Patents

Literature

101results about How to "Reduce agitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

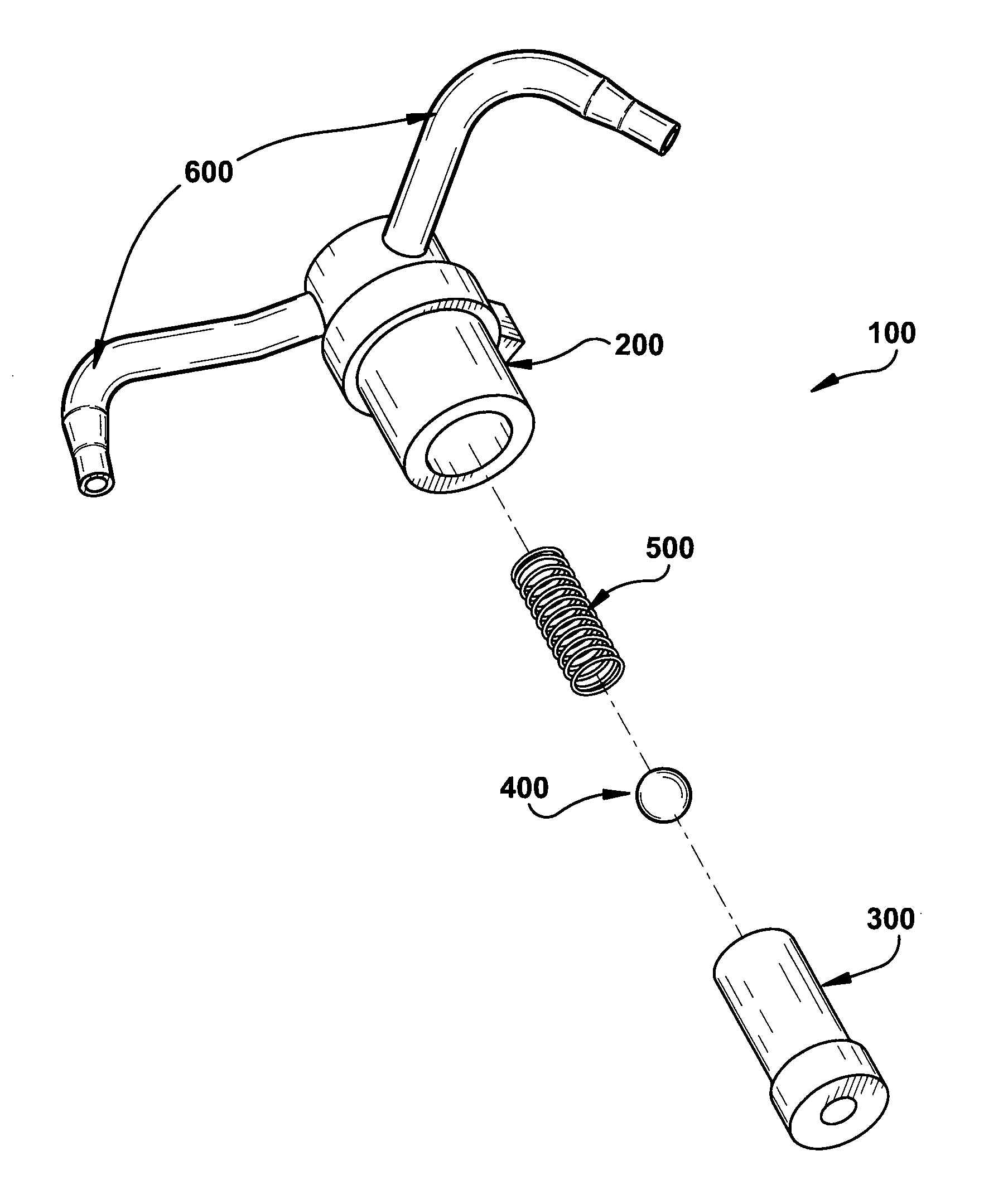

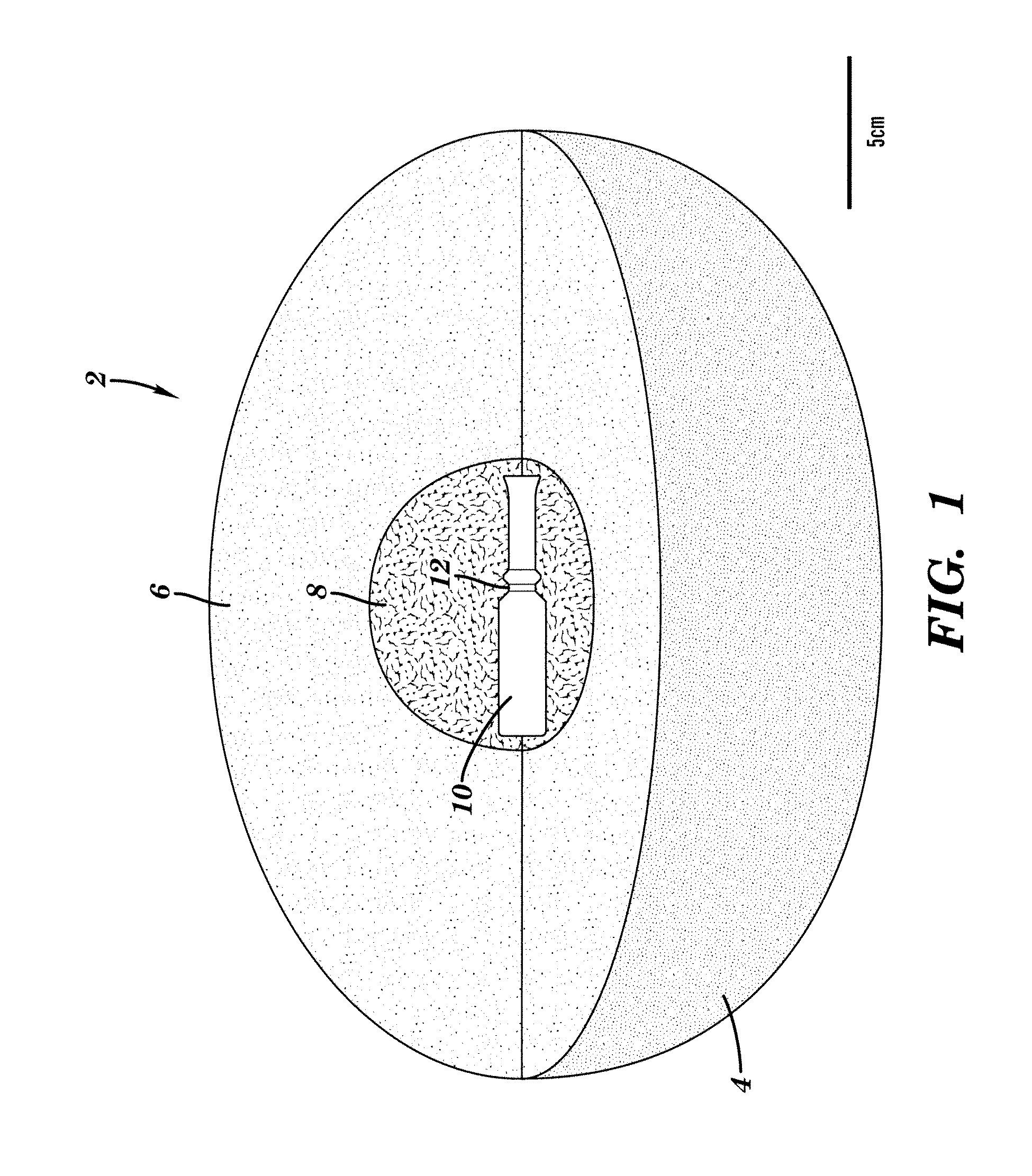

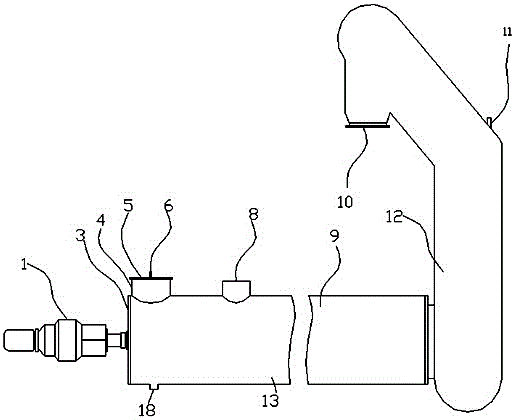

Piston cooling jet with tracking ball orifice

InactiveUS20100001103A1Reduce agitationReduce aerationLiquid coolingAir coolingMechanical engineeringPiston

An oil jet assembly includes a body, a tube, a cap insert, a ball, and a spring. The body includes a bore passing longitudinally through the body; a tube aperture passing through the body near a first end of the body; and an opening at a second and opposite end of the body. The tube is attached to the body and in fluid communication with the tube aperture. The cap insert is positioned within the bore of the body. The cap insert includes a bore that passes longitudinally through the cap insert to form a wall. The cap insert also includes an oil exit aperture passing though the wall and is in fluid communication with the bore of the body. The ball and spring are positioned within the bore of the insert cap. The spring is positioned between the ball and the first end of the body.

