Composite plastic woven bag for fine powder product

A composite plastic and woven bag technology, applied in paper/cardboard containers, container manufacturing machinery, containers, etc., can solve the problems of vehicle soiling, environmental pollution, sticking, etc., and achieve the effect of preventing external leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

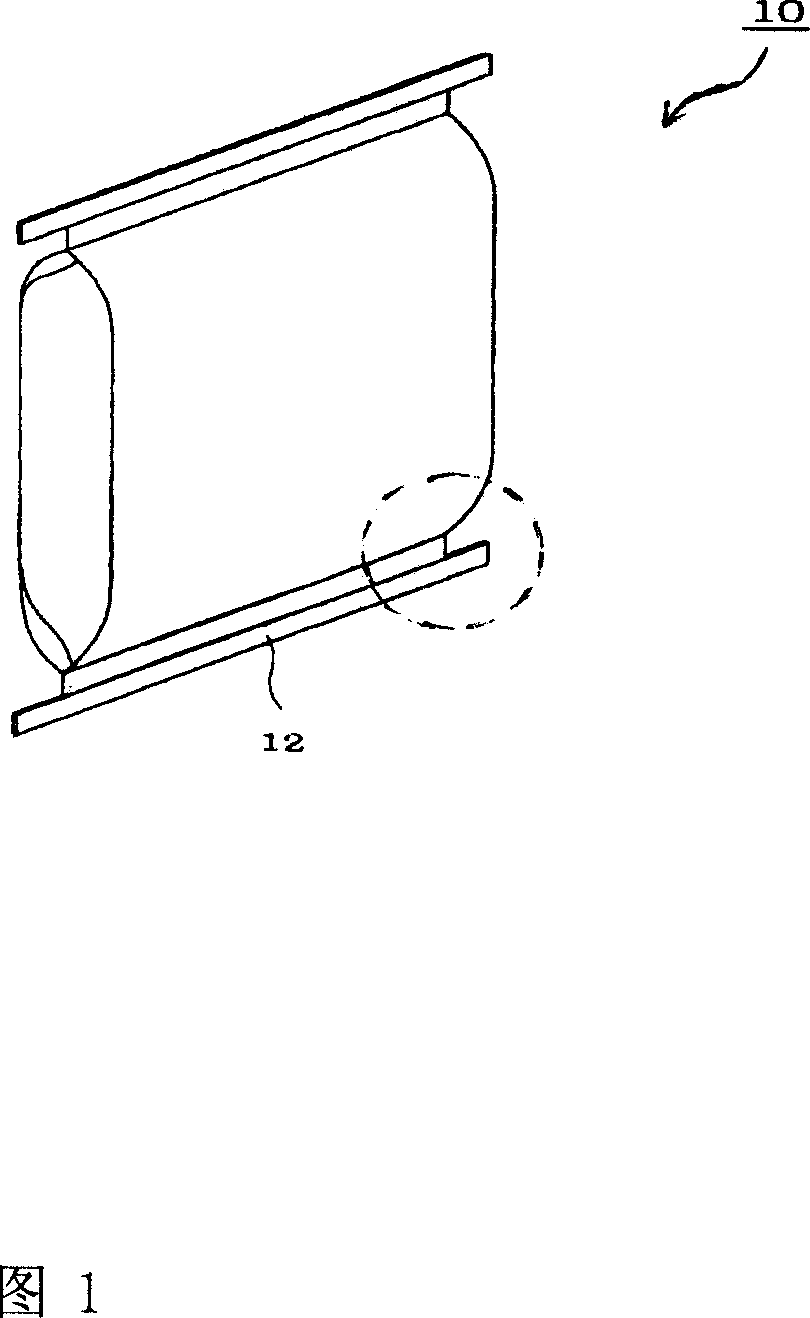

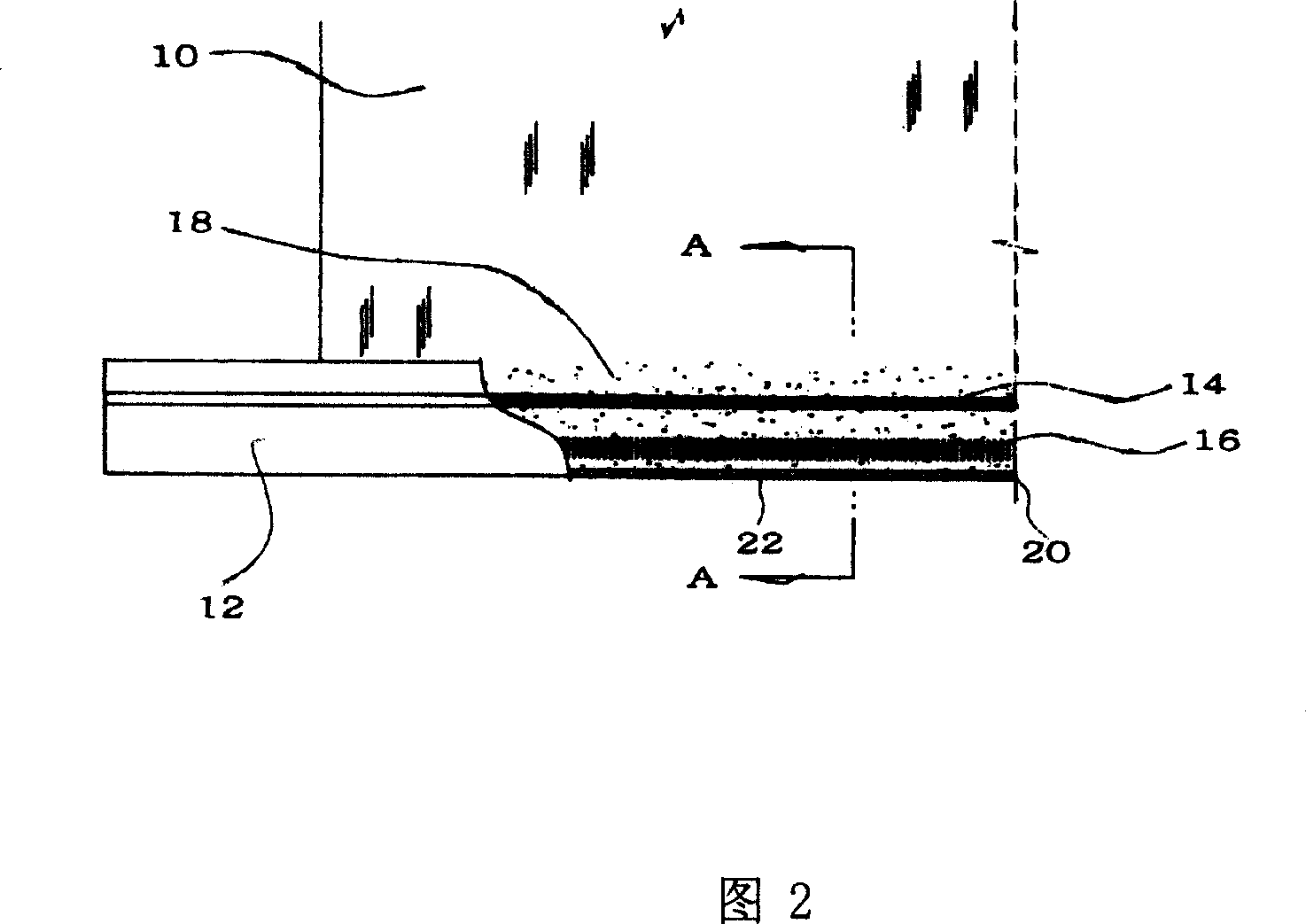

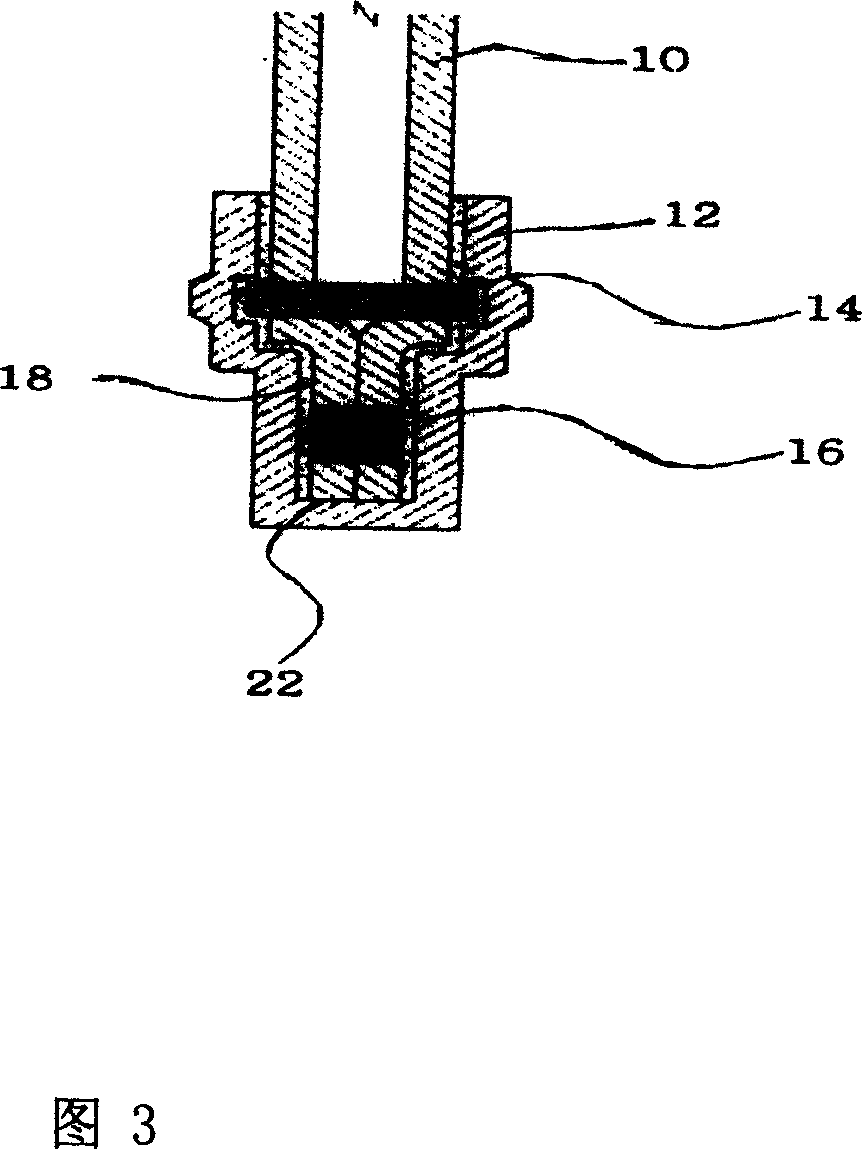

[0014] The composite plastic woven bag for fine powder products provided by the present invention will be described in detail below with reference to the accompanying drawings. Figure 1 is a perspective view of the structure of the composite plastic woven bag for fine powder products provided by the present invention. As shown in FIG. 1 , the composite plastic woven bag 10 for fine powder products provided by the present invention is an ordinary composite plastic woven bag, the lower edge of which is covered by sealing paper 12 . That is, the sealing paper 12 is folded and pasted on the bottom edges of the front and rear sides of the composite plastic woven bag 10. One method of pasting the sealing paper 12 is to apply a layer of ordinary adhesive or latex on the surface of the sealing paper 12. , and then stick it on the bottom edge of the composite plastic woven bag 10 . The sealing paper 12 can also be pasted on the bottom edge of the composite plastic woven bag 10 after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com