Patents

Literature

31results about How to "Guaranteed anchoring force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

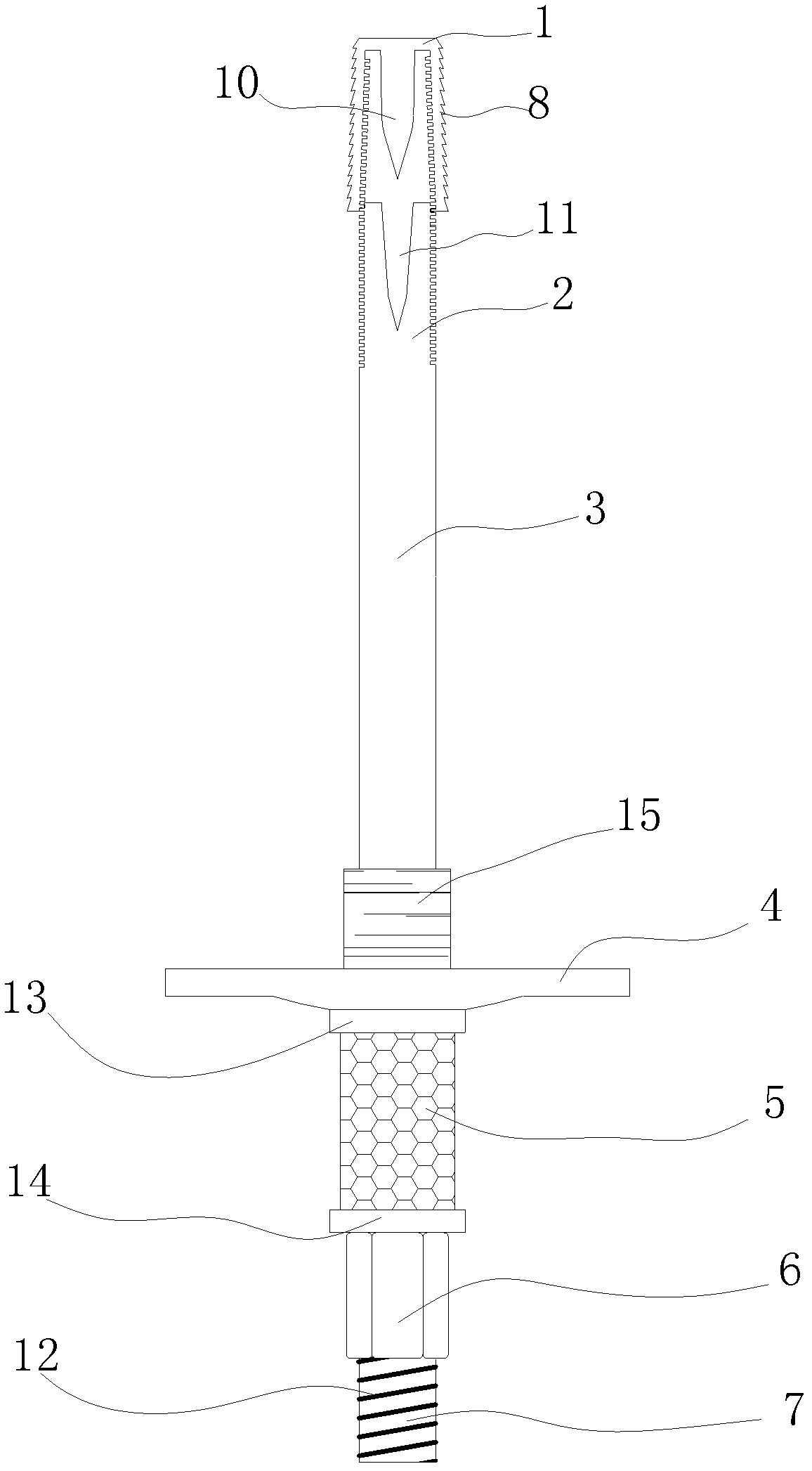

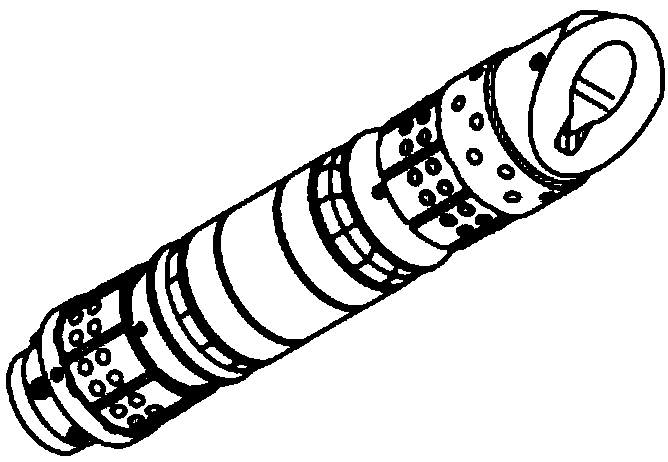

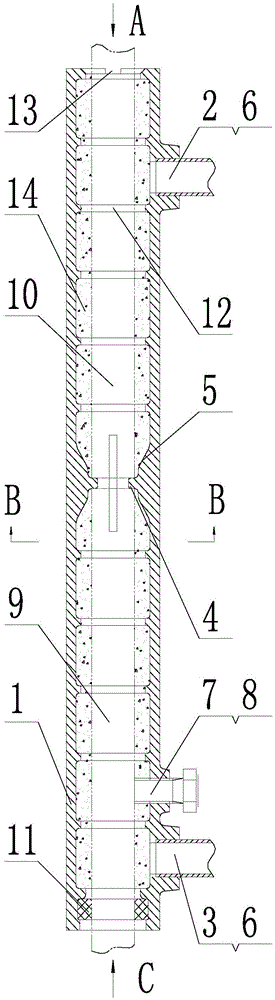

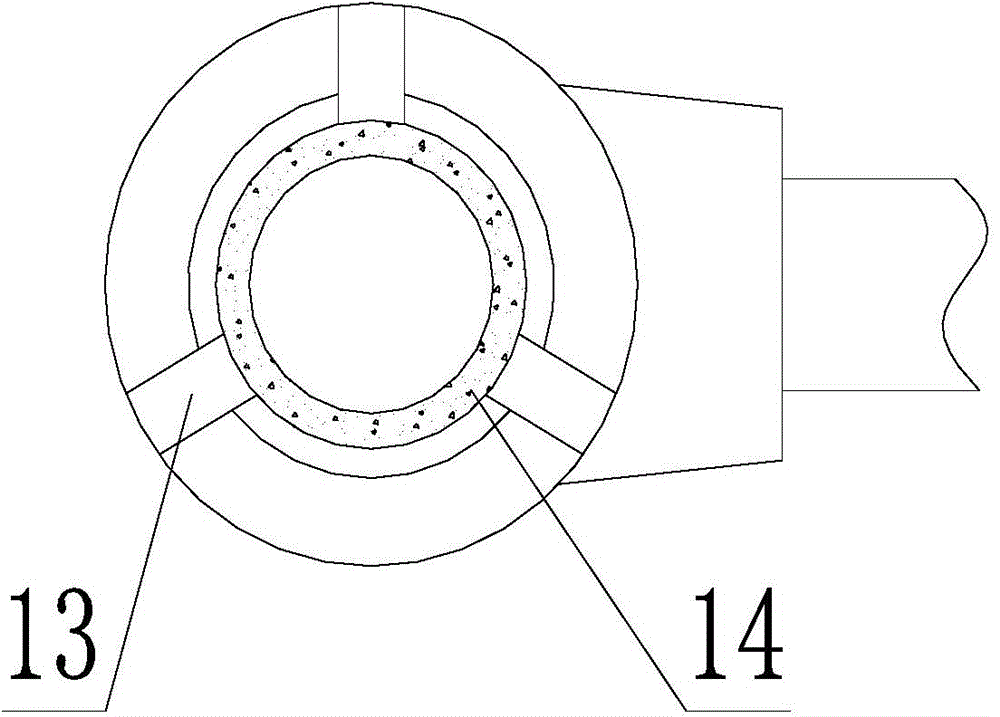

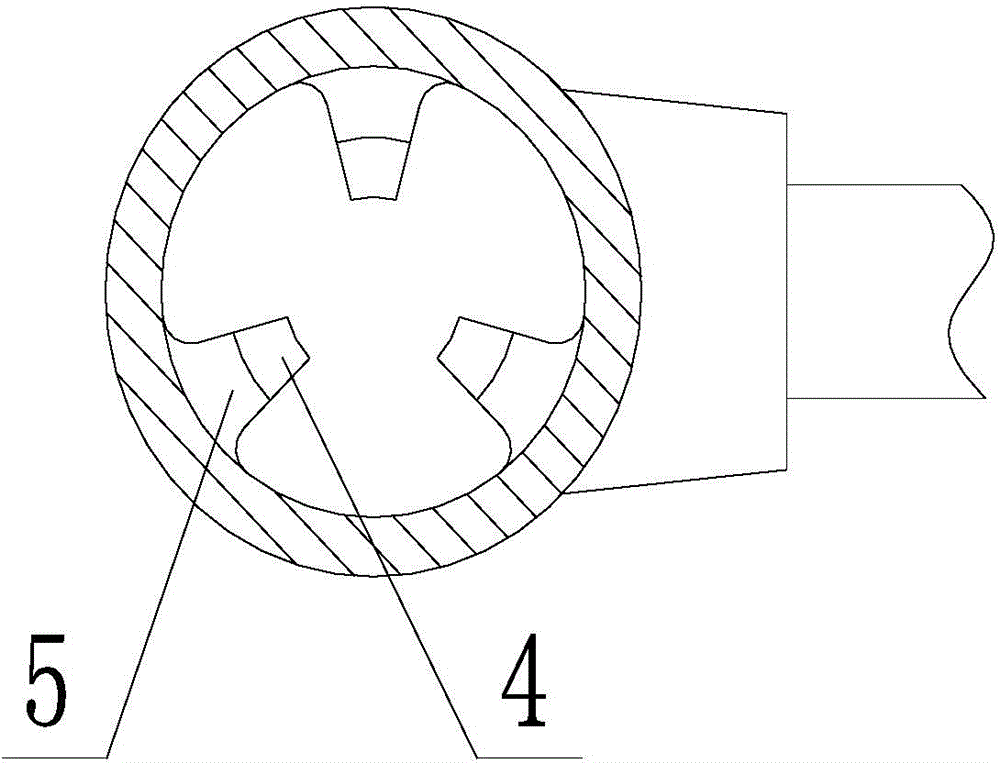

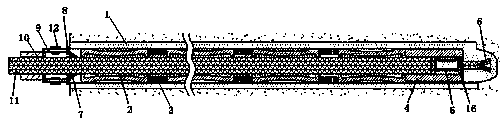

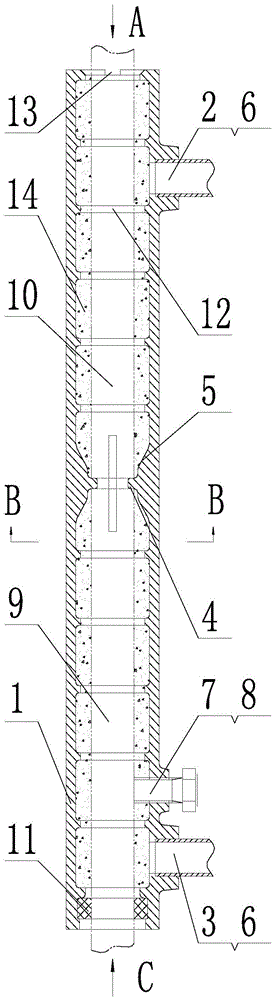

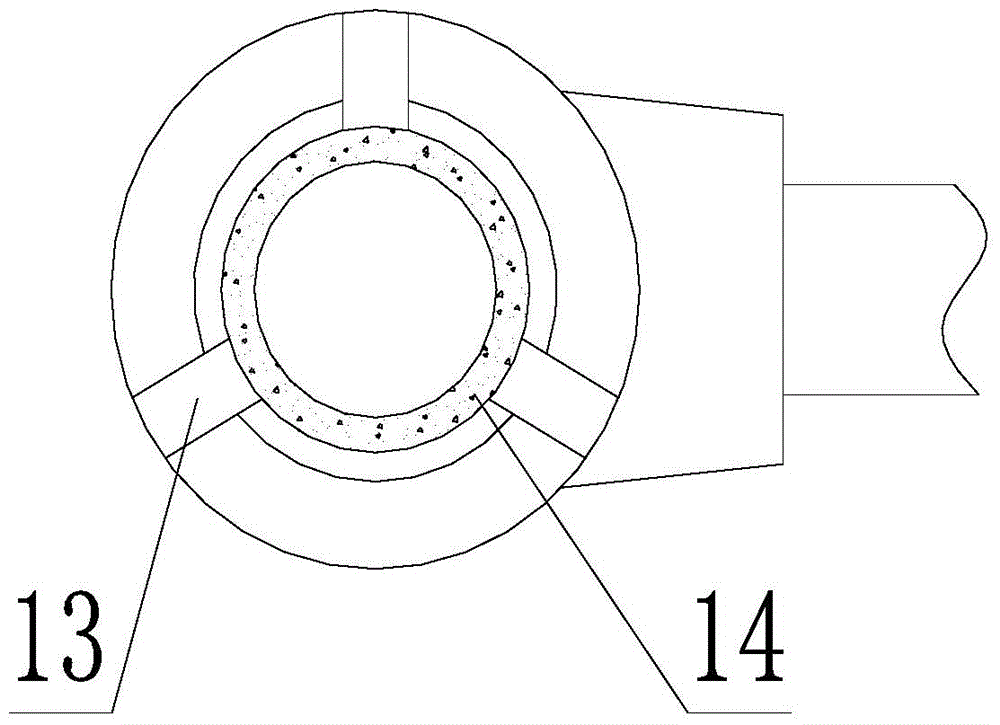

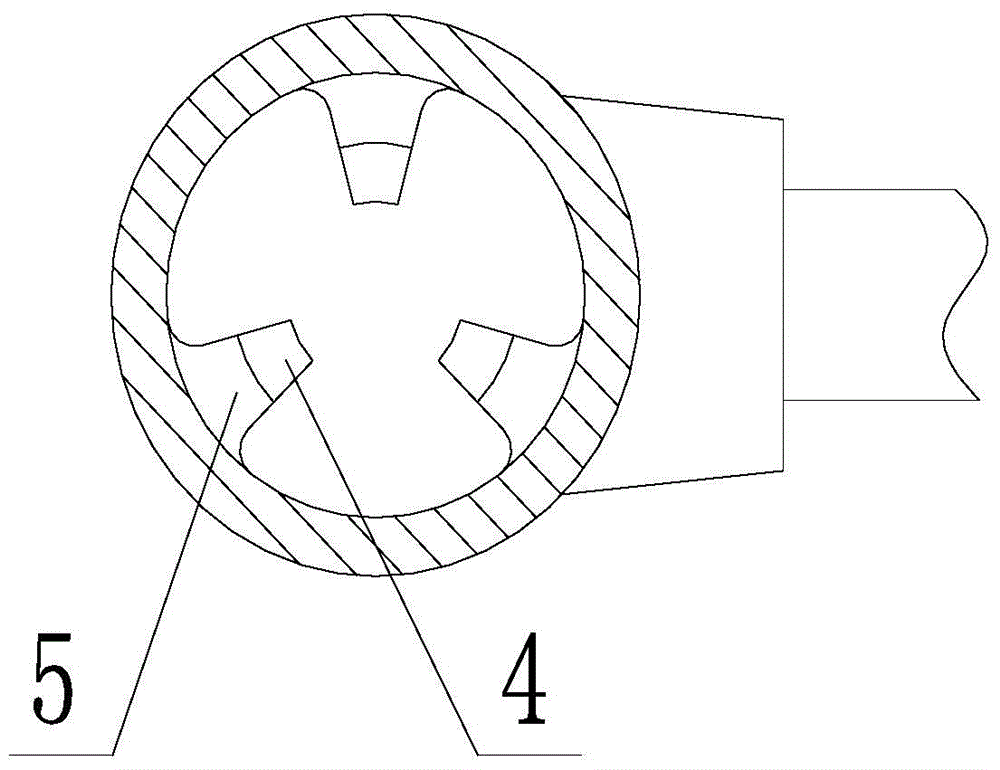

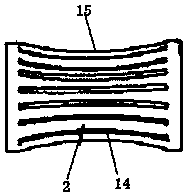

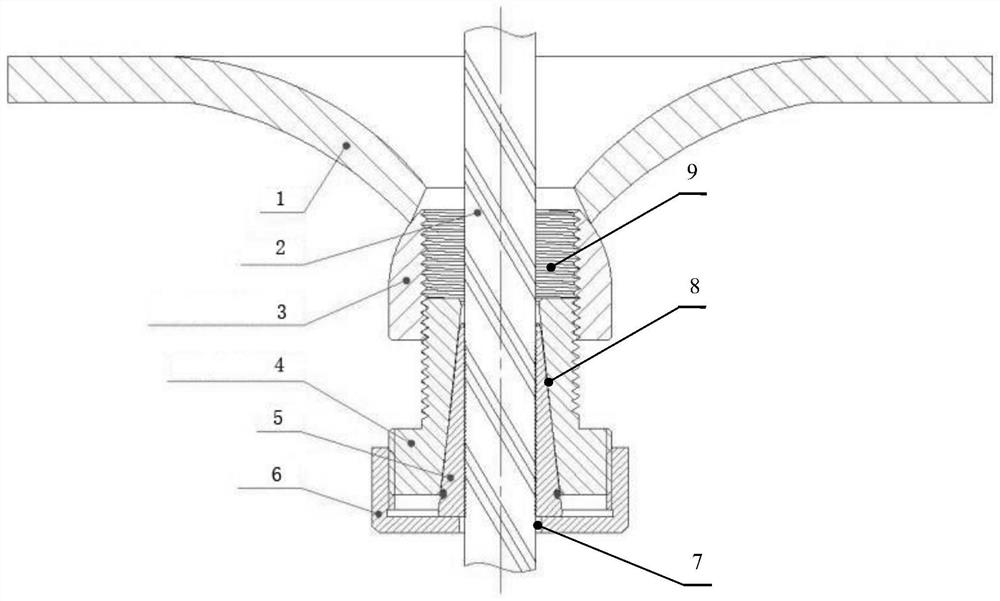

Quickly mounted efficient energy-absorbing mining anchor rod

The invention discloses a quickly mounted efficient energy-absorbing mining anchor rod which comprises an expansion shell, a rod head, a rod body, a tray, an anti-seismic buffering material, a nut and a rod tail, wherein a tooth-shaped bulge is arranged on the outer surface of the expansion shell; matched threads are respectively arranged on the inner surface of the expansion shell and the outer surface of the rod head; a tapered bulge is arranged in the expansion shell; a tapered groove is arranged at the top of the rod head; a vertex angle of the tapered bulge is more than the vertex angle of the tapered groove; the thread is arranged on the rod tail; and the tray and the anti-seismic buffering material are respectively sleeved on the rod tail and are positioned and pre-tensioned by the nut. According to the invention, quick loading is realized by the anchor rod; mounting process is simplified; mounting time is shortened; driving speed is increased; the anti-seismic buffering material has a compressing buffering function when rock is burst, so as to effectively resist the dynamic loading effect at rock bursting moment; a certain anchoring force is kept by the anchor rod; and the anchor rod is prevented from being broken and invalid. Besides, the quickly mounted efficient energy-absorbing mining anchor rod has the beneficial effects of simple structure, convenience in mounting, high operability, and the like, and is widely applied to underground supporting for deep well.

Owner:CENT SOUTH UNIV

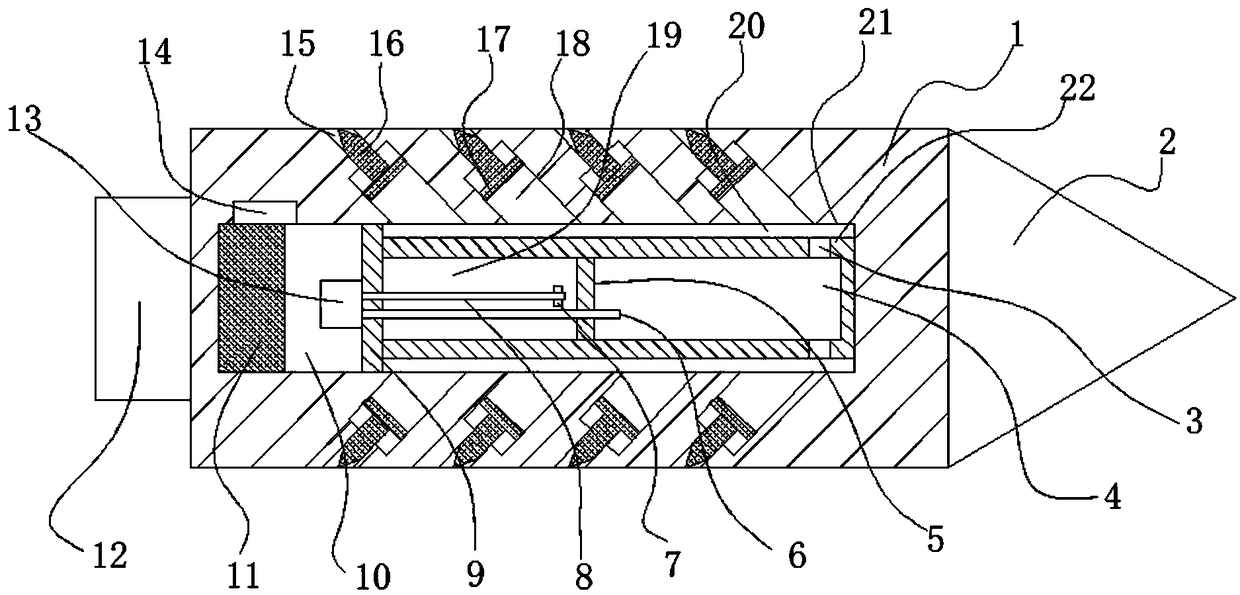

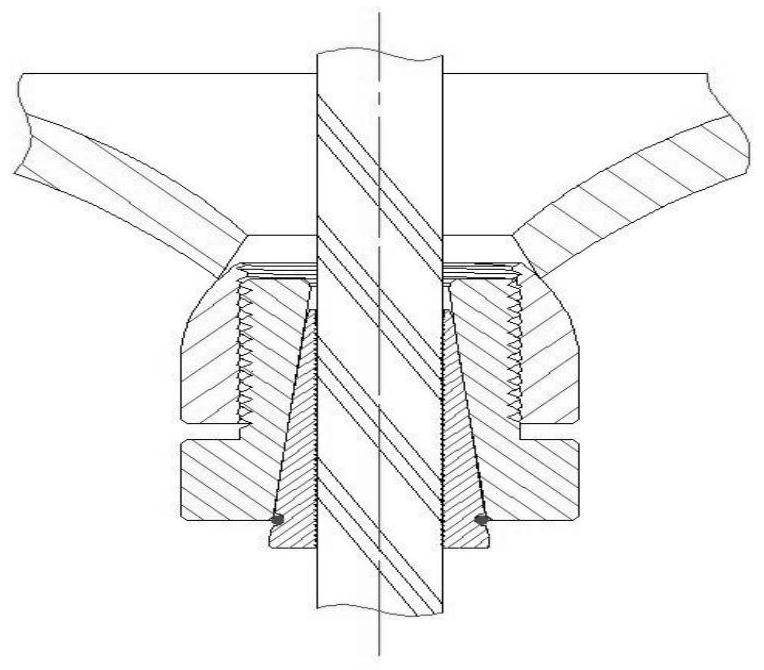

Magnesium-based metal-soluble bridge plug

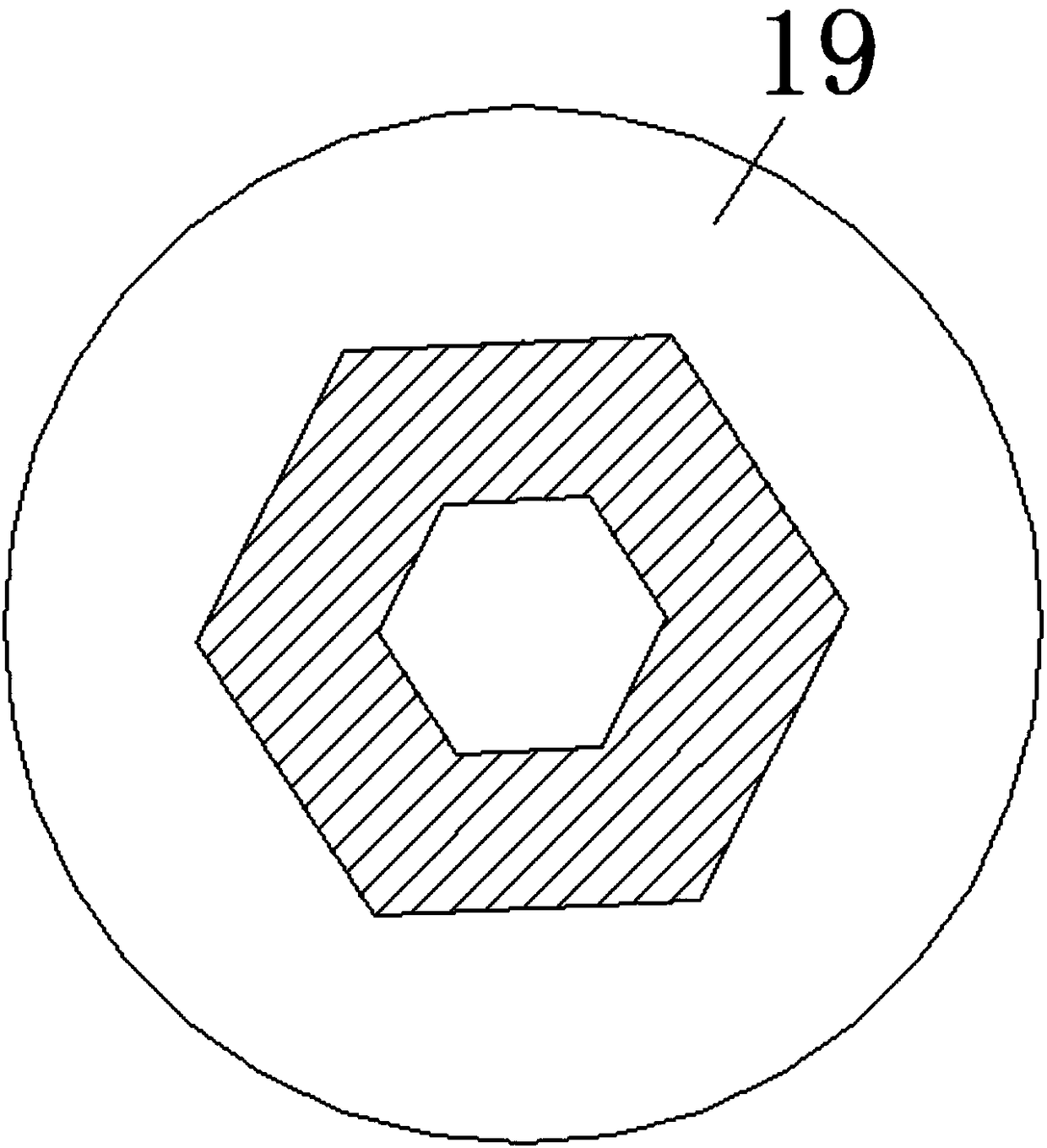

InactiveCN109236230AGuaranteed anchoring effectGuaranteed anchoring forceSealing/packingMetallic materialsEngineering