Owner:METALDYNE LLC

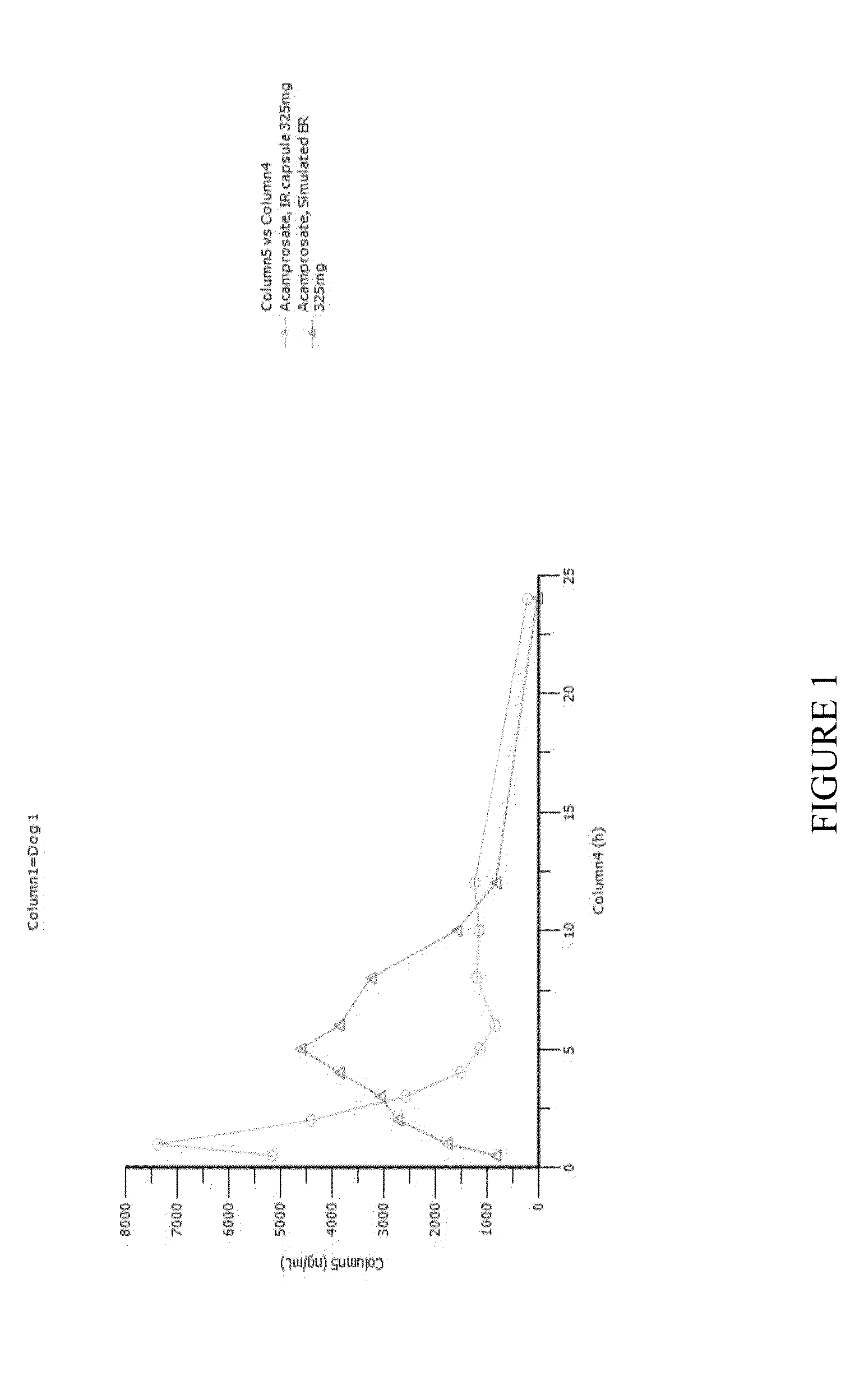

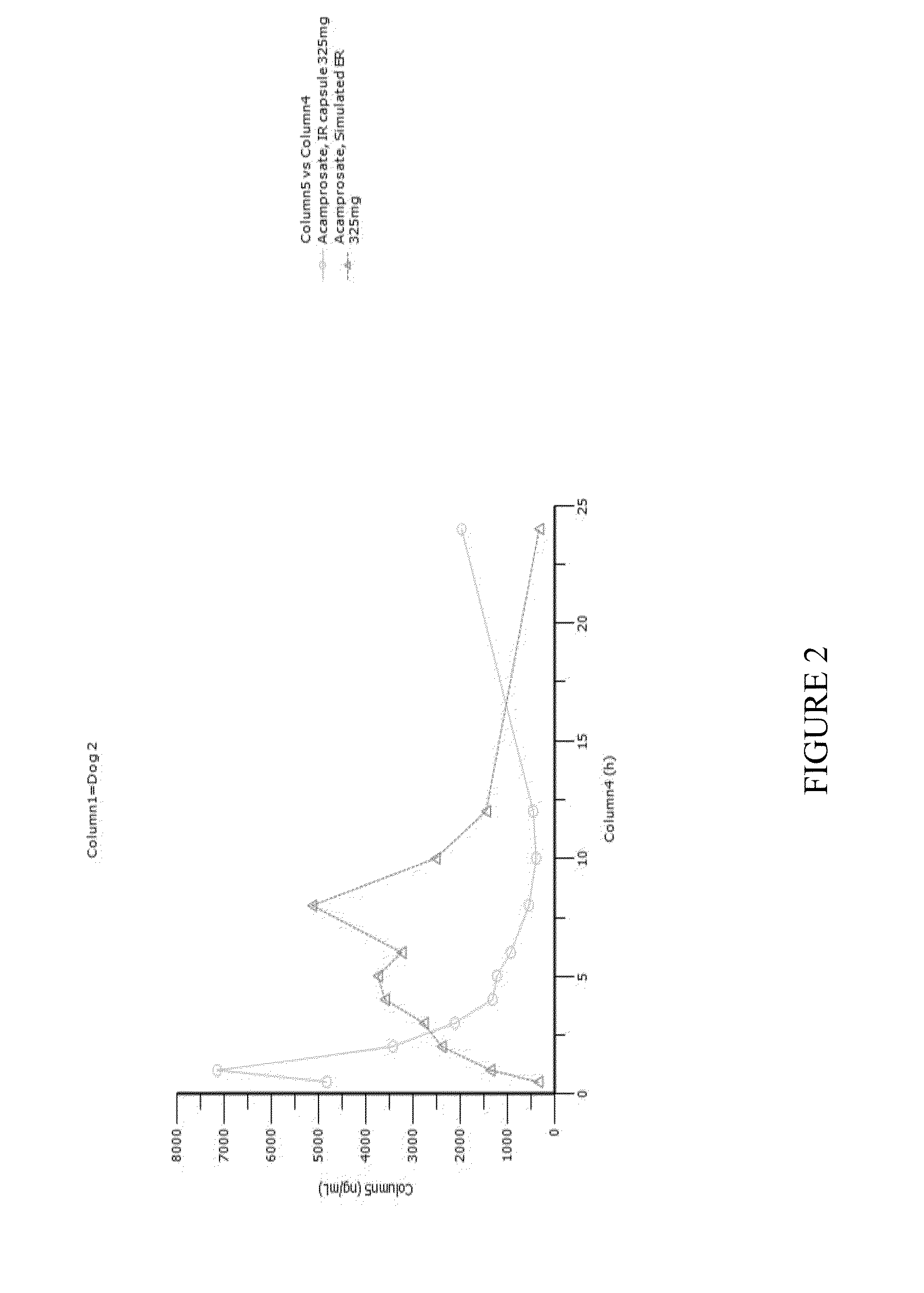

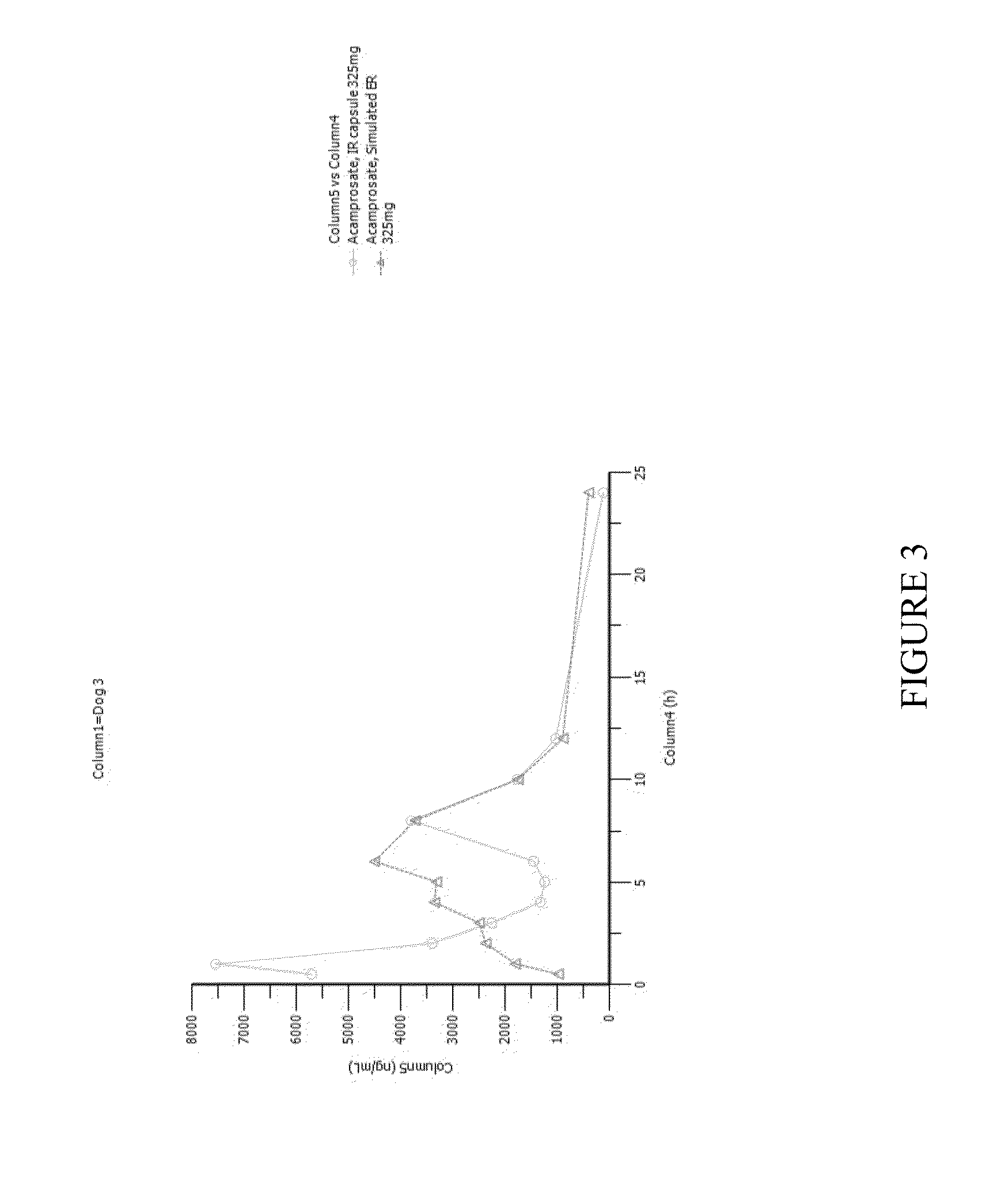

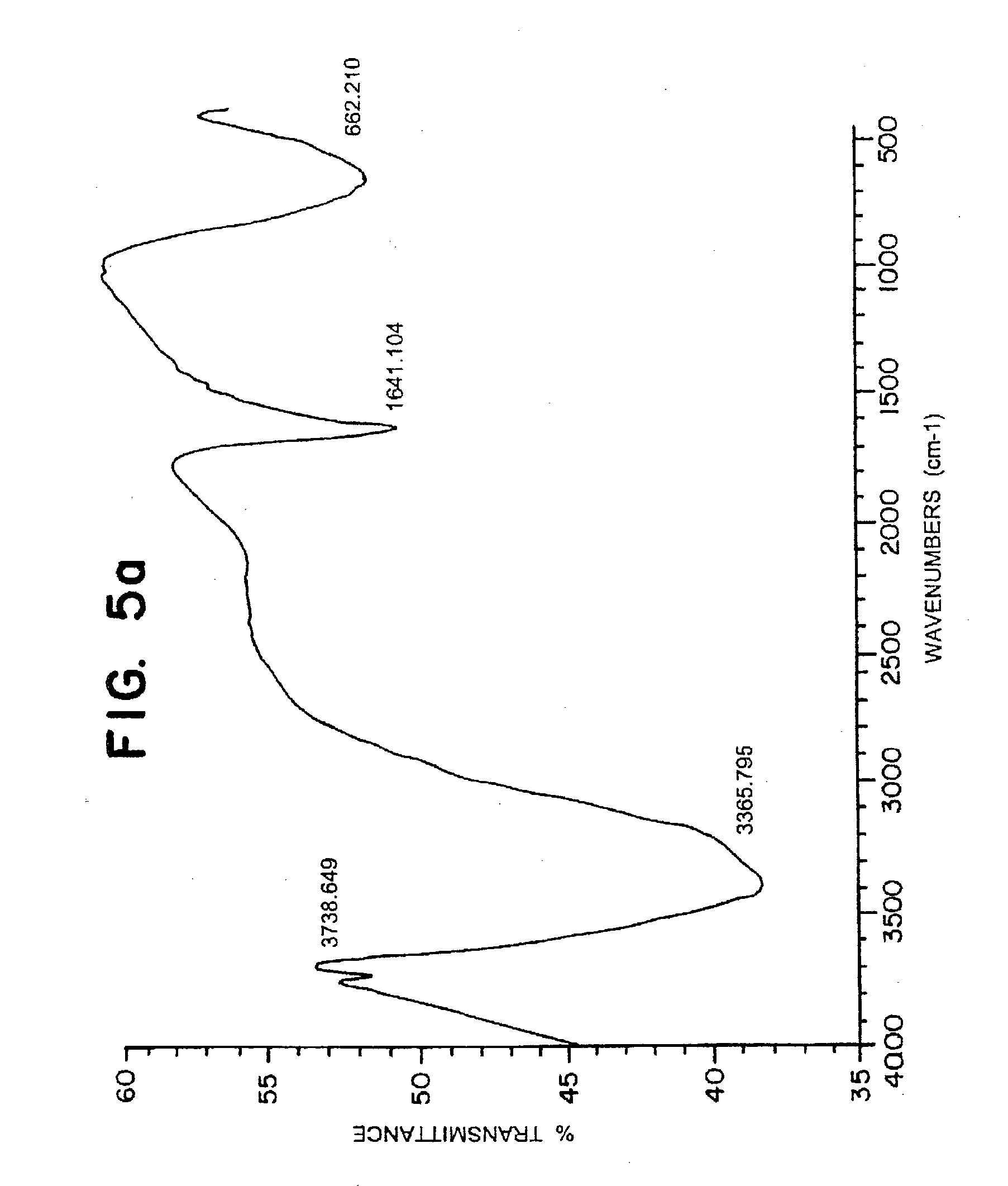

Acamprosate formulations, methods of using the same, and combinations comprising the same

Embodiments disclosed herein generally relate to acamprosate formulations, methods of use of the formulations, to methods of using the formulations in combination with at least one other medication, and to combination products and compositions comprising the formulations and at least one other medication, such as neuroleptic (antipsychotic) and / or antidepressant drugs.

