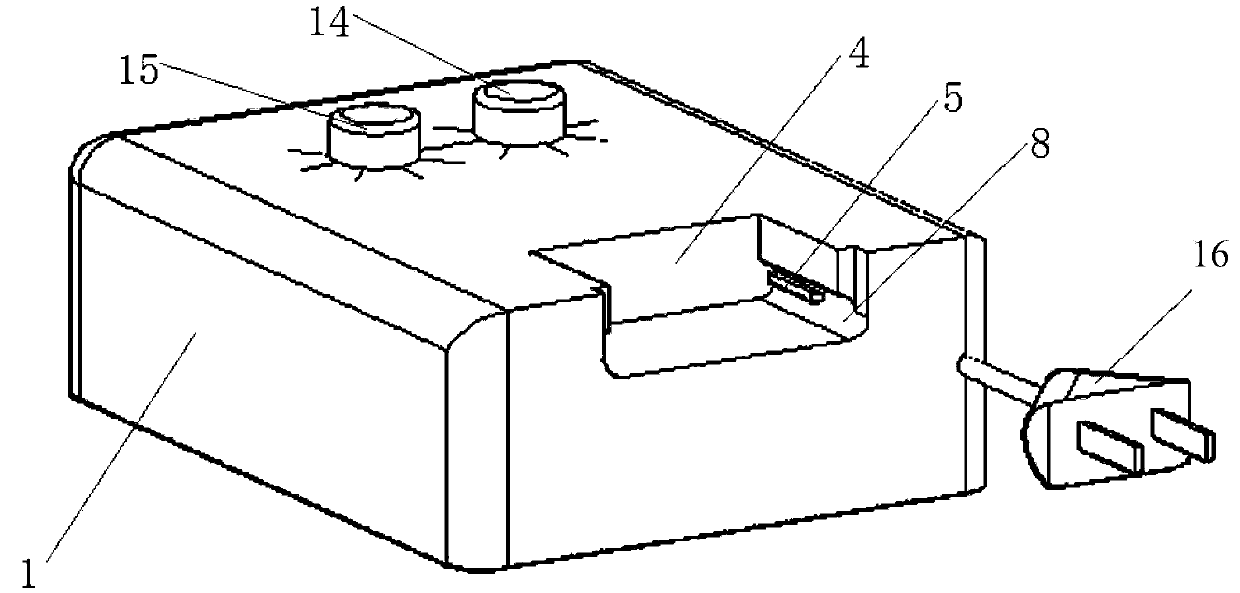

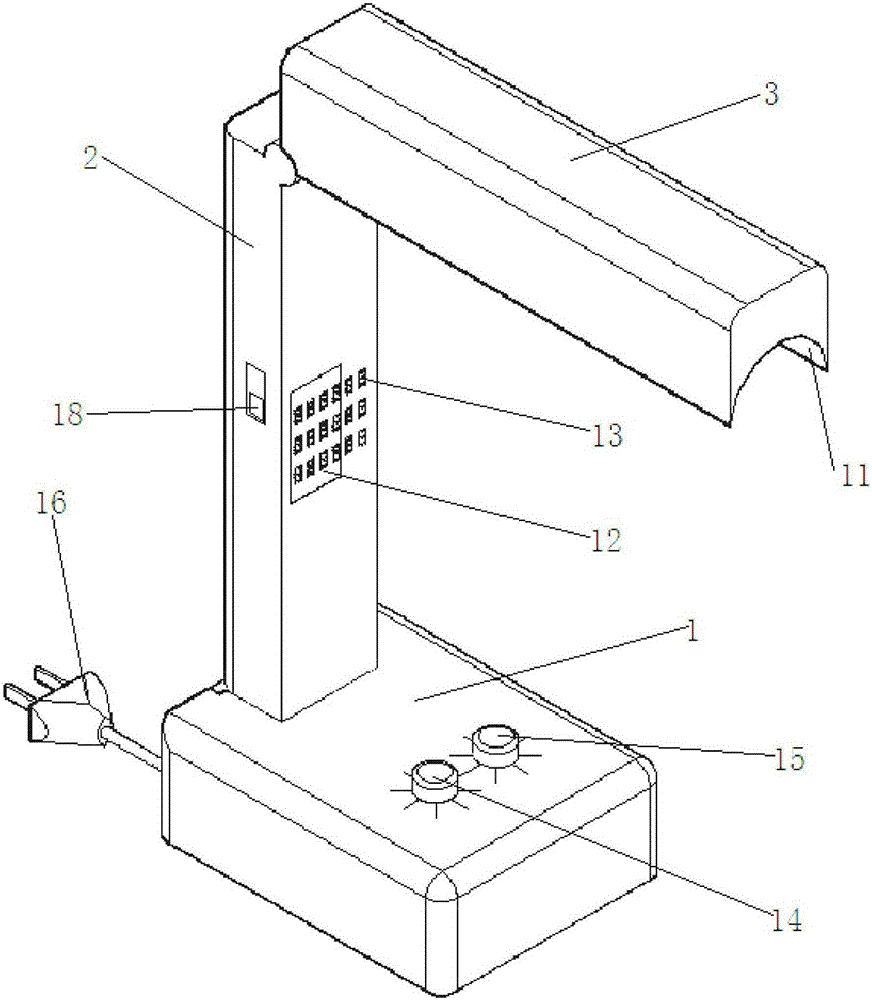

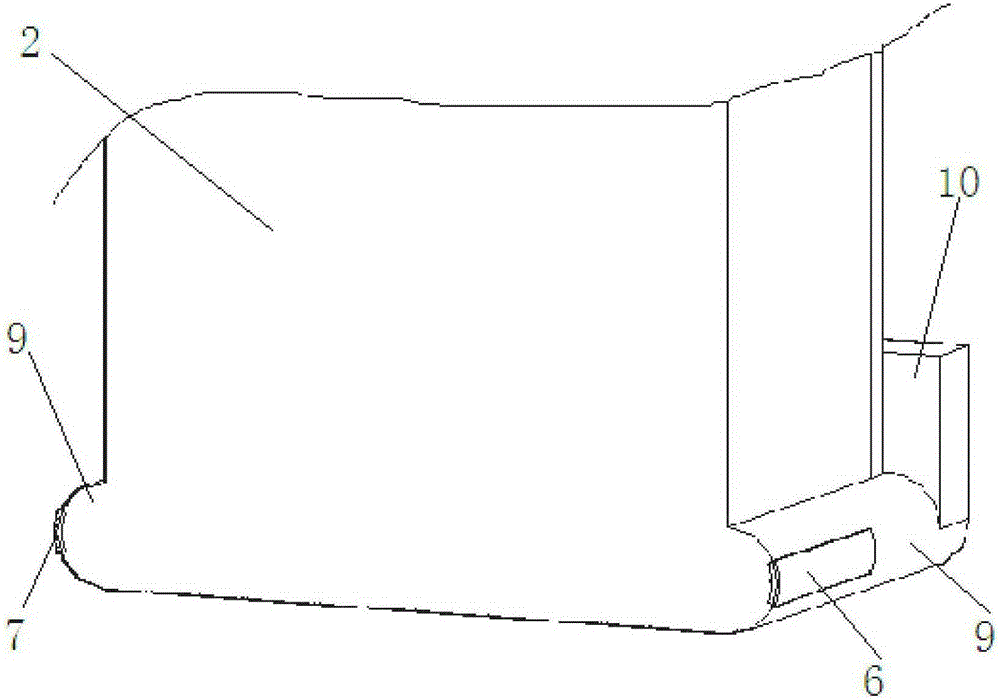

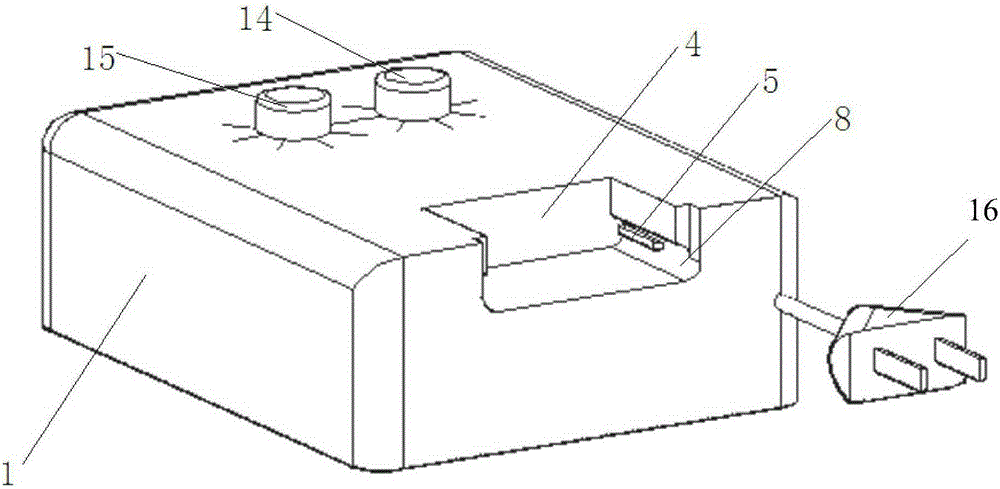

LED (Light Emitting Diode) desk lamp with torch and manufacture method thereof

InactiveCN103742854APrevent reverse installationFirmly connectedPoint-like light sourceLighting support devicesLight headLight-emitting diode

The invention discloses an LED (Light Emitting Diode) desk lamp. The LED desk lamp comprises a base with a plug, a bracket and a lamp holder, wherein the base is connected with one end of the bracket in a detachable way, the lamp holder is connected with the other end of the bracket by a hinge, a clamp groove is formed in the edge part of the upper surface of the base, a positive pole spring plate and a negative pole spring plate which are electrically connected with the plug are respectively arranged on the two inner side walls of the clamp groove, a positive pole contact and a negative pole contact which are electrically connected with the lamp holder are respectively arranged in the corresponding positions of the end part of the bracket, a battery is built in the bracket, the built-in lamp holder which is electrically connected with the battery is arranged at the hinged end part of the bracket, a switch for controlling the built-in lamp holder is arranged on the side wall of the bracket, and the bracket can be disassembled and used as a torch.

Owner:DONGGUAN YOUNAI IND CO LTD

Manufacturing method for LED table lamp with flashlight

ActiveCN105333345APrevent reverse installationFirmly connectedLighting support devicesElectric circuit arrangementsFlashlightEngineering

The invention discloses a manufacturing method for an LED table lamp with a flashlight. The LED table lamp comprises a base, a support and a lamp holder, wherein the base is provided with a plug; the base is detachably connected with one end of the support; the lamp holder is hinged with the other end of the support; a clamping groove is formed in the side of the upper surface of the base; a positive-pole elastic piece and a negative-pole elastic piece which are electrically connected with the plug are arranged on two inner side walls of the clamping groove respectively; a positive-pole contact and a negative-pole contact which are electrically connected with the lamp holder are arranged at corresponding positions of the end portions of the support respectively; a battery is arranged in the support; a built-in lamp holder which is electrically connected with the battery is arranged at a hinged end of the support; a switch controlling the built-in lamp holder is arranged on the side wall of the support; and the support can be detached and used as a flashlight.

Owner:广州兰玉新能源有限公司

Loudspeaker magnetic circuit structure and assembling method thereof

InactiveCN106792392AReduce offsetPrevent reverse polarityElectrical transducersLoudspeakersRelative displacementLoudspeaker

The invention discloses a loudspeaker magnetic circuit structure and an assembling method thereof. The loudspeaker magnetic circuit structure comprises a spring washer, a magnet and a yoke. The yoke comprises a containing cavity. The spring washer comprises a spring washer body and an edge structure. The spring washer body is of a cavity structure with one open end, and extends outwards from the open edge of the cavity structure to form an edge structure; the edge structure is located inside the containing cavity, and the magnet is located inside the spring washer body. The magnet and the spring washer are fixed through the cavity structure and the edge structure of the spring washer respectively, so that large relative displacement between every two of the magnet, the spring washer, the cavity structure and the edge structure is avoided so as to ensure the concentricity of the spring washer, the magnet and the yoke, and the yield of a finished loudspeaker is improved; when a loudspeaker magnetic circuit is assembled, assembling and magnetizing are performed in succession, the phenomenon that magnetic poles are assembled reversely in the magnet assembling process can be effectively avoided, and therefore the phase equalization of the finished loudspeaker is ensured.

Owner:SUNWAY COMM JIANGSU CO LTD

Screening device

ActiveCN107098143AAvoid scratchesAvoid wastingConveyorsConveyor partsPattern recognitionProcess efficiency

The invention relates to a screening device. The screening device comprises a discharge unit, a turnover unit and a pickup unit, and further comprises a recognition unit. The obverse side and the reverse side of a material can be accurately judged through the recognition unit, the recognition speed is high, recognition is precise, and thus the problem of low artificial recognition process efficiency is solved. In the artificial recognition process, problems such as visual fatigue and wrong judgment are prone to occurring, obverse side and the reverse side recognition errors generated by artificial recognition can be effectively avoided through the recognition unit, and the percent of pass of products in the subsequent product assembly process is further guaranteed.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

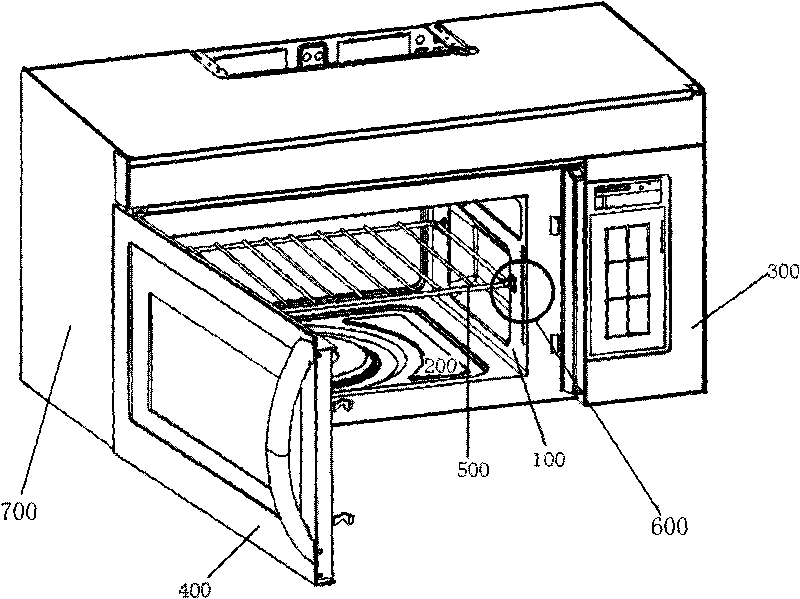

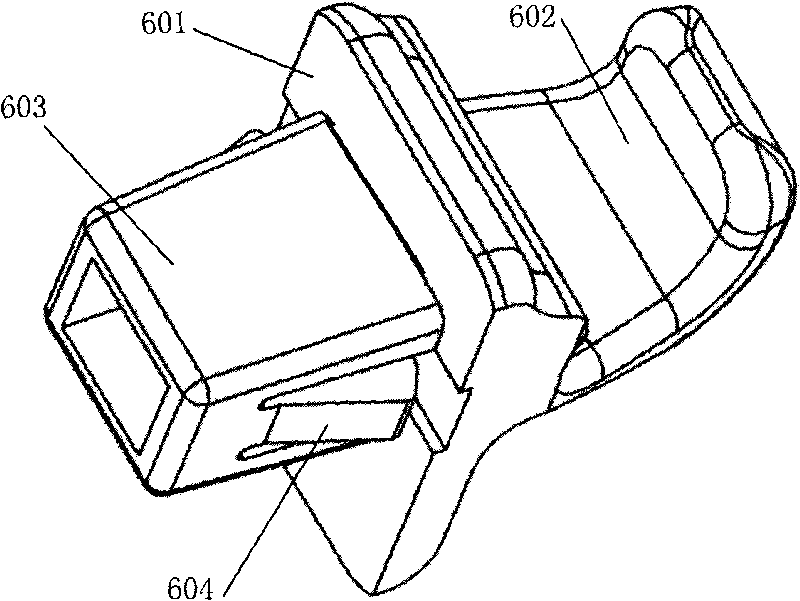

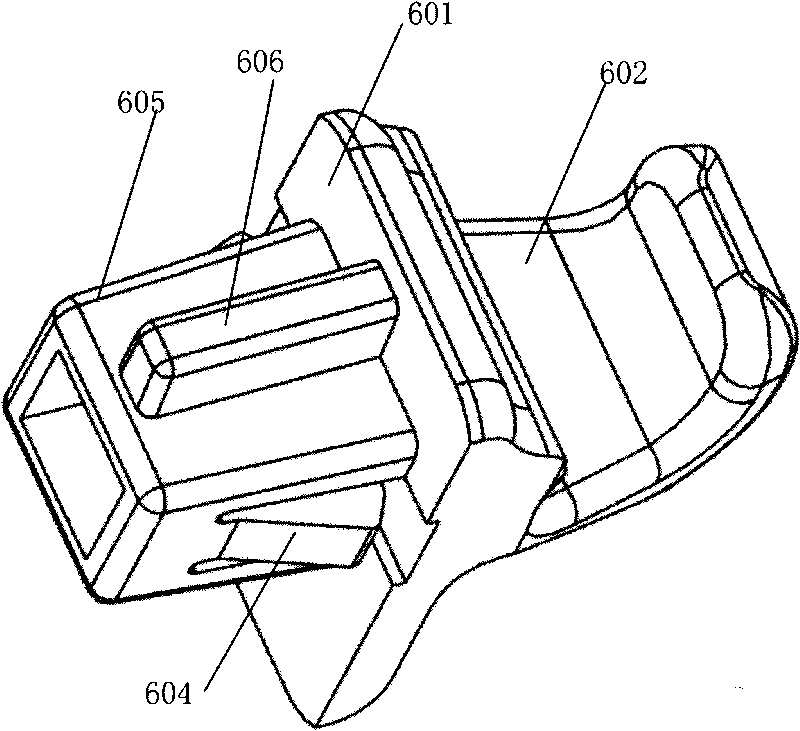

Support structure of microwave oven grill

InactiveCN101749769APrevent reverse installationImprove work efficiencyStoves/ranges shelves or racksMicrowave ovenBiochemical engineering

