Soil extrusion expansion anchor rod structure

An expansion bolt and bolt technology, applied in basic structure engineering, sheet pile wall, excavation and other directions, can solve the problems of insufficient anchoring force, burst failure, insufficient mechanical properties, etc., to achieve strong practicability, reduce friction resistance, Guarantee the effect of anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

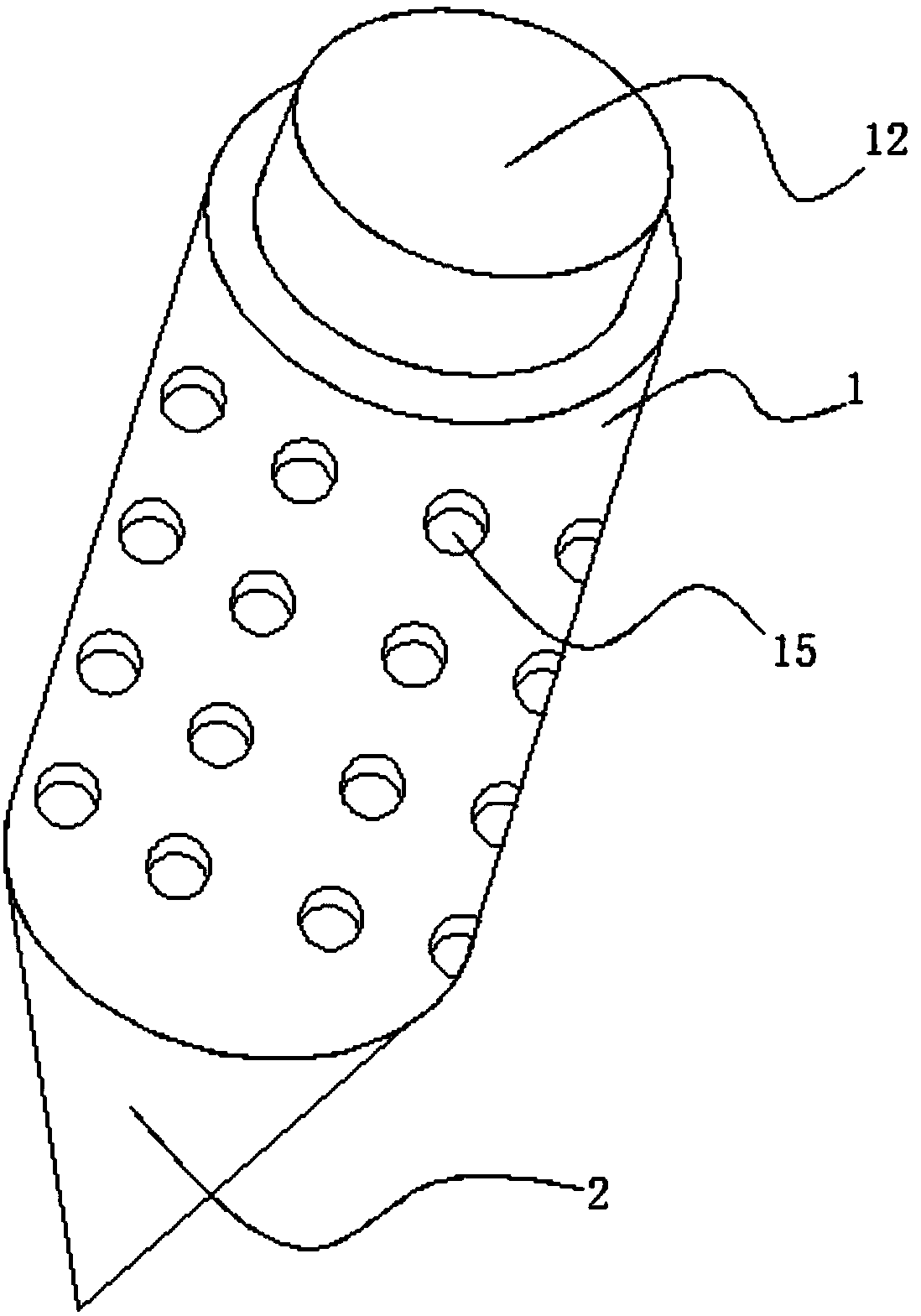

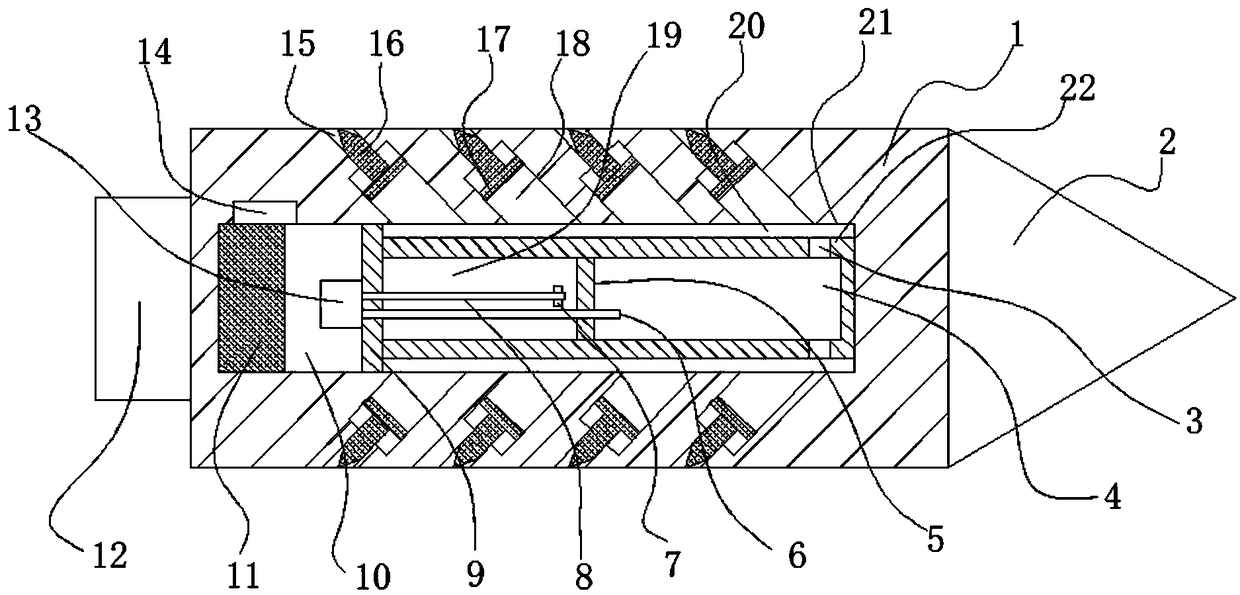

[0023] see Figure 1~3 , in an embodiment of the present invention, a soil-squeezing expansion anchor structure includes an anchor body 1, the anchor body 1 is a cylindrical structure integrally formed, the right end of the anchor body 1 is provided with a tip 2, and the anchor There is an installation cavity 21 inside the rod body 1, and the left port of the installation cavity 21 is fixed with a cover by welding. The