Owner:SYNCHRONEURON

Drugs, bio-affecting and body treating compositions

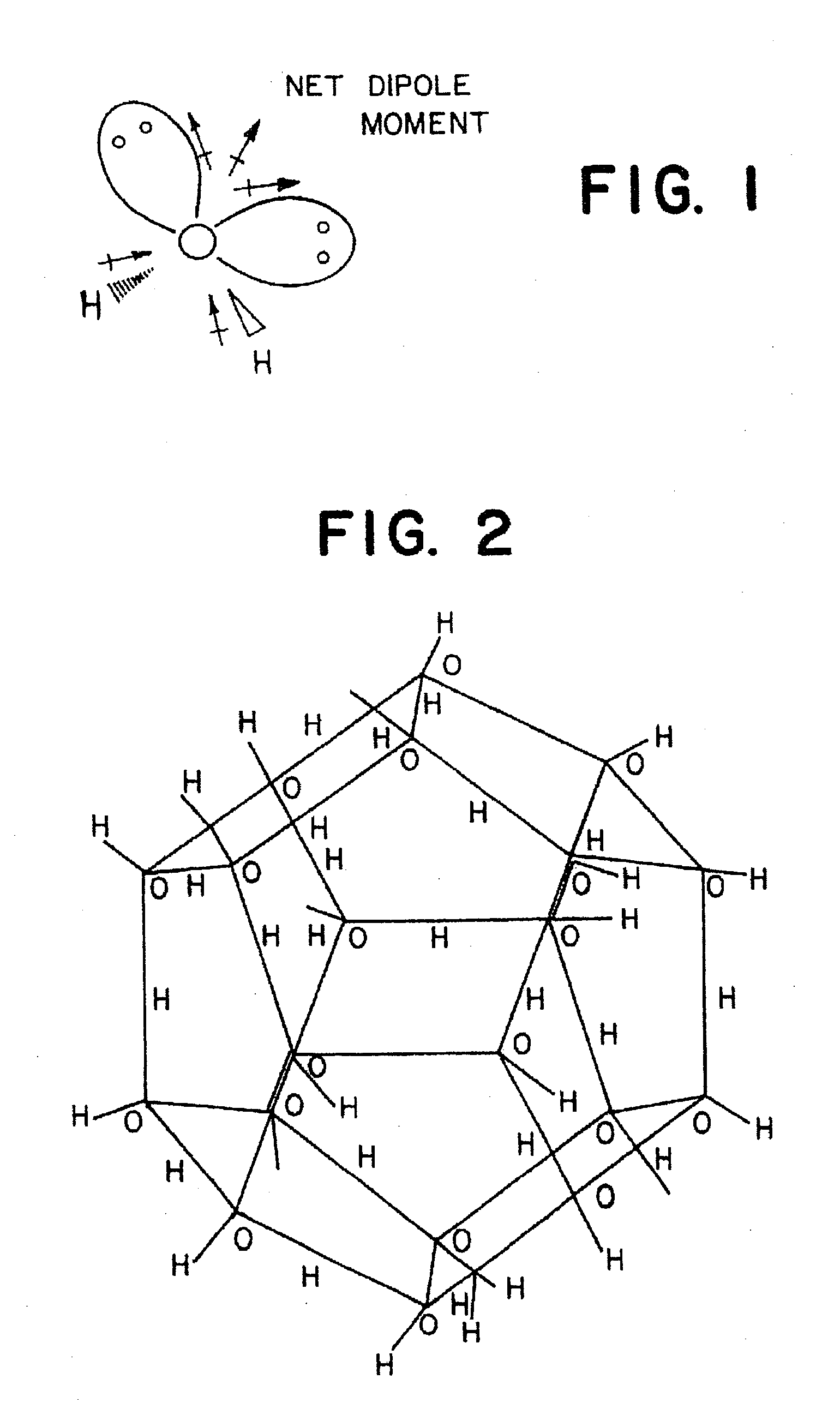

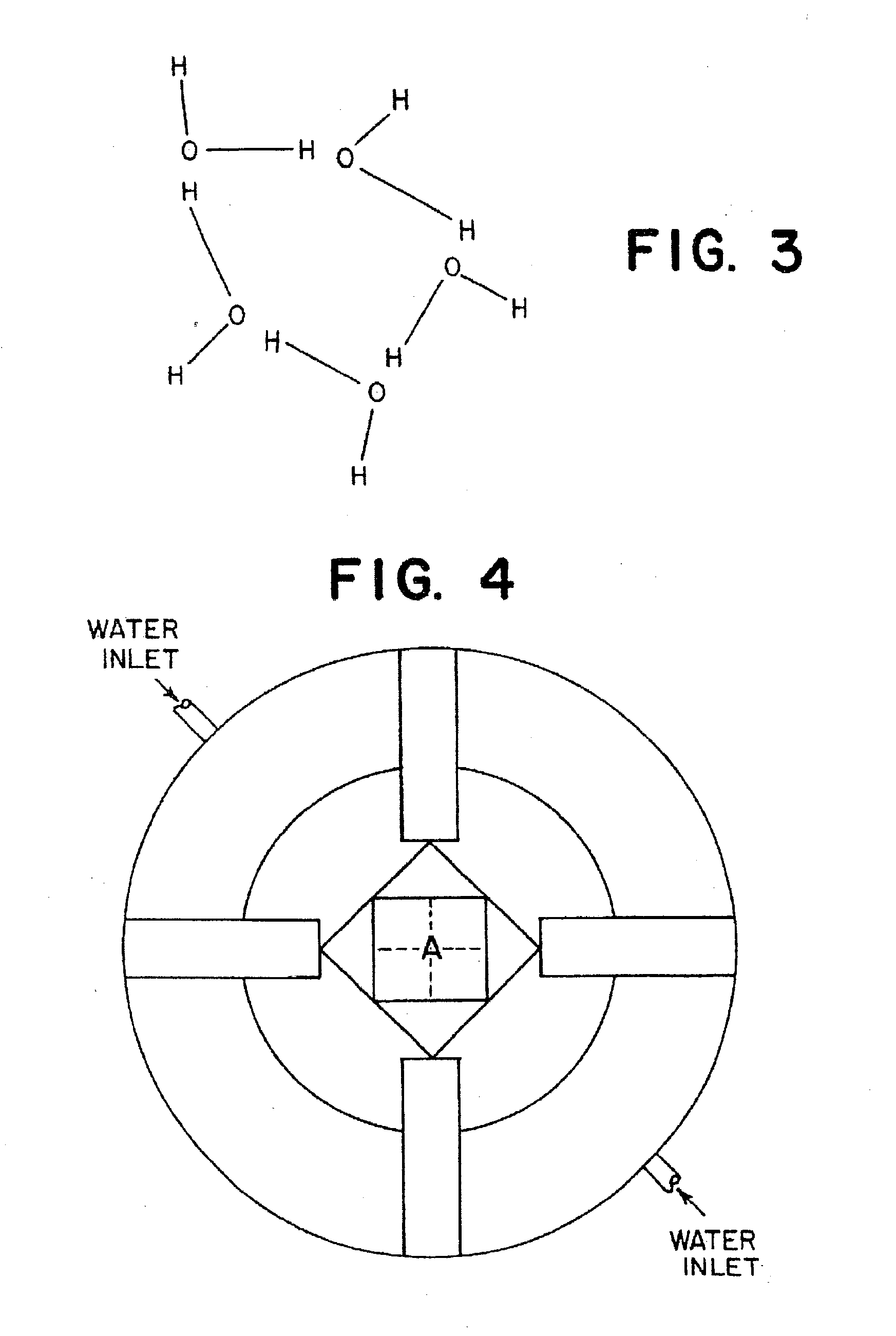

Micro-clustered water compositions of bio-affecting agents, body-treating agents, and adjuvants or carriers, pharmaceutical and diagnostic compositions thereof. Methods of using the compositions involving administering them ex vivo to cells, tissues or organs, or in vivo to living bodies; and methods of making the compositions.

