Pile plate anchoring rope and construction method for reinforcing side slope of backfilled roadbed supported by said anchoring rope

A technology of anchor cable support and pile slabs, which is applied in foundation structure engineering, sheet pile walls, excavation, etc., and can solve the problems of uneven stress on pile slabs and slopes, large loads on pile slabs, and poor anchoring effects , to achieve the effect of long-term stability, large anchoring force, and guaranteed anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

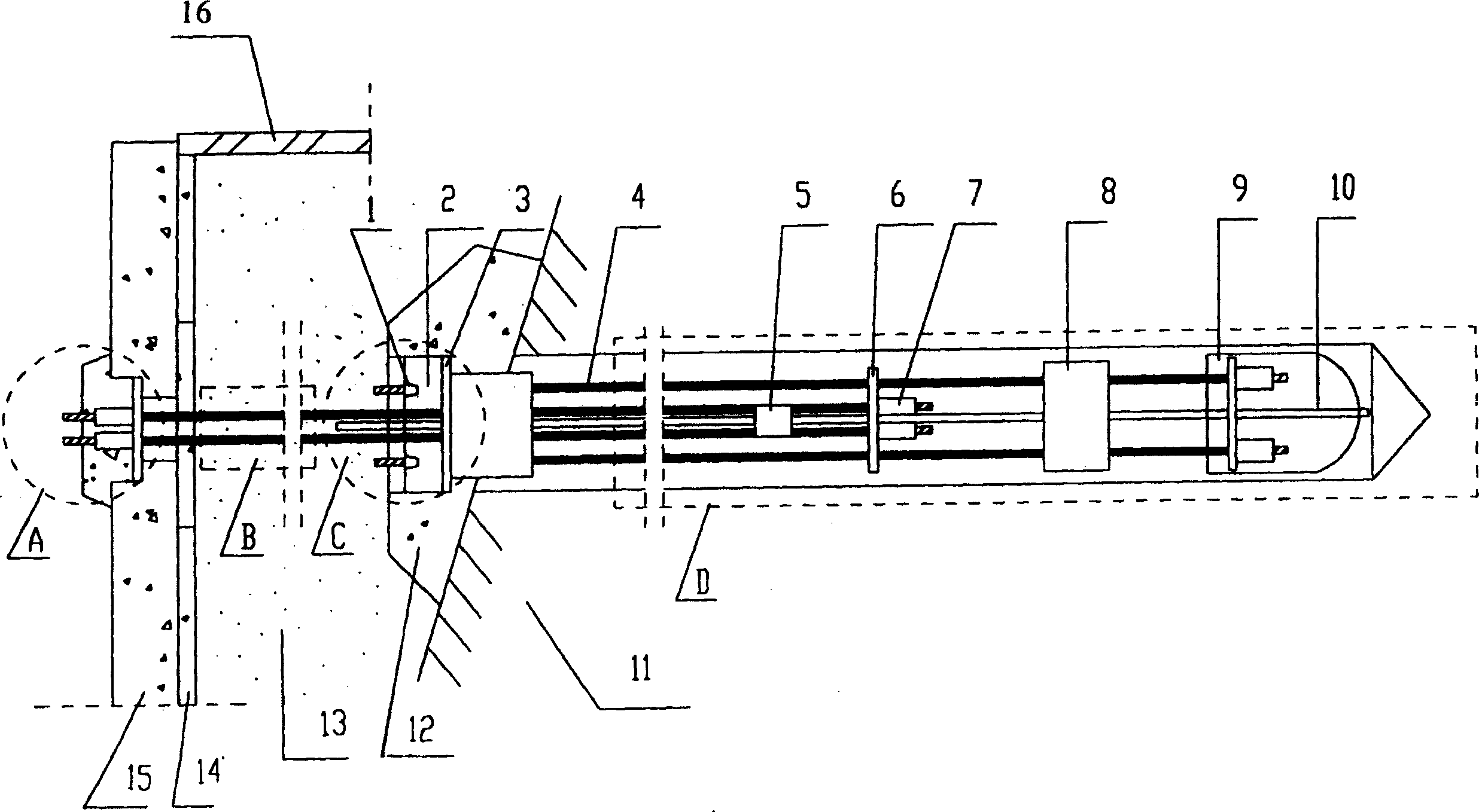

[0040] A pile plate anchor cable.

[0041] Such as figure 1 As shown, the pile-slab anchor cable of the present invention is composed of an outer anchor head, a free section B, and an anchor section D. The anchor cable has two outer anchor heads of a pile-slab anchor head A and a slope anchor head C. All steel strands The anchorage section is formed through the anchor head C of the slope body. A part of the steel strand is anchored on the anchor head A of the pile plate, and a part of the steel strand is anchored on the anchor head C of the slope body. Through the steel strand wire and each outer anchor head The number of connected bearing bodies can be equal or unequal. There are m bearing bodies connected to the anchor head A of the pile plate, and n bearing bodies connected to the anchor head C of the slope body. The total sum of the two is m +n, where: 1≤m≤4, 1≤n≤10, n≥m, 2≤m+n≤12;

[0042] In this embodiment, the bearing body connected to the anchor head A of the pile p...