inside of the anchor rod body 1 where the cover is located is provided with a transmission block 12, and the transmission block 12 enters the interior of the anchor hole with the conveying device. The power mechanism of the installation chamber 21 is provided with several piston chambers 18 and storage holes 15 on the wall of the installation chamber 21. The storage chamber 15 communicates with the piston chamber 18. The piston chamber 18 is inclined against the left end of the bolt body 1, and the piston The included angle between the axis of the chamber 18 and...

Embodiment 2

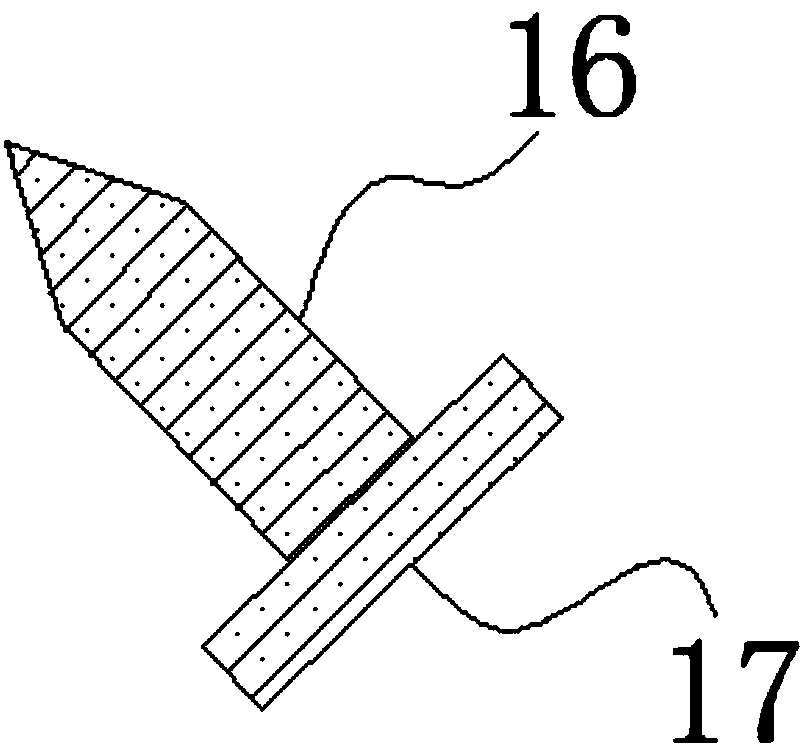

[0029] The difference from Embodiment 1 is that in order to improve the gripping effect of the anchor rod 16, the anchor rod 16 here can be arranged in the shape of a rectangular plate, and the outer end of the rectangular plate is a pointed end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com