Owner:AQUAPHOTONICS INC

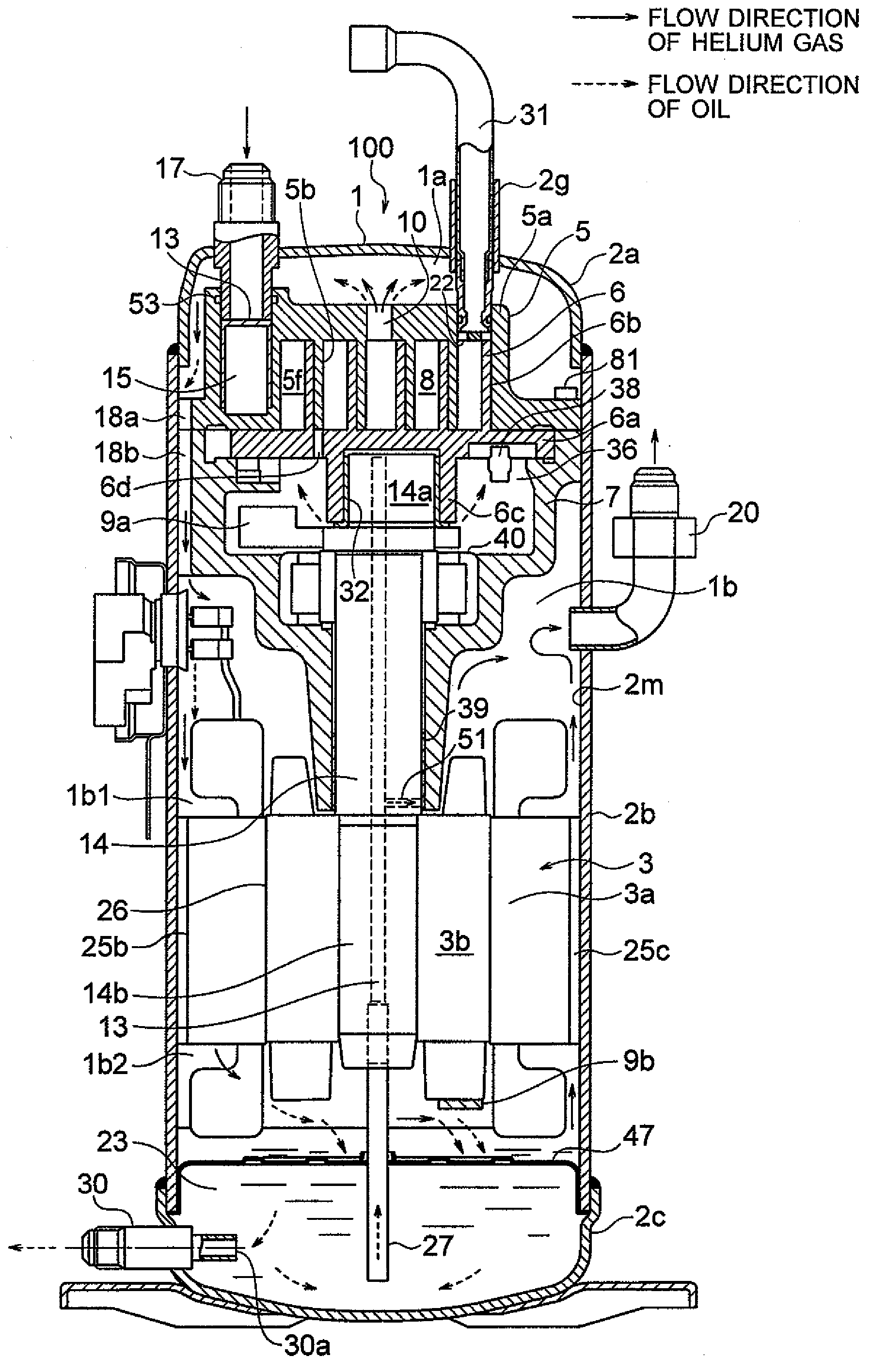

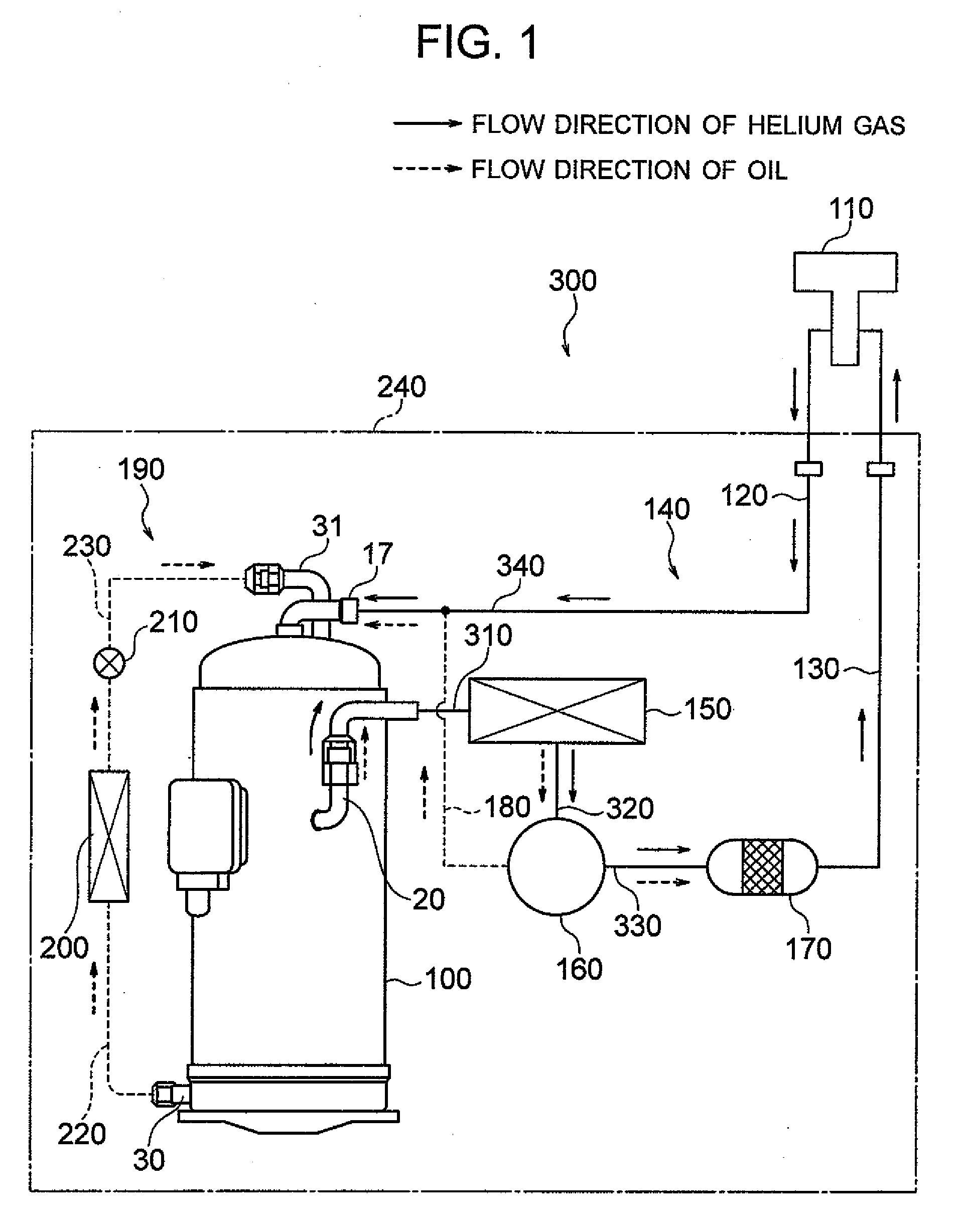

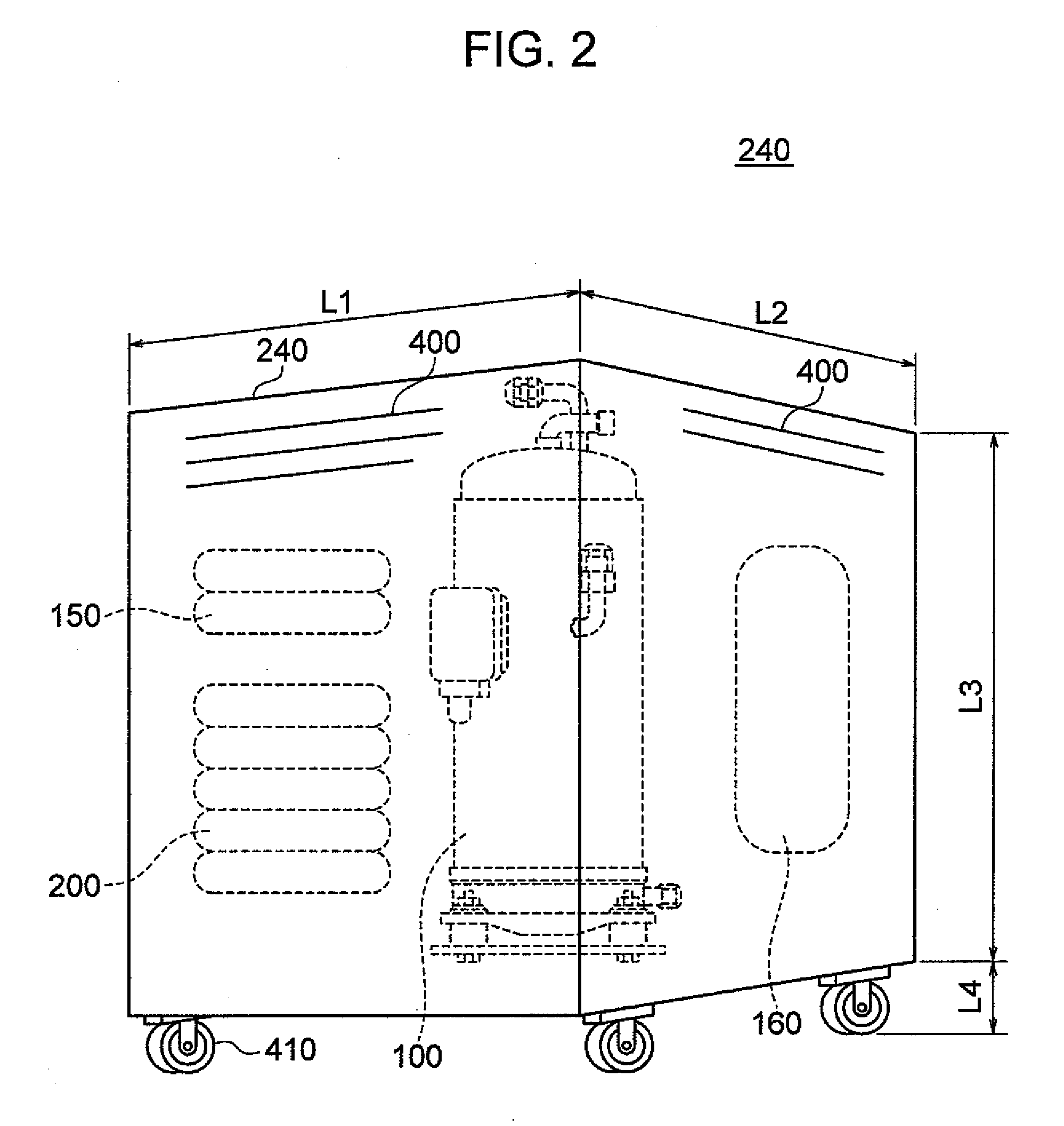

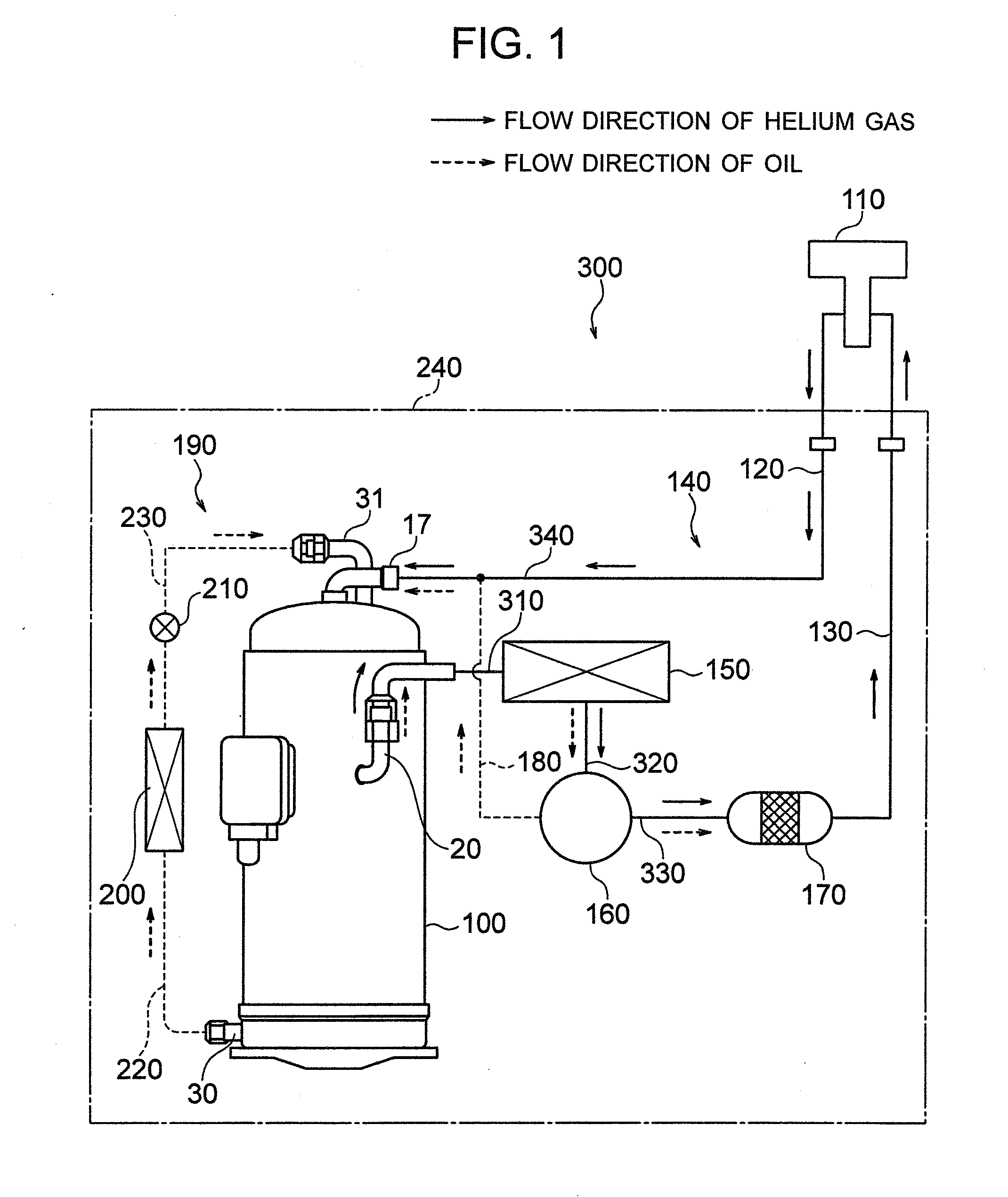

Hermetically sealed scroll compressor

ActiveUS20100129240A1Reduced volumetric efficiencyIncrease in internal compression powerRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringMechanical engineering

In the hermetically sealed scroll compressor, an injection pipe for injecting a fluid to a compression chamber is connected to an injecting port of a fixed scroll. The injecting port includes a first injecting port which is provided in the vicinity of a fixed scroll inner curve and injects the fluid to an orbiting outer compression chamber, and a second injecting port 22b which is provided in the vicinity of a fixed scroll outer curve and injects the fluid to a orbiting inner compression chamber 8b. The second injecting port is placed in parallel in a radius direction with respect to the first injecting port and is placed so that an orbiting scroll wrap does not practically communicate with the orbiting outer compression chamber in the state in which the orbiting scroll wrap is in contact with the outer side of a fixed scroll wrap.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

