Energy-saving and environment-friendly furnace flue gas treatment device

A flue gas treatment, energy saving and environmental protection technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problem of automatic classification and discharge of aqueous solutions that cannot be mixed with harmful substances, short-term convective contact between gas and liquid, and increased furnace smoke Reduce gas treatment costs and other issues, achieve the effects of rational use of water resources, space reduction, and prevention of external leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

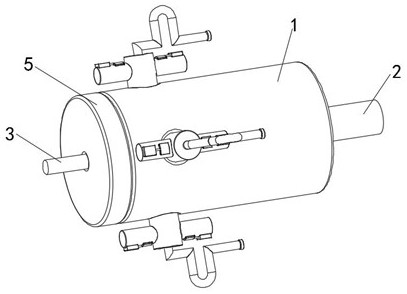

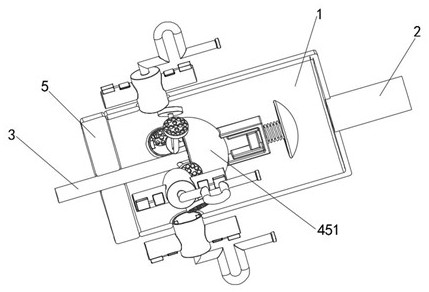

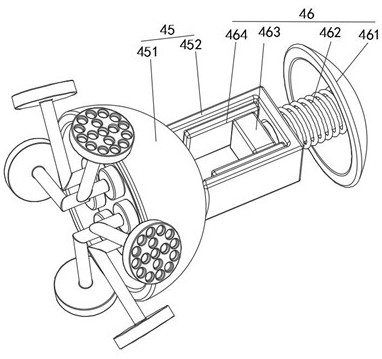

[0032] see Figure 1-7 , an energy-saving and environment-friendly furnace flue gas treatment device, comprising a cylinder body 1, an air inlet pipe 2 is fixedly connected to the right side of the cylinder body 1, an activated carbon filter layer 5 is fixedly connected to the left side of the cylinder body 1, The left side of the cylinder 1 is provided with a water inlet pipe 3, the water inlet pipe 3 penetrates the activated carbon filter layer 5 and extends into the inside of the cylinder 1, and the right side of the water inlet pipe 3 is fixed inside the cylinder 1 A spray device 4 is connected, a discharge device 6 is fixedly connected to the axially outer side of the cylinder 1, a dredging device 7 is arranged on the inside of the discharge device 6, and a protective device is fixedly installed on the outer wall of the discharge device 6 8;

[0033] The spray device 4 includes a transition chamber 41, a solenoid valve 42, a spray pipe 43, a spray block 44, a dispersing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com