The invention discloses a magnesium-based metal-soluble bridge plug. The magnesium-based metal-soluble bridge plug comprises a central tube, a releasing shear nail, a spacer ring, an upper slip, an upper conical body, a rubber cylinder, a protective ring, a lower conical body, a lower slip, a base and an anti-blocking pattern tube; the spacer ring, the upper slip, the upper conical body, the rubber cylinder, the protective ring, the lower conical body and the lower slip separately sleeve the central tube from top to bottom in sequence, and the base is connected with the central tube through anexternal thread of the lower end of the central tube; the upper end of an outer setting cylinder is connected with an ignition setting tool through a T-shaped thread. Compared with the prior art, themagnesium-based metal-soluble bridge plug has the advantages that a magnesium-based soluble metal material is adopted, and the dissolution performance is reliable; an upper-and-lower bidirectional integral slip structure is adopted, the integral slip junction is broken when the thrust reaches 2-3 t, and the slips are opened; slip teeth adopt combinations of ceramic particles and alloy particles to ensure an anchoring effect and an anchoring force; the base has an anti-rotation structure design, and the plug is drilled conveniently when plug drilling is needed in a short time due to sand blockage or complicated well bottom conditions.

Owner:CNPC BOHAI DRILLING ENG

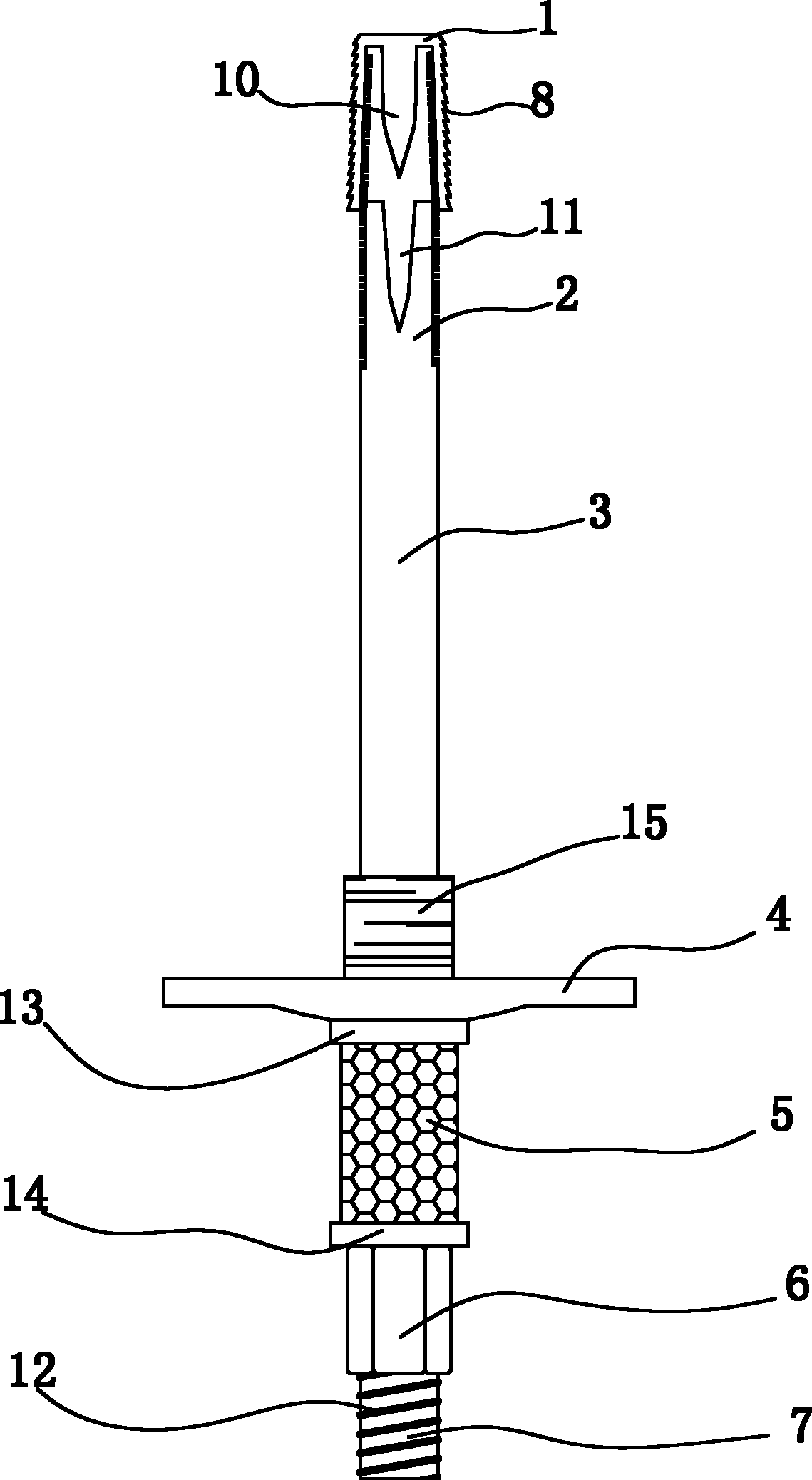

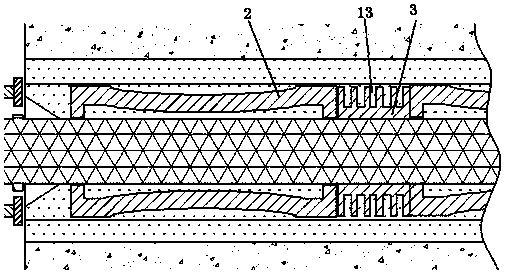

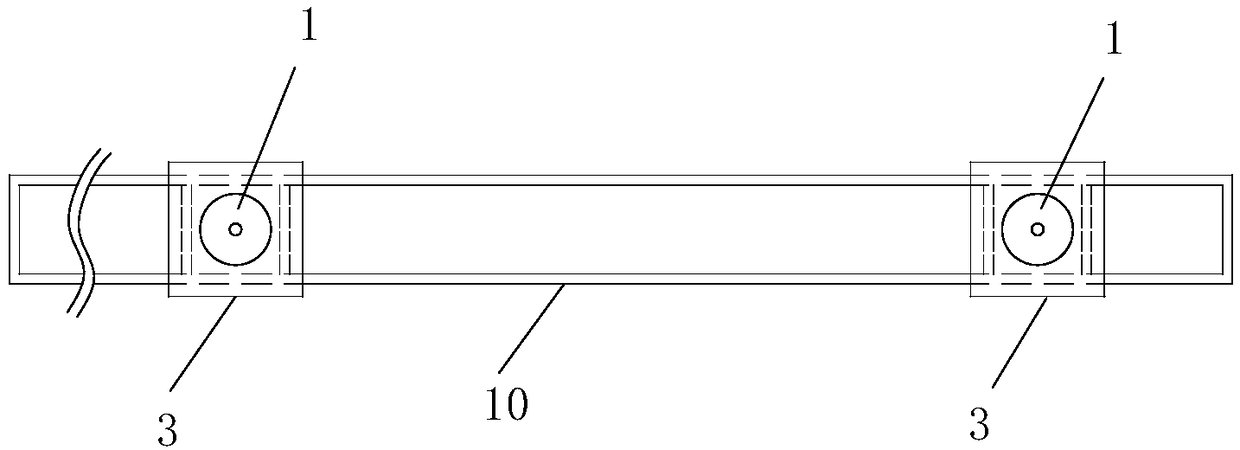

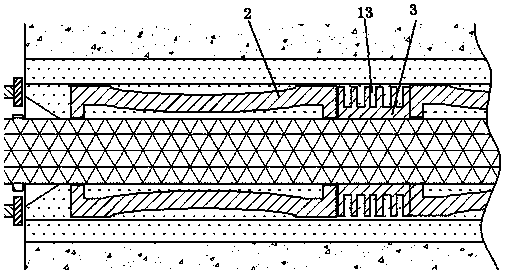

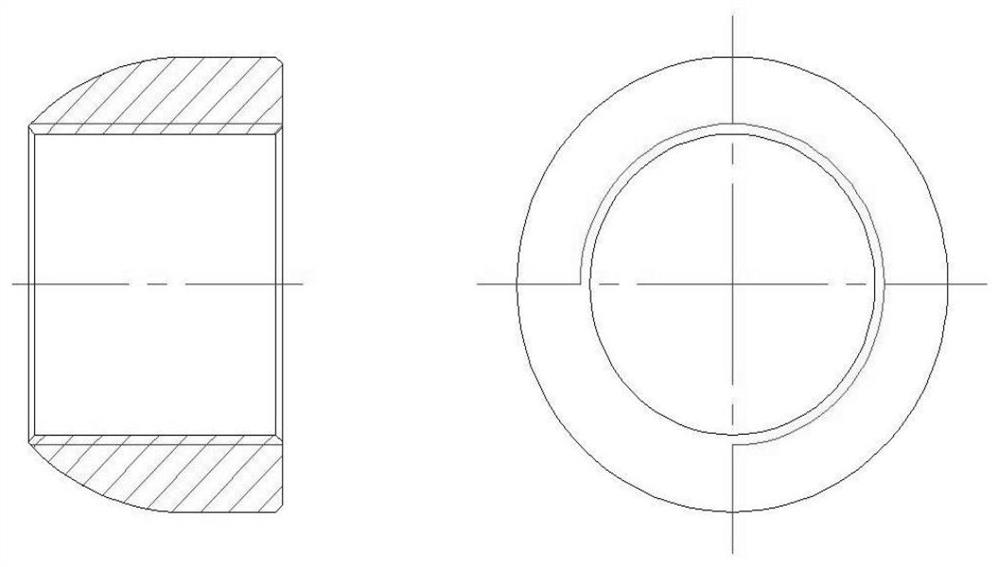

Full-grouting sleeve for connection of construction reinforcing steel bars

InactiveCN104358360APrevent reverse installationGuaranteed positioning accuracyBuilding reinforcementsButt jointArchitectural engineering

The invention discloses a full-grouting sleeve for connection of construction reinforcing steel bars, and belongs to the technical field of building projects. A reinforcing steel bar axial-limiting guide stop dog is arranged on the inner wall in the middle of a sleeve main body; guide slopes are arranged between the stop dog and the inner wall of the sleeve main body; a positioning bolt is arranged on the sleeve main body at the prefabricated end; the reinforcing steel bar at the prefabricated end is axially and radially fixed through the positioning bolt; the sleeve main body is molded by one-step casting of spheroidal graphite cast iron, so that the production cost is low; the outer surface of the sleeve main body serves as a roughened surface, so as to ensure the anchoring force between the grouting sleeve and the concrete; a plurality of convex hooping ribs are arranged on the inner wall of the grouting sleeve; an identification gap is formed in the port face of the sleeve main body at the field poured end, so as to prevent the situation that the grouting sleeve is installed reversely; a seal ring is arranged inside the port of the sleeve main body at the prefabricated end. When the grouting sleeve disclosed by the invention is in axial butt joint with the reinforcing steel bar, the precise axial control can be automatically realized, and the radial positioning can be automatically realized, so as to ensure the positioning accuracy between the reinforcing steel bar and the grouting sleeve, and meet the requirements on building construction quality.

