Roller chain

A technology of chains and rollers, applied in the direction of transmission chains, etc., can solve the problems of power transmission friction loss, large contact area, and large friction resistance, and achieve the effects of reducing friction loss, reducing contact area, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

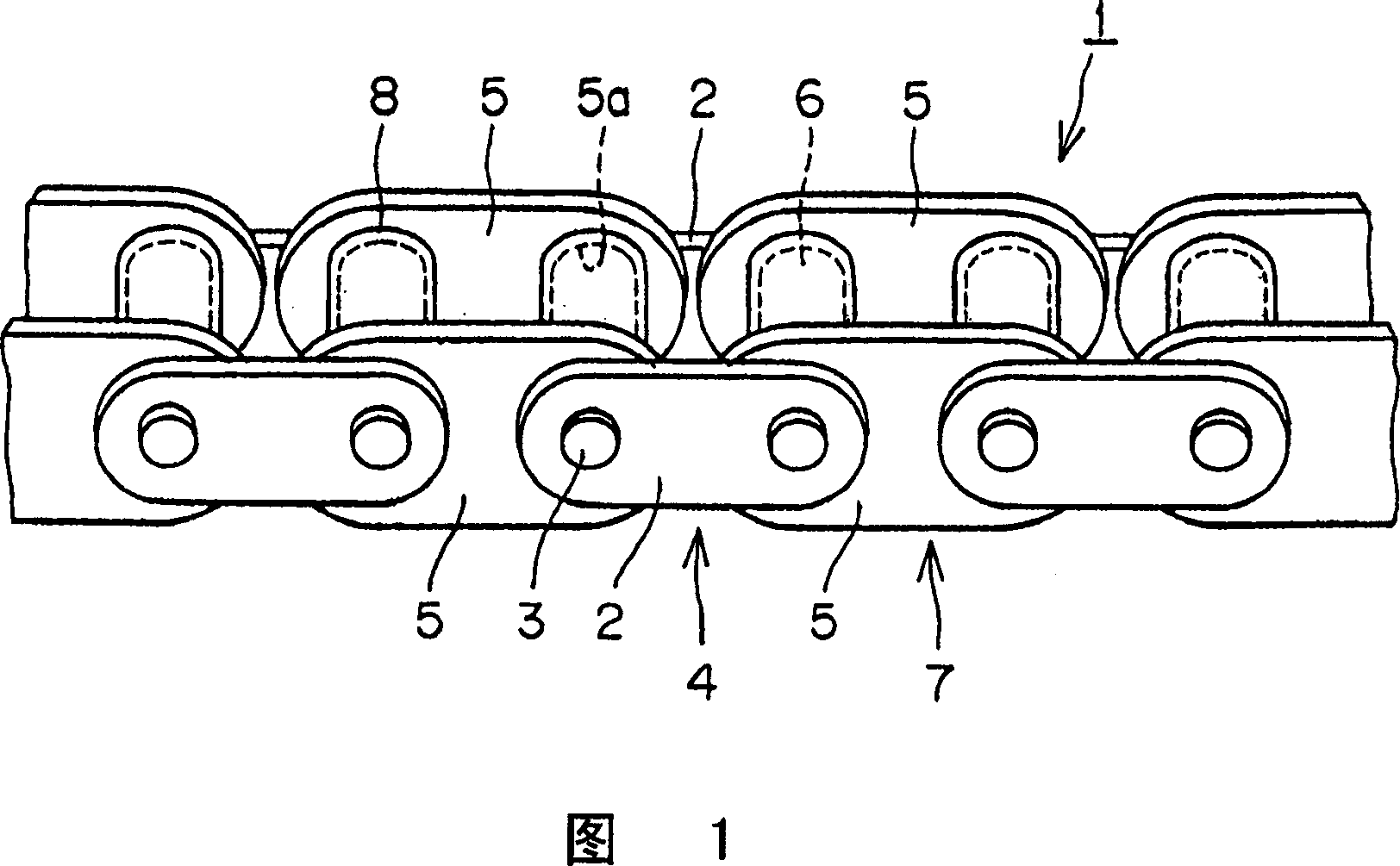

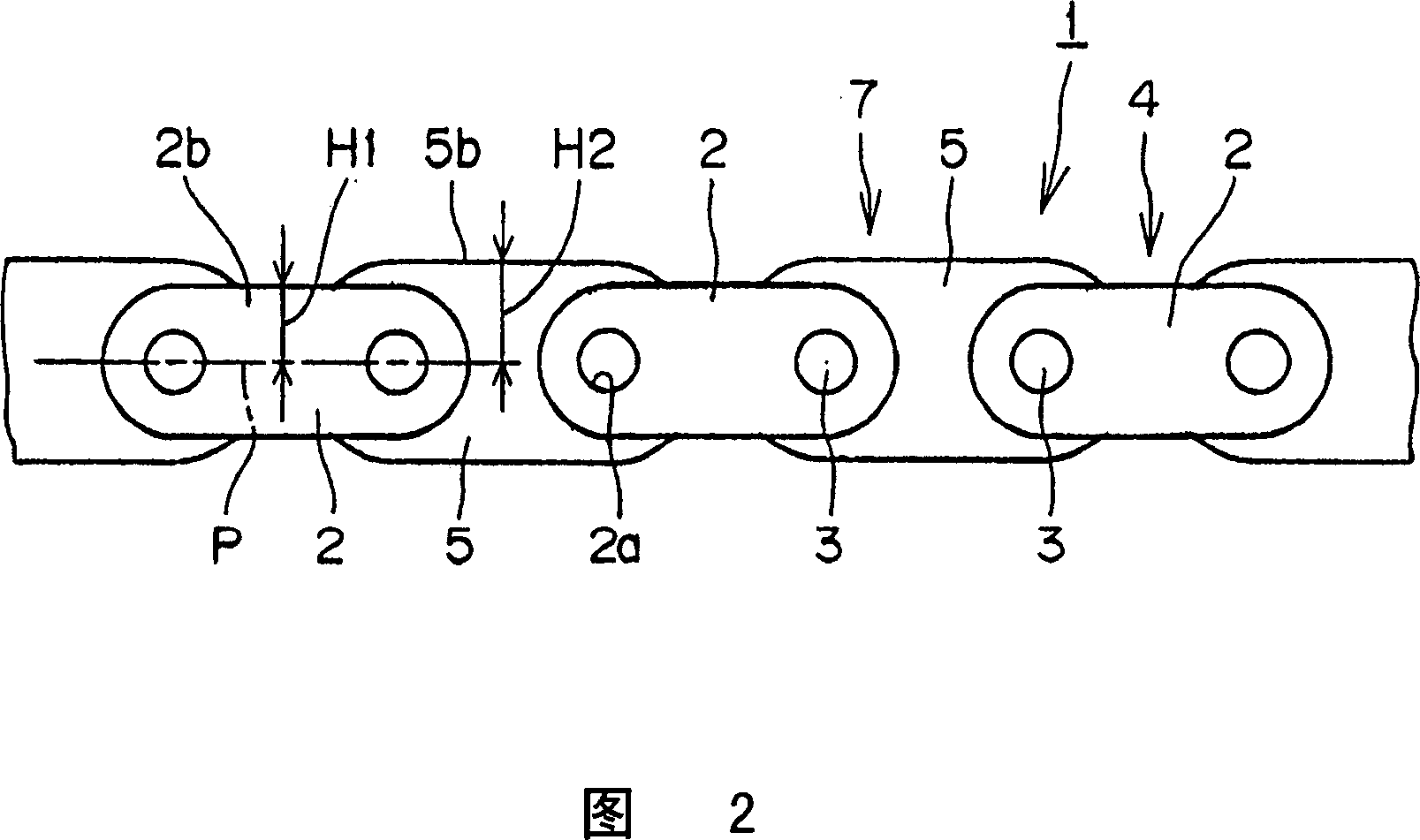

[0044] Embodiment 1 of the present invention will be described with reference to FIG. 1 and FIG. 2 . FIGS. 1 and 2 are partial perspective views and partial side views showing a roller chain exaggeratedly showing a roller chain in which the rear surface height of the outer link plate is lower than that of the inner link plate.

[0045] The roller chain 1 includes: the outer link 4 with the pin 3 embedded and fixed in the pin hole 2a of a pair of outer link plates 2; and the sleeve with the sleeve 6 embedded and fixed in the pair of inner link plates 5 The inner link 7 and the roller 8 in the hole 5a are loosely inserted into the bush 6 so as to be rotatable. Further, the roller chain 1 is formed to be bendable by loosely inserting the pins 3 into the bushes 6 to alternately connect the outer links 4 and the inner links 7 .

[0046] In the roller chain 1, the outer link plate 2 of the outer link 4 and the inner link plate 5 of the inner link 7 all form an ellipse. In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com