Crankshaft forging identifying device

A marking device and marking technology, applied in the field of forging, can solve problems such as reversed marking installation, wrong printing of markings, troublesome marking replacement, etc., and achieve the effects of preventing reversed installation, reducing operation actions, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

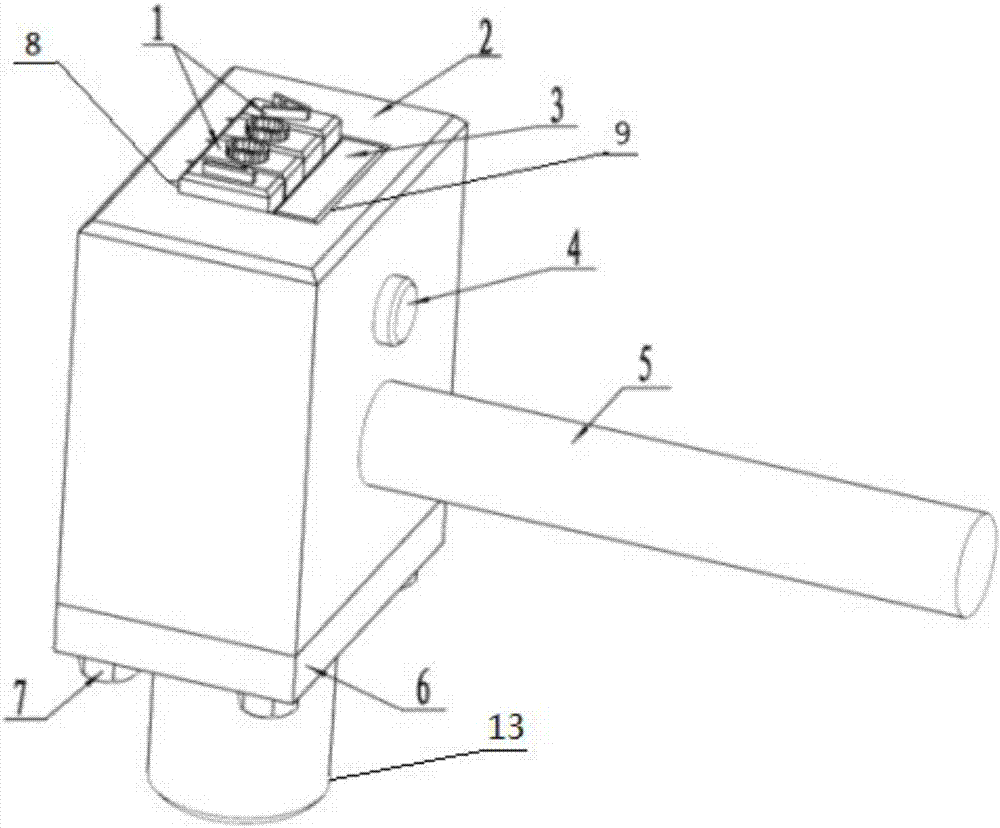

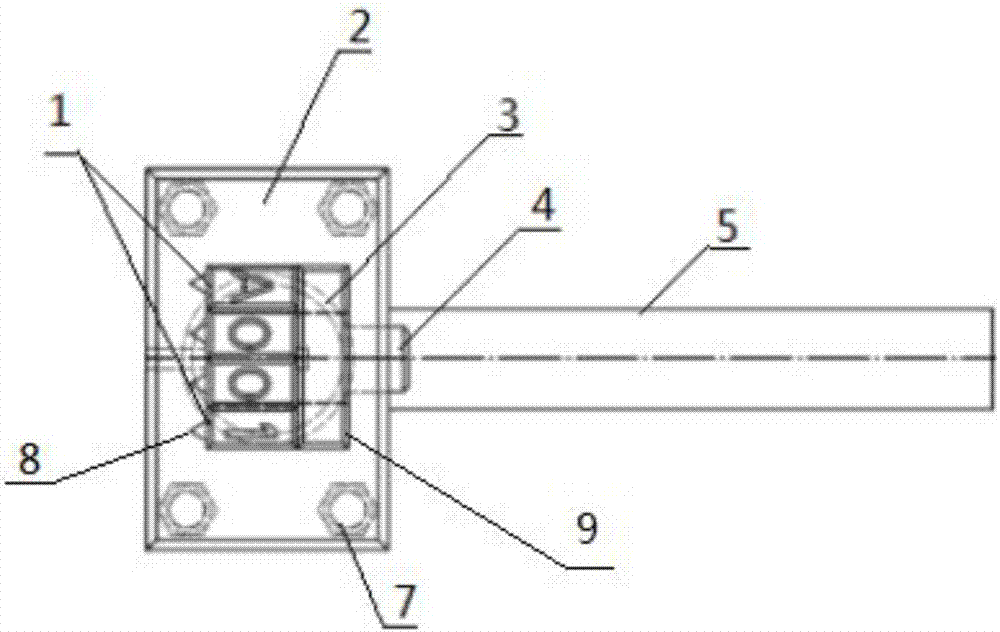

[0020] Such as figure 1 As shown, the present invention includes an identification box 2, an identification block 1 and a base 6, the upper part of the base 6 is an identification box 2, and the base 6 and the identification box 2 are connected by fixing bolts 7, and the identification box 2 has a Marking box groove 9, in described marking box groove 9, be provided with marking block 1 and magnet 3, the height of described marking block 1 is higher than the height of marking box 2 and magnet 3, each on the inner wall of described marking box 2, magnet 3 A hole that can pass through the pin 4 is provided, the