Anchor rod sealing structure, anchor rod and anchor rod injection molding method

A sealing structure and anchor rod technology, which is applied in the installation of anchor rods, valve casing structures, earthwork drilling and mining, etc., can solve the problems of controlling injection pressure and complex expansion structures, and achieves reduced volume, improved anchoring force, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

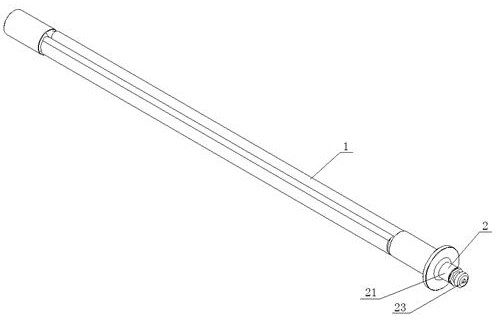

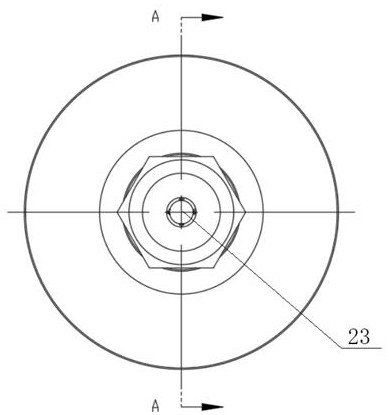

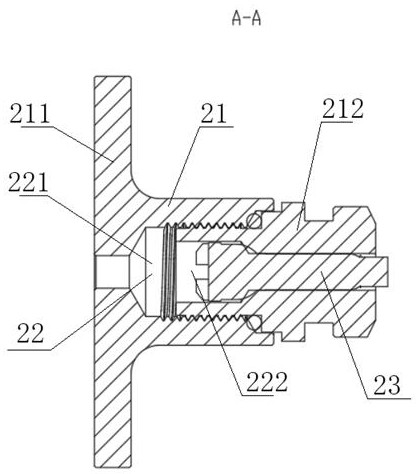

[0053] see Figure 1 to Figure 4 , the present invention provides a sealing structure for anchor rods, including a housing 21 fixedly connected to the rod body 1 of the anchor rod. Inside the housing 21, there is an inner cavity 22 penetrating through both ends. When the sealing structure is connected to the rod body 1 of the anchor rod , the inner cavity 22 communicates with the injection cavity 101 inside the rod body 1 of the anchor rod;

[0054] The interior of the inner cavity 22 is provided with two stepped structures that shrink the inner diameter in turn, and the two stepped structures are respectively formed as a first-level chamber 221 corresponding to the first-level sealing state, and a second-level chamber 222 corresponding to the second-level sealing state; the first-level cavity The inner diameter of the chamber 221 is greater than the inner diameter of the secondary chamber 222; when the sealing structure is used, one end of the shell 21 connected to the rod bo...

Embodiment 2

[0067] On the basis of Embodiment 1, the casing 21 includes a fixed casing 211 and a movable casing 212, and a primary chamber 221 is provided in the fixed casing 211;

[0068] The movable shell 212 is socketed inside the fixed shell 211, and the part of the movable shell 212 located in the fixed shell 211 is provided with a secondary chamber 222; the movable shell 212 is also provided with a liquid injection hole corresponding to the valve stem 233;

[0069] The movable shell 212 is sleeved inside the fixed shell 211 , and a gasket 3 is provided at the joint between the movable shell 212 and the fixed shell 211 .

[0070] The inner wall of the primary chamber 221 is provided with tight fine-pitched internal threads, and the part of the movable shell 212 inside the fixed shell 211 is provided with tight fine-pitched external threads, and the movable shell 212 and the fixed shell 211 are screwed together.

[0071] A connecting flange is provided on one side of the fixed shell 2...

Embodiment 3

[0074] refer to Figure 1-5 On the basis of the above-mentioned embodiments, this solution provides a kind of anchor rod, including the rod body 1 of the anchor rod, and the aforementioned anchor rod sealing structure 2, the discharge end of the sealing structure 2 is fixedly connected with the rod body 1 of the anchor rod; the rod body of the anchor rod 1. An injection cavity 101 is provided inside; the injection cavity 101 communicates with the inner cavity 22;

[0075] The rod wall of the rod body 1 of the anchor rod is a full-length expandable structure.

[0076] There is a groove on the wall of the rod body 1 of the anchor rod, and the long axis of the groove is parallel to the axis of the rod body 1; the groove is formed by one-time roll forming of a seamless steel pipe whose outer diameter is larger than the anchor hole diameter.

[0077] The injection chamber 101 corresponds to the groove as a special-shaped cavity.

[0078] There is one groove, and the wall of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com