Welding fixture for automobile seat angle adjuster

A technology for welding tooling and car seats, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as incorrect marking, blurred workers, and difficult to clearly identify, so as to improve product quality and reduce scrap rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

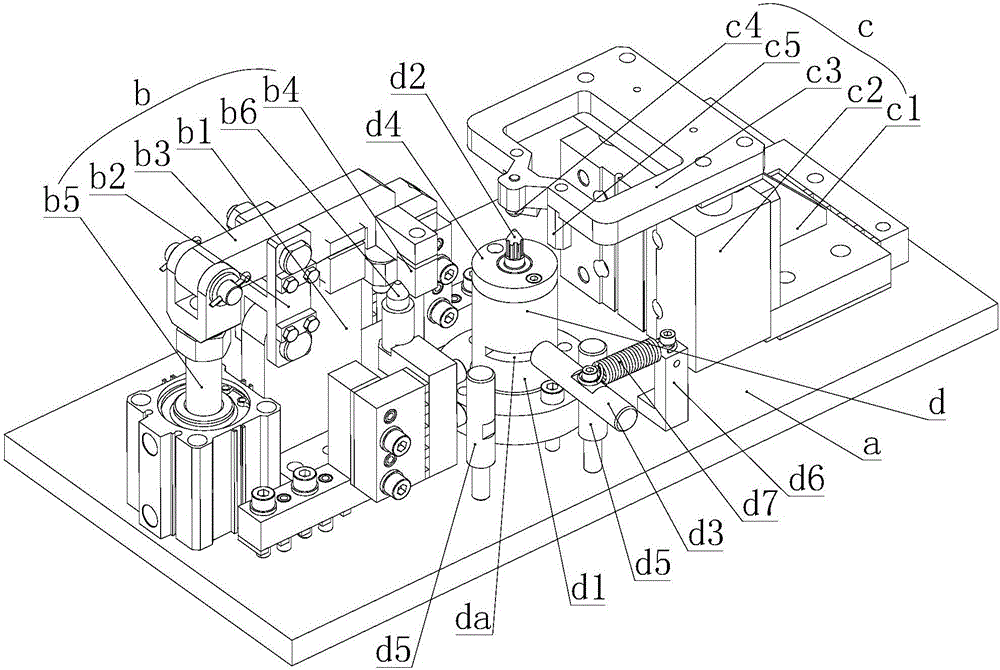

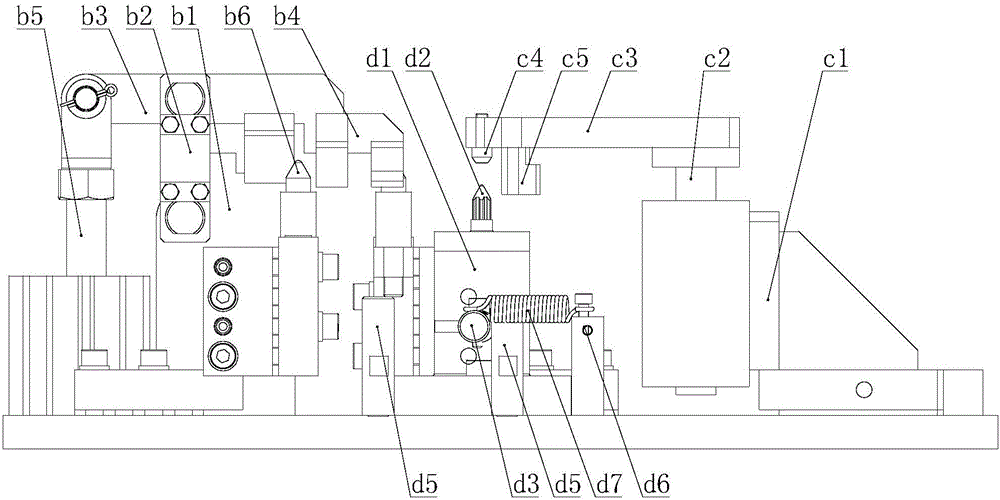

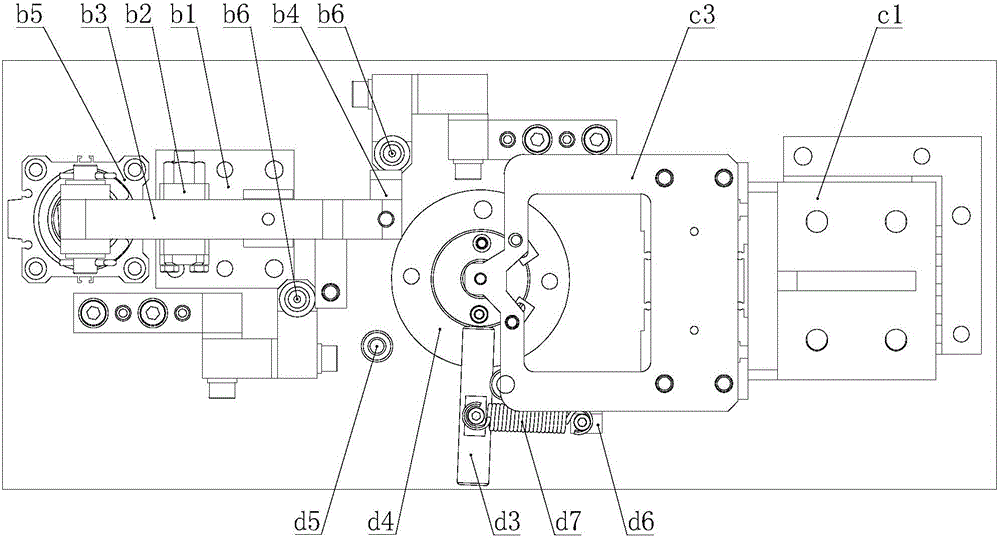

[0026] like figure 1 , 2 , 3 and 4, a car seat recliner welding tool, including a base a, on the base a is provided with a connecting plate clamp b and a core member clamp c, the connecting plate clamp b and A simulated unlocking mechanism d is provided between the core clamps c, and the clamping portion of the core clamps c is located above the simulated unlocking mechanism d.

[0027] The analog unlocking mechanism d includes a sleeve d1, an unlocking pin d2, a handle d3, an end cover d4, a stroke positioning column d5, an extension spring seat d6 and a return extension spring d7,

[0028] The sleeve d1 is arranged vertically, the lower end of the sleeve d1 is fixed on the base a, the unlocking pin d2 is axially penetrated in the sleeve d1, and the unlocking pin d2 passes through two The rolling bearing is installed in the sleeve d1, and a bushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com