Device and method for treating filament yarn and fancy knotted, migrated, and false-twist yarn

A filament yarn and yarn technology, applied in the field of snowflake yarn and false twisted yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

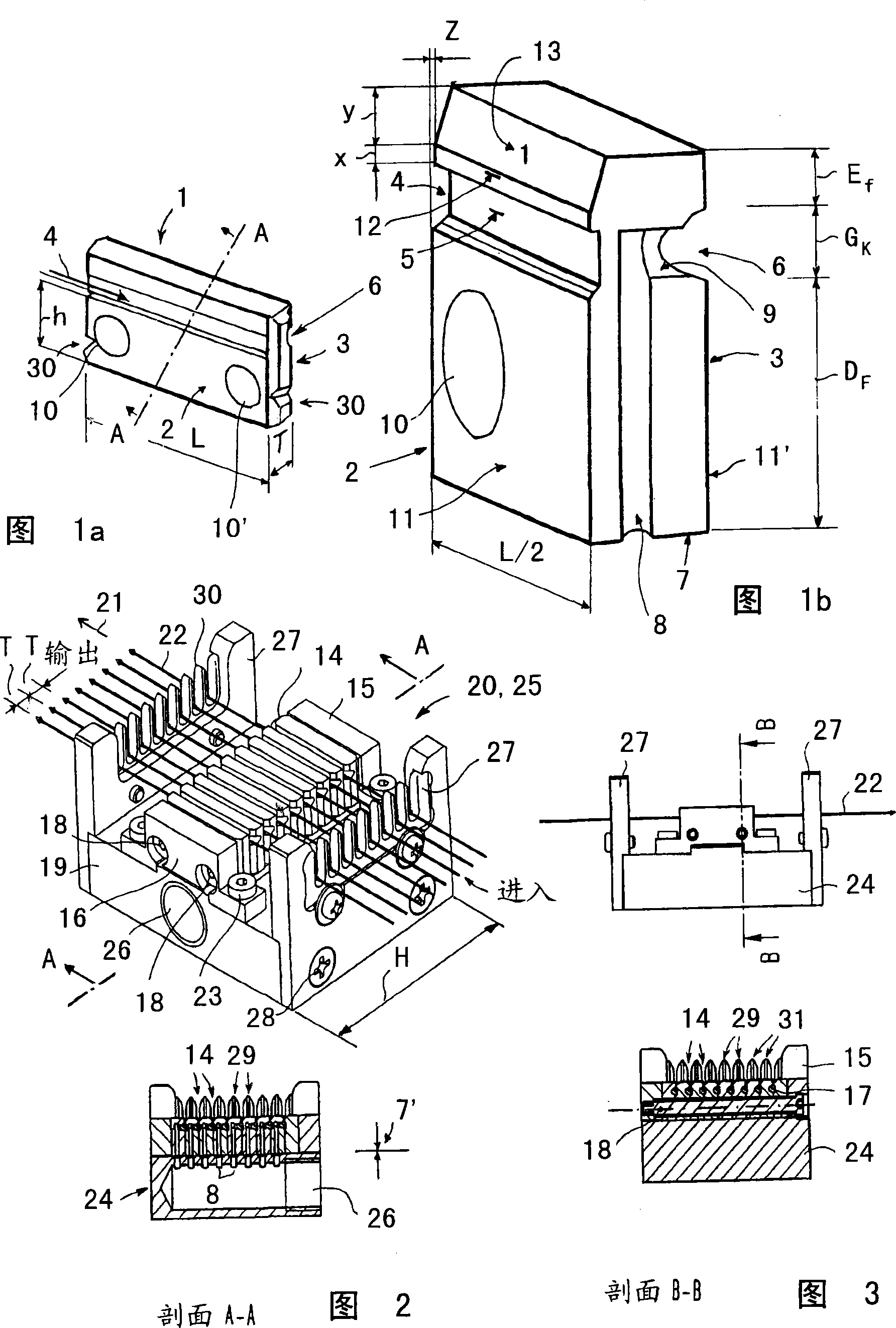

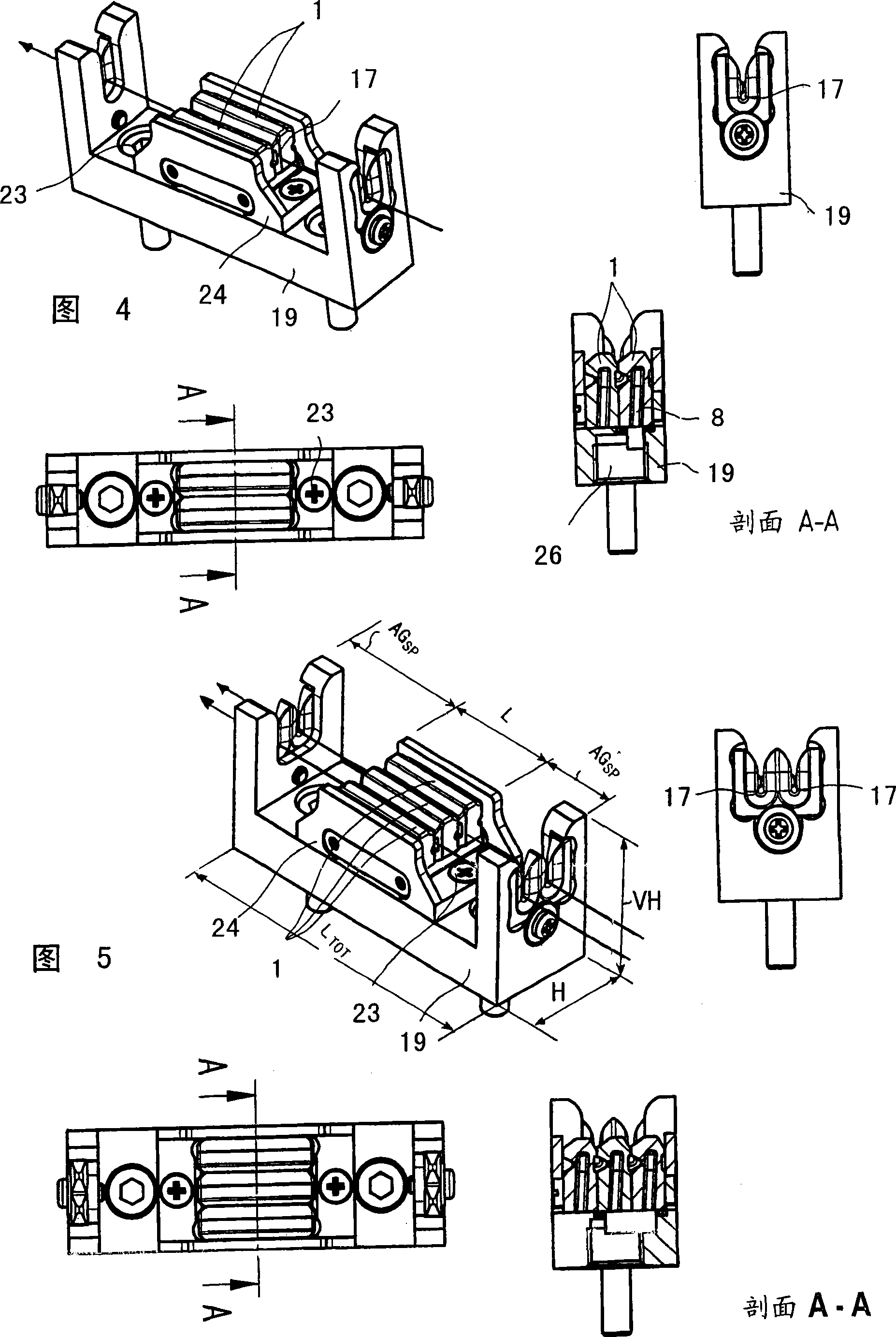

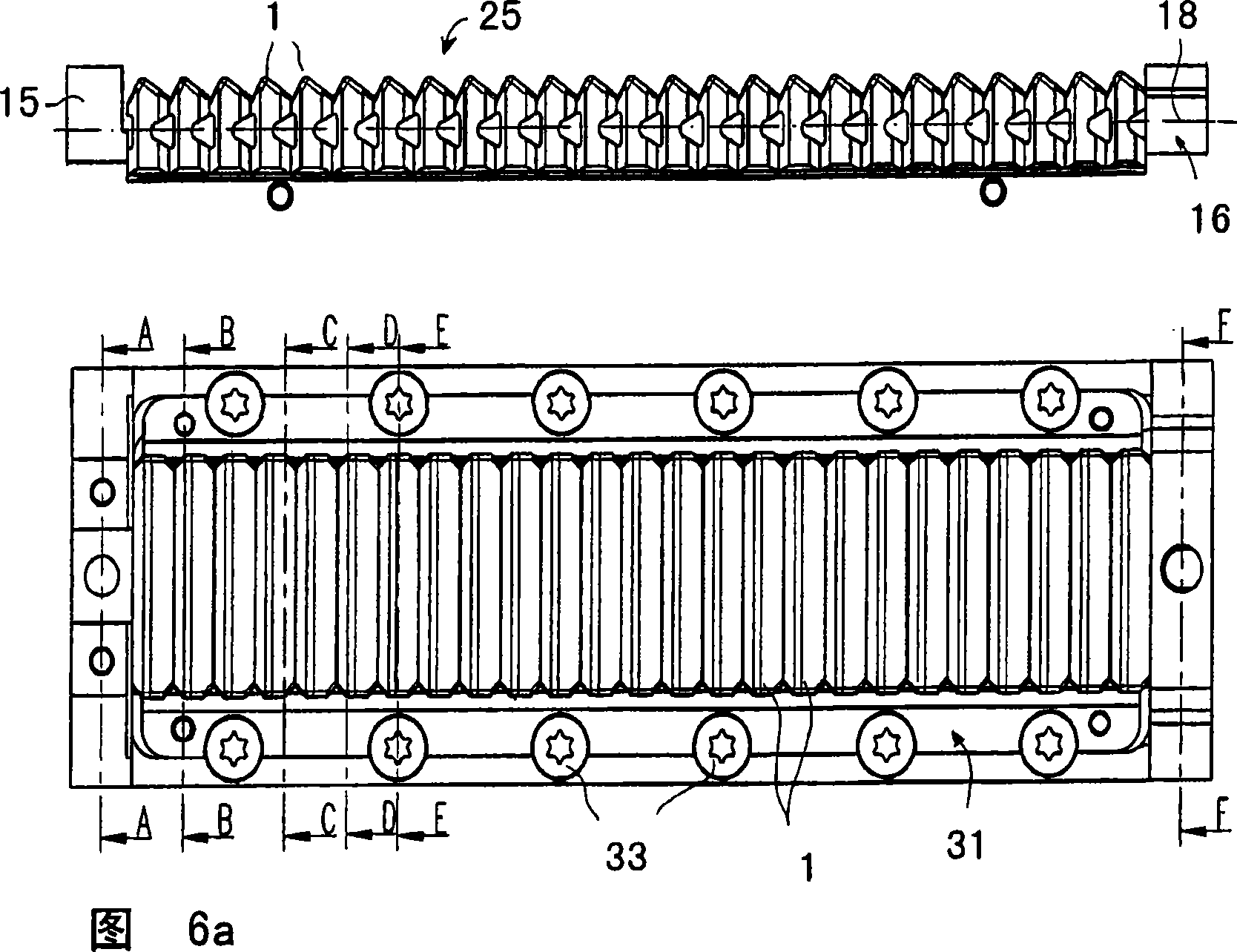

[0061]FIGS. 1 and 1 a show a spinneret / cover plate 1 , which is at the same time a cover plate and a spinneret plate, with a corresponding half of the yarn channel 17 . The front side shows the cover plate side 2 and the back side shows the spinneret side 3 , each having one half of the yarn channel 17 . On the front side 2 half 4 of the yarn channel enters the spinneret / cover plate 1 with the deflector 5 . On the back side of the spinneret side is half of the yarn channel 6 . An air supply channel 8 can be seen in section in FIGS. 1a and 2 (below). The air inlet channel 8 is introduced with a transverse hole 9 into the half 6 of the yarn channel with the spinneret 7 . The spinneret / cover plate 1 has two through holes 10 and 10' for the clamping plate 1. As can be seen from FIG. 3 , each two spinneret / cover plates 1 are in close contact with each other end-to-end. The corresponding sealing surface part 11 is designated by the dimension parameters h and L, wherein L is simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com