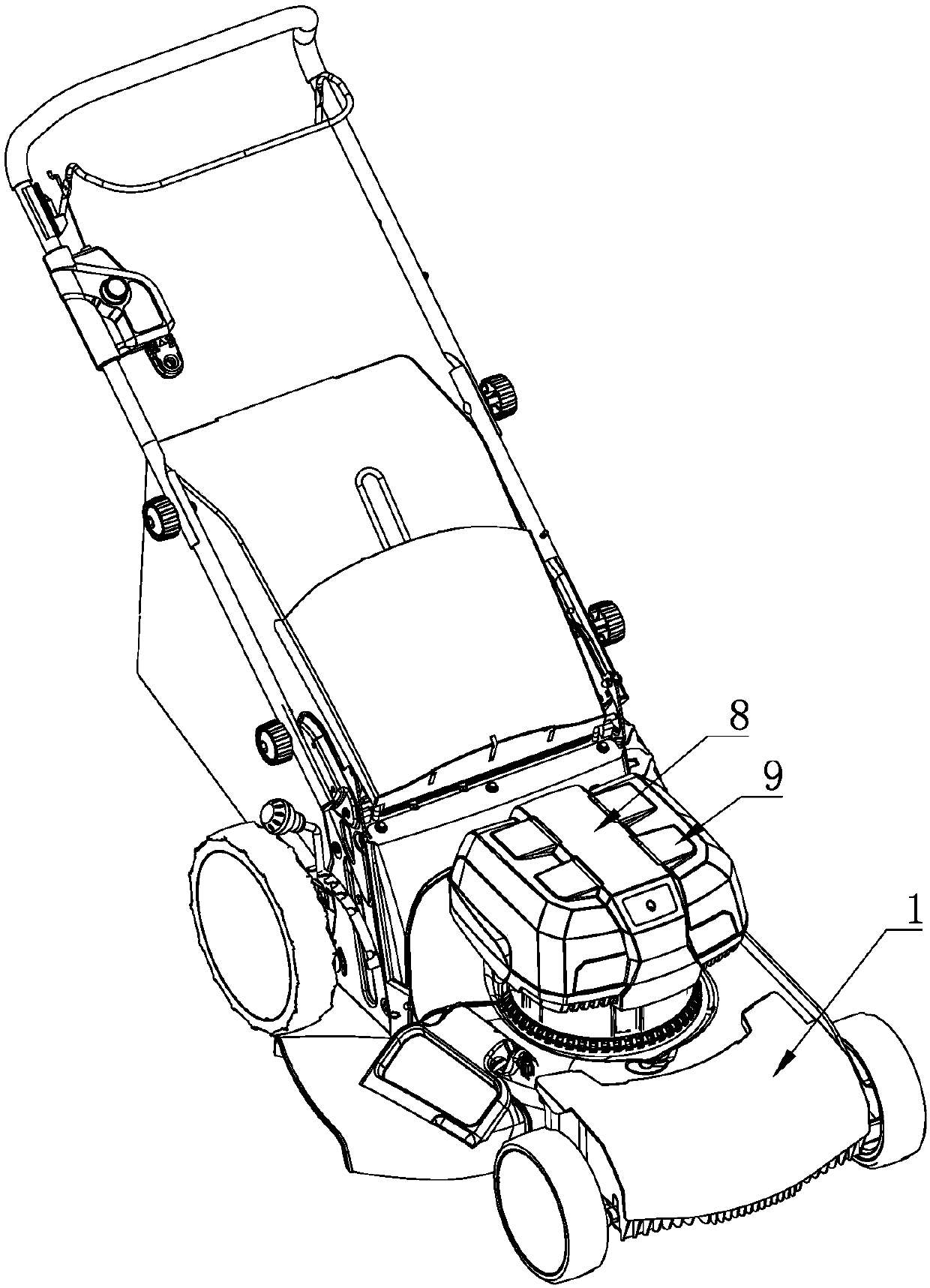

Cooling lawn mower

A technology of lawn mowers and heat dissipation chambers, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of reduced service life, inconvenient use, and excessive heat dissipation devices, so as to reduce production costs and improve heat dissipation. Good, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

