Bearing

A bearing and bearing outer ring technology, applied in ball bearings, bearing components, shafts and bearings, etc., can solve the problems of complex manufacturing process, rough workpiece surface, bearing running outer ring, etc., to achieve simple structure, convenient installation, prevent running The effect of the outer ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

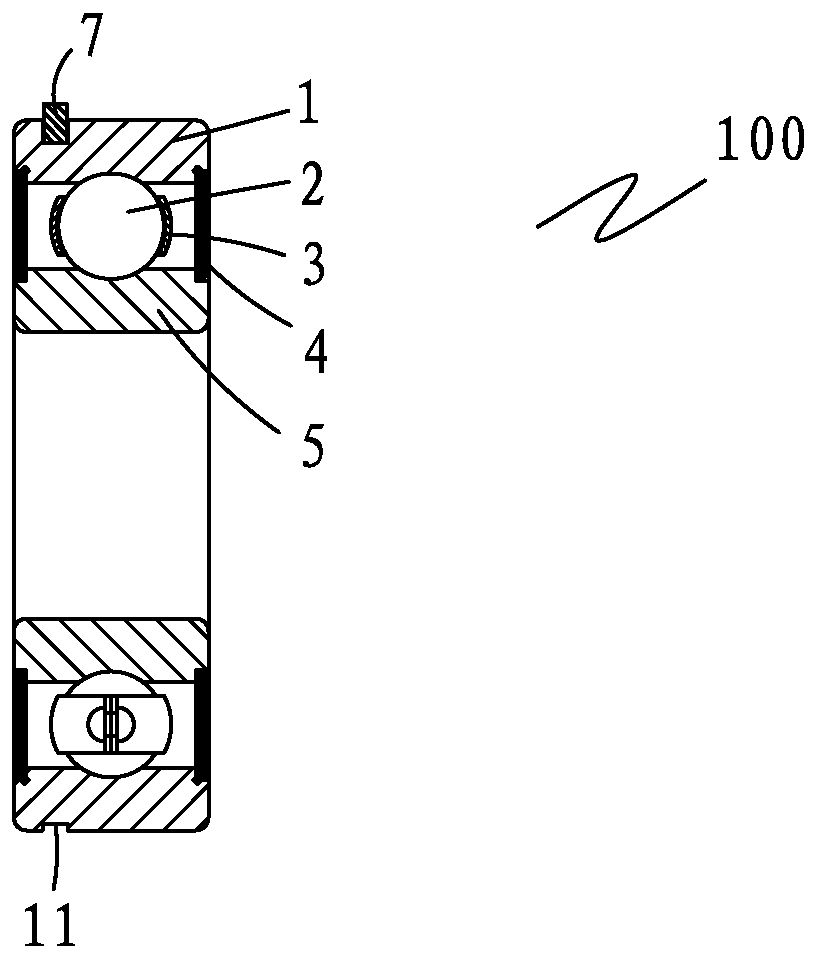

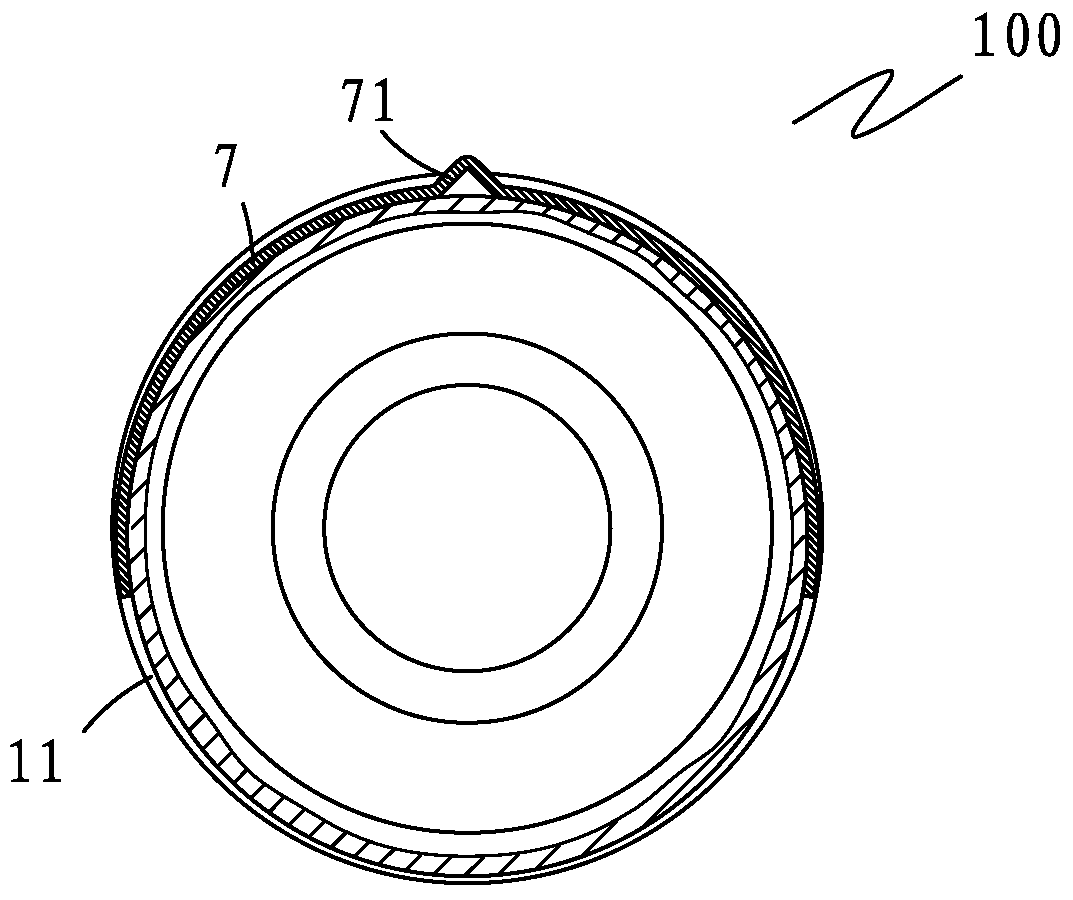

[0020] see Figure 1-2 with Figure 6-7 , a bearing 100, comprising a bearing outer ring 1, a rolling element 2, a cage 3, a sealing cover 4, a bearing inner ring 5 and a bearing chamber 6 for installing the bearing 100; the outer wall of the bearing outer ring 1 It is recessed inward to form an eccentric