The invention discloses a support structure of a microwave oven grill, which comprises a microwave oven cooking chamber side wall and a grill support; the grill support is provided with a support body; one side surface of the support body is provided with an insertion fixing part to be inserted into an installation hole arranged on the microwave oven cooking chamber side wall, and the other side surface thereof is provided with a support hook for supporting the grill; the insertion fixing part is provided with an insertion guiding lug; and the installation hole on the microwave oven cooking chamber side wall is provided with a guiding lug insertion slot which corresponds to the insertion guiding lug on the insertion fixing part. The insertion guiding lug is arranged on the upper end surface or the lower end surface of the insertion fixing part. The left side and the right side of the insertion fixing parts are symmetrically provided with limit pieces. The support structure of the microwave oven grill only needs to be provided with a location guiding structure for guiding the installation on the prior grill support, thereby totally preventing the reverse installation problem of the grill support, and improving the working efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

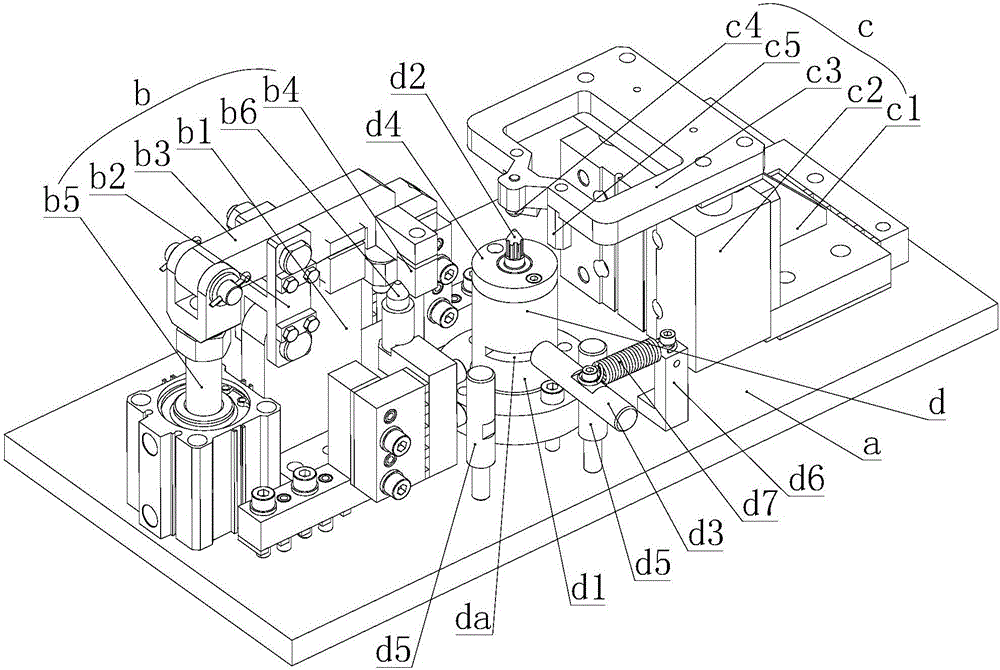

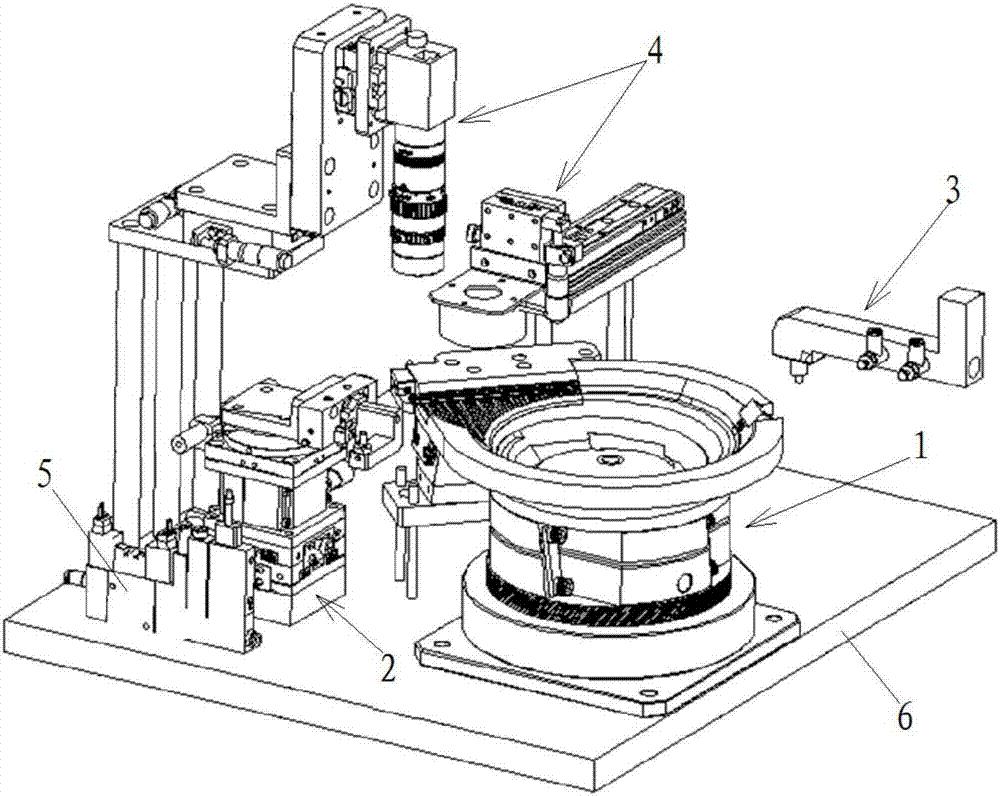

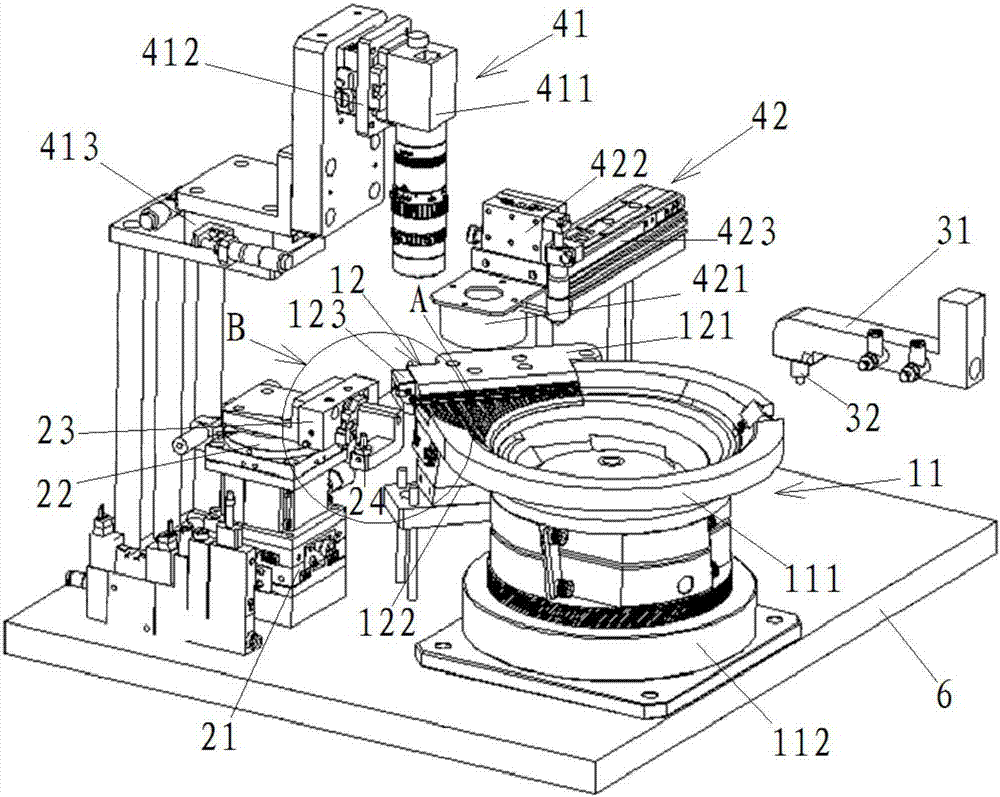

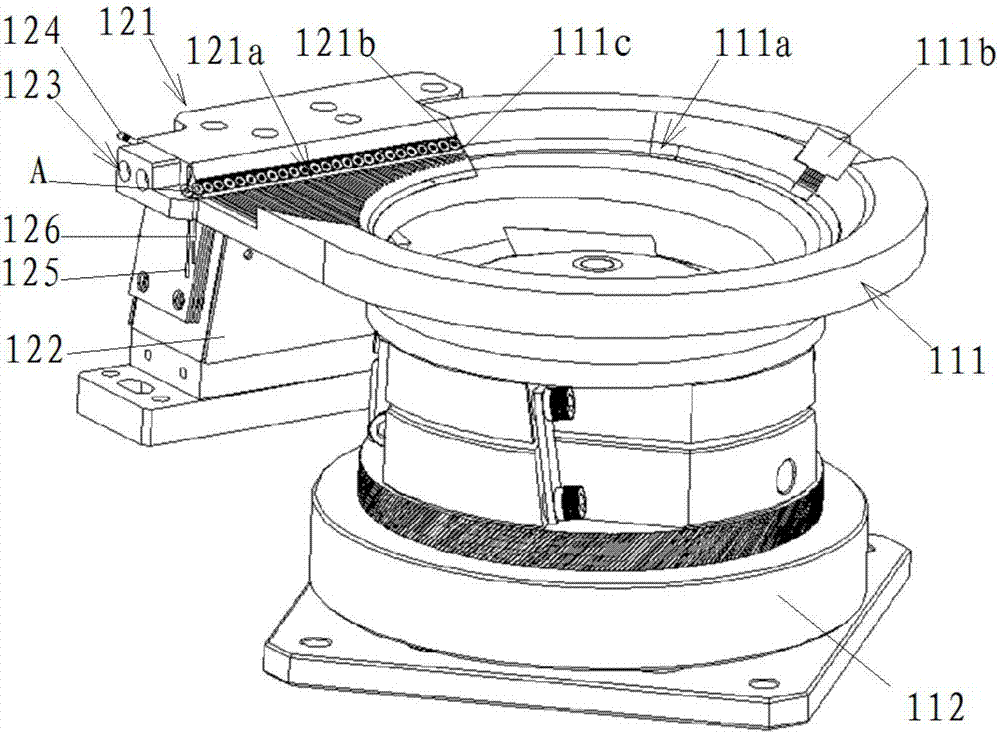

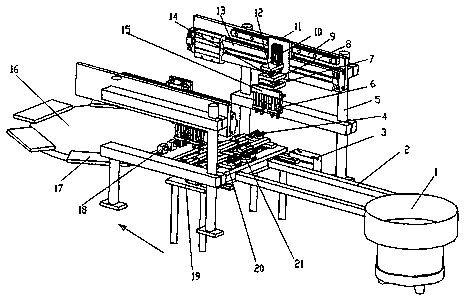

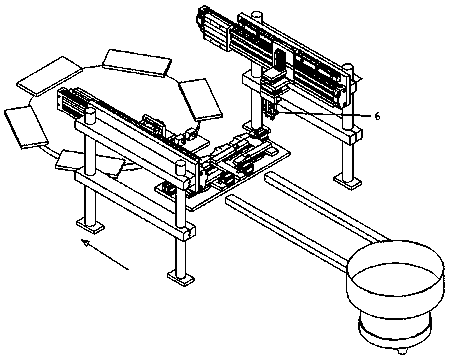

Automatic insertion and positioning device for injection-molded embedded hardware

PendingCN110561682APrevent reverse installationImprove work efficiencyCoatingsTransfer mechanismAnnular array

The invention discloses an automatic insertion and positioning device for injection-molded embedded hardware. The automatic insertion and positioning device comprises a vibrating disk, a guide chute body, a workbench, hardware fixing devices, a rotary table, clamps and hardware grabbing and transferring mechanisms, wherein a mobile carrier is arranged on the workbench, and the hardware fixing devices are arranged on the mobile carrier at intervals; the guide chute body is arranged at a discharging port of the vibrating disk and points to the mobile carrier; the hardware grabbing and transferring mechanisms are arranged on one side or two sides of the mobile carrier and the guide chute body and transfer hardware on the guide chute body onto the hardware fixing devices; a plurality of clampfixing seats are arranged on the rotary table in a mode of a ring array; and the clamps are respectively arranged on the clamp fixing seats. By the way, the automatic insertion and positioning devicefor the injection-molded embedded hardware avoids the problem that the hardware is installed backwards, and improves the working efficiency of the hardware being inserted into the clamps.

Owner:江苏骏伟精密部件科技股份有限公司

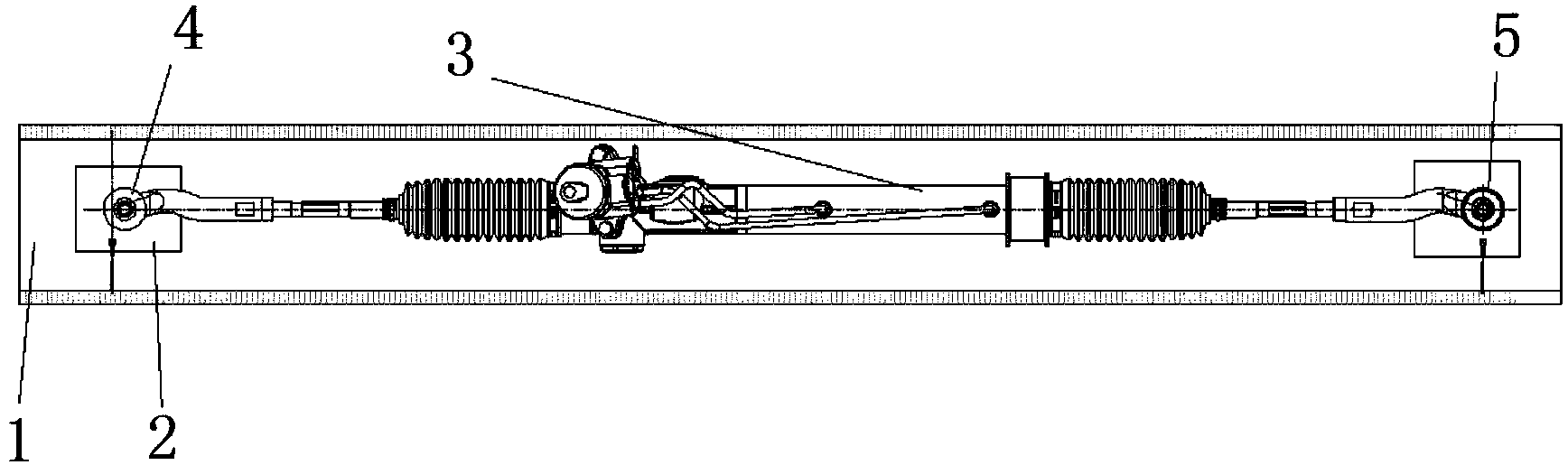

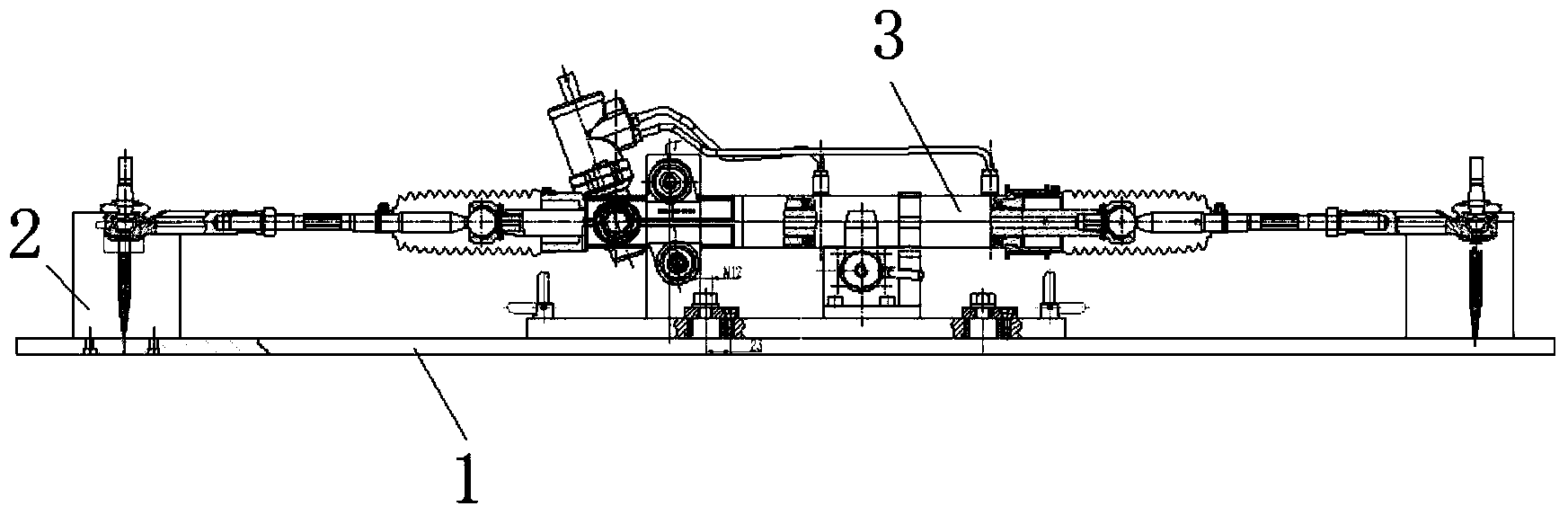

Assembling mistake-proofing device and method for external spherical heads of steering machine assembly

The invention discloses an assembling mistake-proofing device for external spherical heads of a steering machine assembly. The assembling mistake-proofing device comprises a bar-type supporting plate and two clamping blocks which are respectively arranged at two ends of the bar-type supporting plate, wherein a clamping slot matched with a left external spherical head of the steering machine assembly in shape is formed in one clamping block; a clamping slot matched with a right external spherical head of the steering machine assembly in the shape is formed in the other clamping block. Due to the adoption of the structure and a method, the assembling mistake-proofing device has the advantages that the left external spherical head and the right external spherical head of the steering machine assembly are respectively assembled in the clamping slots of the two clamping blocks; if the shapes of the external spherical heads are matched with each other, the external spherical heads are rightly assembled; if the shapes of the external spherical heads are unmatched with each other, the external spherical heads are assembled by mistake, and the left external spherical head and the right external spherical head of the steering machine assembly are reversely assembled on the steering machine assembly, so that the reverse assembling of the left external spherical head and the right external spherical head during assembling can be avoided.