Owner:SHENYANG JIANZHU UNIVERSITY

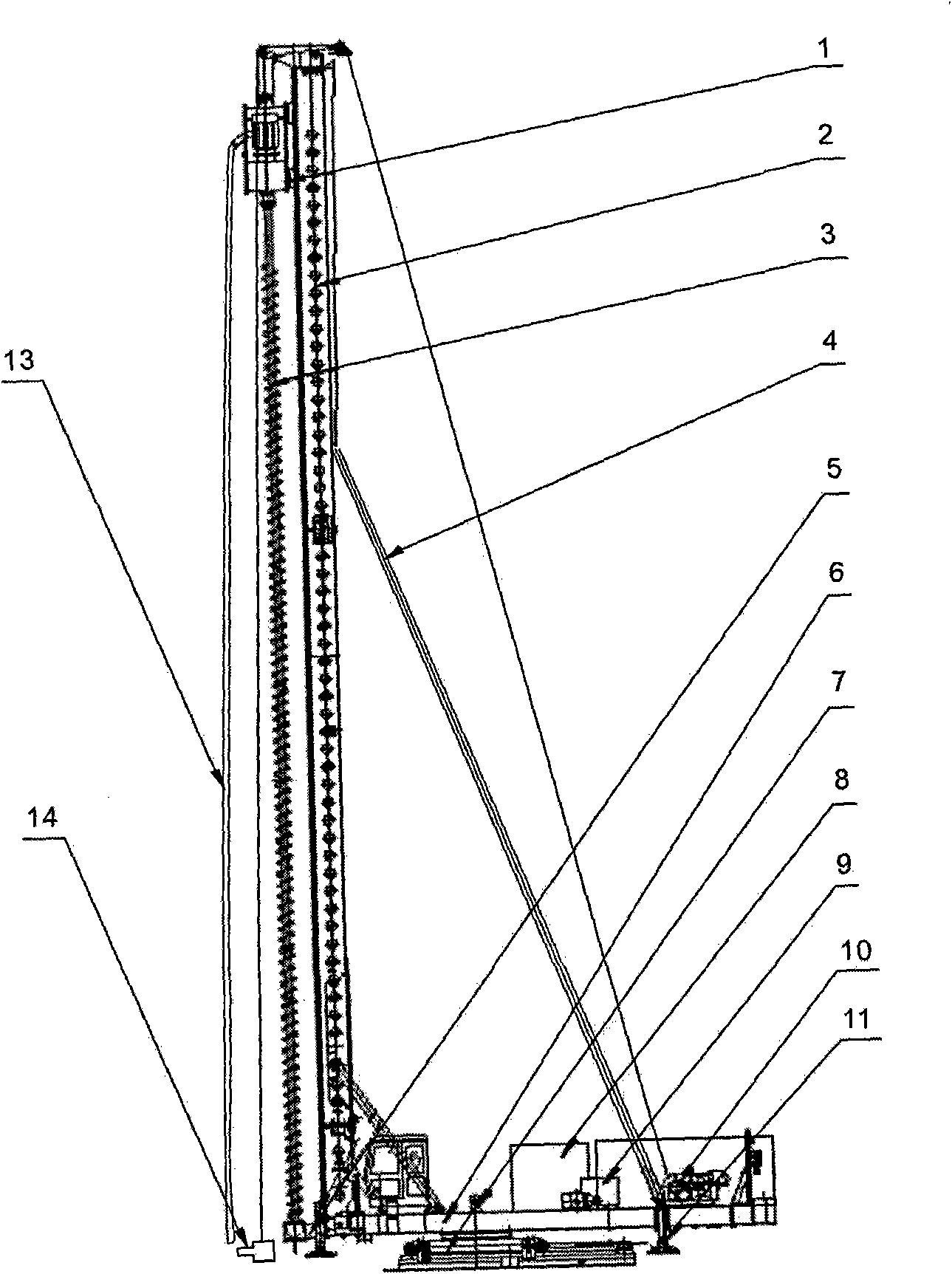

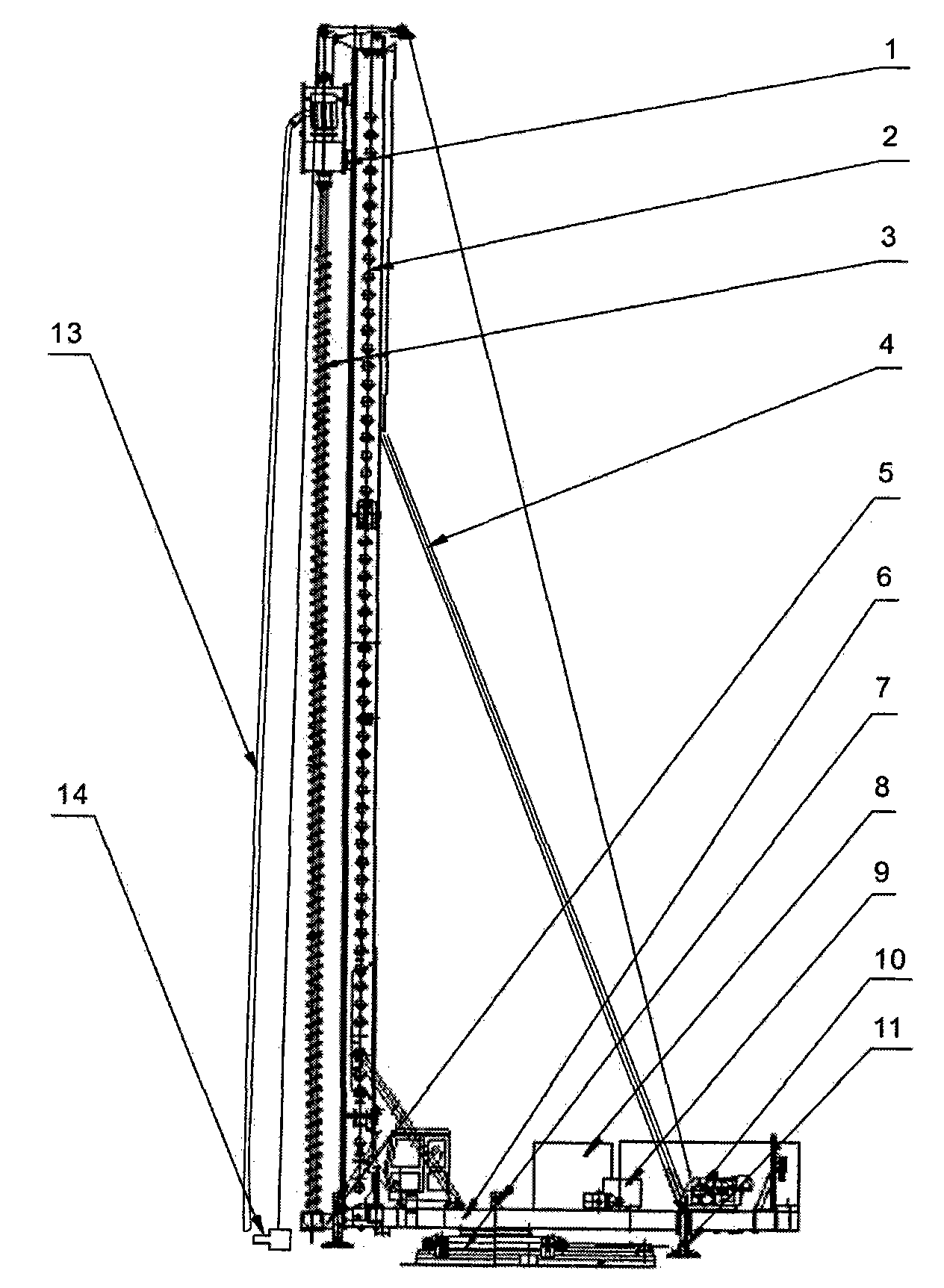

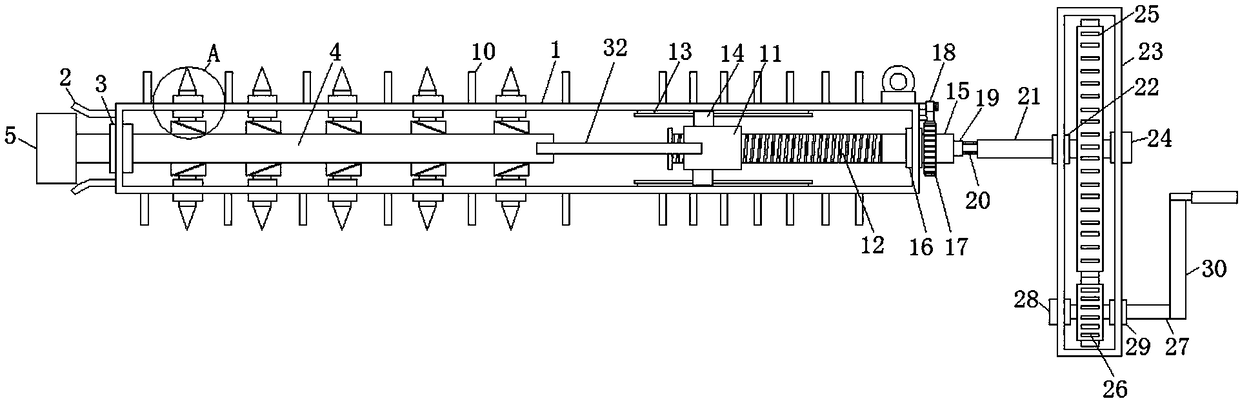

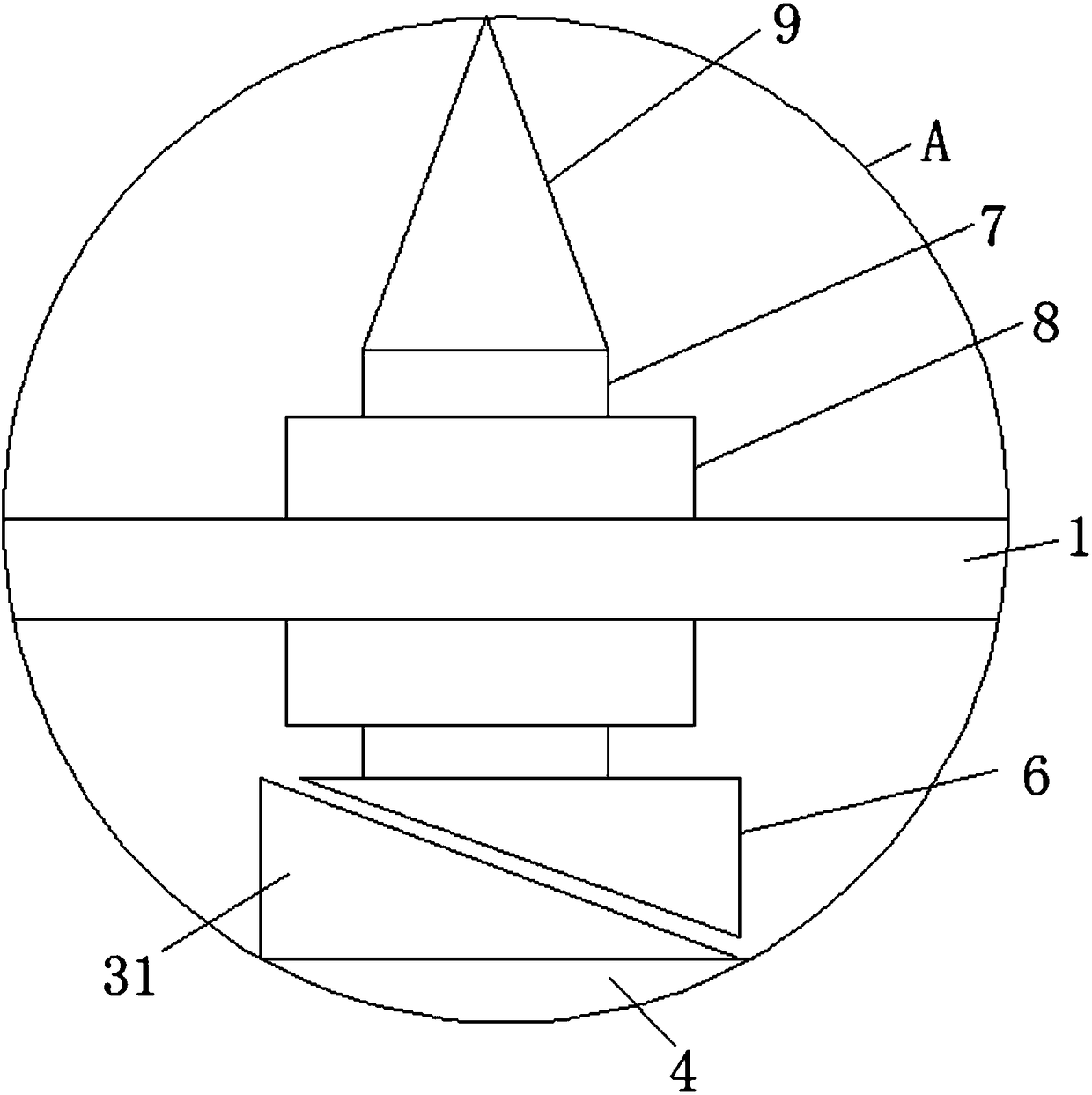

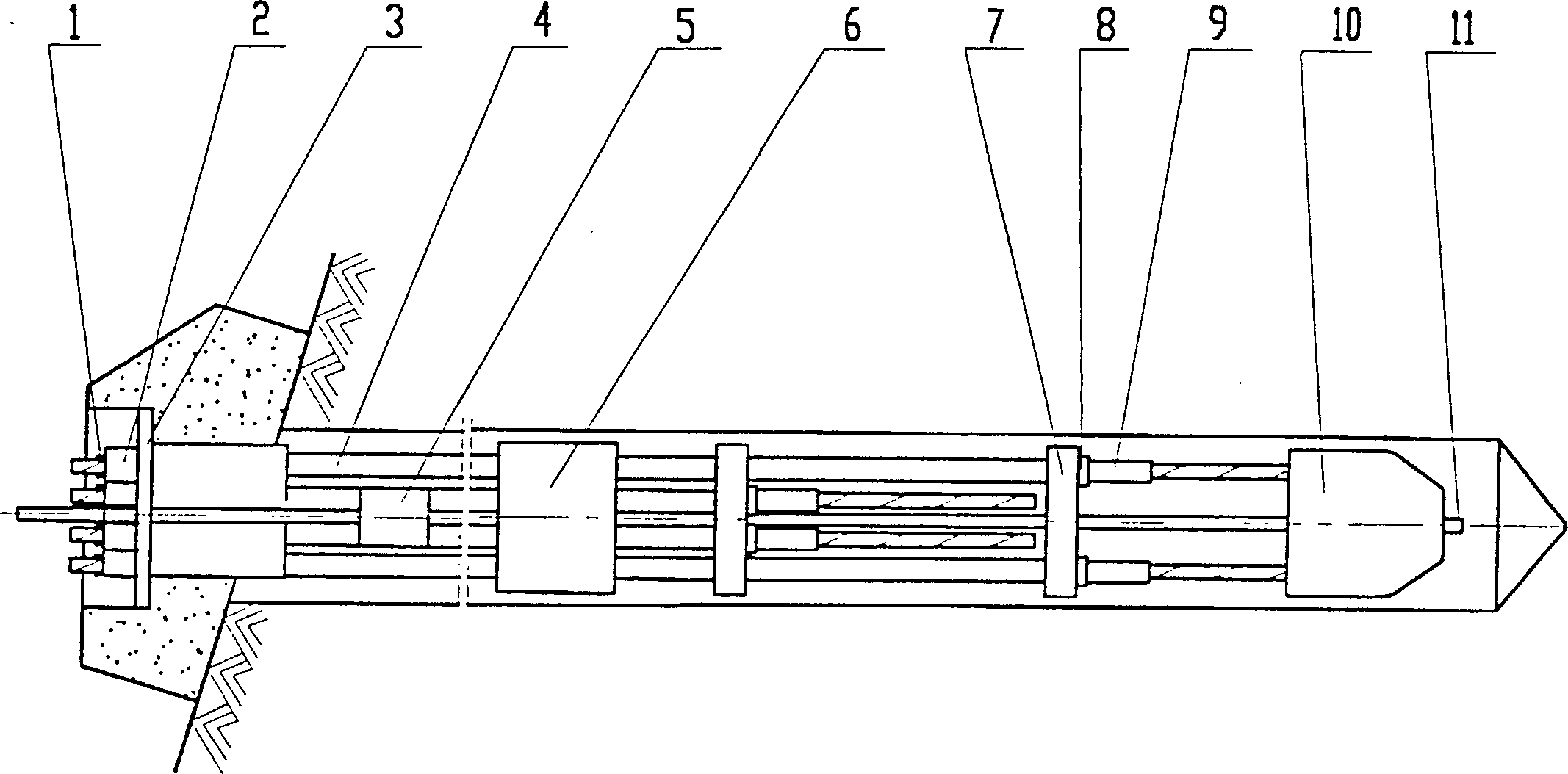

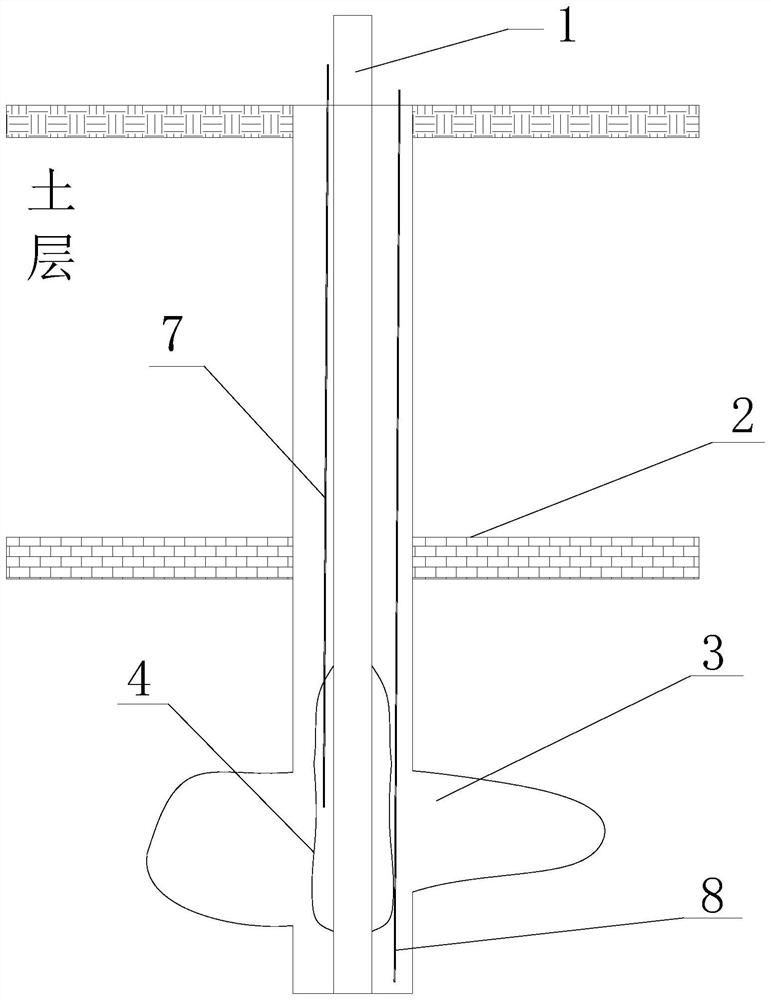

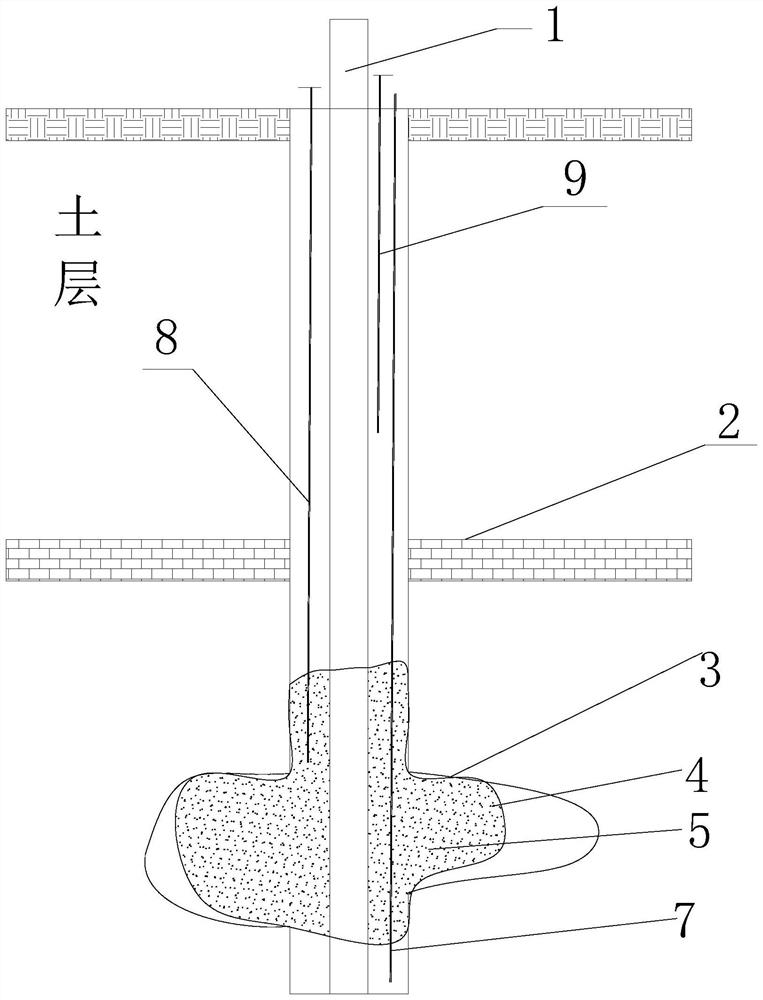

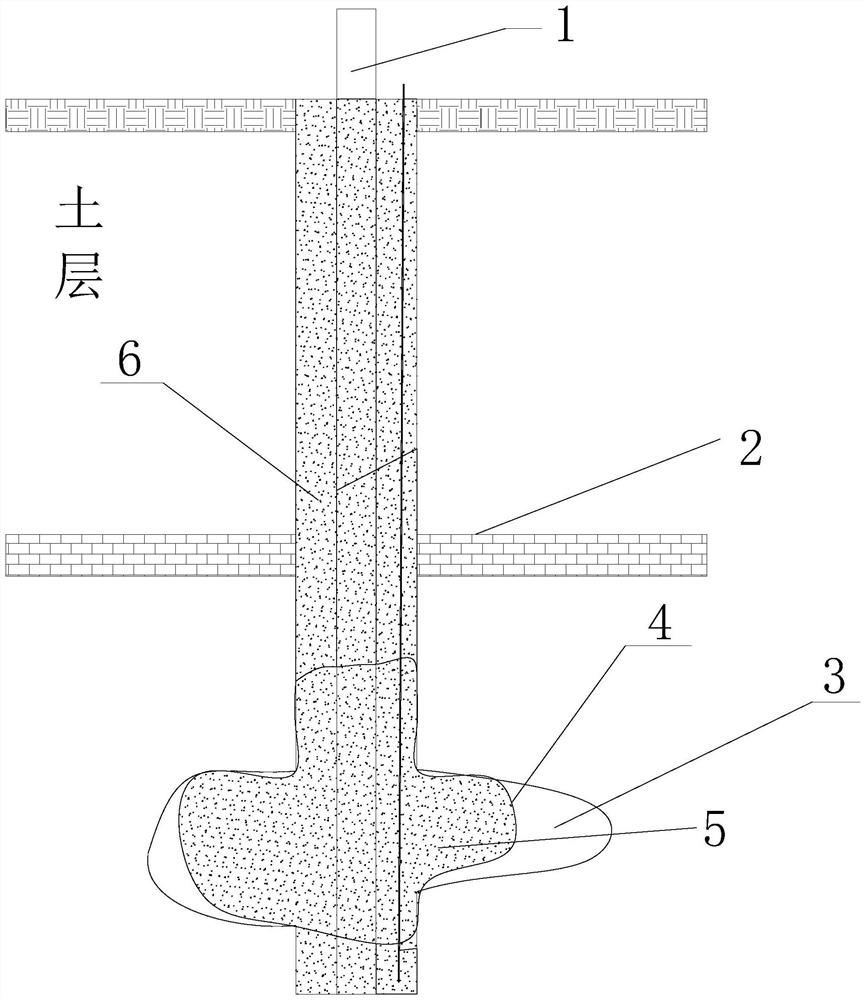

Construction method for anti-floating anchor rod and special long auger

InactiveCN101914915AGuaranteed lengthGuaranteed anchoring forceDrilling rodsRotary drillingEngineeringMaterial resources

The invention discloses a construction method for an anti-floating anchor rod and a special long auger. The long auger replaces a traditional hydraulic anchor rod drilling machine or a rotary drilling machine for anti-floating anchor rod construction; and the long auger is modified so as to perform small-bore diameter drilling construction and high pressure grouting. By fully utilizing high construction speed, dry bore formation, capacity of lifting the anchor rod, and other characteristics of the long auger, the construction method for the anti-floating anchor rod has the advantages of capacity of improving the construction efficiency of the anti-floating anchor rod by over ten times, no on-site mud bore formation, cleanliness, neatness, bore-forming material conservation, capacity of greatly saving manual labor, material resources and financial resources by employing the long auger for anti-floating anchor rod construction, and certain environmental protection.

Owner:YANTAI ENG INVESTIGATION

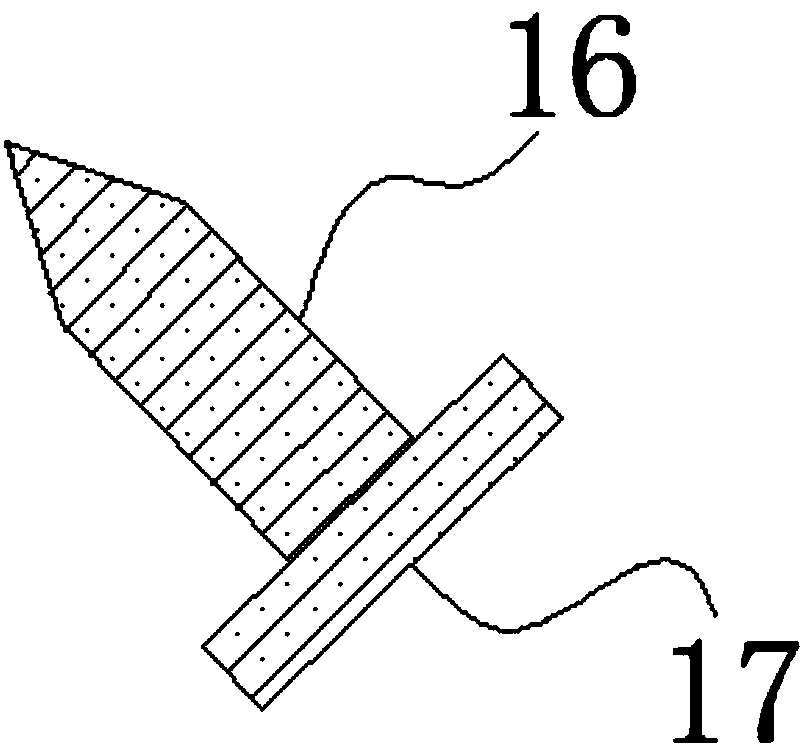

Reinforcing anchor rod for tunnel construction

ActiveCN108412527AIncrease anchoring forceGuaranteed anchoring forceAnchoring boltsMetal sheetRock bolt

The invention relates to the technical field of construction tools and discloses a reinforcing anchor rod for tunnel construction. The reinforcing anchor rod comprises a rod body, one side of the rodbody is fixedly connected with one side of each metal sheet and in insertion connection with one side of a slide sleeve, and the inner wall of the slide sleeve is in sleeve connection with the surfaceof a slide rod. One side of the slide rod is fixedly connected with one side of a retaining block, the top of the slide rod is fixedly connected with the bottom of each first oblique block, the top of each first oblique block is in lap joint with the bottom of a second oblique block, and the top of each second oblique block is fixedly connected with the bottom of a moving rod. The reinforcing anchor rod for tunnel construction has advantages that by reinforcing rods fixedly connected to the surface of the rod body, the metal sheets fixedly connected to one side of the rod body, a rotating rod, a threaded rod, a threaded sleeve, a pull rod, the slide rod, the retaining block, the first oblique blocks, the second oblique blocks, the moving rods, fixing sleeves and sharp blocks, when the threaded sleeve moves, the retaining block pushes the metal sheets to warp to increase the anchoring force, and then the sharp blocks are inserted into soil to enhance the anchoring force of the anchor rod.

Owner:ANHUI QIANYI INTELLIGENT EQUIP CO LTD

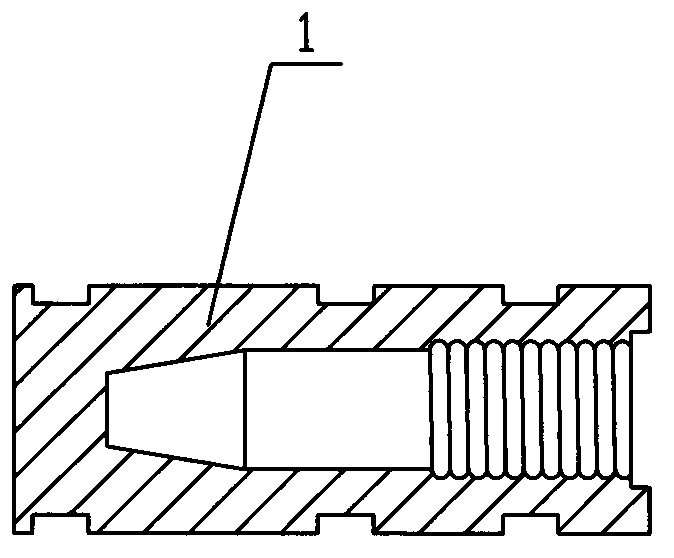

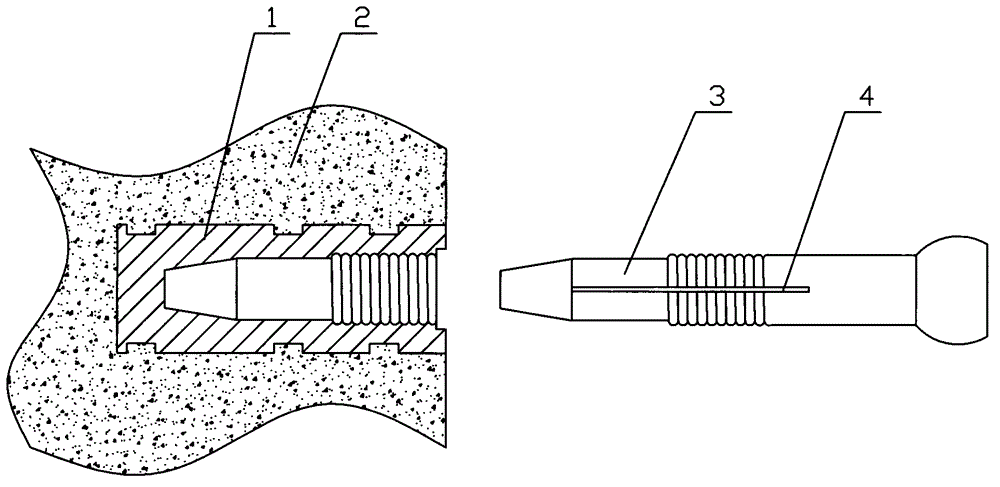

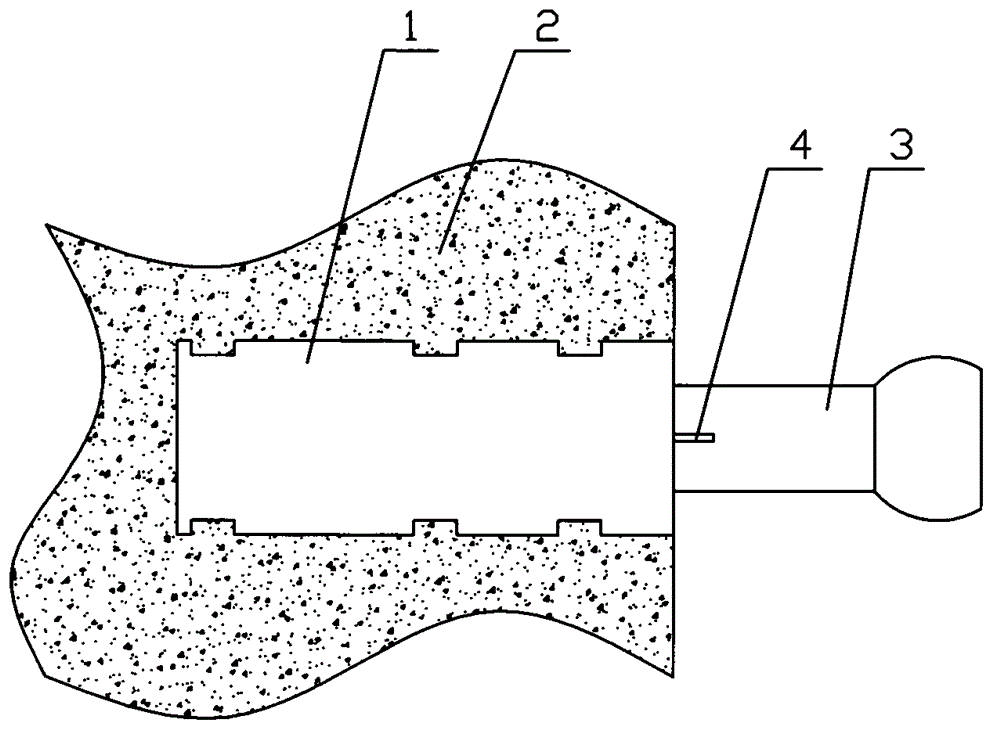

Embedded part on settlement observation point and application method thereof

InactiveCN102721414AIncreased durabilityImprove securityMeasuring points markingHeight/levelling measurementObservation pointEmbedded system

The invention provides an embedded part on a settlement observation point and an application method thereof. The embedded part on the settlement observation point consists of an embedded bushing, a bolt and a screwed plug. Before concrete is poured on a building wall or a building column on a position where a settlement observation point is arranged, the embedded bushing is embedded on the position of a corresponding settlement observation point, then concrete is poured, and a sheath of the embedded bushing is guaranteed to be leveled to the skin of the building wall and the building column; when the observation of the settlement point is not carried out, the screwed plug is screwed into the embedded bushing; and when the observation of the settlement point is needed, the screwed plug is unscrewed, the bolt is screwed into the embedded bushing, and then the settlement point is observed. Compared with the prior art, the sheath of the embedded bushing is guaranteed to be leveled to the skin of the building wall and the building column, so that the safety of the settlement observation point during the non-observation period is guaranteed, the overlong exposed length of the embedded bushing is prevented from influencing the walking of personnel, manmade destruction factors can be reduced, and the settlement observation point is more beautiful.

