Blower resistor installation mistake-proof structure

A blower and resistor technology, applied in the field of automotive parts, can solve problems such as irrationality, waste of assembly time, and failure to be controlled, and achieve the effects of simple structure, improved assembly efficiency, and reduced assembly judgment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further describe the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited within the scope of the embodiments.

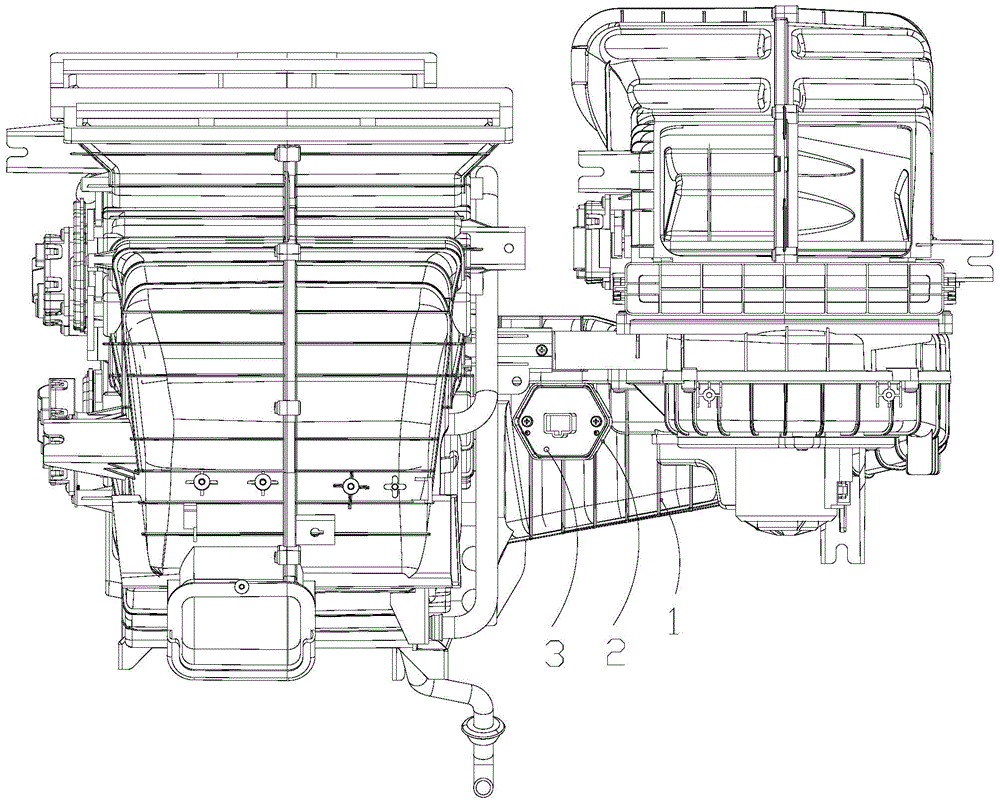

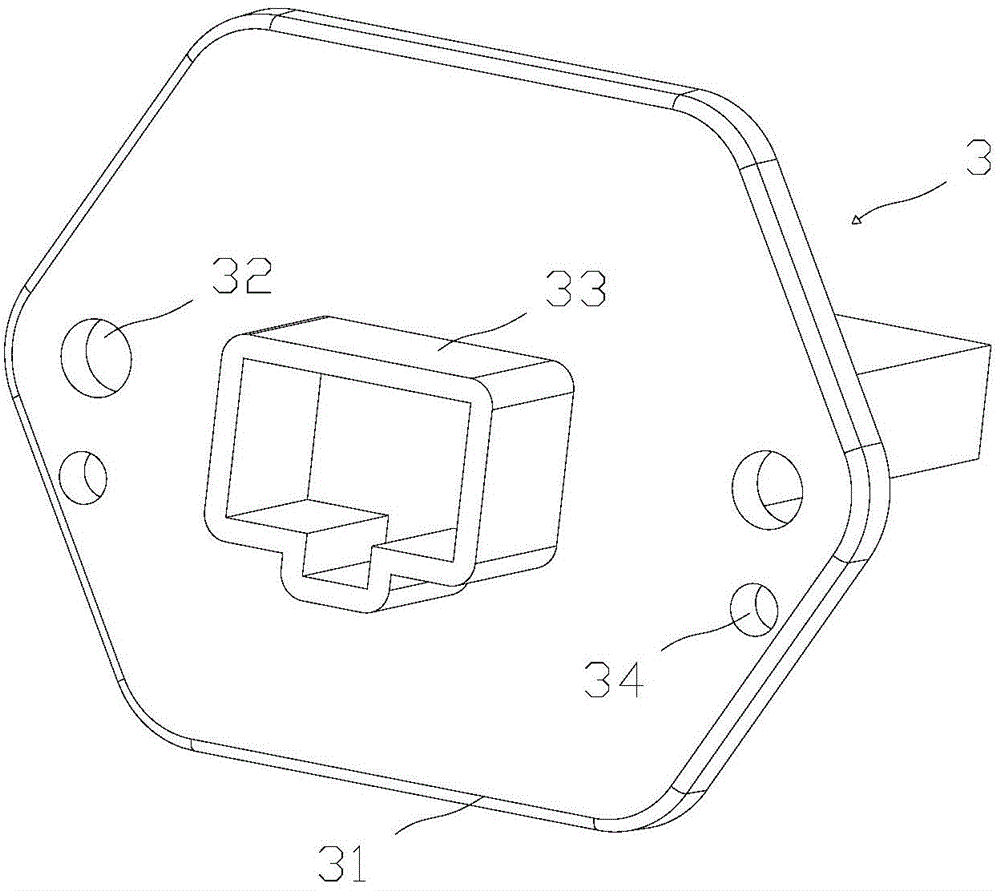

[0012] see Figure 1-3 As shown, a blower resistance installation error-proof structure includes a blower housing 1 