Owner:WUHU STERLING STEERING SYST

Display assembly and air purifier

ActiveCN105261890APrevent reverse installationFast assemblyLighting and heating apparatusIncorrect coupling preventionEngineeringDisplay device

The invention relates to a display assembly and an air purifier, and mainly employs a technical scheme that the display assembly comprises a display body and an installation frame; the display body and the installation frame are respectively provided with a plurality of conductive structures and a plurality of sockets, wherein the number of the conductive structures on the display body is consistent with the number of the conductive structures on the installation frame, the number of sockets on the display body is consistent with the number of sockets on the installation frame, the conductive structures are arranged correspondingly, and the sockets are arranged correspondingly. The display assembly comprises a fool-proof structure, and the fool-proof structure comprises a first clamping part and a second clamping part, wherein the first and second clamping parts are matched with each other, and are respectively disposed on the display body and the installation frame. The display assembly is mainly used for preventing a display from being installed reversely or wrongly to affect the normal display of the air purifier when the display is assembled on the complete machine of the air purifier.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Rear end cover of electric generator

InactiveCN103545966APrevent the phenomenon of running out of the circleHigh strengthSupports/enclosures/casingsThermal stateEngineering

The invention provides a rear end cover of an electric generator. The rear end cover comprises a rear end cover body, wherein four fan-shaped through holes are formed in the rear end face of the rear end cover body, a rib plate is formed between every two of the four fan-shaped through holes, a boss extending backward is arranged in the central position of the rear end face, a stair-shaped through hole inside the boss forms a bearing chamber, the inner wall of the bearing chamber caves inward to form an axial groove, and the axial groove is formed in the middle of the rib plate close to the top portion of the bearing chamber. The lower portion of the side wall of the rear end cover body expands outward to form an arc-shaped protruding portion, a plurality of louver blades are evenly arranged on the protruding portion at intervals, the louver blades are arranged in a parallel and inclined mode, and an air inlet is formed between every two adjacent louver blades. The rear end cover prevents a bearing from easily going to the outer ring in the thermal state and has the advantages of being simple in structure, high in strength and novel and attractive in appearance.

Owner:FUJIAN EVERSTRONG LEGA POWER EQUIP CO LTD

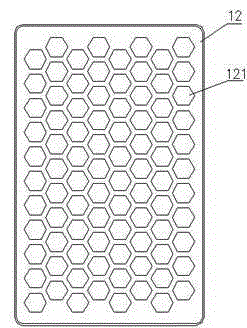

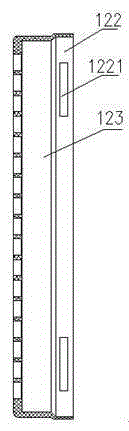

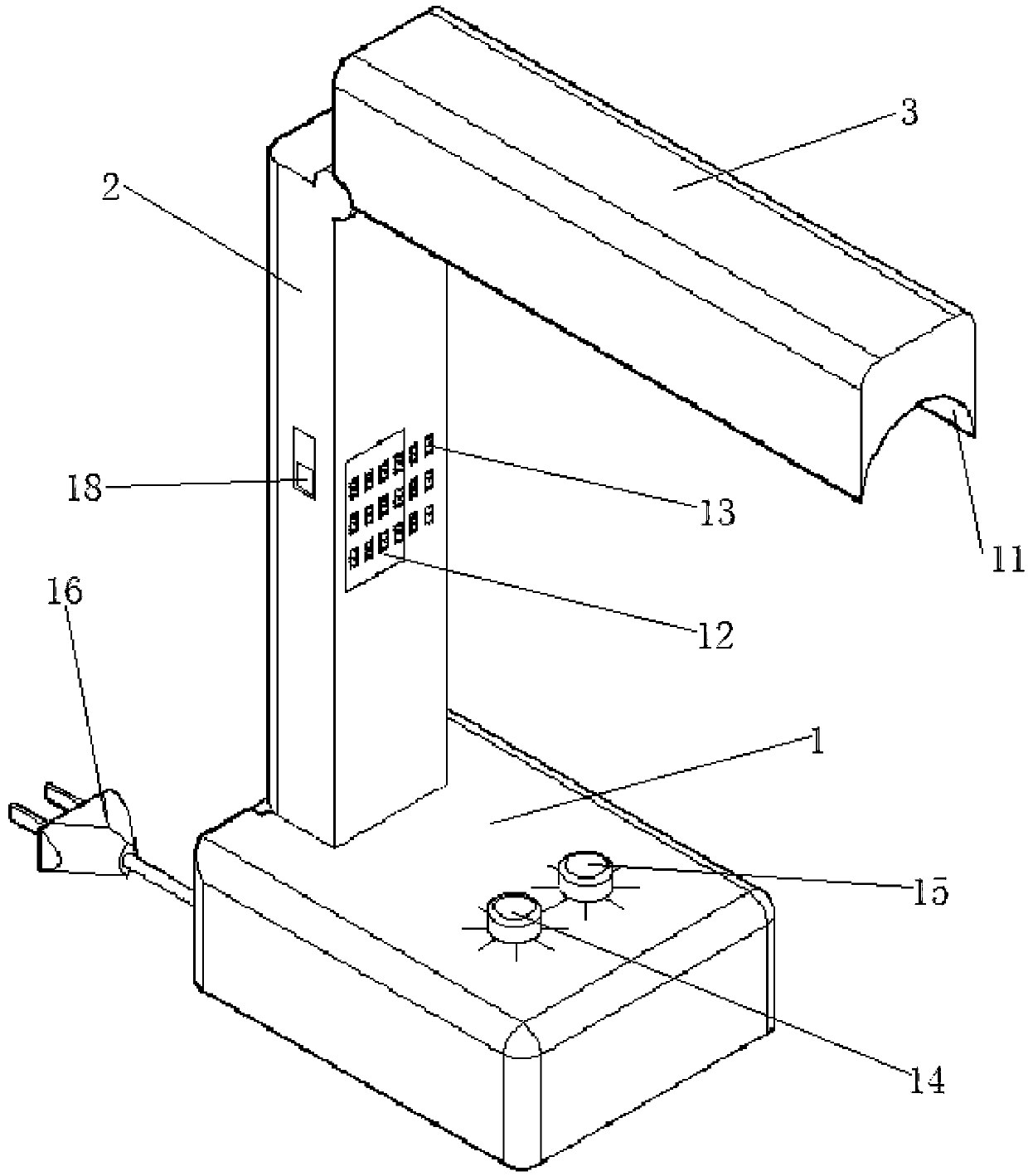

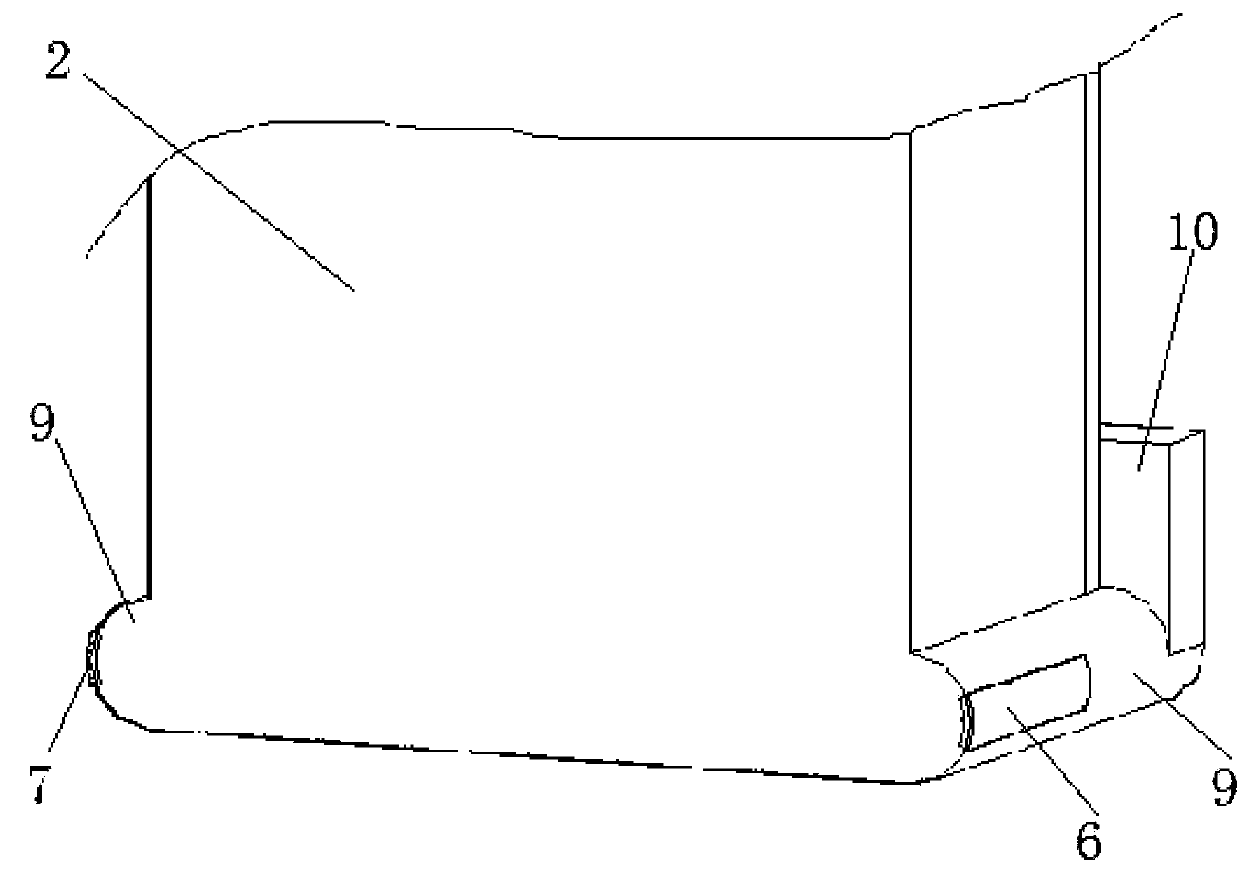

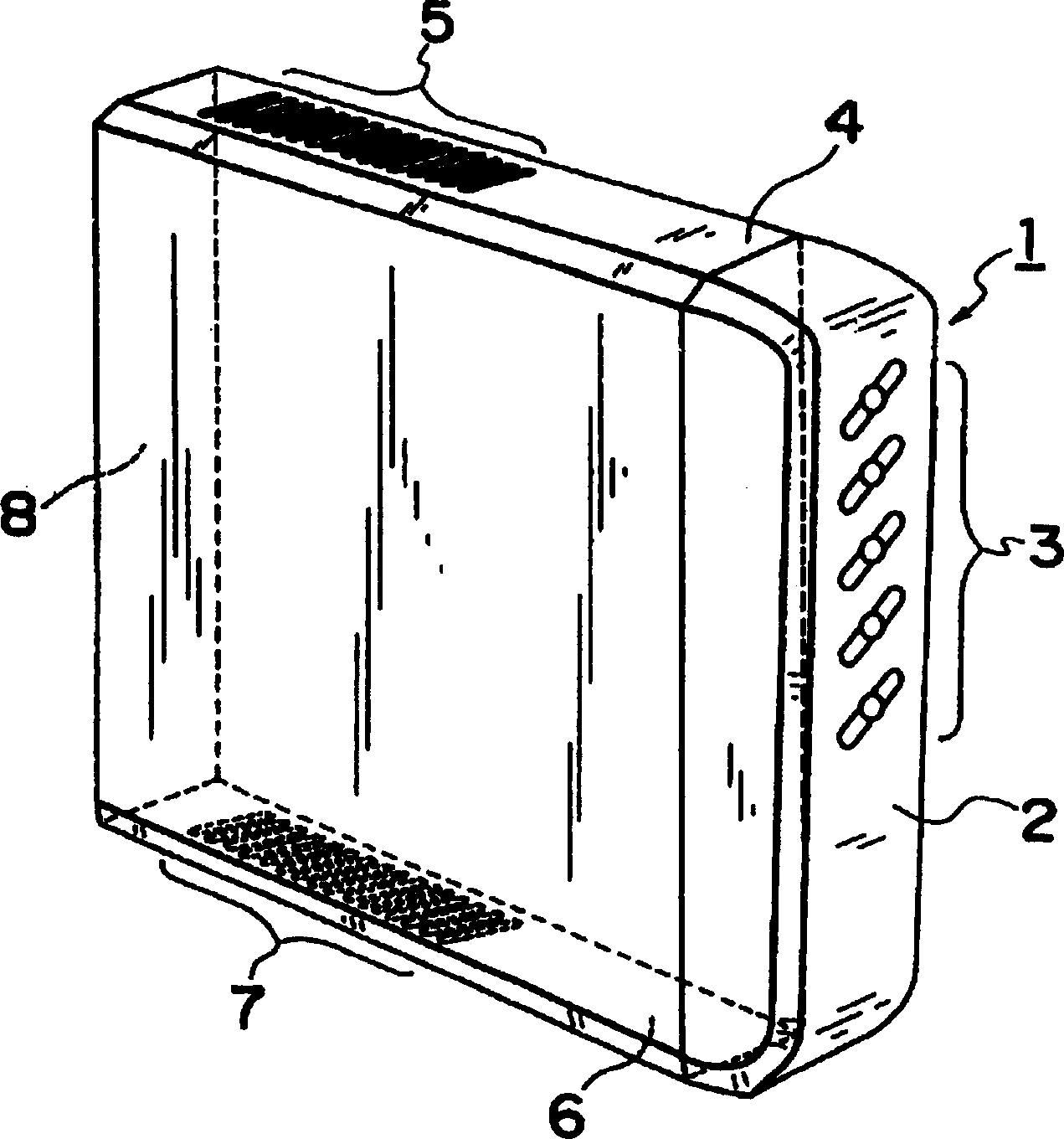

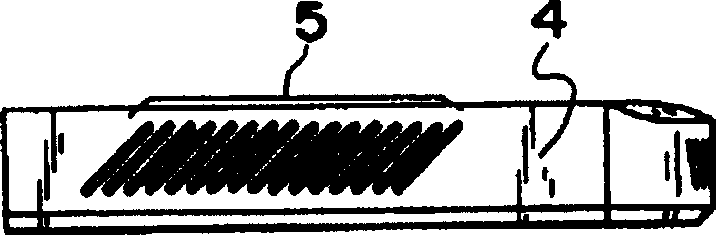

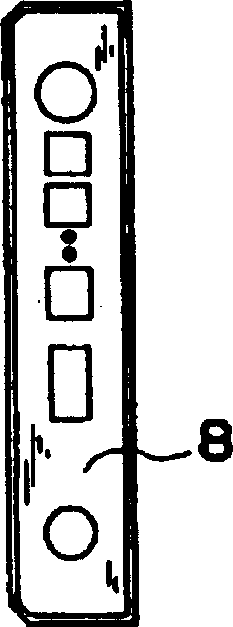

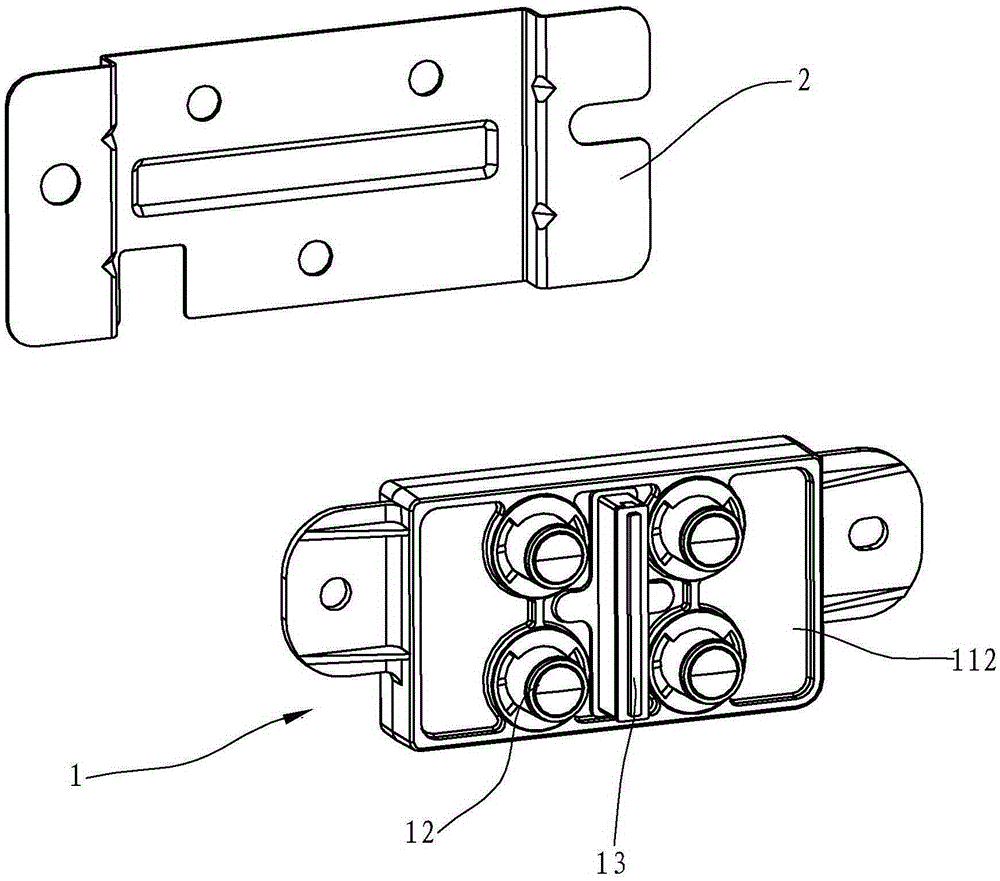

Thin type cable modem and stand for mounting the same

InactiveCN1102332CPrevent reverse installationCasings with display/control unitsTelephonic communicationLED displayModem device

A high reliability cable modem is provided, which is superior in assembling workability, heat radiation, mounting stability. The cable modem includes a circuit board 10 which is a substantially single board on which a front end section 11, a logic circuit section 12 and an LED display section 13 are mounted; and a housing which covers the circuit board 10 and which has a front face 2, a rear face 8, a left side face, a right side face, a top face 4 and a bottom face 6. The cable modem is provided with a plurality of symbol display 3 for indicating an operational state of the LED display section 13 in the front face 2 of the housing 1, a plurality of exhaust holes 5 for radiating heat generated from the front end section 11 and the logic circuit section 12 mounted on the circuit board 10 in the top face 4 of the housing 1, and a plurality of inlet holes 7 for taking outside air into an interior of the housing 1 in the bottom face 6 of the housing 1. The front section 11 is mounted on the circuit board 10 at a position near the exhaust holes 5.

