Piezoelectric tension monitoring device

A monitoring device, piezoelectric technology, applied in the direction of tension measurement, etc., can solve the problems of small beam pre-camber, small component pre-stress, pressure sensor can not be reused, etc., to achieve good stability and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

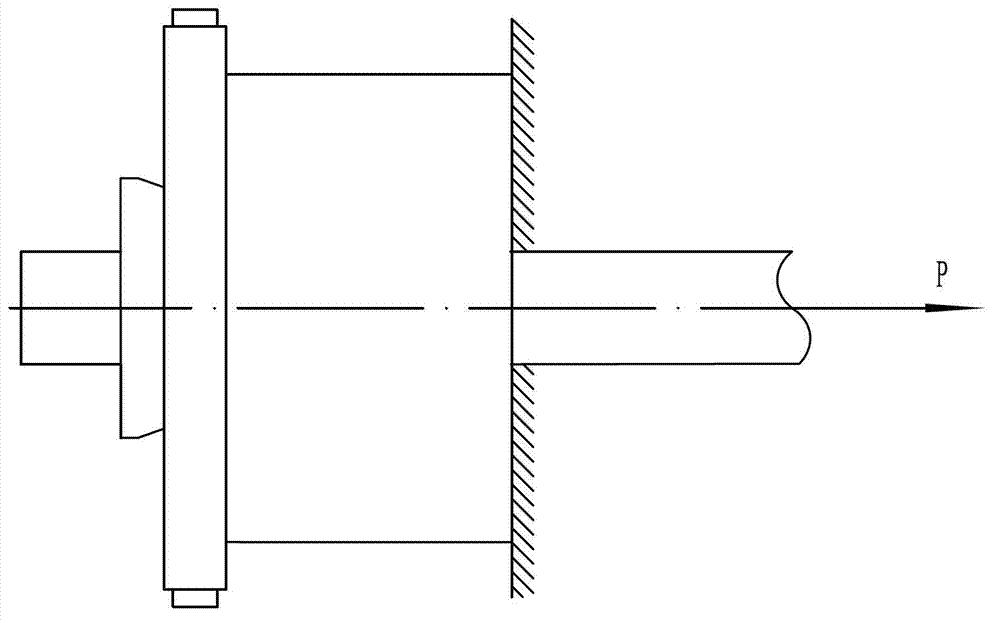

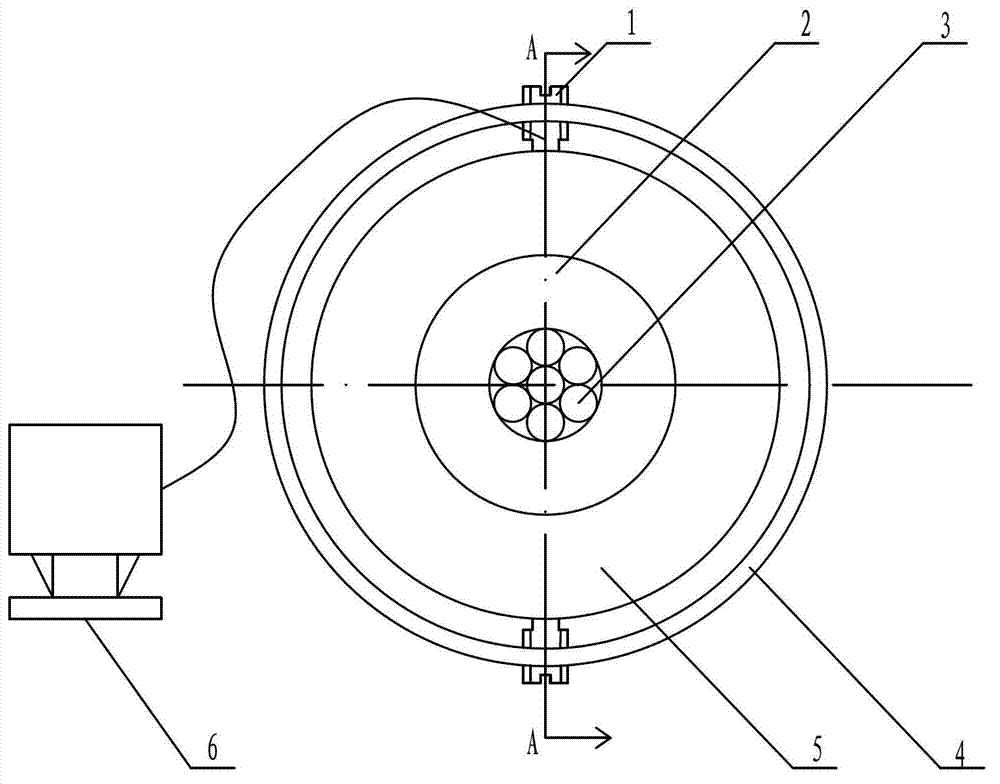

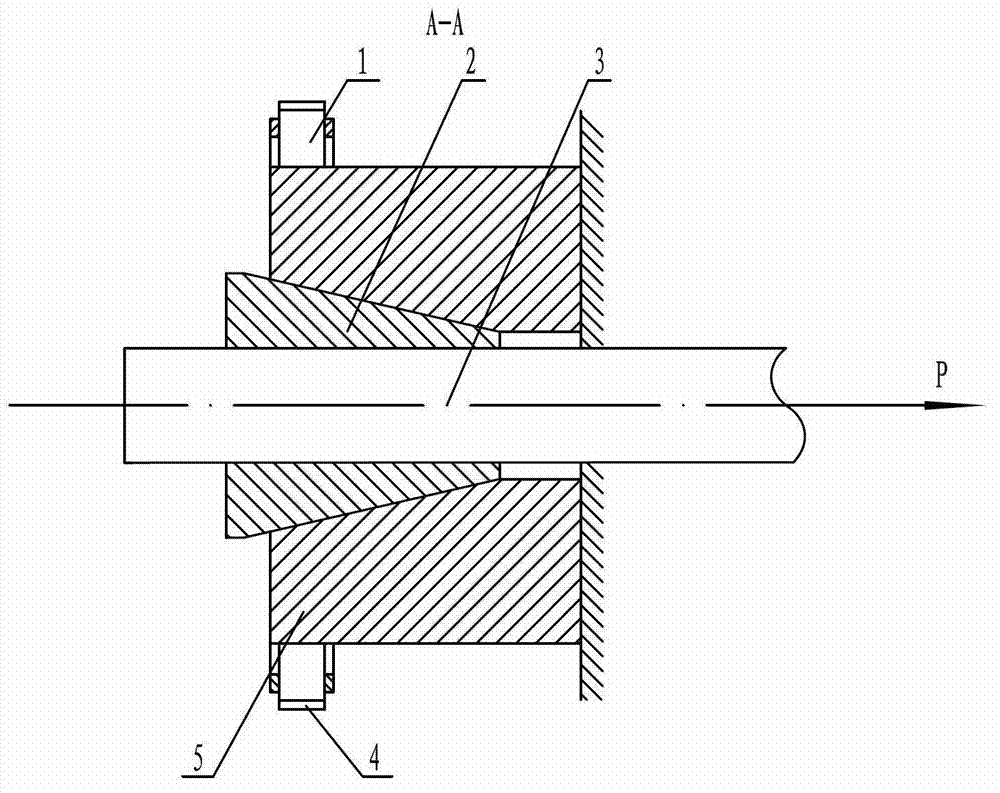

[0016] exist figure 1 , 2 , 3, the piezoelectric tension monitoring device of this embodiment is composed of a piezoelectric sensor 1, a clip 2, a steel strand 3, a ring 4, an anchor ring 5, and a computer 6 connected.

[0017] A clip 2 is installed outside the steel strand 3 to be tested, and the cone angle of the clip 2 is 15°. An anchor ring 5 is set on the outside of the clip 2. The geometry of the clip 2 and the anchor ring 5 is the same as that of the existing project. The anchorage used in is the same, the center of the anchor ring 5 is processed with a center hole, the center hole is a tapered hole, and the taper of the center hole is the same as that of the clip 2. Anchor ring 5 is covered with a ring 4, and two piezoelectric sensors 1 are installed on the ring 4 between the outer surface of the ring 4 and the outer surface of the anchor ring 5 through threads. The centerlines of the two piezoelectric sensors 1 are on the same diameter. The two piezoelectric sensor...

Embodiment 2

