Patents

Literature

170results about How to "Reduce internal leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

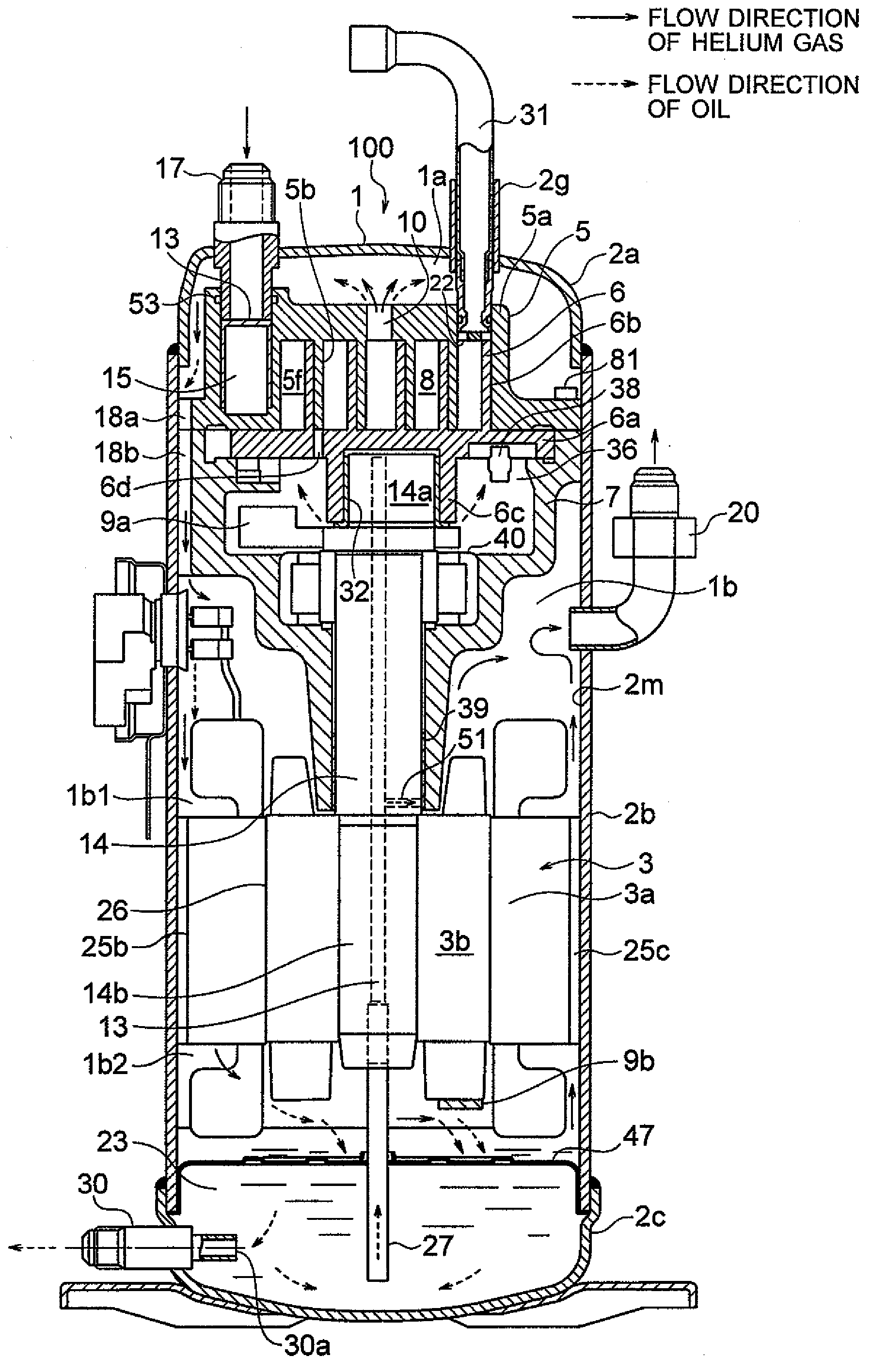

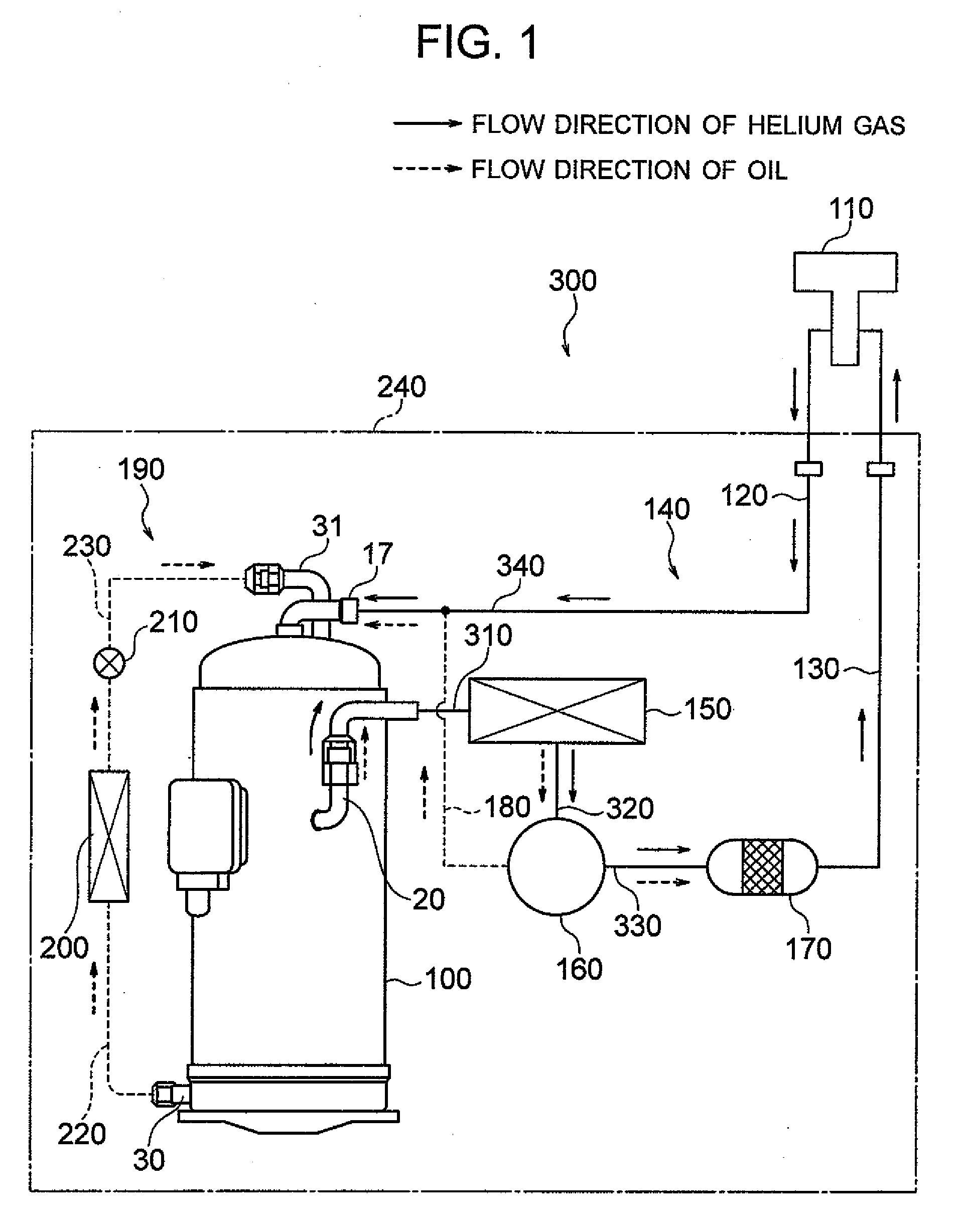

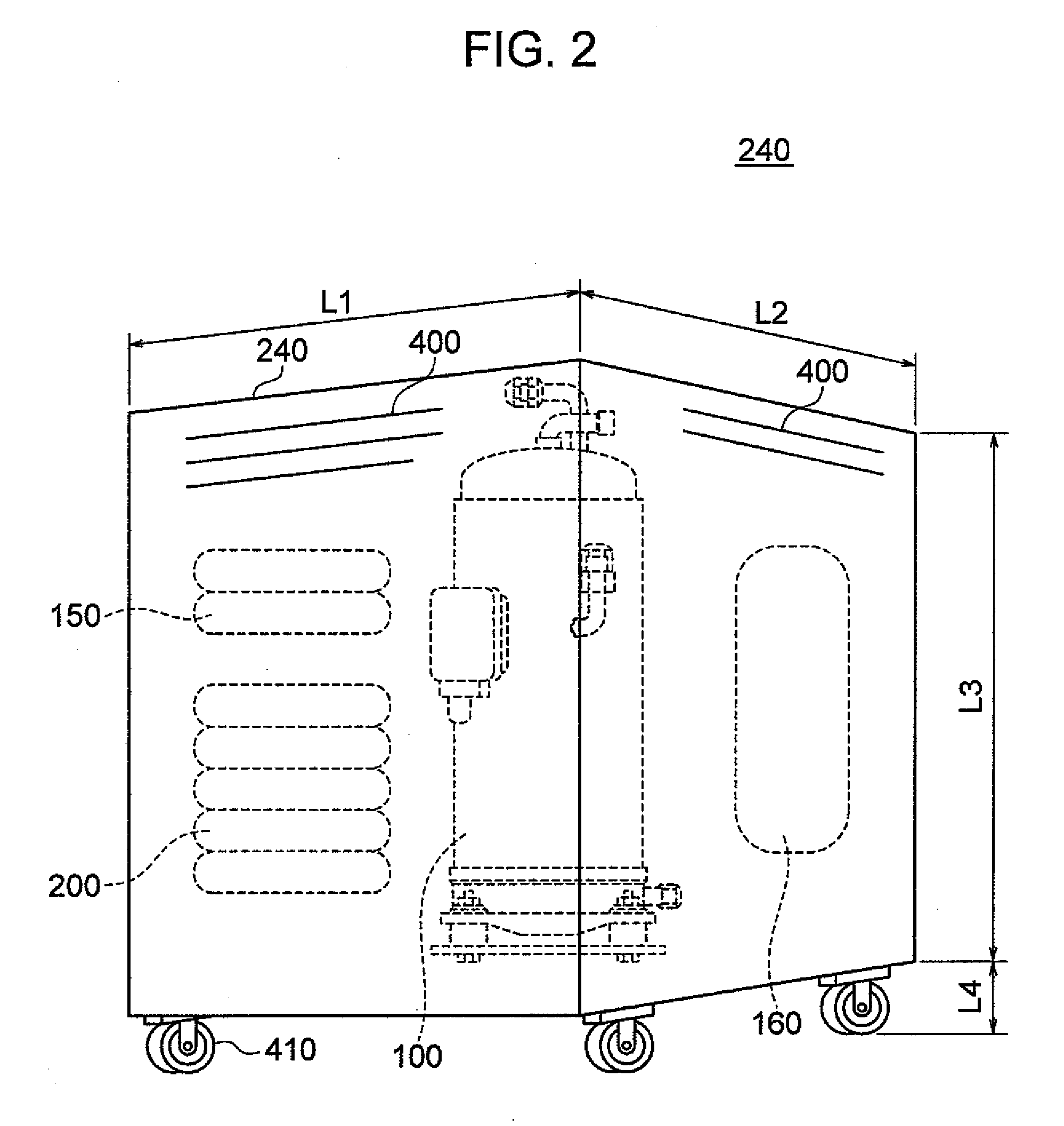

Hermetically sealed scroll compressor

ActiveUS20100129240A1Reduced volumetric efficiencyIncrease in internal compression powerRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringMechanical engineering

In the hermetically sealed scroll compressor, an injection pipe for injecting a fluid to a compression chamber is connected to an injecting port of a fixed scroll. The injecting port includes a first injecting port which is provided in the vicinity of a fixed scroll inner curve and injects the fluid to an orbiting outer compression chamber, and a second injecting port 22b which is provided in the vicinity of a fixed scroll outer curve and injects the fluid to a orbiting inner compression chamber 8b. The second injecting port is placed in parallel in a radius direction with respect to the first injecting port and is placed so that an orbiting scroll wrap does not practically communicate with the orbiting outer compression chamber in the state in which the orbiting scroll wrap is in contact with the outer side of a fixed scroll wrap.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

