Loudspeaker magnetic circuit structure and assembling method thereof

A technology of speaker magnetic circuit and assembly method, which is applied to electrical components, loudspeakers, sensors, etc., can solve problems such as difficulty in ensuring the concentricity of yokes, magnets and washer, adverse effects on speaker sound quality, and impact on speaker performance, etc. Achieve the effect of preventing reverse polarity, improving yield, and ensuring phase consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

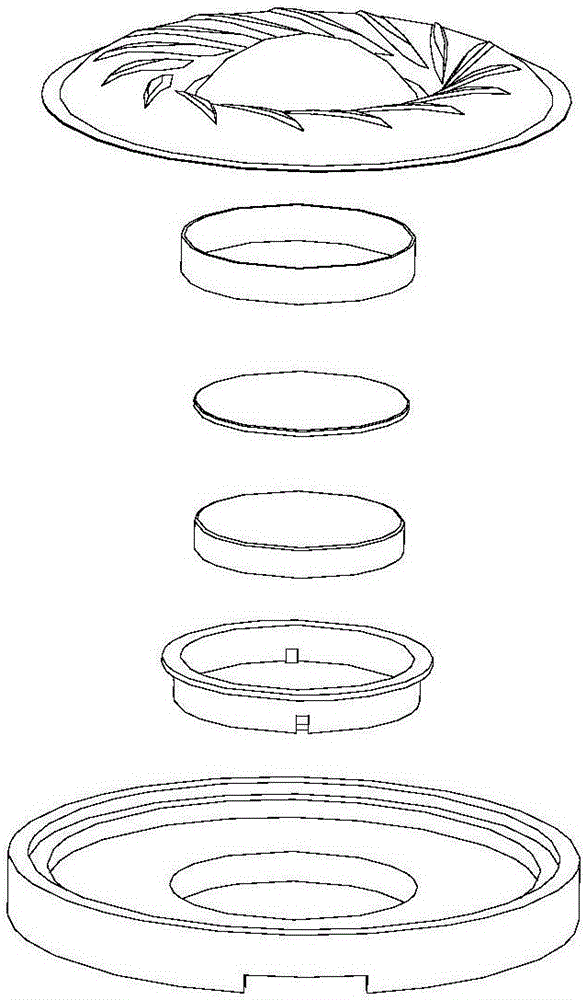

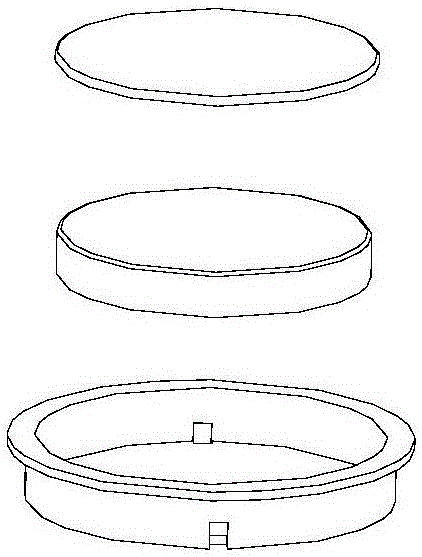

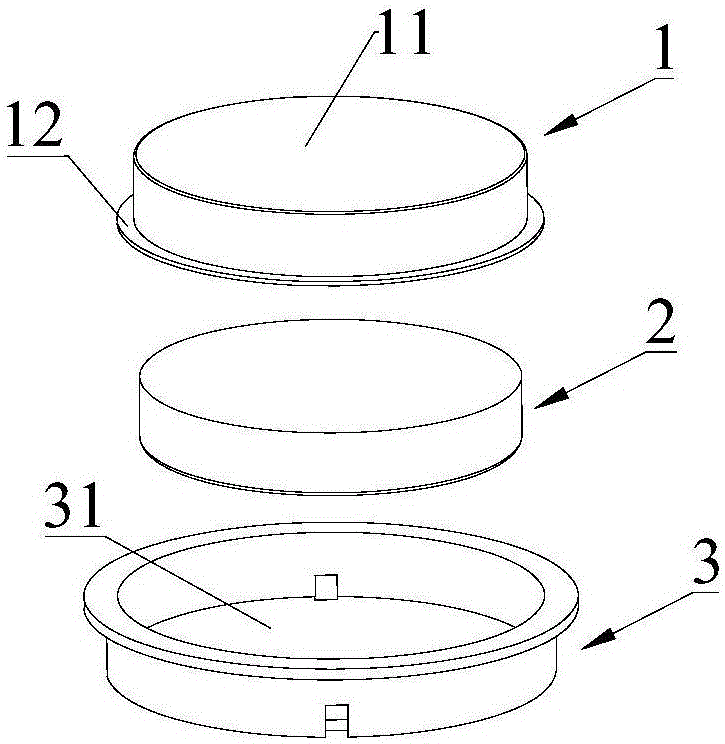

[0037] Please refer to image 3 , Embodiment 1 of the present invention is: a horn magnetic circuit structure, including a washer 1, a magnet 2 and a yoke 3, the washer 1 includes a washer main body 11 and an edge structure 12, and the washer main body 11 is A cavity structure with one end open, the magnet 2 is located in the cavity structure, preferably, the cavity structure can just accommodate the magnet 2, that is, the shape and size of the cavity structure of the cavity structure are consistent with the shape of the magnet 2, The same size can prevent the position of the magnet from shifting relative to the washer. In order to better fix the magnet 2 on the washer 1, a first adhesive layer is provided at the bottom of the cavity structure, through which the magnet 2 can be firmly fixed on the washer to prevent falling off . In this embodiment, both the magnet 2 and the cavity structure are cylindrical, which can generate a stable and uniform magnetic field. The outer di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com