with a resistance installation end face, the resistance installation end face is an installation groove 2 hollowed out in the blower housing 1, and a resistance installation plate 3 is placed in the installation groove 2 in.

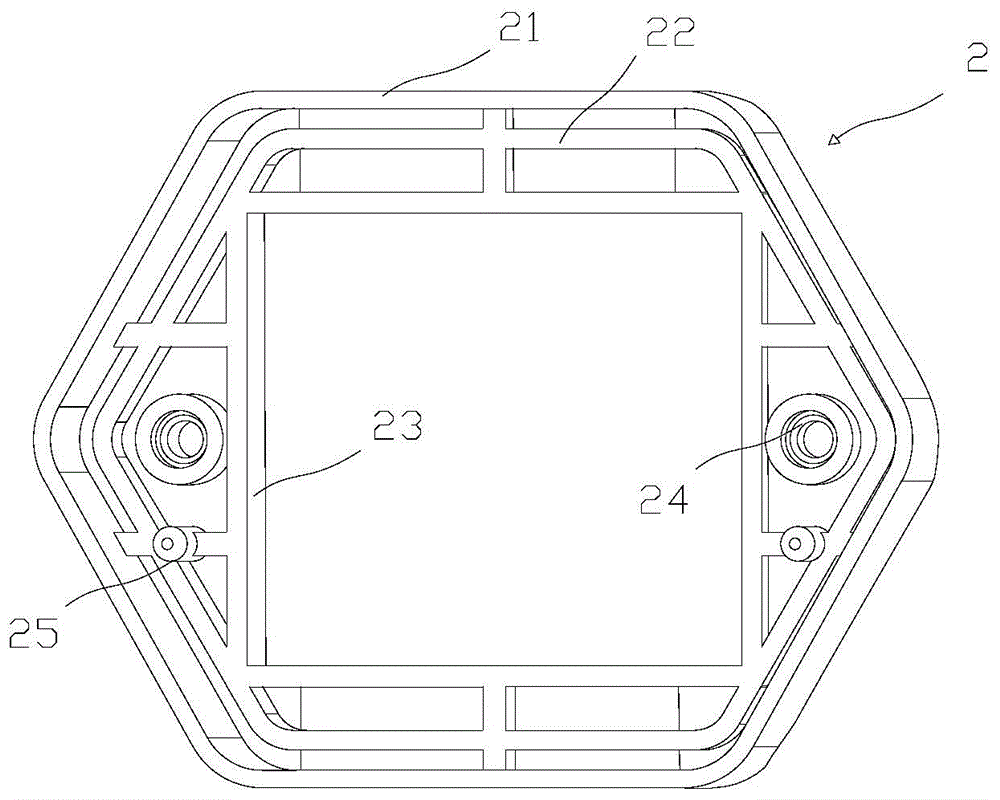

[0013] The mounting groove 2 includes a regular hexagonal frame body 21, the frame body 21 has a regular hexagonal mounting frame 22 whose height is lower than the frame body 21, and the mounting frame 22 has a mounting frame 22 and the like. The tall square support frame 23 is provided with a circular mounting sleeve 24 on the left and right sides of the support frame 23, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com