thin end of the pin 4 passes through the hole on the logo box 2 and is fixed on the inner wall of the logo box 2, and the thick end of the pin 4 passes through the hole on the magnet 3, and the magnet 3 is in the It is fixed on the inner wall of the marking box 2 under the action of its own magnetic force. After the magnet 3 is fixed, put the marking block 1 in turn accord...

Embodiment 2

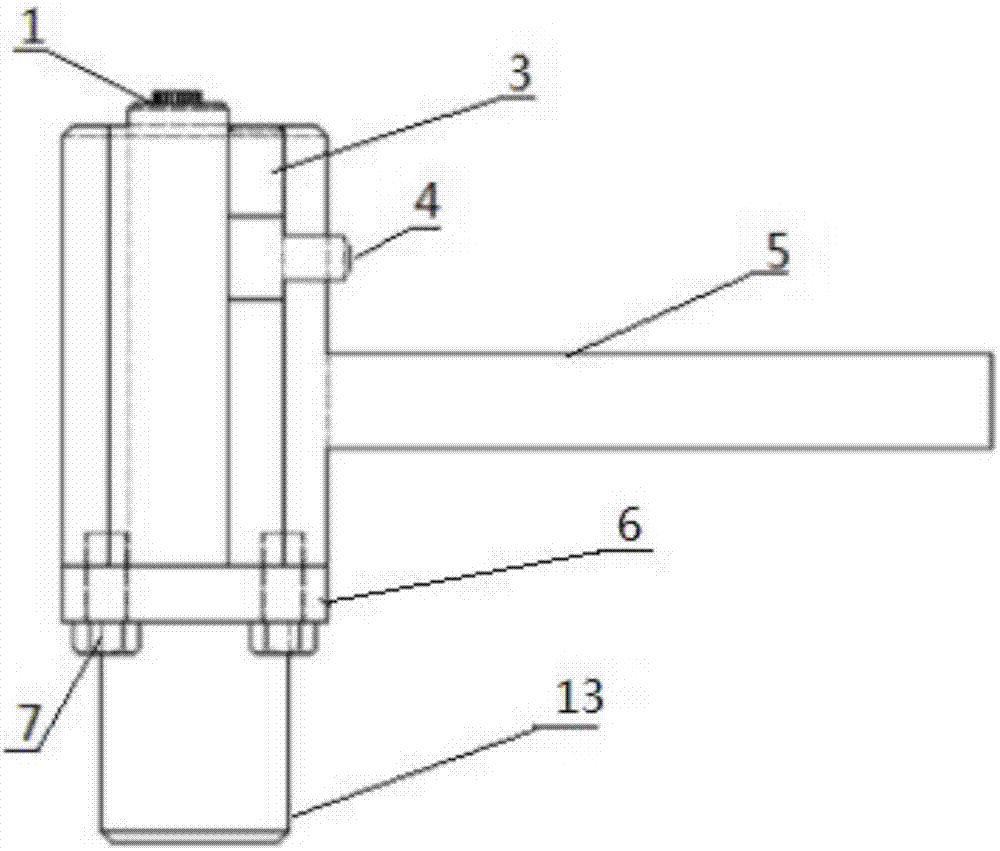

[0022] Such as Figure 4 As shown, the difference with Embodiment 1 is that the cylinder 13 at the bottom of the base is provided with a guide rod 10, and the guide rod 10 cooperates with the guide sleeve 11 provided on the base; The lower end surface is embedded in the positioning groove 12 . With the crankshaft forging marking device, when the external force on the cylinder 13 is not on the same straight line as the axis of the cylinder 13, it can be balanced by the action of the guide rod to prevent the magnet from being broken due to the external force acting on the magnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com