Labyrinth type oil seal structure with holes for high speed axis

A labyrinth seal and labyrinth technology, applied in the direction of engine seals, toothed components, belts/chains/gears, etc., can solve the problems of lubricating oil leakage, decreased sealing effect of lubricating oil, environmental pollution, etc., to achieve Prevent external leakage and weaken the effect of adsorption retardation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

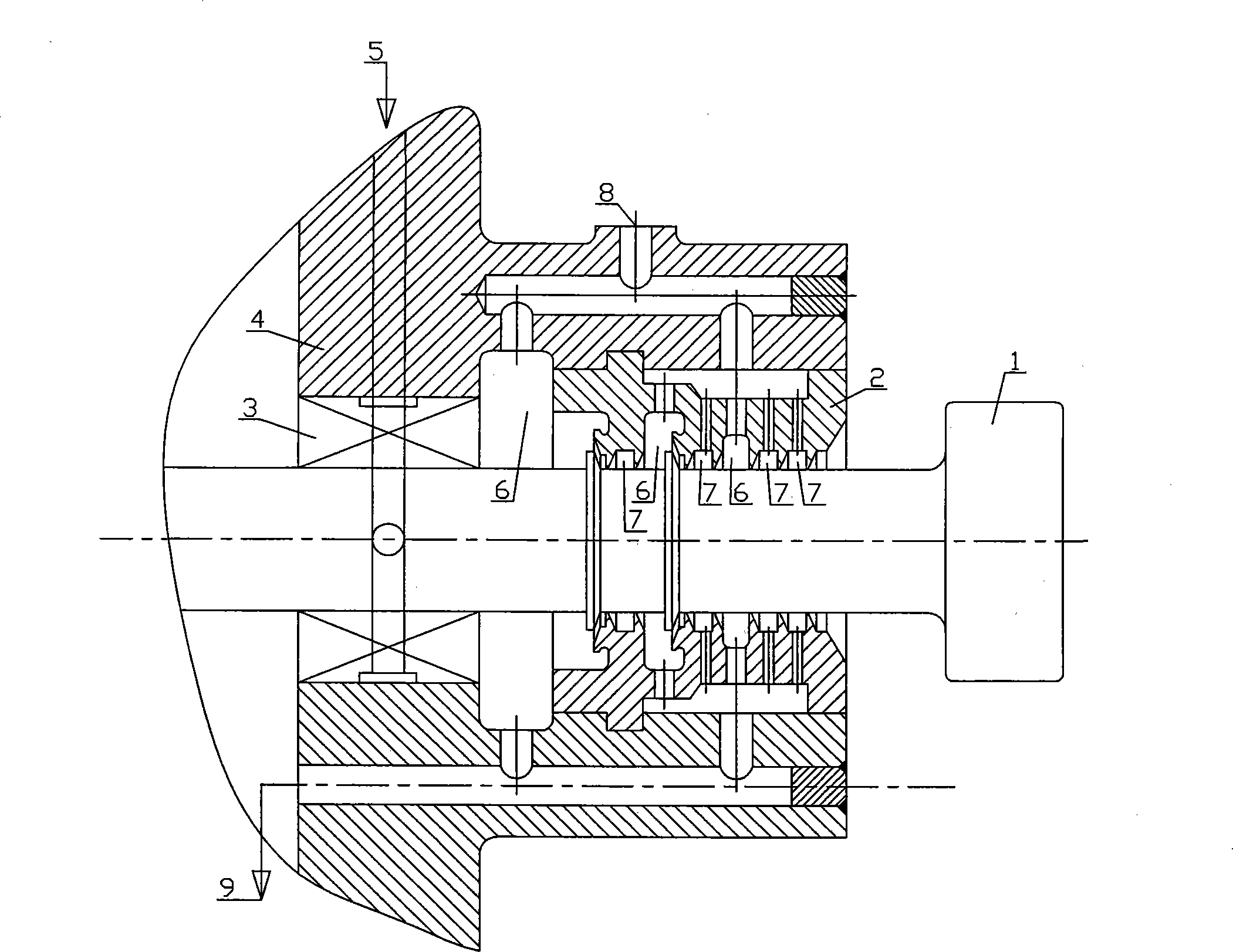

[0010] Such as figure 1 As shown: it mainly includes an output shaft 1, a labyrinth oil seal 2, a tilting pad bearing 3, and a gear box 4. The output shaft 1 is installed in the gearbox body 4, driven by the gear pair, the output shaft 1 rotates at high speed under the support of the tilting pad bearing 3, and the pressure lubricating oil between the shaft and the bearing enters from the oil supply system through the oil inlet 5 , when the amount of oil is large, the lubricating oil is easy to leak from the output shaft under pressure. The effect of labyrinth oil seal 2 is exactly to prevent this external leakage. The labyrinth oil seal 2 is provided with several grooves, and forms a labyrinth seal structure with the output shaft 1 . The labyrinth seal structure is mainly composed of the interstage space 6 and the interdental space 7, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com