Owner:SHARP KK

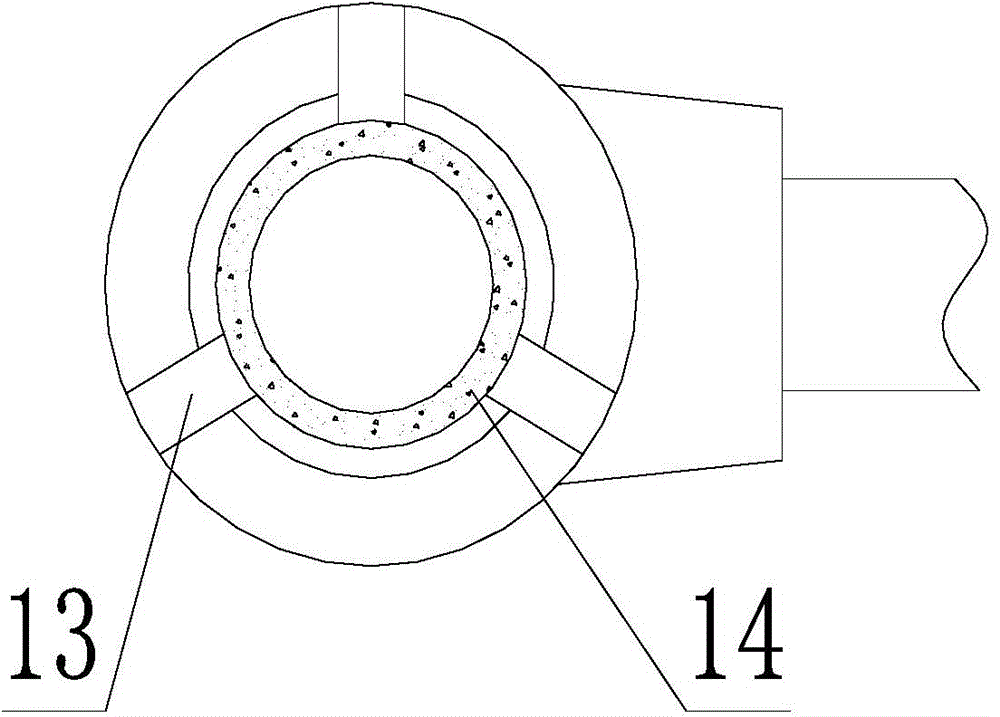

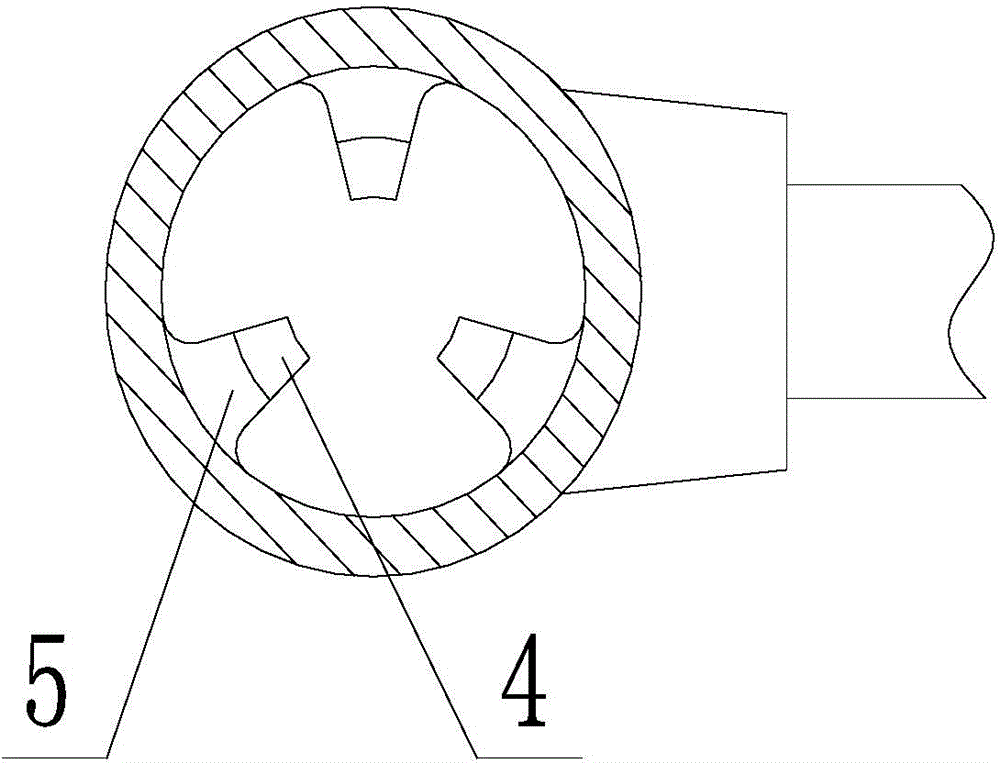

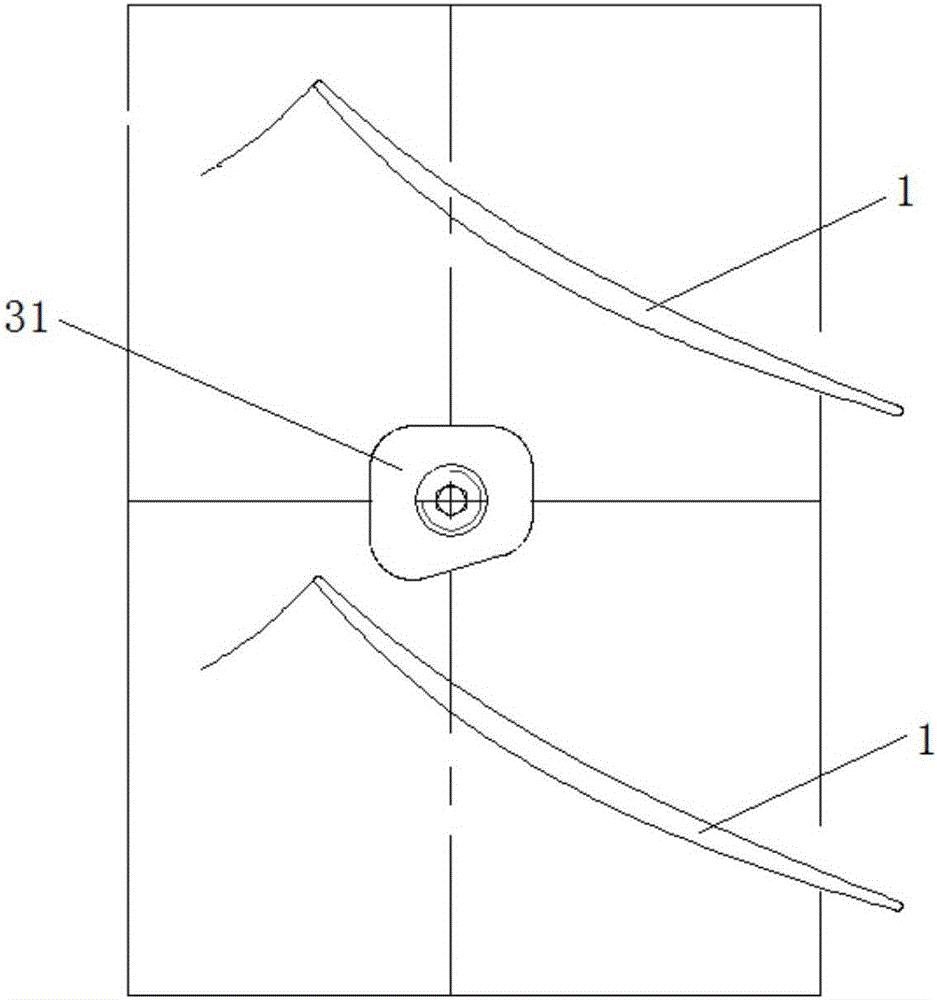

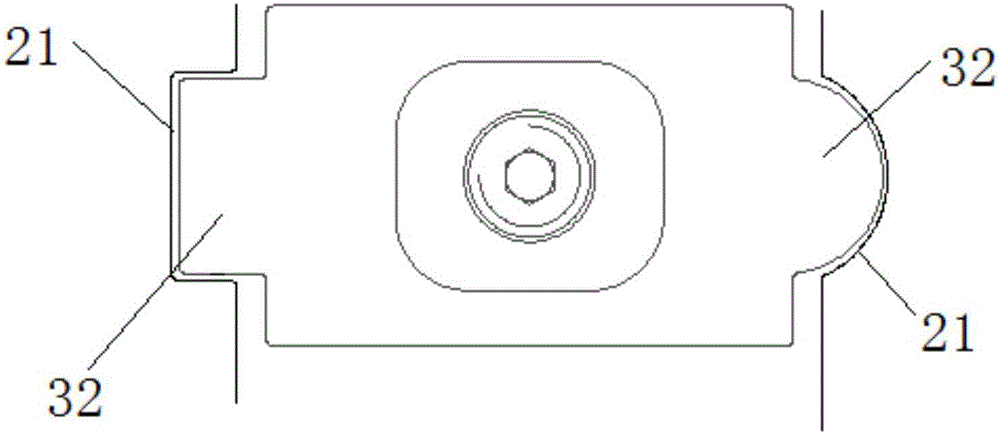

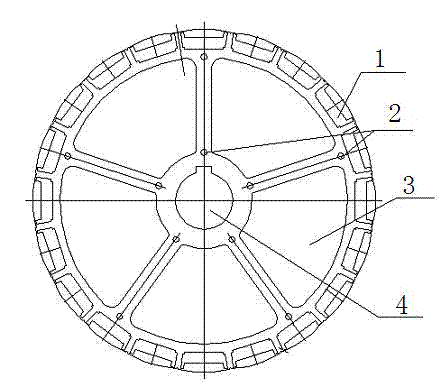

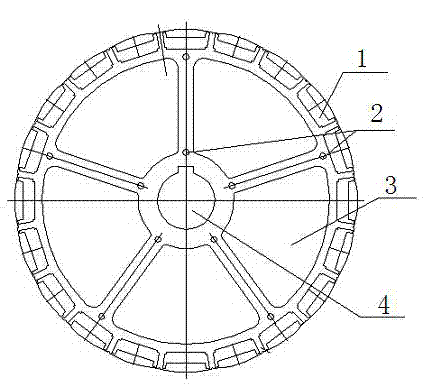

Rotor punching sheet of high-speed permanent magnet motor

InactiveCN102522839AExtended service lifePrevent reverse installationMagnetic circuit rotating partsPunchingPermanent magnet motor

The invention discloses a rotor punching sheet of a high-speed permanent magnet motor. The rotor punching sheet comprises punching sheet inner slots (1), punching sheet combined holes (2), lightening holes (3) and a rotor shaft hole (4), wherein the punching sheet inner slots (1) are distributed on an outer circumferential surface of the punching sheet, the lightening holes (3) are arranged around the rotor shaft hole (4) in a surrounding manner, the punching sheet combined holes (2) are arranged among the lightening holes (3), and the rotor shaft hole (4) is arranged at the center of the punching sheet. According to the rotor punching sheet of the high-speed permanent magnet motor disclosed by the invention, a permanent magnet block is embedded in the punching sheet inner slot so that the permanent magnet block can be prevented from falling off during a high-speed operation; due to an integrated punching sheet structure, a magnetic flux forms closed circulation so as to prevent the permanent magnet block from loss of excitation, and the service life of the permanent magnet motor is prolonged; and reverse installation of the punching sheet is avoided by utilizing asymmetrical webs in the punching sheet.

Owner:DALIAN YULIN ELECTRIC MOTOR

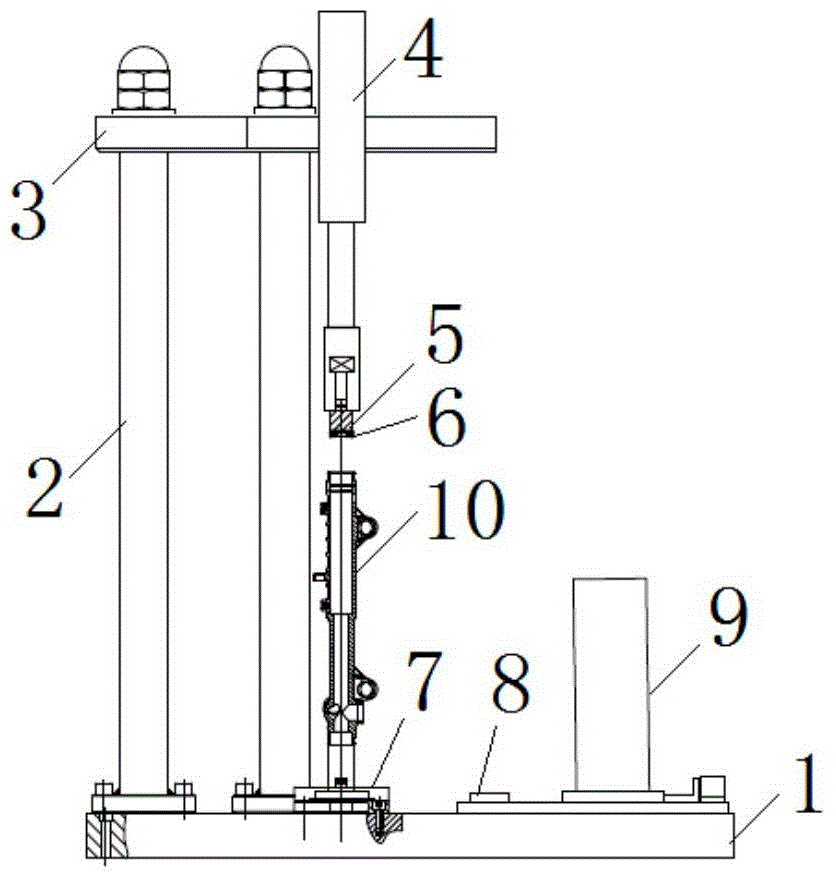

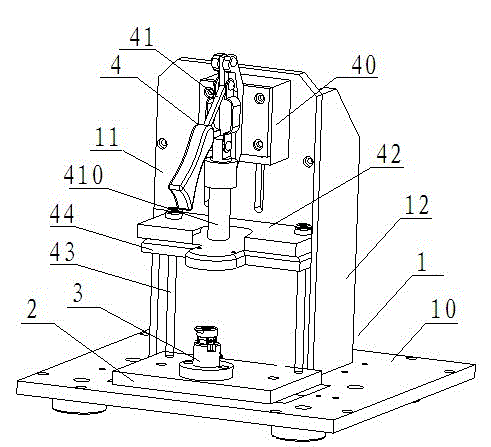

Installation equipment and installation method for oil seal in steering shell

InactiveCN104476164APrevent reverse installationPreventing the danger of oil spillsMetal working apparatusSteering wheelPetroleum engineering

The invention discloses installation equipment and an installation method for an oil seal in a steering shell. The installation equipment comprises a base plate, a press-fitting cylinder, a pressure head, and a material taking mechanism for taking out one oil seal; the press-fitting cylinder is fixed on the base plate through a bracket; the pressure head is installed on a piston rod of the press-fitting cylinder through a pressure lever; the end of the pressure head is provided with an oil seal positioning structure which is fitted with one side of the oil seal with an annular groove; a shell positioning seat for positioning the bottom of the steering shell is arranged on the base plate; and the material taking mechanism is installed on the base plate. The oil seal is correctly positioned by the oil seal positioning structure at the end of the pressure head, the oil seal can be quickly installed in an oil cylinder, and the oil seal can be prevented from reverse installation; and one oil seal can be taken out at one time, a phenomenon that an operator forgets to take the oil seal or take more than one oil seals can be avoided, and neglected loading or over loading can also be avoided.