groove 11 , and the eccentric groove 11 is covered with a stop ring 7 . The inner wall of the bearing chamber 6 has a positioning groove 61, and the positioning groove 61 has been formed during the die-casting of the aluminum alloy end cover of the motor.

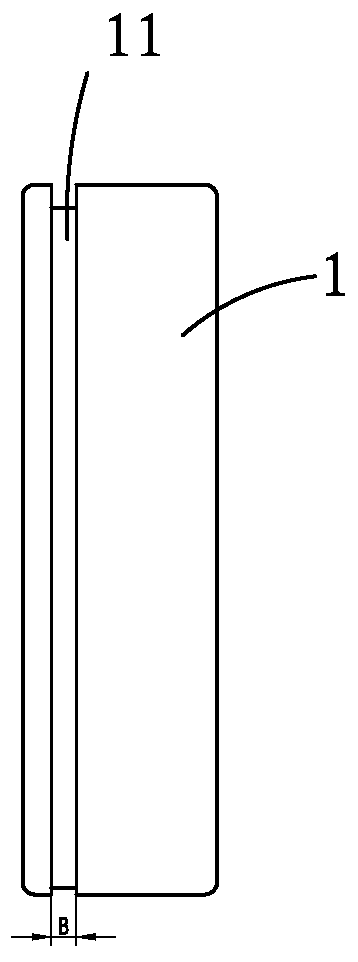

[0021] see again Figure 3-4 , the eccentric groove 11 is provided adjacent to one end of the bearing outer ring 1 , because the thickness of the bearing outer ring 1 is relatively thick here, and the setting of the eccentric groove 11 here will not affect the strength of the bearing outer ring 1 . The depth of the eccentric groove 11 gradually deepens from the bottom to the top, and the eccentric distance e of the ecce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com