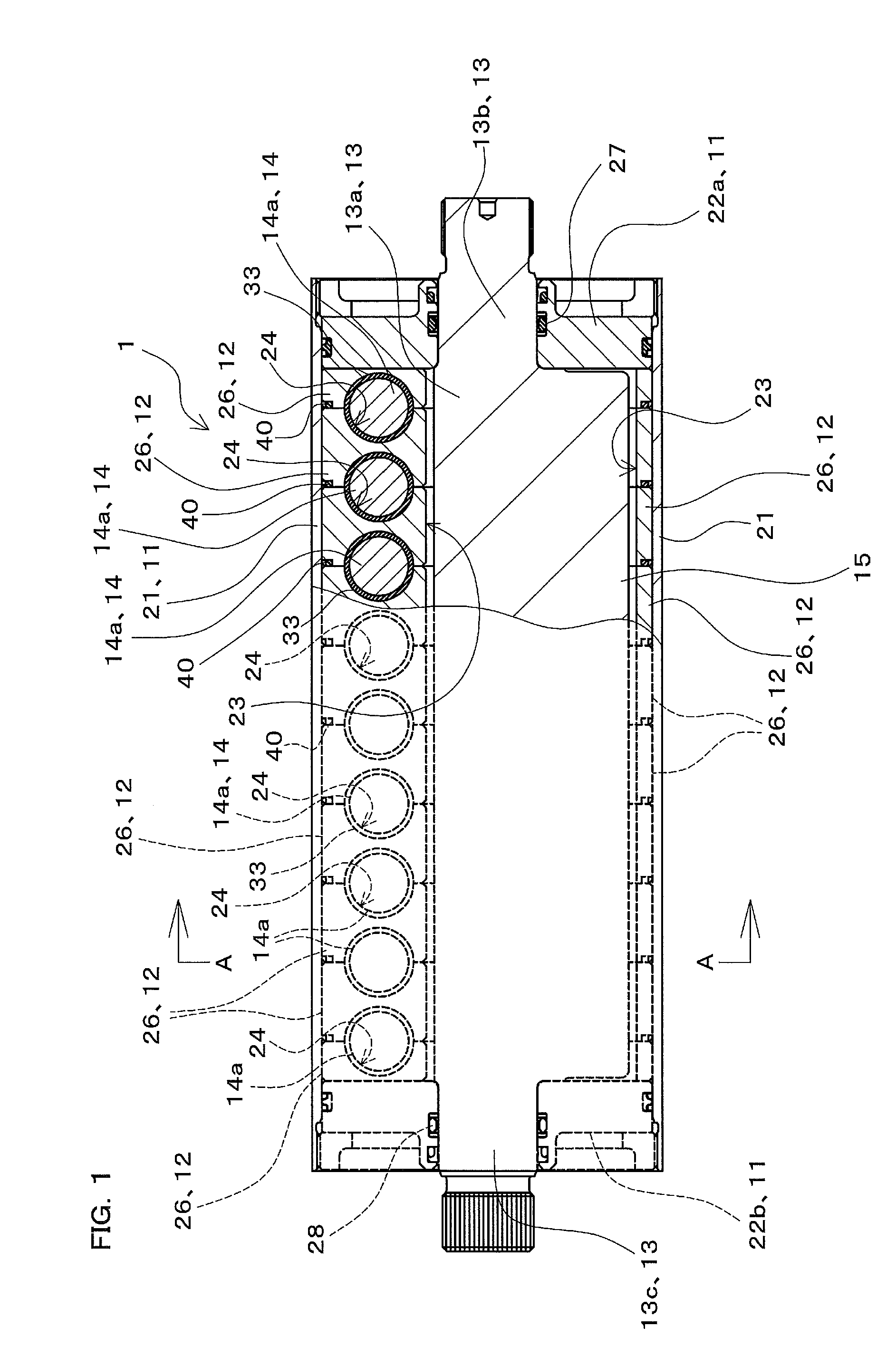

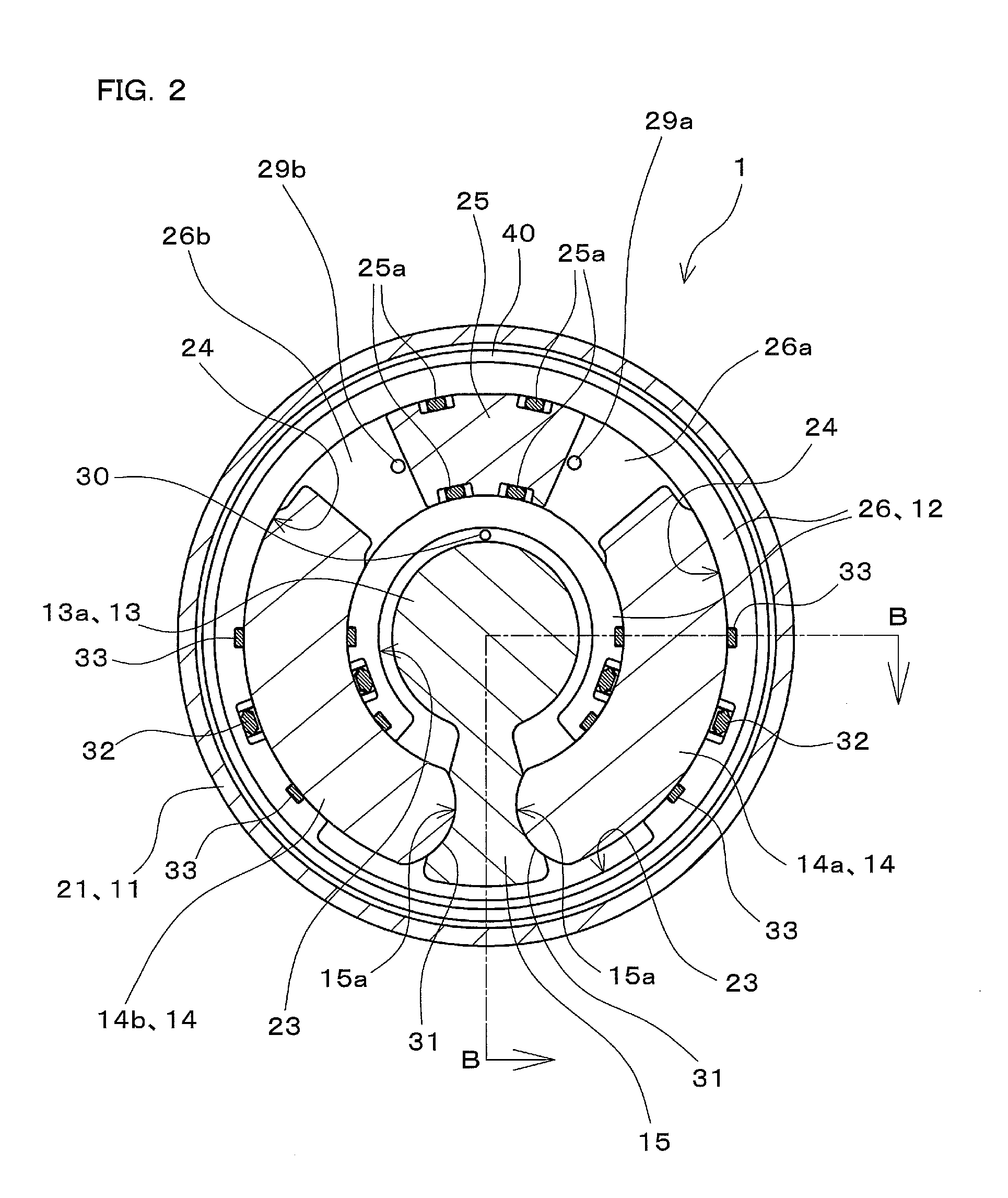

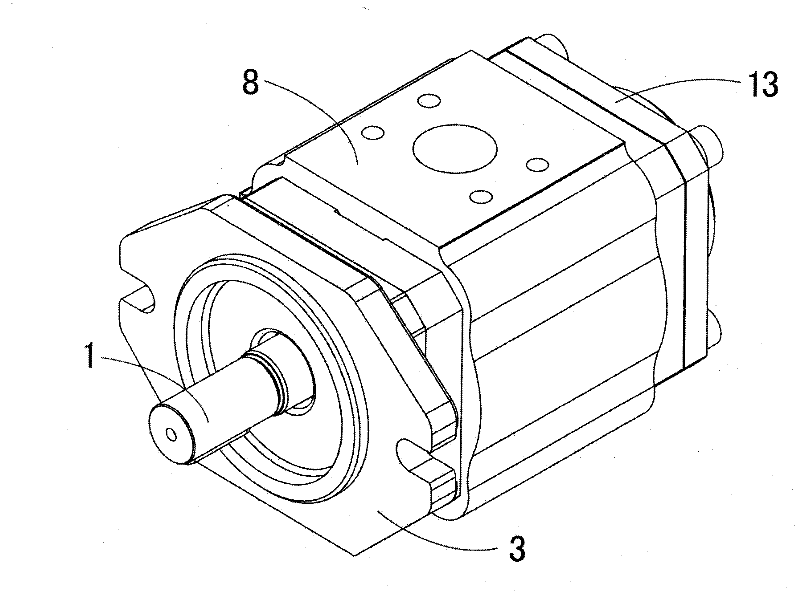

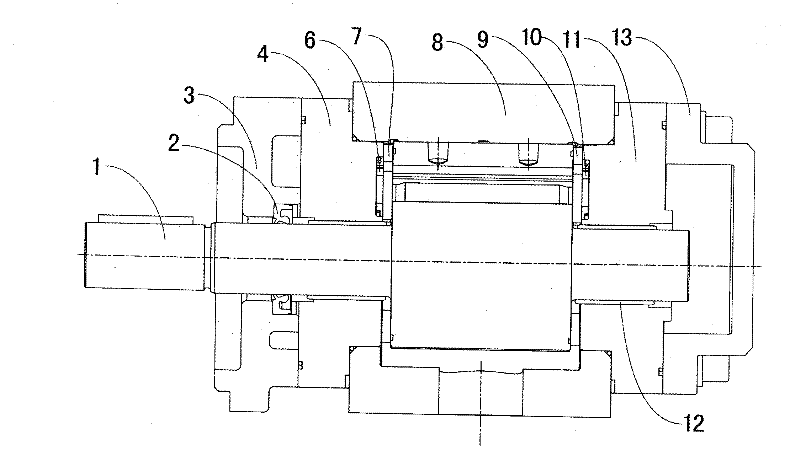

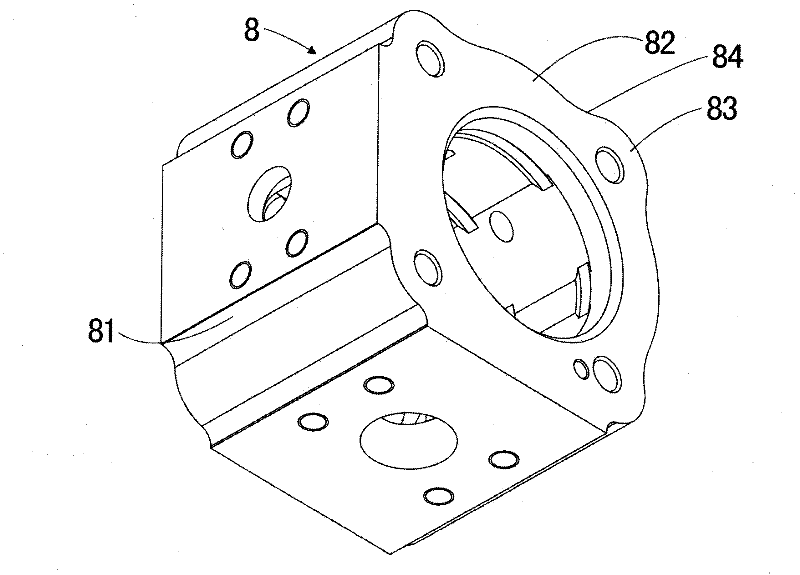

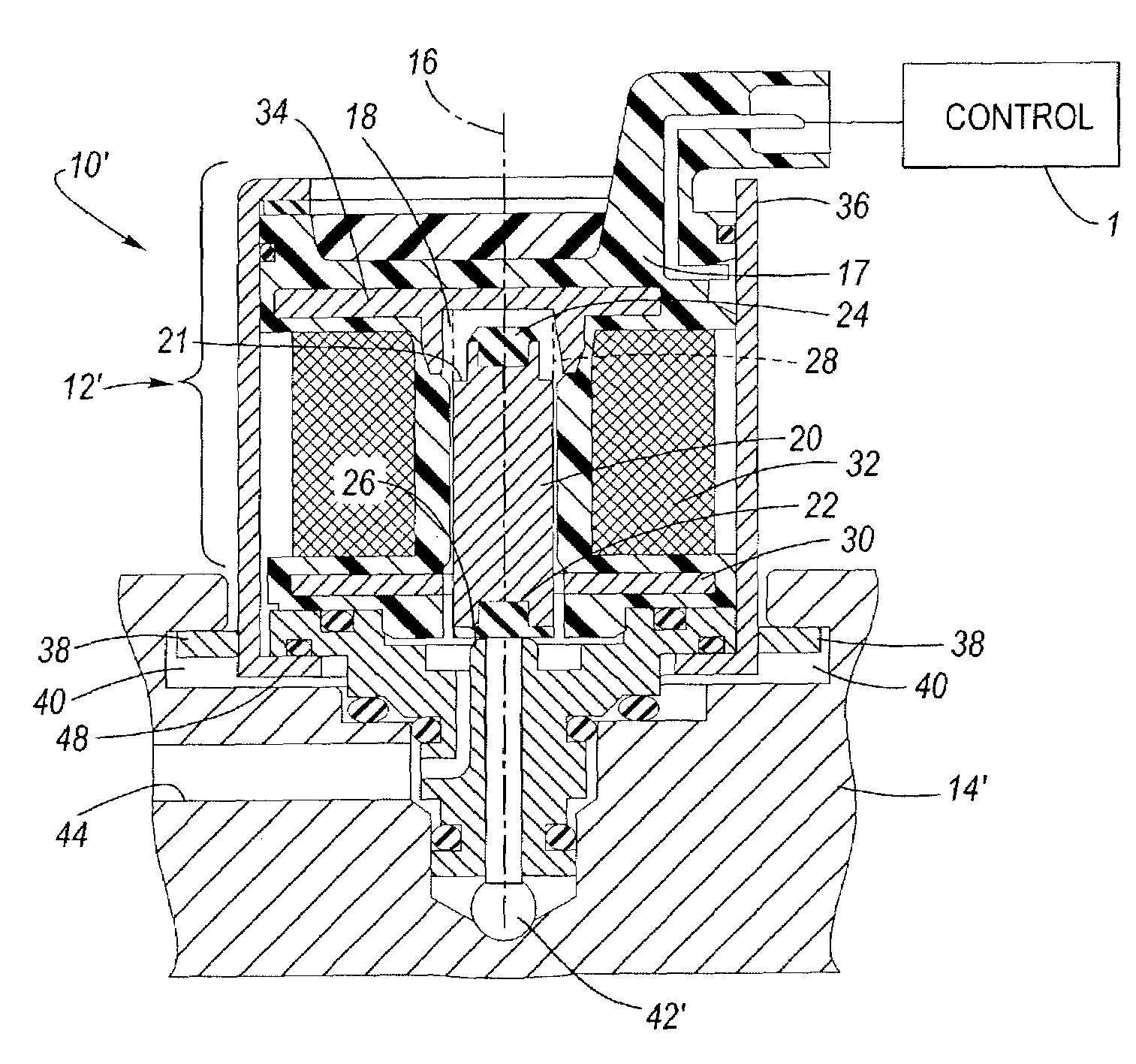

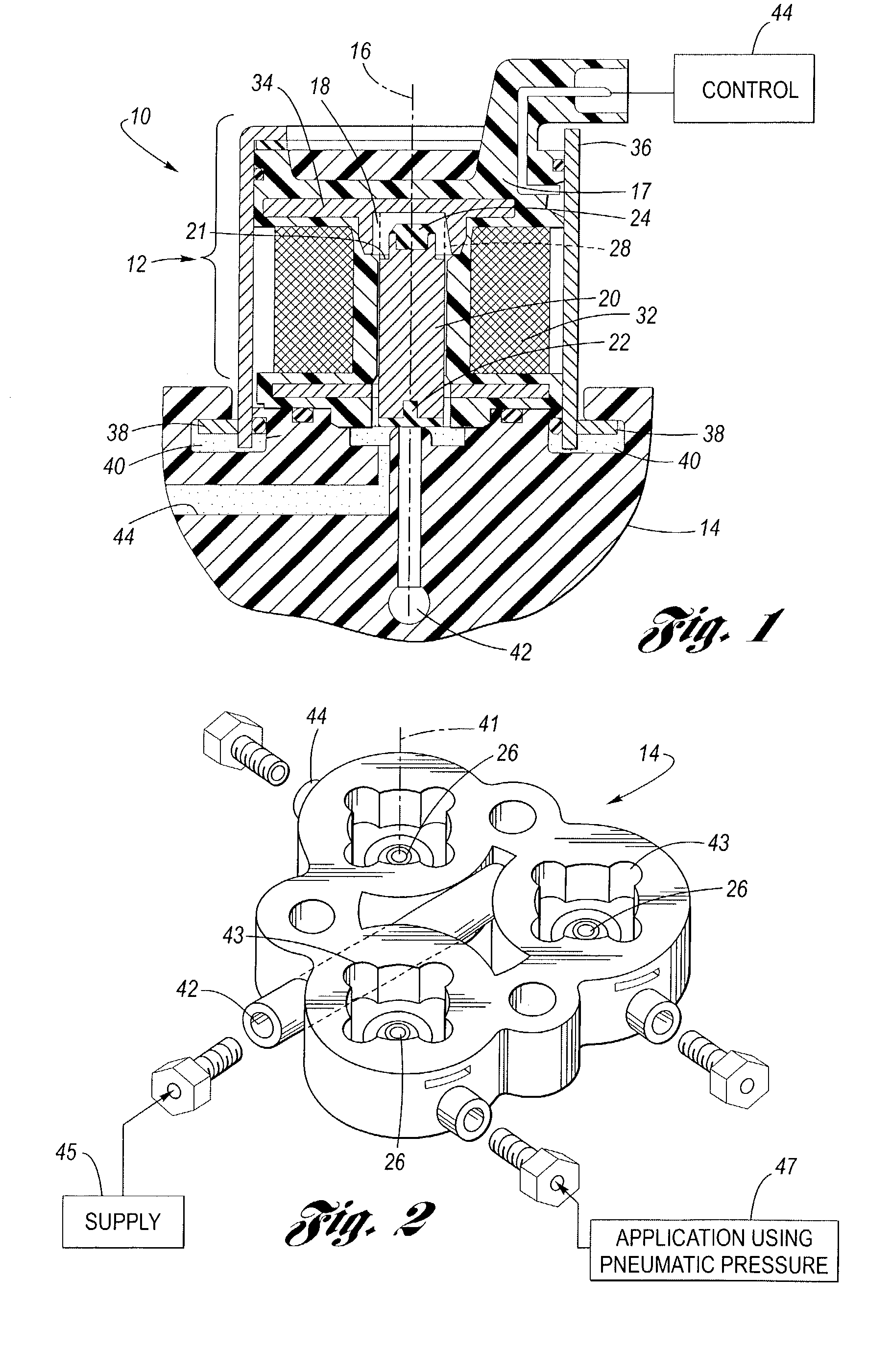

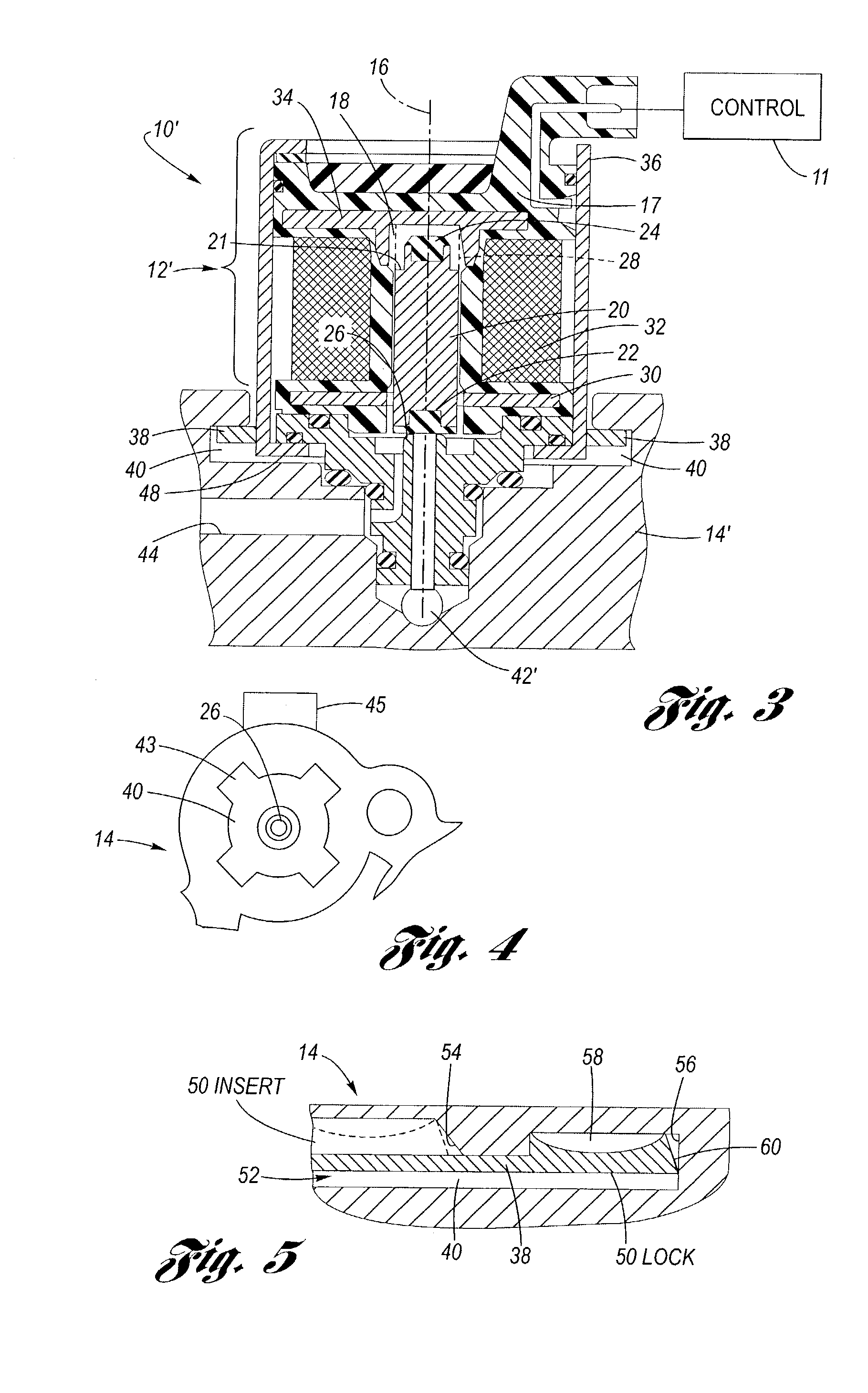

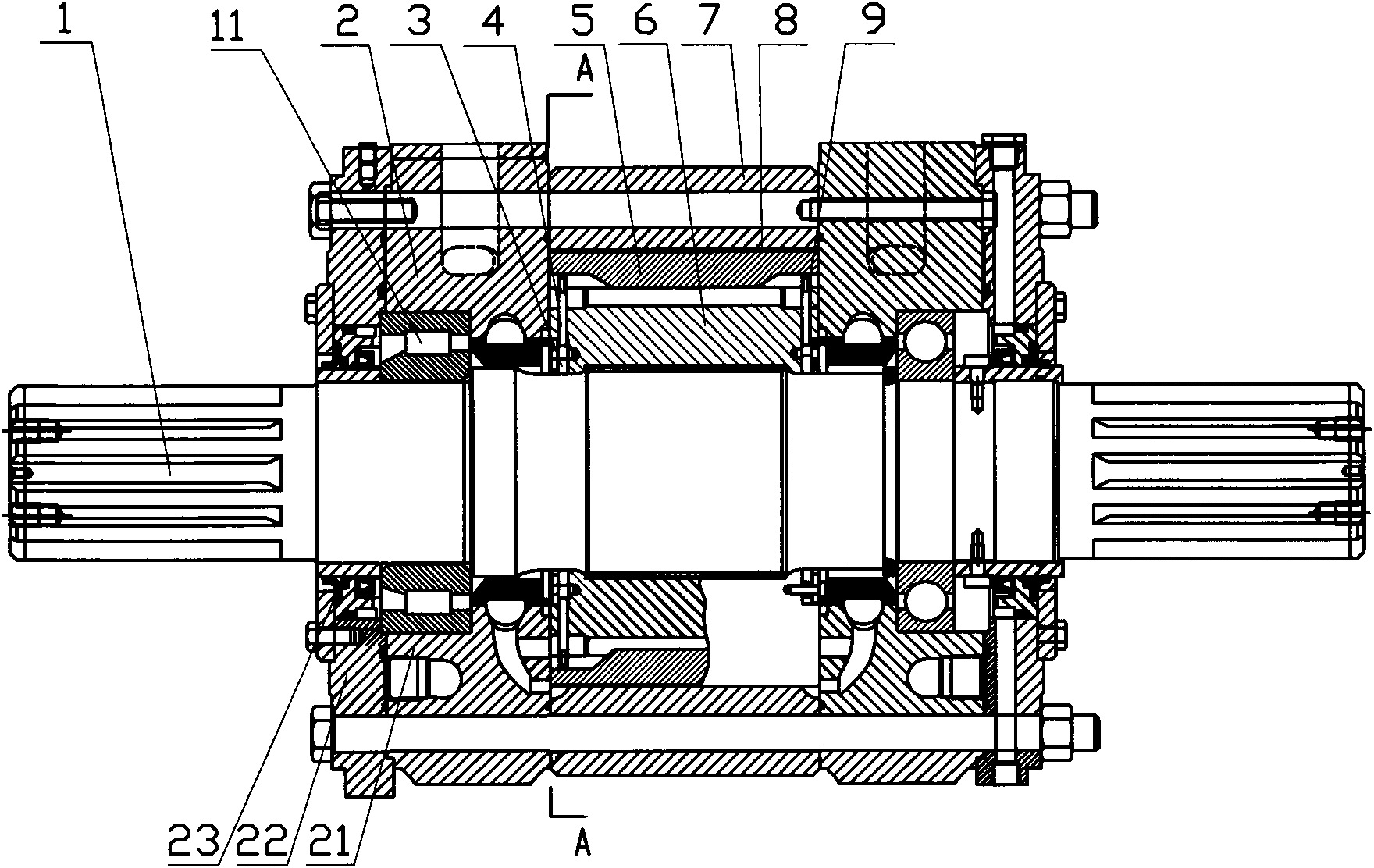

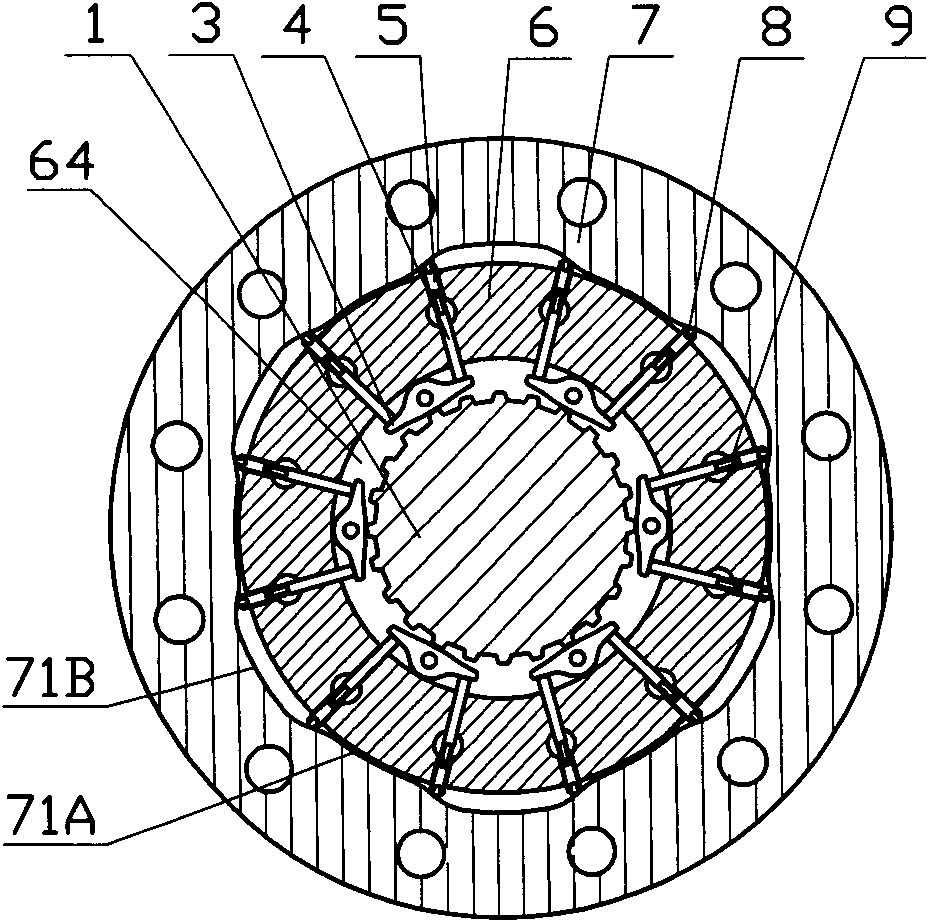

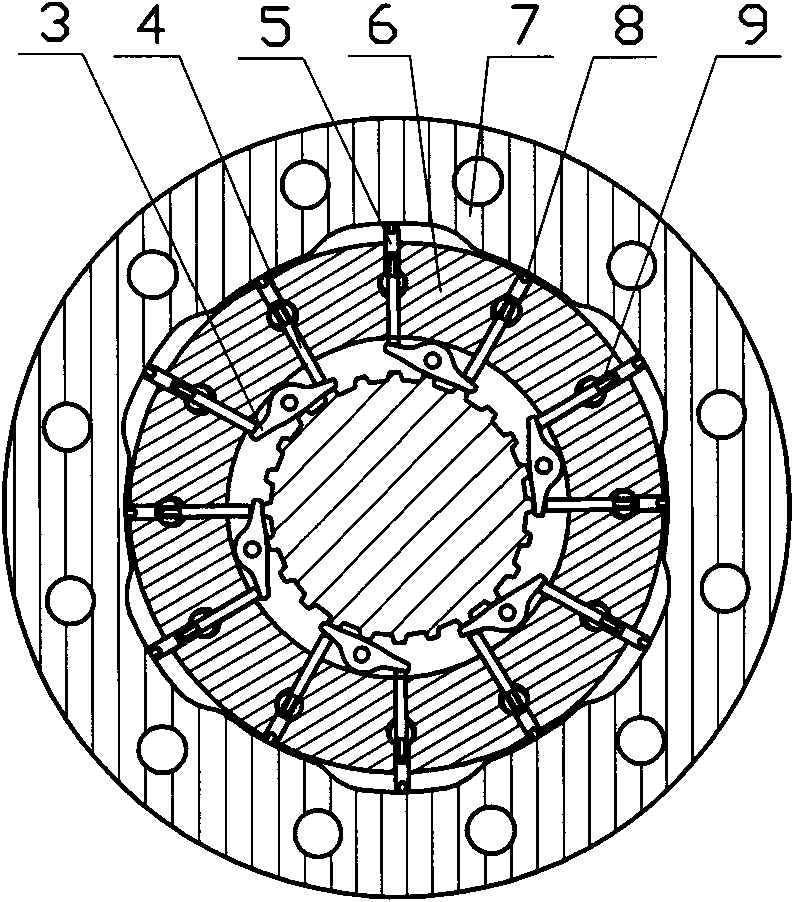

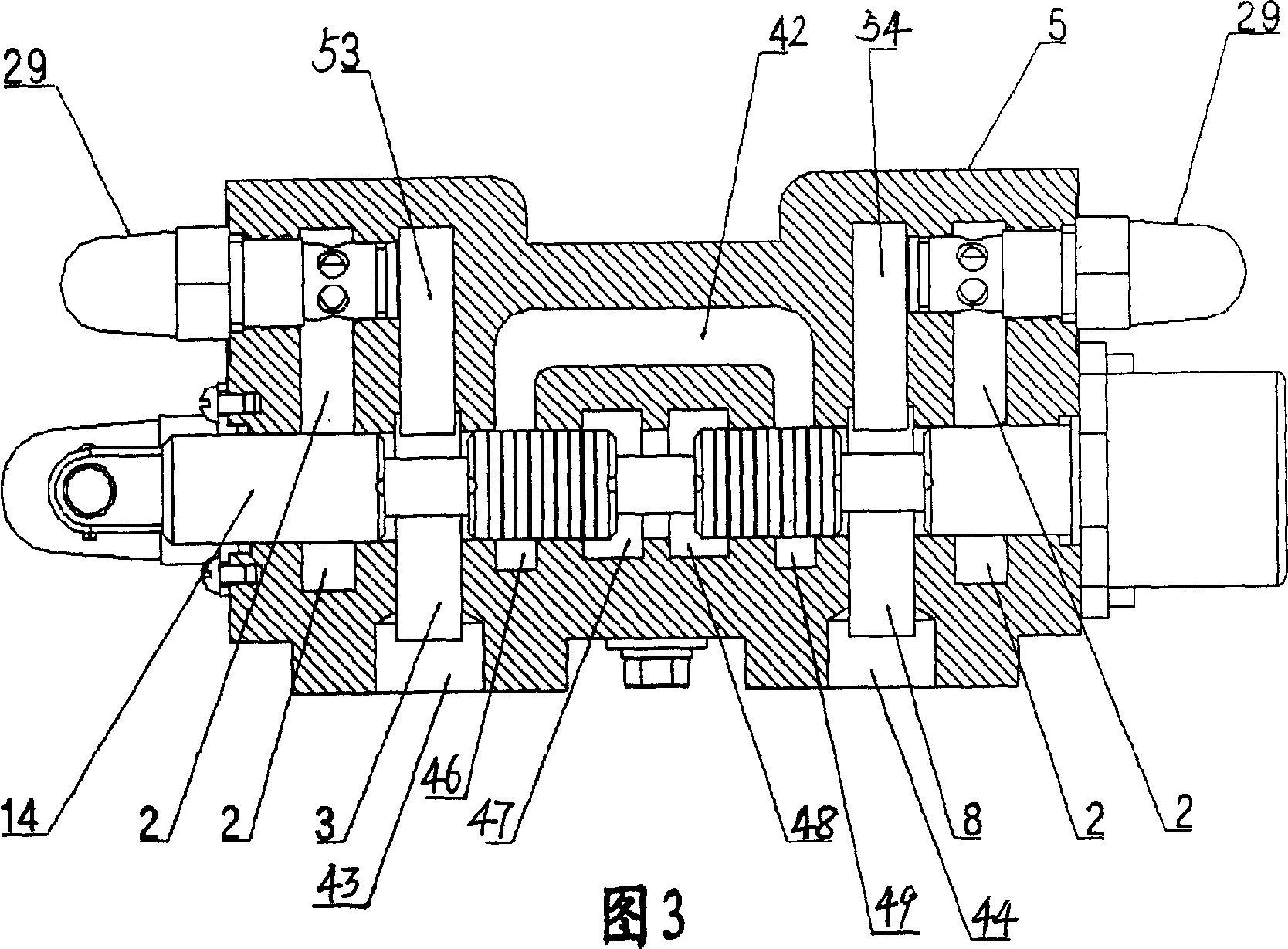

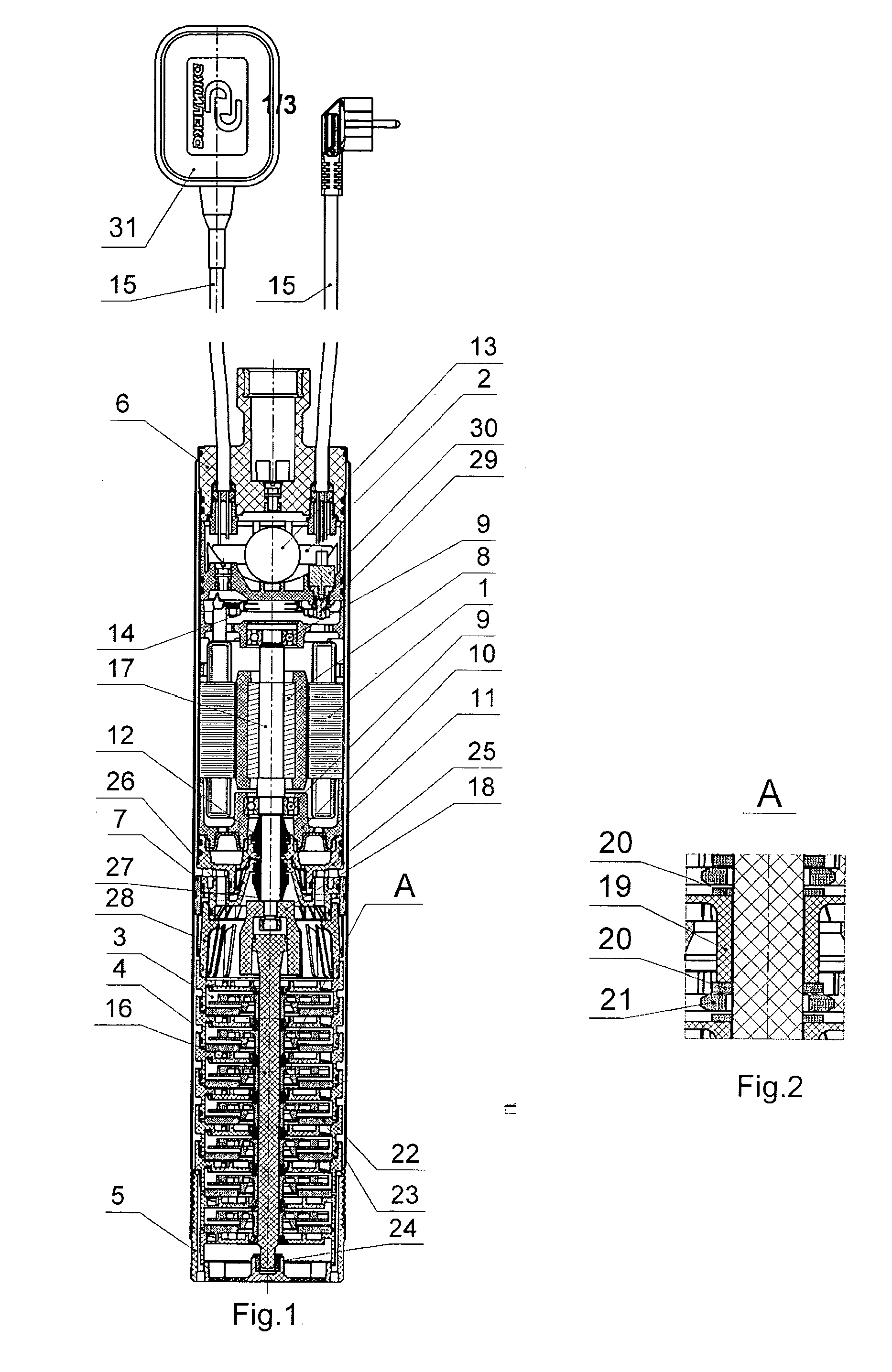

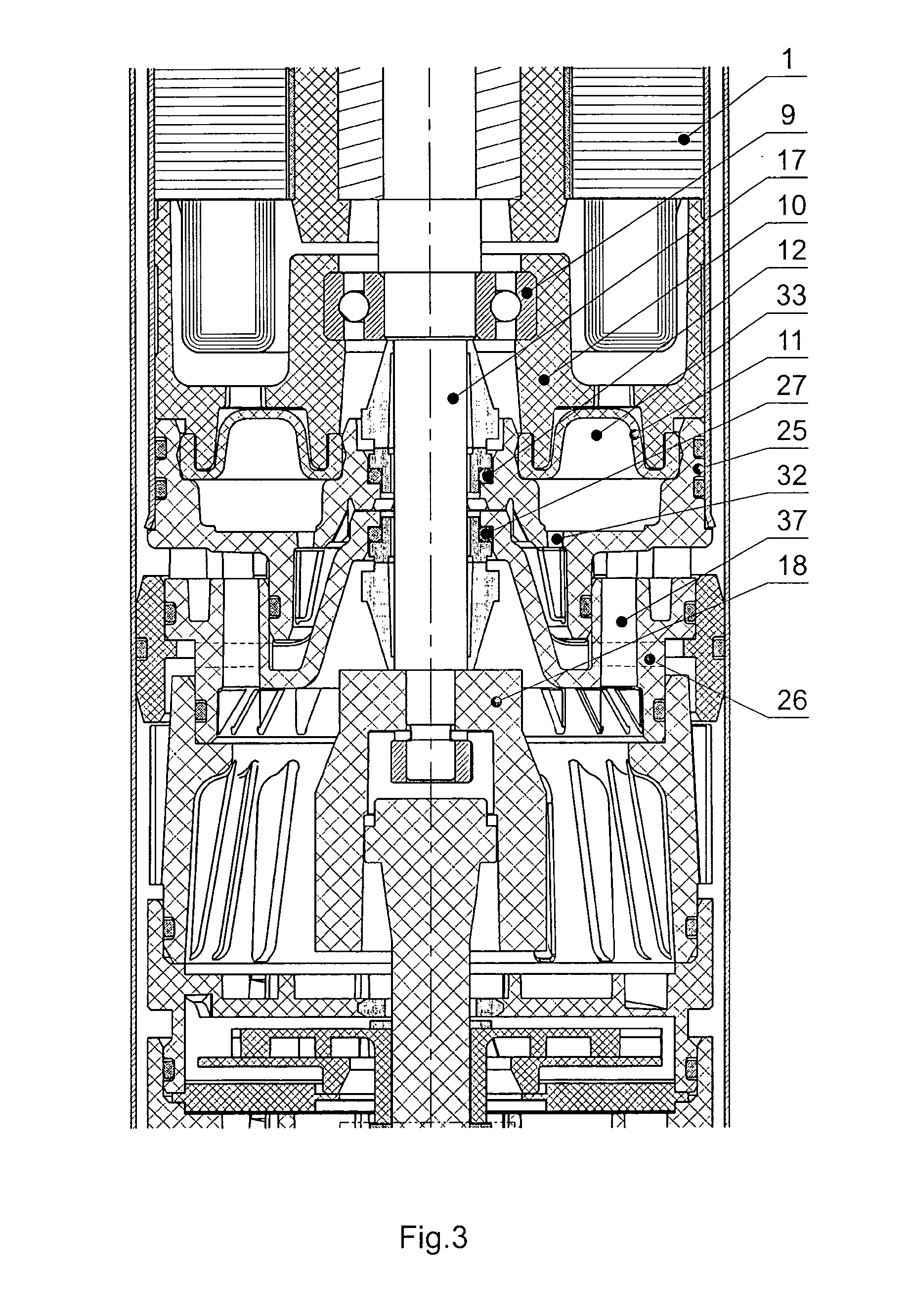

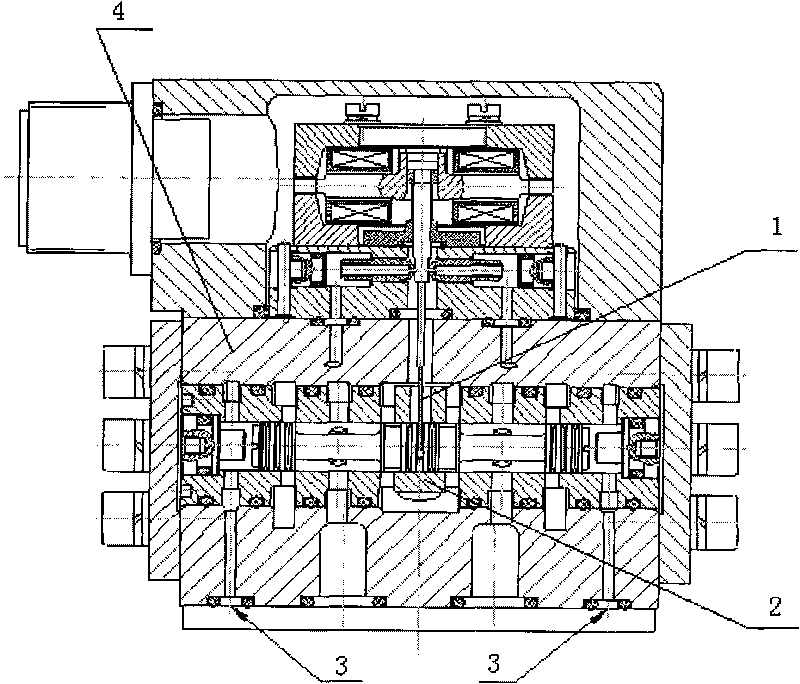

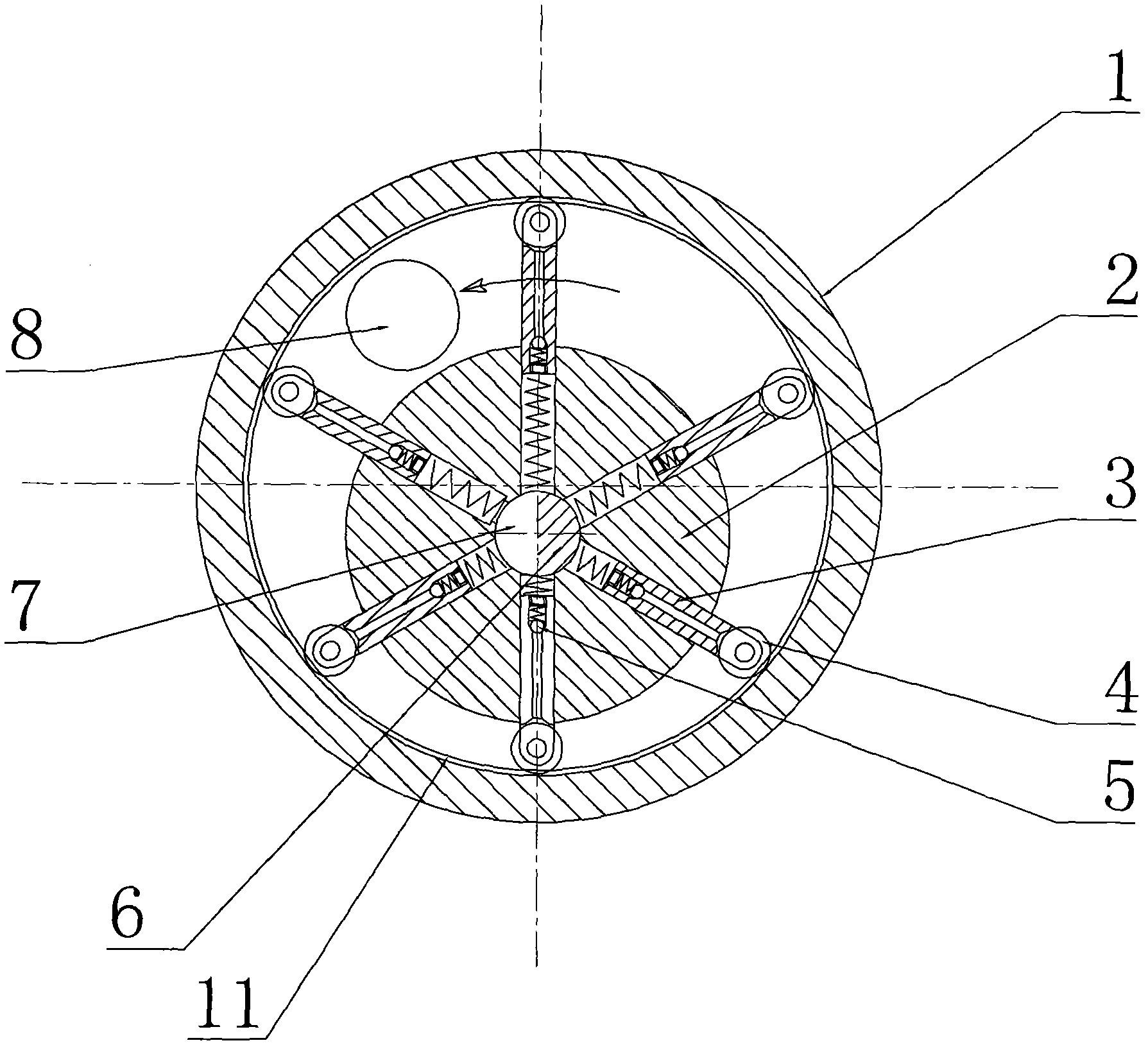

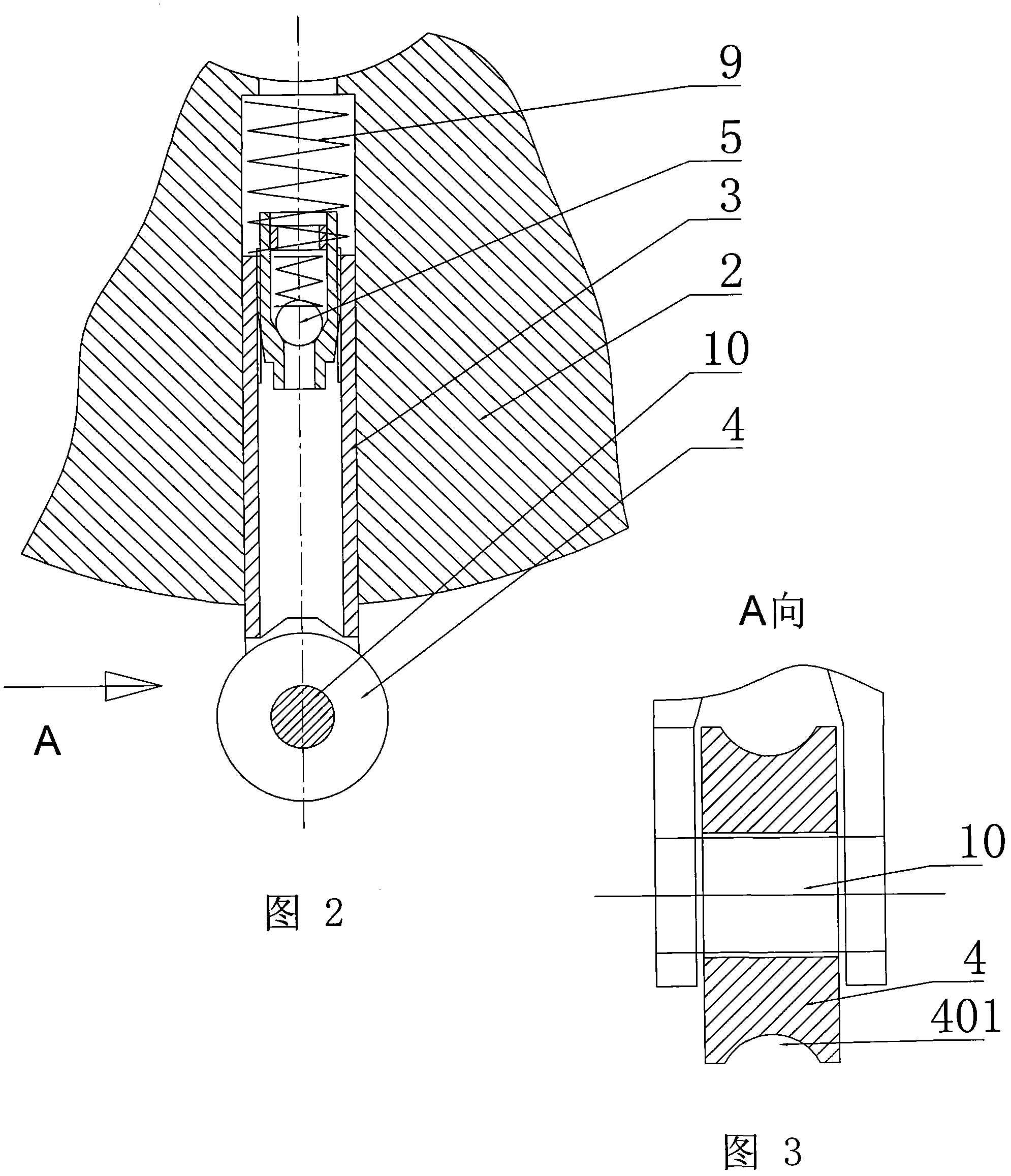

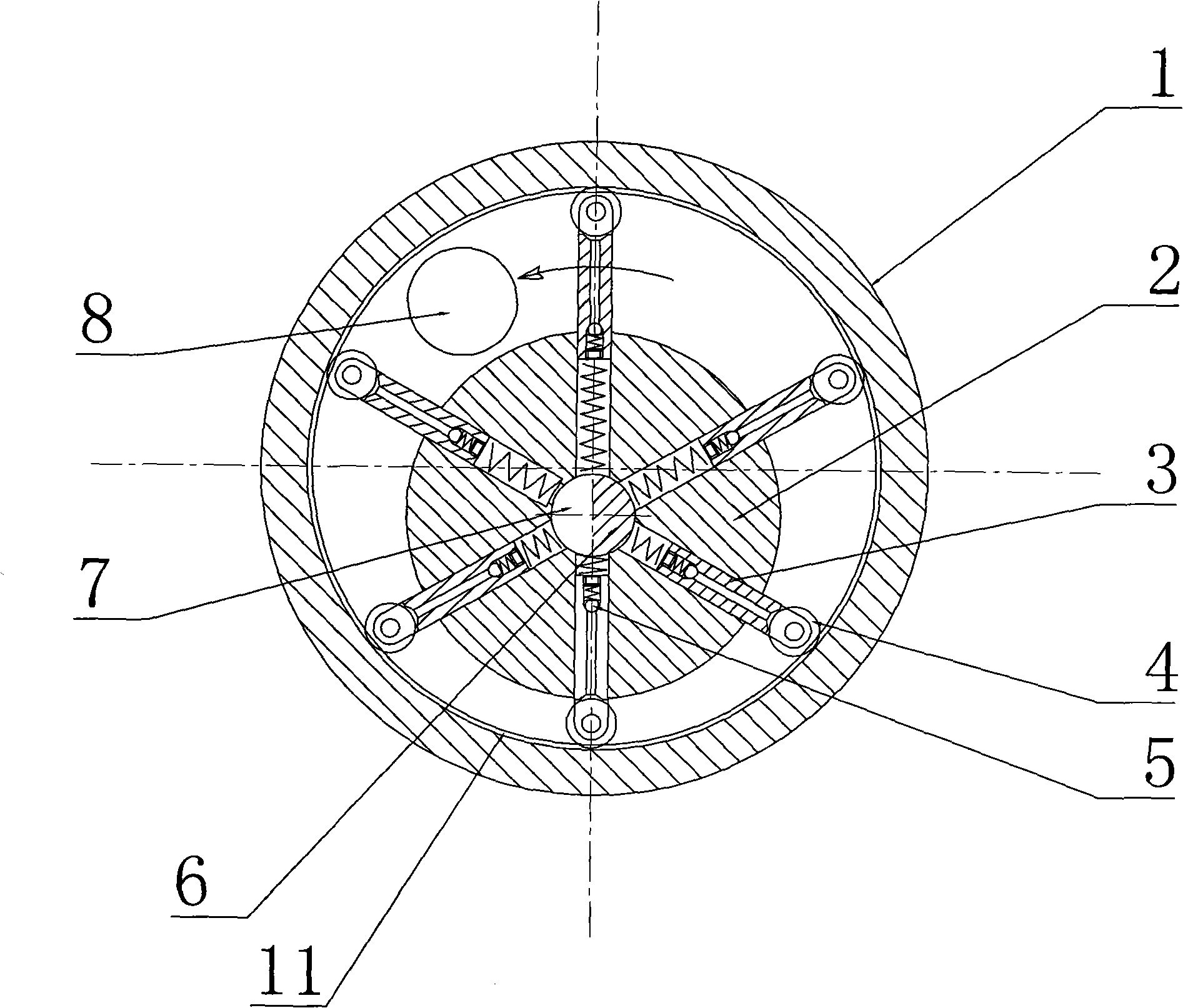

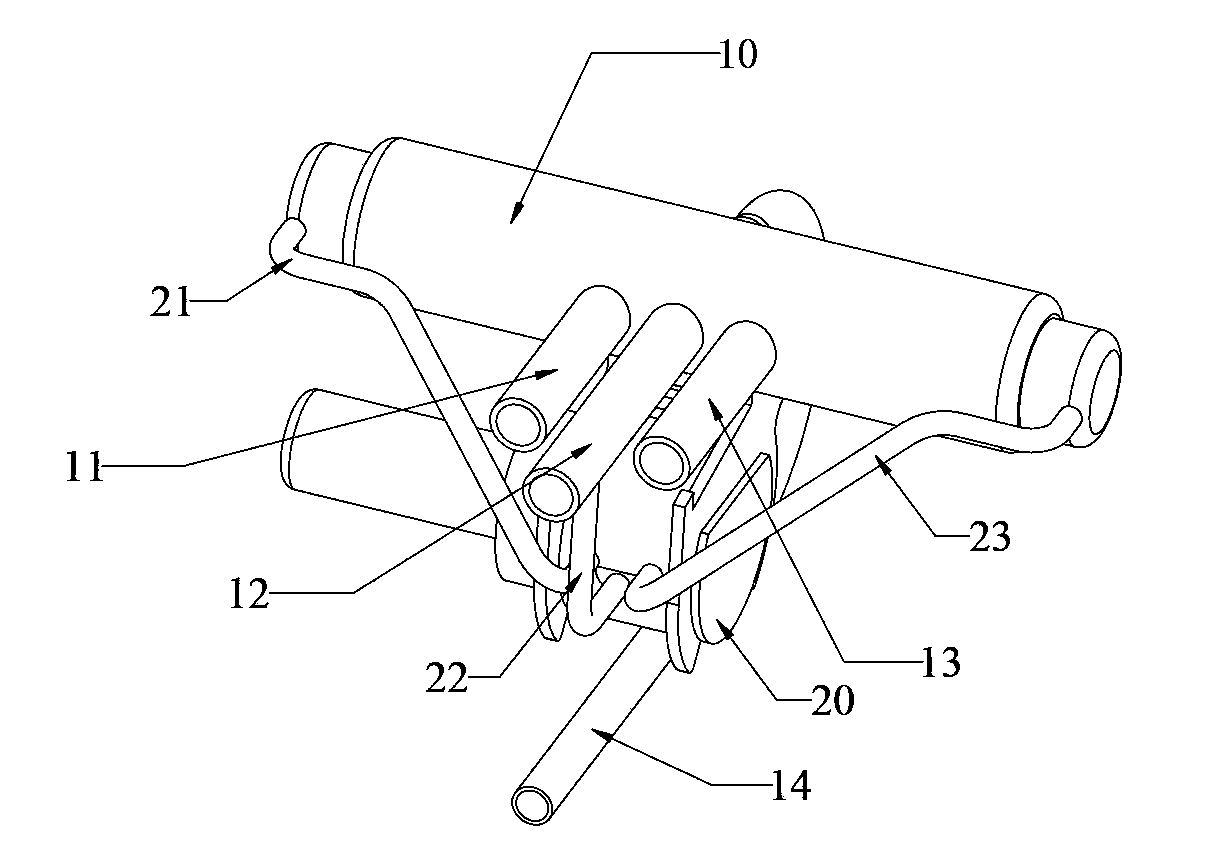

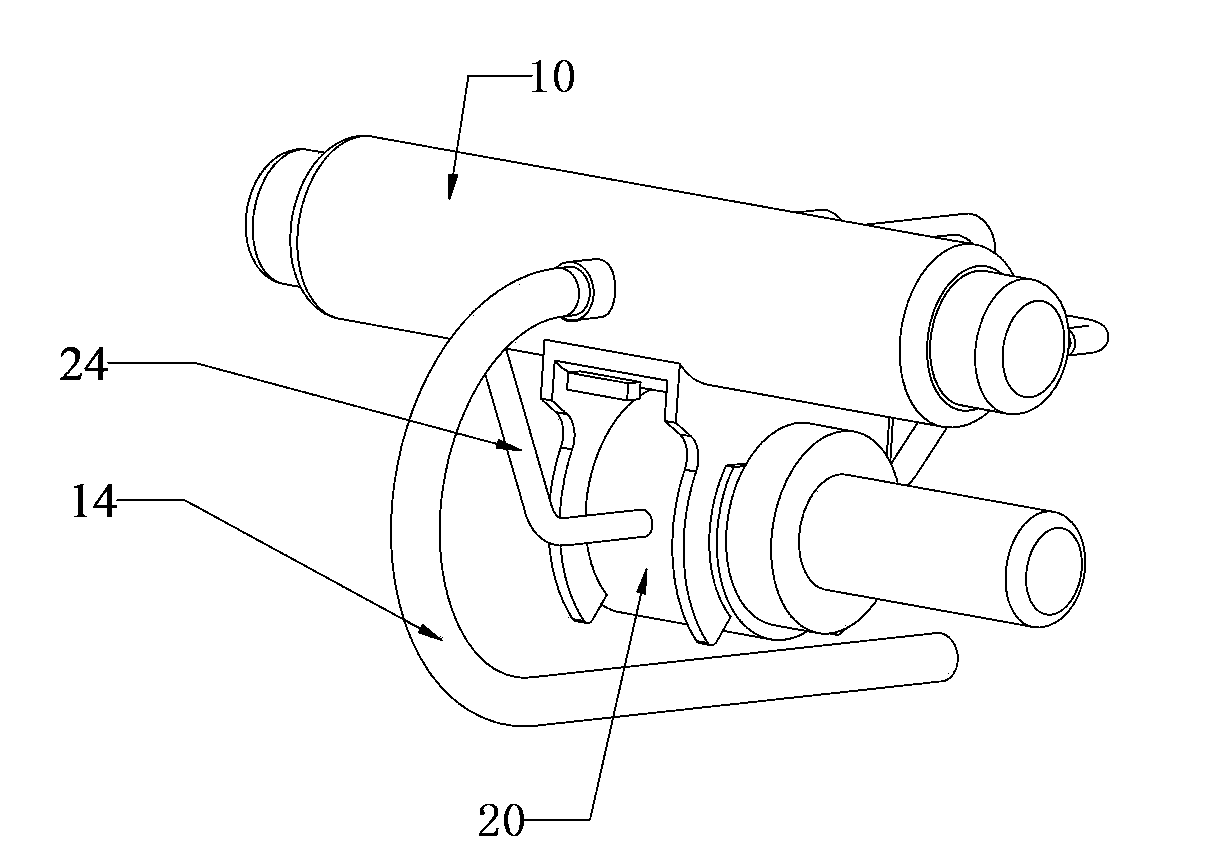

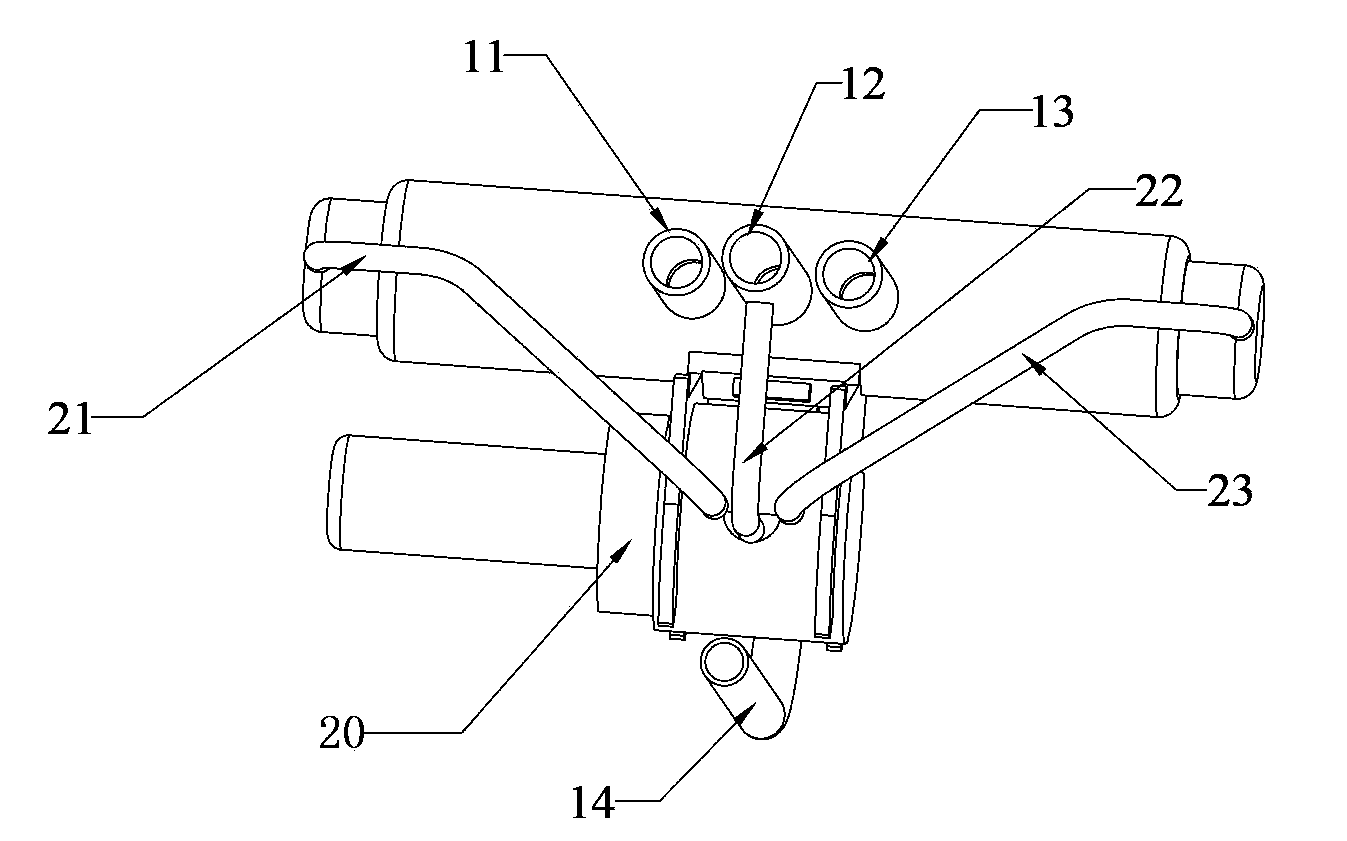

Rotary actuator

ActiveUS20130104729A1Reduce internal leakageThe implementation process is simpleGearingFluid-pressure actuatorsControl theoryRotary actuator

A cylinder is installed within a case. An output shaft is installed in a hollow space within the cylinder. A pair of pistons extend in an arc, and is supported so as to be able to slide and be displaced along a circumferential direction of the cylinder within the cylinder. The pair of pistons is able to urge an arm integrated with the output shaft from two sides of the arm. Pressure chambers into which a pressure medium is introduced are defined between the cylinder and each piston in the pair of pistons. The pressure medium is fed to one of the pressure chambers and drained from the other, and thus the arm is displaced, and the output shaft pivots in a rotational direction.

Owner:NABLESCO CORP

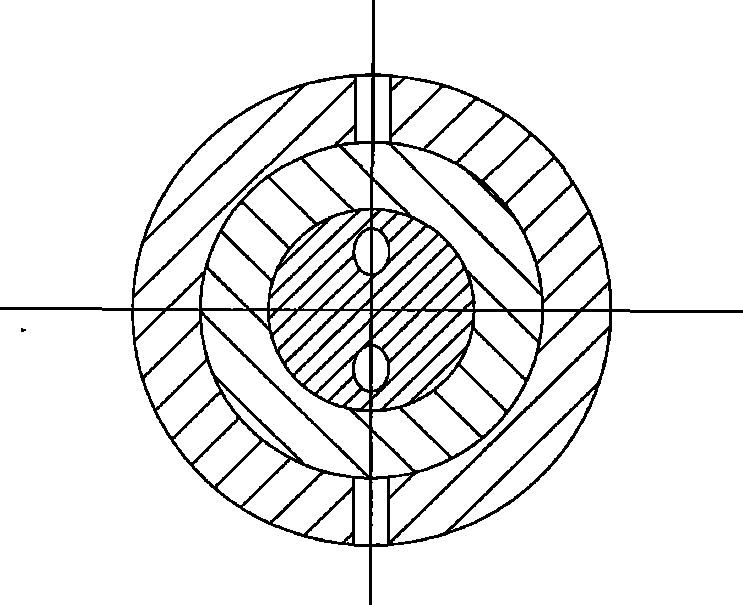

Internal gear pump

ActiveCN102400907AReduce leakageIncrease pressureRotary piston pumpsRotary piston liquid enginesGear pumpPre compression

The invention discloses an internal gear pump with low leakage rate, high feeding power, high pressure and energy-saving capability. The internal gear pump comprises a pump body, a front cover, a rear cover, an internal gear, an internal gear shaft, an irregular sheet, a front valve plate, a rear valve plate, a front support, a rear support, and elastic sealing members, wherein the front cover and the rear cover are arranged at two ends of the pump body; the internal gear and the internal gear pump shaft are eccentrically meshed inside the pump body; the irregular sheet is used for dividing a cavity formed by meshing the internal gear and the internal gear shaft in the pump body into two parts; the front valve plate and the rear valve plate as well as the front support and the rear support are