Owner:WUHU STERLING STEERING SYST

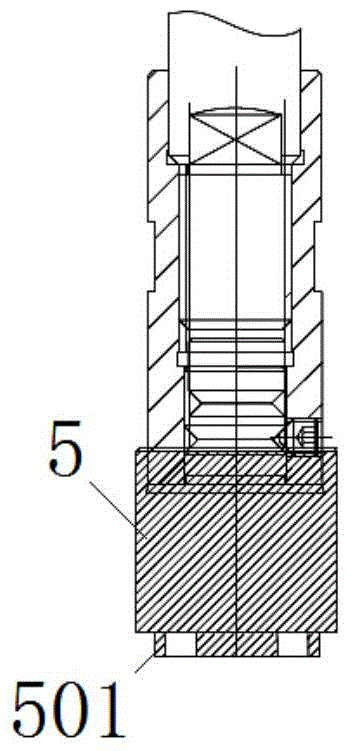

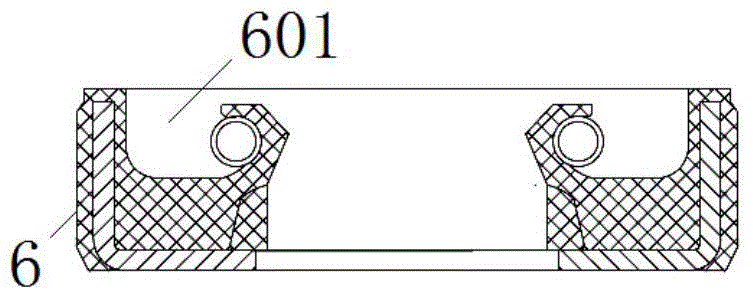

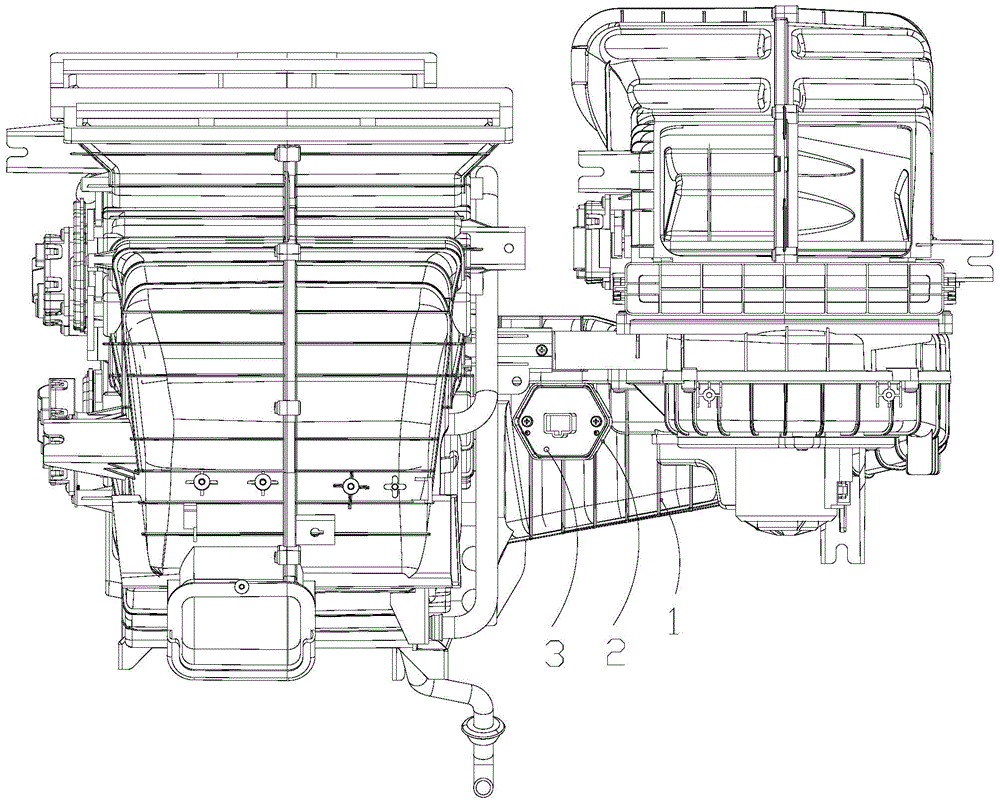

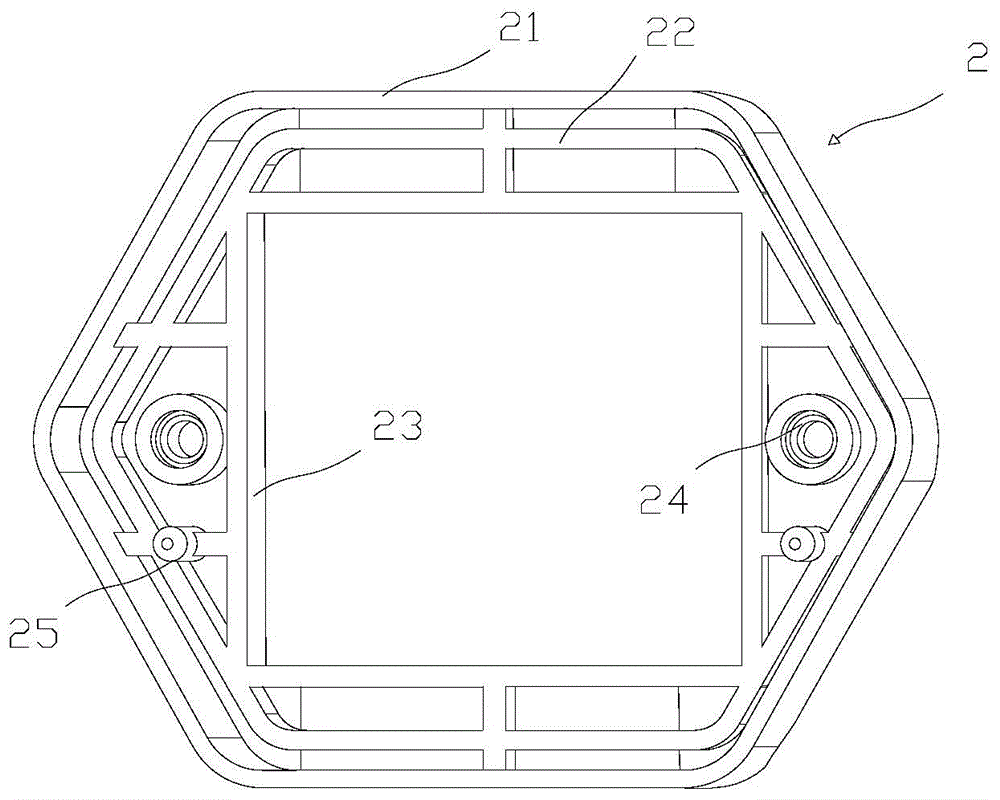

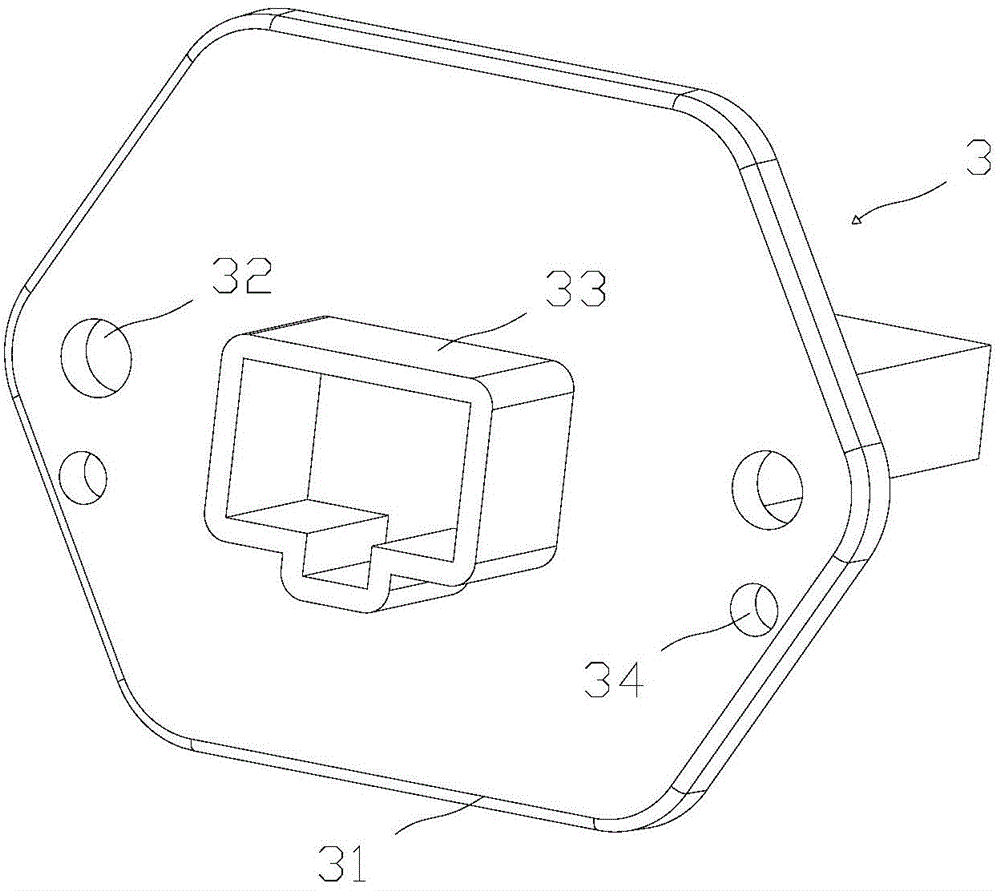

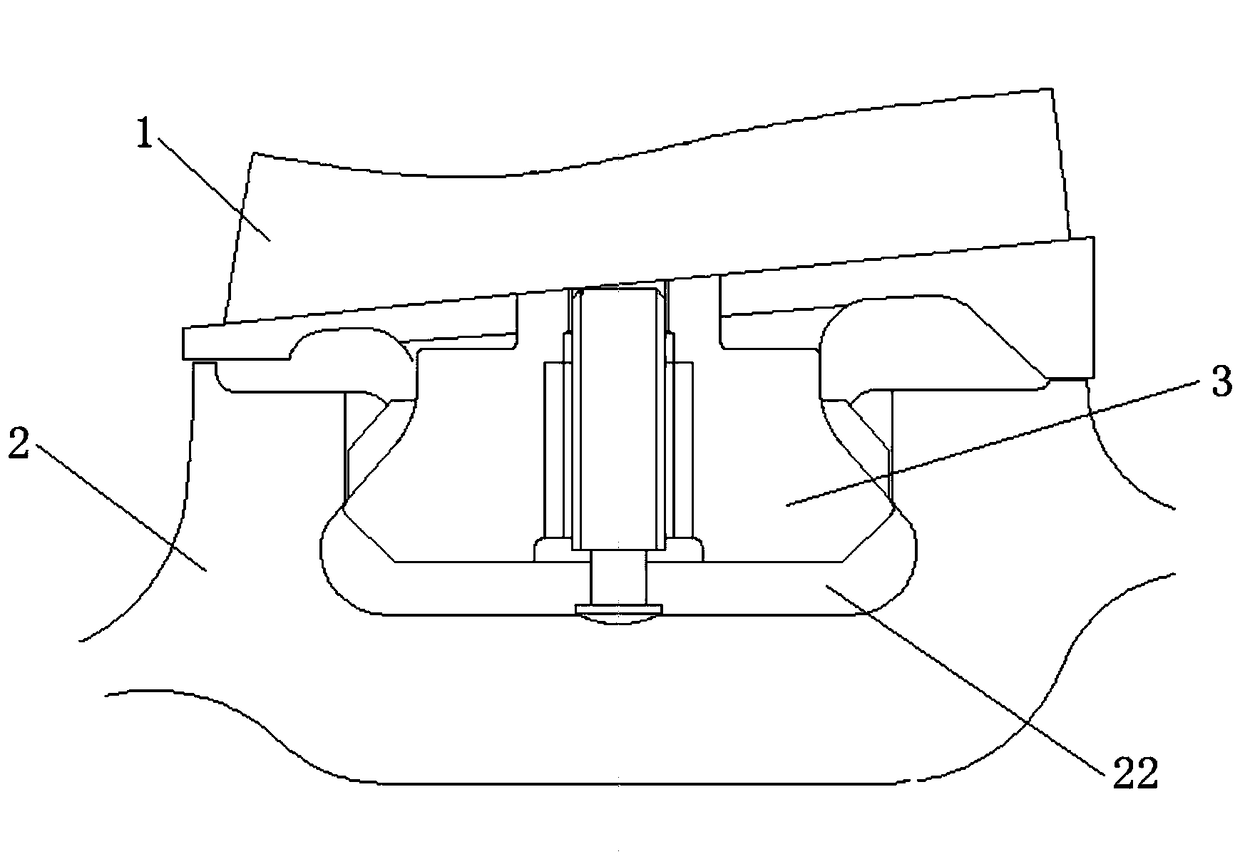

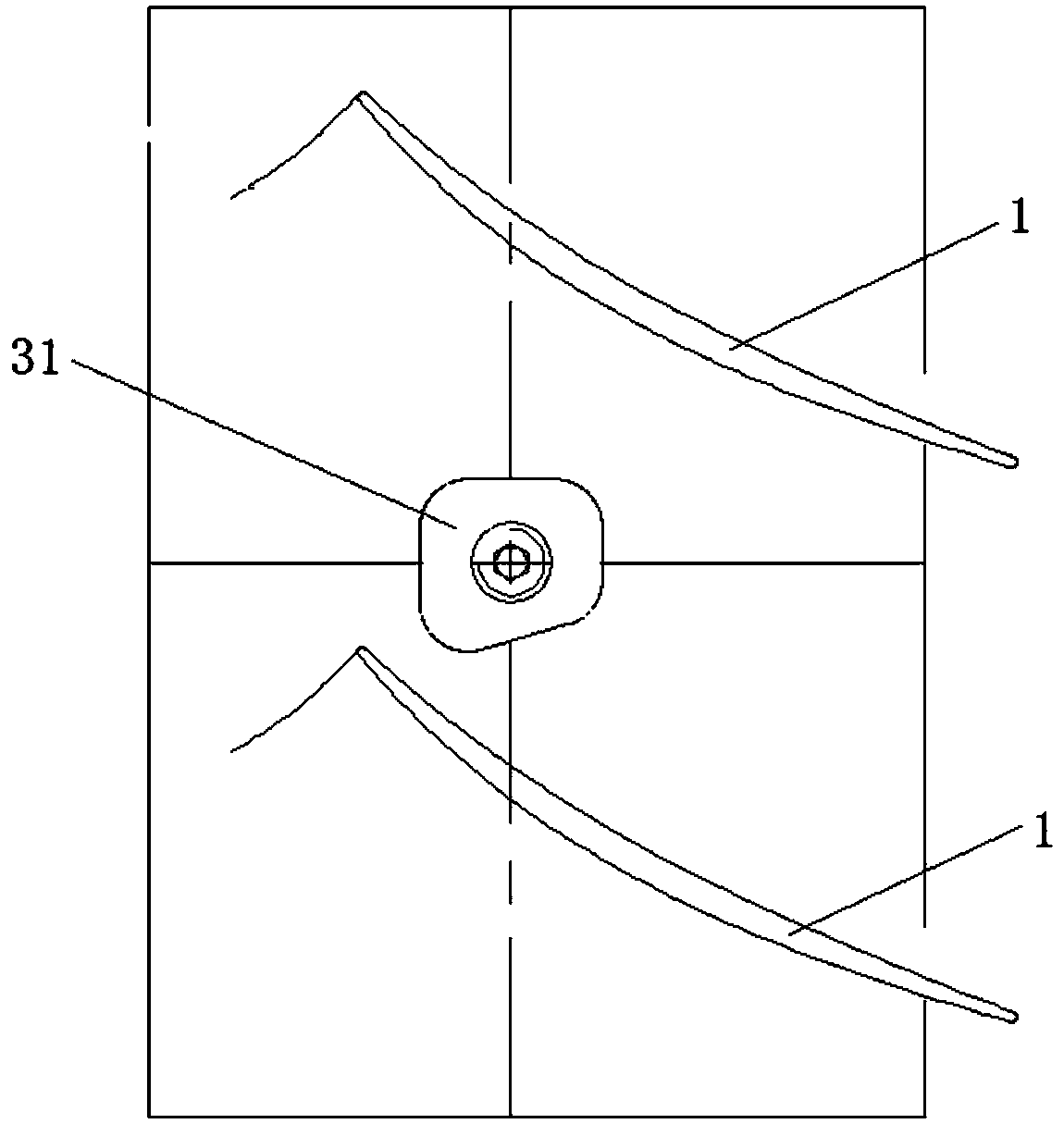

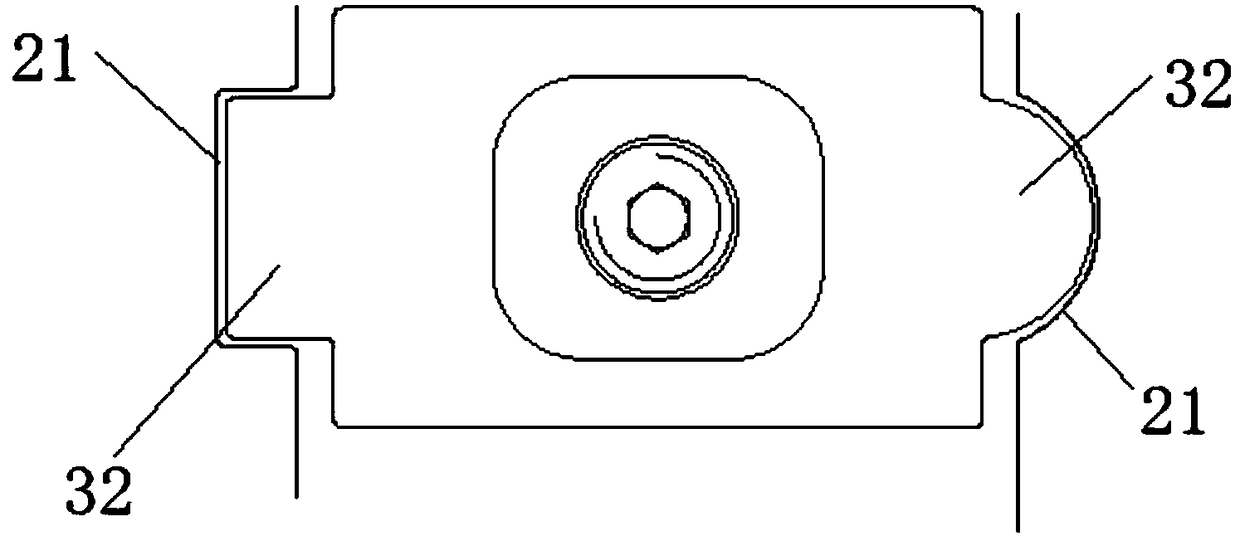

Blower resistor installation mistake-proof structure

InactiveCN104948506APrevent misassemblyReduce assembly judgment timePump componentsPumpsSoftware engineeringResistor

The invention relates to the technical field of parts for vehicles, in particular to a blower resistor installation mistake-proof structure. The blower resistor installation mistake-proof structure comprises a blower shell with a resistor installation end face, a resistor installation plate is arranged in an installation groove, a regular hexagonal installation frame smaller than a frame body in height is arranged inside the frame body, a square supporting frame equal to the installation frame in height is arranged inside the installation frame, the left side and the right side of the supporting frame are each provided with a round installation sleeve, and a positioning boss is arranged at the position, beside each round installation sleeve, of the installation frame; the left side and the right side of a flat plate part are each provided with a round installation hole for the round installation sleeve to penetrate through, and a positioning hole for the corresponding positioning boss to penetrate through is formed beside each round installation hole. The shell is in asymmetrical positioning design, so that revered installation is prevented. The structure is simple, and the resistor fixing effect through cooperation can be achieved only through right assembling. The assembling judgment time of an assembling worker is shortened, and mistake assembling by a user is prevented, and the assembling efficiency is improved.