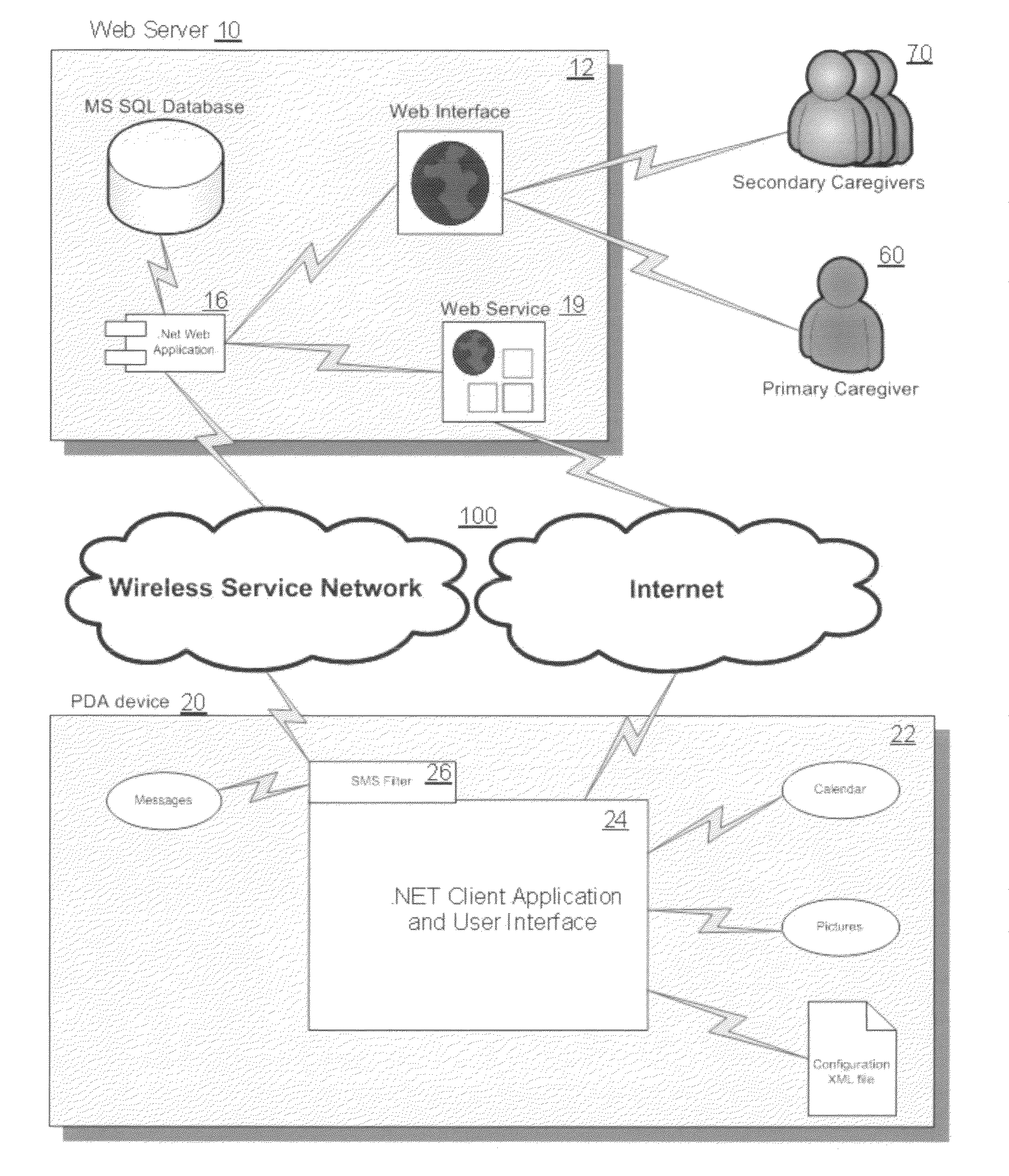

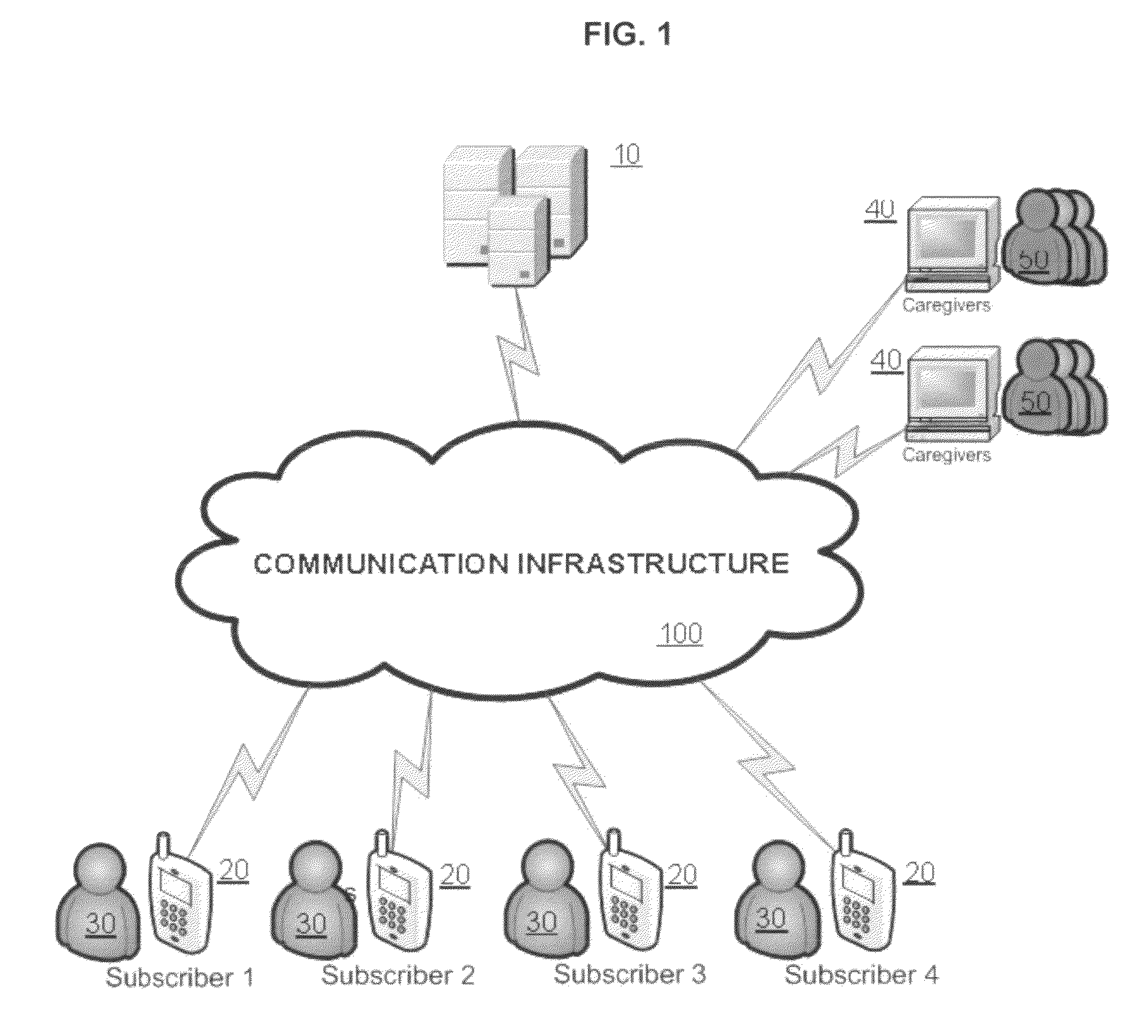

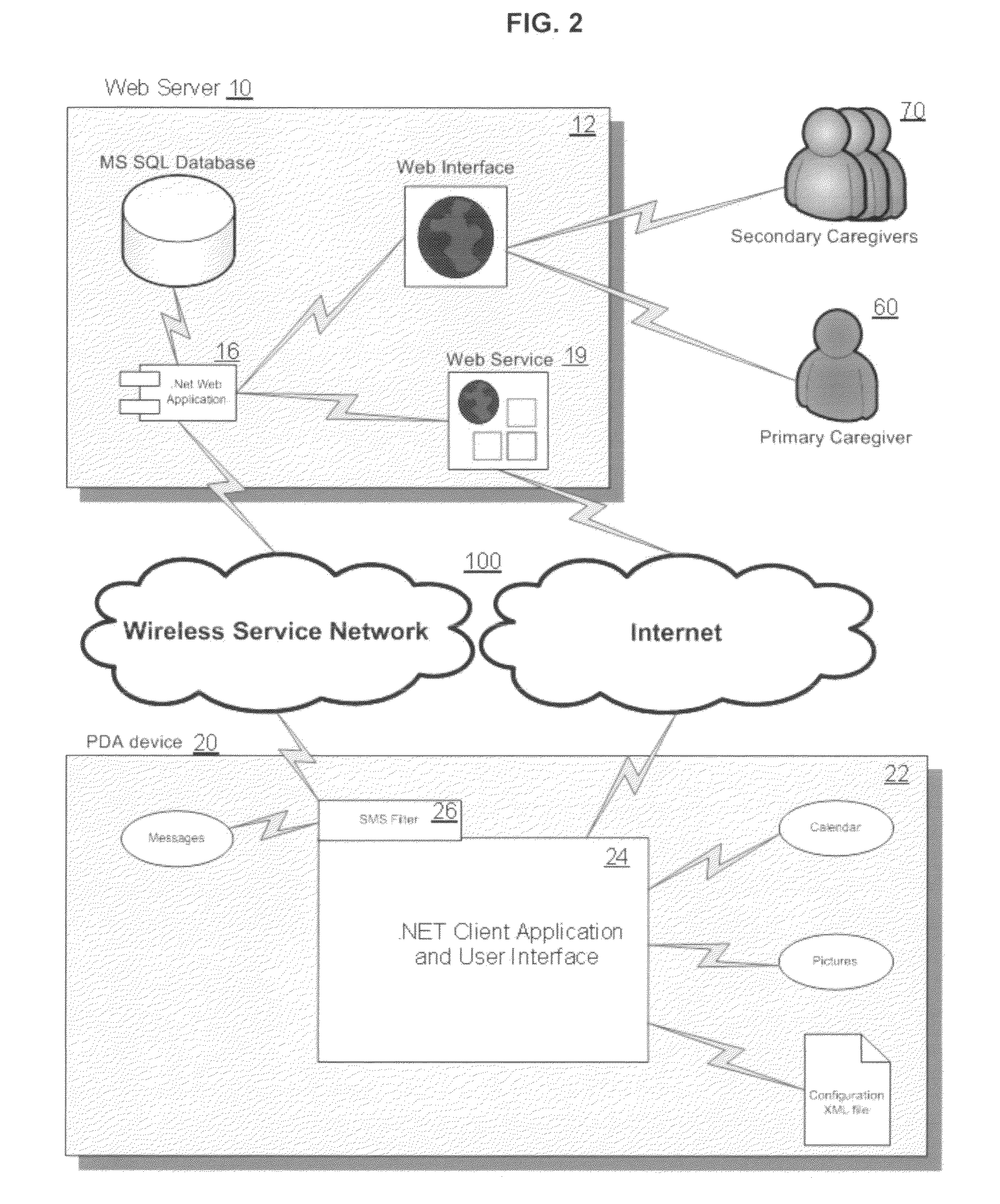

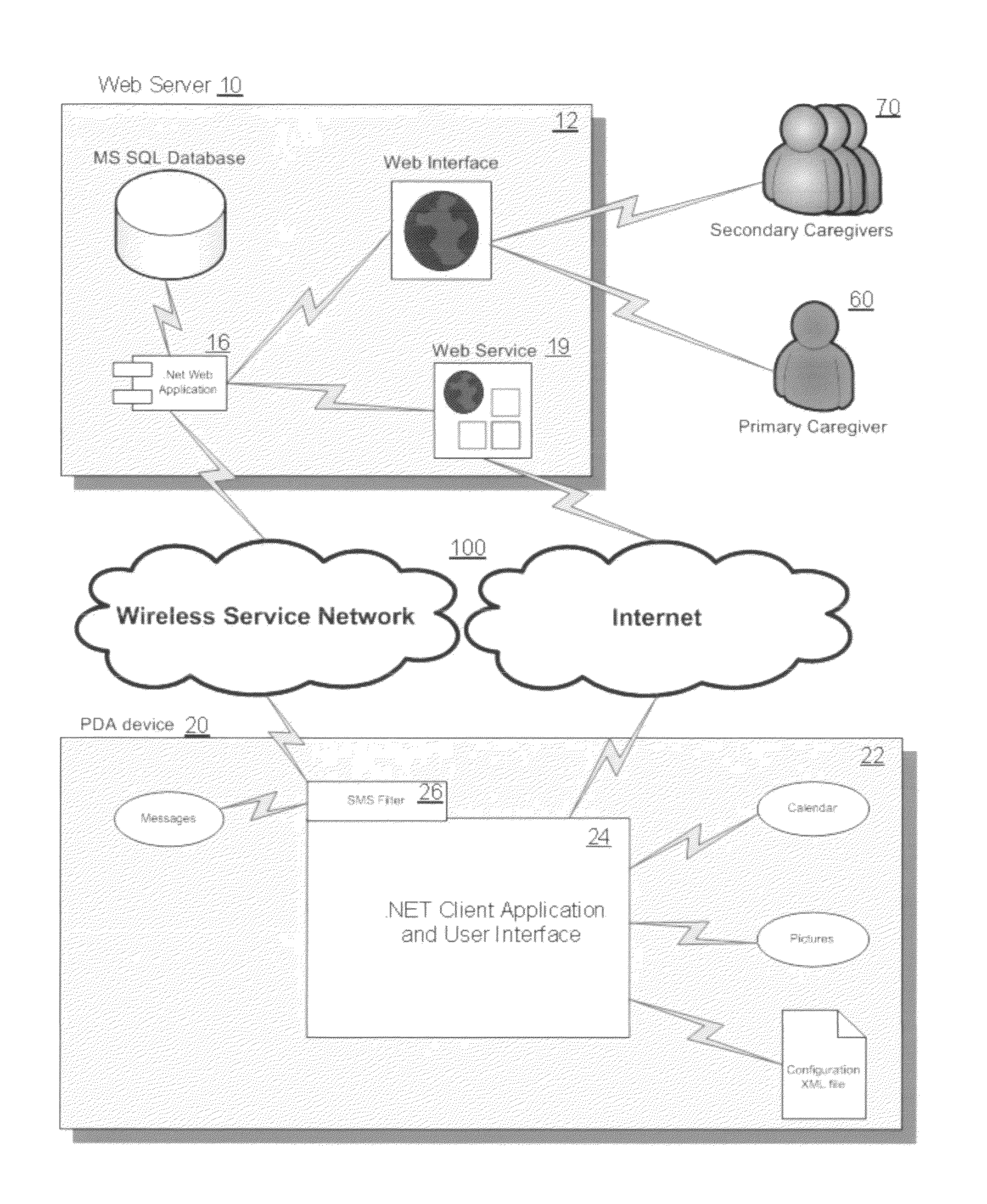

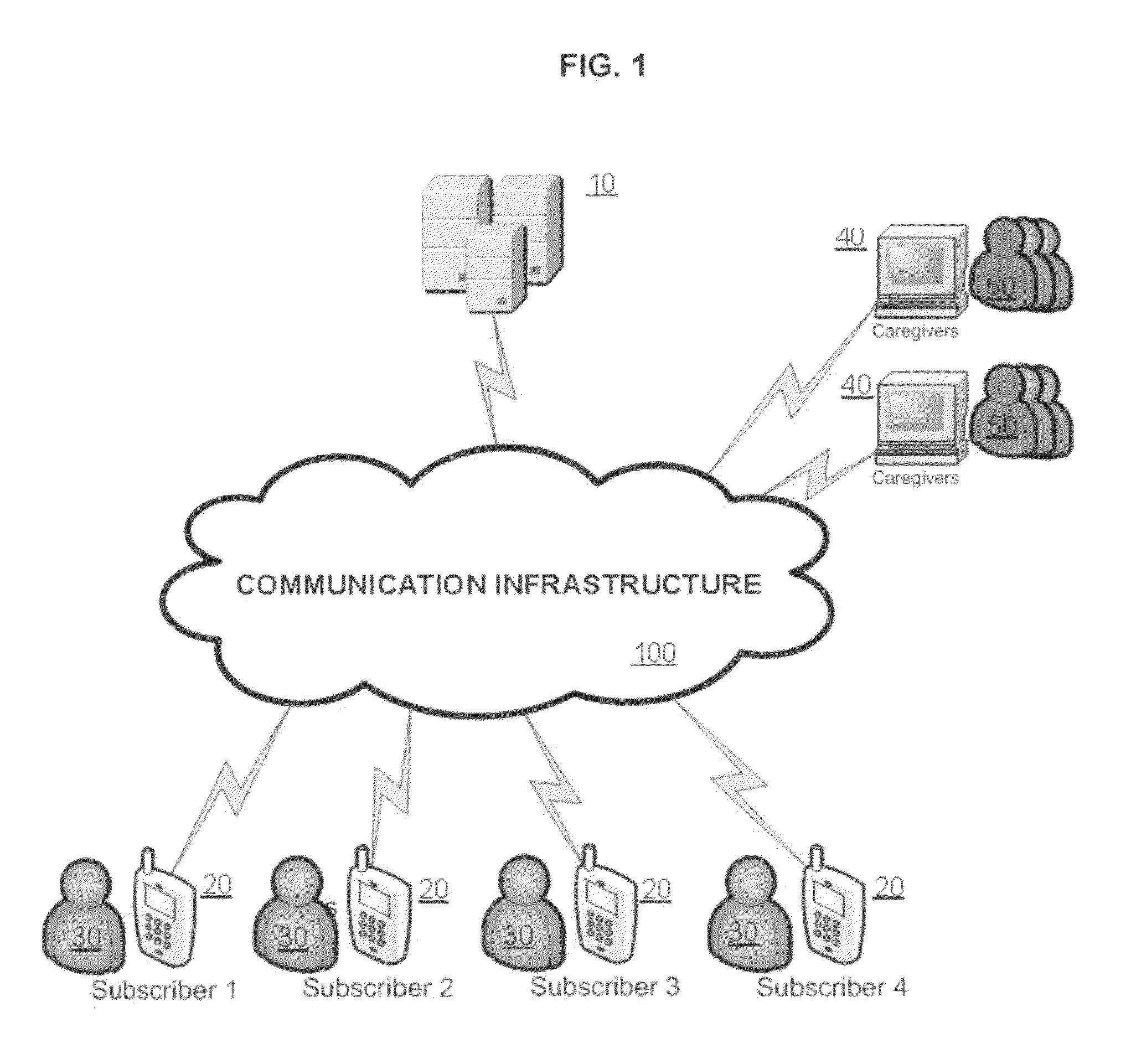

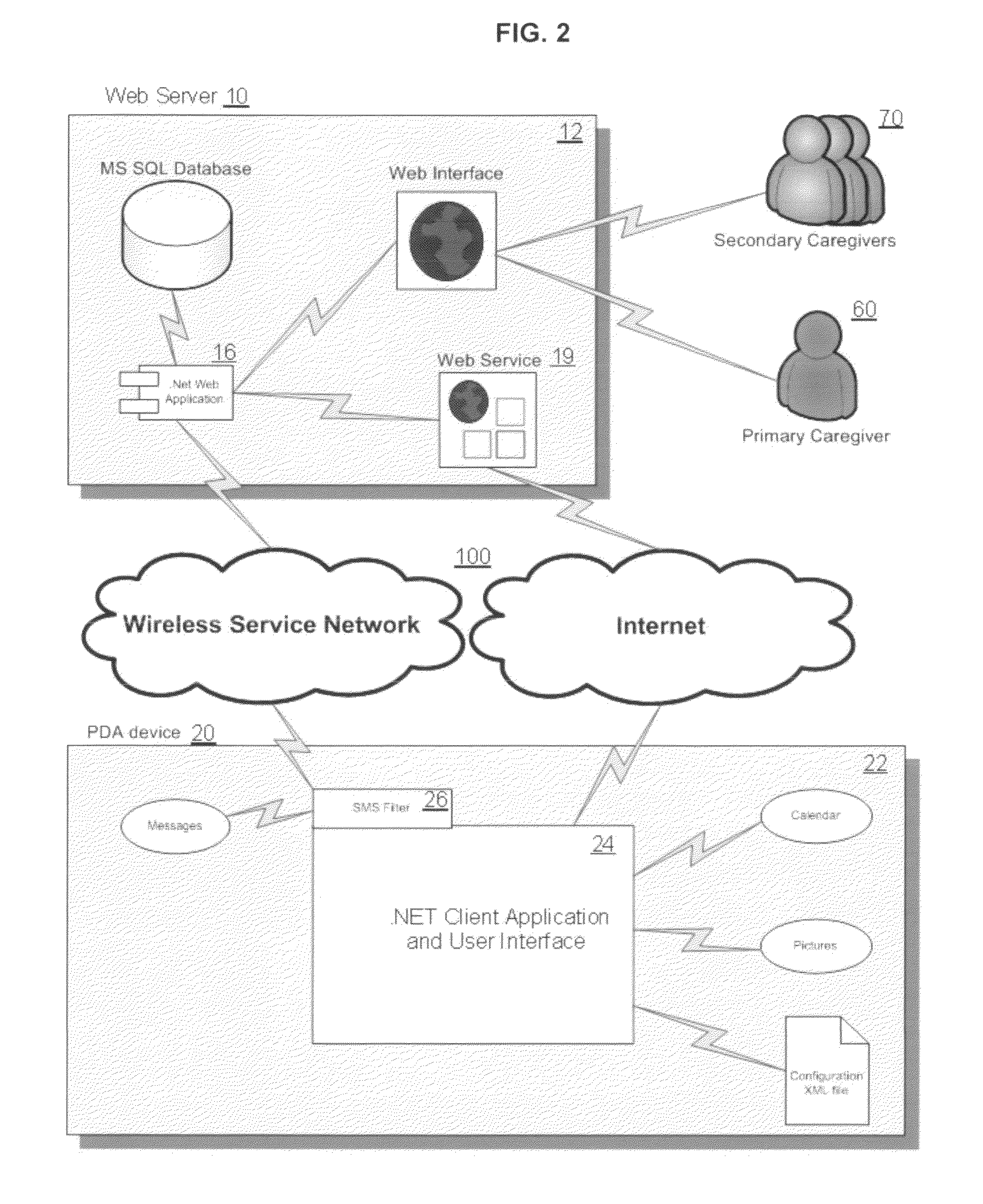

Method, system and apparatus for encouraging frequent and purposeful electronic communications from caregivers to individuals with impaired memory

InactiveUS20100191824A1Simple user interfaceIncrease frequency and qualityInput/output for user-computer interactionMental therapiesReceiptElectronic communication

A computer implemented system and method for encouraging frequent and purposeful electronic communications from caregivers to individuals with impaired memory to, inter alia, alleviate feelings of isolation and improve memory. The system includes a Web-based application through which caregivers send text, image, voice and other forms of data for receipt by the sufferer on a PDA having a simple user interface. The Web application records the dates and nature (i.e., text, audio, photograph, video) of communications sent by each caregiver, processes the data in order to display it in a variety of meaningful ways to all caregivers, thus creating a peer-pressure environment to encourage more frequent communication. The Web application can also be programmed to send electronic reminders to all caregivers who opt-in to the service requesting that they send a communication to the sufferer, and more particularly to individual caregivers whose frequency of communication has been inadequate relative to a group of caregivers or to predefined expectations.