respectively and sequentially arranged between the irregular sheet and the front cover as well as between the irregular sheet and the rear cover; the elastic sealing members are respectively arranged between the front cover and the rear cover as well as between the front support and the rear support; a crescent sheet is further arranged on the irregular sheet and is matched with the irregular sheet to divide the cavity in the pump body into two parts; and a spring is arranged between the irregular sheet and the crescent sheet. According to the invention, the pre-compression amount of the elastic sealing members and the pre-pressure of the spring are utilized to fulfill an axial compensation function and a radial compensation function respectively, so that the internal leakage of the entire pump is prevented.

Owner:重庆沃菲特泵业有限公司 +1

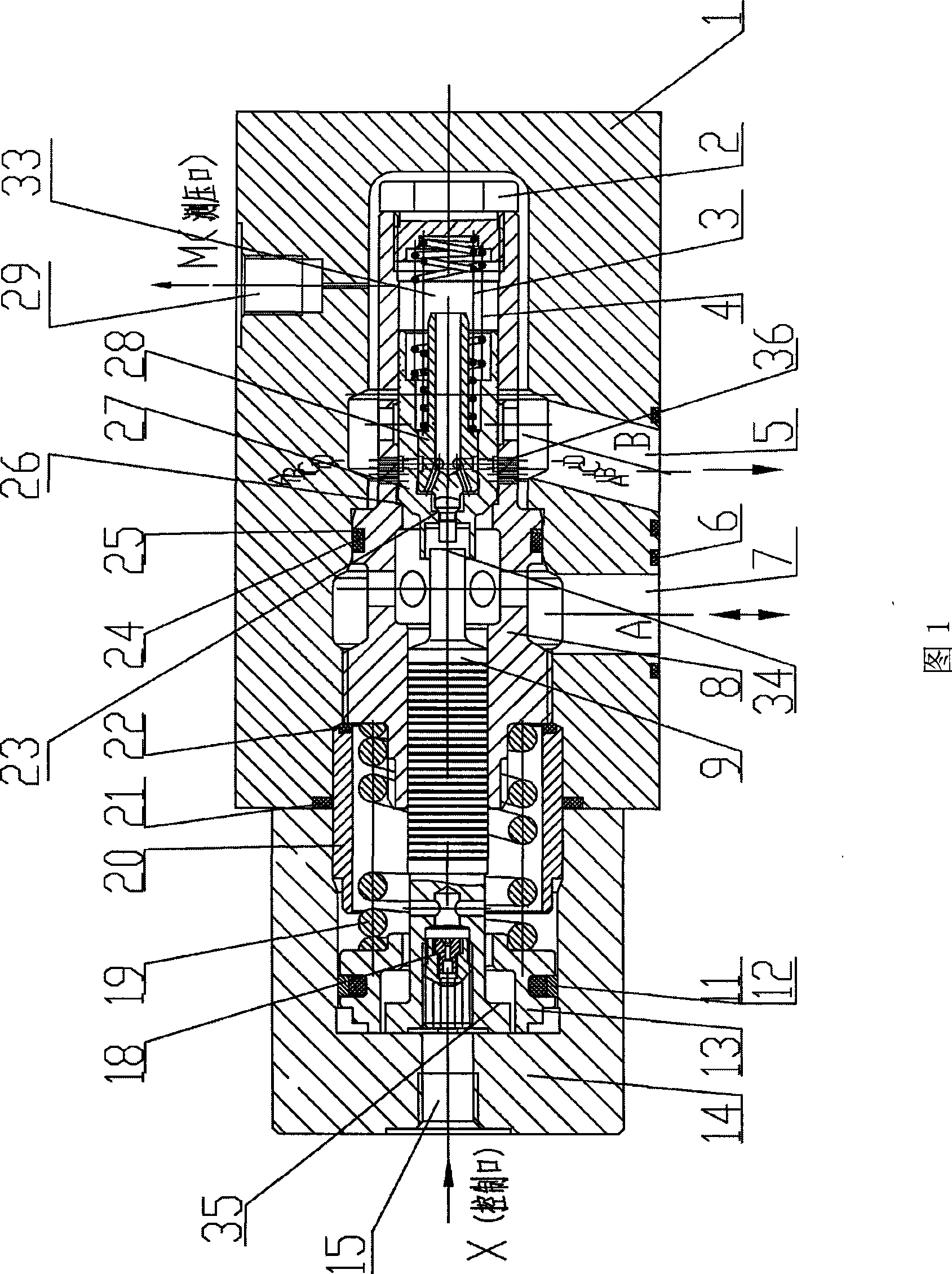

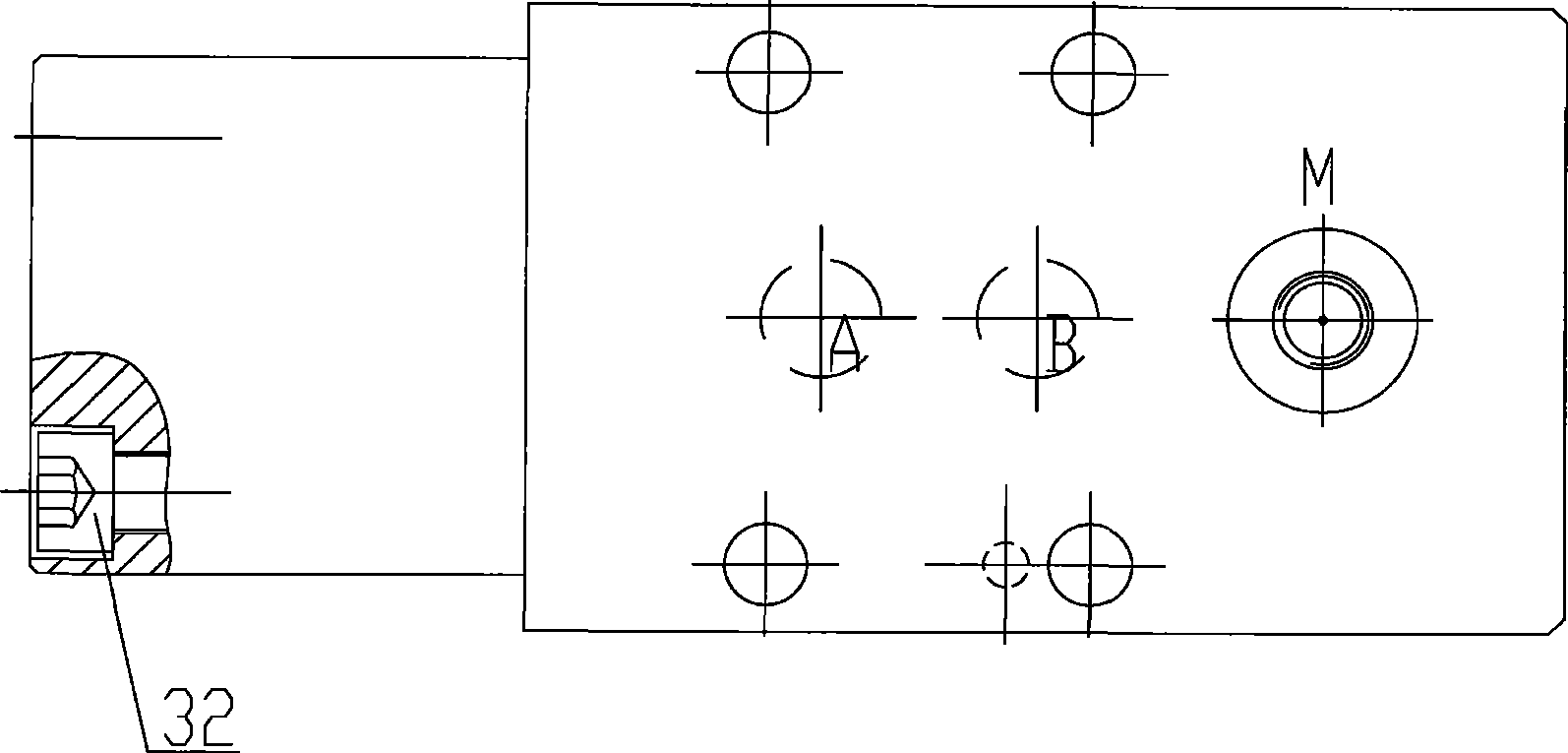

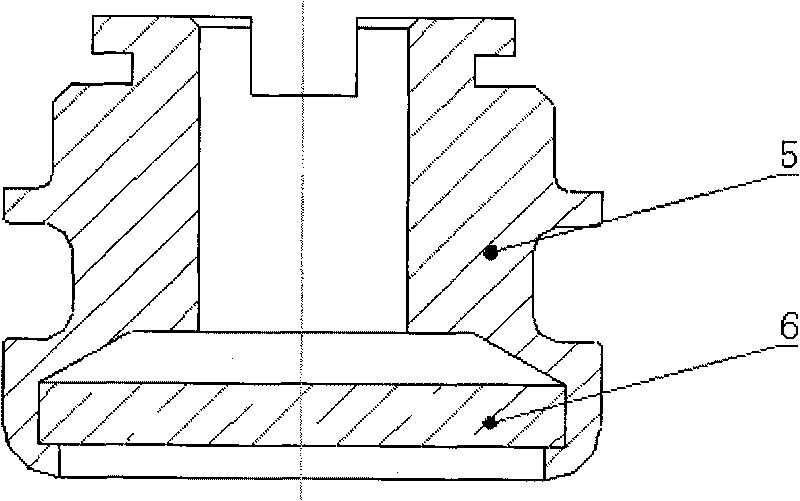

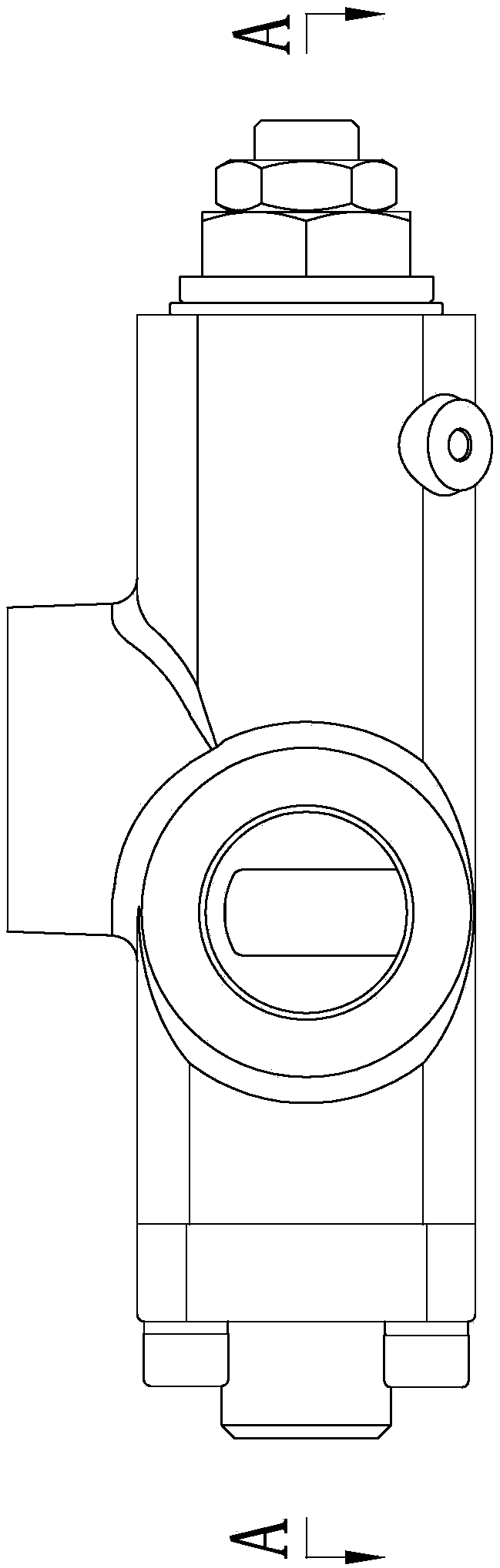

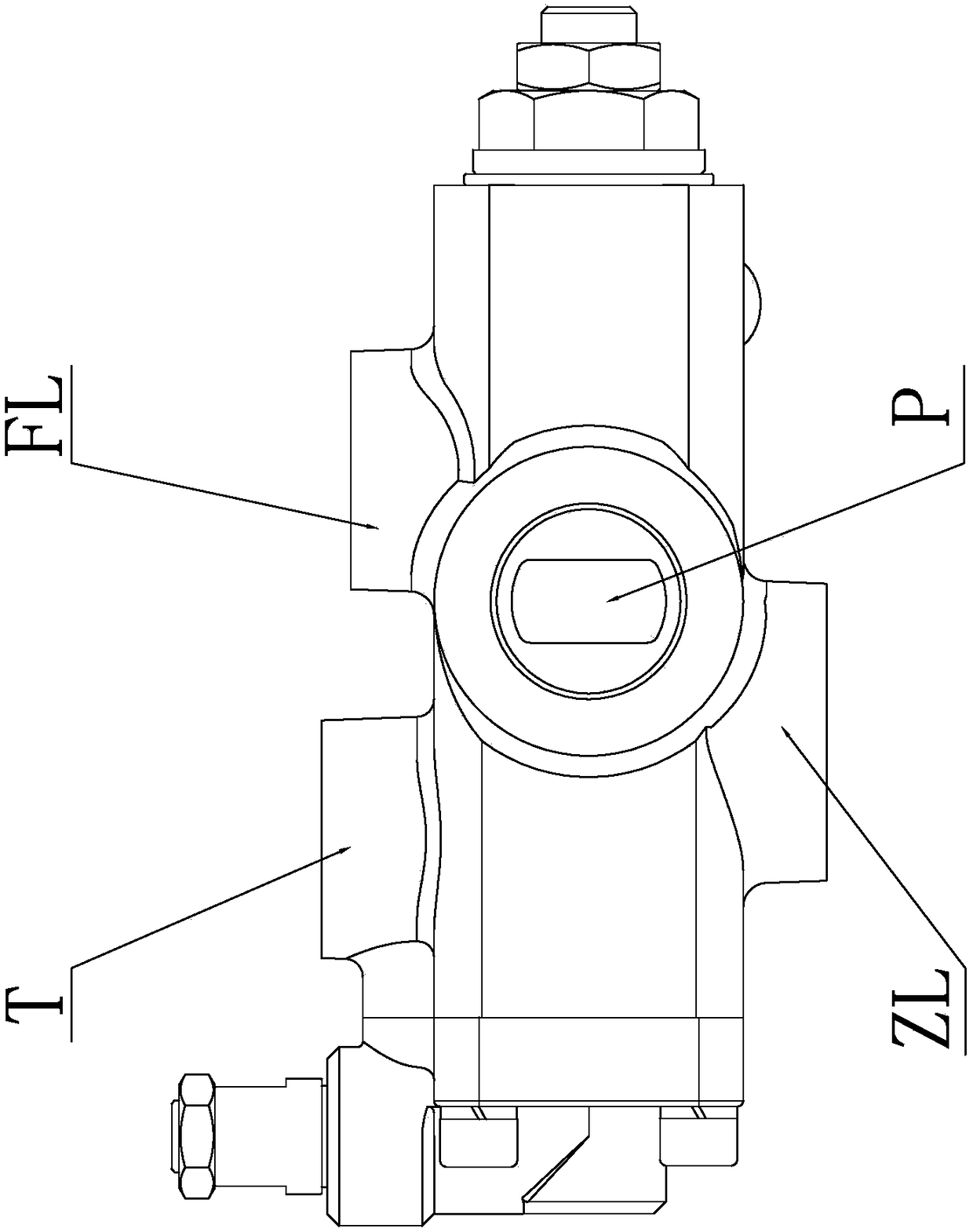

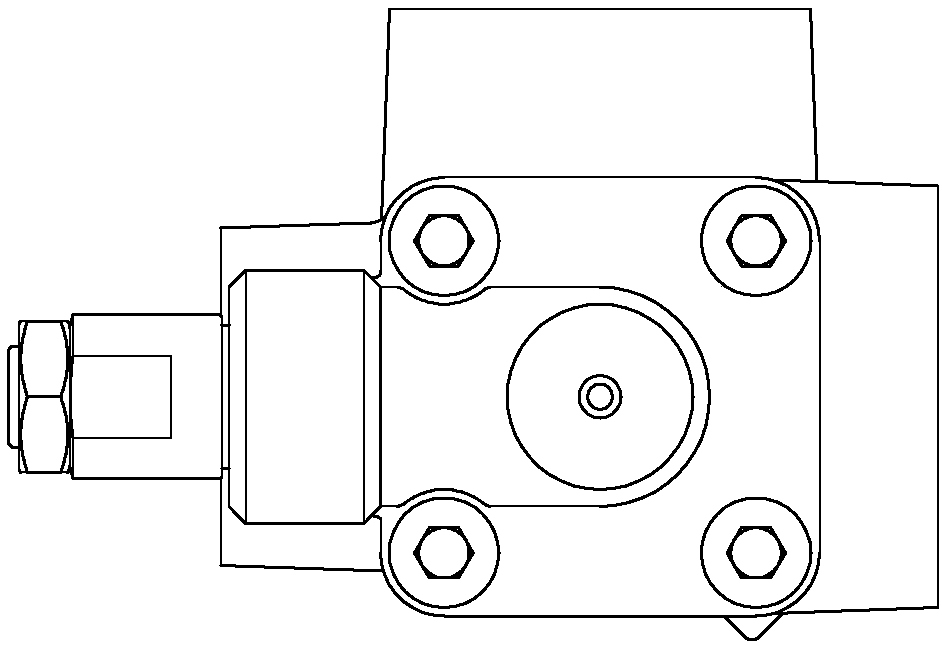

Balance valve

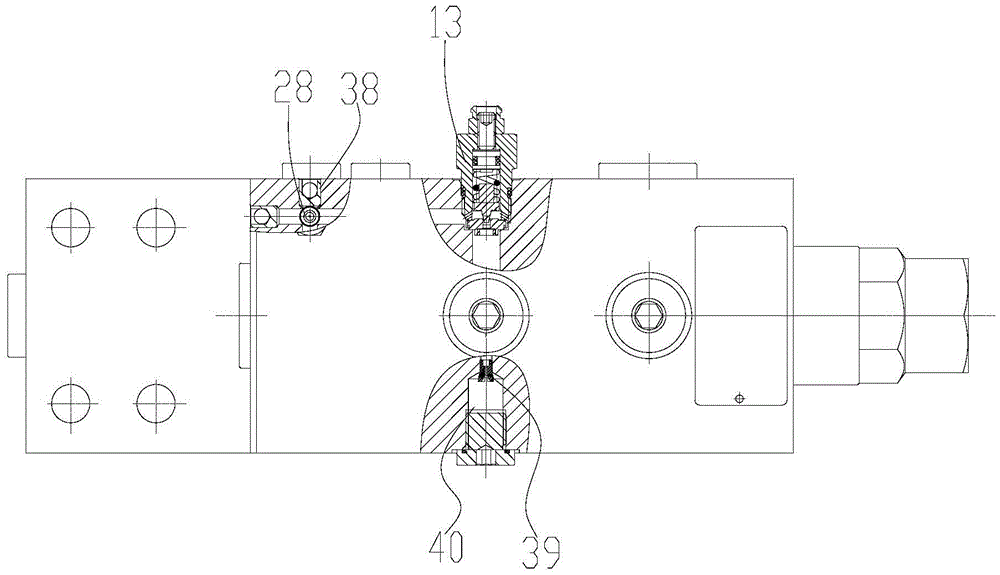

InactiveCN101435446AReduce internal leakagePrevent external leakageServomotor componentsEngineeringPilot valve

The invention provides a balance valve which is used to solve the problems that the prior balance valve has a complex structure, high manufacturing cost and poor sealing performance. The balance valve comprises a valve body; the end part of the valve body is provided with an end cover; the side of the valve body is provided with a first main oil port and a second main oil port; the end face of the end cover is provided with a control port; the valve body is manufactured into a main valve hole along the length direction; a balance valve component and a main valve are sequentially arranged in the main valve hole; the balance valve component comprises a valve sleeve; the valve sleeve is provided with axial through holes; and a cone valve, a pilot valve and springs are sequentially arranged in the valve sleeve. The balance valve is characterized in that the pilot valve is a pilot cone valve; and the number of the springs is two. In the balance valve, the pilot valve and the main valve have a cone valve structure so as to improve the sealing performance of a one way valve; the pilot valve and the main valve are controlled through two springs with different rotating directions, on the premise of reducing no composite force of the springs, the balance valve reduces the force of a single spring, thereby improving the service life of the springs; and the right end of a sleeve is added with a sealing ring so as to improve the sealing performance of a control chamber.

