Rear end cover of electric generator

A technology of back end cover and generator, which is applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of electric leakage, burnout, and failure to reach the protection level of the motor, and achieves a high-strength, simple structure, novel and beautiful appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

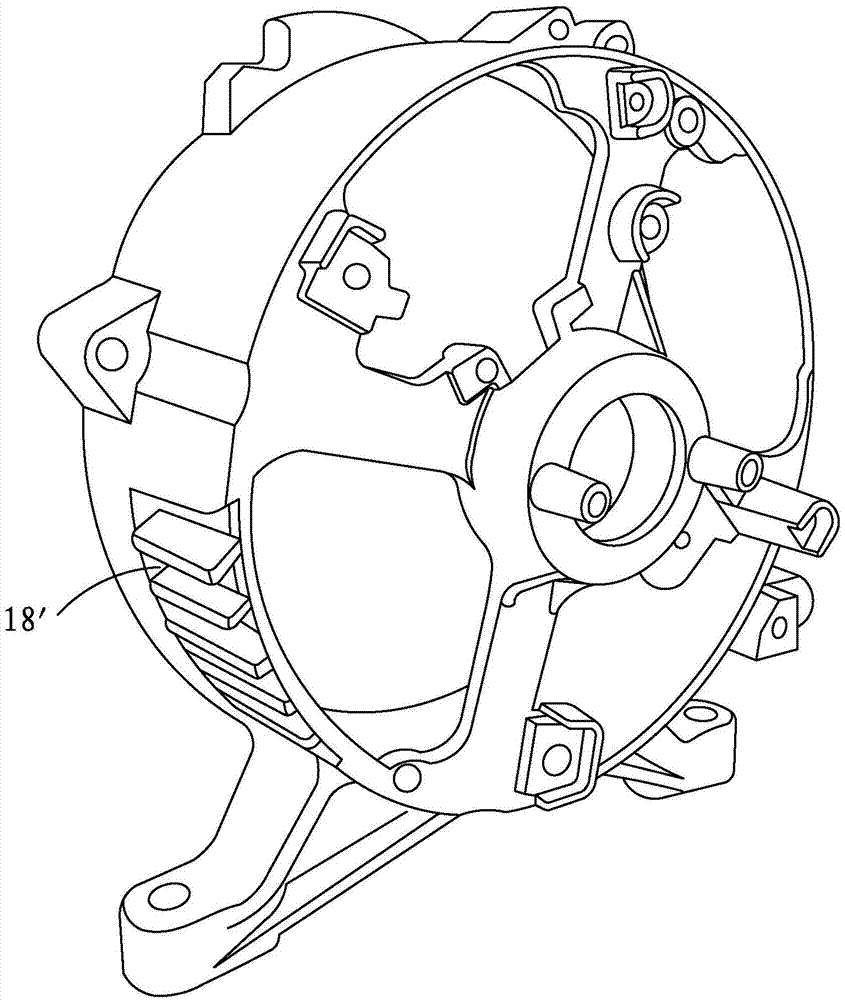

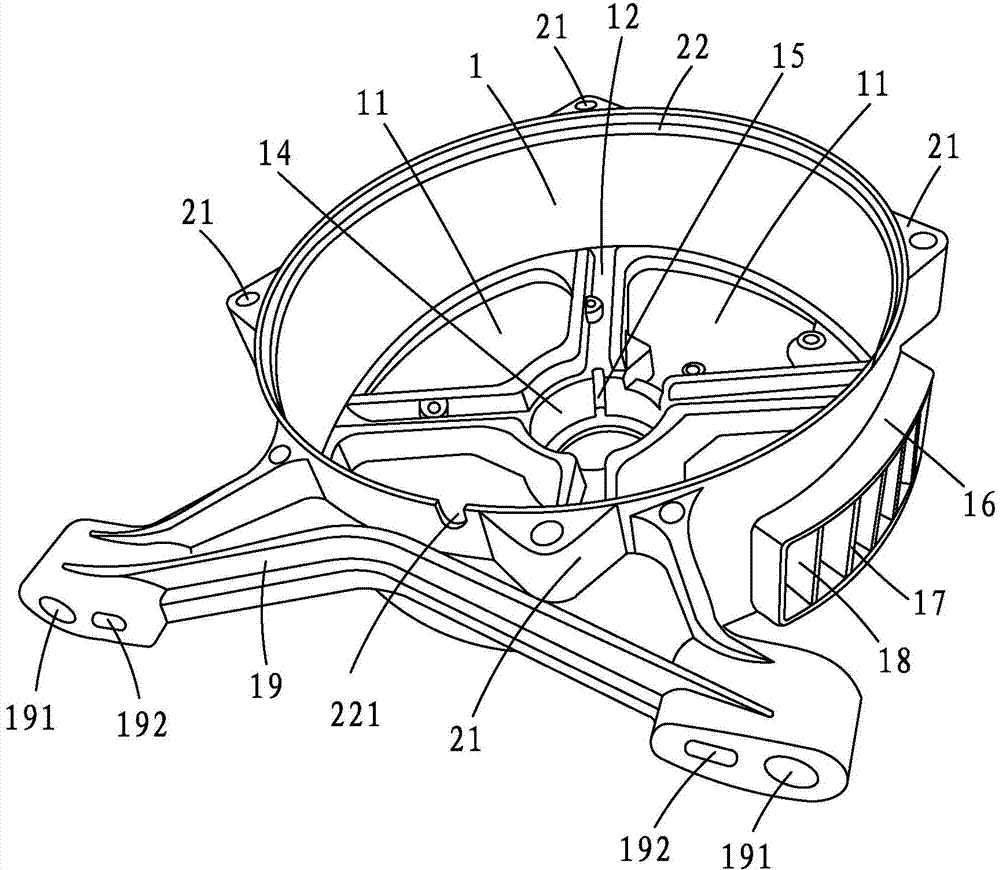

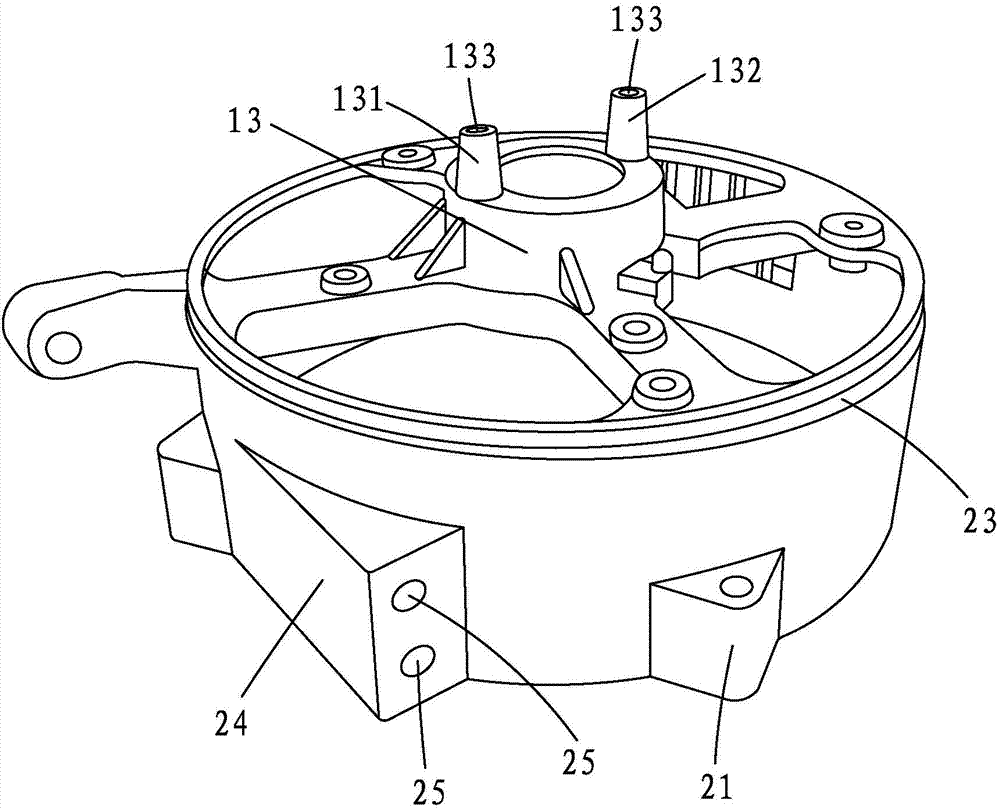

[0028] see Figure 2-4 , a generator rear end cover, comprising a rear end cover body 1, the rear end surface of the rear end cover body is provided with four fan-shaped through-holes 11, and two of the four fan-shaped through-holes 11 are formed It is a rib plate 12; a boss 13 extending backward is provided at the center of the rear end surface, and the inside of the boss 13 is a stepped through hole to form a bearing chamber 14; the inner wall of the bearing chamber 14 is recessed inward to form an axial Groove 15, the axial groove 15 is arranged in the middle of one of the ribs 12 adjacent to the top of the bearing chamber 14, and is used for installing a stop device of a bearing (not shown) with a radial stop device on the outer ring It is higher than the side part of the outer ring of the bearing (such as a cylindrical pin or the convex part of the stop ring) to prevent the bearing from running out of the outer ring in a hot state. The slot 15 is located here to facilitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com