Owner:LINDSAY TED

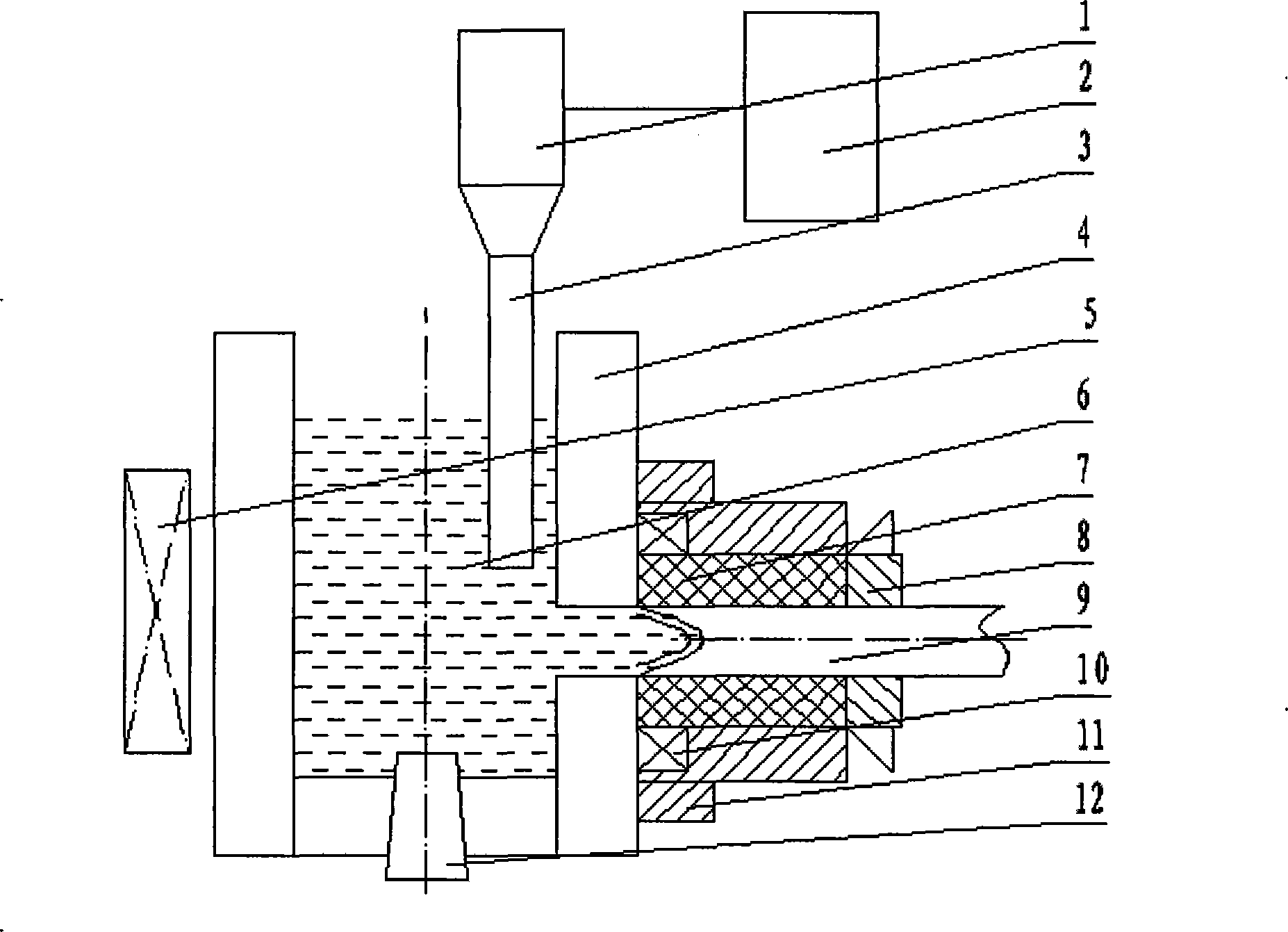

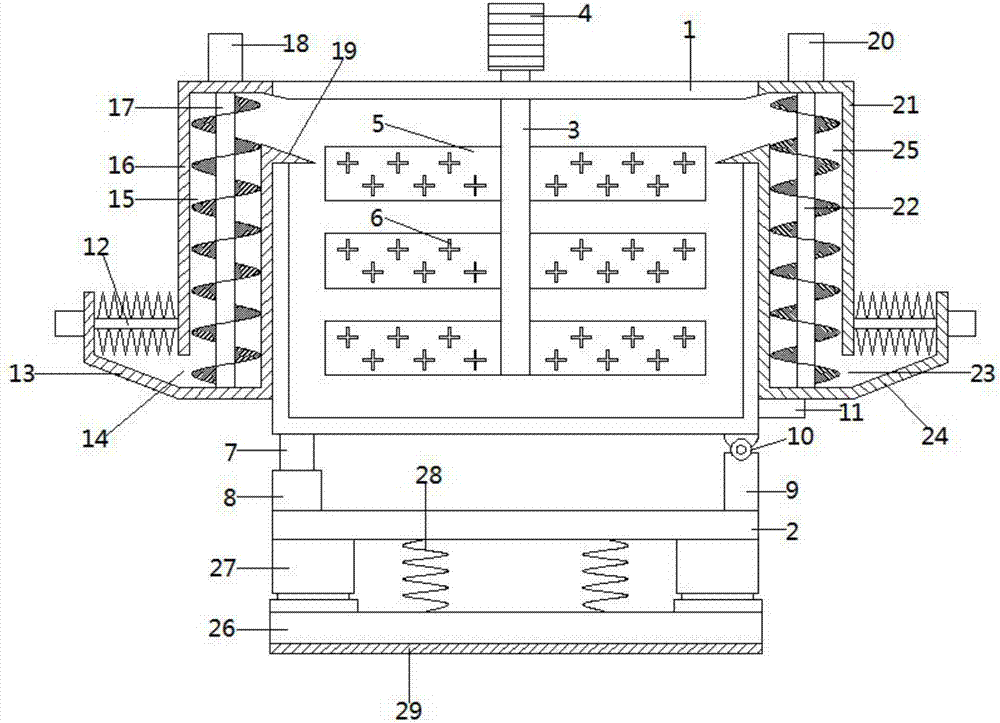

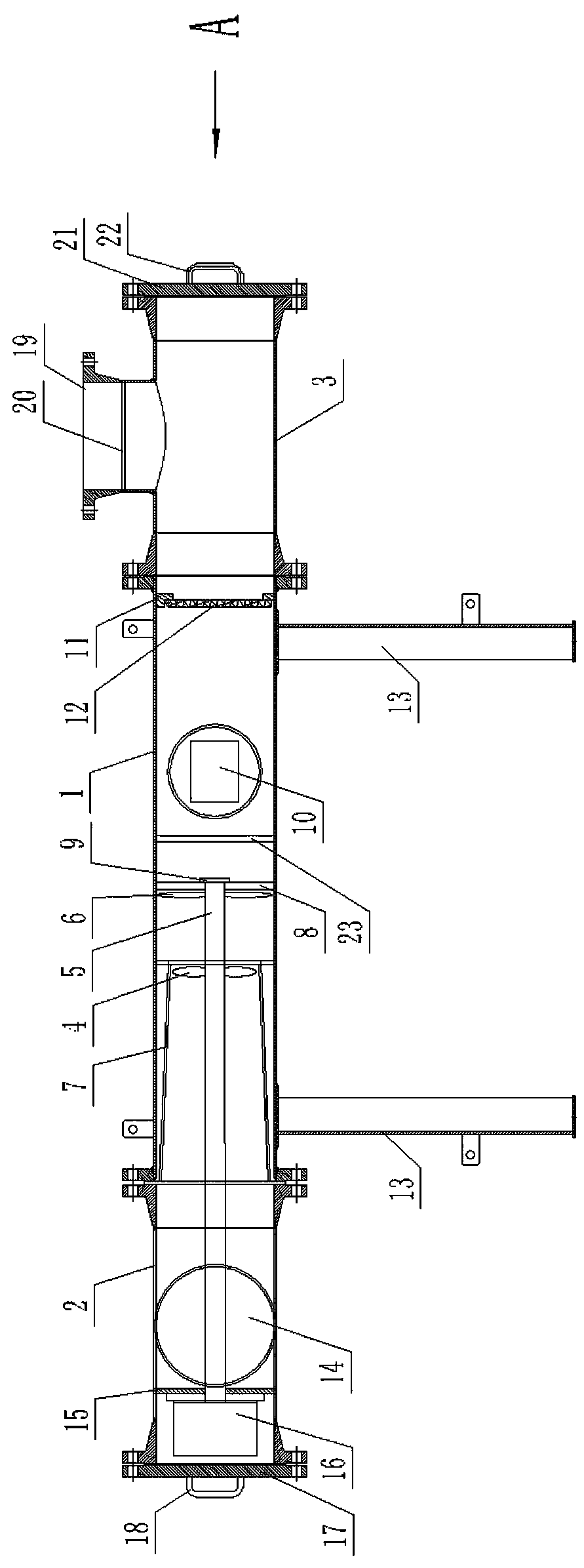

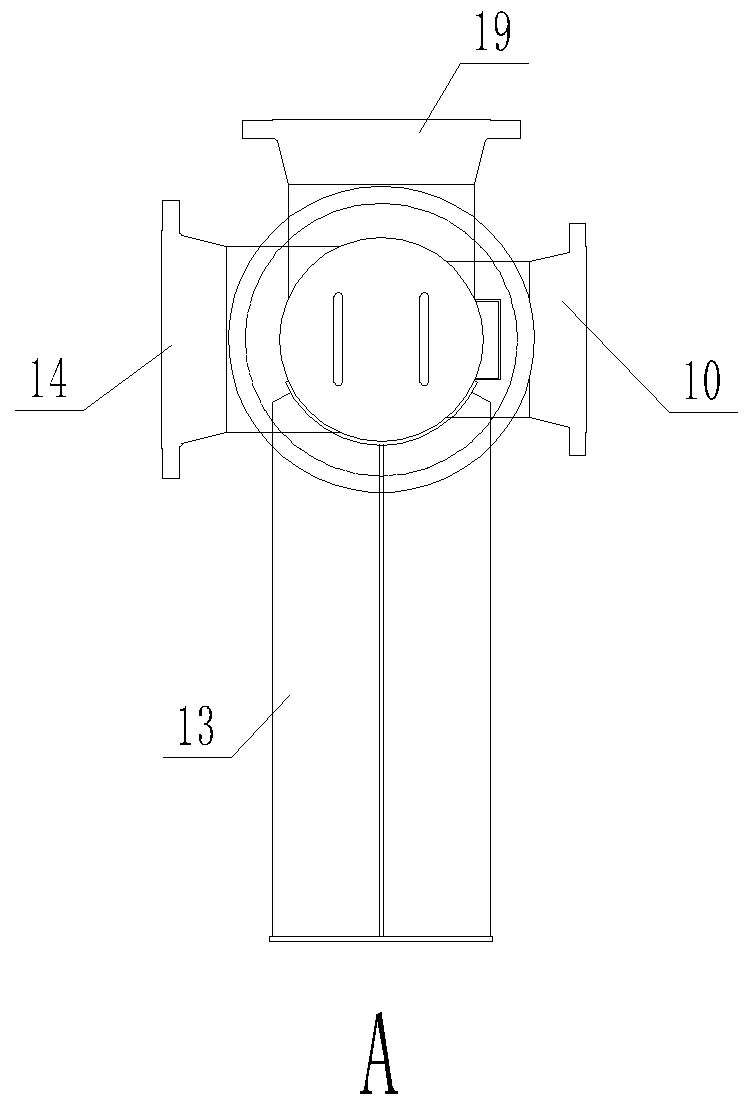

Method and apparatus for improving horizontal continuous casting billet quality by applying composite field

The invention relates to a quality improving method for horizontal continuous casting blanks by applying complex field and the device, belonging to the technical field of preparation of metal material, in particular to the technology of applying complex electromagnetic field and ultrasonic field in the continuous casting process of metal casting blanks. The device is characterized in that a generator of inert gas is arranged at the center of the bottom of a holding furnace; a generator of traveling wave magnetic field is arranged on the side of the holding furnace; a power ultrasonic device is arranged on the holding furnace close to the water port; a restriction electromagnetic coil is arranged on the outer side of a crystallizer. The device has the advantages that: firstly, the production technology is simple, the operation is easy, and the efficiency is high; secondly; the disadvantages of easy broken in rolling and drawing process of casting blank due to more impurity and pores is solved; thirdly, the solidification structure of the casting blanks is uniform, the crystal grain is fine, and the casting blanks can be rolled directly at casting state. The quality improving method and the device are mainly used for the field of metal continuous casting.