Owner:CHINA CONSTR EIGHTH ENG DIV

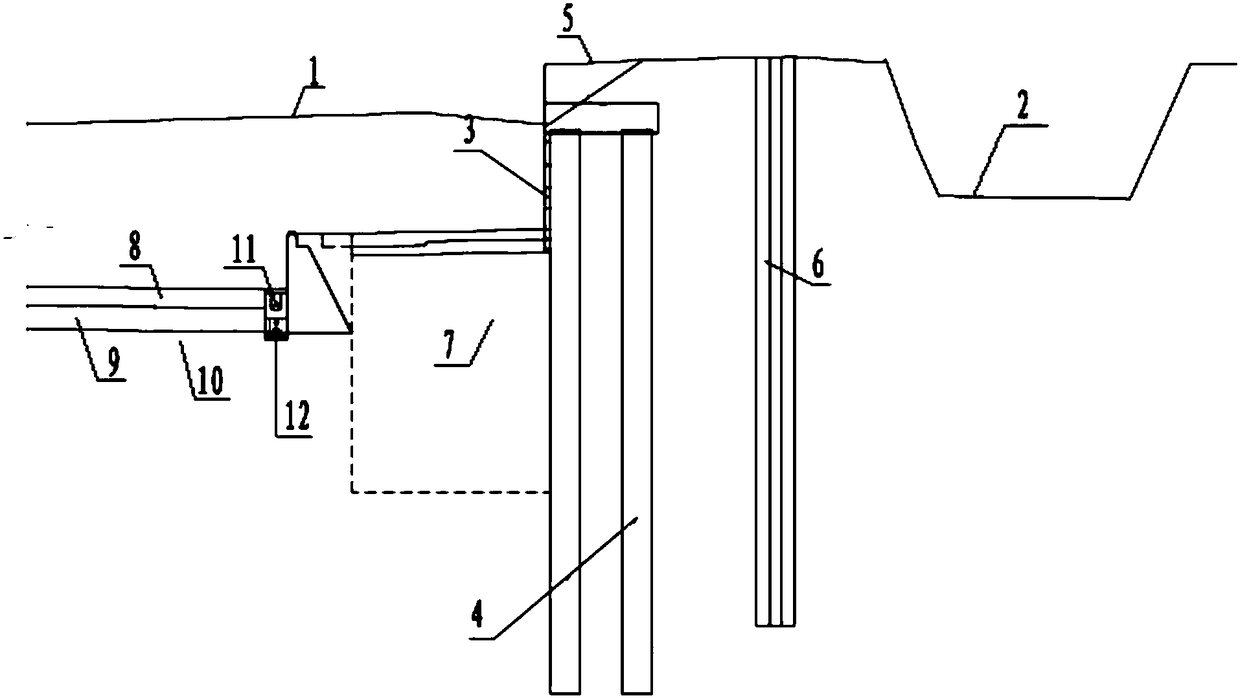

Construction method for underground water road cutting for road in area along river during crossing underneath existing railway

InactiveCN108571000ALower the water levelGuarantee the construction qualityArtificial islandsPaving gutters/kerbsEngineeringRoad surface

The invention discloses a construction method for an underground water road cutting for a road in an area along a river during crossing underneath existing railway. The method comprises steps as follows: a waterproof curtain is arranged by high-pressure rotary jet grouting piles in the original ground between the road and the river channel, and water in the river channel cannot perform convectivepenetration with the road cutting; a rotary drilling rig is adopted for drilling, and underwater concrete is poured; soil mass in front of the piles is reinforced by taking any one of composite foundation treatment measures of cement-mixed piles, multi-directional stirring cement mortar piles or CFG (cement flyash gravel) piles; excavation is performed and a hanging board is manufactured; drainageditches are excavated on two sides in the road cutting during excavation of the road cutting, water is collected to the low-lying section and underground water is drained to the outside of the road cutting by a water suction pump in a waterway drain manner; underground drainage systems such as longitudinal blind ditches and the like are constructed; a roadbed is subjected to replacement filling treatment and compaction. The construction method has beneficial effects as follows: the construction quality of the underground water road cutting in the area along the river is guaranteed, anchorageforce required by the design is provided by soil mass at anchorage sections of the double-row piles, stable roadbed slope and qualified road surface deflection are guaranteed, and the roadbed is prevented from being damaged by diseases.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

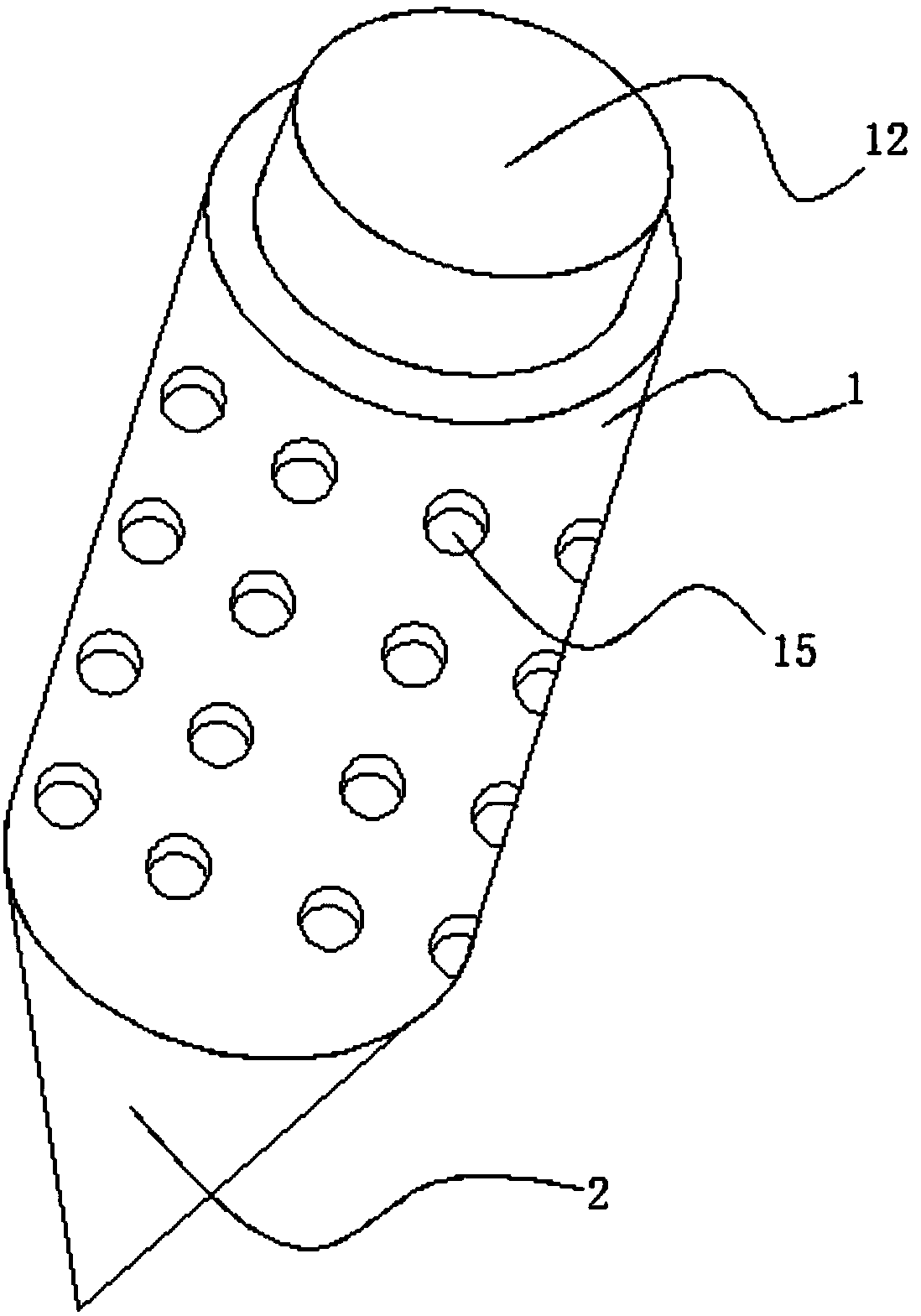

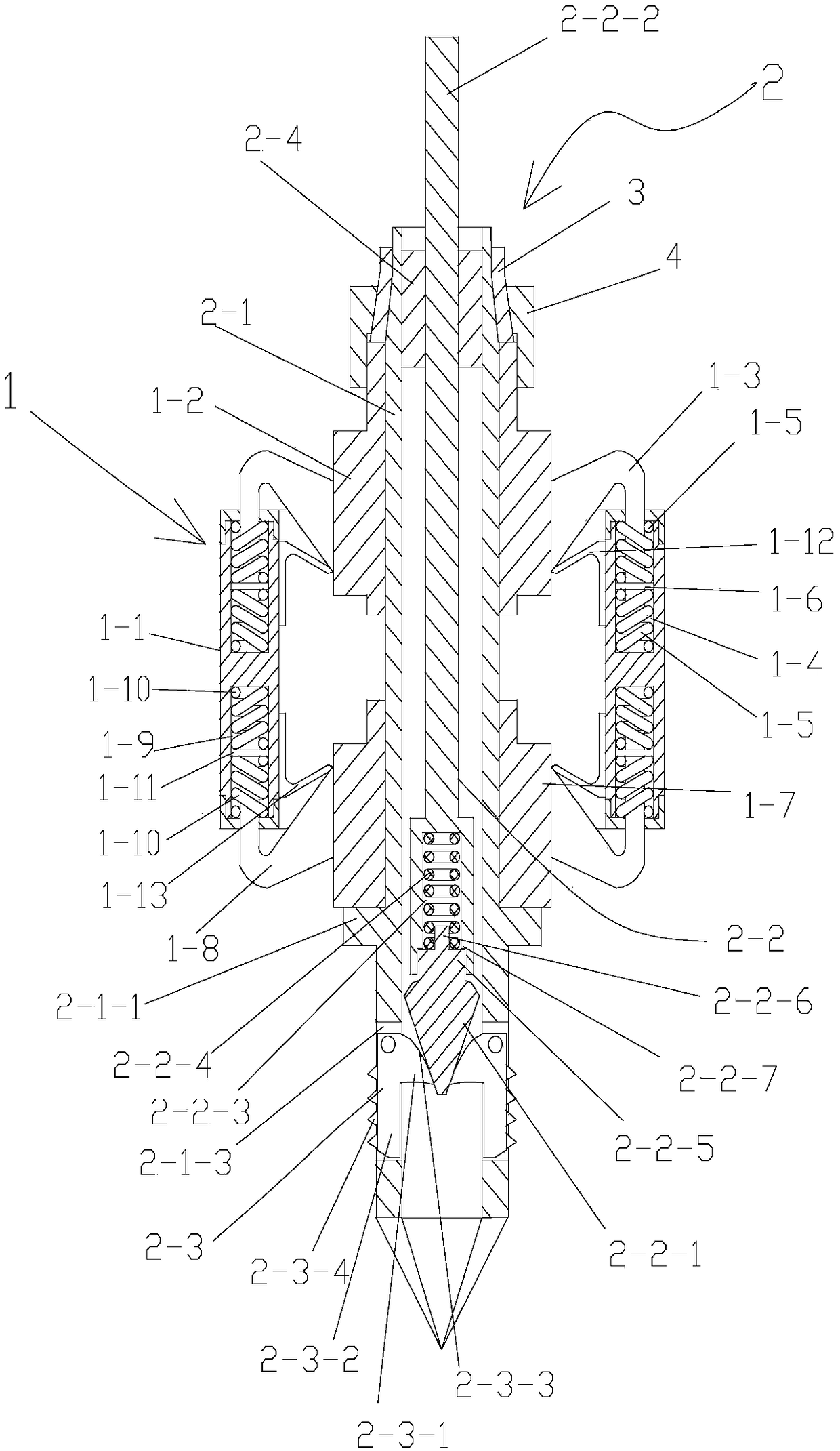

Soil extrusion expansion anchor rod structure

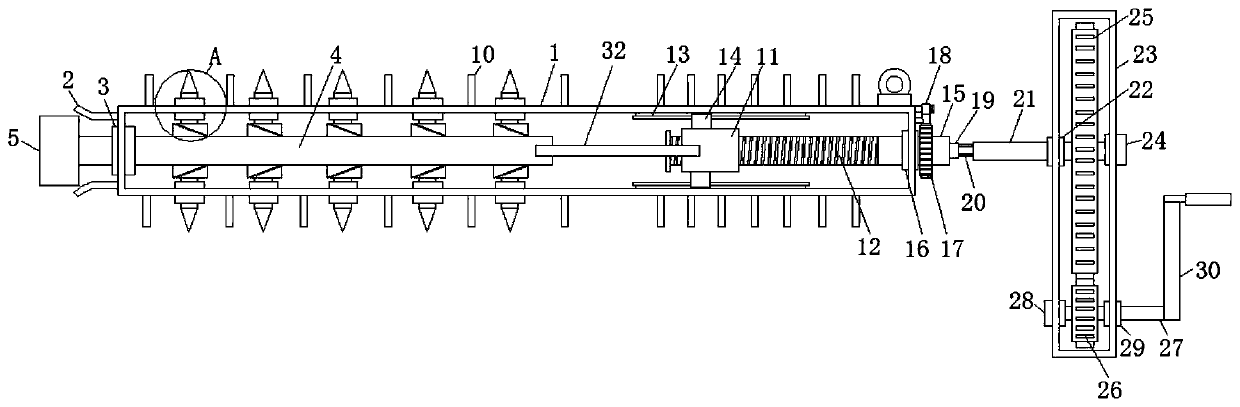

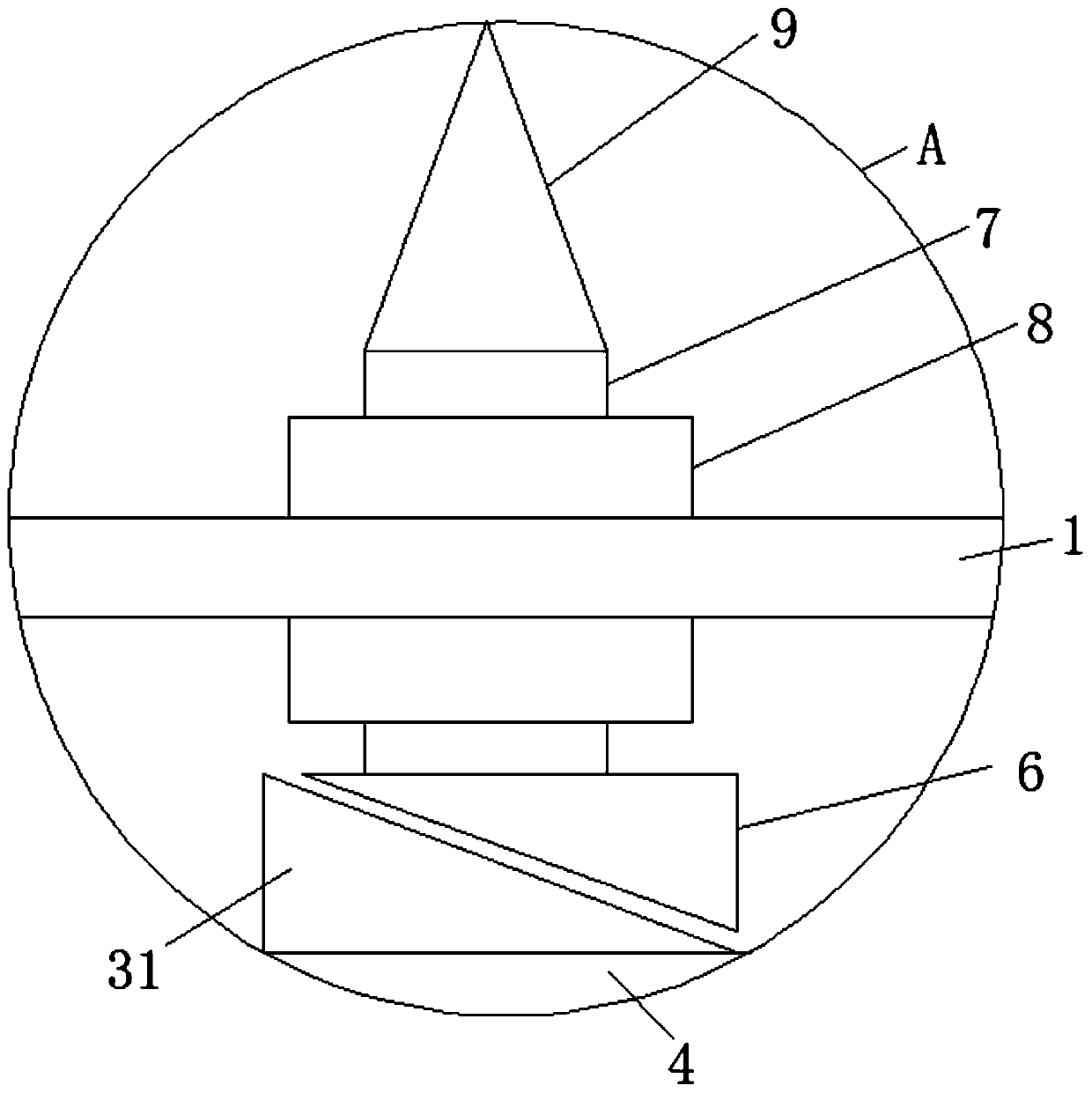

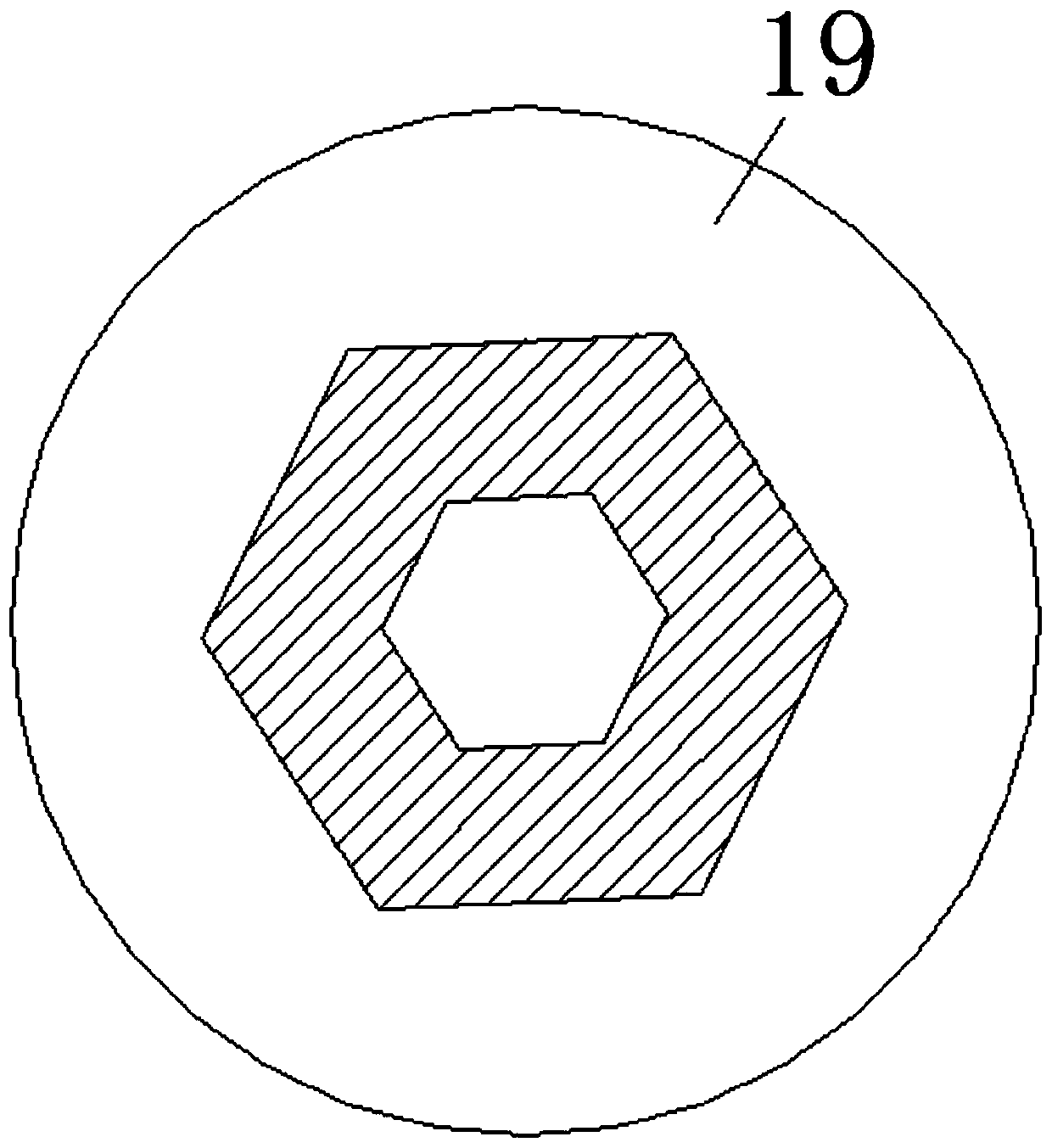

InactiveCN109487806AReduce frictional resistanceGuaranteed anchoring forceExcavationsBulkheads/pilesPistonEngineering

The invention discloses a soil extrusion expansion anchor rod structure. The structure comprises an anchor rod main body; the anchor rod main body is of a cylindrical structure integrally molded; a sharp end is arranged at the right end of the anchor rod main body; a mounting cavity is formed in the anchor rod main body; a sealing cover is fixed in a left port of the mounting cavity through welding; a transmission block is arranged in the anchor rod main body of the sealing cover; the transmission block is connected with a power mechanism for conveying devices into an anchor hole during acting; multiple piston cavities and storage holes are formed in a wall of the mounting cavity; storage cavities communicate with the piston cavities; piston plates are slidingly arranged in the piston cavities; and anchoring rods are fixed at the upper ends of the piston plates. The structure is optimized aiming at the defects of a traditional device, is provided with the anchoring rods capable of realizing extension storage, can reduce the friction resistance when conveying the anchoring rods in the anchor hole, guarantees the anchoring force, and achieves high practicability.