Owner:ANHUI JIANGHUAI SONGZ AIR CONDITIONING

A locking structure for rotor blades

ActiveCN106014490BPrecise positioningPrevent reverse installationBlade accessoriesMachines/enginesEngineeringMechanical engineering

Owner:AECC SHENYANG ENGINE RES INST

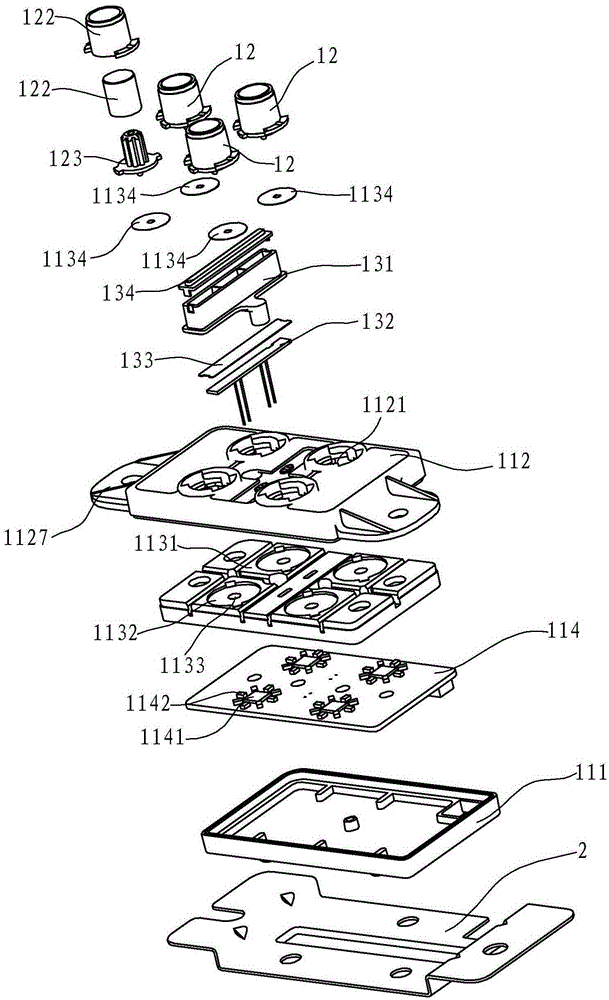

Using method of earphone press-fitting jig

InactiveCN104683930APrevent reverse installationAvoid misalignmentElectrical transducersEngineeringHeadphones

The invention discloses a using method of an earphone press-fitting jig. The using method of the earphone press-fitting jig comprises step 1: pulling open a manual direct pushing clamp of an earphone outer cover pressing-in mechanism; step 2: installing an earphone body into an earphone body die holder and then assembling an earphone outer cover through the mistake-proof groove of the earphone body die holder; step 3: downwards pulling the handle of the manual direct pushing clamp of the earphone outer cover pressing-in mechanism, and downwards pressing the earphone outer cover through an upper pressing plate to press-fit the earphone outer cover with the earphone body; step 4: releasing the manual direct pushing clamp of the earphone outer cover pressing-in mechanism and taking out the press-fit earphone body. By adopting the method, the earphone outer cover and the earphone body can be accurately positioned and quickly bonded, a worker is effectively prevented from installing the earphone outer cover in an opposite direction or at an incorrect position, the production efficiency of the worker is improved and the labor intensity of the worker is reduced.

Owner:SUZHOU WUZHONG DISTRICT LINHU JUNFENG MACHINERY FACTORY

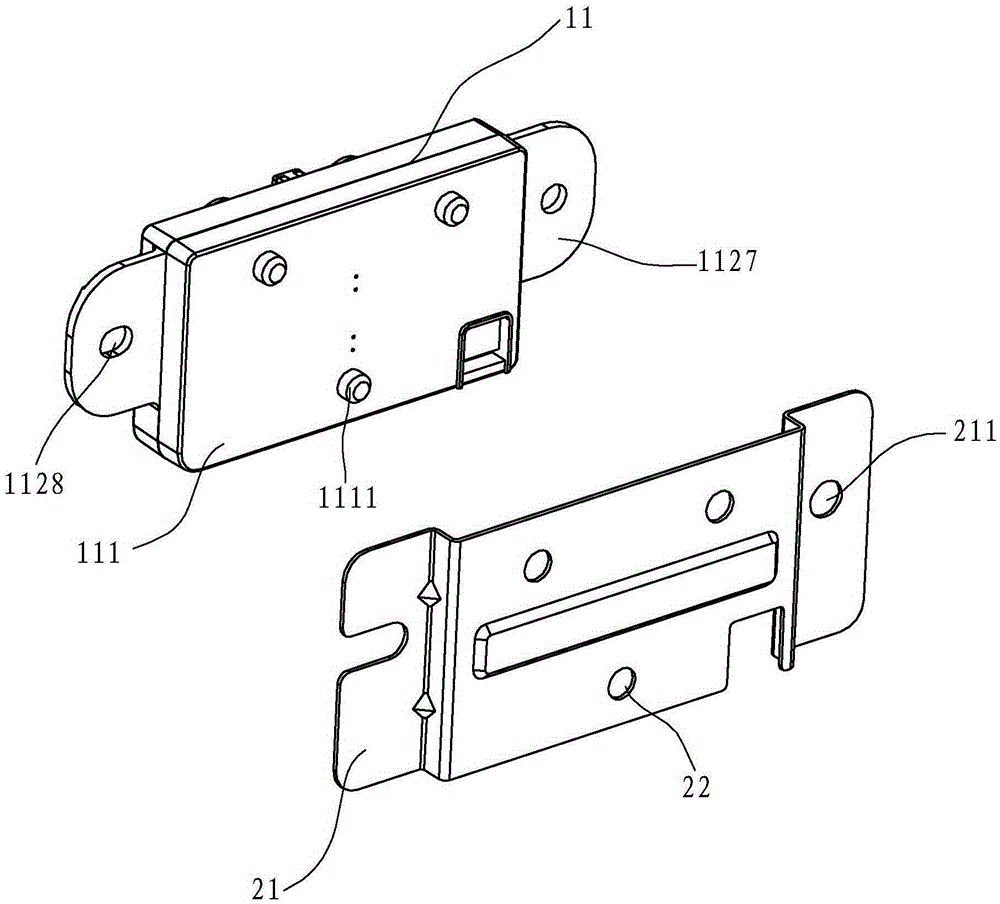

Button switch components for home appliances

ActiveCN103700533BEliminate cross-light phenomenonAvoid misjudgmentElectric switchesHome applianceEngineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

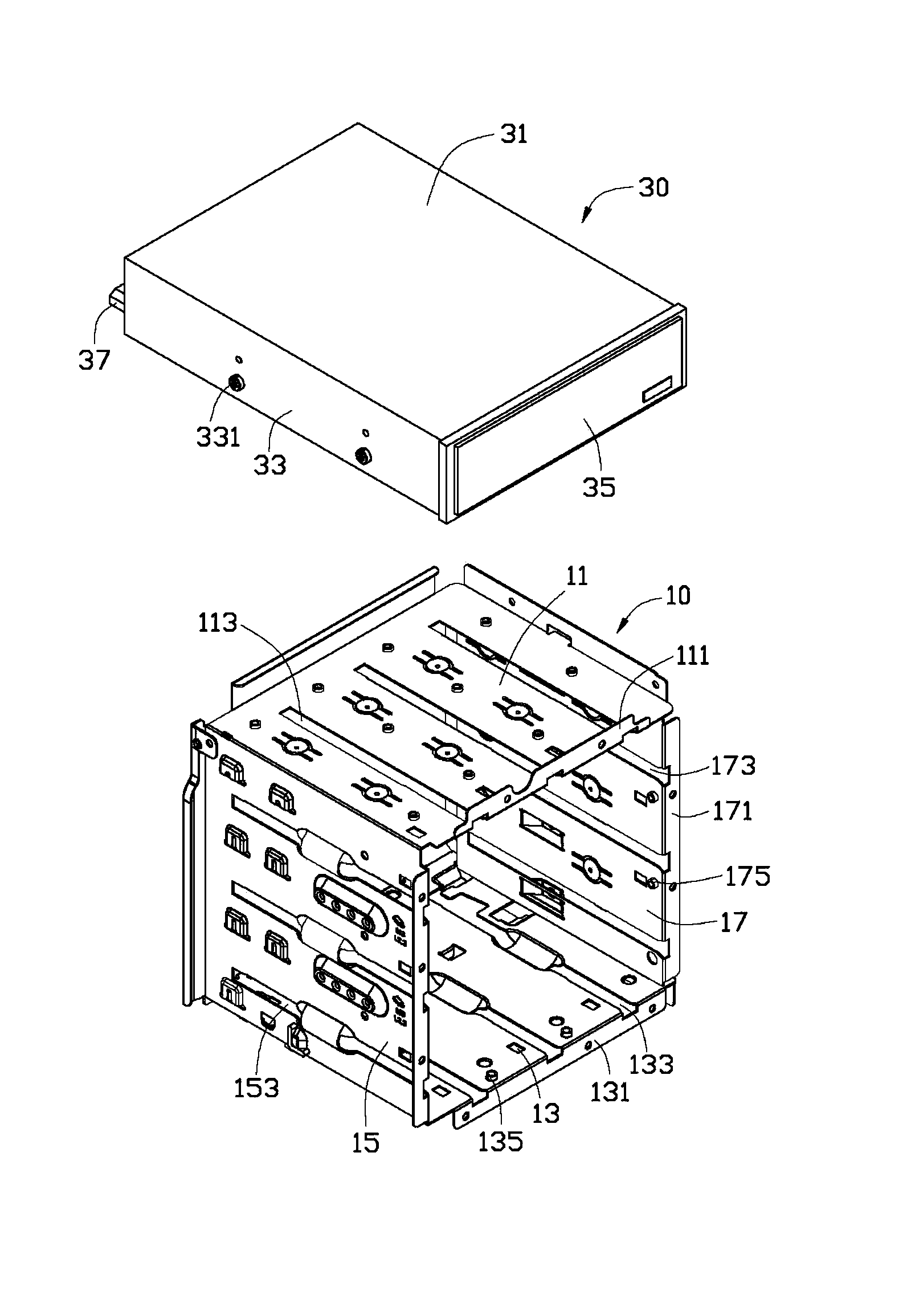

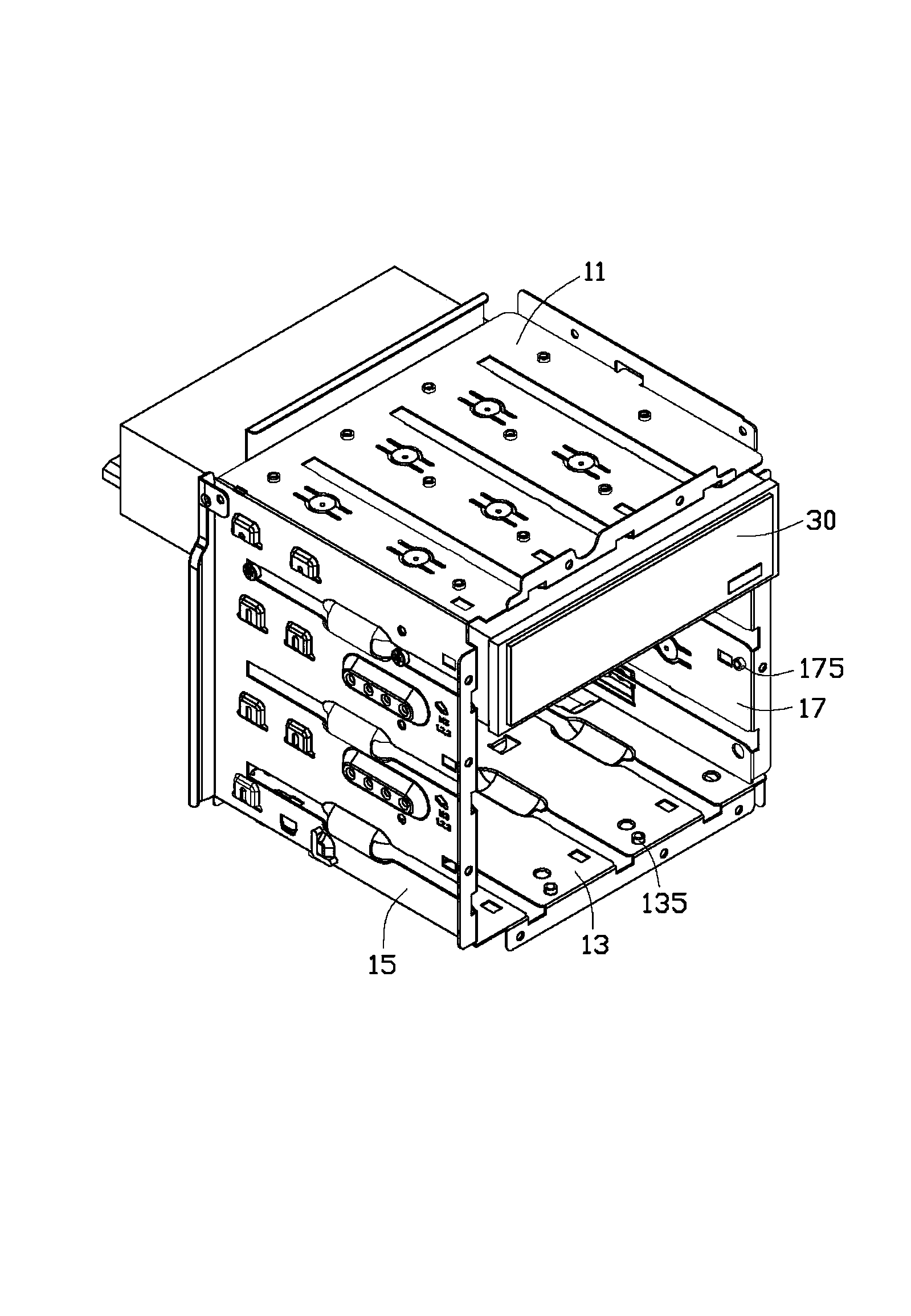

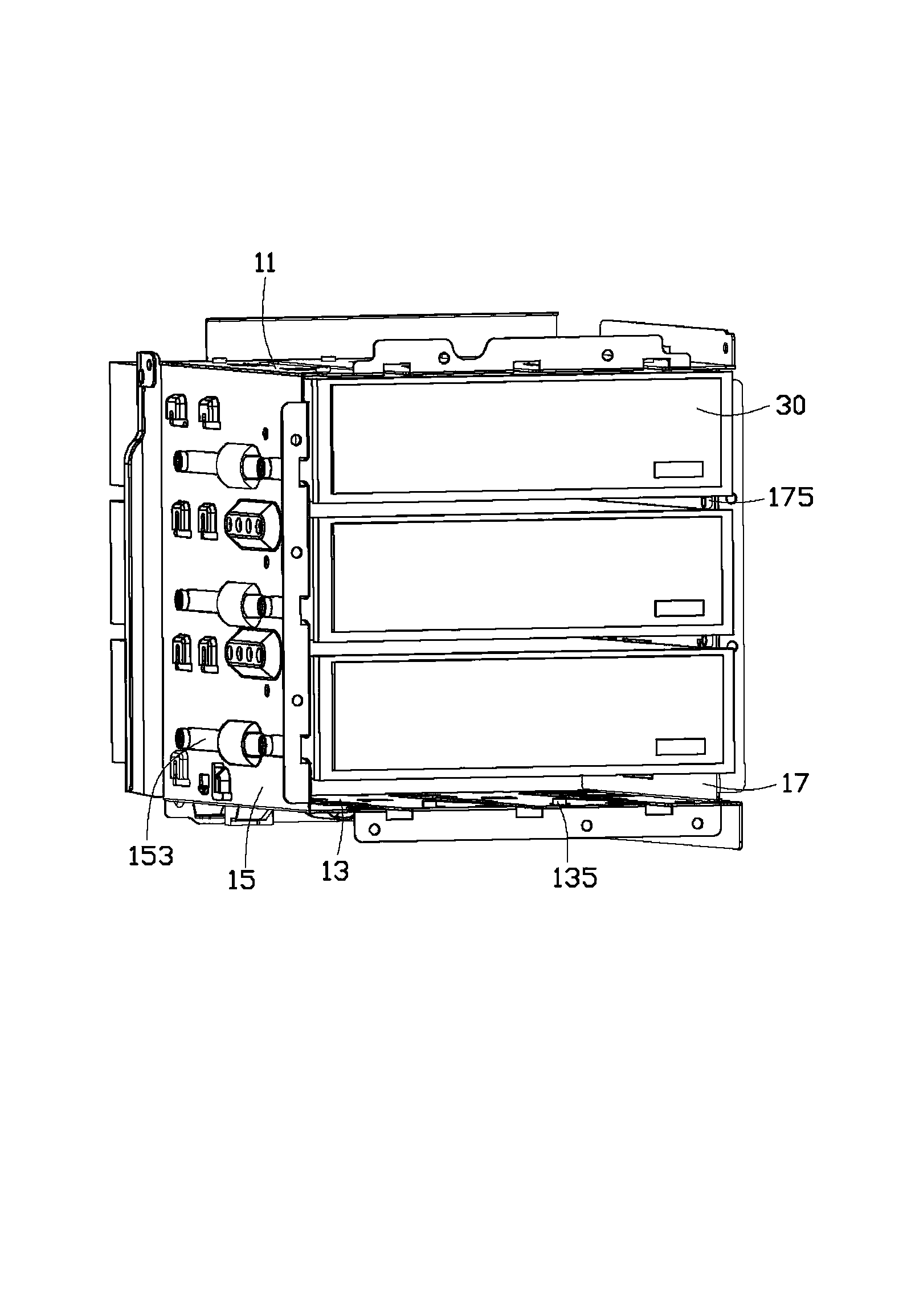

Electronic device

InactiveCN103383588APrevent reverse installationPlay a foolproof roleDigital data processing detailsFurniture partsFastenerEngineering

A data storage device assembly includes a bracket and a data storage device. The bracket includes a top plate and a bottom plate. The top plate and the bottom plate each defines a first engaging slot. A first positioning post is located on the bottom plate. The data storage device includes a top wall, a bottom wall, a first sidewall and a second sidewall. A latch portion is located on each of the first sidewall and the second sidewall. A first distance is defined between the latch portion and the top wall. A second distance is defined between the latch portion and the bottom wall. The first distance is greater than the second distance. When the storage is positioned in portrait orientation, each latch portion is slidably engaged in each first engaging slot, and the first positioning post abuts against the bottom wall.