Owner:SHANGHAI LIXIN HYDRAULIC

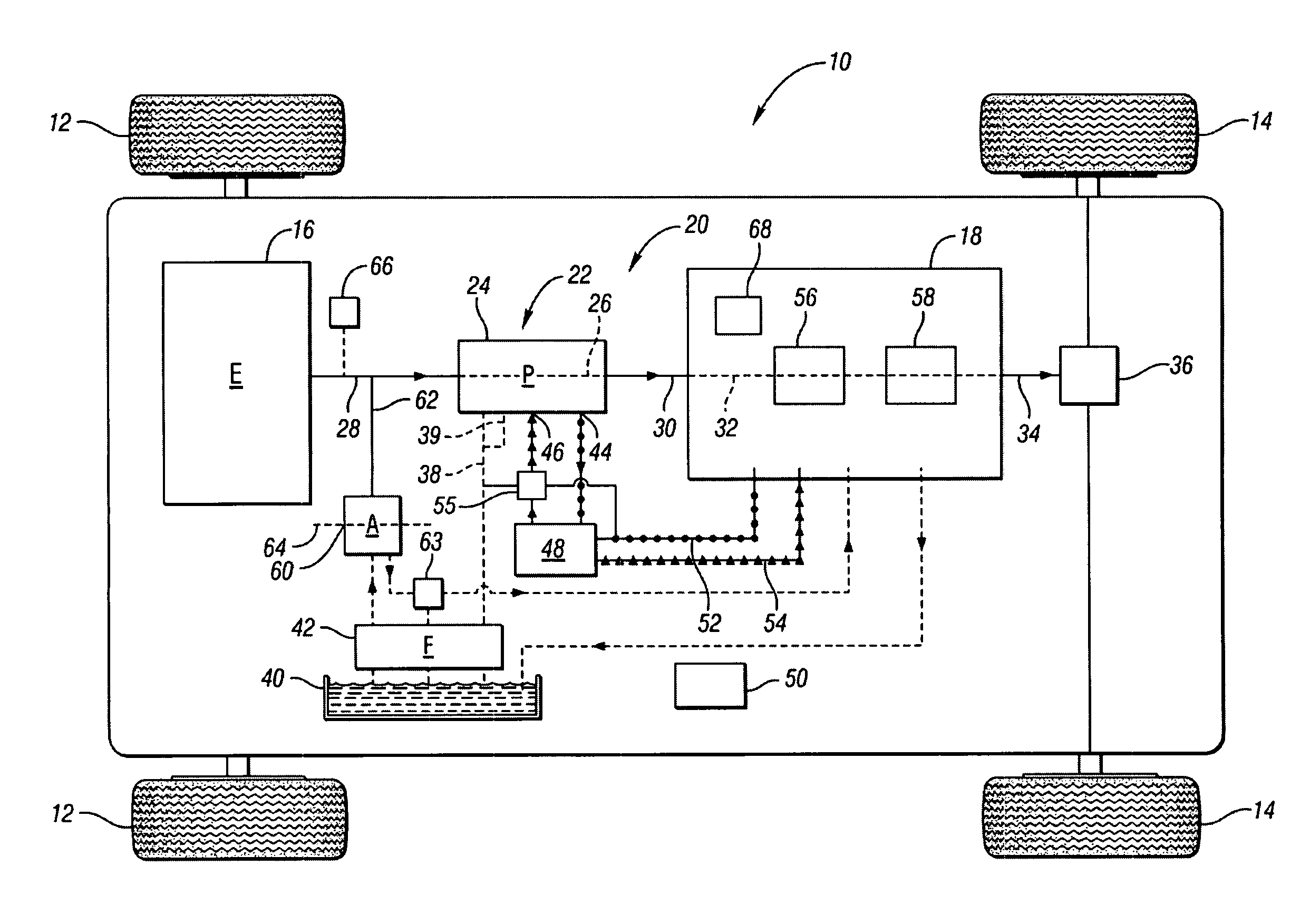

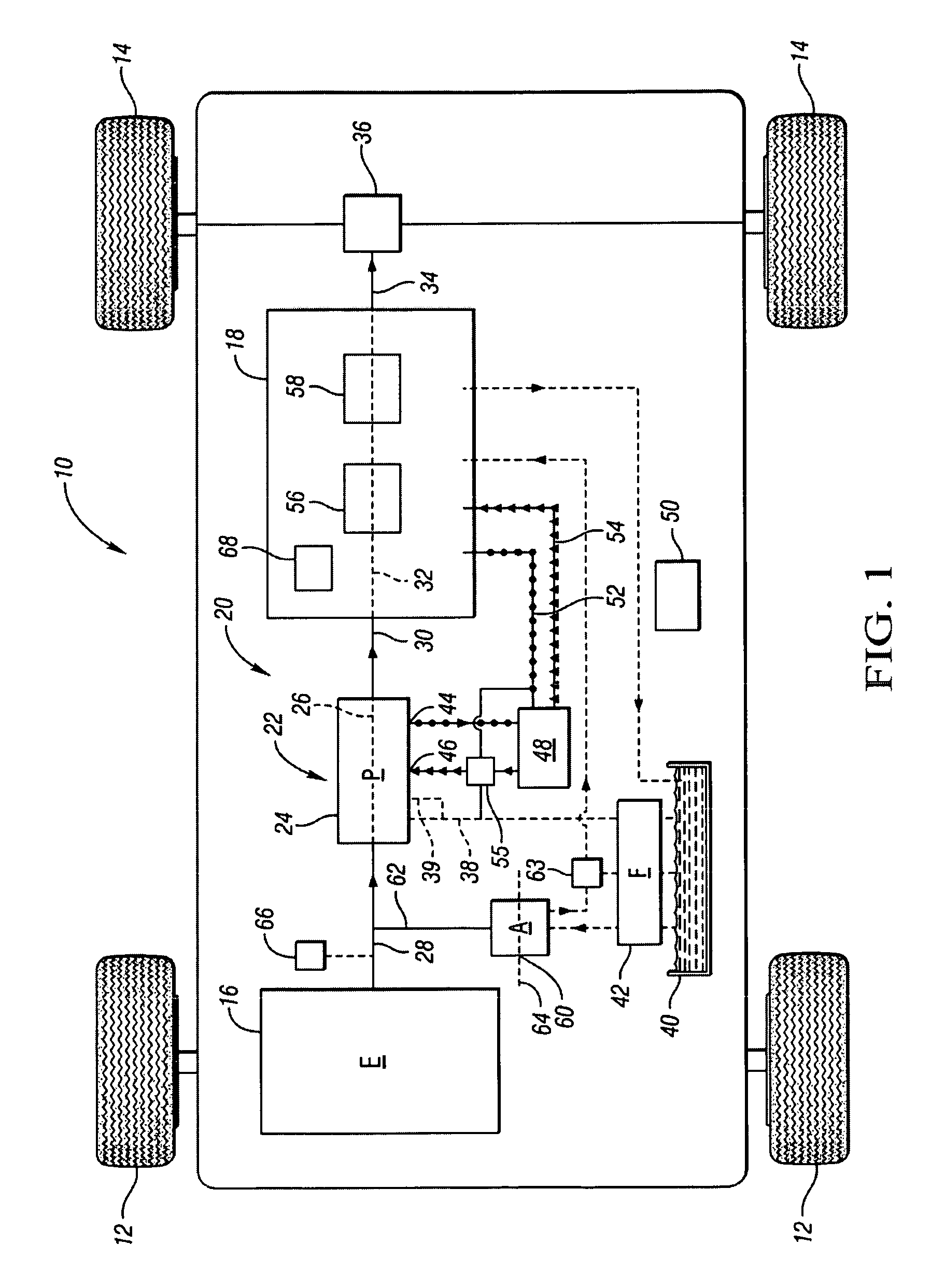

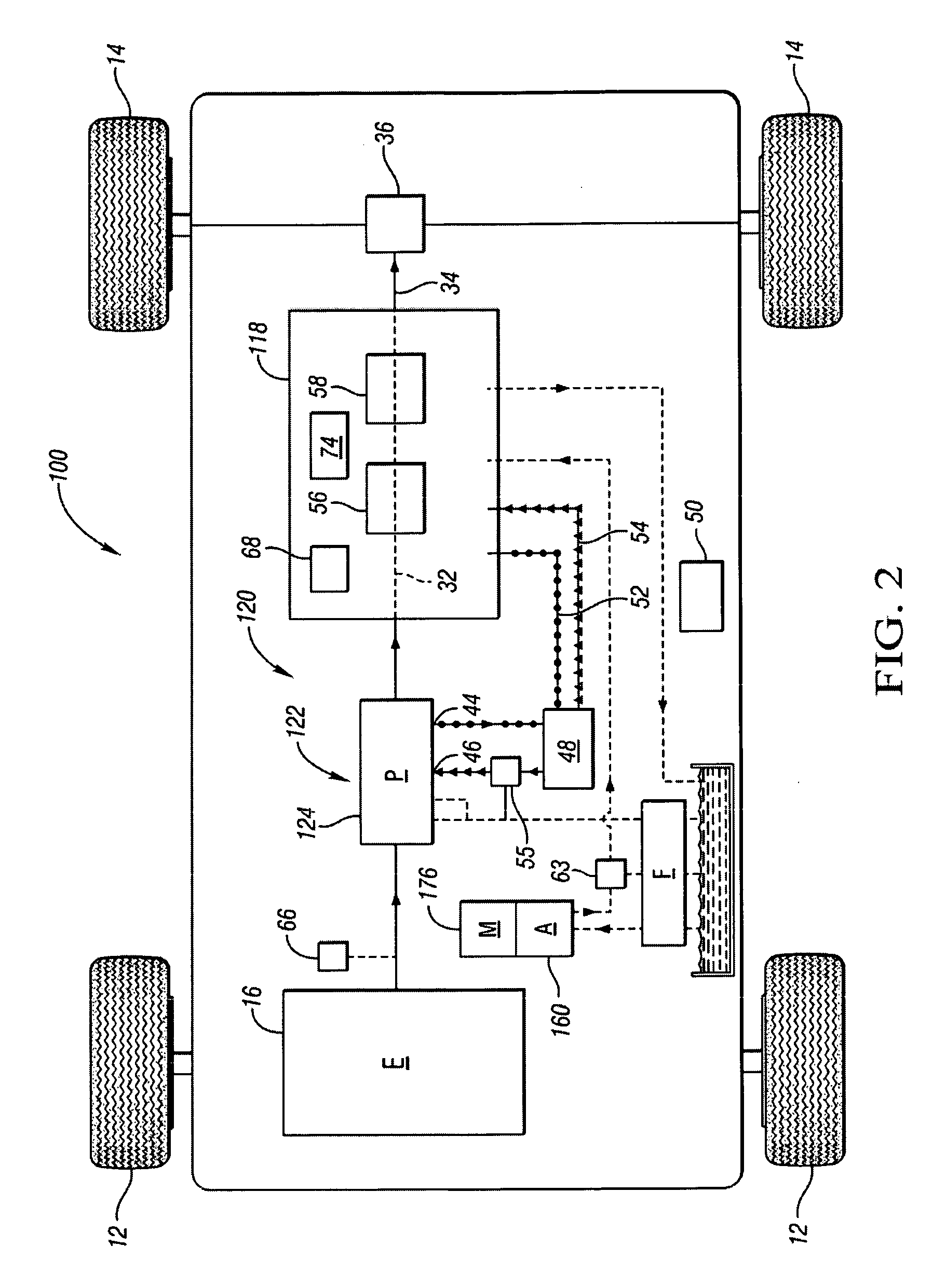

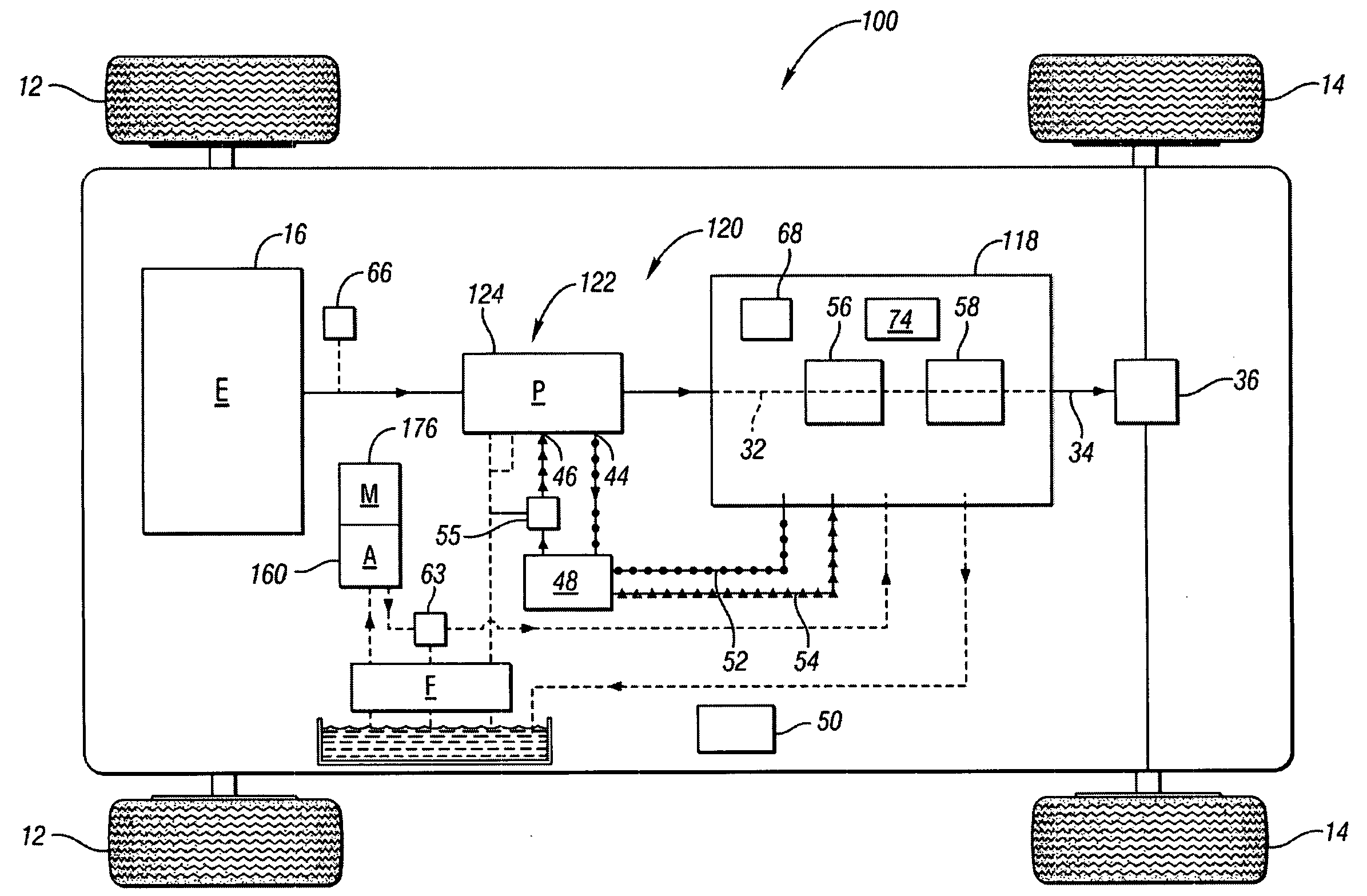

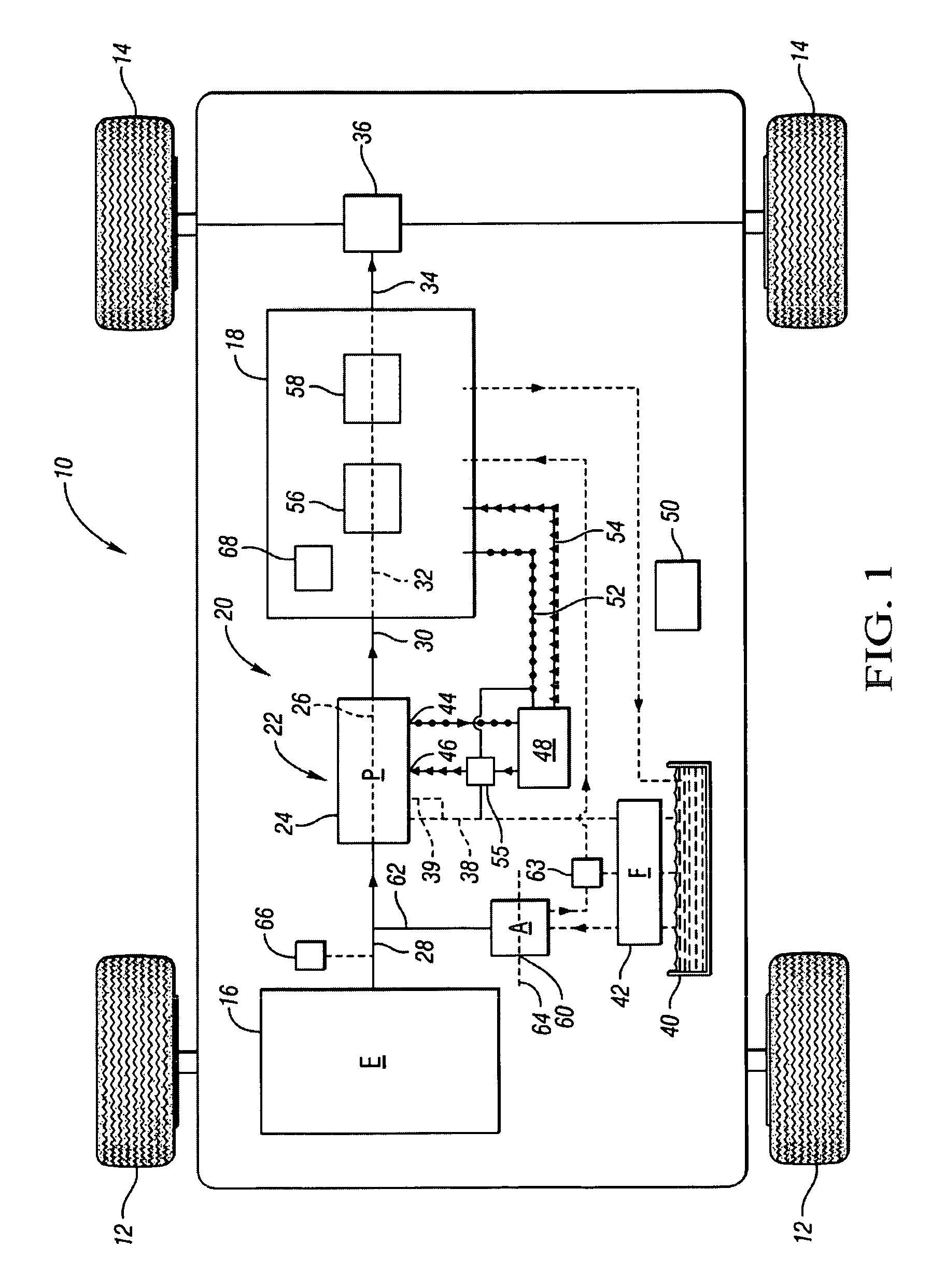

On-demand hydraulic pump for a transmission and method of operation

A fixed displacement binary pump is provided for a powertrain on a vehicle. A hydraulic system is operatively connected with first and second discharge ports of the pump and is operable to alternately permit fluid flow through both discharge ports (i.e., full displacement or volumetric output of the pump) or permit flow through only the first discharge port (i.e., partial displacement or volumetric output of the pump). The pump may be packaged in a front support of the transmission. An auxiliary pump may be provided that is operable to supplement the output of the binary pump or to be used when the binary pump is off. A method of operating the binary pump and auxiliary pump is provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

Pneumatic module

InactiveUS6955337B2Improve abilitiesReduce leakageOperating means/releasing devices for valvesPipe elementsEngineeringActuator

A pneumatic module includes an actuator assembly and a manifold. The actuator assembly includes a main body having a bore, an armature, overmolded primary and secondary plates, a coil and a frame. The manifold includes a valve seat, a control port and a supply port. When the actuator is in a de-energized state, the armature is forced against the valve seat by a spring, sealing off the supply port from the control port. When the actuator is in an energized state, current flows through the coil, thereby generating a magnetic field. The magnetic field forces the armature to move toward the primary plate, causing the valve seat becomes unsealed. Once the valve seat is unsealed, fluid flow is permitted between the supply port and the control port. The one end of the armature has an endcap to minimize mechanical noise generated by movement of the armature against the spring. The frame surrounding the actuator assembly has flanges extending from both ends. These flanges correspond to wells located within the manifold. The flanges and wells are configured such that when the flanges are inserted into the wells, the actuator assembly can be twisted and locked into the manifold without requiring additional traditional fasteners, such as bolts or screws.

Owner:DELPHI TECH INC

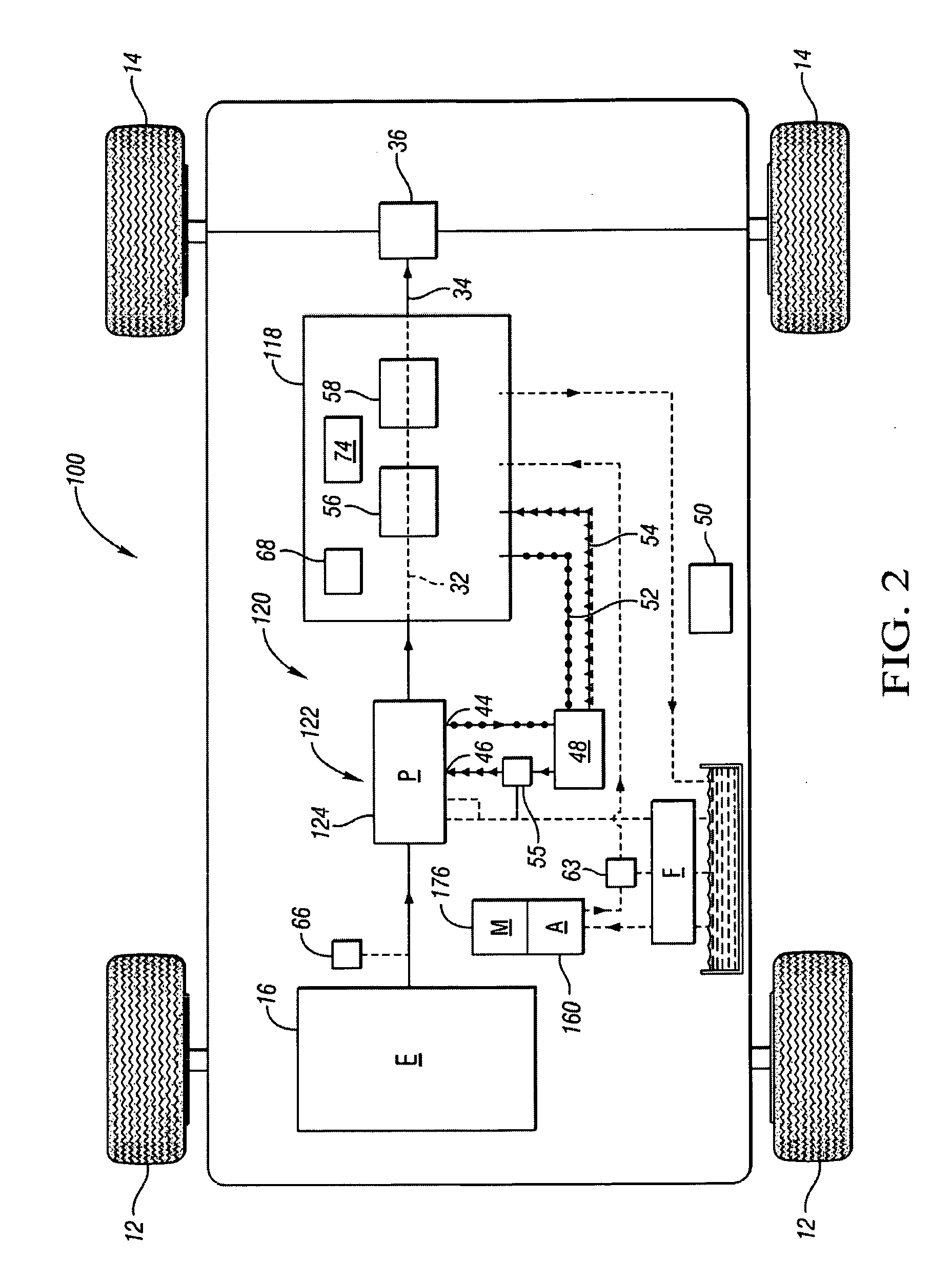

On-demand hydraulic pump for a transmission and method of operation

ActiveUS20090241535A1Less torqueImprove economyRotary clutchesGearing controlHydraulic pumpEngineering

A fixed displacement binary pump is provided for a powertrain on a vehicle. A hydraulic system is operatively connected with first and second discharge ports of the pump and is operable to alternately permit fluid flow through both discharge ports (i.e., full displacement or volumetric output of the pump) or permit flow through only the first discharge port (i.e., partial displacement or volumetric output of the pump). The pump may be packaged in a front support of the transmission. An auxiliary pump may be provided that is operable to supplement the output of the binary pump or to be used when the binary pump is off. A method of operating the binary pump and auxiliary pump is provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

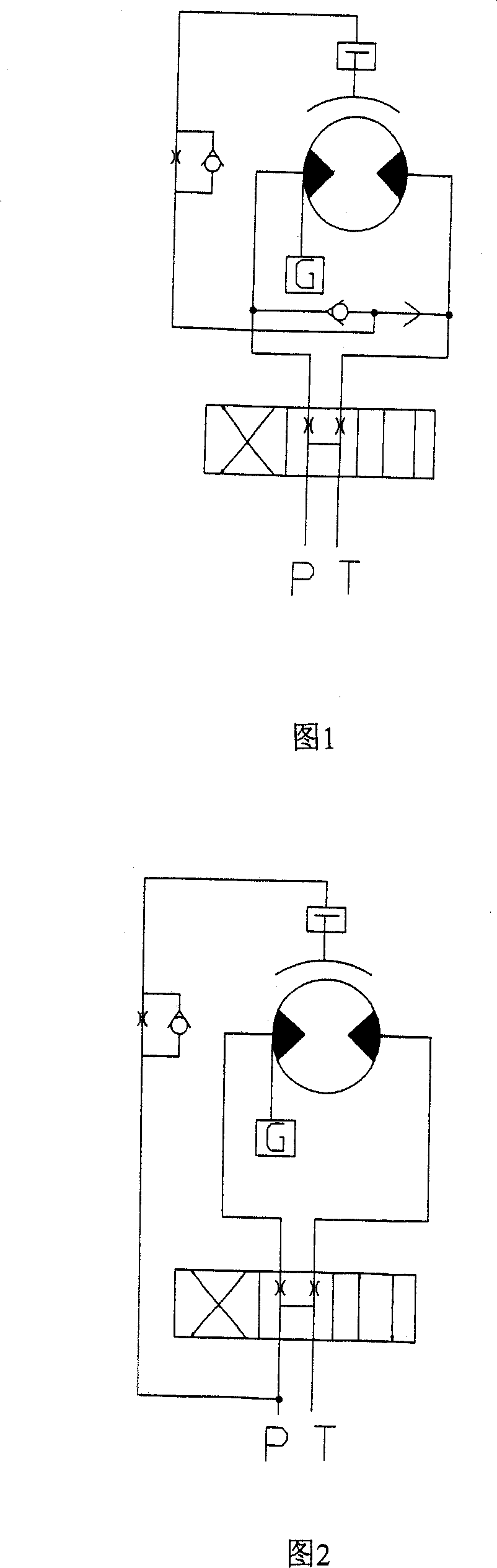

Control valve of brake

InactiveCN101092137AOvercome the opening phenomenonSimple structureApplication and release valvesLoad-engaging elementsLow voltageSystem pressure

The invention relates to control valve of braking device that includes valve body, valve core and shuttle valve. The feature is that the valve core adopts two position and tee coupling valve core. One end of valve core connects to the output end of shuttle valve. The input end of shuttle interface B and C connect to hydraulic system pressure output end. The other end of spring cavity of valve core connects to oil tank. And the input interface of control valve P connects to low voltage constant pressure resource. The cavity of valve core connects to output interface A of control valve through output end. The output interface A connects to brake. Cavity of valve core connects to interface L, which connects to oil tank, through return check valve and control valve. The invention has the advantages of simple and small volume, etc.

Owner:YUZHOU HYDRAULIC EQUIP FACTORY

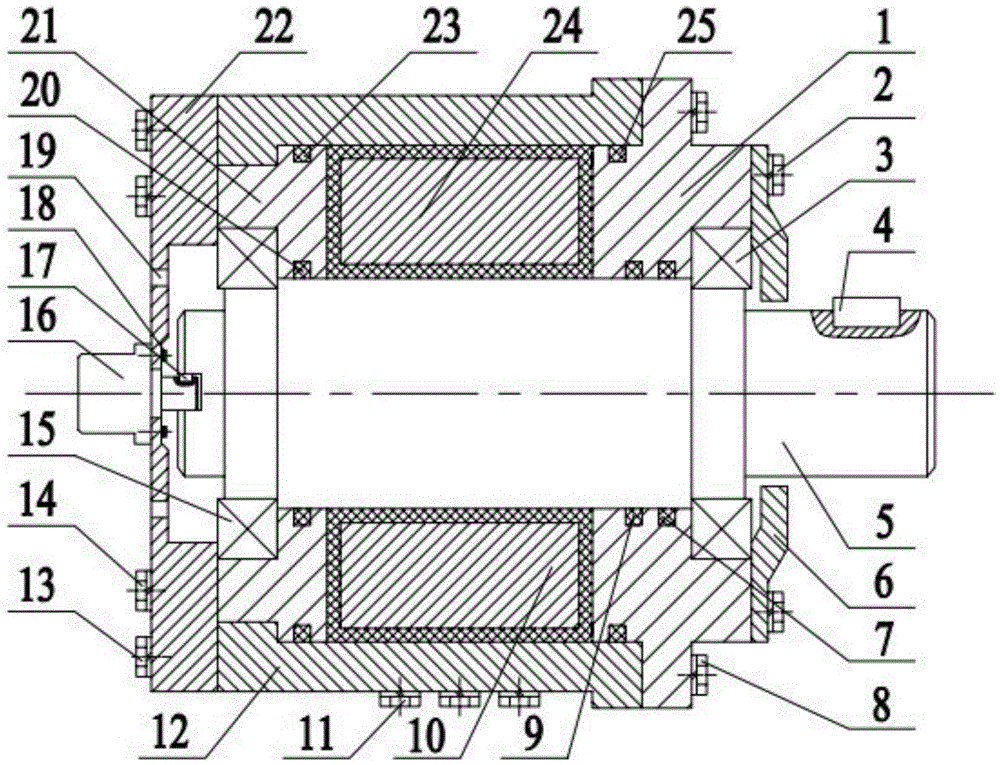

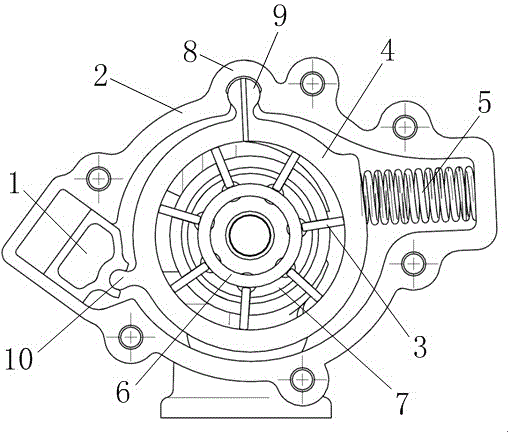

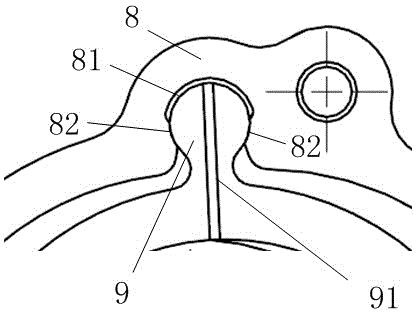

Blade type hydraulic motor with rocker arm structure

ActiveCN102174901AImprove performanceCooperate wellEngine componentsRotary piston enginesHydraulic motorEngineering

The invention discloses a blade type hydraulic motor with a rocker arm structure. The hydraulic motor comprises an end cover, an oil distribution disc, a stator, a rotor and a rotating shaft, wherein the rotor is connected with the rotating shaft by a spline; a plurality of blade grooves are uniformly formed on the rotor; two layers of rocker arm beams are arranged in circular grooves at the two ends of the rotor, each layer comprises a plurality of rocker arm beams, holes are formed in the centers of the rocker arm beams; pin shafts pass through the holes to rotationally connect the rocker arm beams with the rotor; circular cavities are formed at the two ends of each blade groove; through holes which are intersected with the circular cavities along the radial direction are formed below the circular cavities; pull rods and springs are arranged in the through holes sequentially; the bottom surfaces of the pull rods are contacted with the arms of the rocker arm beams; blades are arranged in the blade grooves; the bottom ends of the blades are contacted with the springs; the springs are positioned in the circular cavities; an oil circuit is communicated with the circular cavities; grooves are formed on the tops of the blades; and blade heads are inserted into the grooves, are tightly matched with the blades, are higher than the tops of the blades and are contacted with the inner curve surface of the stator. The hydraulic motor has high sealing performance between the blades and the stator, small abrasion during rotation, higher efficiency and longer service life.