Owner:WEST ANHUI UNIV

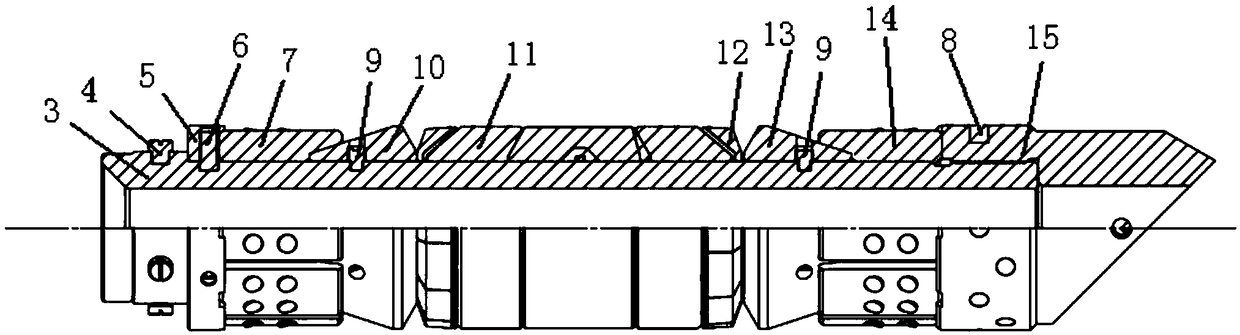

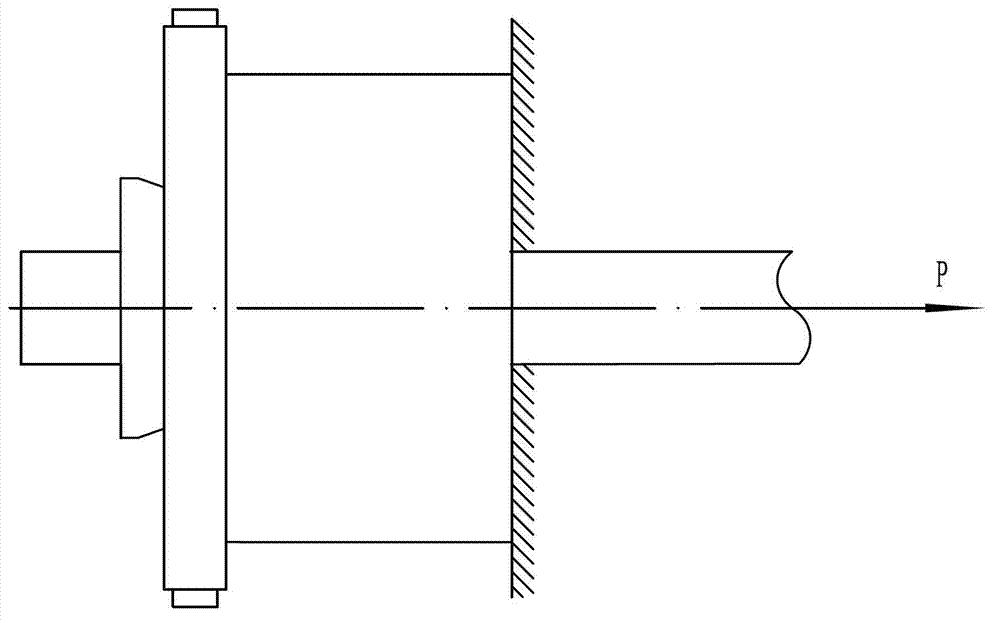

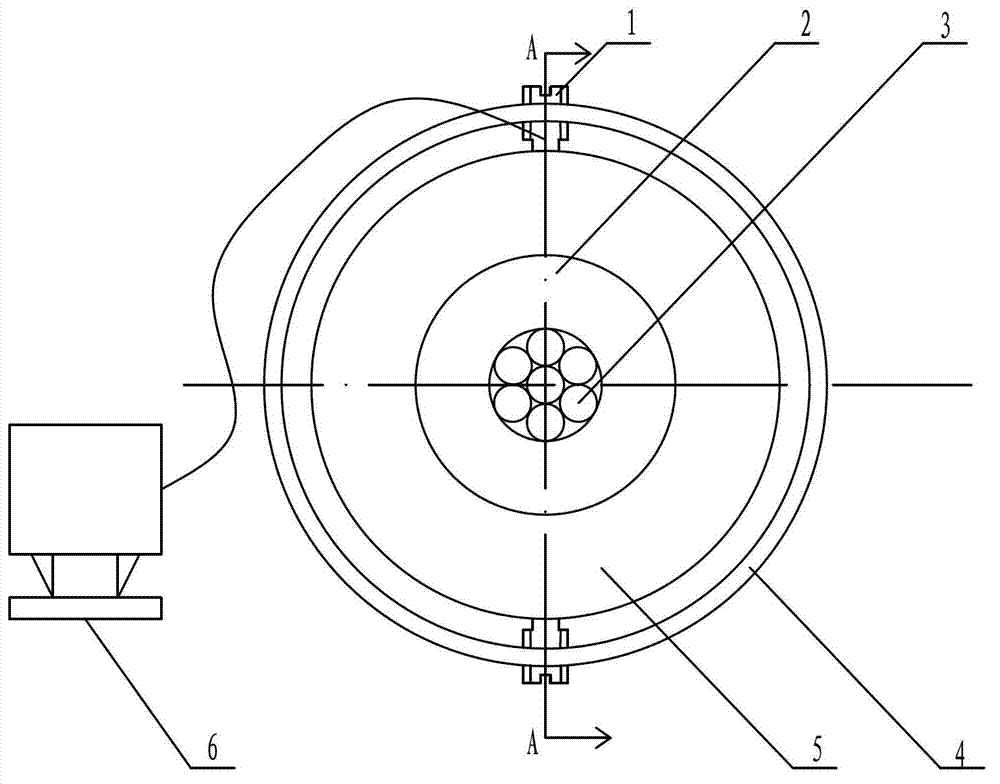

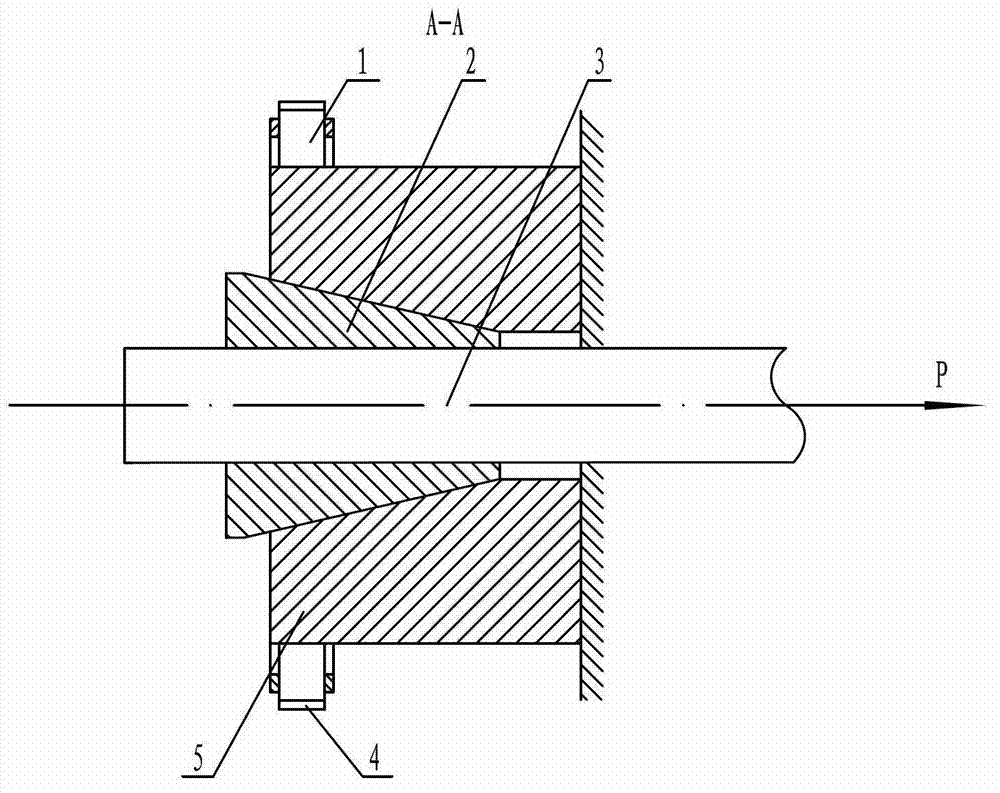

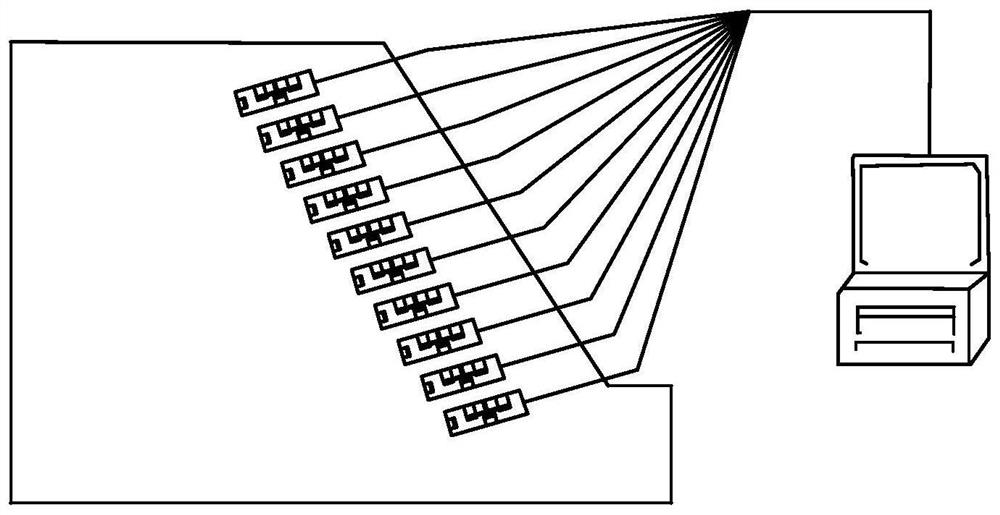

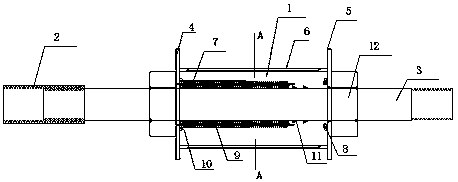

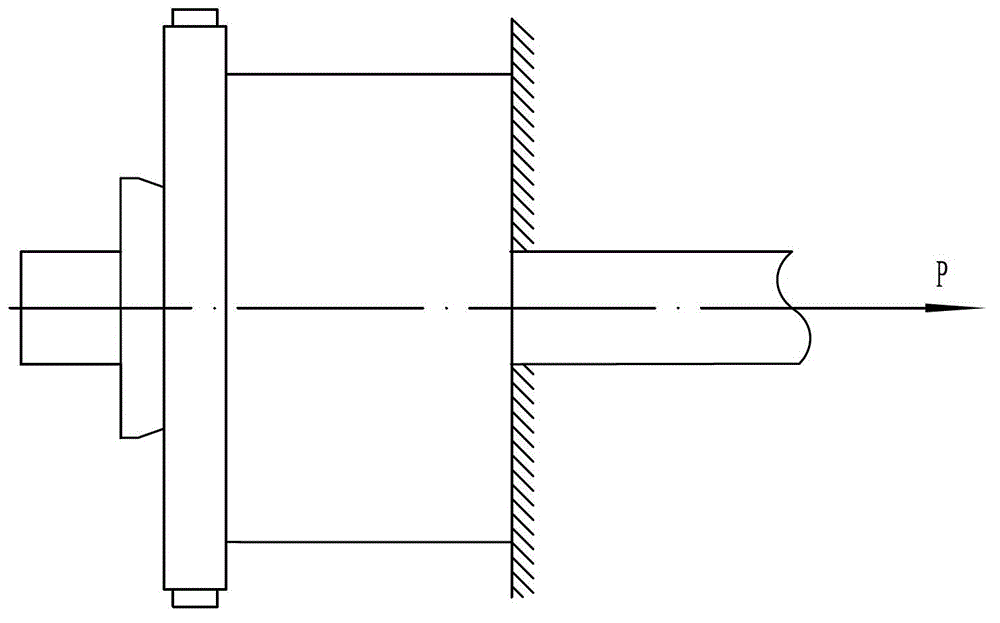

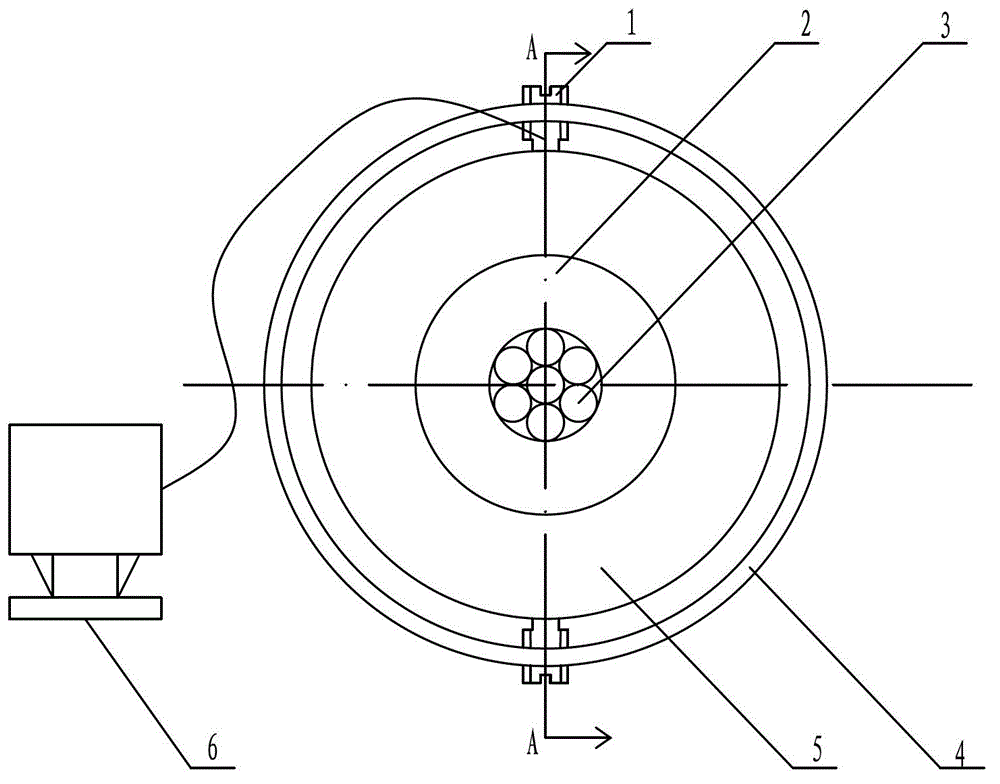

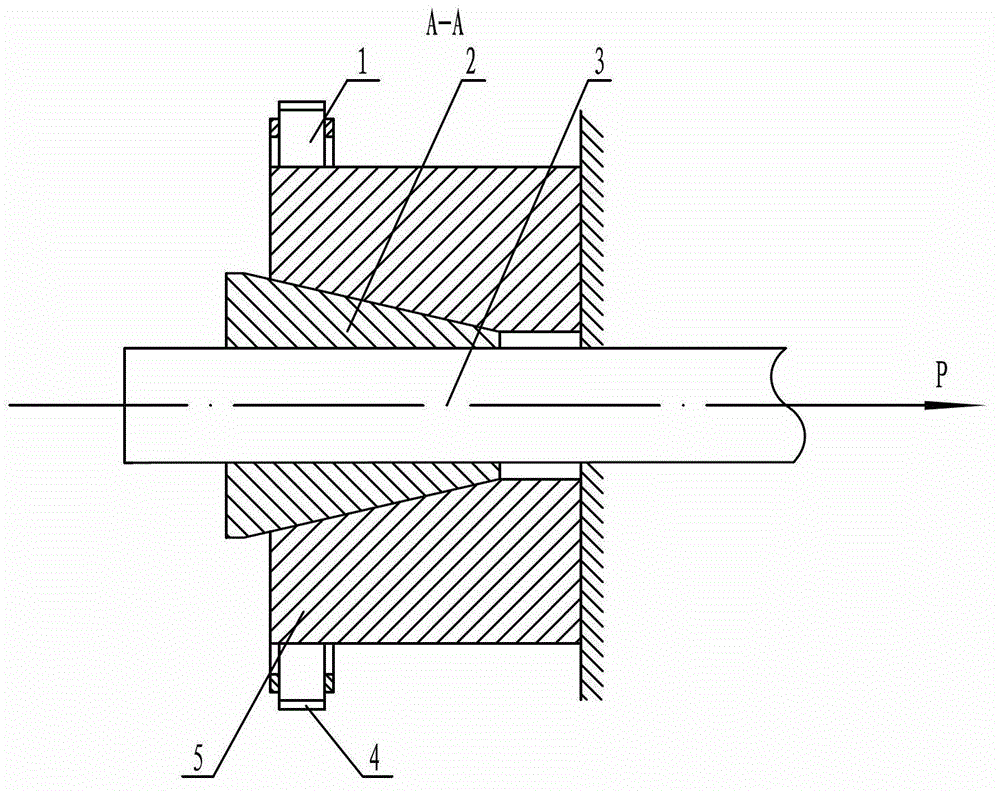

Piezoelectric tension monitoring device

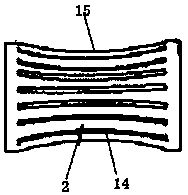

InactiveCN103207041AGuaranteed anchoring forceImprove stabilityTension measurementPre stressPre stressing

The invention discloses a piezoelectric tension monitoring device. A clamping sheet is arranged outside one tested stranded wire or each of 3-5 tested stranded wires, wherein an anchor ring is arranged outside the clamping sheet, a ring is arranged outside the anchor ring, at least two piezoelectric sensors dividing a circumference in equal parts are arranged between the ring and the outer surface of the anchor ring, the piezoelectric sensors are connected with a computer through data wires, and convert the received pressure born by the stranded wire and the pressure born by the stranded wire due to the deformation of the anchor ring through the clamping sheet to electric signals to output to the computer, and the computer computes according to the program set in advance to calculate the tension of the stranded wire. The device disclosed by the invention has the advantages of good stability, high measurement precision, and capability of repeated use, and can be applied to monitoring the tension of the stranded wire when constructing a pre-stressed concrete structure project.

Owner:CHANGAN UNIV

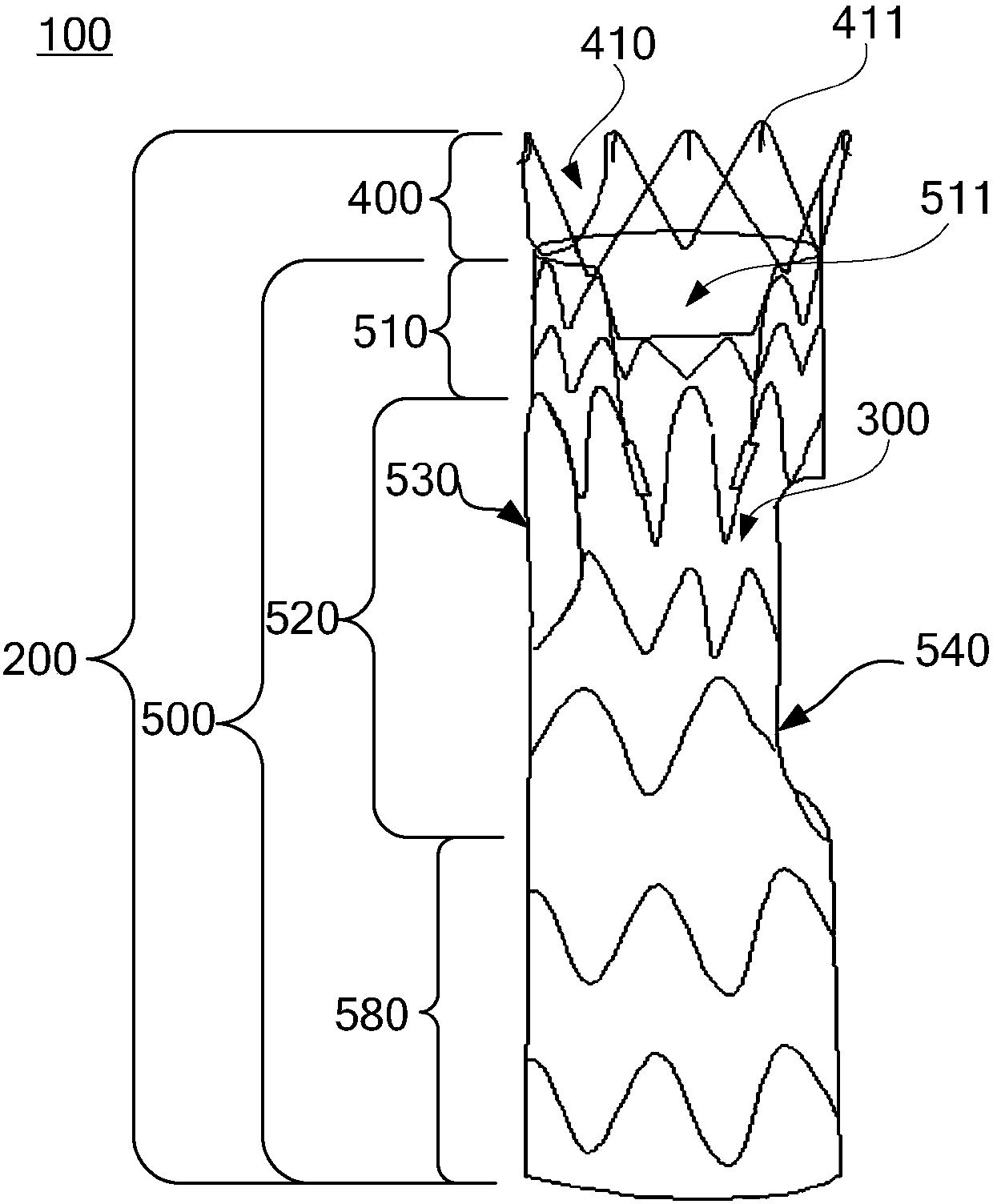

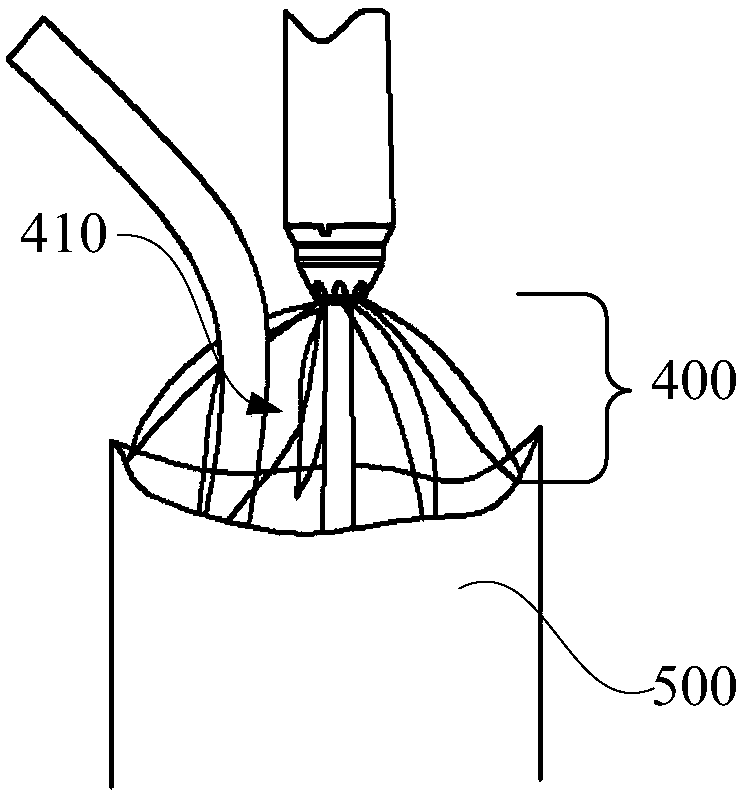

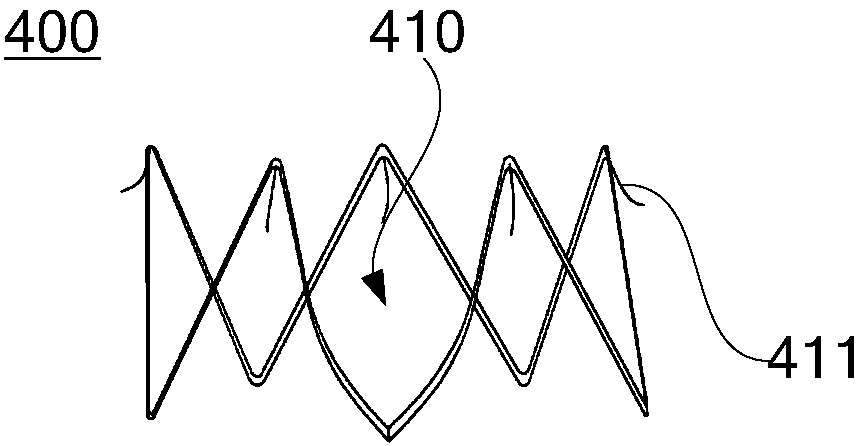

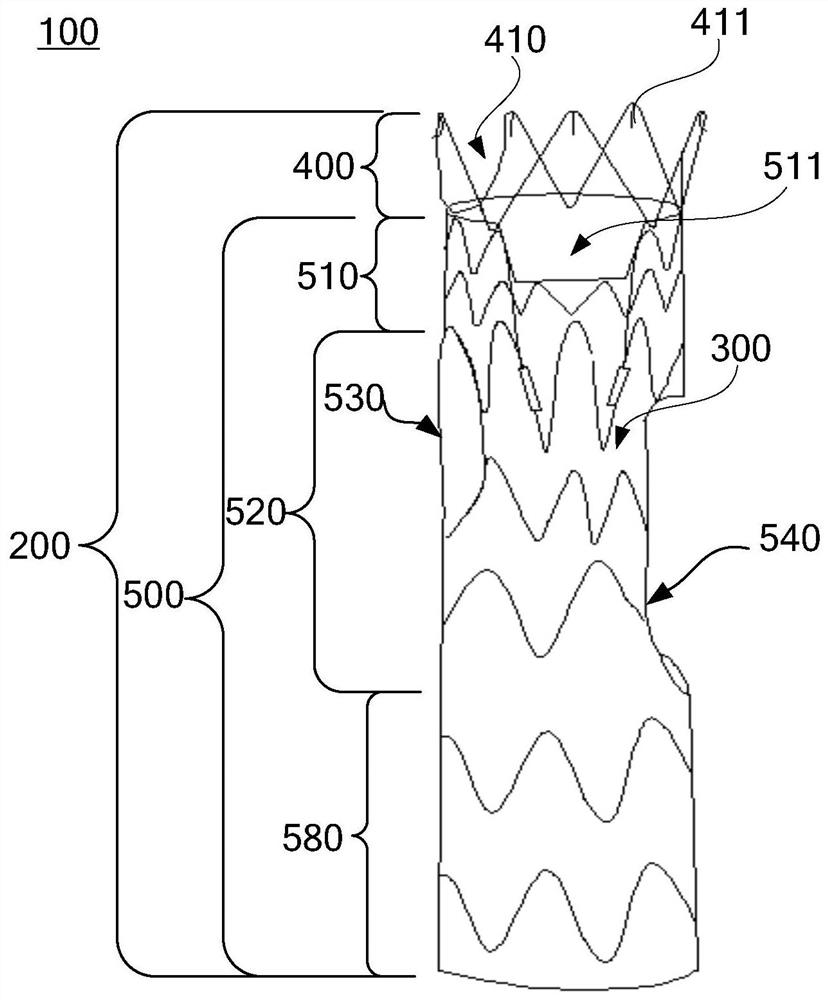

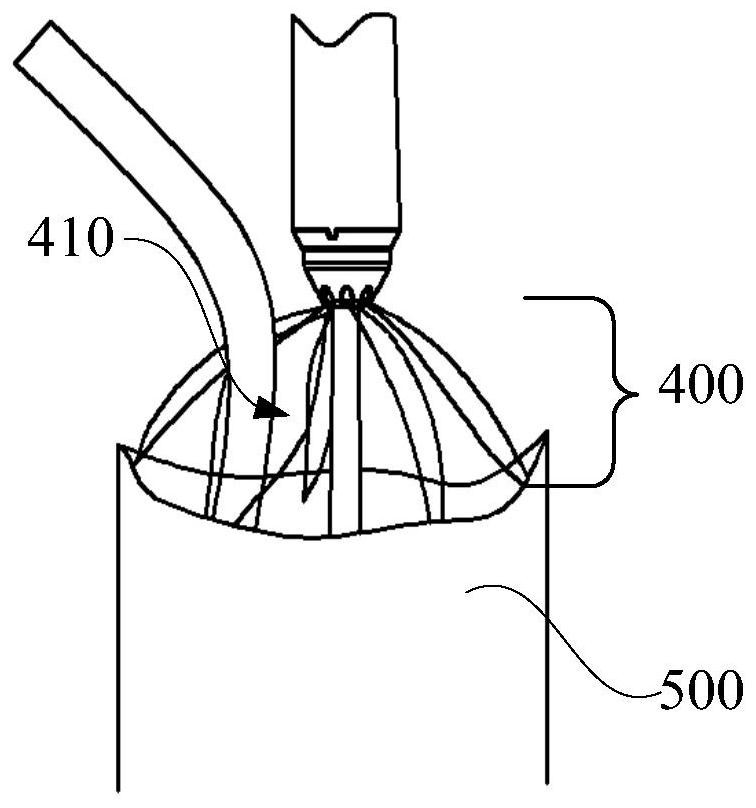

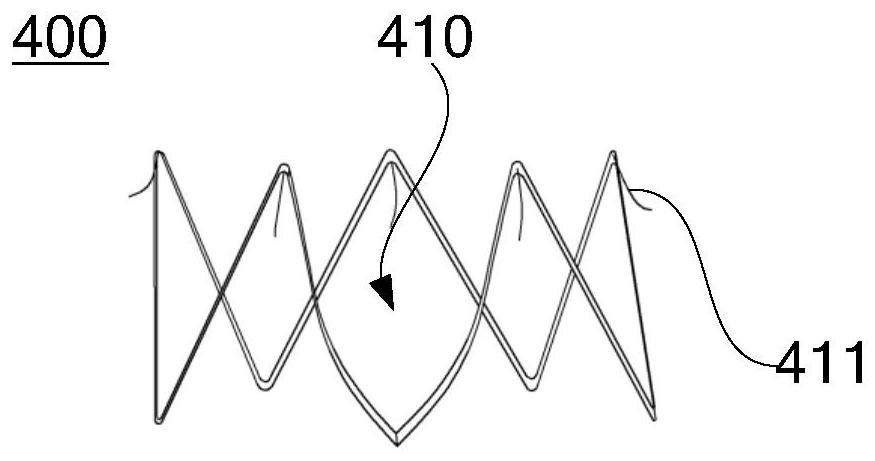

Branch-type coated stent graft and branch-type coated stent graft system

ActiveCN109717986AExcellent adhesionNo risk of disease progressionStentsBlood vesselsInsertion stentStent grafting

