Magnesium-based metal-soluble bridge plug

A magnesium-based metal and bridge plug technology, which is used in wellbore/well components, earthwork drilling, sealing/packaging, etc. problem, to achieve the effect of reliable dissolution performance, rapid dissolution, and increased flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

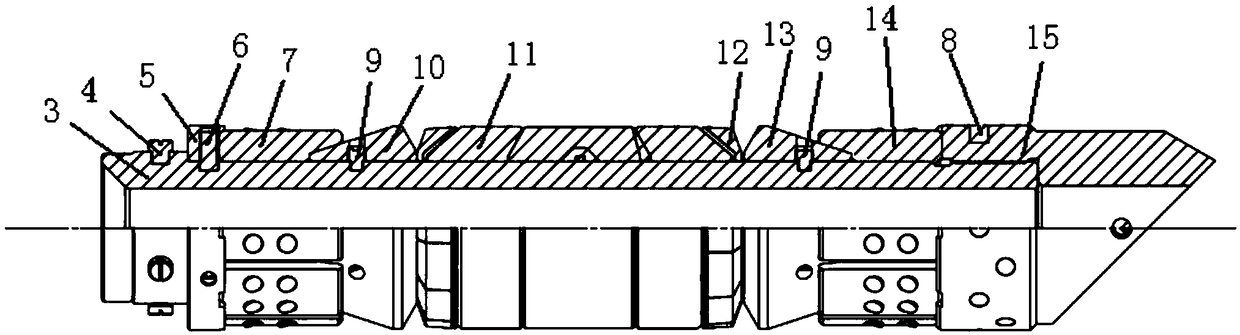

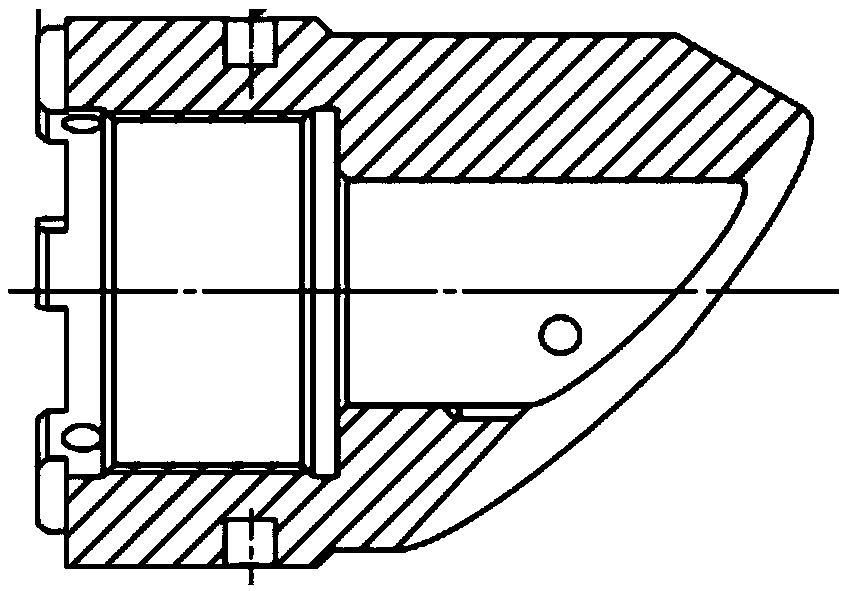

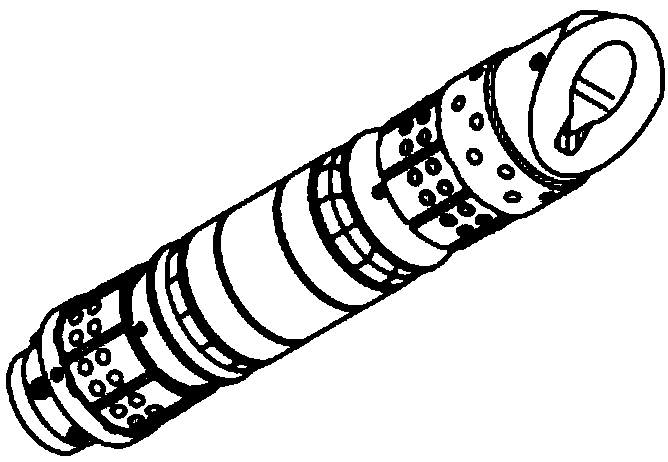

[0028] A magnesium-based metal dissolvable bridge plug, such as Figure 1~4 As shown, it includes central tube 3, throwing shear nails 4, spacer ring 5, upper slips 7, upper vertebral body 10, rubber tube 11, protective ring 12, lower vertebral body 13, lower slips (14) and base (15 ); the spacer ring 5, the upper slip 7, the upper vertebral body 10, the rubber tube 11, the protective ring 12, the lower vertebral body 13, and the lower slips 14 are set on the central tube 3 from top to bottom in sequence, and the base 15 passes through The external thread at the lower end of the central tube 3 is connected to the central tube 3; the upper end of the central tube 3 is fixed on the connecting head of the setting cylinder through the shear nail 4, and the upper end of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com