Owner:宁波恒通诺达液压股份有限公司

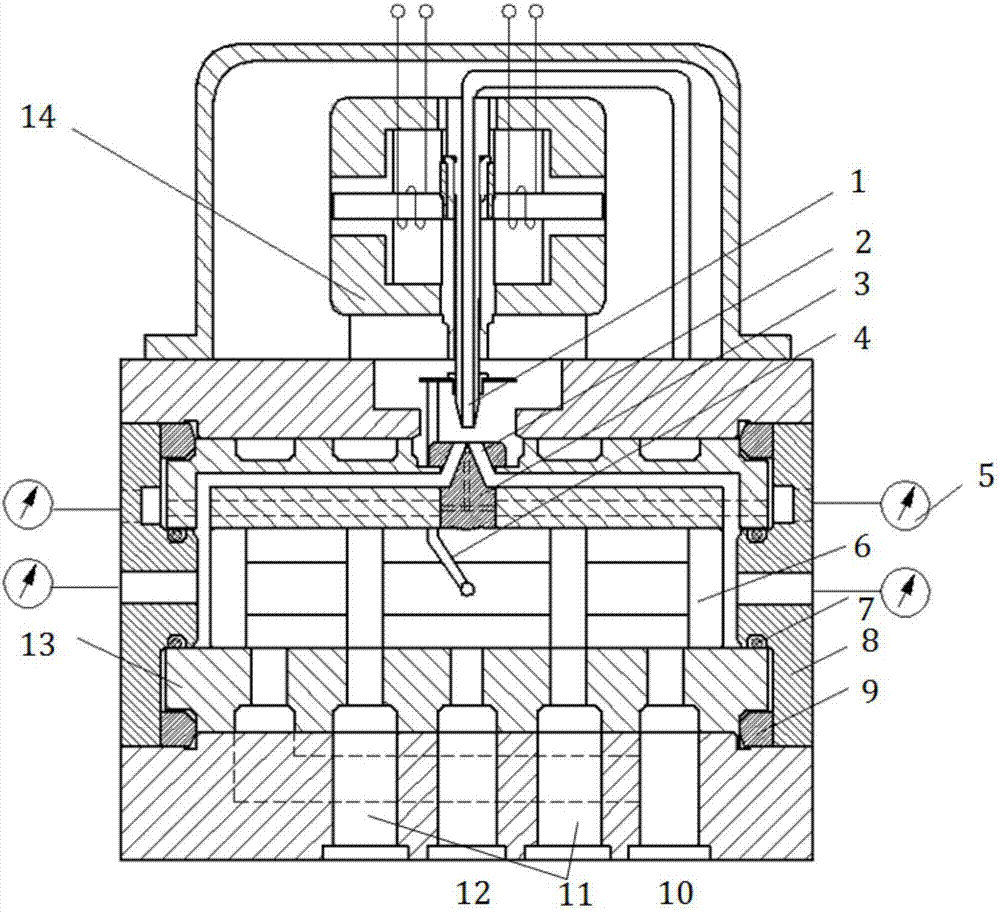

Water-hydraulic single-vane type oscillating cylinder

ActiveCN105545863ANo pollution problemSolving Corrosion ProblemsFluid-pressure actuatorsEngineeringHydraulic seal

The invention discloses a water-hydraulic single-vane type oscillating cylinder, and belongs to key parts of underwater robot joints. The water-hydraulic single-vane type oscillating cylinder is mainly composed of a front end cover, a front sealing cover, a bearing, a rotating shaft, a rotating vane, a fixed vane, a housing, a packaging encoder, a rear sealing cover, a rear end cover and the like, and accordingly two working water cavities are formed. The rotating vane and the fixed vane are both provided with specially-made rectangular sealing rings and pressing and buffering devices; and the bearing is a water lubricating bearing. The water-hydraulic single-vane type oscillating cylinder adopts an all-water lubricating mode and is integrated with the encoder so as to be simple and compact in structure and capable of precisely controlling the output position and speed of the rotating shaft, and be widely applied to driving and controlling of joints of water and underwater robots.

Owner:BEIJING UNIV OF TECH

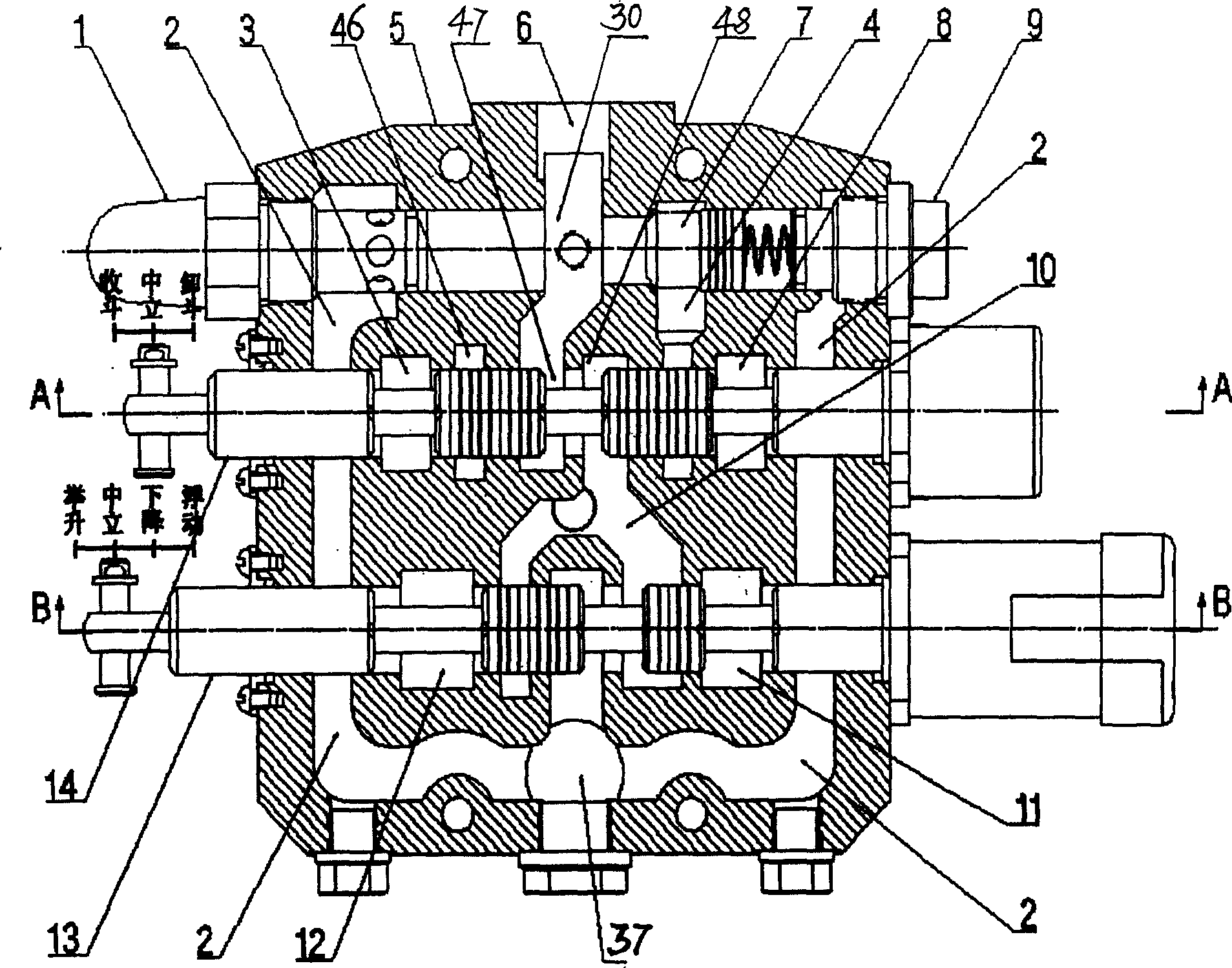

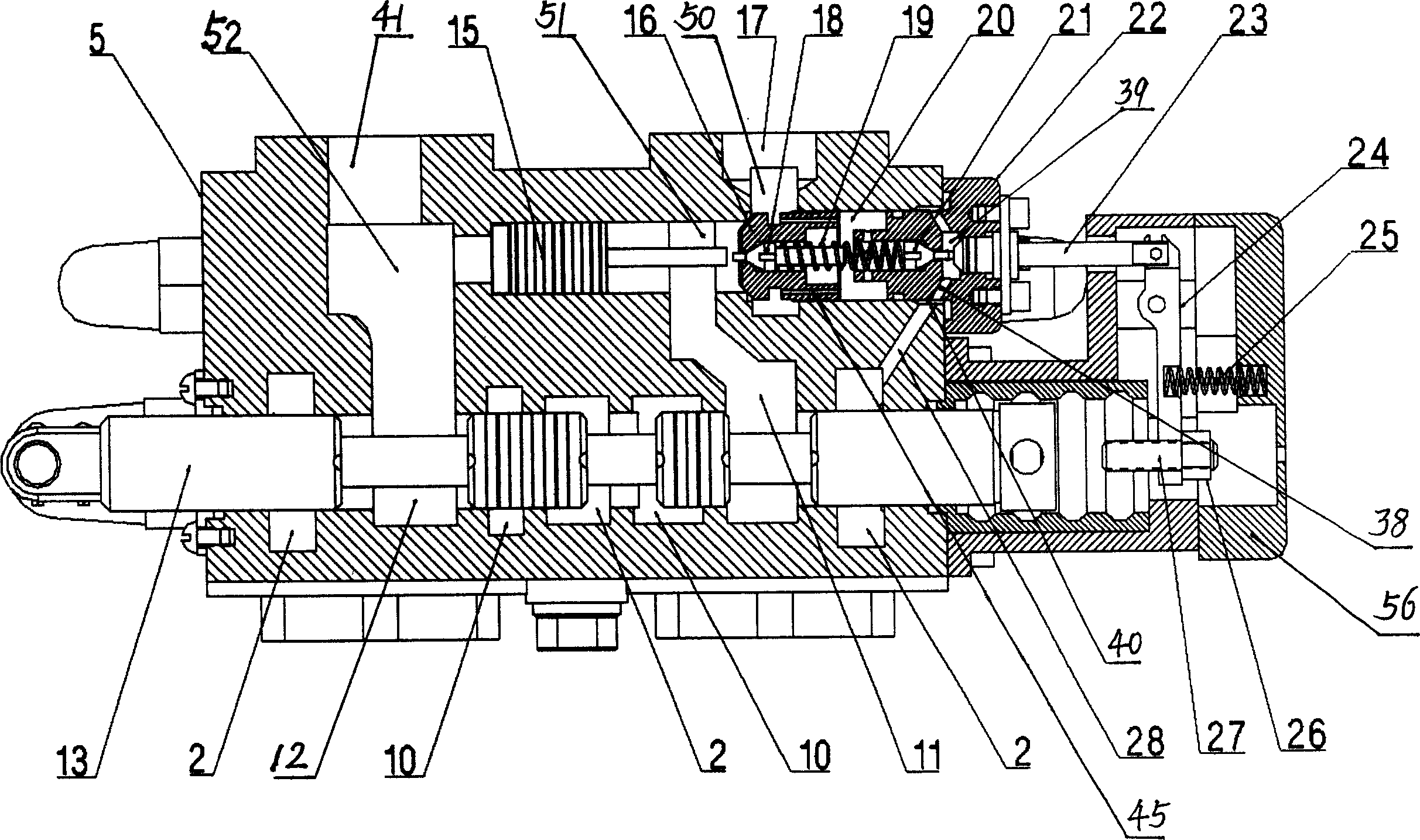

Integrated manual multiple directional control valve for lader

InactiveCN1560480AEliminate the disadvantages of oil leakageQuality assuranceServomotor componentsLifting devicesRotary valveEngineering

The invention discloses a integral manual multi-path reversal valve applied in loader, which includes integral valve, six apertures are drilled in the valve, three of them are connected with oil inputting channel and the return channel, the valve has a inlet and a return outlet connected to the channels, the aperture is assembled with a moving arm valve pole, rotary valve pole, safe valve, overload valve, outlay common single-way valve and hydraulic control lock device, the moving arm valve pole and the rotary valve pole are the solid valve pole, the hydraulic control lock has pilot and double-direction starting functions, it is sealed in the oil path with the circle line. The valve hydraulic oil has no leakage, the inner leakage is small, it can prevent the moving arm form falling, avoids the lock and oversize manipulating force, it is safe and flexible.

Owner:尚继良

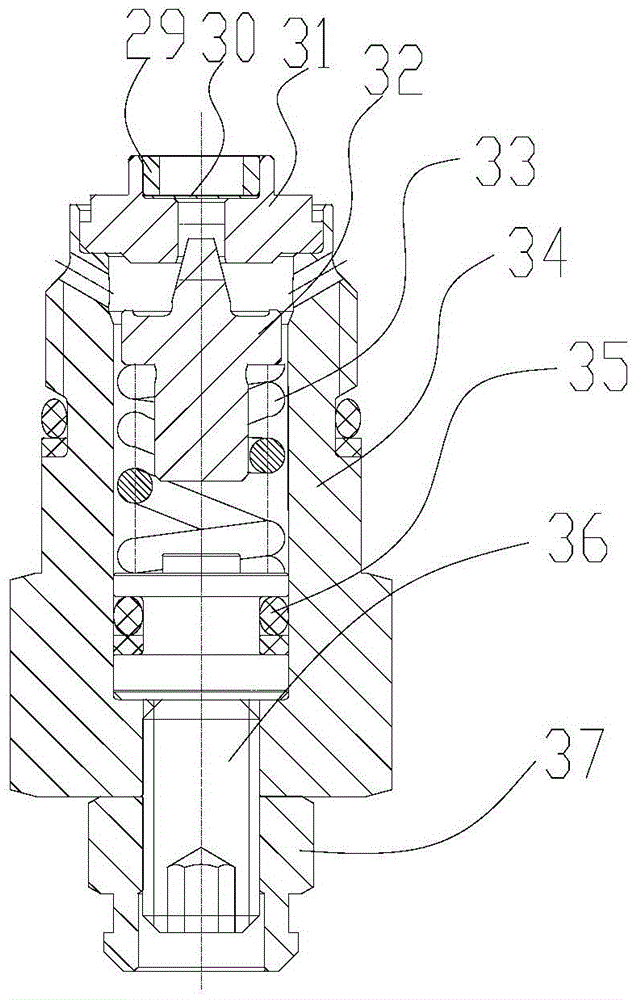

Jet pipe servo valve capable of adjusting axis position of nozzle and adjustment method

InactiveCN107131167AIncrease output flowIncrease jet receiving areaFluid-pressure actuator testingServomotor componentsJet flowTorque motor

The invention discloses a jet pipe servo valve capable of adjusting axis position of a nozzle. The jet pipe servo valve comprises a valve body, a jet nozzle which is arranged on the upper part of the valve body is controlled through a torque motor, adjustment end covers which are arranged on two ends of the valve body, a pressure detection device, a valve bush arranged in the valve body, a valve core arranged in the valve bush and a receiving base which is embedded in the valve core and is used for receiving a flow beam of nozzle jet flow, wherein two jet flow receiving holes are formed in the jet flow receiving base; the two jet flow receiving holes separately communicate with cavities at two ends of the valve core in the valve bush through receiving slot holes formed in the wall of the valve bush; the pressure detection device comprises two pressure detection holes formed in the jet flow receiving base and first pressure sensors arranged on the end covers; and the two pressure detection holes are separately connected with the pressure sensors through detection slot holes formed in the wall of the valve bush. Compared with the prior art, the jet pipe servo valve has the advantages that the axis position of the nozzle can be adjusted; the nozzle is arranged with the axis being centered front and back, so that a leakage rate in the jet pipe servo valve is lowered; and the like.