The invention provides a coated stent graft for the abdominal aorta and a coated stent graft system for the abdominal aorta. The coated stent graft for the abdominal aorta comprises a stent main-bodyand a coating; the stent main-body comprises a plurality of sequentially connected stent loops; and the stent main-body is coated with the coating. From the near-end to the far-end, the branch-type coated stent graft sequentially comprises an upper main-body section, a windowed section and a lower main-body section; at least one first-branch window is arranged on the windowed section; each of thefirst-branch window comprises a stent frame; each of the stent frame is encircled by two adjacent complete stent rings; openings are arranged on the coating with which the stent frames are coated, thereby allowing communicating with branch vessels; and the coating sunks, within the range of the stent frames, toward the interior of the stent. The coated stent graft for the abdominal aorta and the coated stent graft system for the abdominal aorta provided by the invention can be used for interventional treatment of perirenal abdominal aortic aneurysm with short neck; moreover, the coated stent graft for the abdominal aorta and the coated stent graft system for the abdominal aorta show excellent anchorage stability.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

Anchor rod assembly for supporting coal mines

ActiveCN107916948AImprove anchor stabilityImprove securityAnchoring boltsStructural engineeringSlurry

The invention discloses an anchor rod assembly for supporting coal mines. An anchor rod sleeve comprises an anchor rod sleeve section I, an anchor rod sleeve section II and an anchor rod sleeve section III which are integrally arranged, wherein a plurality of axial through slots are formed in the anchor rod sleeve section I along the axial direction of the anchor rod sleeve section I, and a plurality of radial round slots are formed in the anchor rod sleeve section II along the radial direction of the anchor rod sleeve section II; and an anchor rod comprises an anchor rod body, an inner anchorrod fixing section and an inner anchor rod clamping section which are integrally arranged, the inner end of the anchor rod body is connected with the inner anchor rod clamping section through the inner anchor rod fixing section, and the inner anchor rod fixing section is provided with an extension strip slot along the axial direction of the inner anchor rod fixing section. According to the anchorrod assembly, the slots in the anchor rod sleeve section I and the anchor rod sleeve section II can be well filled with solidifying slurry, so that the anchoring stability of the anchor rod sleeve isimproved, and the radial and longitudinal anchoring forces of the anchor rod sleeve are guaranteed; and meanwhile, the inner anchor rod fixing section and the inner anchor rod clamping section are arranged at the inner end of the anchor rod, the steadiness of the anchor rod can be further guaranteed, and the loosening of the anchor rod after anchoring can be prevented; and the anchor rod assemblyis reliable in structure, and the supporting safety of the coal mines can be effectively enhanced.

Owner:HENAN POLYTECHNIC UNIV

Anchor-cable anchoring method and structure in loose coal body

The invention relates to the technical field of coal body shoring, in particular to an anchor-cable anchoring method and structure in a loose coal body. The anchor-cable anchoring method comprises the following steps that S1, an anchor cable hole is drilled on the coal body; S2, a first anchoring agent with diffusivity is injected into the anchor cable hole; S3, a second anchoring agent used for sealing holes is injected into the upper portion of the first anchoring agent in the anchor cable hole; and S4, an anchor cable is inserted into the first anchoring agent along the anchor cable hole to be stirred till the partial first anchoring agent diffuses into the coal body around the first anchoring agent. Firstly the first anchoring agent is put into the drilled anchor cable hole, then the second anchoring agent is put into the drilled anchor cable hole, and finally the anchor cable is inserted into the drilled anchor cable hole and stirring is conducted. According to the anchor-cable anchoring method and structure in the loose coal body, the anchoring force crushing a side anchor cable of the coal body can be ensured, the pretightening force of the side anchor cable is improved, and the shoring effect of the anchor cable is developed; and deformation of the side portion of a roadway is controlled, and the problem that the roadway is repaired continuously due to the fact that the convergence of the side portion of the roadway of the crushed coal body is large is solved. Meanwhile the anchor-cable anchoring method is convenient to construct underground, an original anchor cable construction process is not added, application and popularization are facilitated, and the anchor-cable anchoring method has a high technical economical effect.

Owner:HUOZHOU COAL ELECTRICITY GROUP +1

Construction method of sandy ground hole-forming anti-floating anchor of steel pipe and PVC pipe compound bushing

InactiveCN108589724AEasy to operateSimple constructionProtective foundationBulkheads/pilesSoil horizonCorrosion

The invention discloses a construction method of a sandy ground hole-forming anti-floating anchor of a steel pipe and PVC pipe compound bushing. The method comprises the following steps: (I) positioning and numbering anchor holes; (II) taking a conventional hole drill in position and drilling a steel sleeve; (III) blowing and cleaning holes at a high pressure and lifting a drill; (IV) putting a PVC bushing down and pulling out the steel bushing; (V) grouting; and (VI) putting the anti-floating anchor down. The process method solves the hole collapsing problem by drilling the steel bushing to form holes and blowing and cleaning the holes, so that the anti-floating anchor is smoothly hole-formed. According to the process method, a protective wall is formed by means of the PVC bushing, so that the hole collapsing problem in the grouting construction process is solved, and meanwhile, the anti-floating anchor plays a role of corrosion resistance. The process method is simple to operate andsimple to construct, and can form holes within a relatively short time and construct the anti-floating anchor. The process method can solve the problem of an anchoring force of the anti-floating anchor in a soil layer effectively; and holes are formed by means of a conventional hole drill through the process method, and the steel bushing is repeatedly used, so that the extra cost is prevented frombeing increased.

Owner:QINGDAO XINHUAYOU CONSTR GROUP

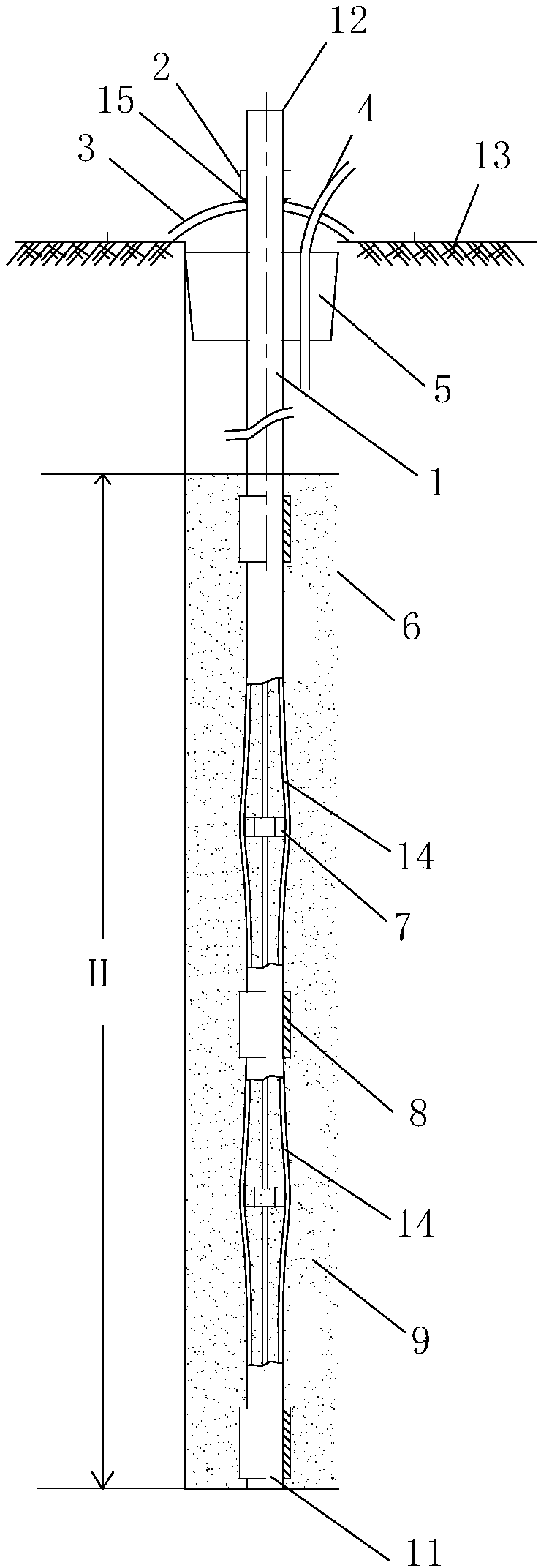

Construction method of anchor cable for prestressed grouting bird cage on floor of roadway

InactiveCN109083669AFacilitated DiffusionGuaranteed anchoring forceAnchoring boltsPre stressShear capacity

The invention relates to the technical field of coal mine roadway, in particular to a construction method of an anchor cable for a prestressed grouting bird cage on the floor of a roadway. The methodincludes the steps of pre-grouting a floor broken coal rock mass, drilling a floor anchor cable hole on the floor coal rock mass after the pre-grouting, inserting the bird cage anchor cable into the floor anchor cable hole, pouring a precast cement slurry into the floor anchor cable hole, after a preset time passes, stably anchoring a bird cage end of the bird cage anchor cable, stretching, pre-tightening and locking the bird cage anchor cable, and grouting the floor anchor cable hole. The construction method can solve the problem of pucking in a coal mine effectively and economically, under the condition of ensuring the anchoring force of the bird cage anchor cable and the length of a free section, spread a pre-tightening force applied to a wider range of a rock mass, through grouting, restore the integrity of broken surrounding rocks around the bird cage anchor cable so that the pre-stress can spread better, improve the shear resistance of the bird cage anchor cable, and prevent thecorrosion of the anchor cable.

Owner:TIANDI SCI & TECH CO LTD

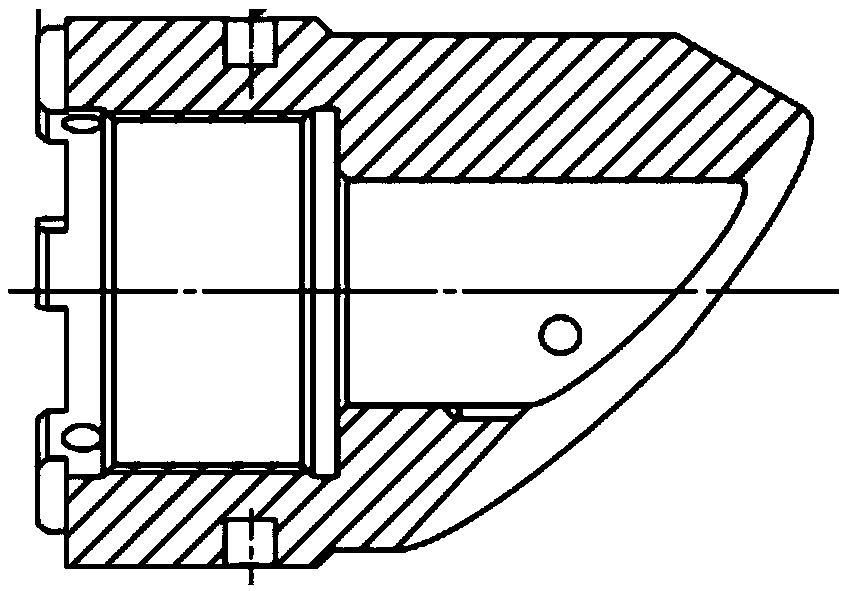

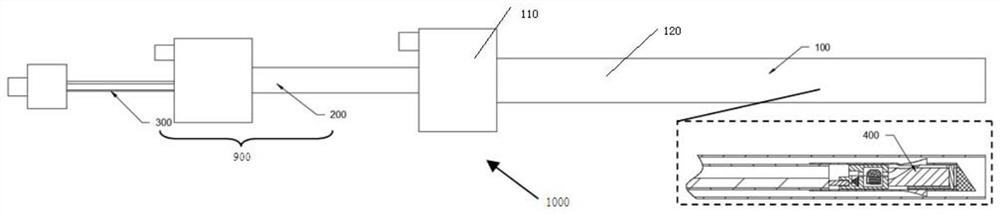

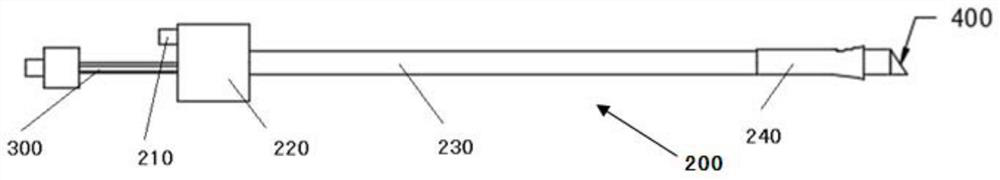

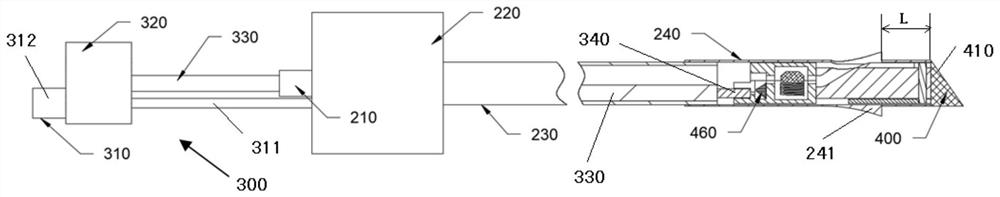

Locking anchoring device and transcatheter locking anchoring system

PendingCN113491598AReduce volumeGuaranteed anchoring forceAnnuloplasty ringsStaplesHuman bodyCardiac muscle

The invention provides a locking anchoring device and a transcatheter locking anchoring system. The locking anchoring device comprises an adjusting assembly, a releasing assembly and an anchor, wherein the adjusting assembly comprises a catheter and a stop seat arranged at the far end of the catheter in a protruding mode, the stop seat is provided with a thread inlet groove for a suture to pass through, the anchor is contained at the far end of the stop seat, the far end of the anchor extends out of the stop seat, and the releasing assembly penetrates through the catheter and the stop seat and is detachably connected with the anchor. In the heart intervention process, the anchor can be contracted into the catheter, and the conveying difficulty and the damage to human tissue are reduced; and the depth of the anchor penetrating into the myocardium is limited through the stop seat, and the damage to the tissue is reduced while the anchoring force is guaranteed.

Owner:HANGZHOU VALGEN MEDTECH CO LTD

A kind of full grouting sleeve for building reinforcement connection

InactiveCN104358360BPrevent reverse installationGuaranteed positioning accuracyBuilding reinforcementsButt jointArchitectural engineering

The invention discloses a full-grouting sleeve for connection of construction reinforcing steel bars, and belongs to the technical field of building projects. A reinforcing steel bar axial-limiting guide stop dog is arranged on the inner wall in the middle of a sleeve main body; guide slopes are arranged between the stop dog and the inner wall of the sleeve main body; a positioning bolt is arranged on the sleeve main body at the prefabricated end; the reinforcing steel bar at the prefabricated end is axially and radially fixed through the positioning bolt; the sleeve main body is molded by one-step casting of spheroidal graphite cast iron, so that the production cost is low; the outer surface of the sleeve main body serves as a roughened surface, so as to ensure the anchoring force between the grouting sleeve and the concrete; a plurality of convex hooping ribs are arranged on the inner wall of the grouting sleeve; an identification gap is formed in the port face of the sleeve main body at the field poured end, so as to prevent the situation that the grouting sleeve is installed reversely; a seal ring is arranged inside the port of the sleeve main body at the prefabricated end. When the grouting sleeve disclosed by the invention is in axial butt joint with the reinforcing steel bar, the precise axial control can be automatically realized, and the radial positioning can be automatically realized, so as to ensure the positioning accuracy between the reinforcing steel bar and the grouting sleeve, and meet the requirements on building construction quality.

Owner:SHENYANG JIANZHU UNIVERSITY

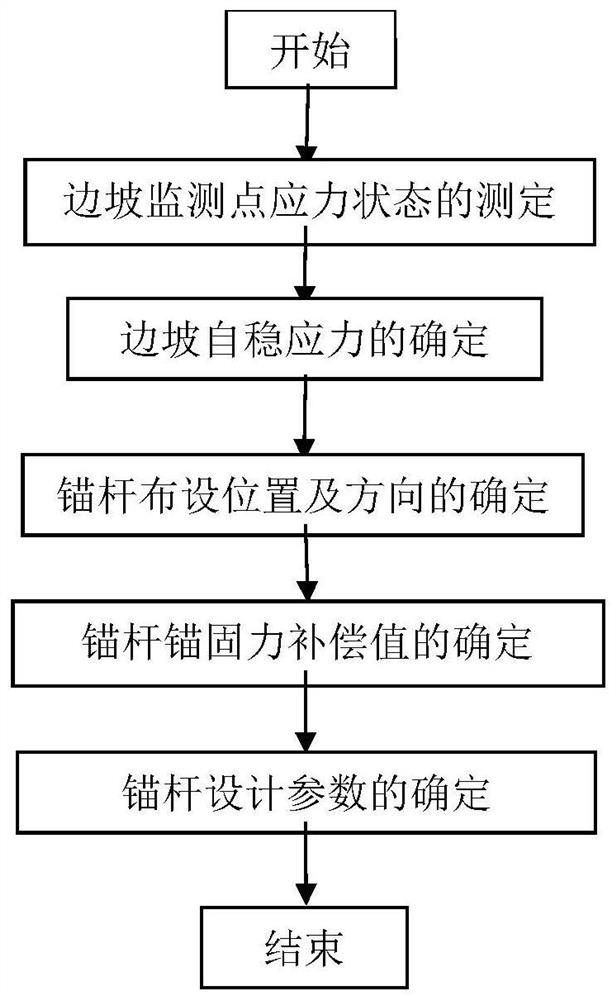

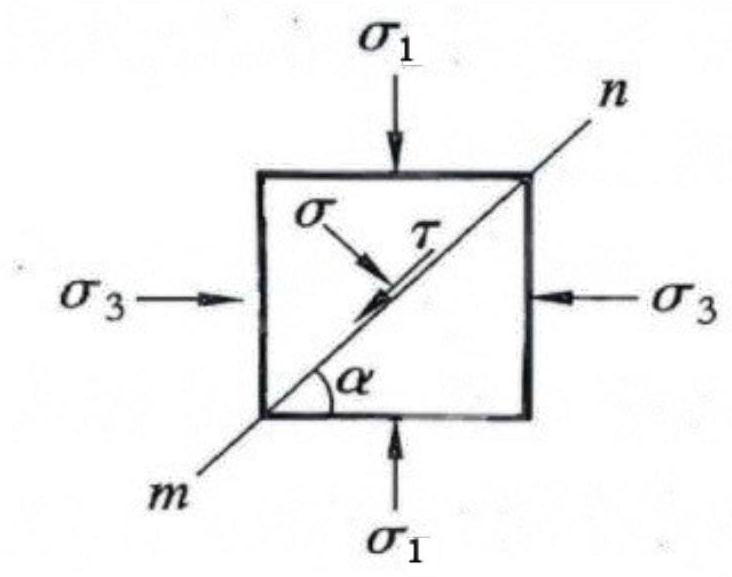

Slope anchor rod anchoring method based on stress compensation

ActiveCN113326547ADesign economySafe and reasonable designGeometric CADClimate change adaptationClassical mechanicsMechanics

The invention discloses a side slope anchor rod anchoring method based on stress compensation. The side slope anchor rod anchoring method comprises the following steps: measuring the physical and mechanical parameters of a side slope body; monitoring the three-dimensional stress state of each point in a slope body through an instrument, then determining the arrangement position of an anchor rod and the anchoring force compensation direction in combination with the limit stress state of a monitoring point determined by the Mohr-Coulomb criterion; and according to the stress state of the slope under the given safety coefficient and the stress state obtained through actual monitoring, calculating to obtain an anchoring force compensation value required by the anchor rod and an anchor rod parameter value. According to the scheme, the arrangement range and direction of the anchor rods can be accurately determined, the anchoring force can be determined according to the slope stress distribution state when it is guaranteed that the slope reaches the target safety coefficient, the anchor rod arrangement scheme is designed more economically, reasonably and safely through the method, and higher practical and popularization value is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

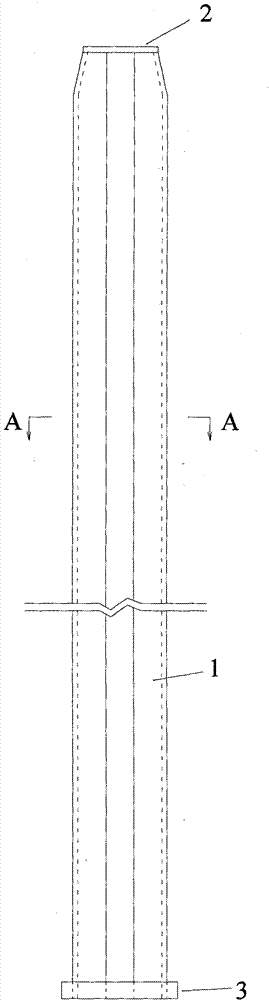

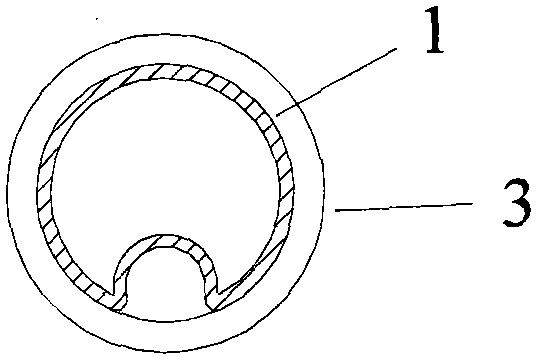

Closed pipe seam anchor rod body

InactiveCN104805838BIncrease anchoring forceGuaranteed anchoring forceBulkheads/pilesAnchoring boltsHigh intensityRock bolt

The invention discloses a closed tube seam anchor rod body and relates to an anchor rod body of a tube seam anchor rod device of geotechnical engineering support. The closed tube seam anchor rod body aims at overcoming the defects of the great effect on anchor force and the failure of anchor rods caused by the fact that the prior longitudinal slotted steel tube rod tube seam anchor rod anchor force is low, the slotted steel tube radial low rigidity elastic deformation restricts the improving of the tube seam anchor rod anchor force and when engineering service time in roadways and the like are long and water sprays, the inner walls of the tube seam anchor rod longitudinal slotted steel tube rod bodies are exposed in the spray water completely and can be corroded easily. The closed tube seam anchor rod body comprises a section local concave hollow high-strength thin-wall steel tube, a seal plate and a retaining ring. An inner groove is formed along the longitudinal direction of the total length. The seal plate is connected and fixed with an inner end opening of the section local concave hollow high-strength thin-wall steel tube, and the retaining ring is connected and fixed with an outer end opening of the section local concave hollow high-strength thin-wall steel tube. Compared with prior tube seam anchor rods, the closed tube seam anchor rod body has the advantages that the anchor force is improved apparently, the anchor force is large, the rock reinforcement effect is good, and the effect on the anchor rod anchor force by exposure of tube seam anchor rod body inner walls in the spray water is prevented.

