Support structure of microwave oven grill

A technology for supporting structures and grills, applied in the direction of stove/stove brackets/shelves, etc., can solve the problems of time and labor waste, inability to support barbecue grills, etc., and achieve the effect of improving work efficiency and avoiding reverse installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, the supporting structure of the microwave oven grill of the present invention will be described in detail with reference to the accompanying drawings.

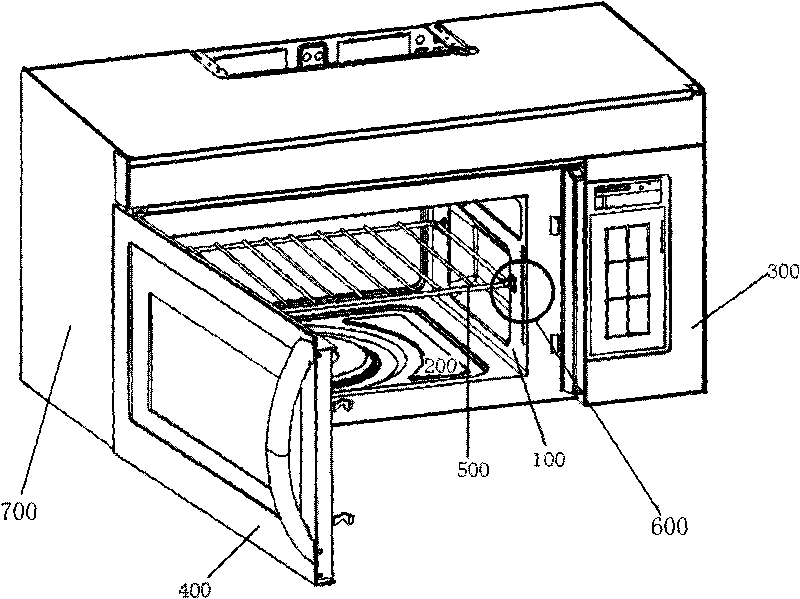

[0024] The supporting structure of the microwave oven grill of the present invention includes: a microwave oven cooking cavity side wall 100 constituting the microwave oven cooking cavity 200 and a grill support bracket 600 for supporting the grill.

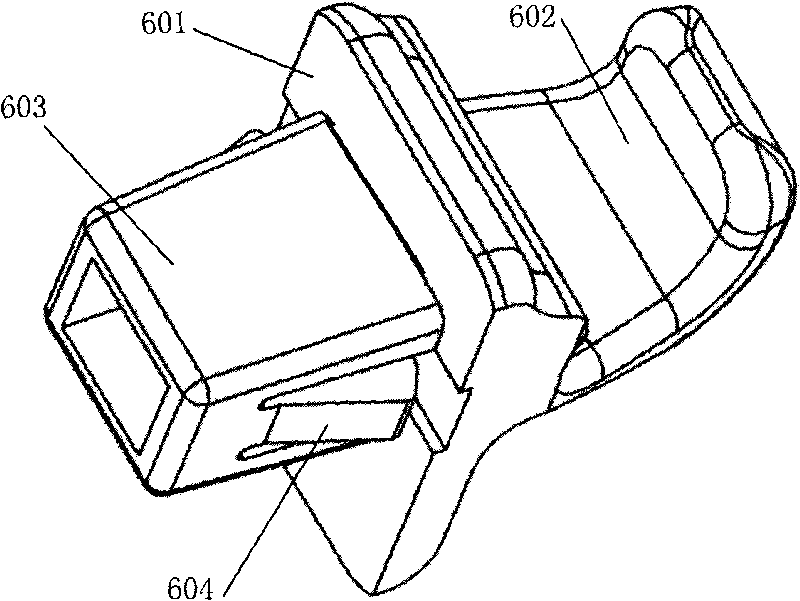

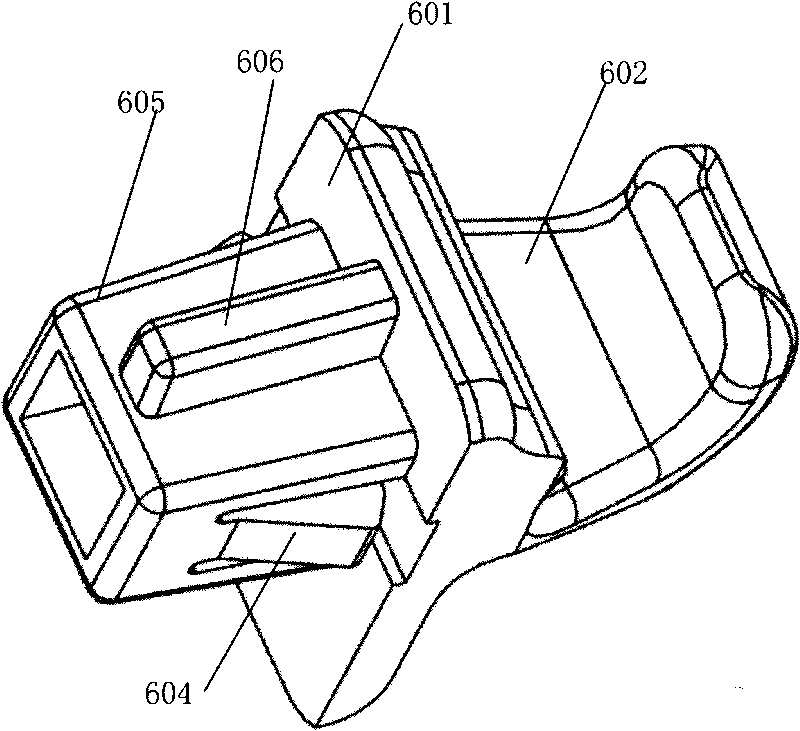

[0025] Such as image 3 As shown, the grill support bracket 600 has a support bracket main body 601, a support hook 602 for supporting the grill 500 is formed on one side of the support bracket main body 601, and a useful hook 602 is formed on the other side of the support bracket main body 601. For the insertion fixing part 605 inserted into the installation hole formed on the side wall 100 of the microwave oven cooking cavity, the present invention forms an insertion guide protrusion 606 higher than the end surface of the fixing part 605 on the insertion fixing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com