Owner:TONGJI UNIV

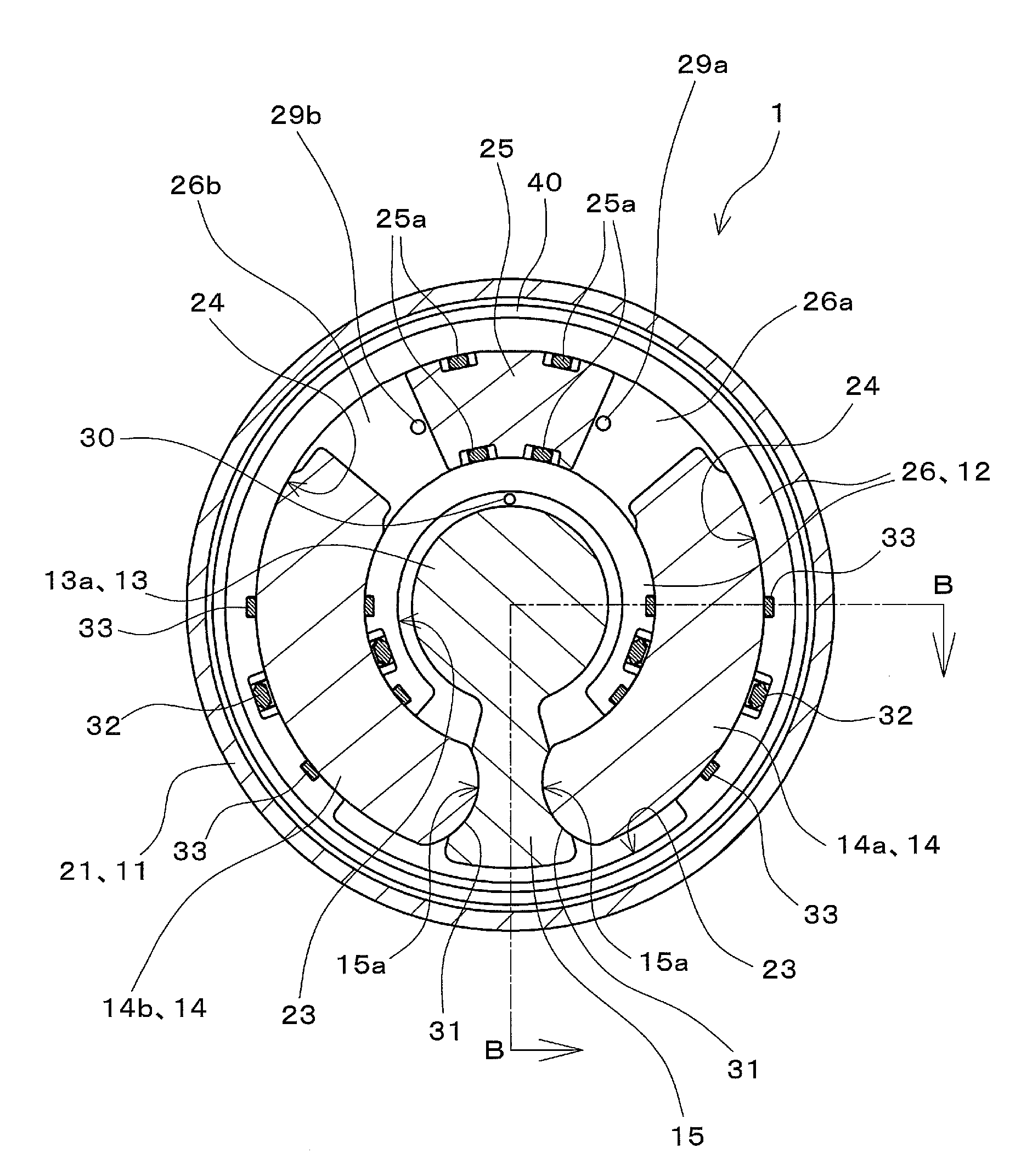

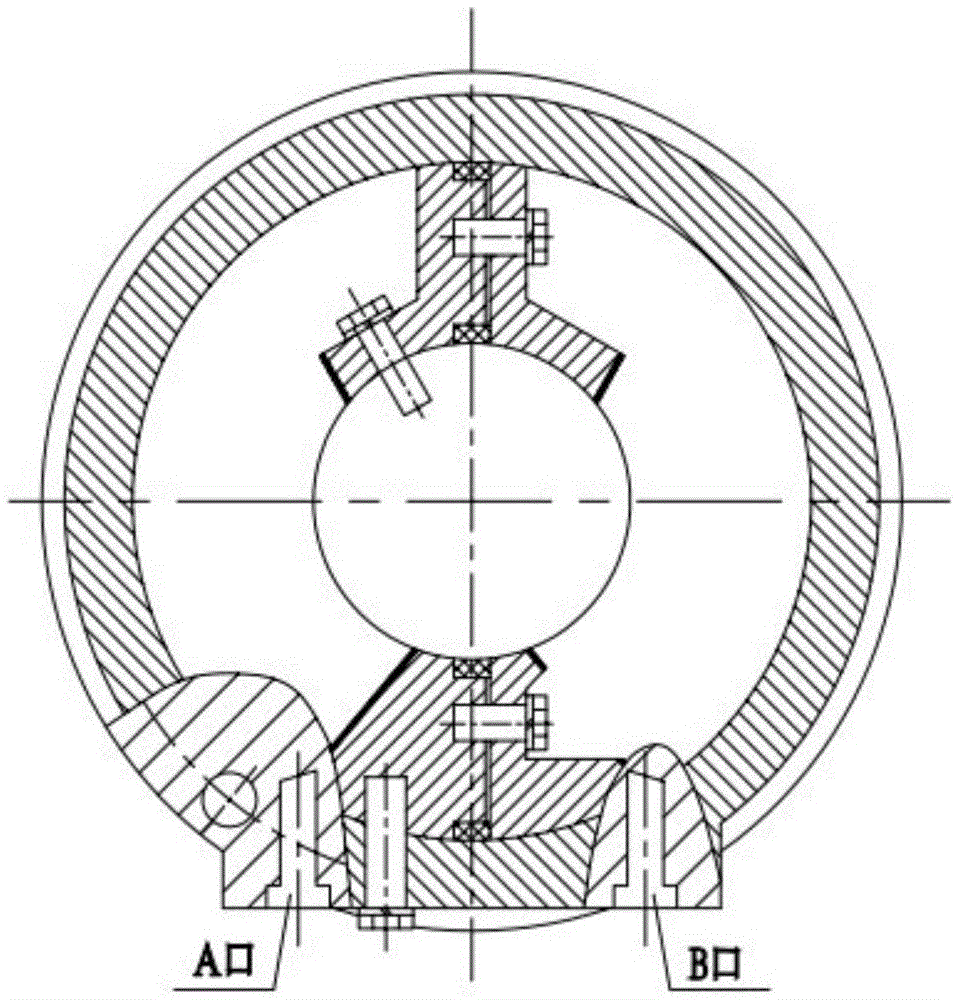

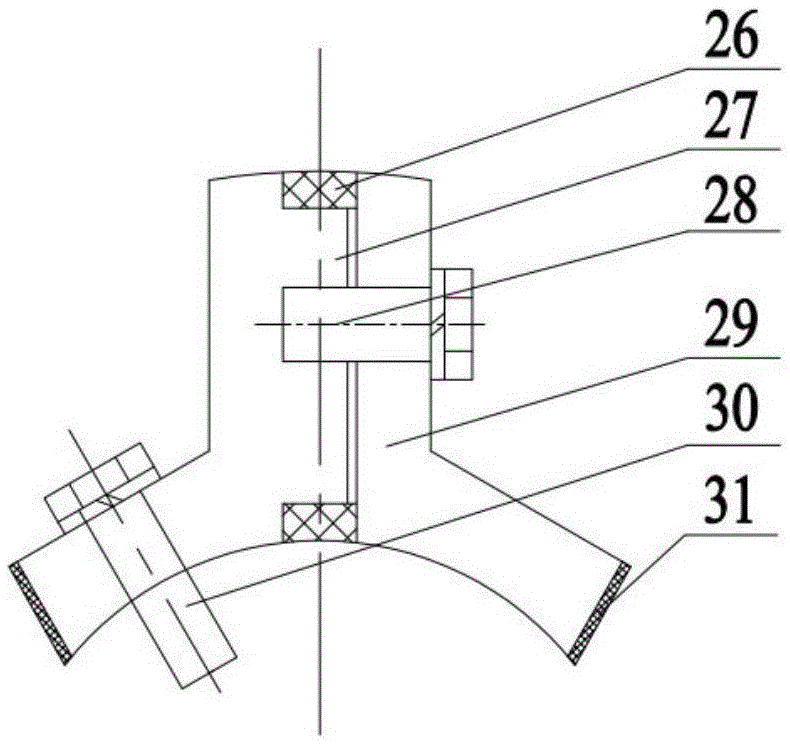

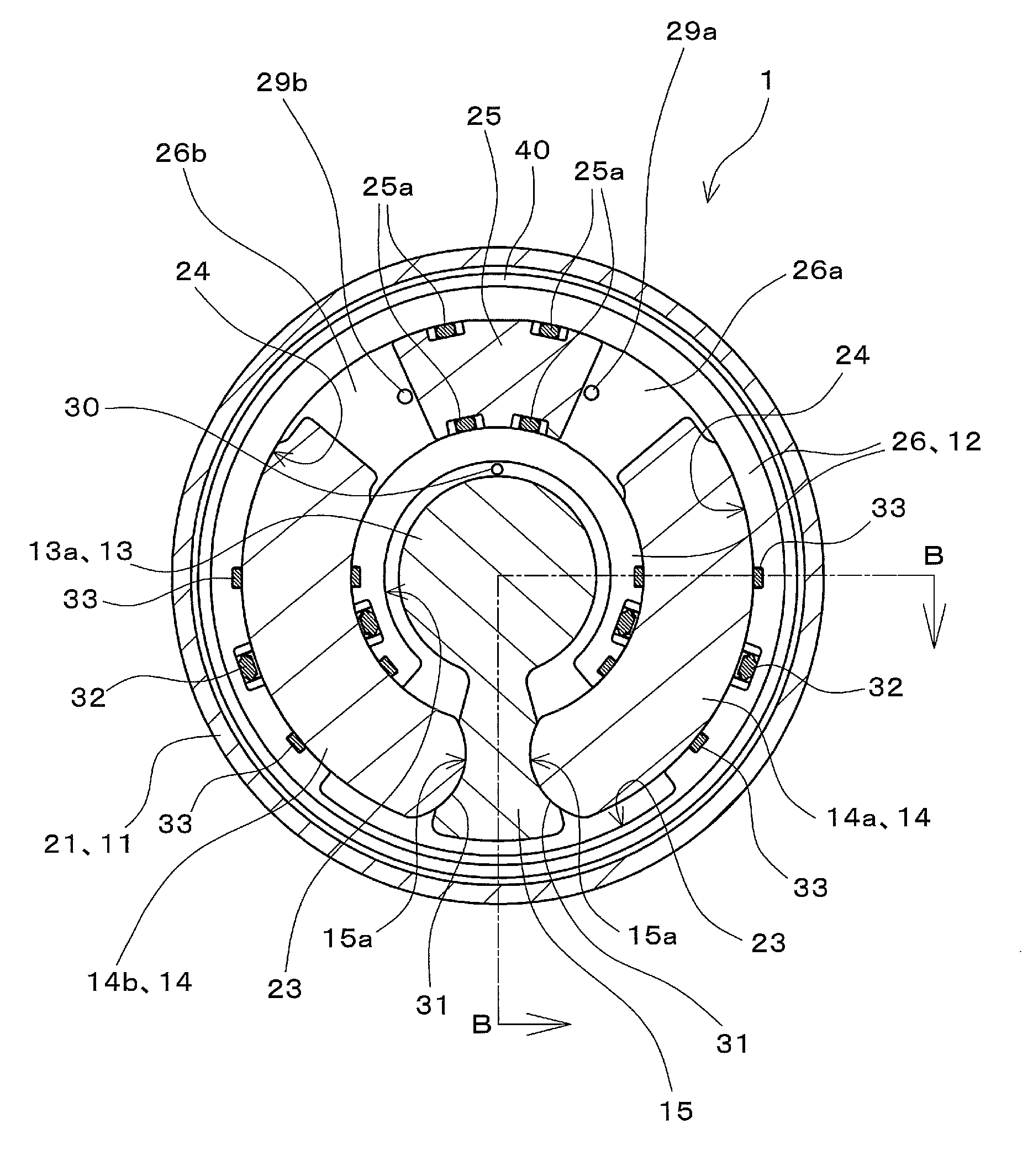

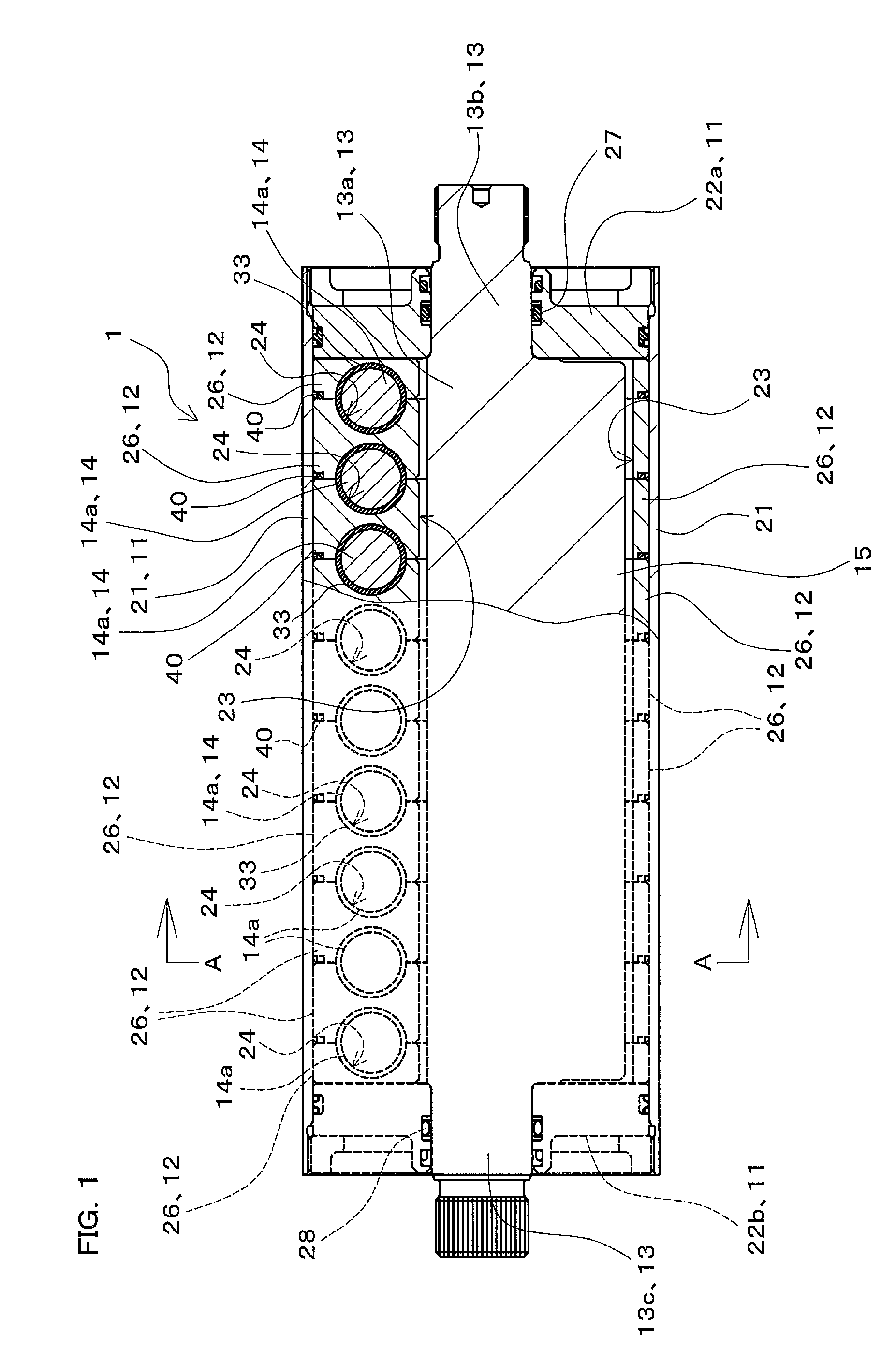

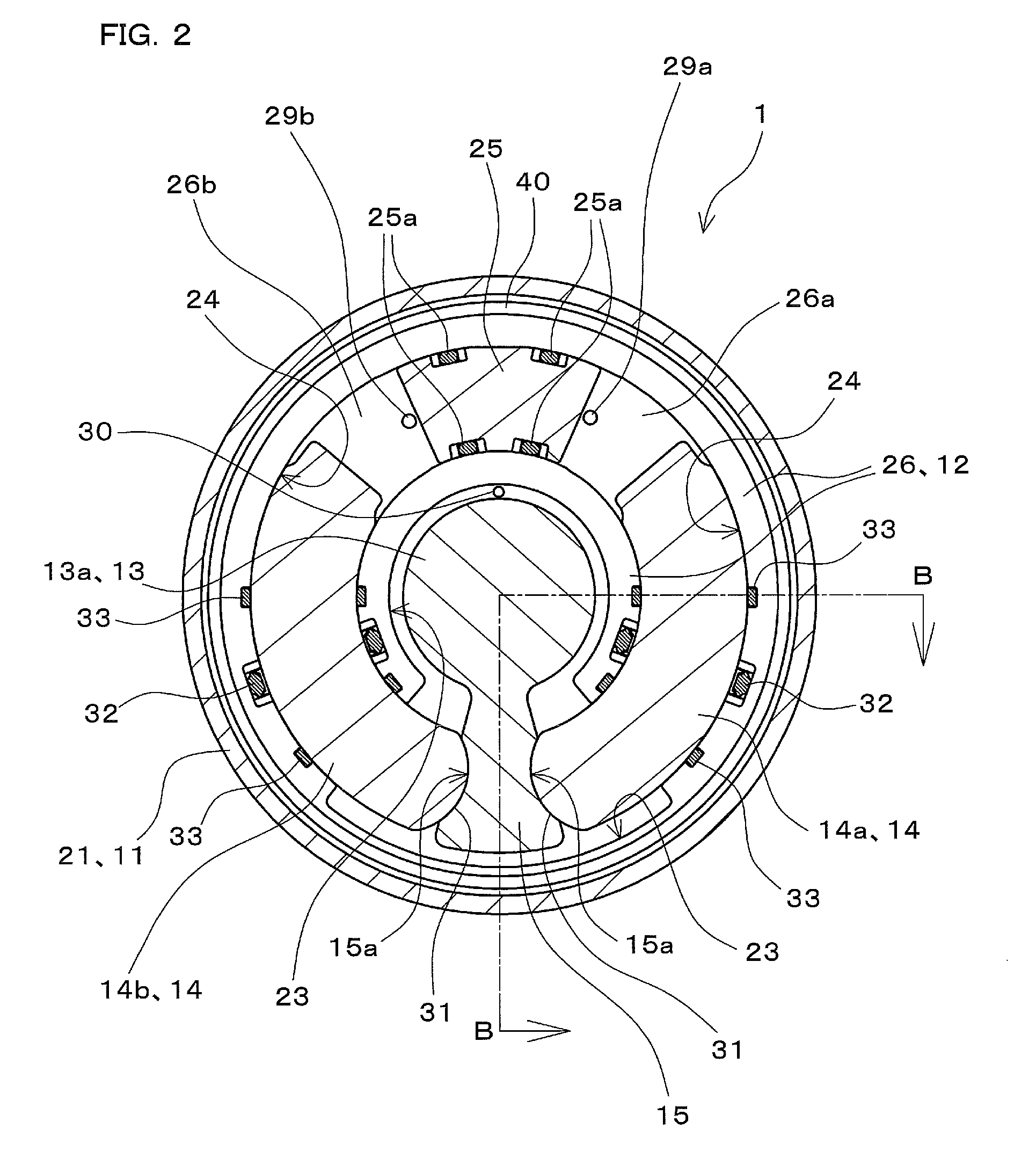

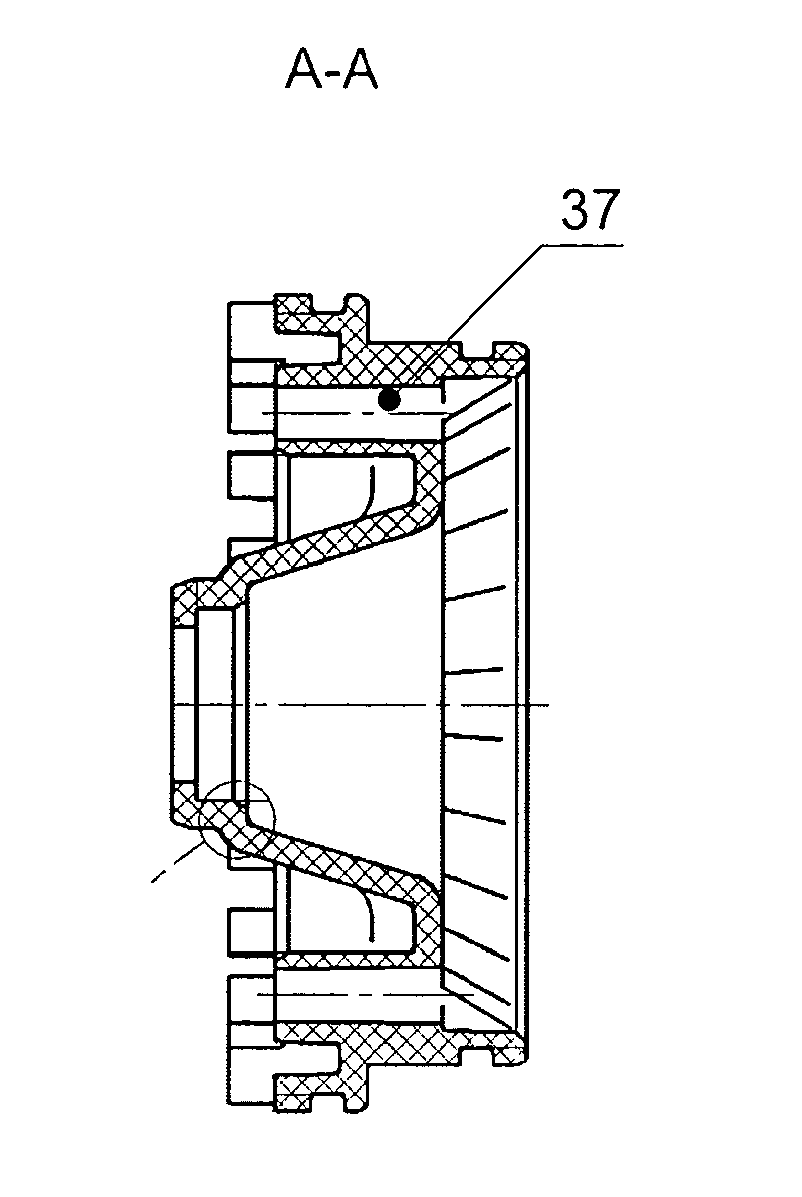

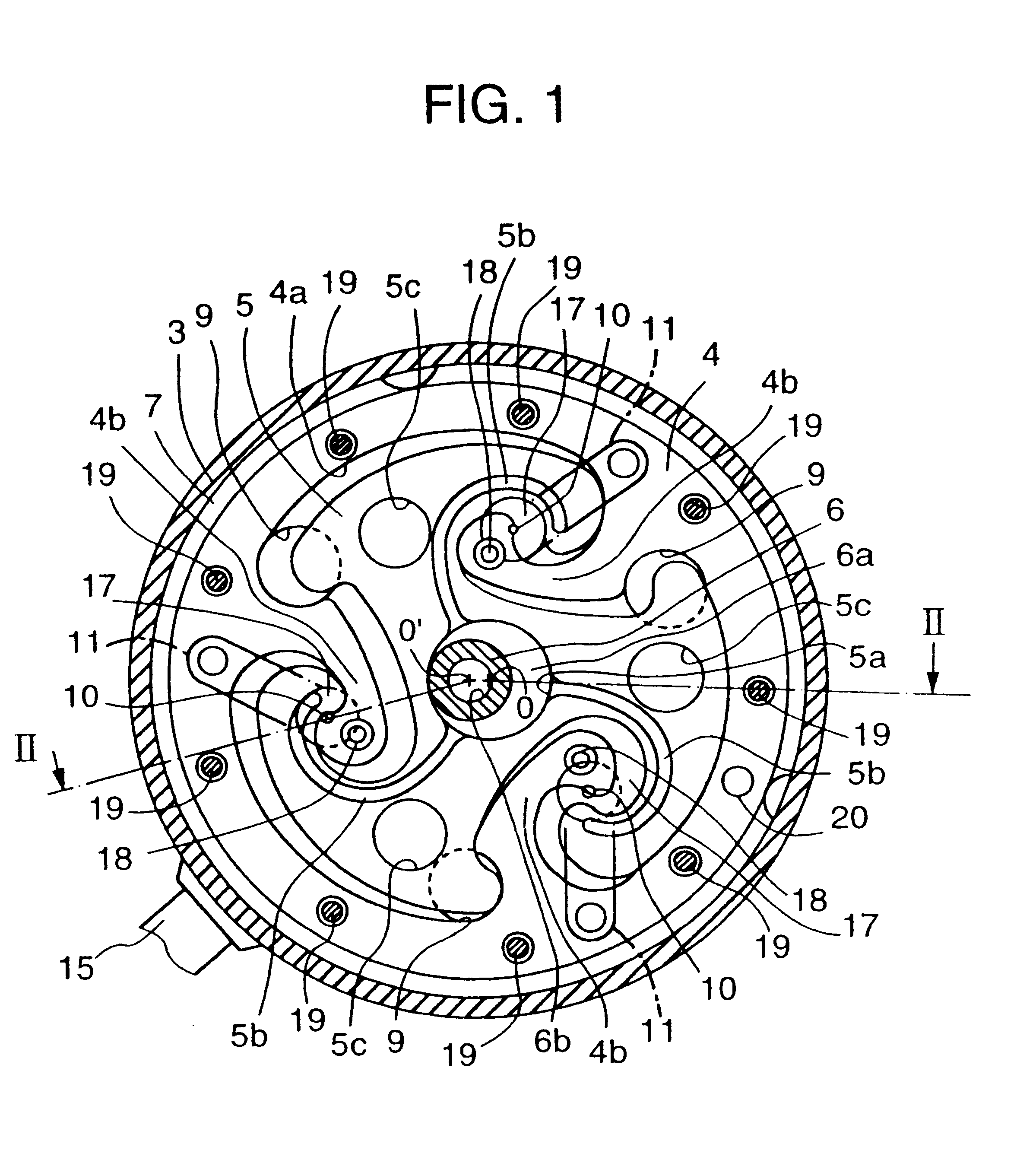

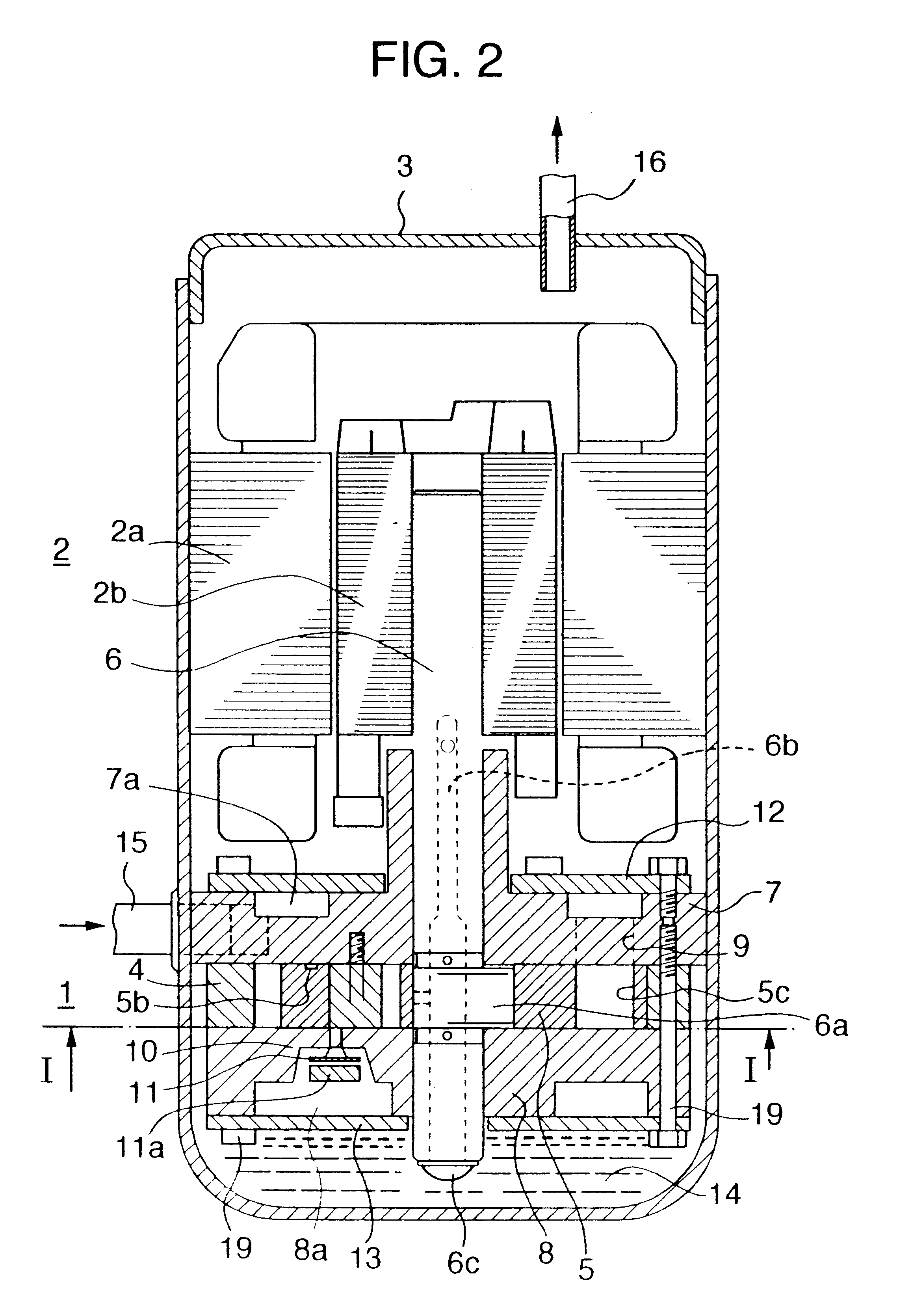

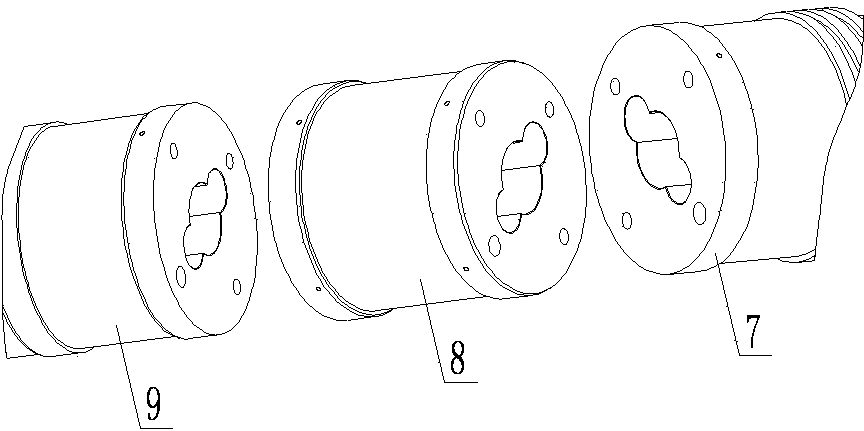

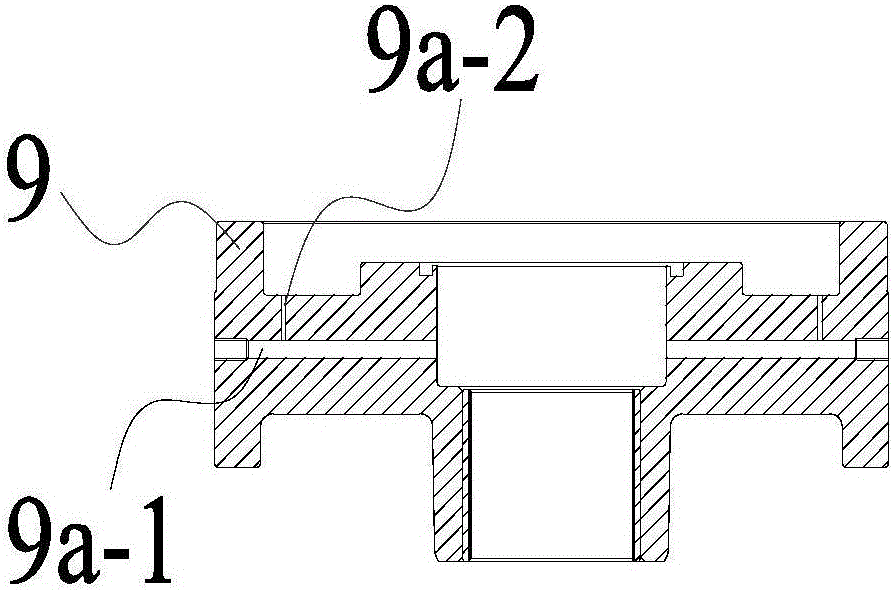

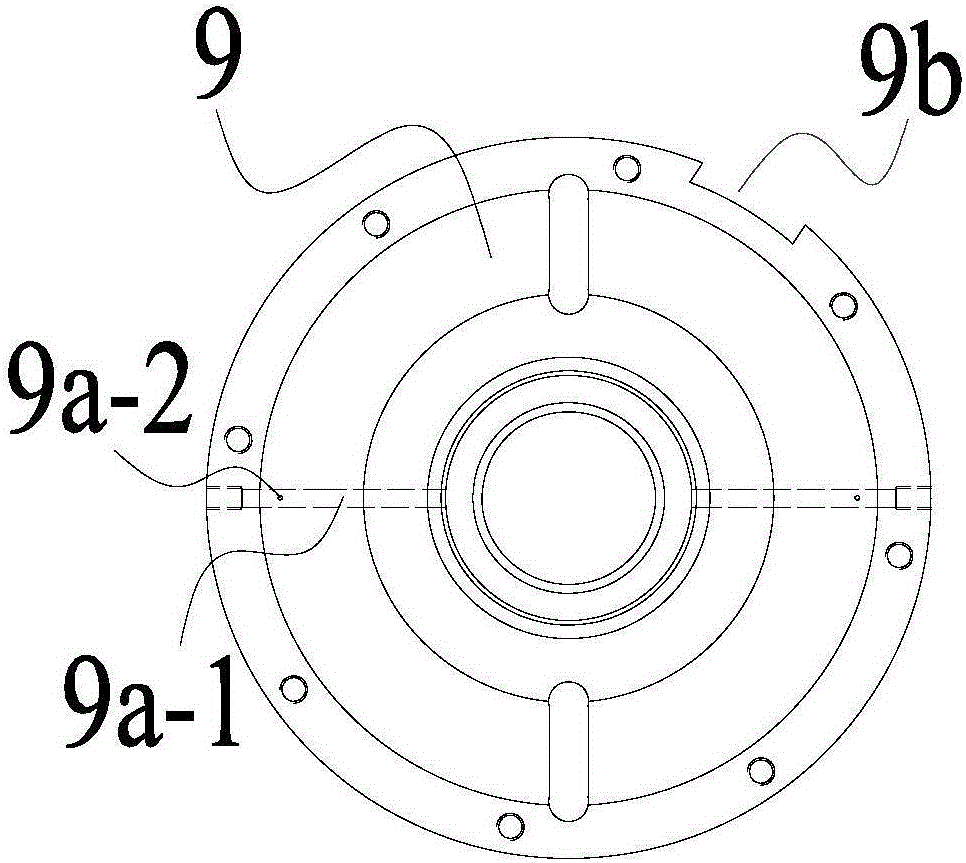

Rotary actuator

ActiveUS9133923B2Reduce internal leakageThe implementation process is simpleGearingFluid-pressure actuatorsRotary actuatorControl theory

A cylinder is installed within a case. An output shaft is installed in a hollow space within the cylinder. A pair of pistons extend in an arc, and is supported so as to be able to slide and be displaced along a circumferential direction of the cylinder within the cylinder. The pair of pistons is able to urge an arm integrated with the output shaft from two sides of the arm. Pressure chambers into which a pressure medium is introduced are defined between the cylinder and each piston in the pair of pistons. The pressure medium is fed to one of the pressure chambers and drained from the other, and thus the arm is displaced, and the output shaft pivots in a rotational direction.

Owner:NABLESCO CORP

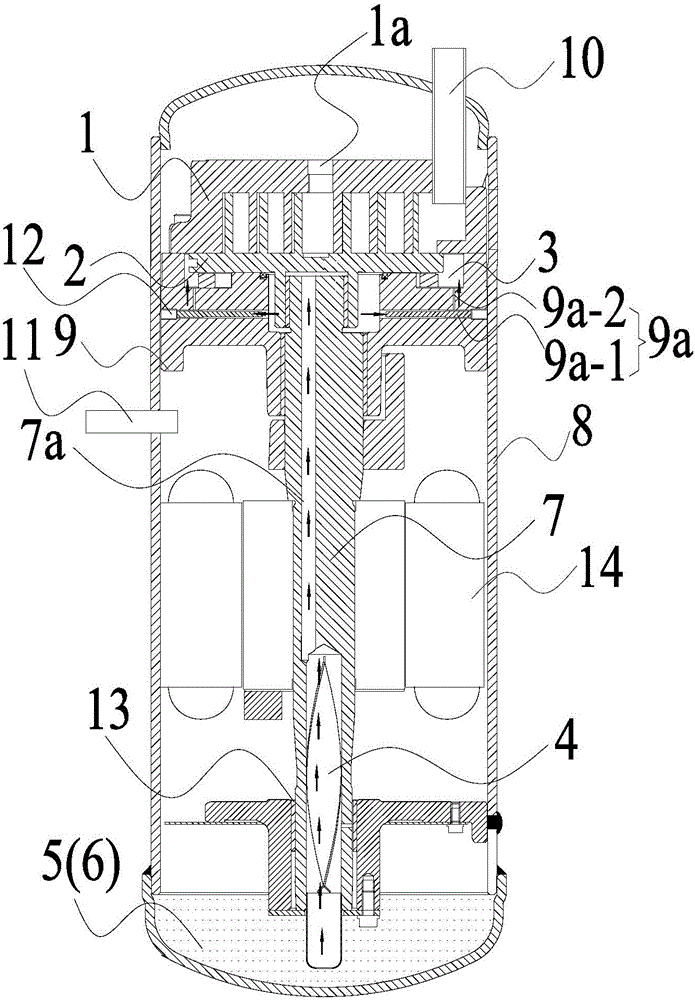

Centrifugal multiple-impeller electric pump

InactiveUS20150192130A1Increasing pump service lifeIncreasing operation reliabilityPiston pumpsPump installationsImpellerEngineering

A centrifugal multistage pump “VODOMET-WATER CANNON” contains electric motor, condensing case and pump stages, installed on the pump cases. The pump stages are located inside the case and are centered by the covers, and also by the support. The bearing end shield of the electric motor is sealed with the elastic diaphragm. The condensing case is a leakproof cavity where the condenser and the cable connectors, of the electric motor are placed. The thermoswitch is located in the condensing box on the heat contactor. The pump stages include guide wheels and antifrictional washers. The washers interact with the axial supports—ceramic inlays that are inserted into the guide wheels. The inlays rest on the end clamps on the butt ends of the guide wheels. The guide wheels are sealed with radial inlays and together with pump stages create a hermetic tank.

Owner:YAZYKOV ANDREY YURIEVICH

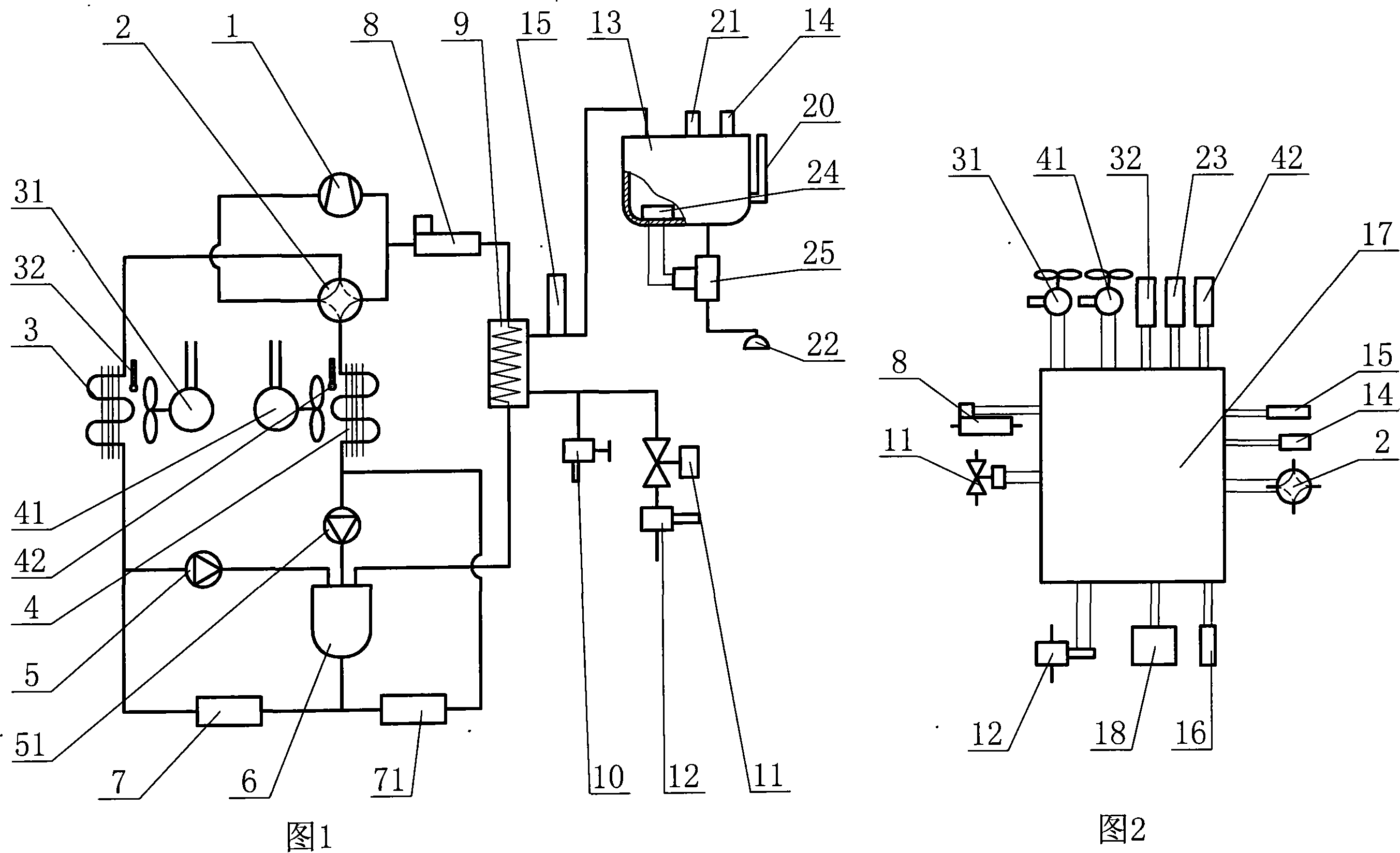

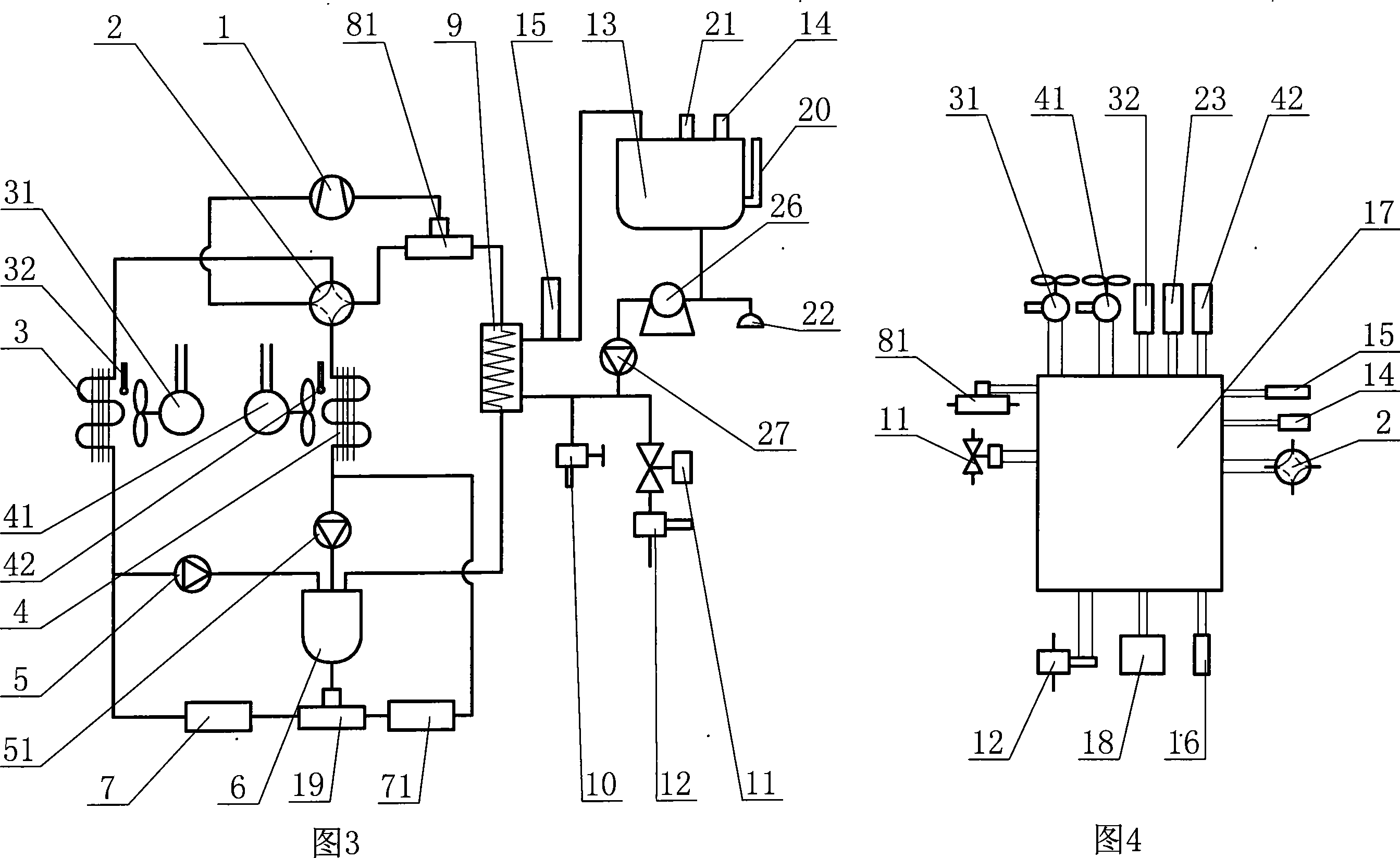

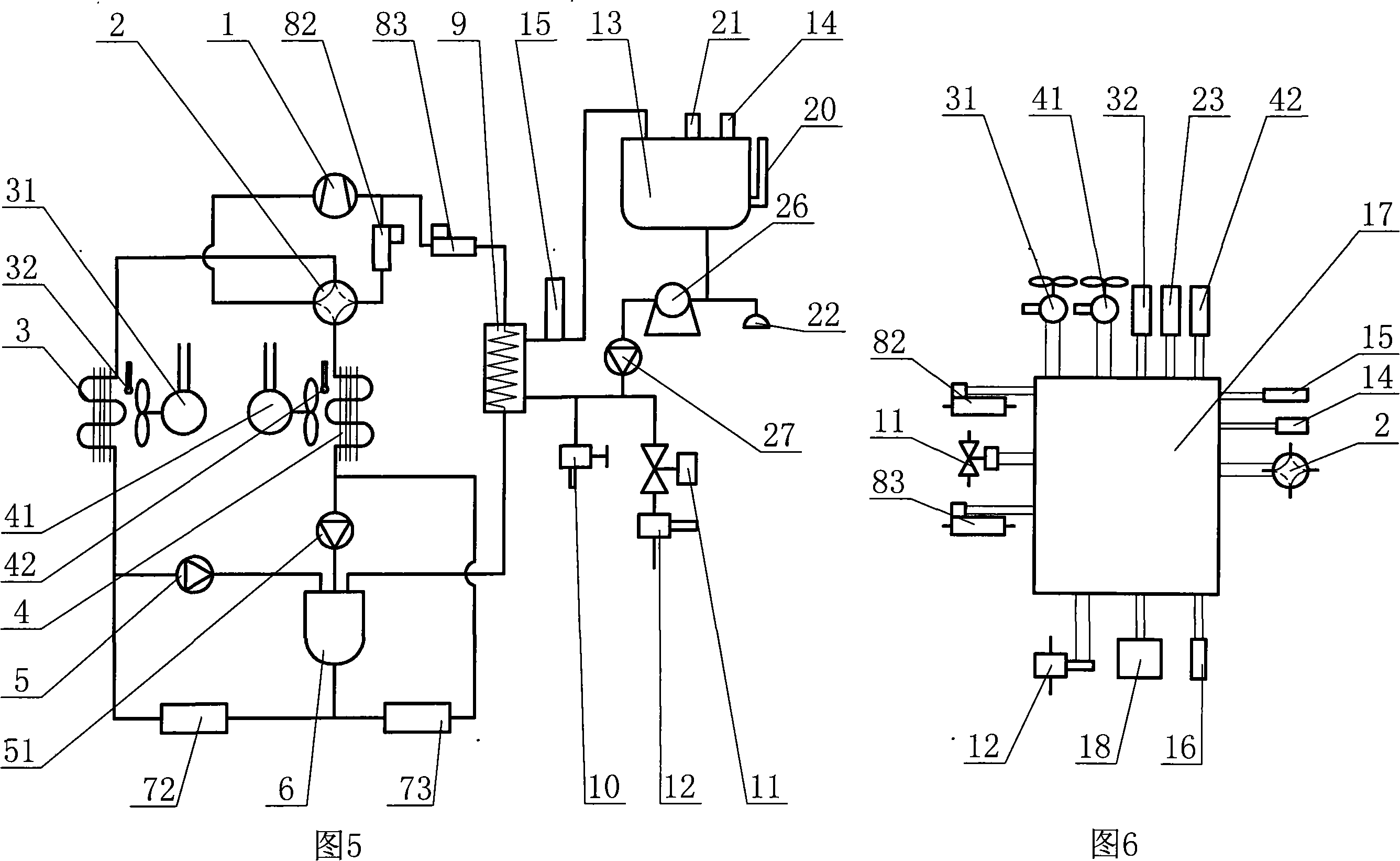

Air-conditioning water heater set

ActiveCN101131249AHigh performance ratioMeet the needs of lifeFluid heatersEnergy efficient heating/coolingWater sourceEngineering

The air conditioning and water heating set includes one compressor, one change-over valve with two ports connected separately to the high pressure exhaust pipe and low pressure inlet pipe of the compressor, one indoor heat exchanger with one indoor fan and one outdoor heat exchanger with one outdoor fan connected separately to two other parts of the change-over valve, one liquid collector communicated with the indoor heat exchanger and the outdoor heat exchanger, one first flow regulator and one second flow regulator with high pressure ends communicated with the liquid outlet of the liquid collector, and one water condensator with water inlet pipe and water outlet pipe communicated separately to one cold water source and one water tank. The present invention has domestic water heated with the afterheat of air conditioner and by means of heat pump, and possesses best utilization of heat, environment friendship, high performance / cost ratio and other advantages.