Owner:HENAN POLYTECHNIC UNIV

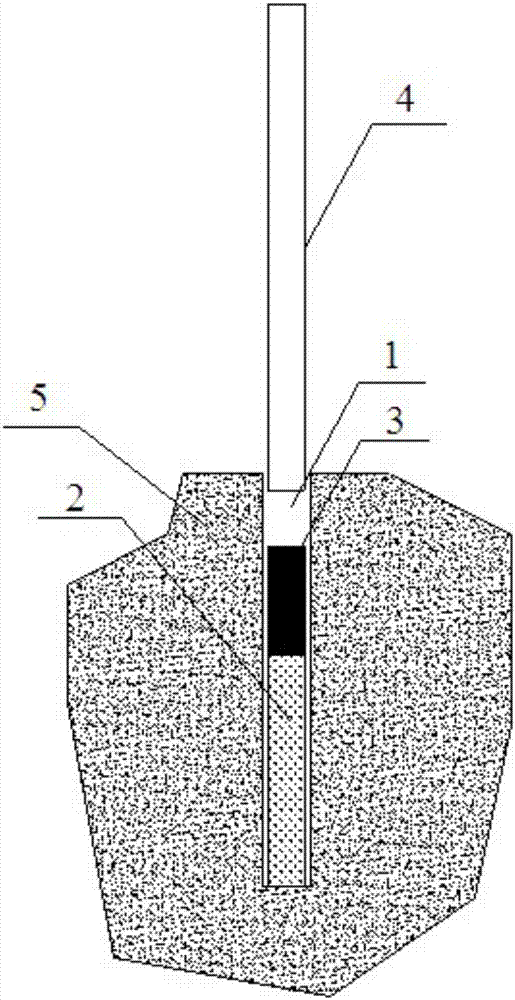

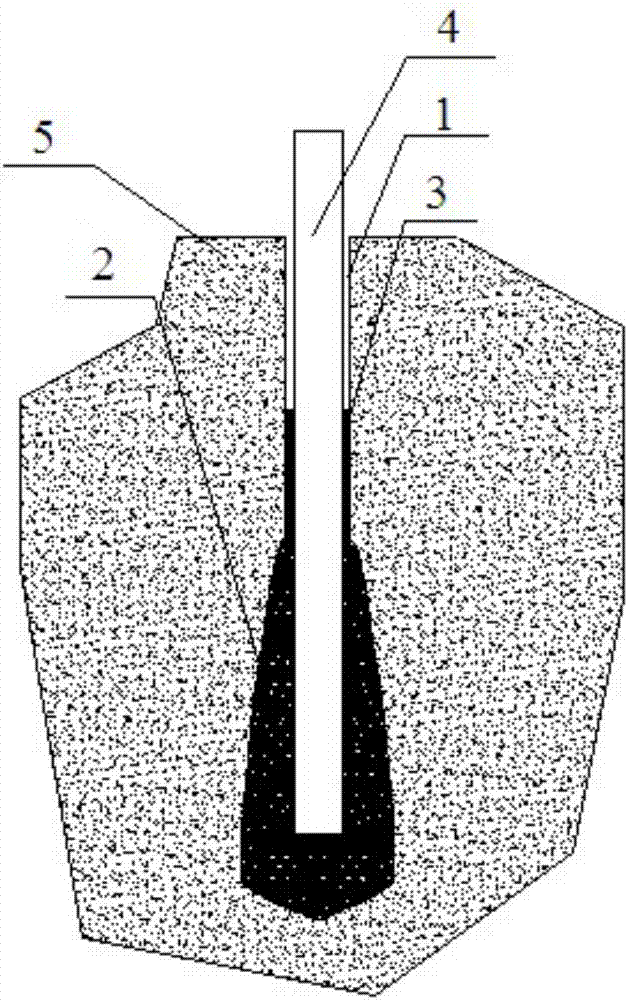

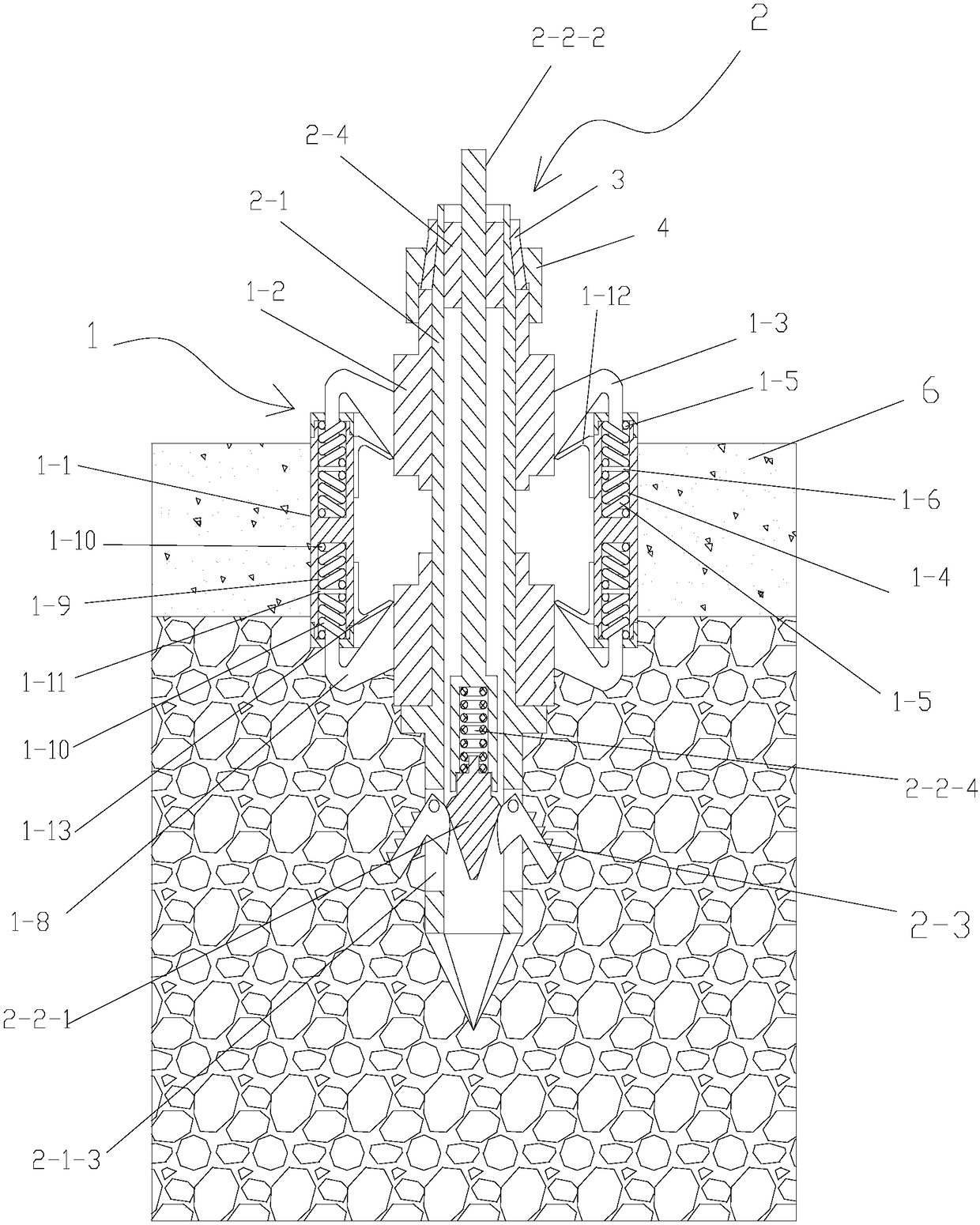

ground anchor

ActiveCN106480883BAvoid shakingGuaranteed anchoring forceBulkheads/pilesShock resistanceEarth anchor

The invention discloses a novel ground anchor. The novel ground anchor comprises an anchoring pile used for being inserted into the ground for anchoring and an anchoring support used for mounting the anchoring pile and buffering vibration caused by external loads. The anchoring support comprises a support sleeve and a fixing mechanism which is arranged on the support sleeve and used for fixedly supporting the anchoring pile. The fixing mechanism is internally provided with damper springs, and a pile pipe is fixed to the fixing mechanism. In the using process, the anchoring pile is inserted into the ground for anchoring, the anchoring support is fixed through a concrete foundation or external fixing pieces, and the anchoring pile and the anchoring support form a whole. An external rope is connected to the anchoring pile, when the external rope suffers from external wind loads or other loads to vibrate, the caused vibration can be buffered under the action of supporting arms and the damper springs of an upper fixing assembly and a lower fixing assembly so that the condition of anchoring pile shaking caused by the stress of the rope under the load action can be prevented, and therefore anchoring force of the anchoring pile is guaranteed while buffering and shock resistance are achieved.

Owner:CHONGQING TECH & BUSINESS INST

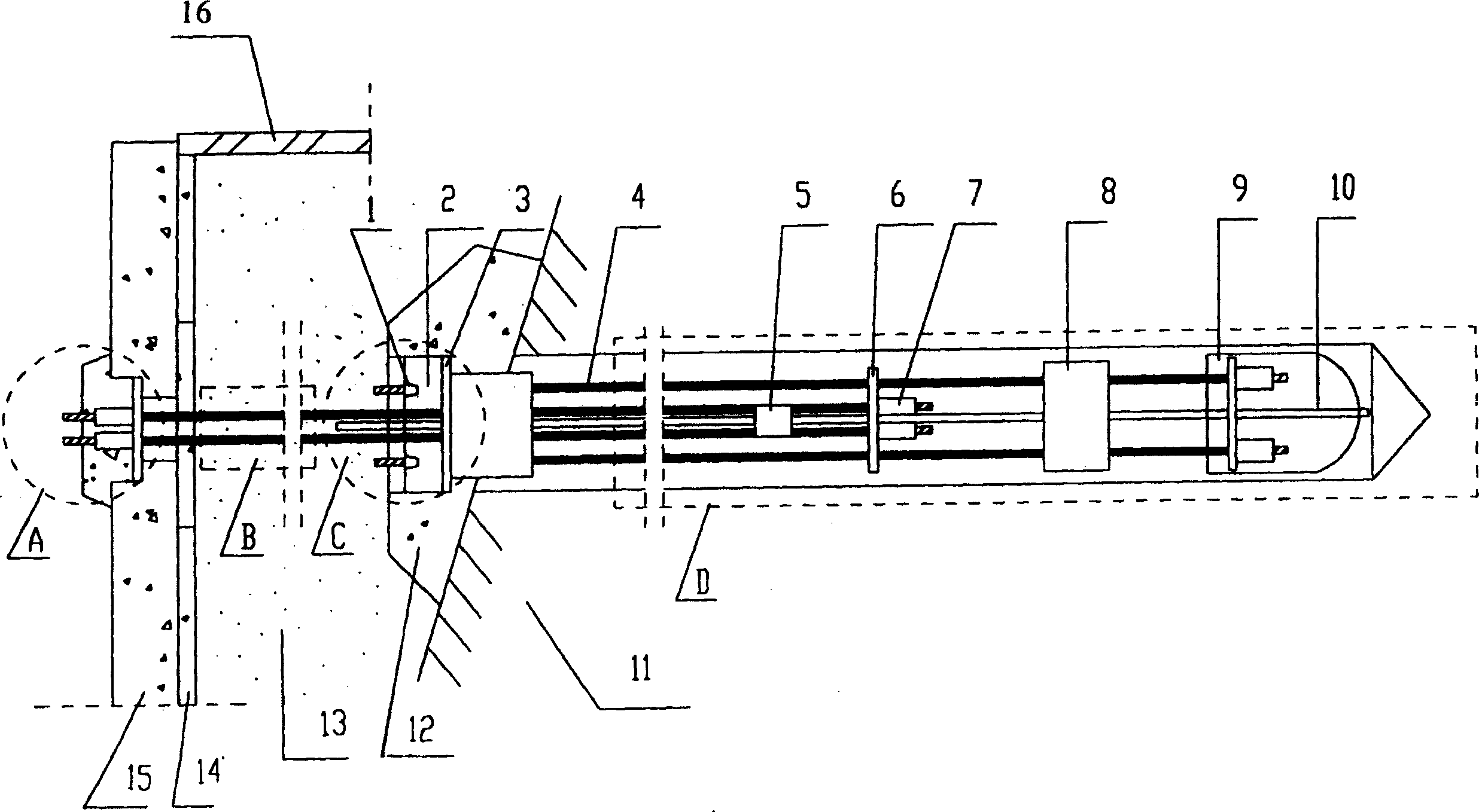

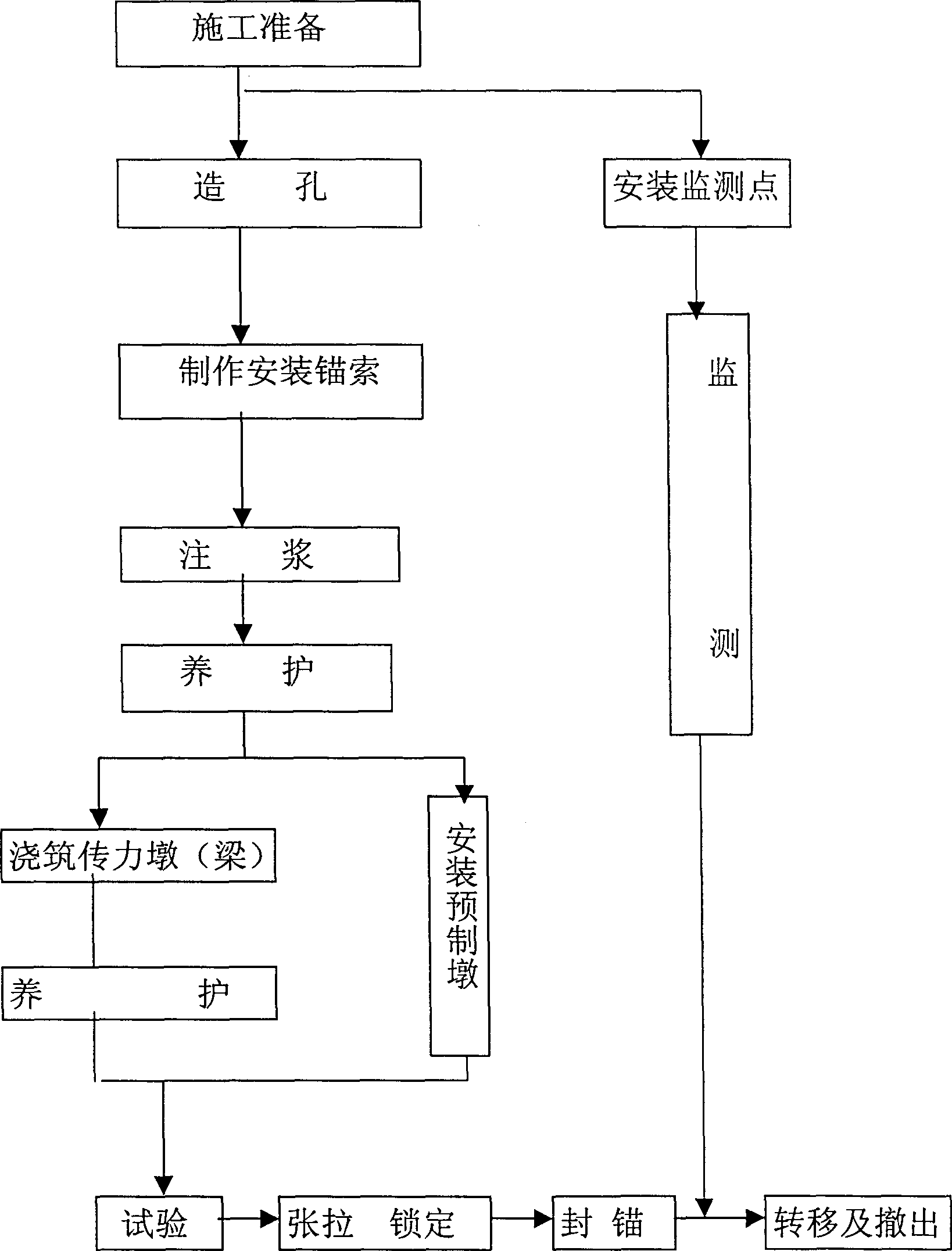

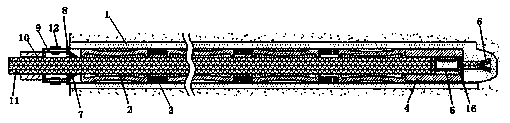

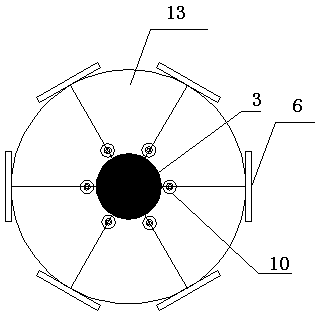

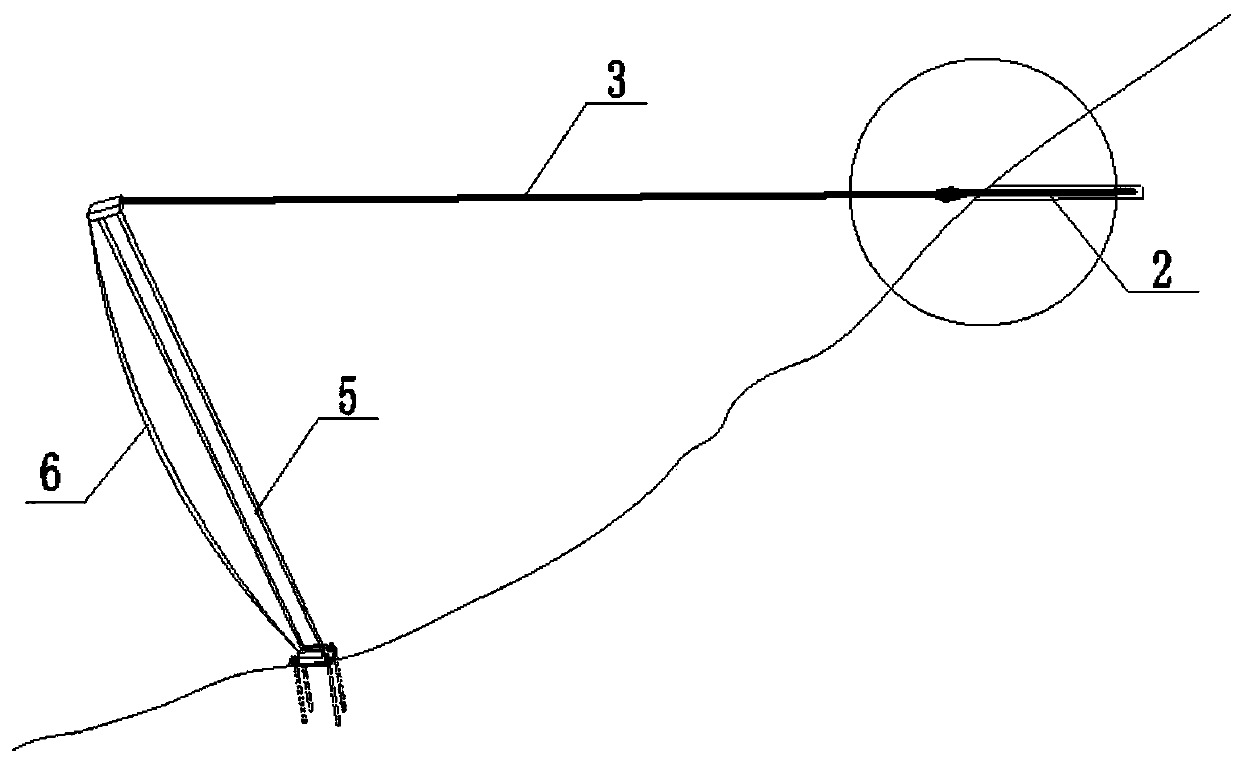

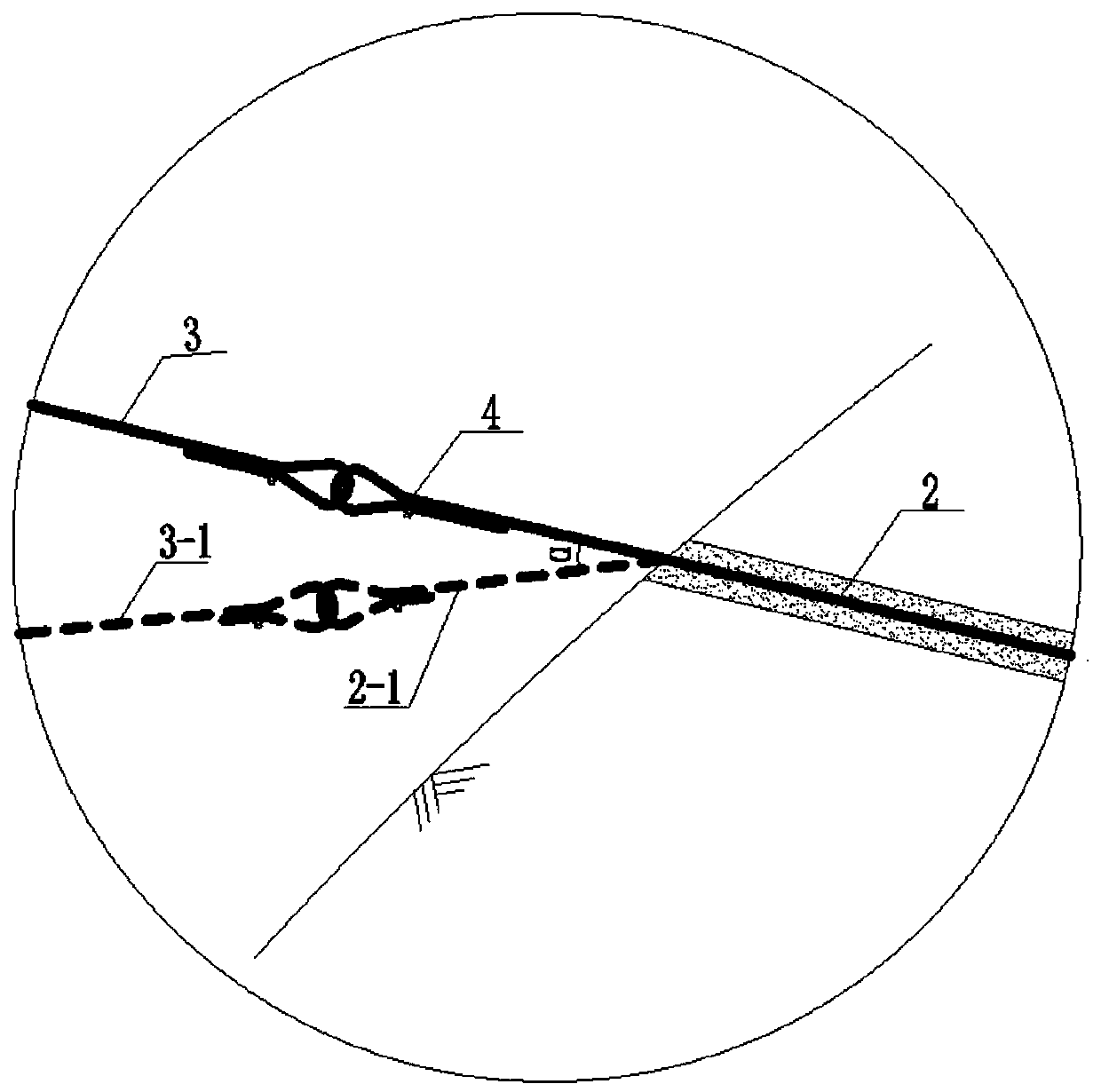

Pile plate anchoring rope and construction method for reinforcing side slope of backfilled roadbed supported by said anchoring rope