Owner:HONG FU JIN PRECISION IND WUHAN CO LTD +1

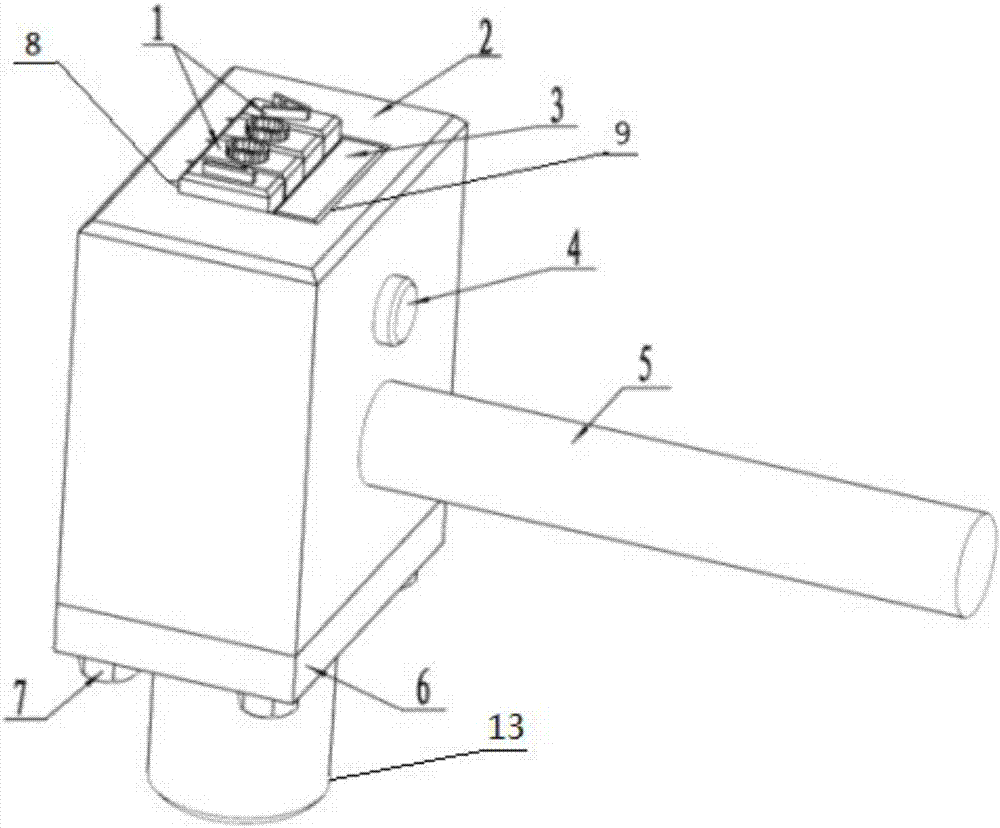

Crankshaft forging identifying device

ActiveCN107240352AFor quick replacementMinimize the actionStampsIdentification meansSoftware engineeringEngineering

The invention provides a crankshaft forging identifying device. The crankshaft forging identifying device comprises an identifying box, an identifying block and a base. The identifying box is arranged on the base, the base and the identifying box are connected through fixing bolts, an identifying box groove is formed in the identifying box, the identifying block and a magnet are arranged in the identifying box groove, and the height of the identifying block is larger than that of the identifying box and the magnet. The magnet is positioned through a pin and fixed to the inner wall of the identifying box through magnetic force, one end of the identifying block is fixed beside the magnet through magnetic force, a triangular boss is arranged at the other end of the identifying block, a triangular groove corresponding to the triangular boss in shape is formed in the corresponding position, and a holding handle is installed on the identifying box. According to the crankshaft forging identifying device, replacement of the identifying block is convenient and rapid, operation actions can be reduced, and the production efficiency is improved. The triangular box is arranged at one end of the identifying block of the crankshaft forging identifying device, and reverse installation of the identifying block can be well avoided.

Owner:LIAONING 518 INTERNAL COMBUSTION ENGINE FITTINGS

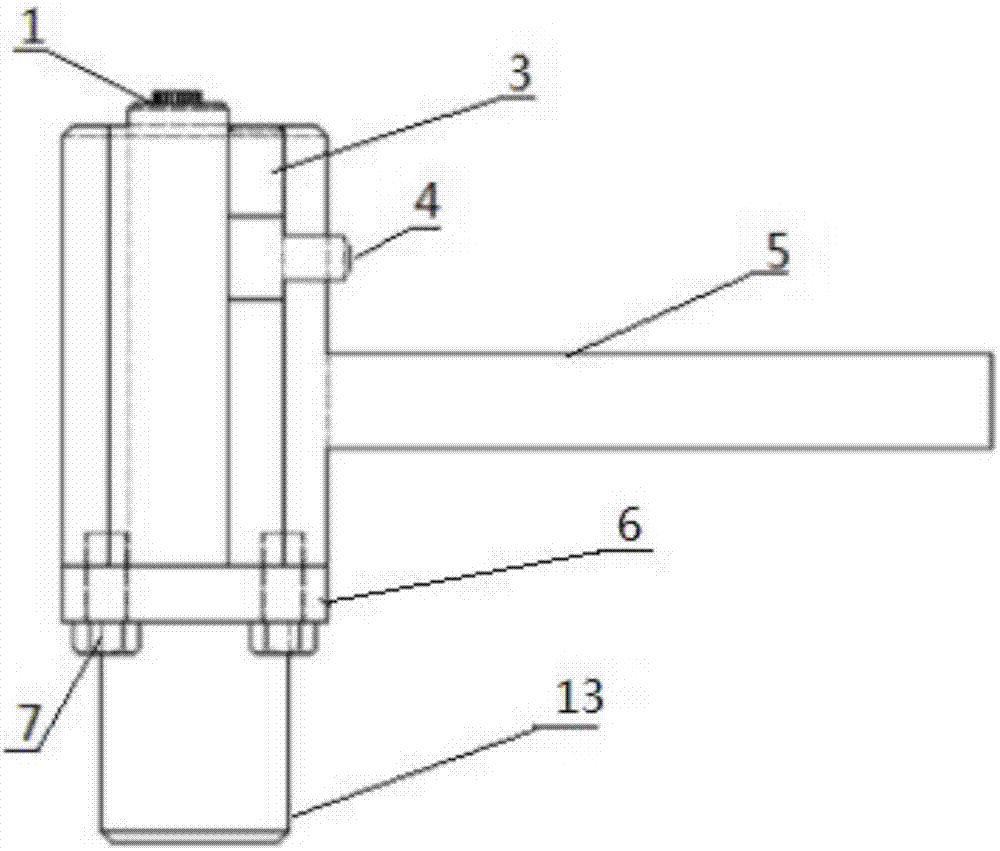

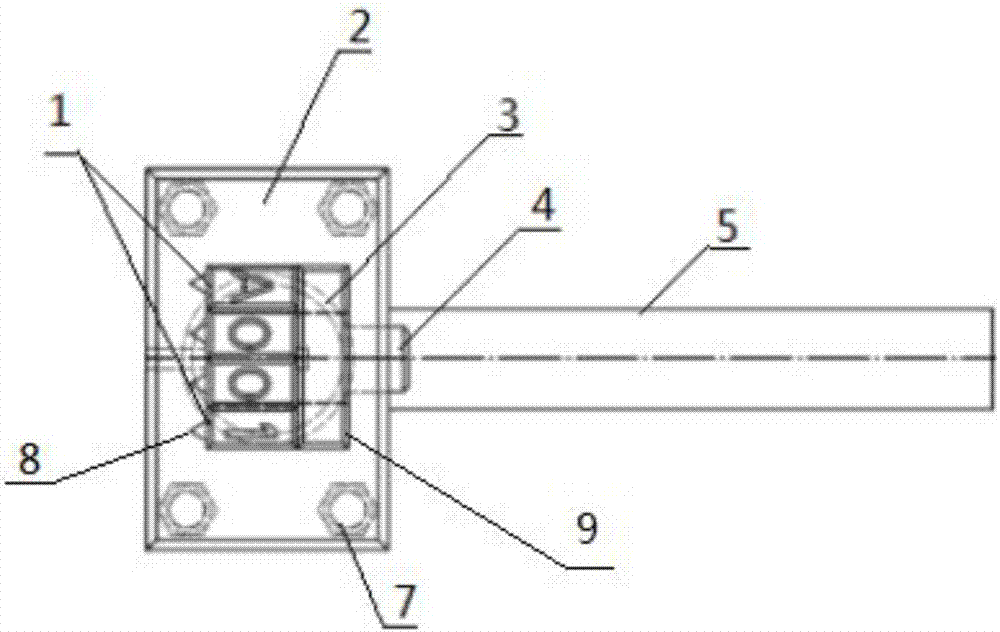

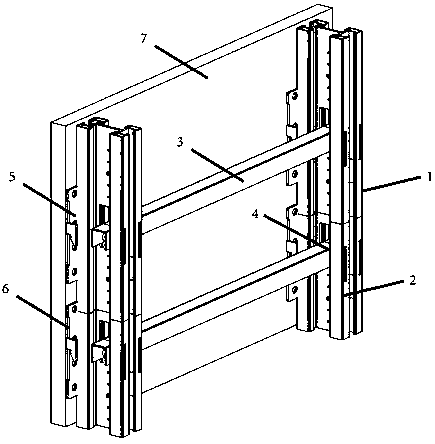

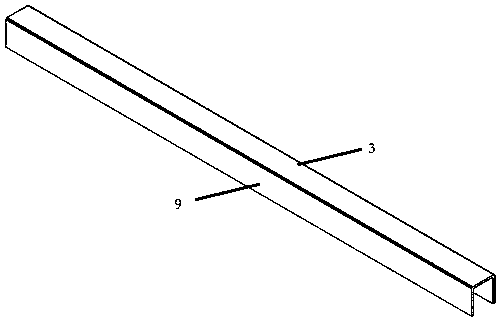

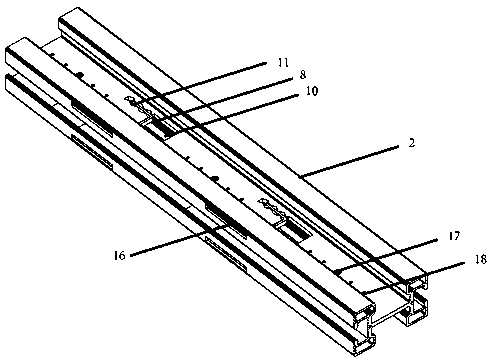

Fabricated partition wall steel keel system and fabricating method

The invention belongs to the technical field of decorative building materials, particularly relates to a fabricated partition wall steel keel system, and meanwhile further provides a fabricating method of a fabricated partition wall steel keel. The designed partition wall steel keel system is overall of a steel structure, a steel keel profile is a cold-bent closed profile, a hanging plate verticalhole, a ceiling and floor connecting piece hole, a transverse keel groove and the like are prefabricated, the size precision error is less than or equal to 0.5 mm, and the precision of an aluminum profile and the strength of the keel profile are integrated. According to the fabricated partition wall steel keel system and the fabricating method of the fabricated partition wall steel keel, the problems that the precision of a traditional steel bent profile is inaccurate, batches are inconsistent, and the strength of the aluminum extruded profile is low are solved, and the beneficial technical effects of factory prefabrication, on-site fabricating, fast and convenient mounting, high precision, high strength and reutilizing are achieved.