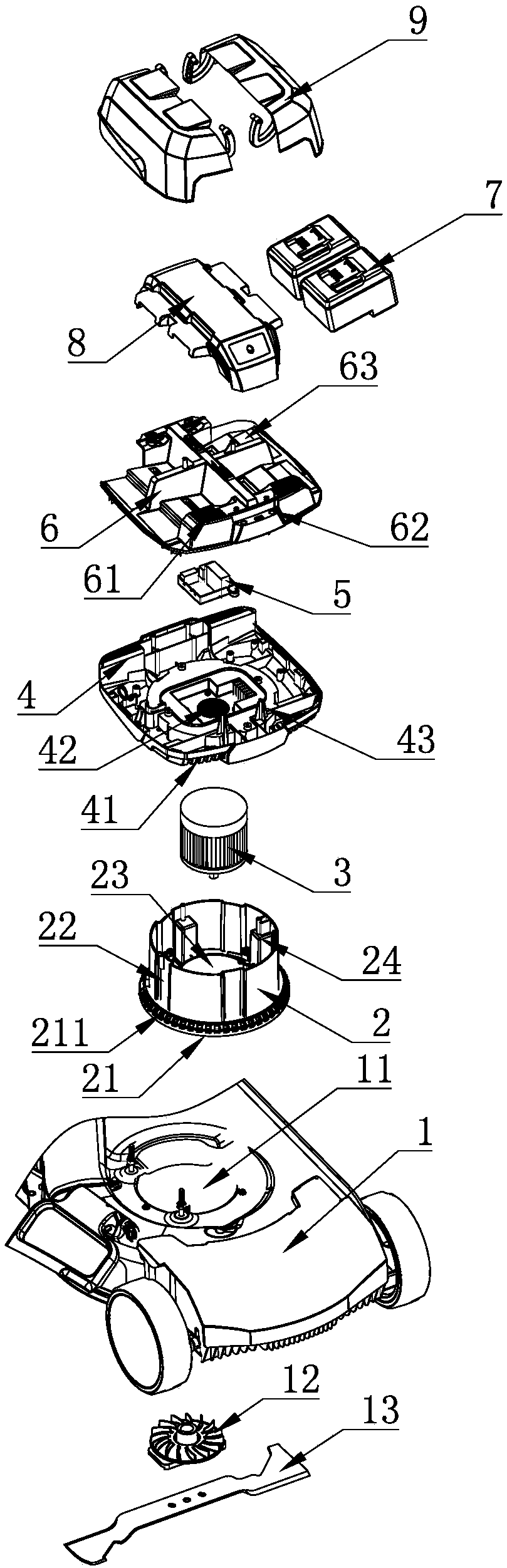

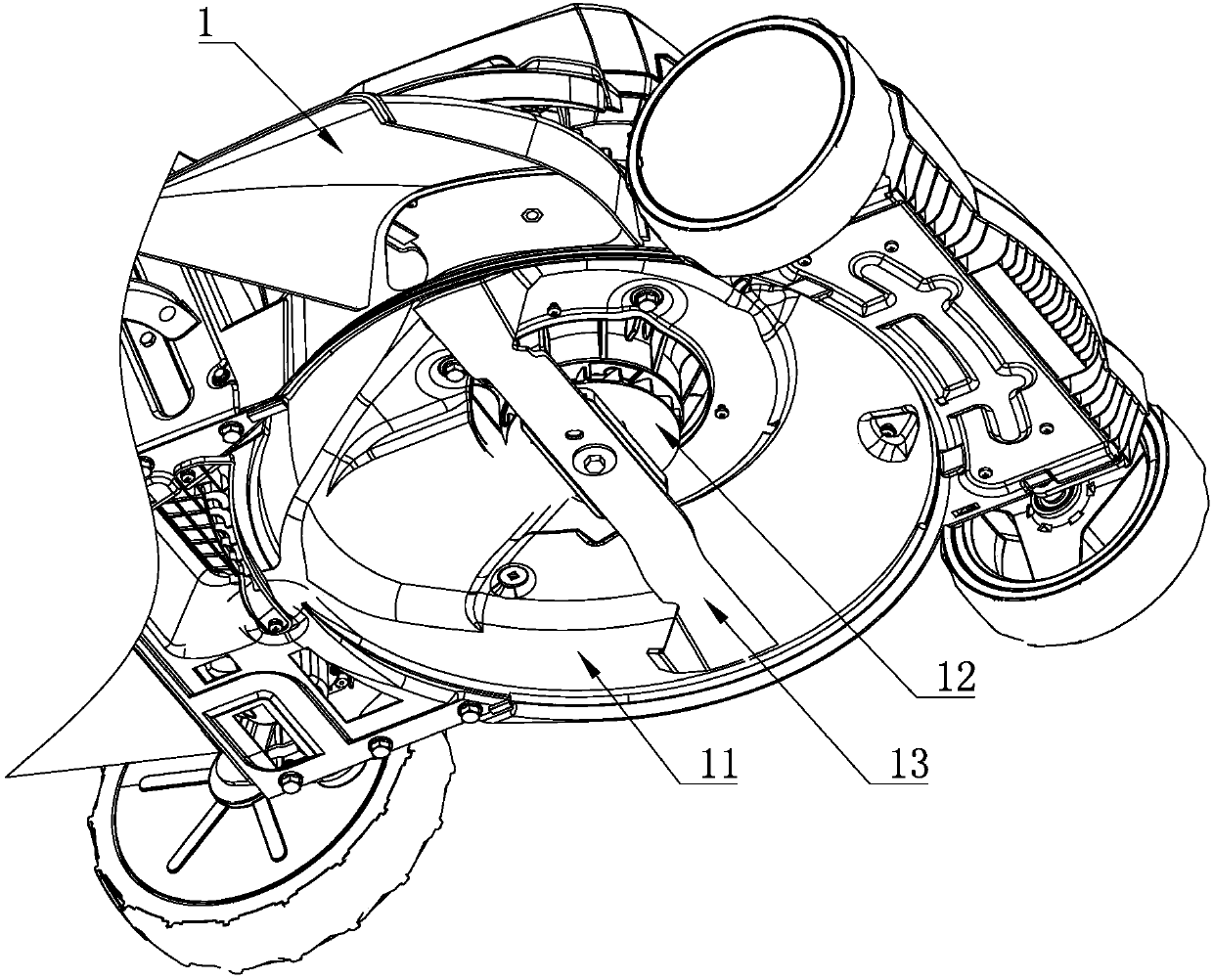

[0033] refer to Figure 1 to Figure 5 The embodiment of a heat dissipation lawnmower of the present invention will be further described.

[0034] A heat-dissipating lawn mower, comprising a main housing 1, the main housing 1 is provided with a cutting cavity 11 that runs through the upper and lower ends of the main housing 1, the main housing 1 is connected with a motor fan cover 2 by screws, and the motor fan cover 2 A motor air chamber 23 communicating with the cutting cavity 11 is formed inside, a motor 3 is arranged in the motor air chamber 23, and a plurality of positioning posts 24 are arranged on the inner wall of the motor wind cover 2, and the positioning posts 24 and the motor 3 are far away from the output shaft of the motor 3. One end is connected by a screw, and the output shaft of the motor 3 is connected with a fan blade 12. The fan blade 12 includes a base plate perpendicular to the output shaft of the motor 3, a sleeve sleeve connected to the output shaft of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com