Embodiment 2

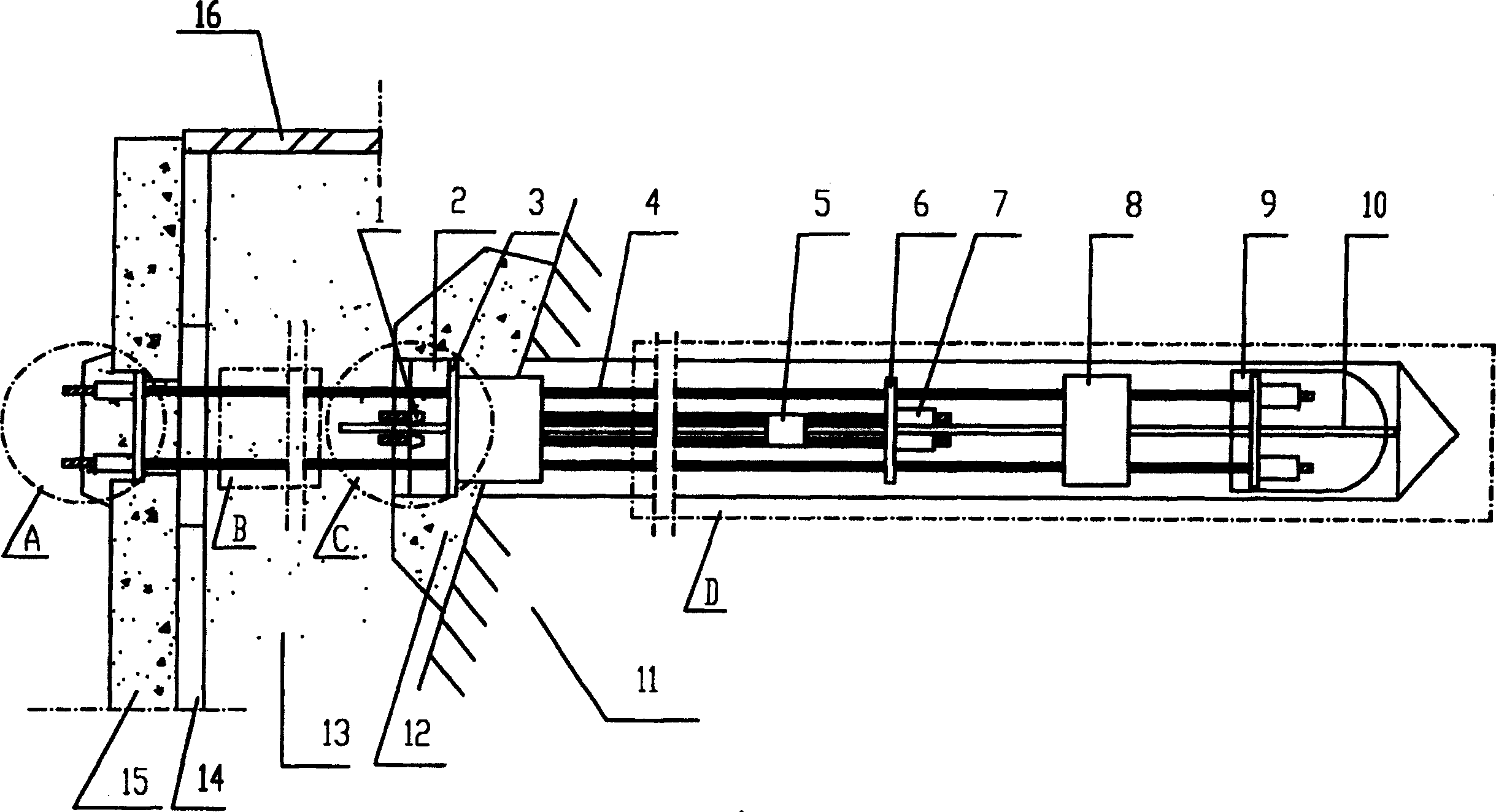

[0055] A pile plate anchor cable.

[0056] Such as figure 2 As shown, the pile-slab anchor cable is still composed of an outer anchor head, a free section B, and an anchor section D. The anchor cable has two outer anchor heads, the pile-slab anchor head A and the slope body anchor head C. The pile-slab anchor cables are the same; the difference is that the positions of the bearing bodies connected to the pile-slab anchor head A through the steel strands are different. In the pile-slab anchor cables of this embodiment, the The bearing body connected to the anchor head A is the 1st to m ones farthest from the anchor head of the slope in turn, and 1≤m≤4.

