Retaining ring

A clasp and fastener technology, which is applied to flange connections, pipes/pipe joints/fittings, passing components, etc., can solve problems such as injury to installers, unsafe clasps, and inability for installers to complete locking operations with bare hands , to achieve the effect of preventing outward leakage and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

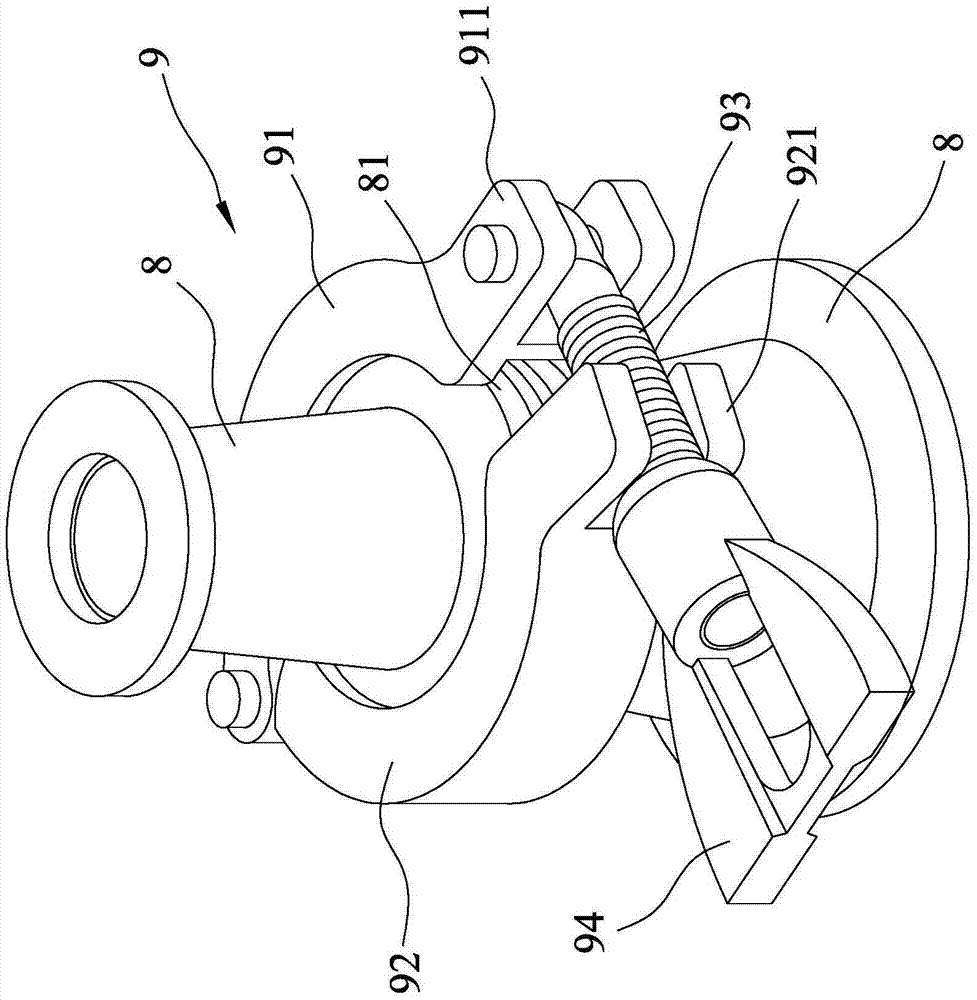

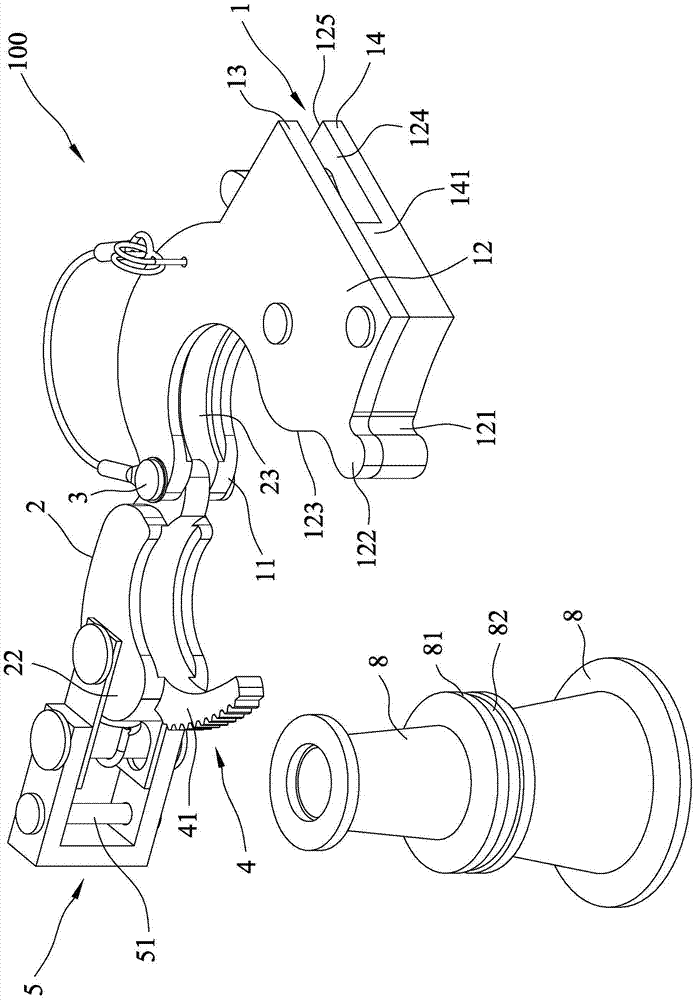

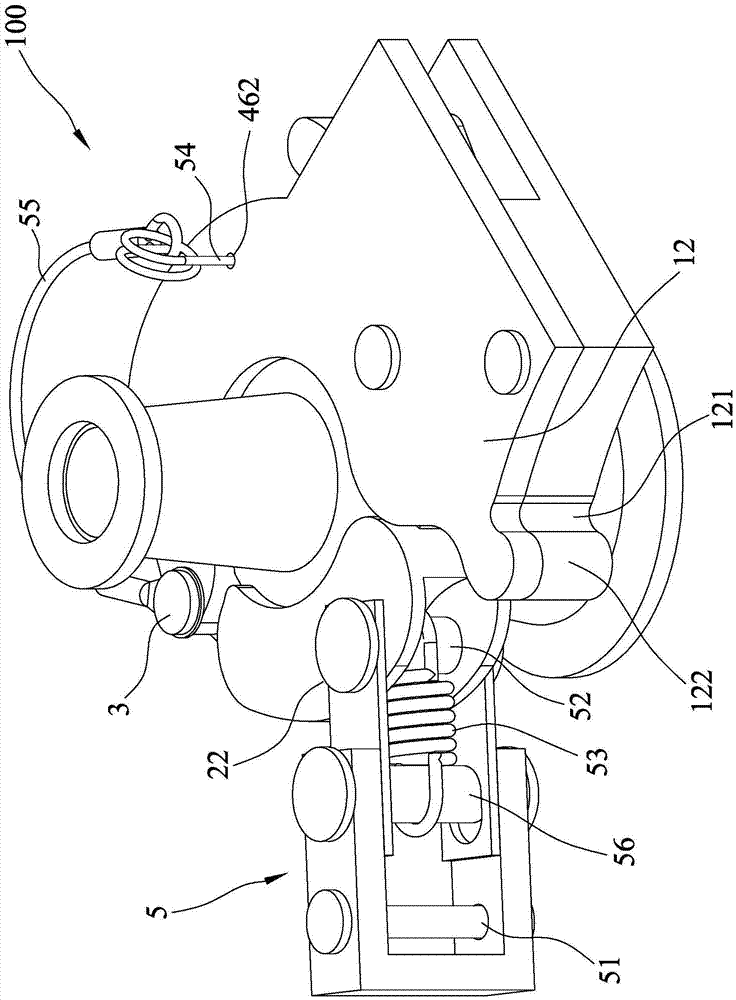

[0038] refer to Figure 2 to Figure 5 , a first embodiment of the clasp 100 of the present invention is suitable for installation at the joint 81 of two pipes 8, and a seal 82 is interposed between the pipes 8. In this first embodiment, the seal 82 For the O-ring.

[0039] The clasp 100 includes a first half fastener 1 , a second half fastener 2 , a fixed shaft 3 , a tightening unit 4 , and an anti-release unit 5 .

[0040] The first half fastener 1 includes a first pivoting end portion 11 , a first positioning end portion 12 , an upper cover 13 , and a lower cover 14 . The first positioning end portion 12 has a flange 122 including an abutting surface 121 , and a first opening 123 ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com