Screening device

A technology of screening device and material distribution device, applied in transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as reverse loading, no solution proposed, fatigue, misjudgment, etc., to ensure imaging quality and promote clarity Imaging, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

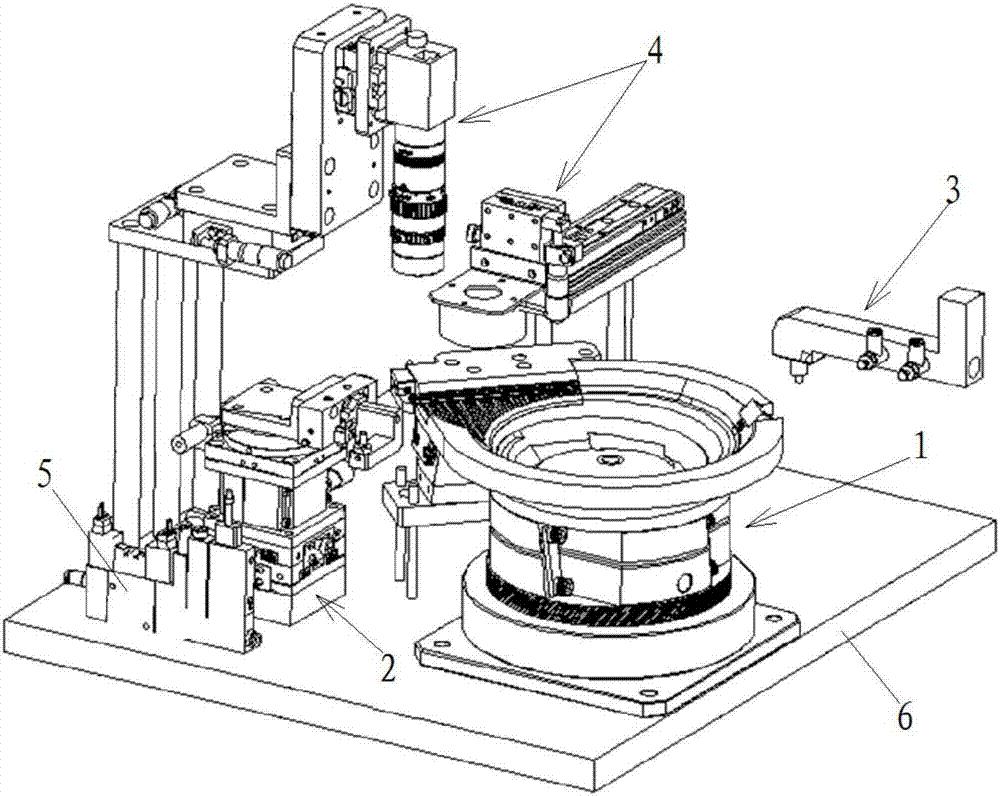

[0044] figure 1 is a perspective view schematically showing a screening device according to an embodiment of the present invention;