InactiveCN1153871CShorten the lengthTake advantage ofExcavationsBulkheads/pilesSupport planeGeotechnical engineering

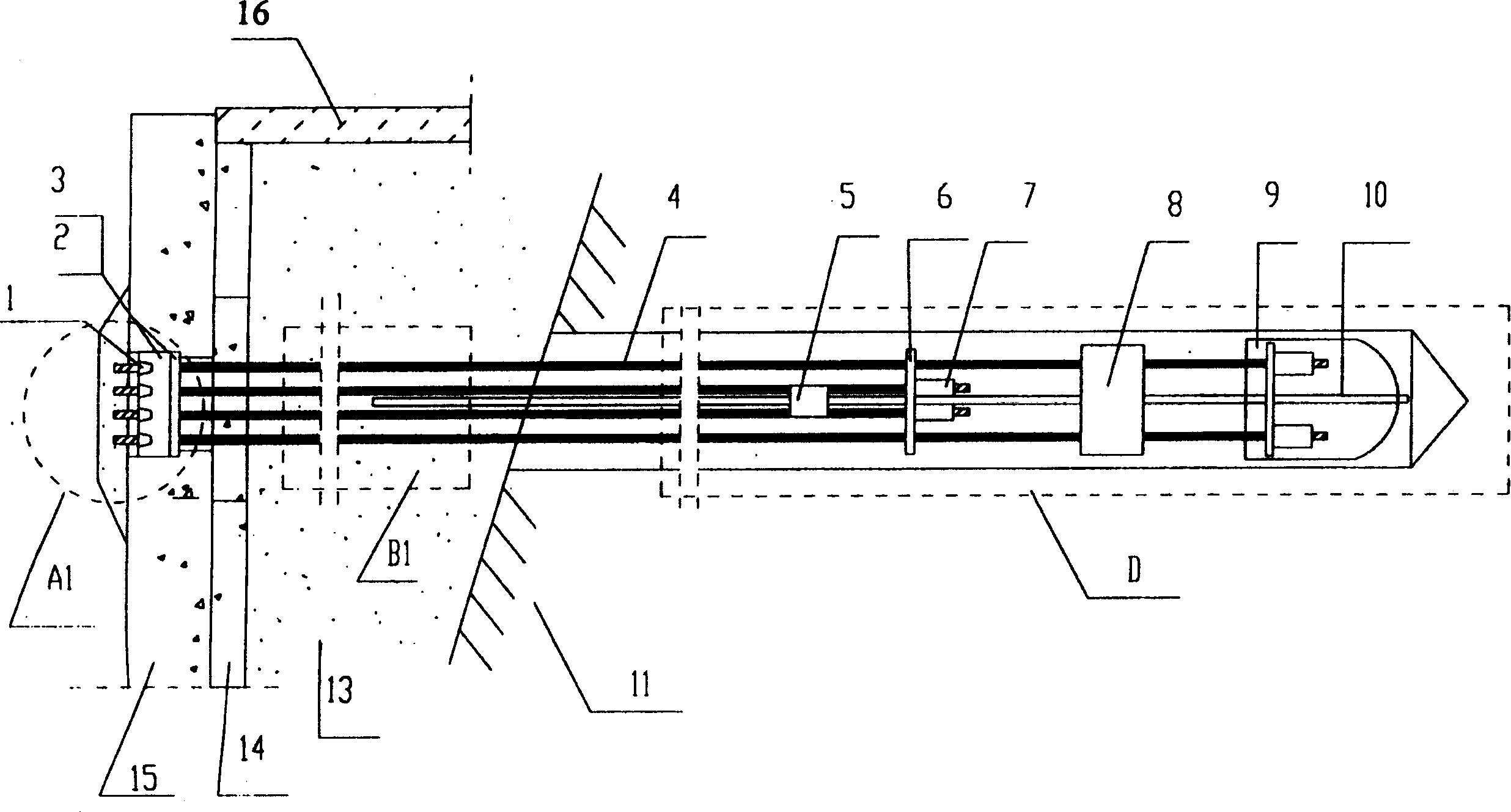

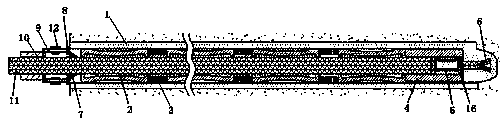

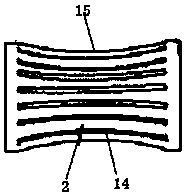

The invention is pile-plate anchroage cable, including external anchor head, free segment and anchor fixing segment. The cable has slope external anchor head A and pile-plate external anchor head B. The external anchor head comprises clamp piece, anchor plate and backling plate. All the steel strands pass through A to compose the anchor fixing segment; the internal support and the external support 8 is covered on the non-binding steel strand, and there are 2-12 load bearing bodies distributed on the anchor fixing segment and each load-bearing body consists of the steel strand, load bearing plate, spring shim and extrusion cover and these is guide cap on the longest steel strand. The construction method includes the main steps of making holes, making and installing anchorage cable, slip casting, thrice spreading-dragging locking and twice closing the anchor and so on.

Owner:LIUZHOU OVM MASCH CO LTD

Safety support anchor rod in coal mine well

The invention discloses a safety support anchor rod in coal mine well. A anchor sleeve comprises a first anchor rod sleeve section integrally arranged, a second anchor rod sleeve section and a third anchor rod sleeve section. A plurality of axial direction through grooves are formed in the first anchor rod sleeve section in axial direction of the first anchor rod sleeve section, and a plurality ofradial direction circumferential grooves are formed in the second anchor rod sleeve section in the radial direction of the second anchor rod sleeve section. The anchor rod comprises an anchor rod body integrally arranged, an anchor rod internal solid section and an anchor rod internal clamping section, the anchor rod internal solid section is used to be connected with the anchor rod internal clamping section on the inner end of the anchor rod body, and an extending strip groove is formed in the anchor rod internal solid section in the axial direction of the anchor rod internal solid section.Grooves of the first anchor rod sleeve section and the second anchor rod sleeve section can be filled with solidified slurry well, the stability of anchoring of the anchor rod sleeve is improved, andthe anchoring force in radial direction and lengthways direction of the anchor rod sleeve is ensured; at the same time, the anchor rod internal solid section and the anchor rod internal clamping section are arranged on the inner end of the anchor rod, and the stability of the anchor rod is further ensured to prevent the anchor rod from loosing after anchoring. The Safety support anchor rod in coalmine well is reliable in structure, and the safety of coal mine support can be efficiently enhanced.

Owner:陈柯成

A branched stent-graft and a branched stent-graft system

ActiveCN109717986BExcellent adhesionNo risk of disease progressionStentsBlood vesselsTumor neckCovered stent

The present invention provides an abdominal aortic stent-graft and an abdominal aortic stent-graft system, comprising a stent body and a membrane, the stent body includes a plurality of sequentially connected stent rings, and the membrane covers the stent On the main body; the branched stent-graft includes an upper body section, a fenestration section, and a lower main body section from the proximal end to the distal end, and the fenestration section is provided with at least one first branch window; the first branch window has a bracket frame, the stent frame is surrounded by two adjacent complete stent rings, and the covering film covered on the stent frame is provided with openings, and the openings are used to communicate with branch blood vessels, so The covering membrane within the range of the stent frame is sunken toward the inside of the stent. The abdominal aortic stent-graft and the abdominal aortic stent-graft system provided by the present invention can be used as the abdominal aortic stent-graft and the abdominal aortic stent-graft system for the interventional treatment of abdominal aortic aneurysms with a short neck neck, and can have Excellent anchoring stability.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

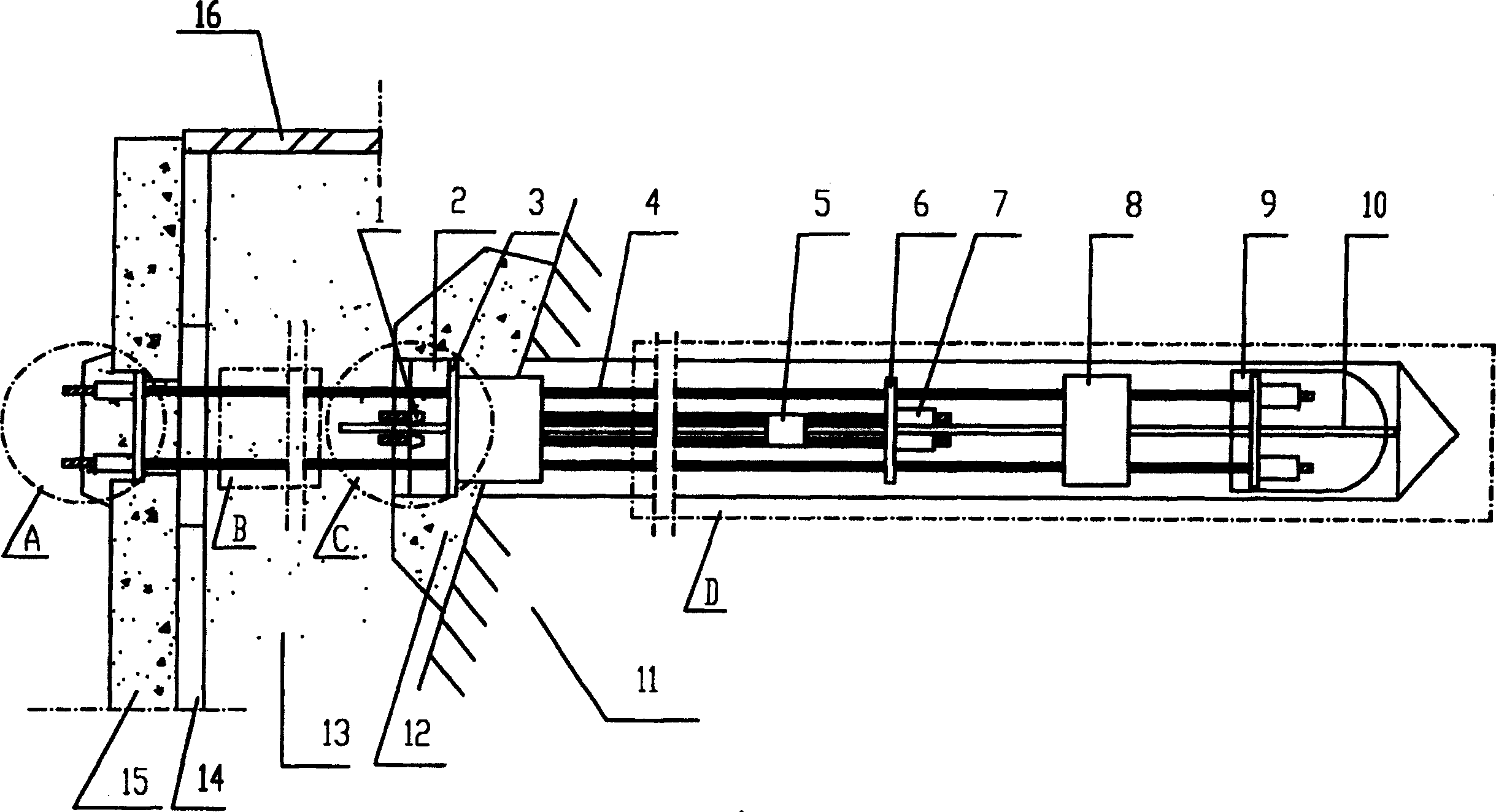

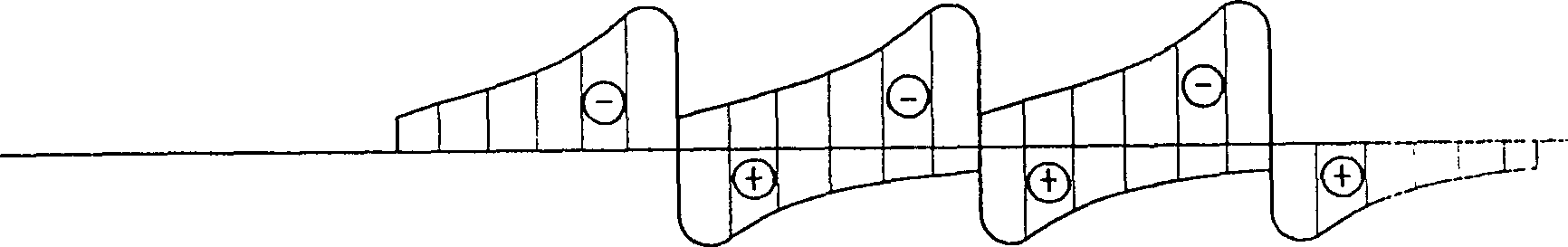

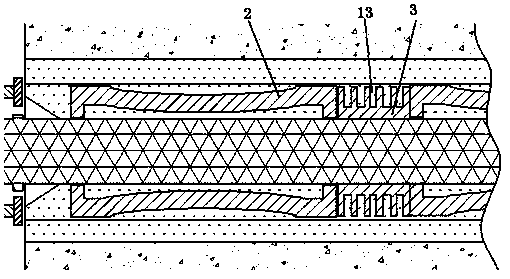

Pull-pressure dispersed protecting anchor cable and its construction method

InactiveCN1122745CUniform stress distributionImprove the anchoring effectBulkheads/pilesStress distributionEngineering

A tension-compression dispersed protective anchor cable and its construction method. The anchor cable is composed of an outer anchor head, a free section, and an anchor section. Two or more bearing bodies are distributed on the anchor section. The steel strand is composed of a bearing plate, an elastic gasket, and an extrusion sleeve that are sequentially placed on the steel strand. The number of steel strands passing through each bearing plate is different, and the end of each steel strand is stripped beyond the bearing plate. For bonded steel strands, the construction method includes drilling holes, making and installing anchor cables, grouting, tensioning and locking and other construction procedures. This type of anchoring has uniform stress distribution, good anchoring and anti-corrosion effects, simple anchor cable structure, The advantages of convenient construction.

Owner:中外合资柳州欧维姆建筑机械有限公司

A bolt assembly for coal mine support

Owner:HENAN POLYTECHNIC UNIV

Construction method of anti-floating anchor rod for karst cave in limestone area

PendingCN114293549AReliable anchoring forceGuaranteed anchoring forceProtective foundationBulkheads/pilesComposite filmKarst

The invention discloses a construction method of an anti-floating anchor rod for a karst cave in a limestone area. According to the construction method, a composite film bag is combined with a fractional grouting technology, a large-size inclusion is formed by grouting in the composite film bag in a karst cave and a fracture development section, an anchoring body larger than the hole diameter of an anchor rod is formed in the karst cave, the embolism effect is achieved, meanwhile, a karst cavity is blocked to a certain degree, and the water stopping effect is achieved; and then grouting is conducted on the anchor rod holes in the upper portion and the lower portion of the film bag correspondingly. The anchoring plug plays an effective anchoring role, and then the grouting effect of the upper section and the lower section of the karst cave is effectively guaranteed, so that the anchoring force of the anchor rod can be guaranteed, and the problem that the anchor rod construction in the karst cave and the corrosion crack area is difficult is solved.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Reinforced anchor rod for tunnel construction

ActiveCN108412527BIncrease anchoring forceGuaranteed anchoring forceAnchoring boltsLap jointArchitectural engineering

The invention relates to the technical field of construction tools and discloses a reinforcing anchor rod for tunnel construction. The reinforcing anchor rod comprises a rod body, one side of the rodbody is fixedly connected with one side of each metal sheet and in insertion connection with one side of a slide sleeve, and the inner wall of the slide sleeve is in sleeve connection with the surfaceof a slide rod. One side of the slide rod is fixedly connected with one side of a retaining block, the top of the slide rod is fixedly connected with the bottom of each first oblique block, the top of each first oblique block is in lap joint with the bottom of a second oblique block, and the top of each second oblique block is fixedly connected with the bottom of a moving rod. The reinforcing anchor rod for tunnel construction has advantages that by reinforcing rods fixedly connected to the surface of the rod body, the metal sheets fixedly connected to one side of the rod body, a rotating rod, a threaded rod, a threaded sleeve, a pull rod, the slide rod, the retaining block, the first oblique blocks, the second oblique blocks, the moving rods, fixing sleeves and sharp blocks, when the threaded sleeve moves, the retaining block pushes the metal sheets to warp to increase the anchoring force, and then the sharp blocks are inserted into soil to enhance the anchoring force of the anchor rod.

Owner:ANHUI QIANYI INTELLIGENT EQUIP CO LTD

Energy-absorbing impact-resistant anchorage device assembly and mounting method thereof

PendingCN114526104AImprove impact resistanceGuaranteed anchoring forceAnchoring boltsEngineeringScrew thread

The invention relates to an energy-absorbing and impact-resisting anchorage device assembly and a mounting method thereof. The energy-absorbing and impact-resisting anchorage device assembly comprises a base plate, an energy-absorbing and impact-resisting aligning pad, an energy-absorbing and impact-resisting anchor ring and a clamping piece. The steel strand is sleeved with the energy-absorbing impact-resistant anchor ring, and external threads are manufactured on the outer wall of the energy-absorbing impact-resistant anchor ring. The upper end part of the energy-absorbing and impact-resisting anchor ring is in threaded connection with the energy-absorbing and impact-resisting aligning pad, and an internal thread through hole matched with the external thread is formed in the energy-absorbing and impact-resisting aligning pad along the axial direction. The impact energy can be effectively absorbed, the impact resistance of an anchorage device assembly part under the impact load is improved, and the anchoring force of the anchor cable is kept.

Owner:天津市振华预应力技术有限公司

Detachable type bit-expanded reinforced soil nail device and use method thereof

The invention discloses a detachable type bit-expanded reinforced soil nail device and a use method thereof. The detachable type bit-expanded reinforced soil nail device comprises at least one bit-expanded reinforced soil nail, the bit-expanded reinforced soil nail comprises an expanded bit, a thread casing pipe and a screw, the expanded bit is fixed in the middle of the screw, the two ends of thescrew are provided with thread connecting segments, adjacent soil nails are connected through the thread casing pipe, the bit-expanded reinforced soil nails are lengthened, or multiple continuous bit-expanded reinforced soil nails are arranged; the device has the beneficial effects that the device is simple in structure, safe in use and convenient to mount. Through the structure, the anchorage force of the soil nails can be ensured, through the external expansion manner of anti-bend reinforced bodies, multiple expanded bits can be formed, the contact area of the soil nail expanded bit and the soil can be greatly increased, frictional resistance is increased, due to the effect of the expanded bit, soil layer counterforce is increased, and the soil nail anchorage strength can be achieved to the maximum limit.

Owner:SHANGHAI YUANFANG GROUNDWORK ENG +4

Piezoelectric tension monitoring device

InactiveCN103207041BGuaranteed anchoring forceImprove stabilityTension measurementPre stressPre stressing

The invention discloses a piezoelectric tension monitoring device. A clamping sheet is arranged outside one tested stranded wire or each of 3-5 tested stranded wires, wherein an anchor ring is arranged outside the clamping sheet, a ring is arranged outside the anchor ring, at least two piezoelectric sensors dividing a circumference in equal parts are arranged between the ring and the outer surface of the anchor ring, the piezoelectric sensors are connected with a computer through data wires, and convert the received pressure born by the stranded wire and the pressure born by the stranded wire due to the deformation of the anchor ring through the clamping sheet to electric signals to output to the computer, and the computer computes according to the program set in advance to calculate the tension of the stranded wire. The device disclosed by the invention has the advantages of good stability, high measurement precision, and capability of repeated use, and can be applied to monitoring the tension of the stranded wire when constructing a pre-stressed concrete structure project.

Owner:CHANGAN UNIV

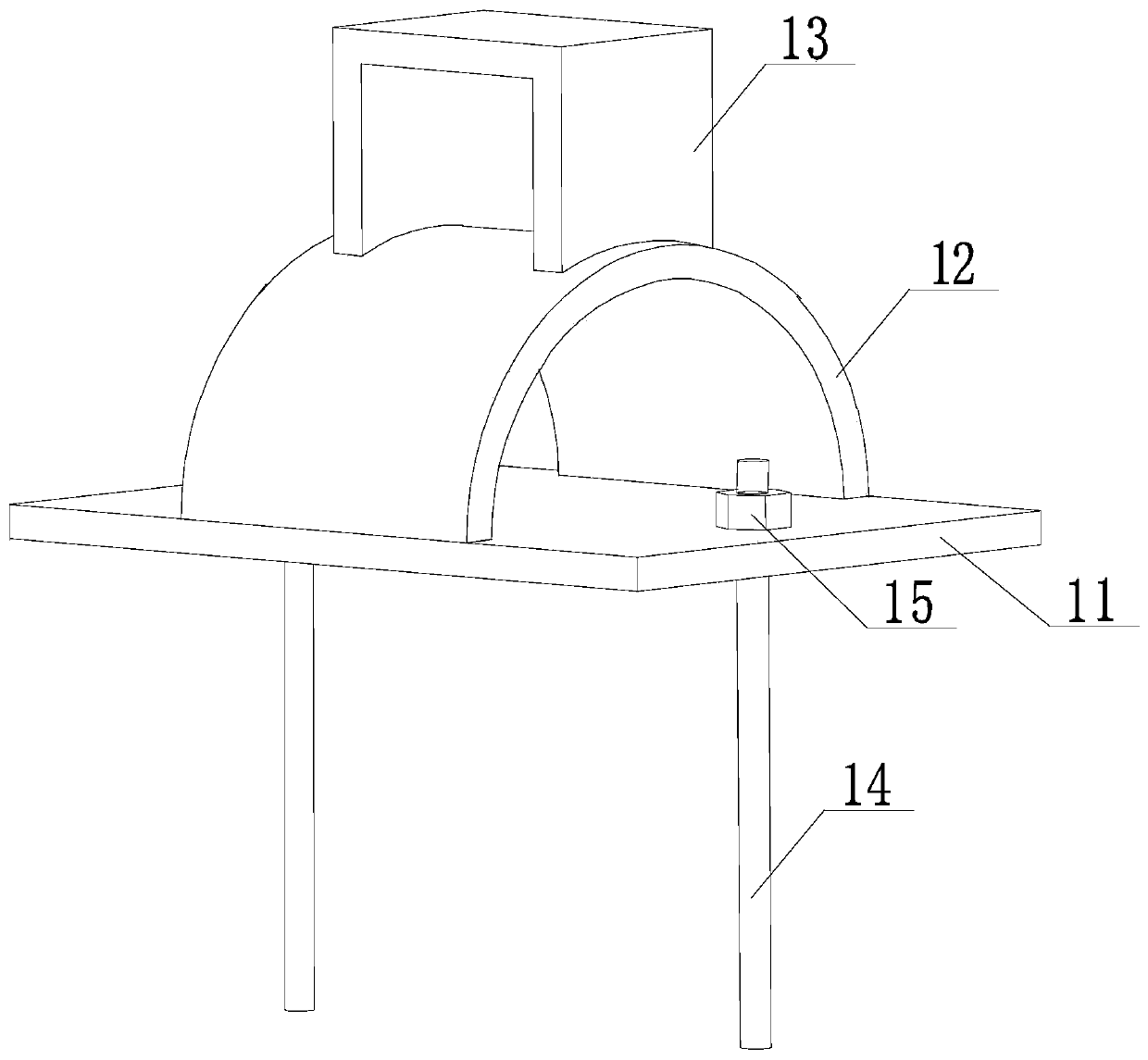

Stress steering device for anchor rope of protective net and mounting method of stress steering device

PendingCN111549692AAvoid chamfersGuaranteed anchoring effectProtective constructionBulkheads/pilesEngineeringWire rope

The invention discloses a stress steering device for an anchor rope of a protective net. The device comprises a bottom plate which is fixedly attached to a slope surface, anchor rods, an arch ring anda limiting plate; one end of each fixed anchor rod is pre-buried in the slope surface fixed by the steel wire rope anchor, the other end of each fixed anchor rod is fixedly connected with the bottomplate, the bottom of the arc-shaped arch ring is fixedly connected with the front side and the rear side of the bottom plate, the steel wire rope anchor is bent to surround the arc-shaped edge of thearch ring, and the limiting plate is arranged at the top of the arch ring and allows the steel wire rope anchor to penetrate. By means of the scheme, the slope protection device has the advantages ofbeing simple in structure, convenient to install, reliable in fixation and the like, and has high practical value and promotional value in the technical field of slope protection.

Owner:SICHUAN RUITIE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com