Owner:邢金良

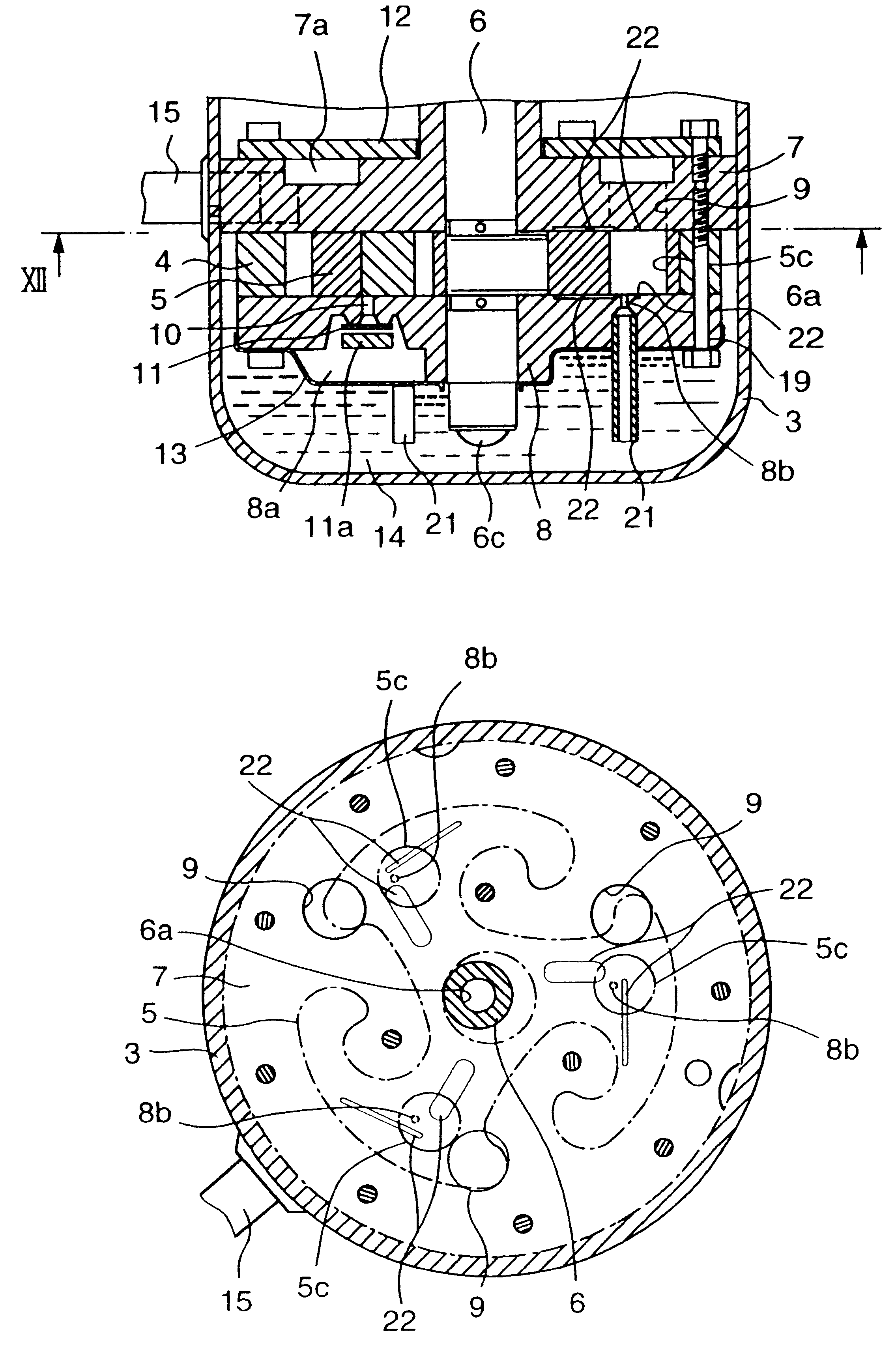

Displacement fluid machine

InactiveUS6217303B1Lower performance requirementsImprove performanceEngine of arcuate-engagement typeOscillating piston enginesWorking fluidEngineering

An orbiting fluid machine has a feature that the speed of sliding movement is low, while vibrations are small, its performance is lowered when the rotational speed becomes high, and this problem is resolved by the following structure. A displacement fluid machine includes a displacer making an orbital motion within a casing into which a working fluid is drawn, thereby drawing and discharging the working fluid, in which an oil retaining mechanism or a seal mechanism is provided at each of opposite end surfaces of the displacer. This results that, axial gaps at the end surfaces of the displacer are effectively sealed so as to reduce a leakage loss, thereby achieving a high performance and a high reliability.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

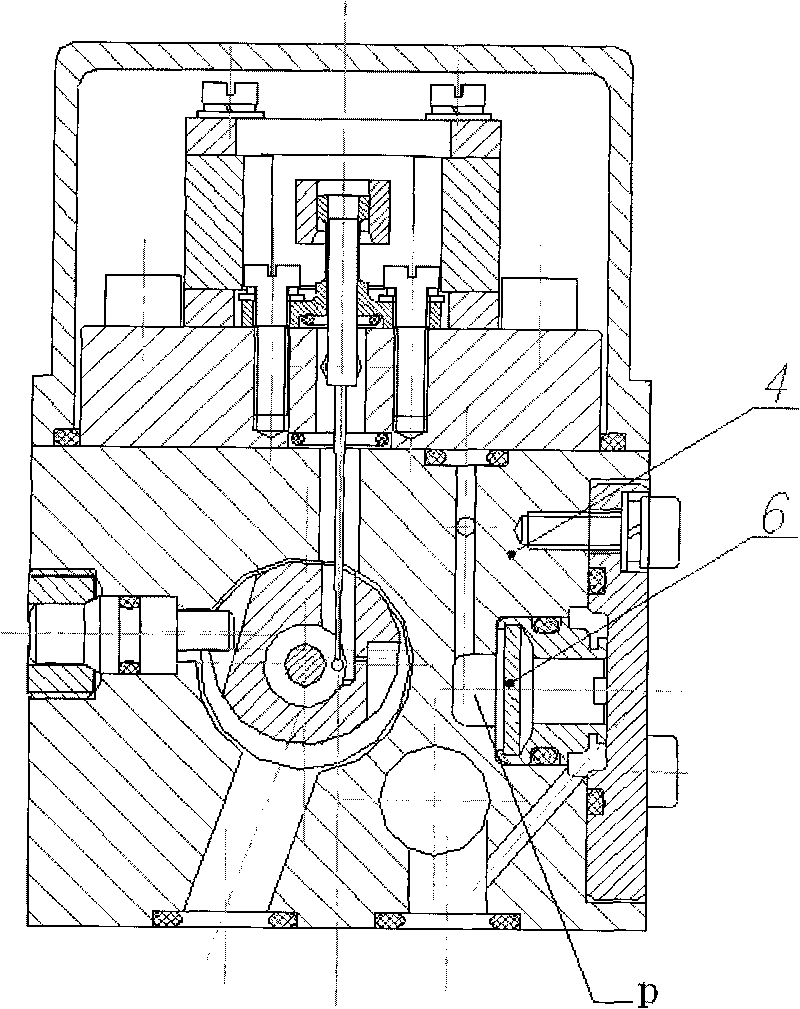

Electro-hydraulic servo valve

InactiveCN101725585ACompact structureReduce internal leakageServomotor componentsElectro hydraulicEngineering

The invention relates to an electro-hydraulic servo valve, which comprises a combined baffle feedback rod (1), a valve core (2), a prestage test hole (3), a filter shell (5) and a filter (6). The electro-hydraulic servo valve is characterized in that: the valve core (2) is positioned at a middle position in an inner cavity of a valve body (4); the combined baffle feedback rod (1) penetrates an upper middle part of the valve body (4), and a ball head at the lower end of the valve body (4) is positioned at an eccentric position of the valve core (2); the filter (6) is rolled inside the filter shell (5); and the filter shell (5) is arranged at the oil inlet (P) of the valve body. The electro-hydraulic servo valve has the characteristics of compact structure, small volume, convenient installation, low pressure, high flow, small internal leakage, less system heat and high frequency response.

Owner:SHANGHAI NUOMA HYDRAULIC SYST

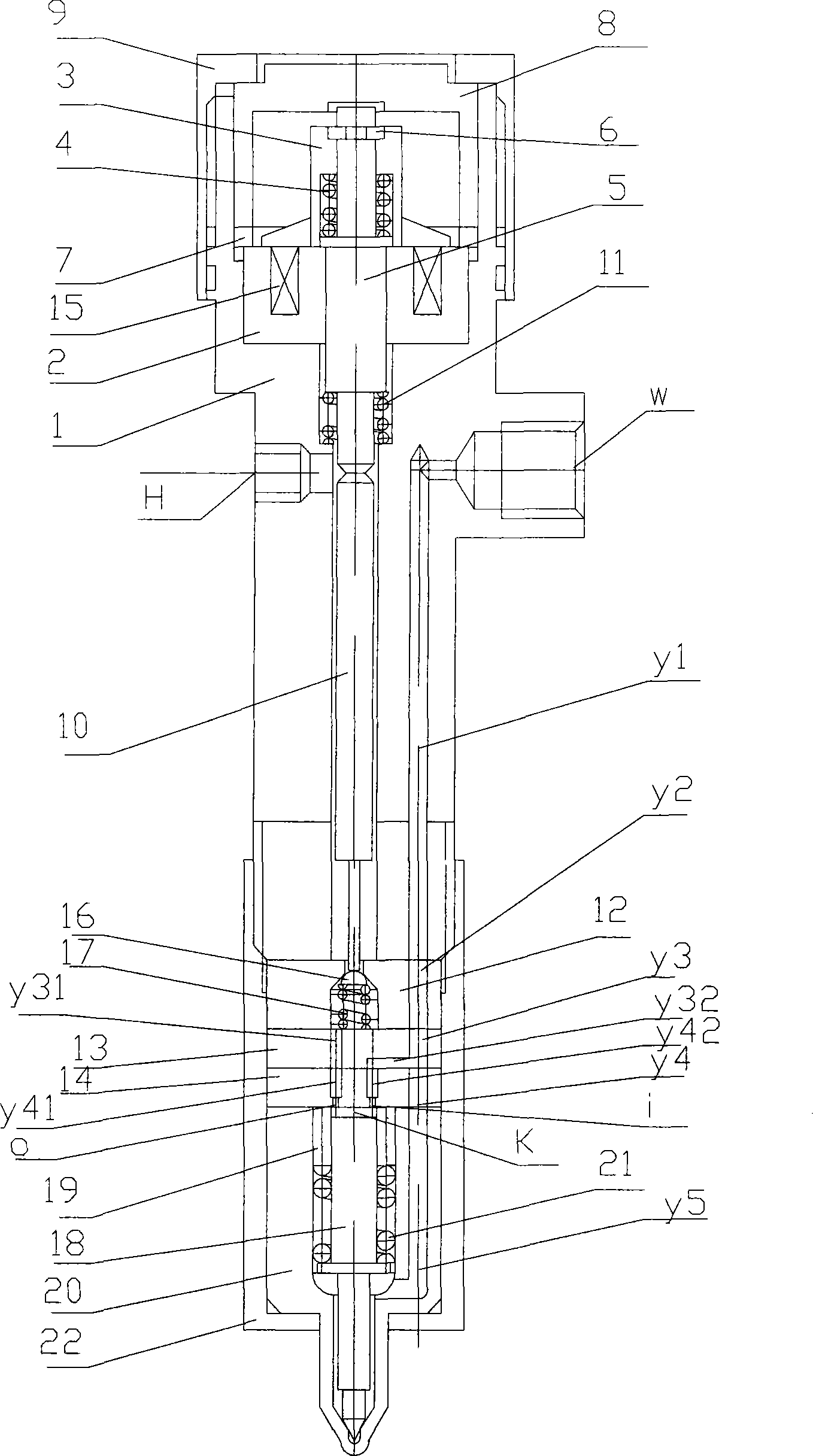

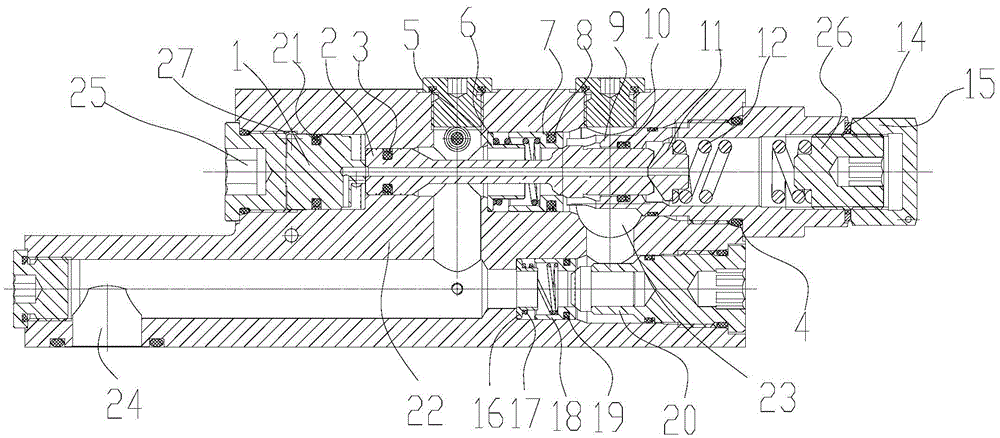

Tappet rod type high pressure co-rail electric-controlled oil ejector

InactiveCN101251067AReduce processing difficultyProcessing is not difficultFuel injection apparatusMachines/enginesCommon railEngineering

The invention provides a tappet type high pressure common rail injector, consisting of an injector body, a high-speed electromagnet, a tappet, a pin valve component, a two-position two-way switch valve and a middle cushion block component, wherein, a central lathy pylome of the injector body is a cascade circular hole, the tappet is arranged inside a small-diameter circular hole of the injector body, the high-speed electromagnet comprises a static iron core, a movable iron core and an offsetting spring. The tappet type high pressure common rail injector has simple structure, greatly reduces the leakage of the high pressure fuel, is easy to establish the high pressure inside the injector body, and realizes the high pressure or the supervoltage fuel injection, thereby satisfying the requirements of much more stringent emission regulations of a diesel engine.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Load maintaining valve

InactiveCN105587701AReliable performanceReduce internal leakageServomotor componentsBack pressureEngineering

The invention discloses a load maintaining valve. The load maintaining valve comprises a valve body and a balance adjustment assembly arranged in the valve body. Two inner cavity main holes are formed in the valve body. A load cavity is pressurized by opening two one-way valve ports of the load maintaining valve, and a load is pushed. The pressure caused by the load acts on a one-way valve element in the balance adjustment assembly, and the one-way valve element is pushed towards a main valve element in the balance adjustment assembly, so that oil is sealed in an oil cylinder, and a leak-free state is achieved. When unloading is required, the main valve element is pushed away from the one-way valve element by generating control pressure which is high enough. Compared with a traditional balance valve, the load maintaining valve has the most outstanding characteristics that the load maintaining valve is not affected by the back pressure of an oil return path, and the performance is stable and reliable.

Owner:SHANGHAI LIXIN HYDRAULIC

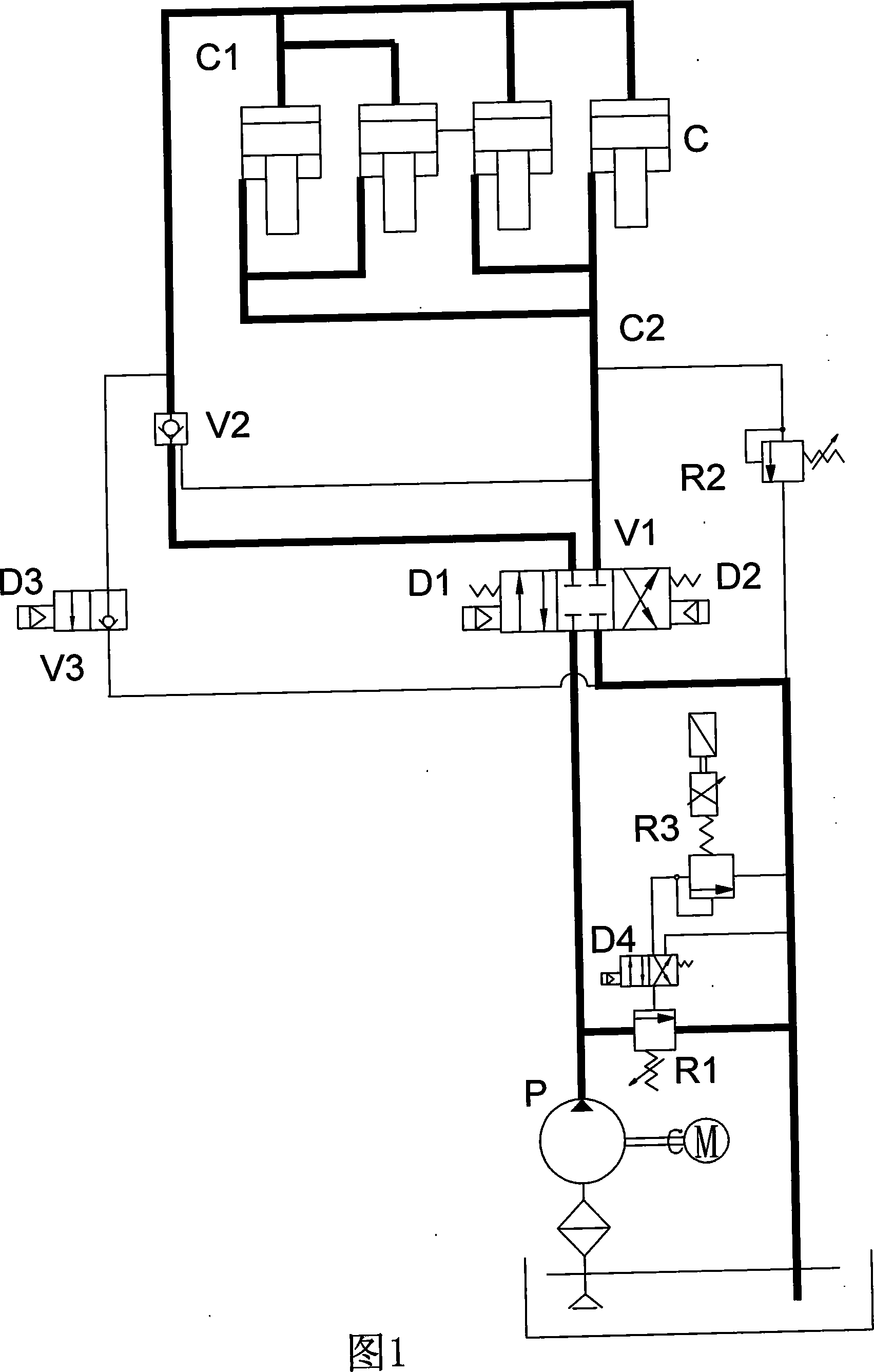

High pressure model-locked loop of double movable plate direct press injection machine

The invention relates to a high pressure die-locking circuit of a dual-motion plate direct pressure injection machine, comprising an oil pump which is driven by an electric motor, an electromagnetic reversing valve, an electromagnetic switch valve, overflow valves, a hydraulic control check valve and a high pressure die-locking oil cylinder; the electric motor drives the oil pump; the oil outlet of the oil pump is connected with the electromagnetic reversing valve; one working oil nozzle of the electromagnetic reversing valve is connected with the high pressure chamber of the high pressure die-locking oil cylinder through the hydraulic control check valve; another working oil nozzle of the electromagnetic reversing valve is connected with the recovery chamber of the high pressure die-locking oil cylinder; the oil outlet of the oil pump and the recovery chamber of the high pressure die-locking oil cylinder are both provided with the overflow valves; the non-rod chamber of the high pressure die-locking oil cylinder is connected with an oil tank through the electromagnetic switch valve. The proposal sufficiently considers the working characteristics of the dual-motion direct pressing injection machine and optimizes and simplifies the high pressure die-locking control oil path, and the invention is the high pressure die-locking circuit of the dual-motion direct pressing injection machine with more reasonable structure.

Owner:广东佳明机器有限公司

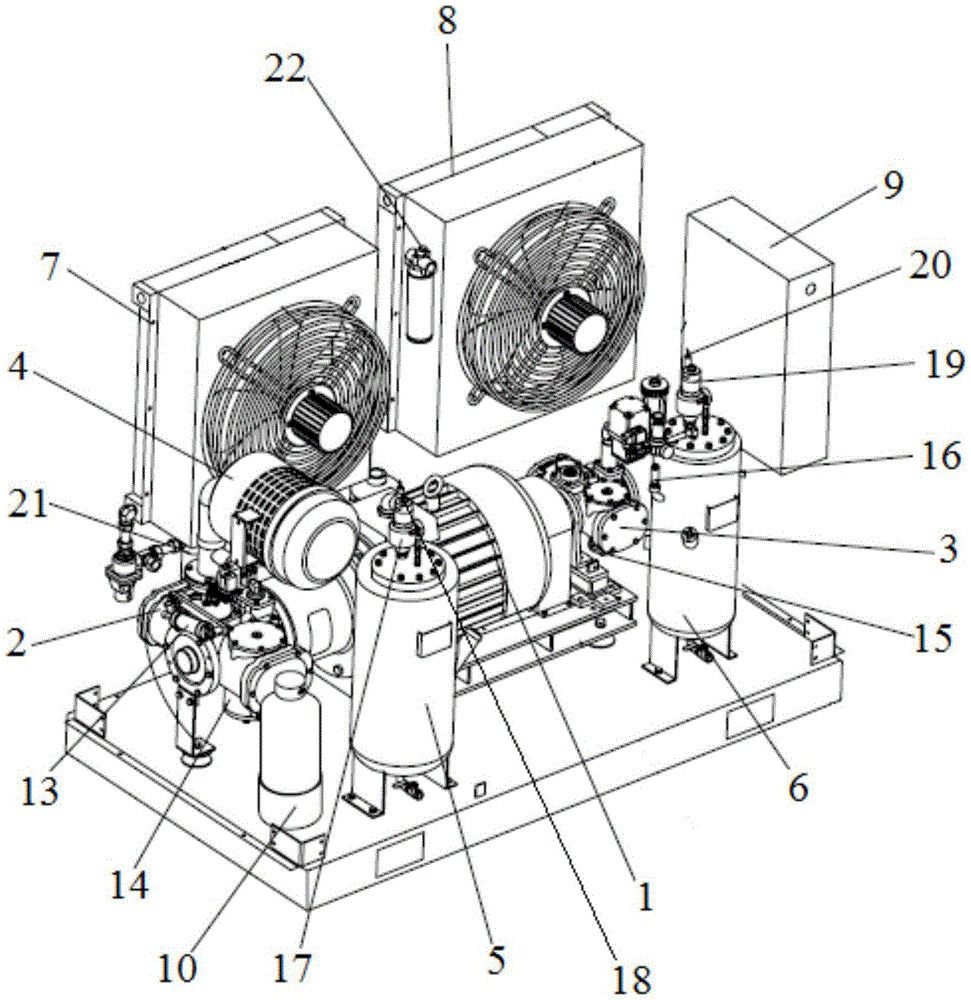

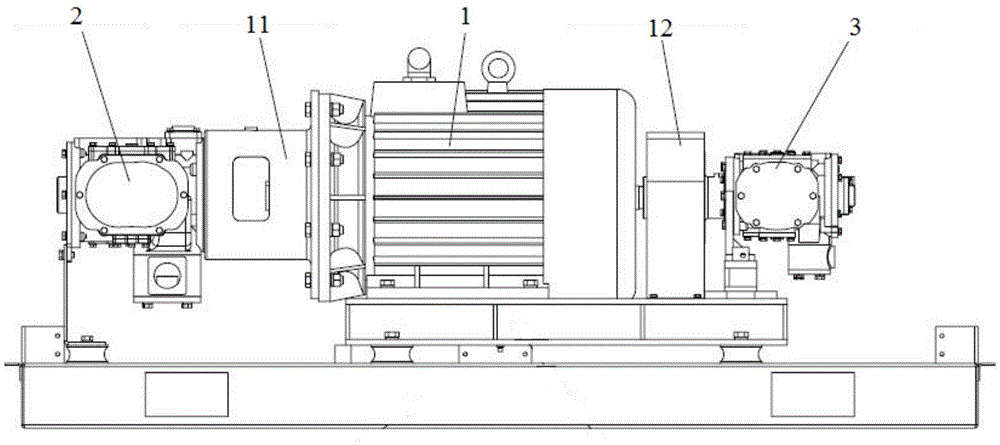

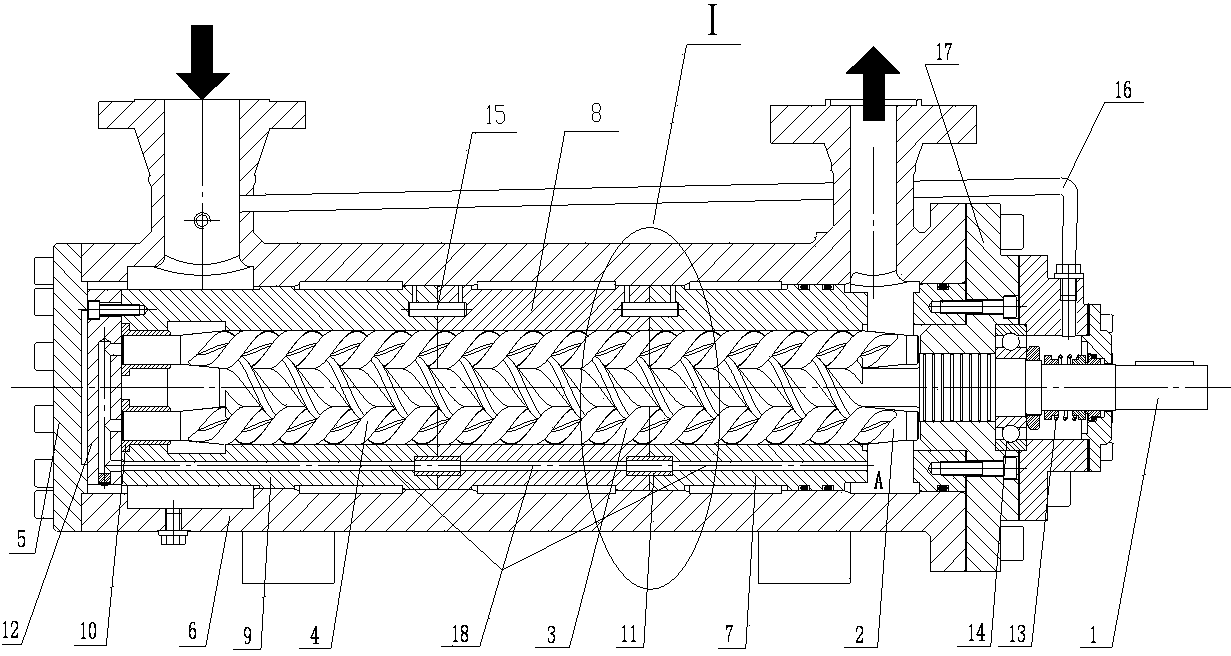

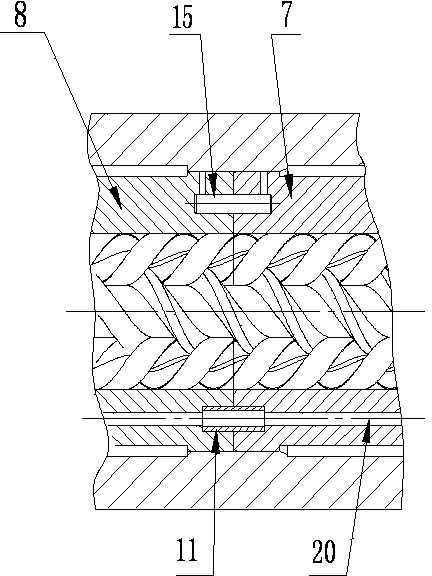

Water-lubrication oil-free medium pressure two-stage-compression single-screw-rod air compressor

InactiveCN105626530AEasy to cleanEnsure safetyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsAir filterGas cooler

The invention relates to a water-lubrication oil-free medium pressure two-stage-compression single-screw-rod air compressor. The air compressor comprises an electric motor, a first-stage single-screw-rod compression main machine, a second-stage single-screw-rod compression main machine, an air filter, a first-stage water and gas separator, a second-stage water and gas separator, a first-stage gas cooler, a second-stage gas cooler and an electrical control box; the first-stage single-screw-rod compression main machine and the second-stage single-screw-rod compression main machine are in transmission connection with the electric motor, and the air filter is connected with a gas inlet of the first-stage single-screw-rod compression main body; and the first-stage gas cooler is connected with the first-stage water and gas separator, the second-stage gas cooler is connected with the second-stage water and gas separator, and the electrical control box is electrically connected with the electric motor. Compared with the prior art, the water-lubrication oil-free medium pressure two-stage-compression single-screw-rod air compressor has the beneficial effects that the whole structure is simple and compact, complex pipelines and valves do not need to be additionally arranged, water lubrication is adopted, resistance losses are small, running reliability is good, volume efficiency is high, oil is avoided, zero emissions are achieved, no environmental pollution exists, running is carried out at the normal temperature, and the air compressor is environment-friendly, energy-saving and low in maintaining cost and has the very good application prospect.

Owner:SHANGHAI GAIRS MACHINERY CO LTD

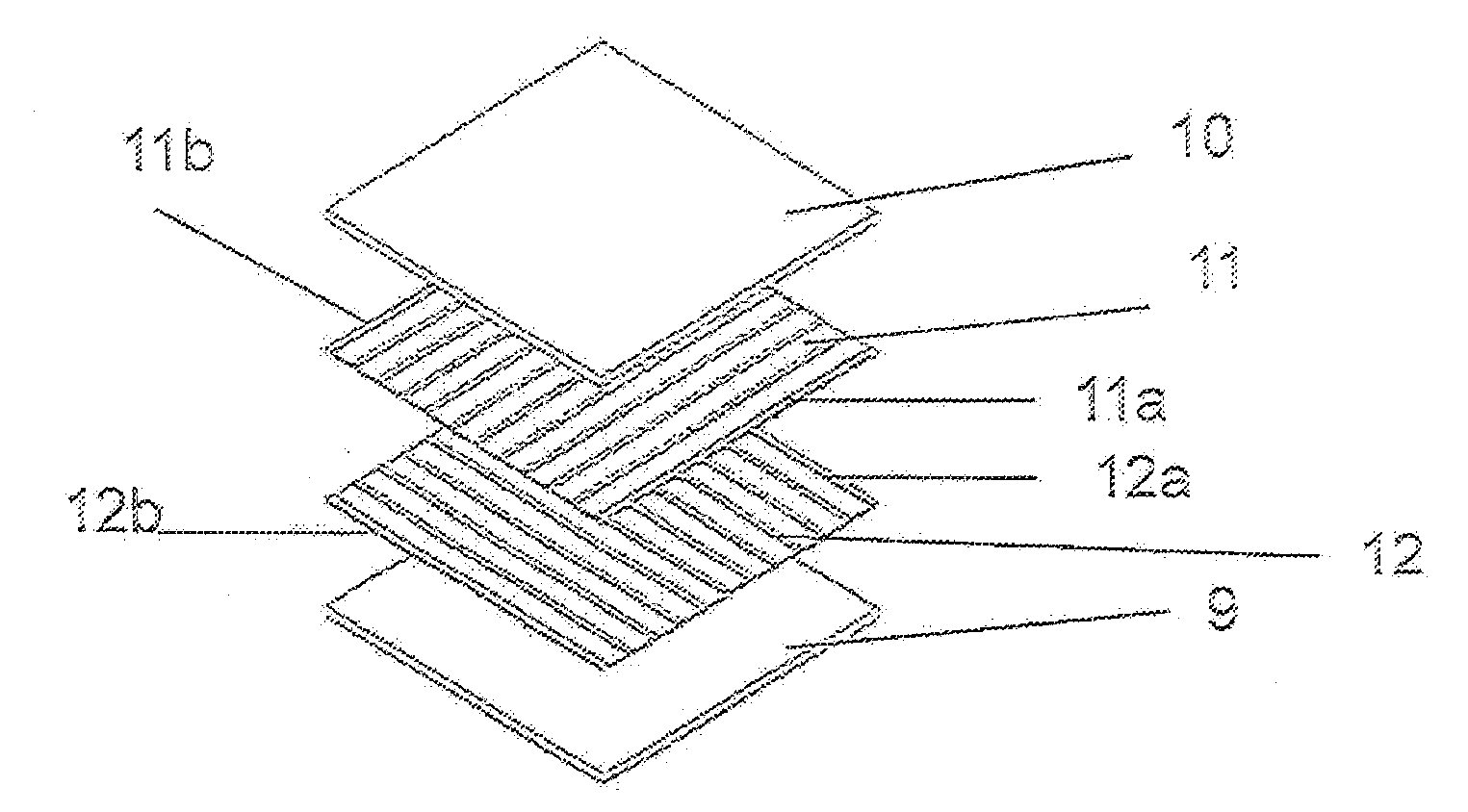

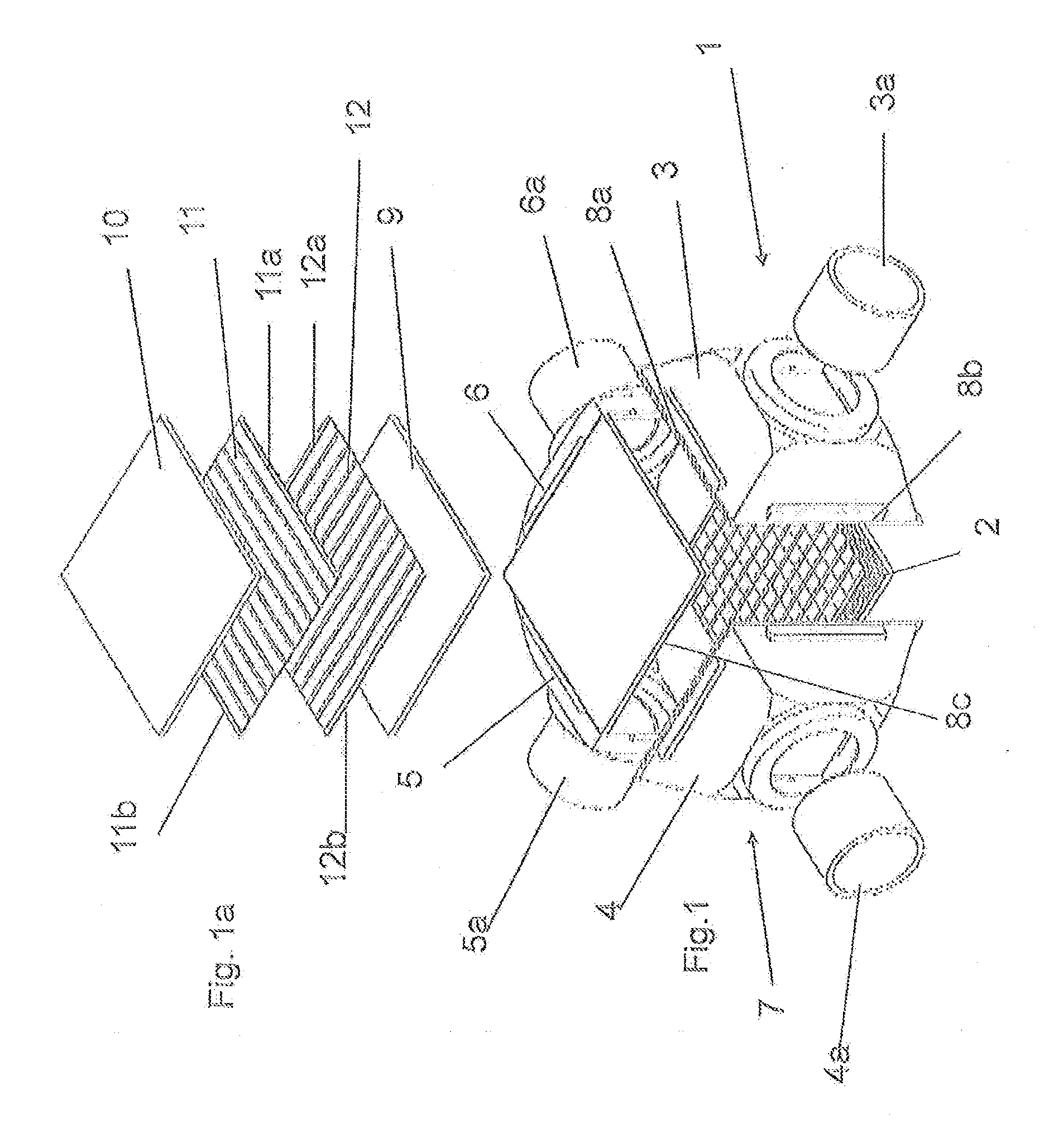

Layer heat exchanger for high temperatures

InactiveUS20120138280A1Sufficient tightnessHigh temperatureSafety devices for heat exchange apparatusHeat exchanger casingsEngineeringElectrical and Electronics engineering

A layer heat exchanger for high temperatures is provided that includes a layer block having layer plates and cover plates and a housing that accommodates the layer block. The housing has a high heat resistance, combined with a high stiffness, and the layer block has a core that is soft and tough relative to the housing.