Owner:DALIAN UNIV OF TECH

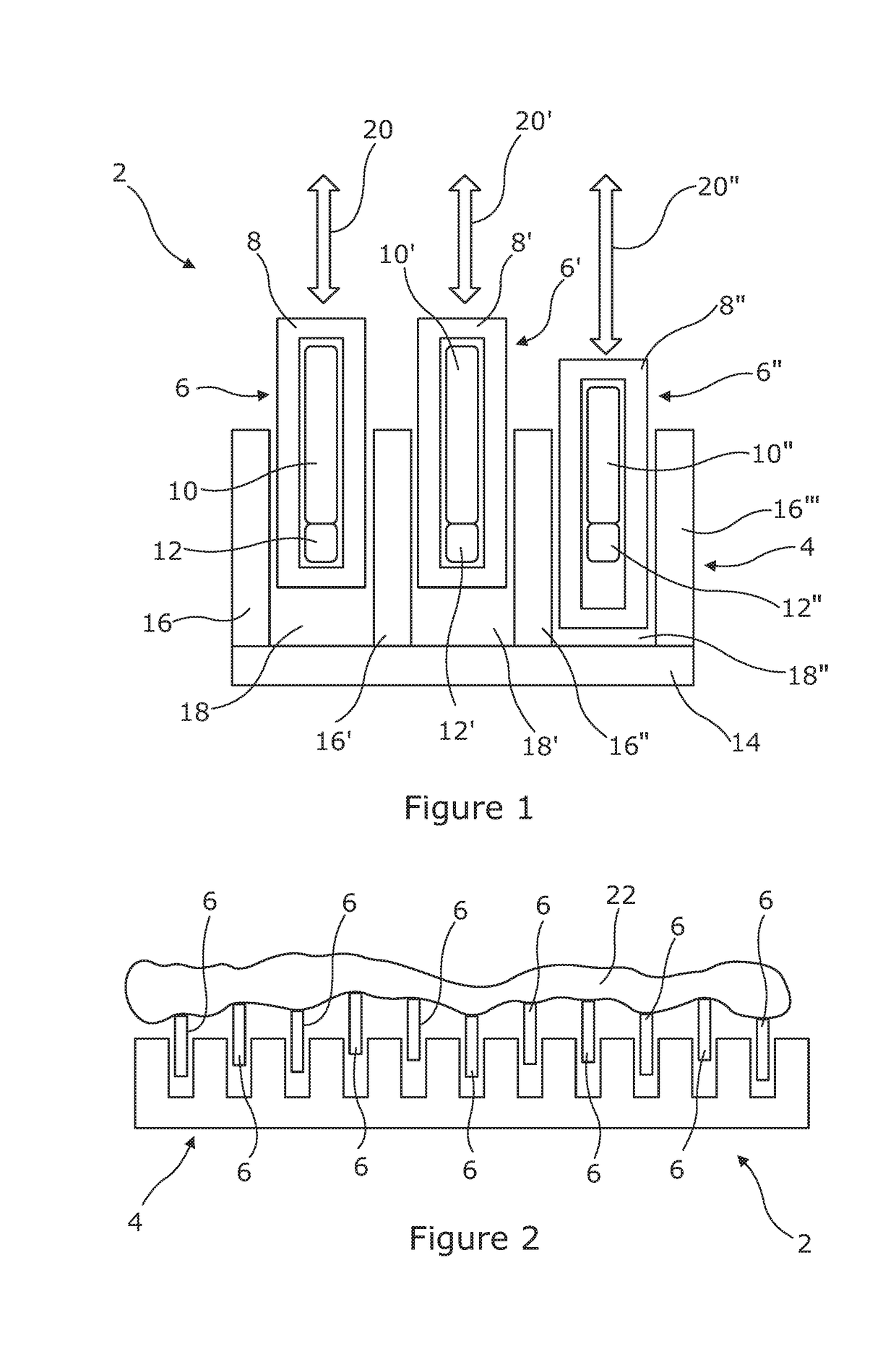

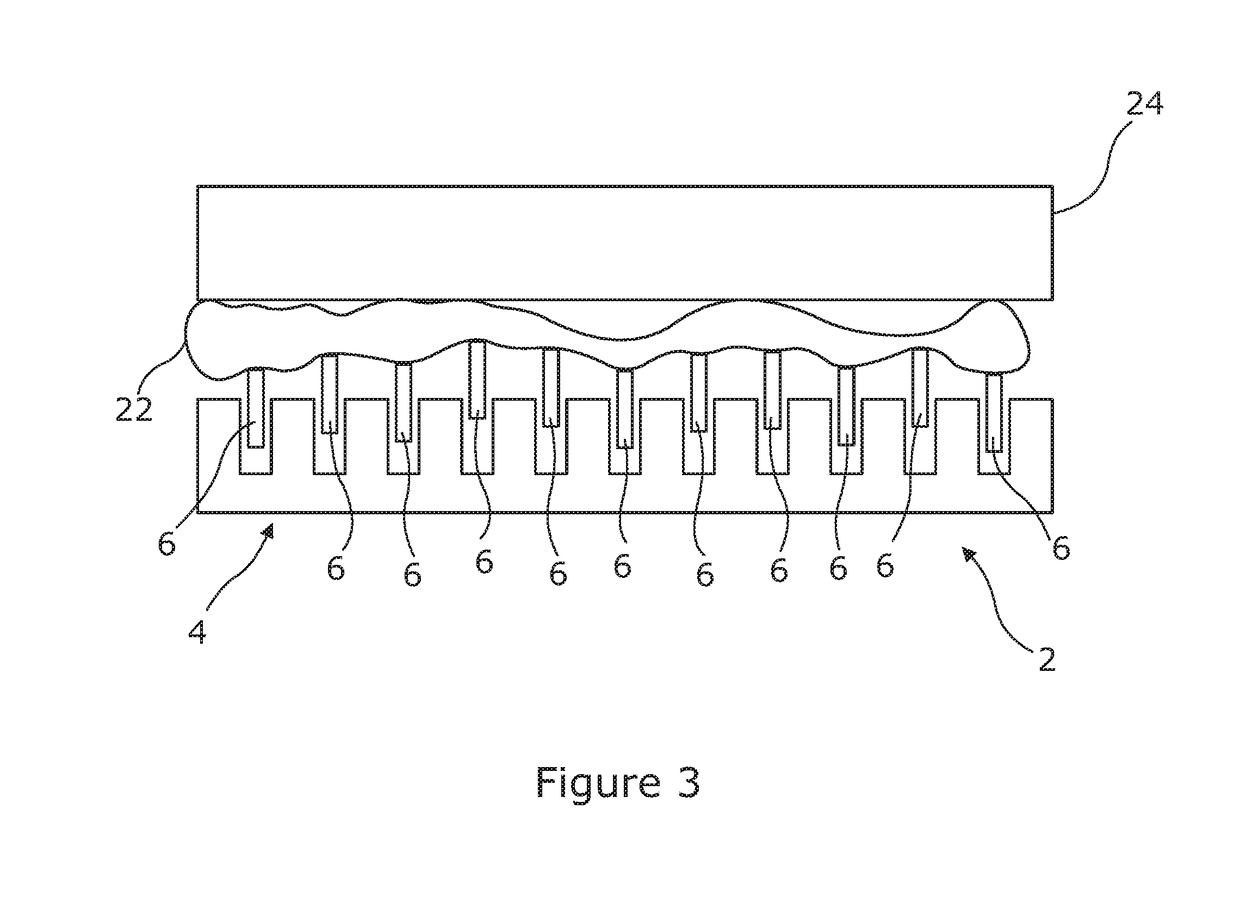

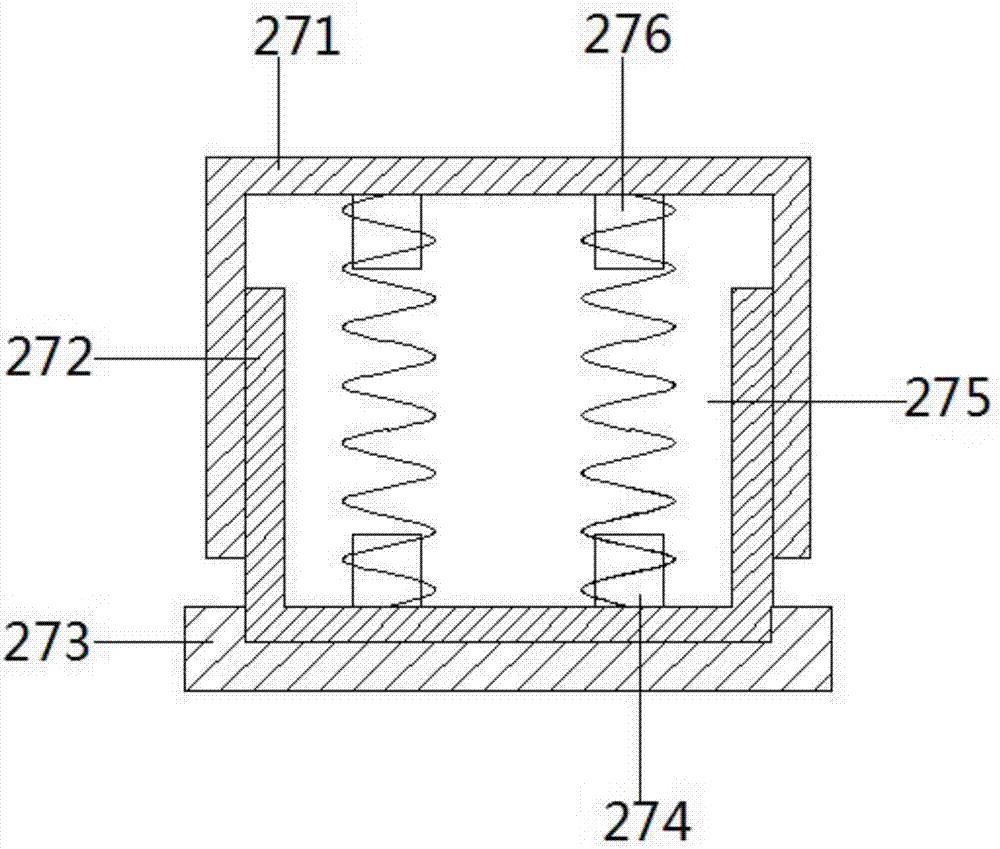

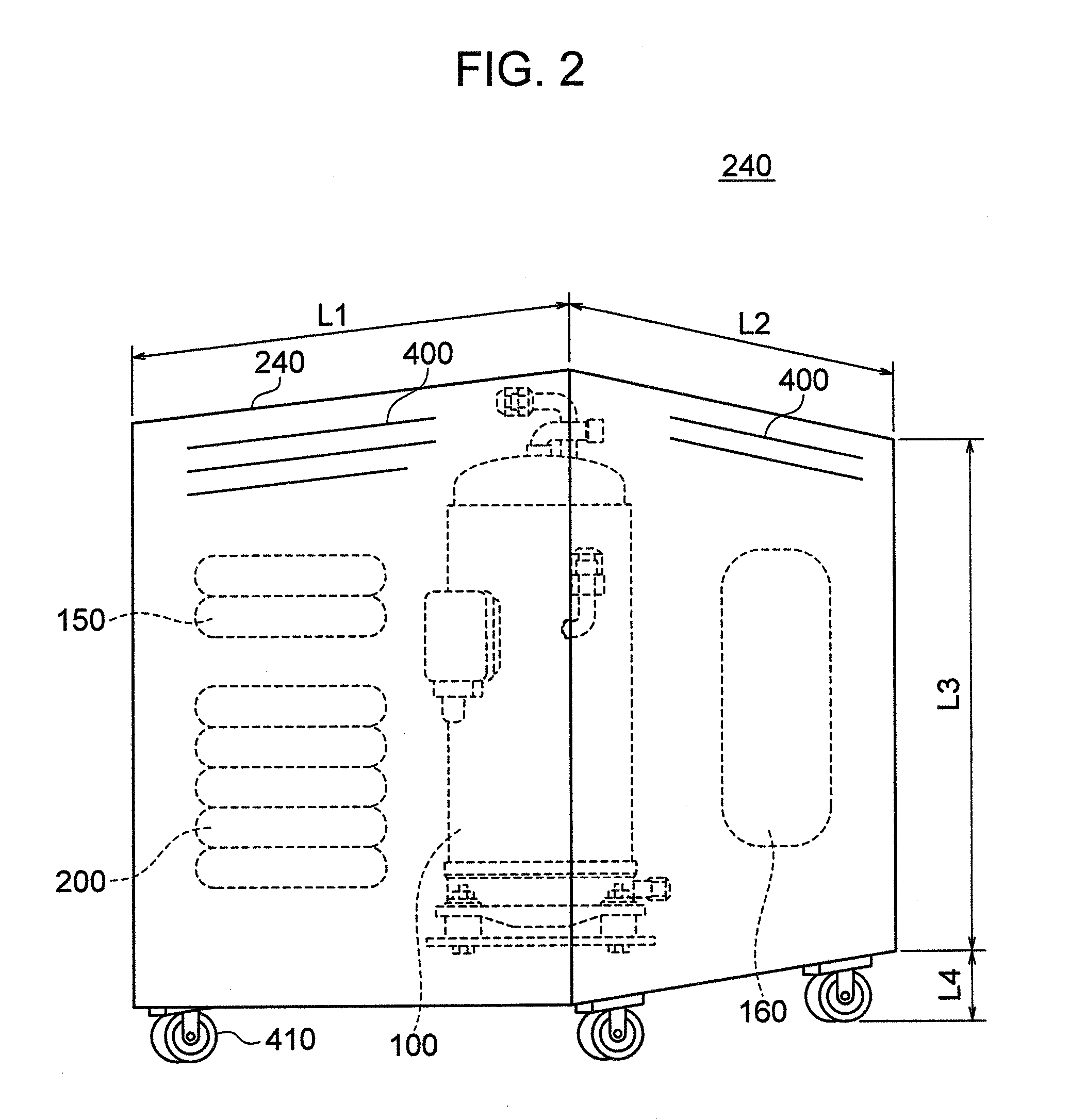

A device and method for heating or cooling a sample

ActiveUS20190075786A1Enhanced agitationImprove the heating effectHeating or cooling apparatusBiological substance pretreatmentsThermal energyCooling curve

A sample heating / cooling device comprises a plurality of members operable in use to heat and / or cool one or more samples. Each member has a sample contact surface and is biased towards a resting position under the operation of a biasing means. The members are movable independently of one another against said bias under the application of a force on the sample contact surface and so are able to conform to the shape of a sample placed on the members to provide a uniform heating / cooling profile. The members may be mounted in a heating / cooling element and adapted to conduct thermal energy between the sample and the element. The device is particularly suitable for thawing frozen sample bags having an irregular shape. A corresponding method is also described.