Embodiment 3

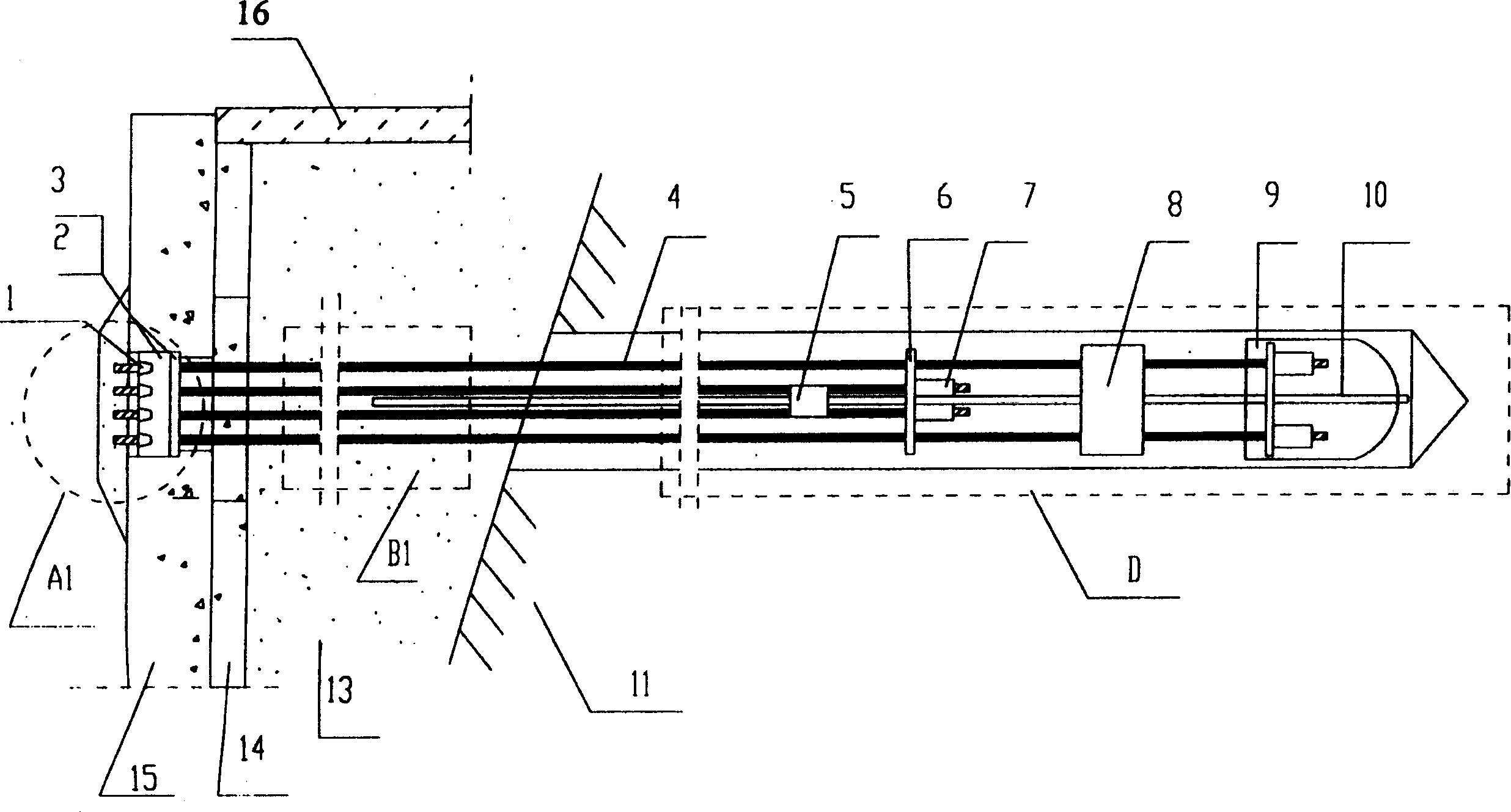

[0057] Embodiment 3: A construction method using the pile plate anchor cable support and backfill roadbed slope reinforcement technology described in Embodiment 1.

[0058] The construction method includes the following main process:

[0059] (1) Hole making:

[0060] (2) Production and installation of anchor cables: Calculate the length of the steel strands of the anchor cable according to the drilling depth and the structure diagram, remove 10-20cm of PE layer from the end of each steel strand, and thread the longest two steel strands of equal length Pass through the topmost first layer of bearing plate, install the elastic gasket, put the extrusion sleeve on the steel strand close to the elastic gasket, squeeze the extrusion sleeve with a through-core extruder and lock it, and then put the second The second-layer bearing plate is set on the longest two steel strands, and the second longest two equal-length steel strands are inserted into the second-layer bearing plate, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com