Owner:HENKEL TIANJIN BUILDING MATERIAL CO LTD

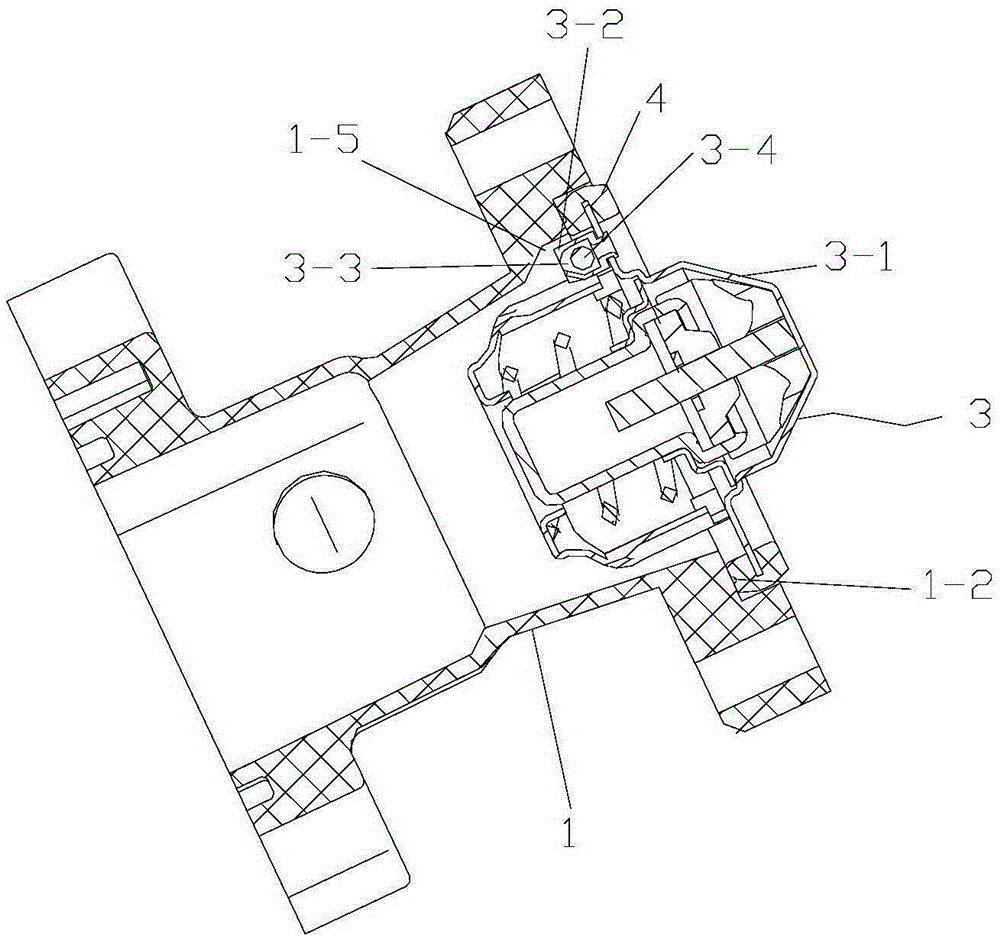

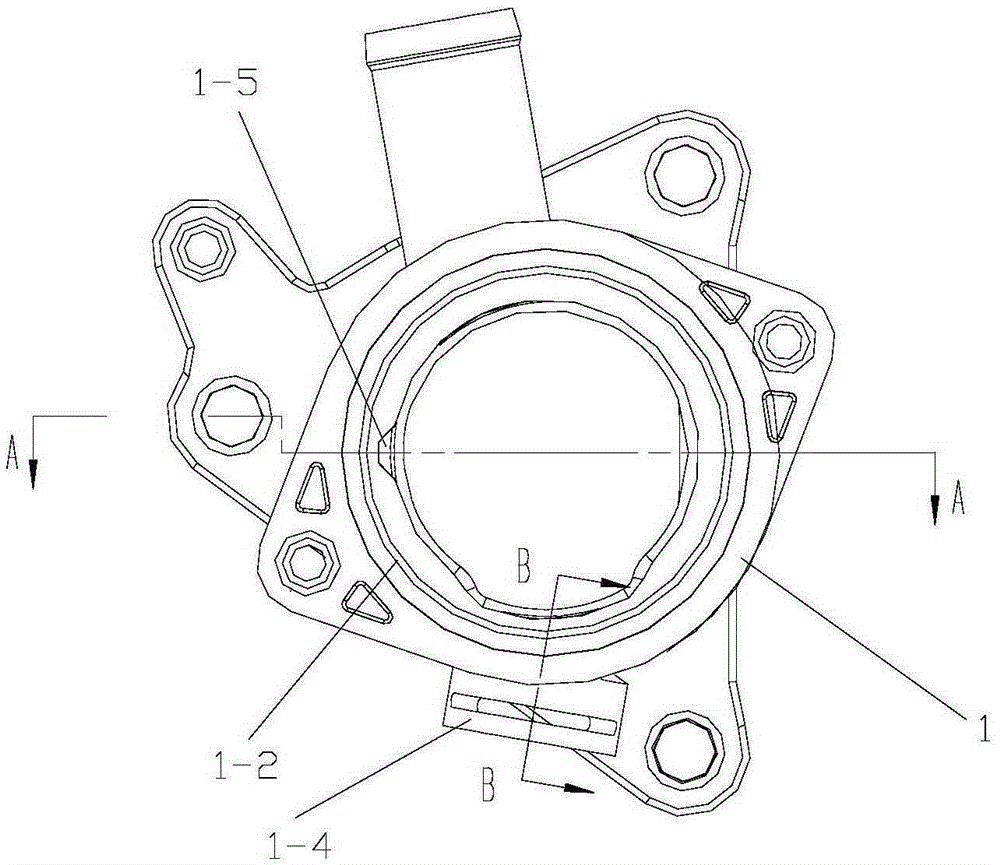

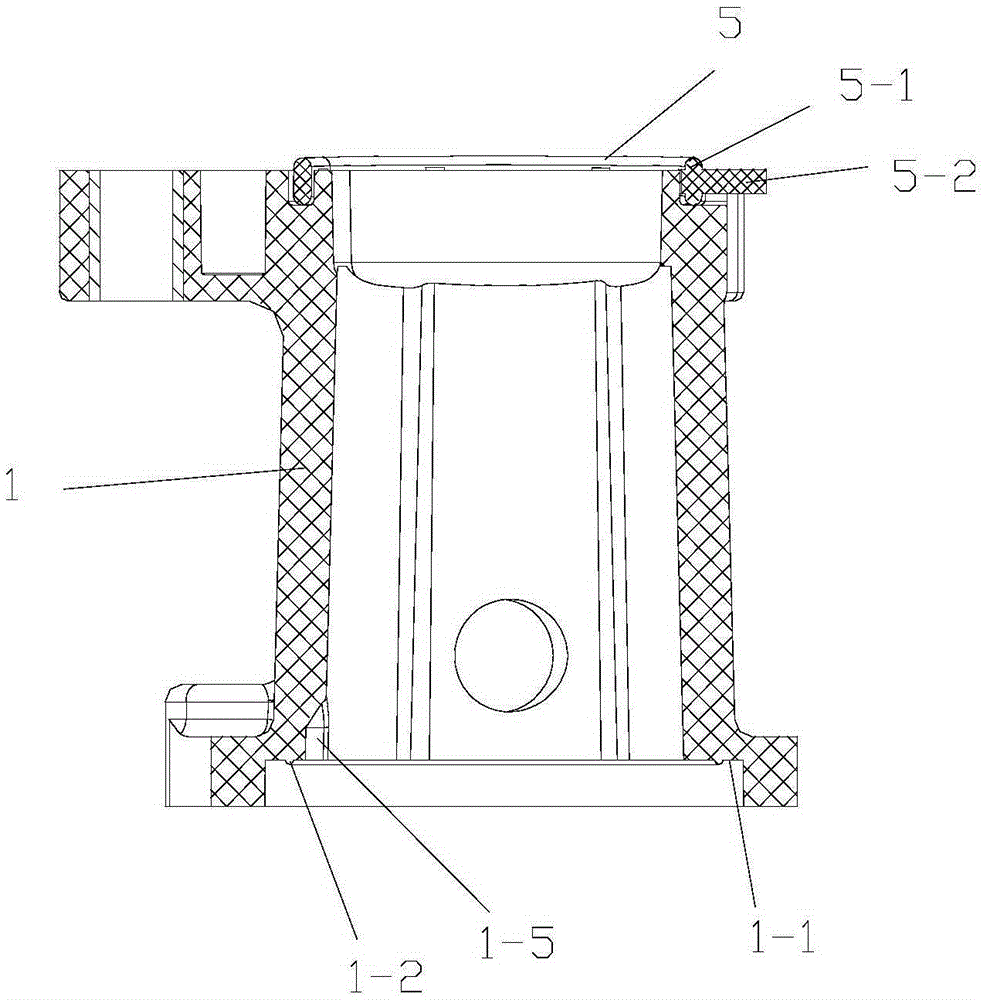

Mounting assembly of thermostat for gasoline engine

ActiveCN105351075ADetermine the installation directionGuaranteed tightnessEngine sealsCoolant flow controlExhaust valveGasoline

The invention discloses a mounting assembly of a thermostat for a gasoline engine. The mounting assembly comprises the thermostat and a thermostat seat, wherein a valve seat for mounting the thermostat is formed at the upper end of the thermostat seat; a limiting groove is formed in the inner wall of the thermostat seat; the thermostat comprises an upper bracket, and a limiting block which is arranged on the upper bracket; an air exhausting channel in the limiting block and a ball body form an one-way air exhaust valve structure; the thermostat further comprises an outer sealing part; the end surface of the valve seat is upwards bulged to form a sealing rib which is in sealing fit with the outer sealing part. According to the mounting assembly of the thermostat for the gasoline engine, the limiting block and the limiting groove are matched to position to achieve limited mounting, so that the quick positioning mounting can be achieved; in addition, the mounting direction of the thermostat can be accurately determined, and thus the thermostat can be prevented from being reversely mounted; meanwhile, the one-way air exhaust valve structure is formed in the limiting block and can be used for exhausting air in a cooling water channel, so as to prevent the sealing from failure due to air accumulation; the bulged sealing rib arranged on the valve seat and the outer sealing part of the thermostat act together to form a maze sealing structure through which the sealing performance can be greatly improved.

Owner:CHONGQING SOKON IND GRP CO LTD

Dust collector filter element neglected loading detection mechanism and dust collector

PendingCN112274060AEasy to replaceRealize detectionSuction filtersElectric equipment installationClassical mechanicsControl theory

The invention provides a dust collector filter element neglected loading detection mechanism. The mechanism comprises a front filter element and a rear filter element, wherein the rear filter elementand the front filter element abut against each other after being correctly installed, and the rear filter element and the front filter element can be detached separately in the detaching process; a neglected loading prevention assembly is located at the top of the rear filter element, and after the rear filter element and the front filter element are both correctly installed, the rear filter element and the front filter element jointly abut against the neglected loading prevention assembly and trigger the neglected loading prevention assembly; the front filter element and the rear filter element are separately assembled, and the front filter element or the rear filter element is convenient to replace due to the non-integrated structure; the neglected loading prevention assembly is arrangedat the top of the rear filter element, so that neglected loading of the front filter element and / or the rear filter element can be detected, and when one of the front filter element and the rear filter element is neglected to be loaded, neglected loading of any one of the front filter element and the rear filter element can be detected by using only one neglected loading prevention assembly; andstructures of the front filter element and the rear filter element are improved, so reverse installation of the front filter element and the rear filter element can be effectively avoided. The invention further provides a dust collector.

Owner:DREAM INNOVATION TECH (SUZHOU) CO LTD

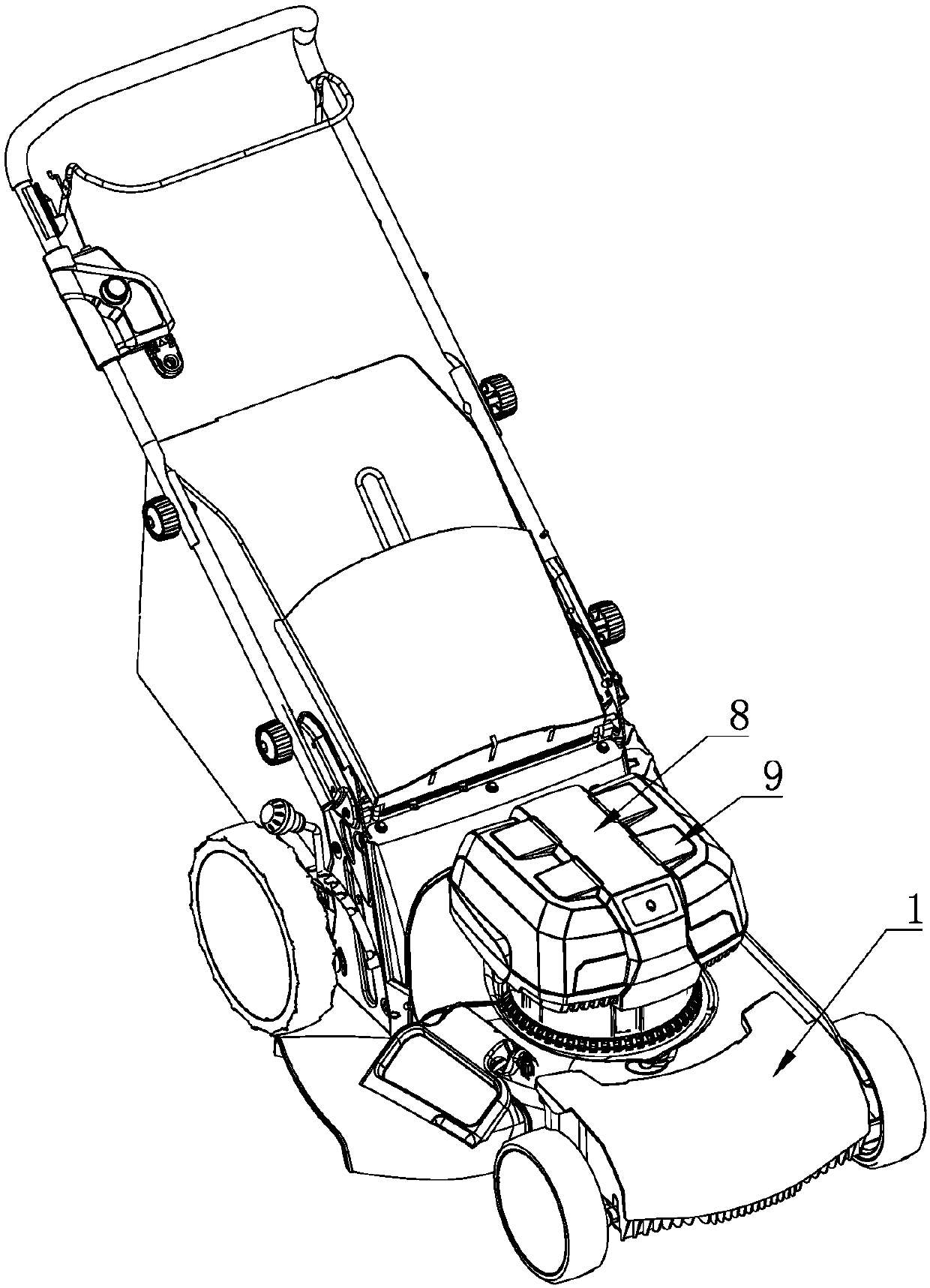

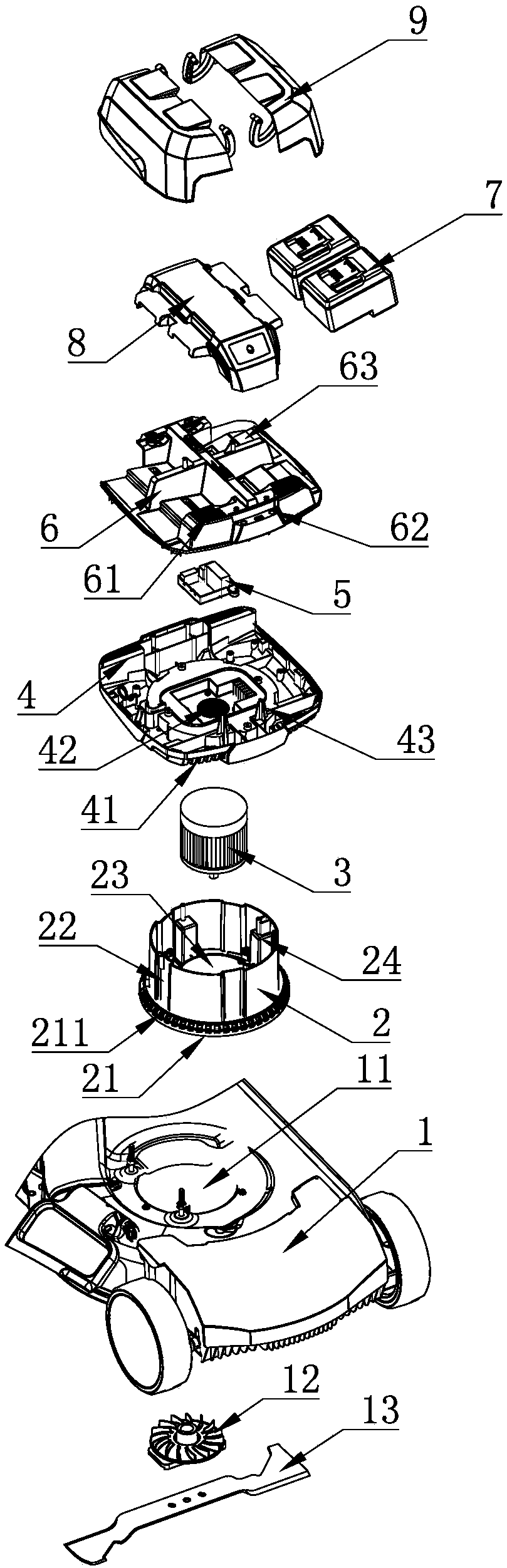

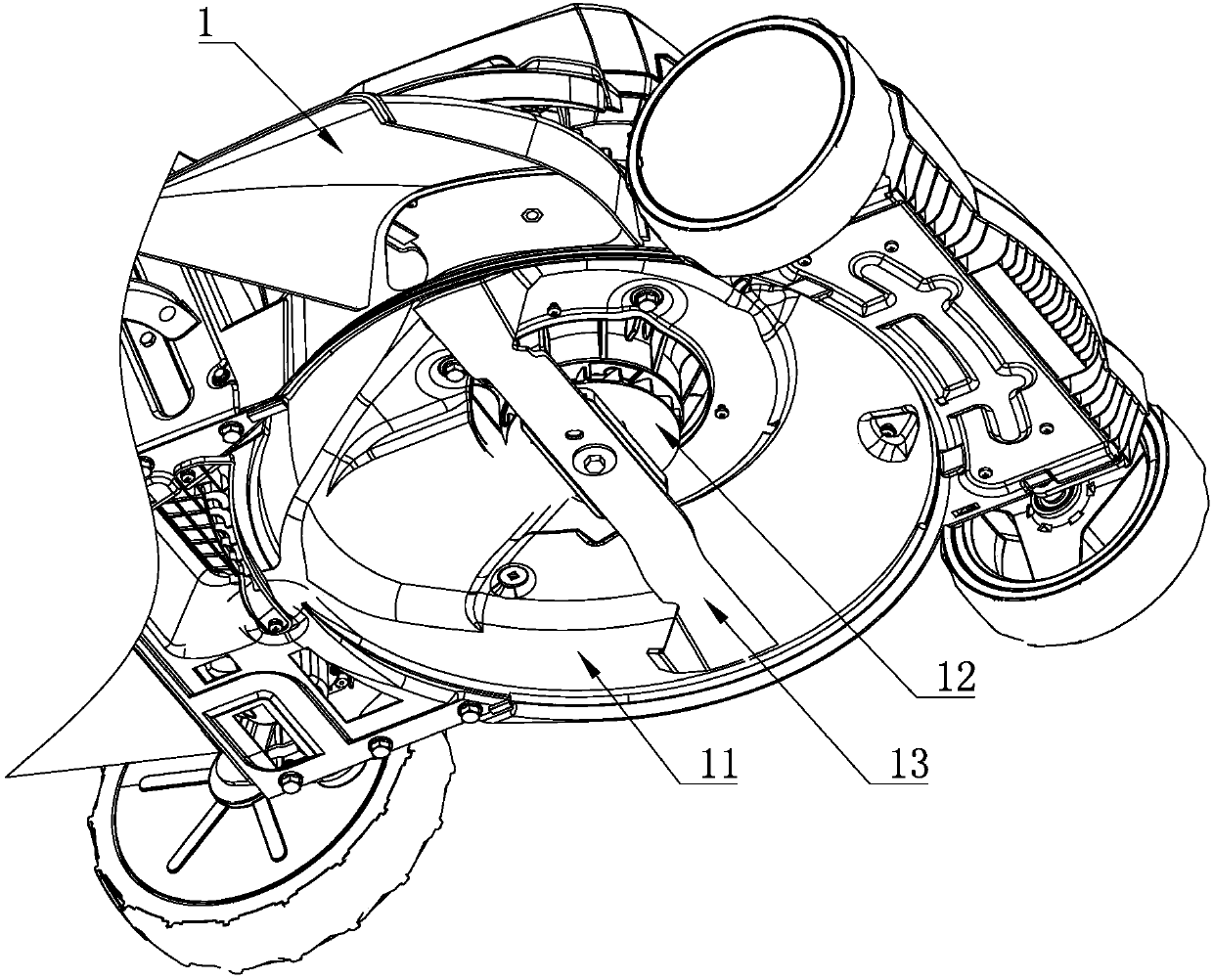

Cooling lawn mower

The invention discloses a cooling lawn mower. The cooling lawn mower comprises a main shell, the main shell is provided with a cutting cavity and a motor fan cover, a motor fan cavity is formed in themotor fan cover, a motor is connected in the motor fan cover, fan blades are connected to an output shaft of the motor, a base and a power supply device are connected to the motor fan cover, a firstcooling cavity is formed between the base and the power supply device, a circuit board is arranged in the first cooling cavity, and the base is provided with a plurality of first air holes and secondair holes. According to the cooling lawn mower, the first cooling cavity, the motor fan cavity and the cutting cavity form a cooling channel through the second air holes and the motor fan cover, the fan blades conduct air extraction on the cooling channel, and air enters the cooling channel from the first air holes to cool all components and then is discharged; the cooling effect is good, it is unnecessary to independently arrange cooling devices nearby the components, the size of the cooling lawn mower is reduced, and the production cost of the cooling lawn mower is reduced.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

A kind of full grouting sleeve for building reinforcement connection

InactiveCN104358360BPrevent reverse installationGuaranteed positioning accuracyBuilding reinforcementsButt jointArchitectural engineering

The invention discloses a full-grouting sleeve for connection of construction reinforcing steel bars, and belongs to the technical field of building projects. A reinforcing steel bar axial-limiting guide stop dog is arranged on the inner wall in the middle of a sleeve main body; guide slopes are arranged between the stop dog and the inner wall of the sleeve main body; a positioning bolt is arranged on the sleeve main body at the prefabricated end; the reinforcing steel bar at the prefabricated end is axially and radially fixed through the positioning bolt; the sleeve main body is molded by one-step casting of spheroidal graphite cast iron, so that the production cost is low; the outer surface of the sleeve main body serves as a roughened surface, so as to ensure the anchoring force between the grouting sleeve and the concrete; a plurality of convex hooping ribs are arranged on the inner wall of the grouting sleeve; an identification gap is formed in the port face of the sleeve main body at the field poured end, so as to prevent the situation that the grouting sleeve is installed reversely; a seal ring is arranged inside the port of the sleeve main body at the prefabricated end. When the grouting sleeve disclosed by the invention is in axial butt joint with the reinforcing steel bar, the precise axial control can be automatically realized, and the radial positioning can be automatically realized, so as to ensure the positioning accuracy between the reinforcing steel bar and the grouting sleeve, and meet the requirements on building construction quality.

Owner:SHENYANG JIANZHU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com