Construction method for underground water road cutting for road in area along river during crossing underneath existing railway

A technology of existing railways and construction methods, applied in the direction of roads, roads, road repair, etc., can solve the problems affecting the safe operation of railways, piping and quicksand, slope instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

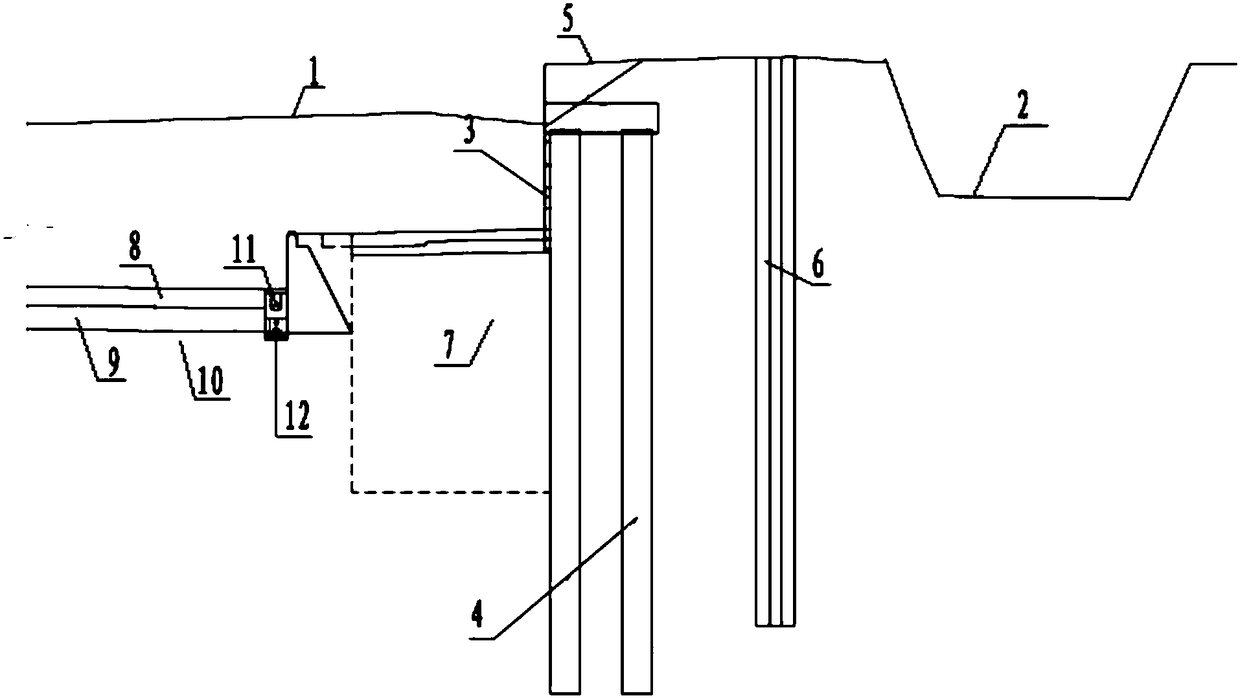

[0057] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0058] The embodiment of the present invention discloses a construction method of underground water cutting when the road along the river passes under the existing railway, including the following steps:

[0059] (1) The silt and sandy soil are distributed in a lens shape within the scope of the underpass engineering site. The groundwater level in this section is relatively high and has a certain degree of pressure, and the project is parallel to the river and is relatively close to the river. In order to prevent foundation pit excavation In case of problems such as piping, quicksand, and a large amount of groundwater seeping into the softened base, high-pressure jet grouting piles are used to set up water-stop curtains on the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com