Owner:BEHR GMBH & CO KG

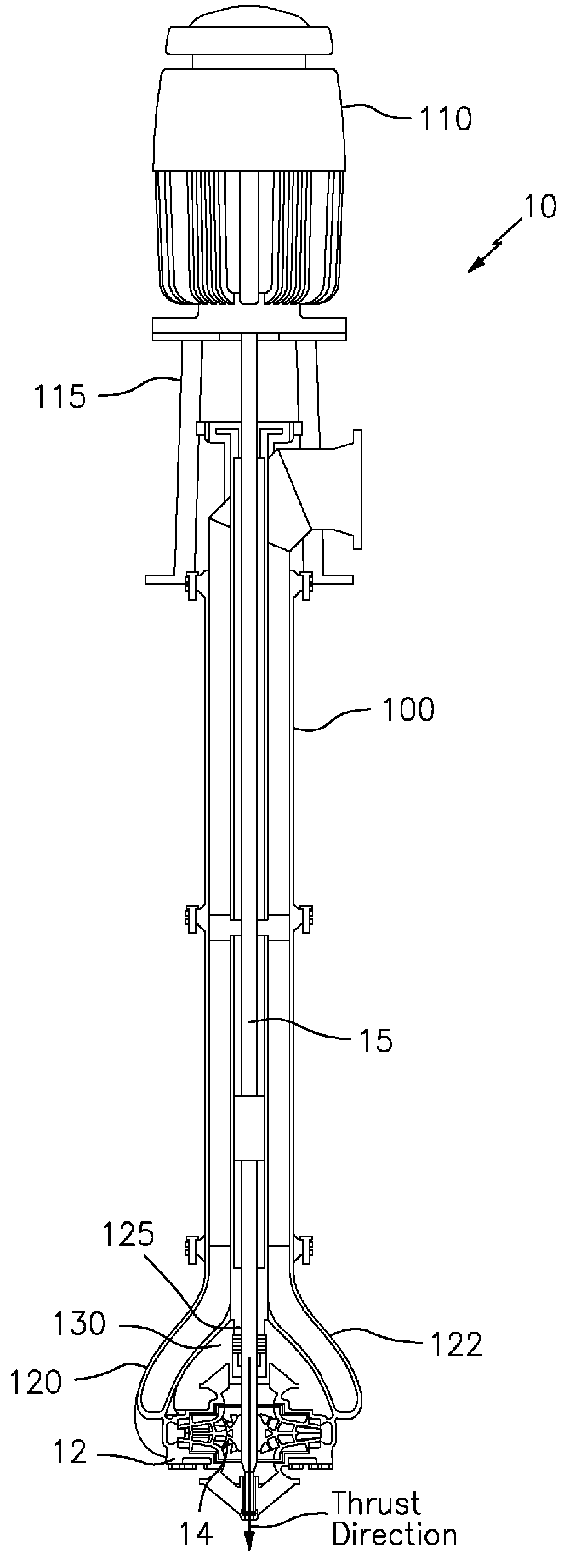

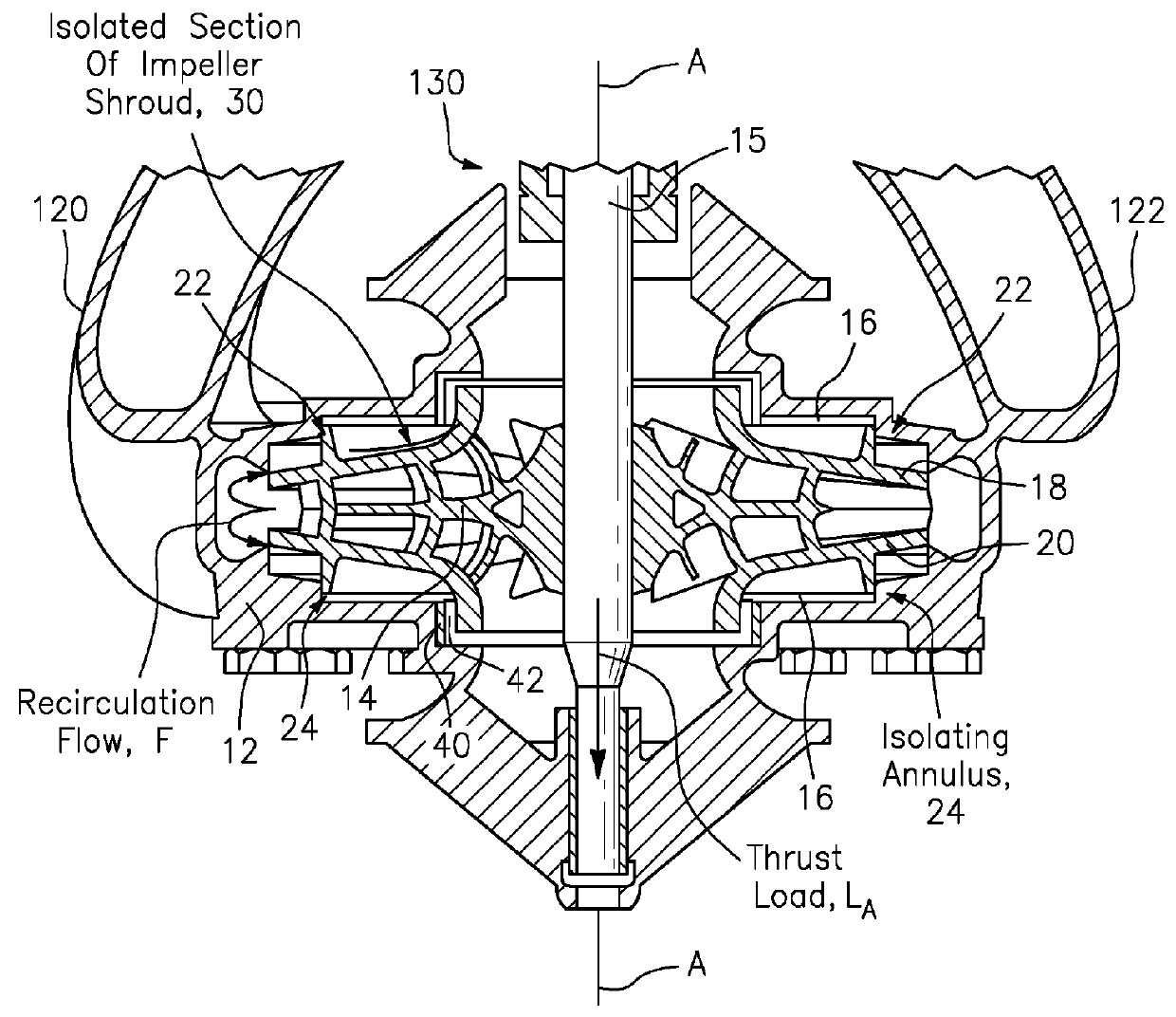

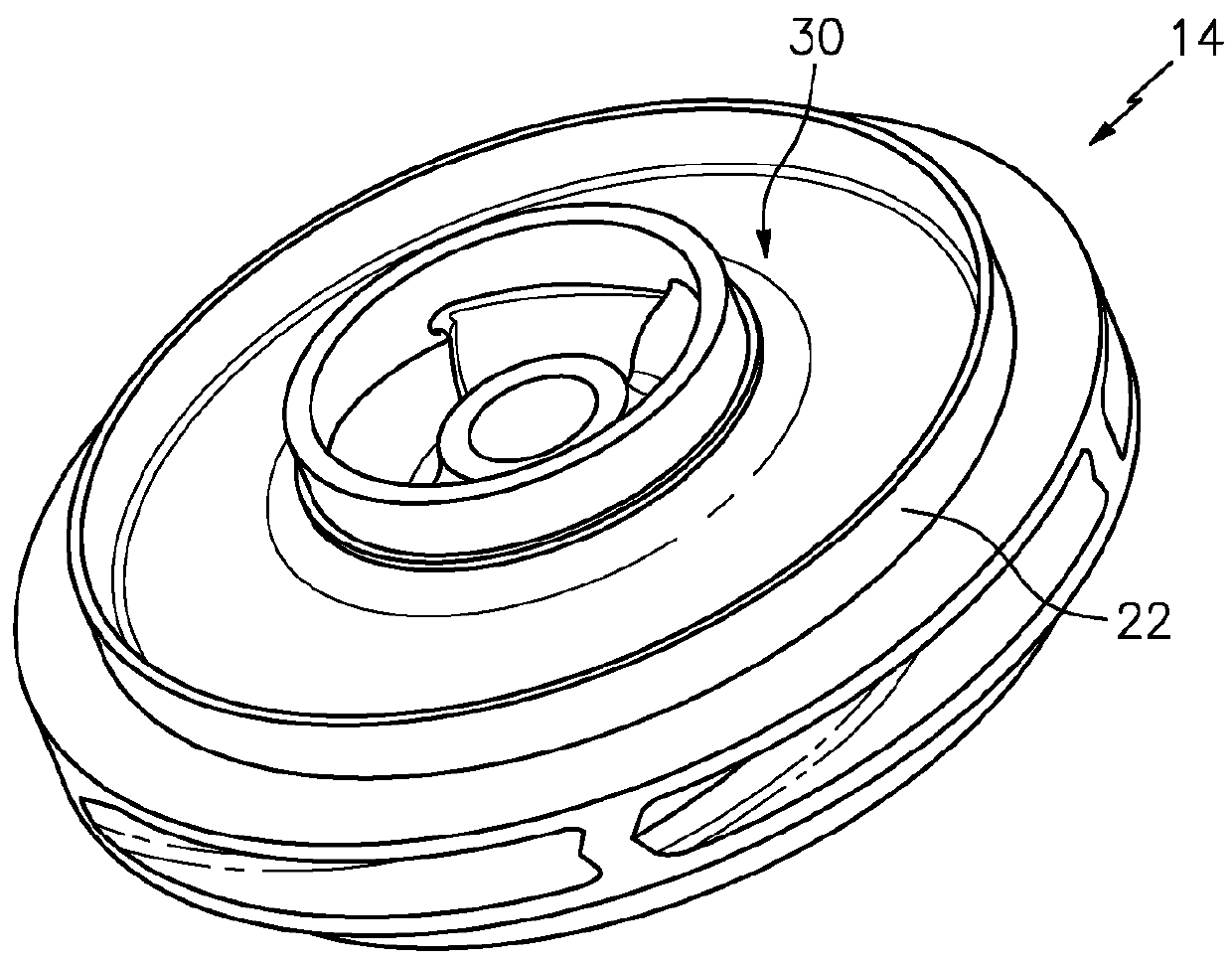

Vertical double-suction pump having beneficial axial thrust

ActiveUS9377027B2High dynamic stiffnessImprove reliabilityPump componentsWorking fluid for enginesImpellerAxial thrust

Owner:ITT MFG ENTERPRISES LLC

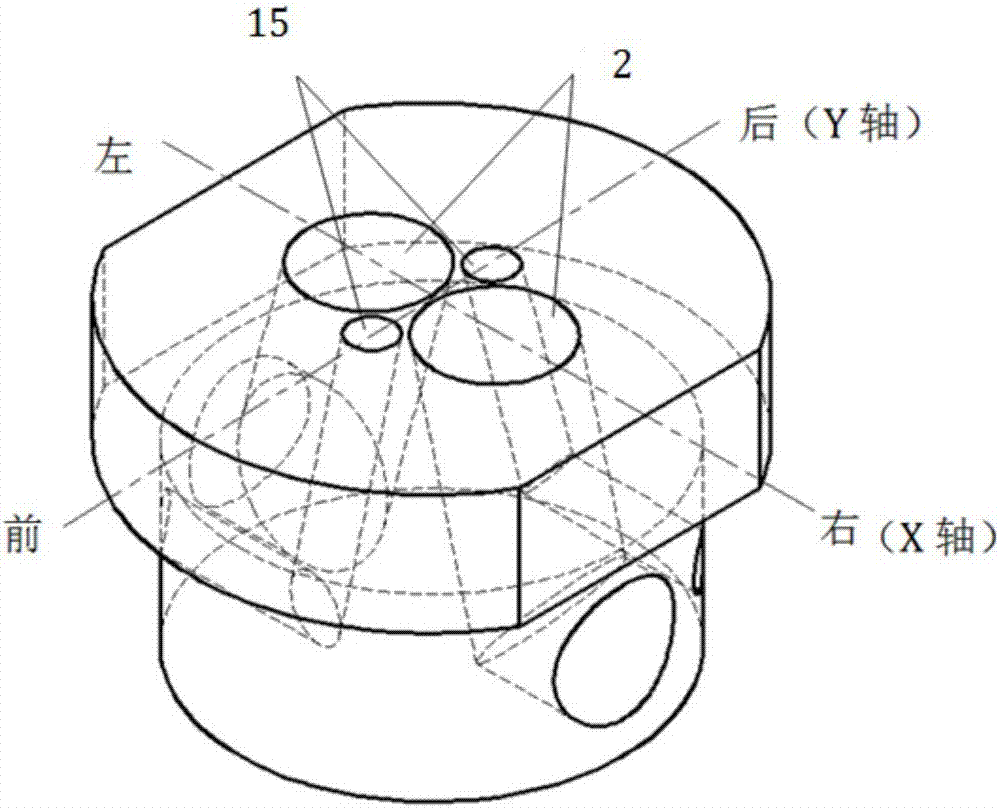

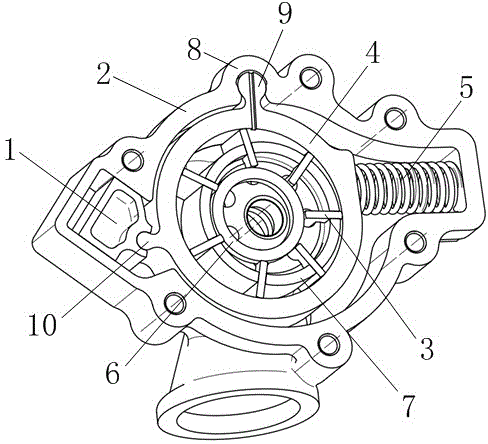

Centrifugal type volumetric pump

InactiveCN102465875AReduce internal leakageReduce wearRotary piston pumpsRotary piston liquid enginesLow speedPump chamber

The invention relates to a centrifugal type volumetric pump, belonging to the field of fluid conveying devices. The centrifugal type volumetric pump comprises a pump casing, wherein a cylindrical pump chamber is arranged in the pump casing, a rotor is arranged in the pump casing in an eccentric manner; end caps are arranged at two ends of the pump casing, and are used for closing the pump chamber, an oil inlet is arranged on any end cap, a plurality of radial holes are uniformly arranged in the circumferential direction of the rotor, plunger pistons are inserted in the radial holes in a matched manner, roller wheels are arranged at end parts of the plunger pistons facing towards the pump chamber; an axial oil outlet is arranged in the rotor, and is communicated with the radial holes; axial through holes are arranged in the plunger pistons, one-way valves are arranged in the axial through holes; a semi-cylindrical oil distributing shaft is arranged in the axial oil outlet, and is fixedly connected with the end cap at one side; when the rotor rotates, the oil distributing shaft can always shade one sides of the radial holes with gradually increasing volume; and springs are arranged in the radial holes, and are used for pushing the plunger pistons to stretch out. The centrifugal type volumetric pump is stable to move, is continuous and smooth to charge and discharge oil, and has the advantages of less internal leakage, low movement noise and reliability in use; moreover, the centrifugal type volumetric pump can be produced to an oil pump with low speed and low flow rate; and therefore the noise caused by movement can be lowered obviously.

Owner:沈广邦

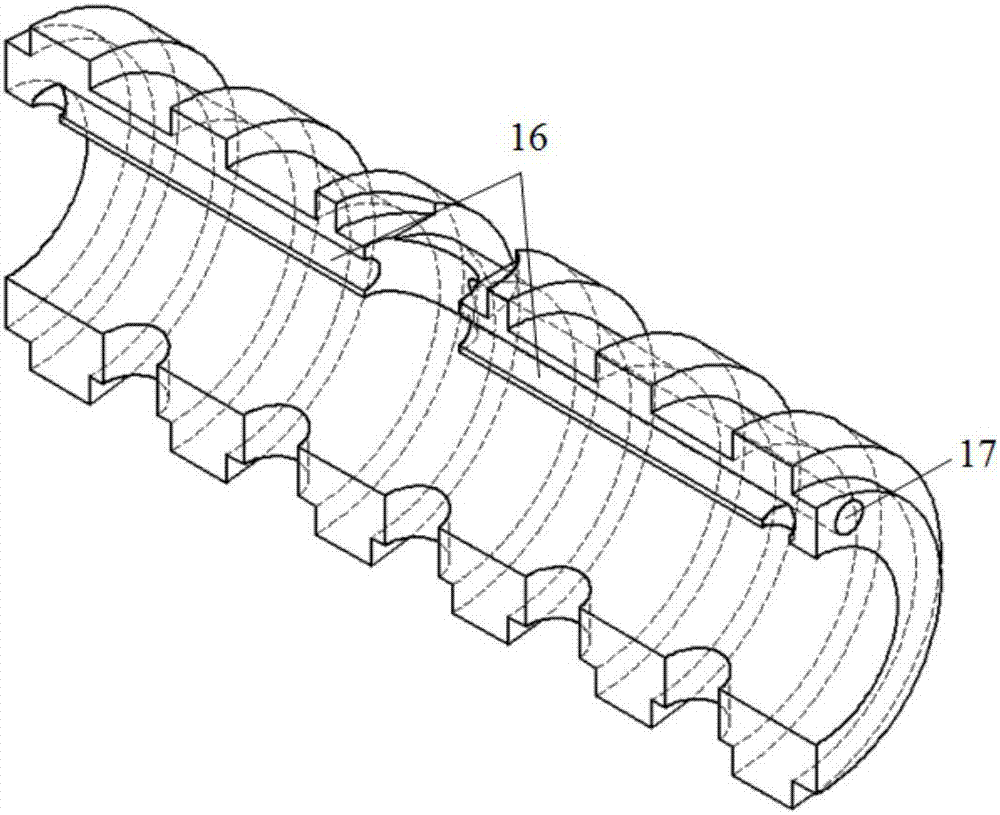

High-property high-pressure three-screw pump

ActiveCN103711690AReduce difficultyGuaranteed machining accuracyRotary piston pumpsRotary piston liquid enginesWorking pressureEngineering

The invention relates to a high-property high-pressure three-screw pump. The high-property high-pressure three-screw pump comprises a pump body, a liner, a driving screw and two driven screws, wherein the liner is formed by connecting three sections of split liners in sequence; three matching holes matched with the driving screw and the driven screws are respectively formed in the both axial ends of each section of the split liner; the three sections of the split liners respectively comprise a front liner, a middle liner and a rear liner; each driven screw consists of a front section screw, a middle section screw and a rear section screw; the outer ends of the front section screws of the two driven screws are respectively arranged on the pump body and are in the shape of a cantilever; the outer ends of the rear section screws of the two driven screws are respectively arranged in the three matching holes in the outer end of the rear liner through axle sleeves in the cantilever shape; the both ends of the middle section screw of each driven screw respectively are in contact with the corresponding front section screw and rear section screw, so that the middle section screws are in a shape of a float rod. According to the high-property high-pressure three-screw pump provided by the invention, the highest working pressure is 20.0MPa, the machining difficulty is reduced, and the matching precision among parts is improved, so that the reliability and the volume efficiency of the pump can be improved.

Owner:黄山工业泵制造有限公司

Scroll compressor and refrigeration system

InactiveCN105697372AReduce internal leakageIncrease contactRotary piston pumpsRotary piston liquid enginesWorking pressureHydraulic pump

The invention relates to the field of compressors, and discloses a scroll compressor and a refrigeration system. The scroll compressor includes a fixed scroll (1) and a movable scroll (2), and the movable scroll (2) Interlock with the fixed scroll (1) to form a compression chamber and can move relatively to compress the medium entering the compression chamber; the back pressure chamber (3), the pressure in the back pressure chamber (3) acts on the movable scroll ( 2) Make the movable scroll (2) in sealing contact with the fixed scroll (1). Wherein, when the movable scroll (2) and the fixed scroll (1) move relative to each other, the back pressure chamber (3) is in fluid communication with the working port of the hydraulic pump (4) or the air source device, so as to pass the hydraulic pressure The working pressure of the pump (4) or the air source device forms a pressure acting on the movable scroll (2) in the back pressure chamber (3). The scroll compressor of the present invention can conveniently make the pressure of the back pressure chamber (3) acting on the movable scroll (2) relatively constant, and has better sealing performance.

Owner:GUANGDONG MIDEA ENVIRONMENTAL TECH CO LTD

Method for determining and maintaining defect of servo valve

ActiveCN102108992AExtended service lifeImprove the accuracy of useFluid-pressure actuator testingRolling millSpare part

The invention relates to a method for determining and maintaining the defect of a servo valve. In the method, the defect type is determined according to the static characteristic curve test result of the servo valve or the roller gap change condition of a rolling mill; the displacement of a valve plug is determined according to the hydraulic output power change of the servo valve, and the abrasion loss of a valve sleeve and the valve plug is determined according to the numerical value fluctuation degree of an internal leakage curve; fit clearance is reduced by improving the assembly accuracy of the valve plug and the valve sleeve; and the electrical zero of the servo valve is adjusted, and the relative position of a valve core and the valve sleeve is adjusted, so that the internal leakageof the servo valve and the abrasion of the valve core and the valve sleeve are reduced, the service life of the servo valve is prolonged, the reserve of spare parts and cost are reduced, and the thickness control accuracy of a steel plate and the qualification rate of a product are improved.

Owner:ANGANG STEEL CO LTD

Four-way valve used for R32 refrigerant, and air conditioner

ActiveCN103423482AReduce internal leakageSmall surface areaMultiple way valvesFluid circulation arrangementFour-way valveEngineering

The invention provides a four-way valve used for an R32 refrigerant, and an air conditioner. The four-way valve comprises a main valve body and multiple connecting pipes, a valve chamber is arranged in the main valve body, a valve core is arranged in the valve chamber, divides two ends of the valve chamber into a first valve chamber and a second valve chamber which are mutually independent, and comprises a valve seat and a slider, the slider is slidably arranged on the valve seat which is fixed on the main valve body, the connecting pipes are communicated with the valve chamber of the main valve body and include a connecting pipe E, a connecting pipe S, a connecting pipe C and a connecting pipe D, the inner diameter of each of the connecting pipe E, the connecting pipe S and the connecting pipe C is between 5.0mm and 7.0mm, and the inner diameter of the connecting pipe D is between 3.2mm and 5.5mm. By the four-way valve, the problem of internal leakage of four-way valves in the prior art can be effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

Piston hinge-type variable-displacement vane pump

ActiveCN104675698AOil pressure fluctuation is smallReduce internal leakageRotary piston pumpsLubricating pumpsThree stageEngineering

The invention discloses a piston hinge-type variable-displacement vane pump. The vane pump comprises a pump shell, a pump cover, a pump control loop, a vane pump rotor, a vane loop and a plurality of vanes, wherein the outer surface of the pump control loop is provided with a first hinge bulge, the first hinge bulge is positioned on a hinge positioning hole of the inner surface of the pump shell, and the pump control loop swings by taking the hinge positioning hole as a base point, so that the volume capacity of the vane pump is changed, the outer surface of the pump control loop and one side of the first hinge bulge are provided with a second hinge bulge, and a piston is hinged with the second hinge bulge; a first control cavity is formed between the piston and the partial inner surface of the pump shell, the first control cavity is capable of introducing a pressurized fluid to generate pressure to move the pump control, so as to decrease the volume capacity of the vane pump, the outer surface of the pump control loop and the other side of the first hinge bulge prop against a reset spring, the reset spring resists the force of the first control cavity, so as to establish balance. The piston hinge-type variable-displacement vane pump is high in reliability, easy for realization of three-stage variable capability, long in force arm length, and small in inner frictional resistance.

Owner:苏州引燃动力科技有限公司

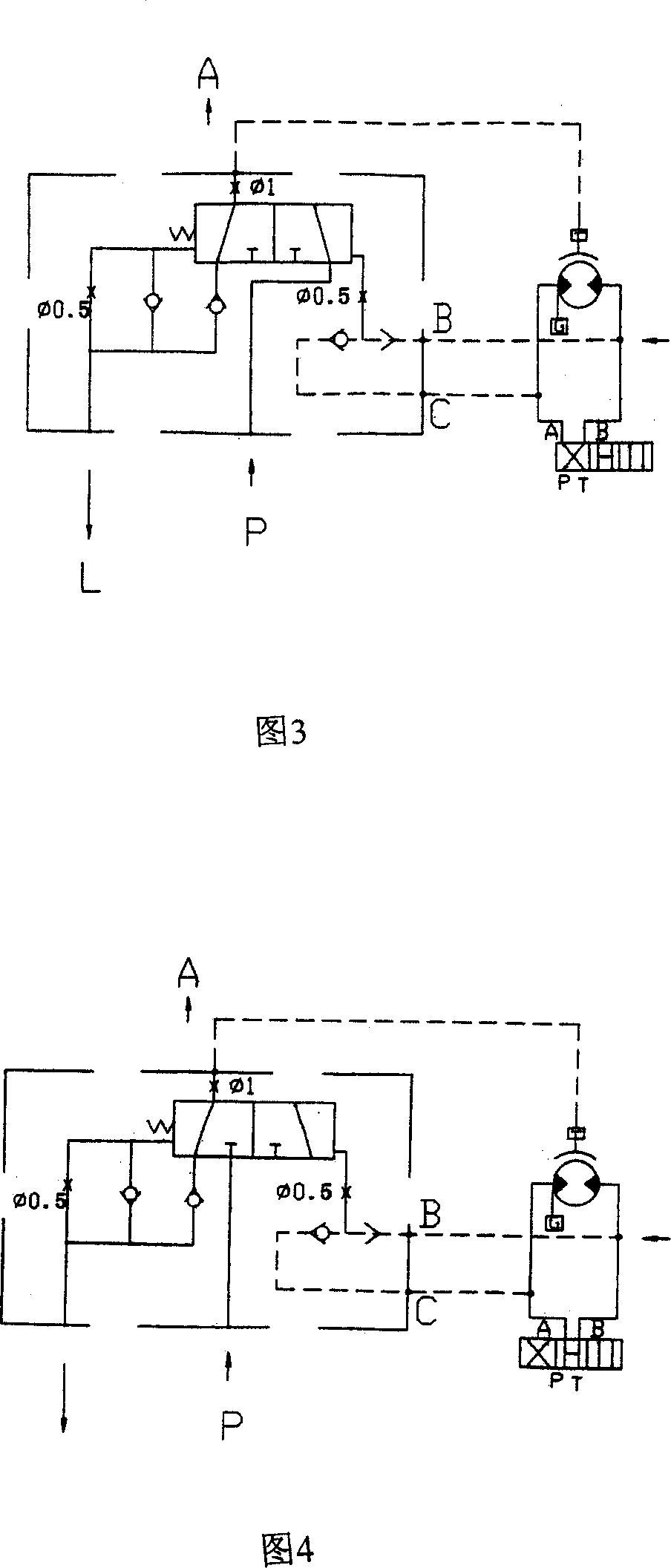

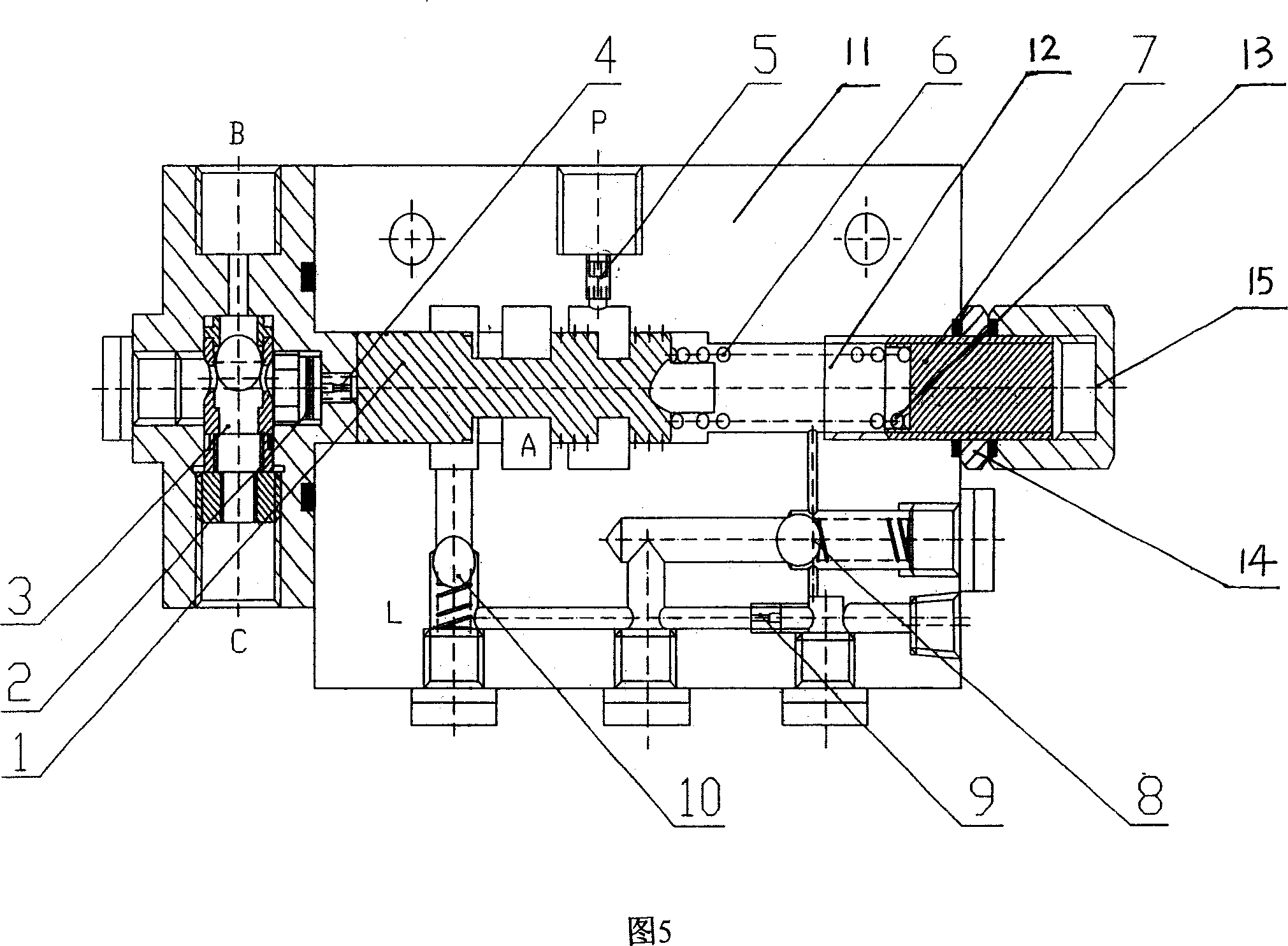

Flow separation, pressure adjustment and speed adjustment reversing integrated valve

ActiveCN108412831ALower level requirementsReduce installationServomotor componentsHigh energyWorking pressure

The invention belongs to a valve, in particular to a flow separation, pressure adjustment and speed adjustment reversing integrated valve. The integrated valve comprises a valve body, an oil inlet andoverflow valve arranged on the valve body, and a pilot pressure adjusting, throttling switching and speed adjusting unit; the valve body is provided with an oil return port, a throttling oil outlet and an oil outlet; an overflow back pressure cavity, an oil outlet cavity, an oil inlet cavity, a throttling oil outlet cavity and a liquid control cavity, axially penetrating through a main hole, arearranged in the valve body at intervals; the throttling oil outlet cavity communicates with the throttling oil outlet; the oil outlet cavity communicates with the oil outlet; the oil outlet cavity communicates with the liquid control cavity by a liquid control hole way; an overflow main valve sleeve is inserted in the main hole to form dynamic seal fit, the outer end thereof is assembled with an outer end stop port of the main hole, and the inner end thereof is provided with a throttling port; and in a non-working state, the overflow main valve sleeve separates the oil inlet cavity from the oil outlet cavity. The integrated valve effectively solves the technical difficulties of high energy consumption, high working medium temperature rise and the like in the prior art, and has the advantages of capability of respectively driving multiple execution elements with different working pressures and flows, lower grade requirement on system modules, capability of realizing speed adjustment andthe like.

Owner:河北华春液压汽配有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com