[0021] In this embodiment, a circular ring 4 is sheathed on the anchor ring 5. Between the circular ring 4 and the outer surface of the anchor ring 5, three piezoelectric sensors 1 are installed on the circular ring 4 through threads. The included angle between the centerlines of the electric sensors 1 is 120°, the structure of the piezoelectric sensors 1 is the same as in embodiment 1, and the three piezoelectric sensors 1 will receive the tensile force and steel strands 3 that are borne by the steel strands 3. The pressure received by the deformation of the anchor ring 5 caused by the clip 2 is converted into an electrical signal and output to the computer 6, and the computer 6 performs calculations according to a preset program to calculate the tension force of the steel strand 3. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0023] In this embodiment, a circular ring 4 is sheathed on the anchor ring 5, and four piezoelectric sensors 1 are installed on the circular ring 4 through threads evenly distributed between the circular ring 4 and the outer surface of the anchor ring 5. The included angle between the centerlines of the electric sensors 1 is 90°, the structure of the piezoelectric sensors 1 is the same as in embodiment 1, and the four piezoelectric sensors 1 will receive the tensile force borne by the steel strands 3, the steel strands 3 The pressure received by the deformation of the anchor ring 5 caused by the clip 2 is converted into an electrical signal and output to the computer 6, and the computer 6 performs calculations according to a preset program to calculate the tension force of the steel strand 3. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com