A slope anchoring device for municipal engineering

An anchoring device and engineering technology, which is applied in basic structure engineering, construction, excavation, etc., can solve the problems that the needles cannot reach the expected insertion depth and affect the anchoring effect of the anchoring support device, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

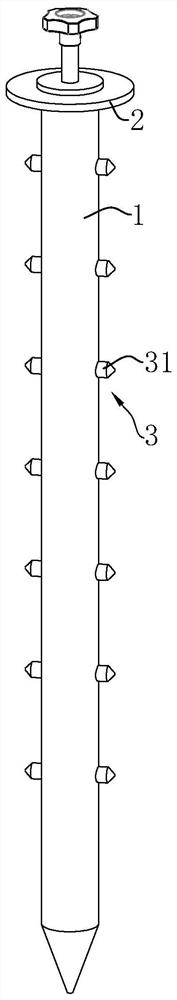

[0039] refer to figure 1, the present invention discloses a slope anchoring device for municipal engineering, which includes an anchor pipe 1 pierced into the slope ground, and the anchor pipe 1 is an oblong pipe body with a hollow inner cavity and an open top. In order to facilitate the insertion of the anchor tube 1, the bottom end of the anchor tube 1 is set as a tip. An anchor pipe fixing plate 2 for abutting against the slope ground is fixedly connected to the outer peripheral surface of the top end of the anchor pipe 1 .

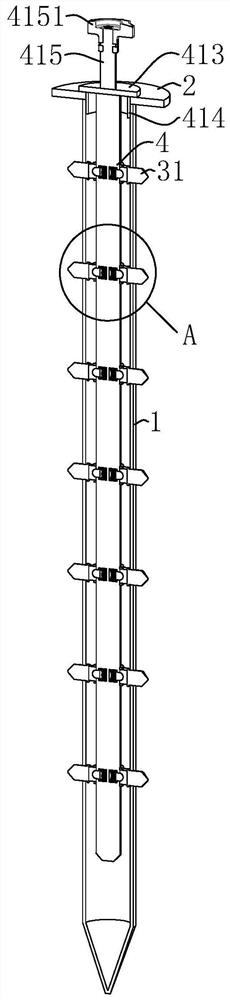

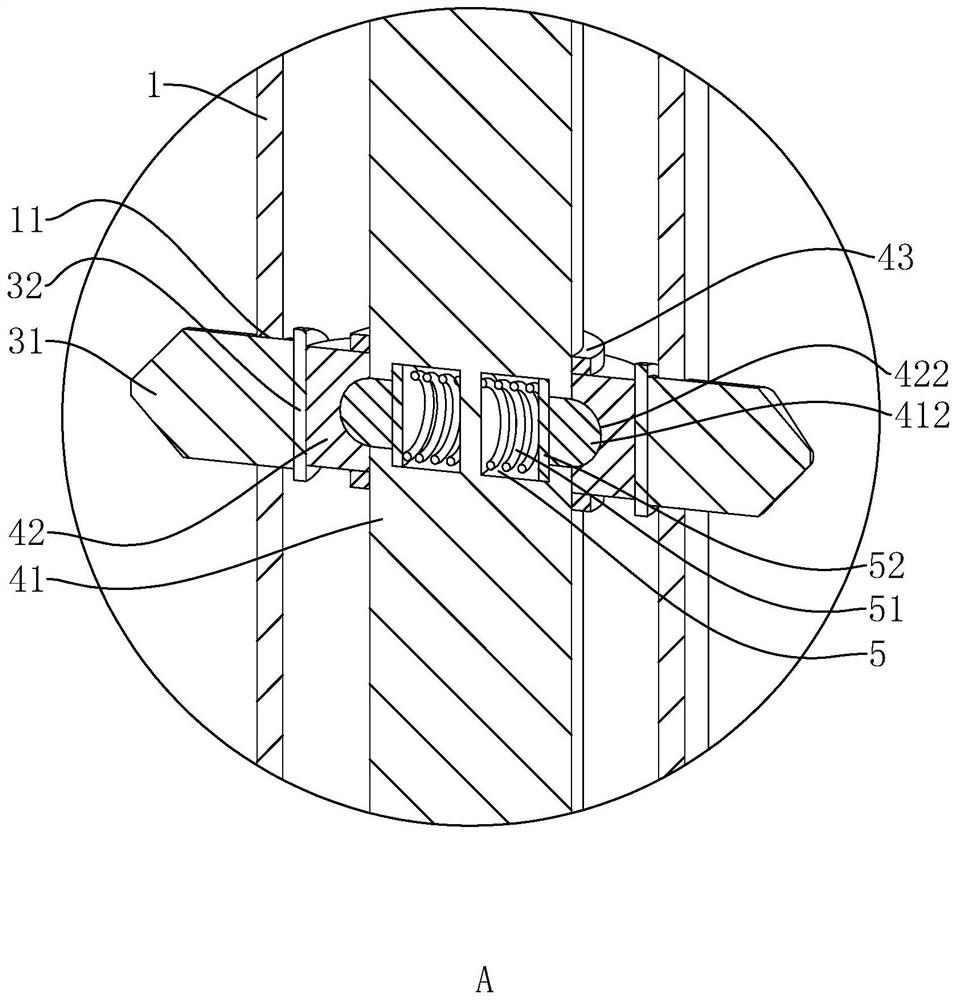

[0040] refer to figure 2 and image 3 The anchor tube 1 is provided with multiple sets of needle assemblies 3 at intervals along its axial direction, each group of needle assemblies 3 includes a plurality of needles 31 uniformly distributed along the circumferential direction of the anchor tube 1, the needles 31 are arranged radially along the anchor tube 1, and the needles 31 The end facing away from the lumen of the anchor tube 1 is the tip. The...

Embodiment 2

[0051] The difference from Embodiment 1 is that, referring to Figure 5 The slot 422 is provided on the inner side of the cam 42 away from the edge of the anchor tube fixing plate 2. The slot 422 is a quarter arc-shaped slot that runs through the inner peripheral surface of the cam 42 and the end surface adjacent to the above-mentioned edge. The slot 422 at the edge is convenient for the staff to process it.

[0052] One end of the snap-in rod 412 away from the force-applying rod 41 extends into the slot 422, and the end surface of the snap-in rod 412 facing the slot 422 abuts against the inner peripheral wall of the slot 422, and the snap-in rod 412 contacts the slot during the movement. The abutting surface of 422 is an arc surface.

[0053] The locking groove 422 can also be opened on the inner side of the cam 42 close to the edge of the anchor tube fixing plate 2, and the effect is the same as that of this embodiment.

Embodiment 3

[0055] The difference from Embodiment 1 is that, referring to Figure 6 and Figure 7 The force applying rod 41 is provided with a pressing assembly capable of pressing one end of the clamping rod 412 against the clamping groove 422. The pressing assembly includes a receiving groove 6 opened on the applying rod 41, and the receiving groove 6 is a The long groove that force rod 41 is axially arranged, the setting of accommodating groove 6 makes force application rod 41 form the hollow hollow pipe body of inner hollow, and force application rod 41 is closed along the two ends of self axial direction, and force application rod 41 top is provided with and accommodates. The one-way valve 61 connected to the cavity of the tank 6 is filled with high-pressure air in the tank 6 .

[0056] A dynamic sealing ring 4111 is fixedly connected to the inner peripheral surface of the sliding groove 411 , and the inner peripheral surface of the dynamic sealing ring 4111 abuts against the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com