Fabricated partition wall steel keel system and fabricating method

A steel keel and assembly technology, applied to walls, building components, buildings, etc., can solve the problems of inaccurate precision, inconsistent batches, low strength of aluminum extrusion profiles, etc., achieve high precision, reduce processing links, and install quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

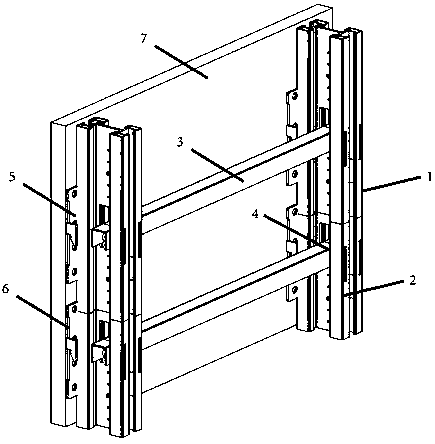

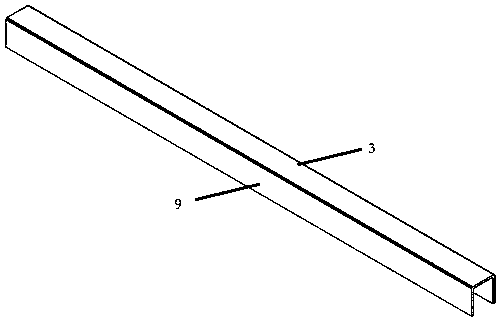

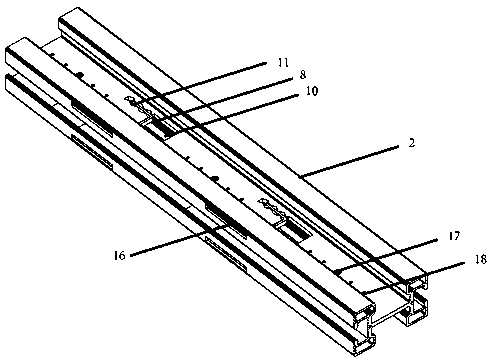

[0041] This embodiment: as figure 1 As shown, a prefabricated partition wall steel keel system includes a horizontal and vertical cross keel 1, and the horizontal and vertical cross keel 1 includes a vertical keel 2 and a horizontal keel 3, and the vertical keel 2 and the horizontal keel 3 are connected by a horizontal keel fixing device 4 The vertical keel 2 is connected to one end of the hanging piece 6 through the vertical hanging piece fixing device 5, and the other end of the hanging piece 6 is connected to the hanging plate 7.

[0042] Since the horizontal and vertical cross keels include vertical keels and horizontal keels, the vertical keels and horizontal keels are connected by a horizontal keel fixing device, and the vertical keels are connected to one end of the pendant through a longitudinal hanger fixing device, and the other end of the pendant is connected to the hanger. As the installation process is to cut steel profiles in the factory, the installation modules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com