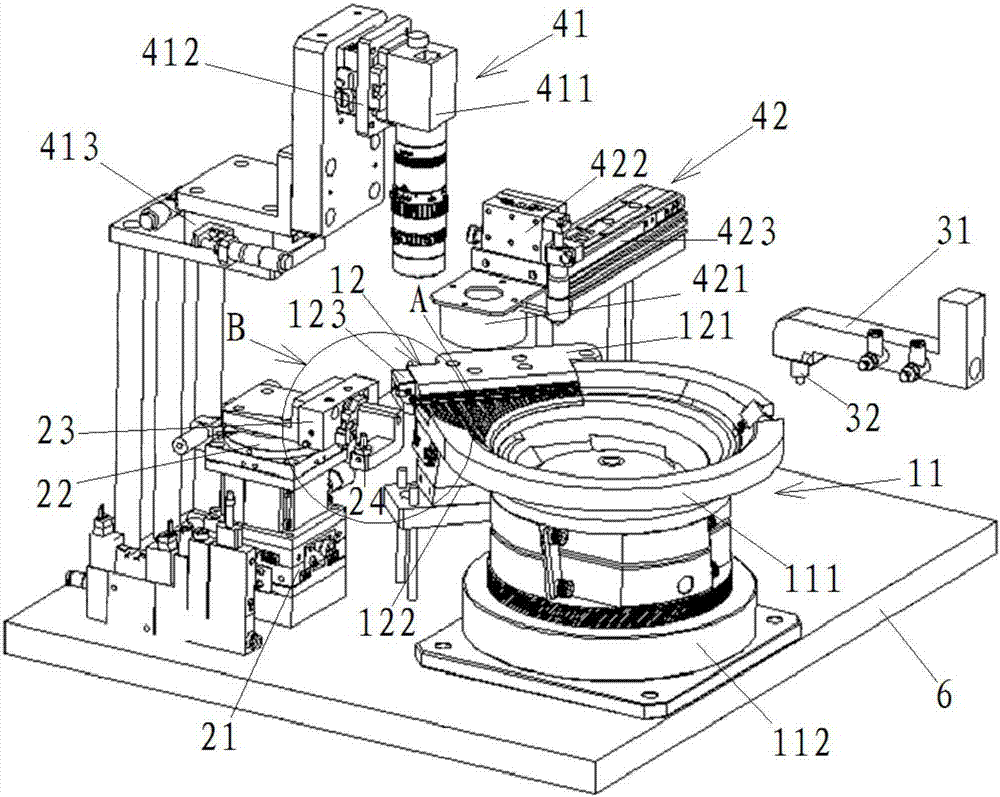

[0045] figure 2 is a perspective view schematically showing a screening device according to one embodiment of the present invention.

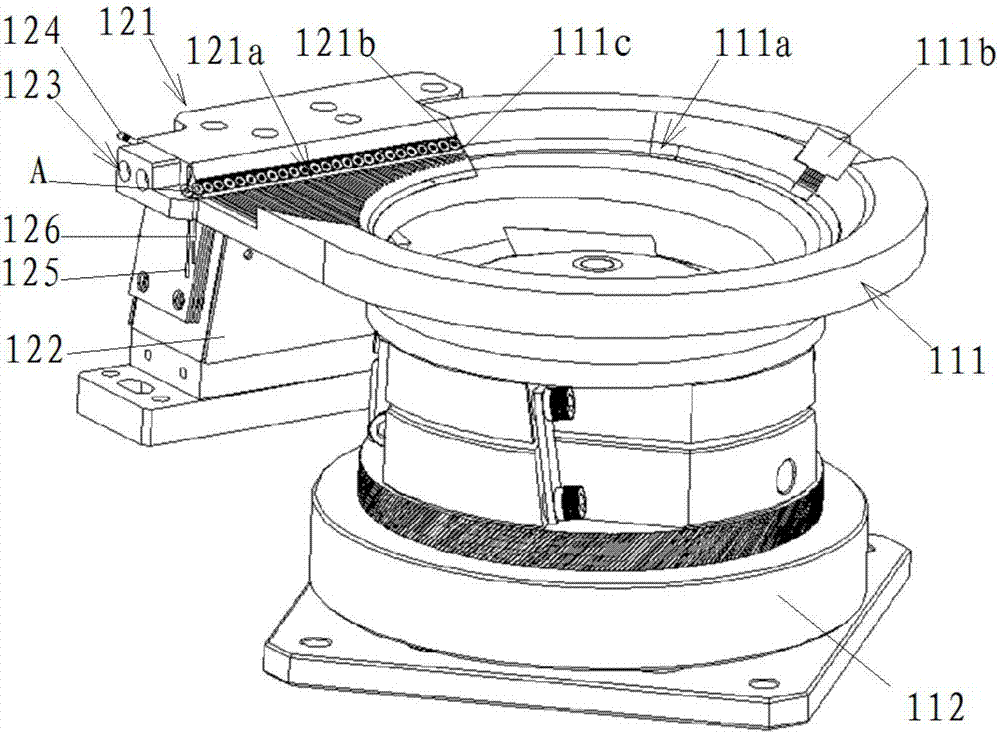

[0046] combine figure 1 and figure 2As shown, according to an embodiment of the present invention, the screening device of the present invention includes a discharge unit 1 , an overturning unit 2 , a picking unit 3 , an identification unit 4 , an air suction device 5 and a support plate 6 . In this embodiment, the discharging unit 1 , the turning unit 2 , the picking unit 3 , the identifying unit 4 and the suction device 5 are all fixedly supported on the support plate 6 . The discharging unit 1 is arranged adjacent to the turning unit 2 , and the identification unit 4 is located above the discharging unit 1 and the turning unit 2 . The discharge unit 1 mainly stores the material A and conveys the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com