Owner:CELL THERAPY CATAPULT

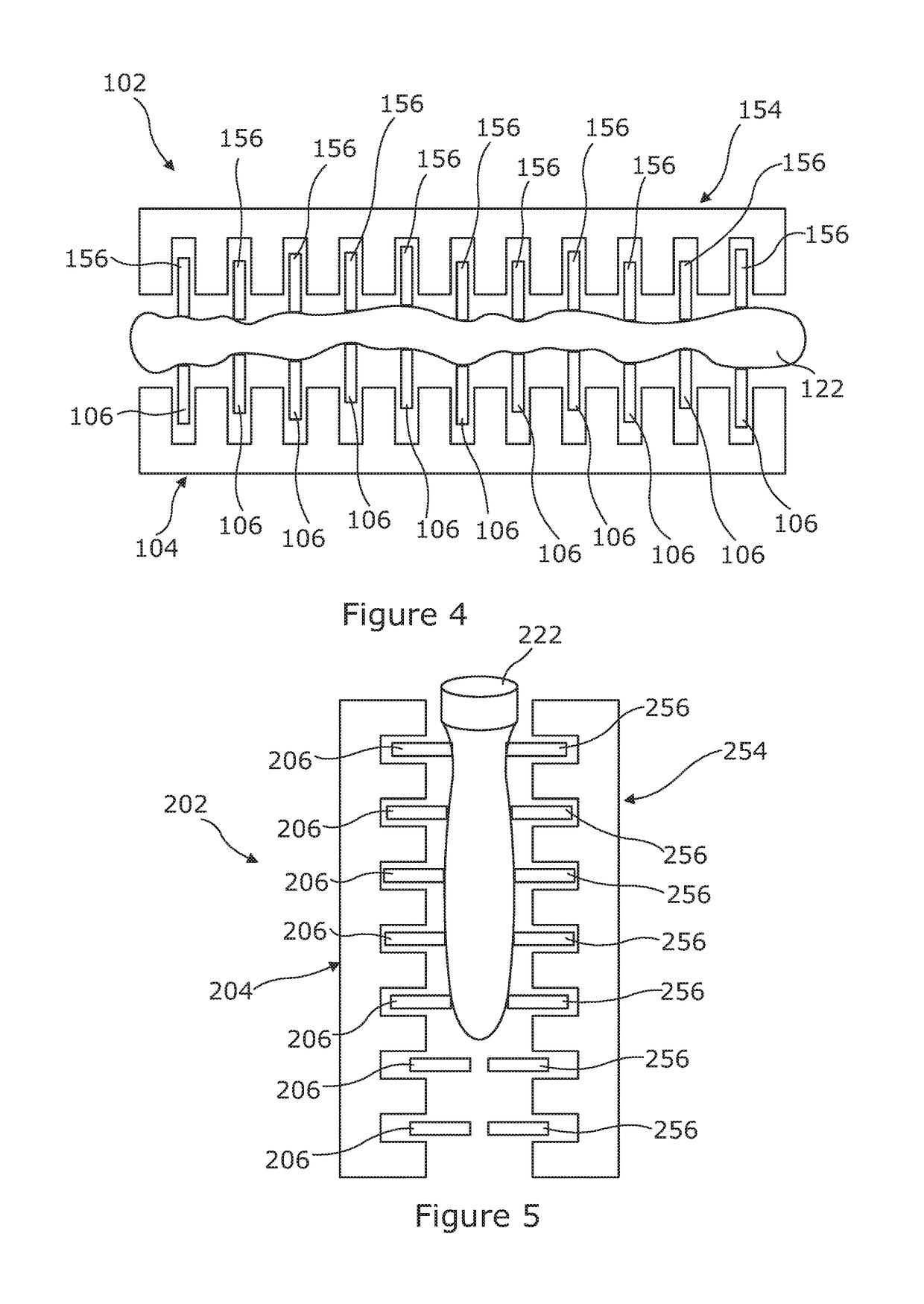

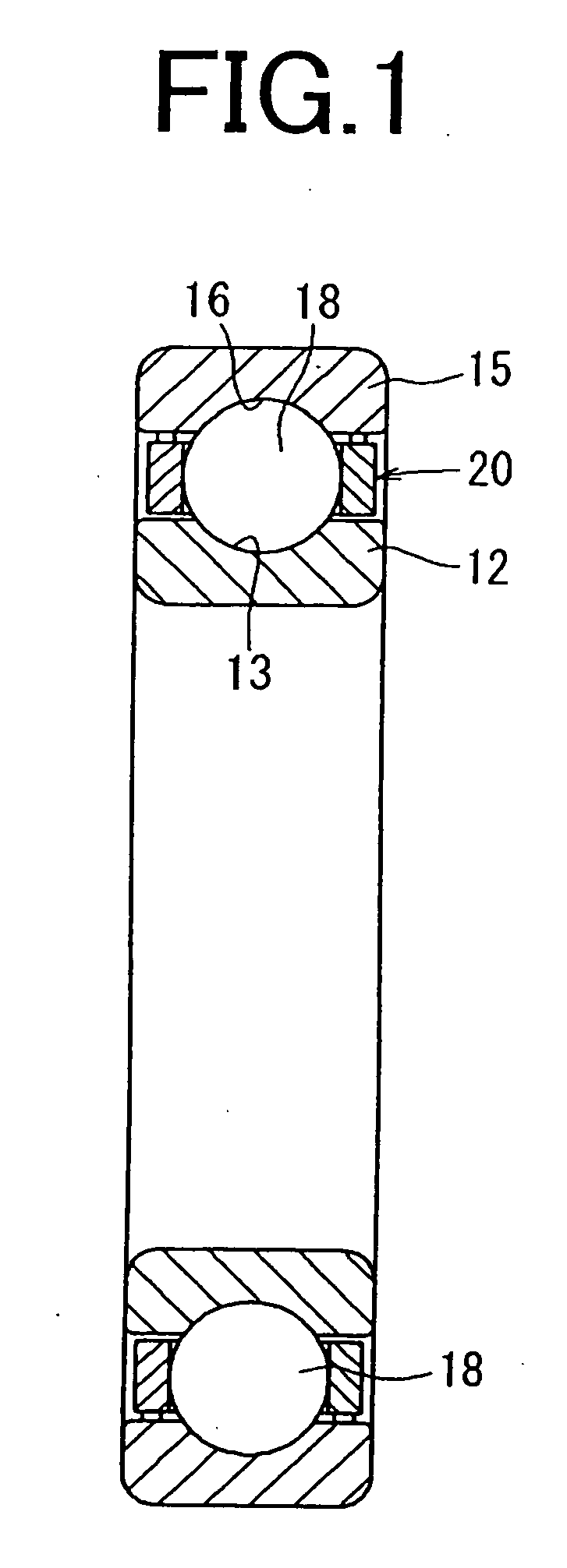

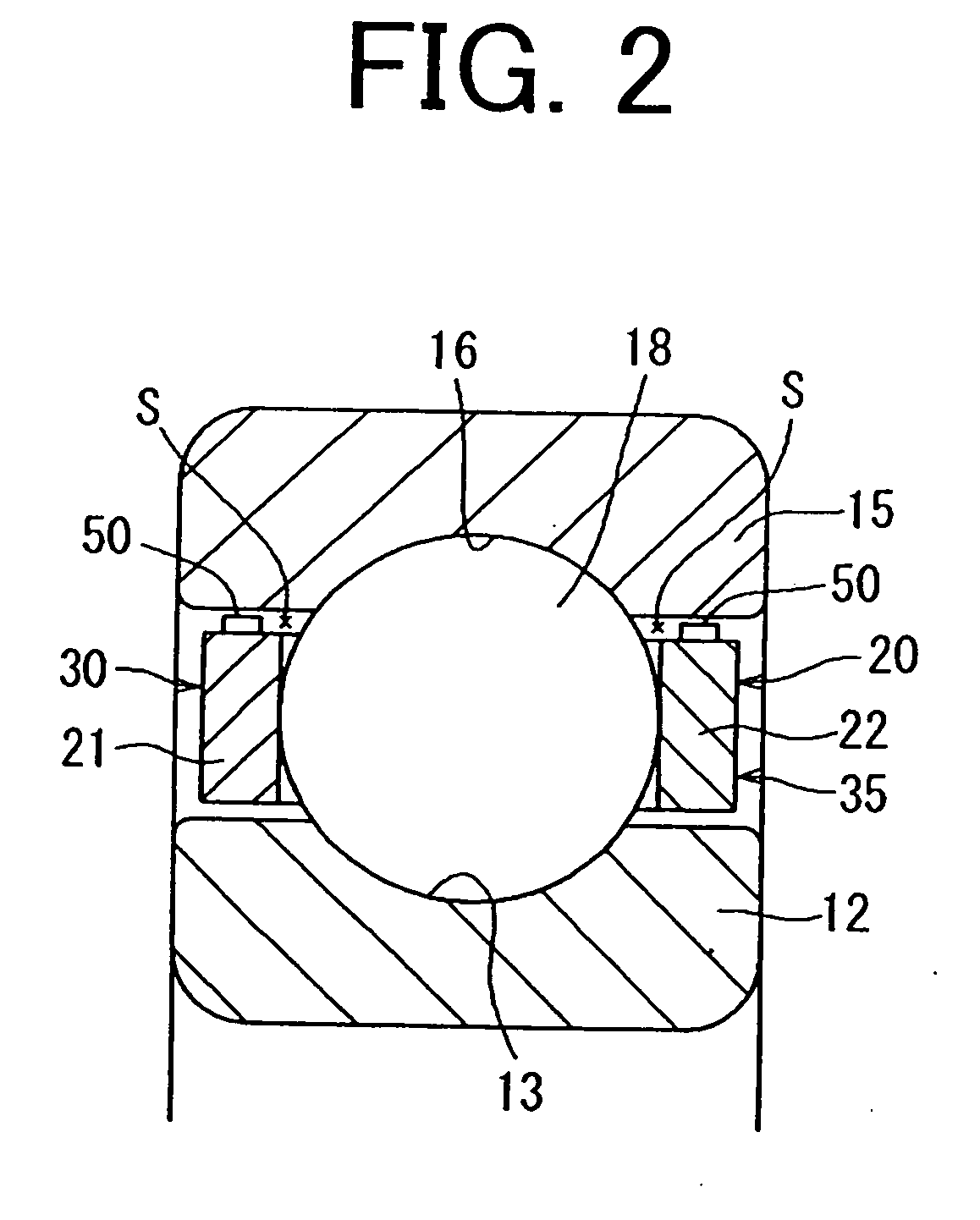

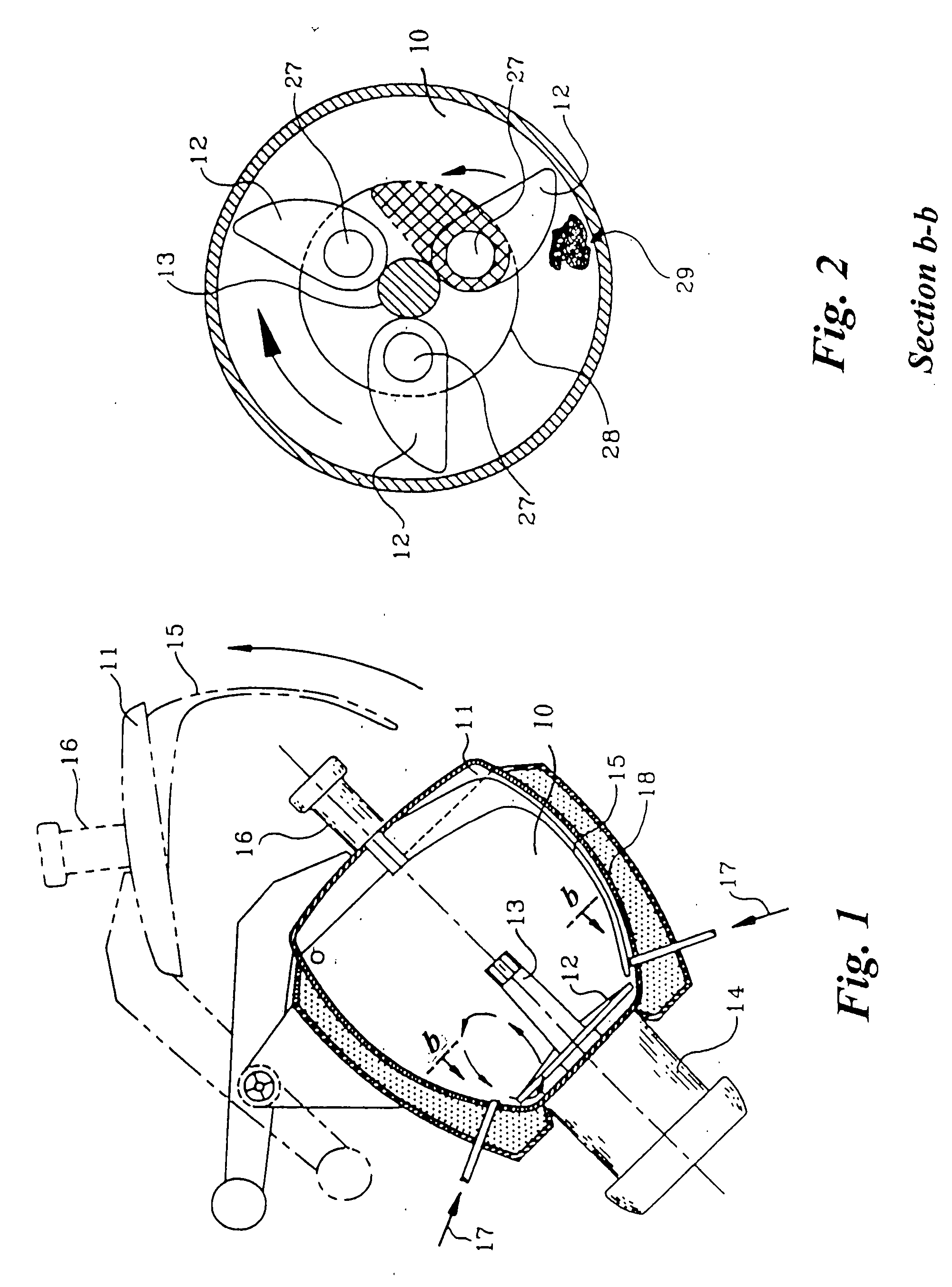

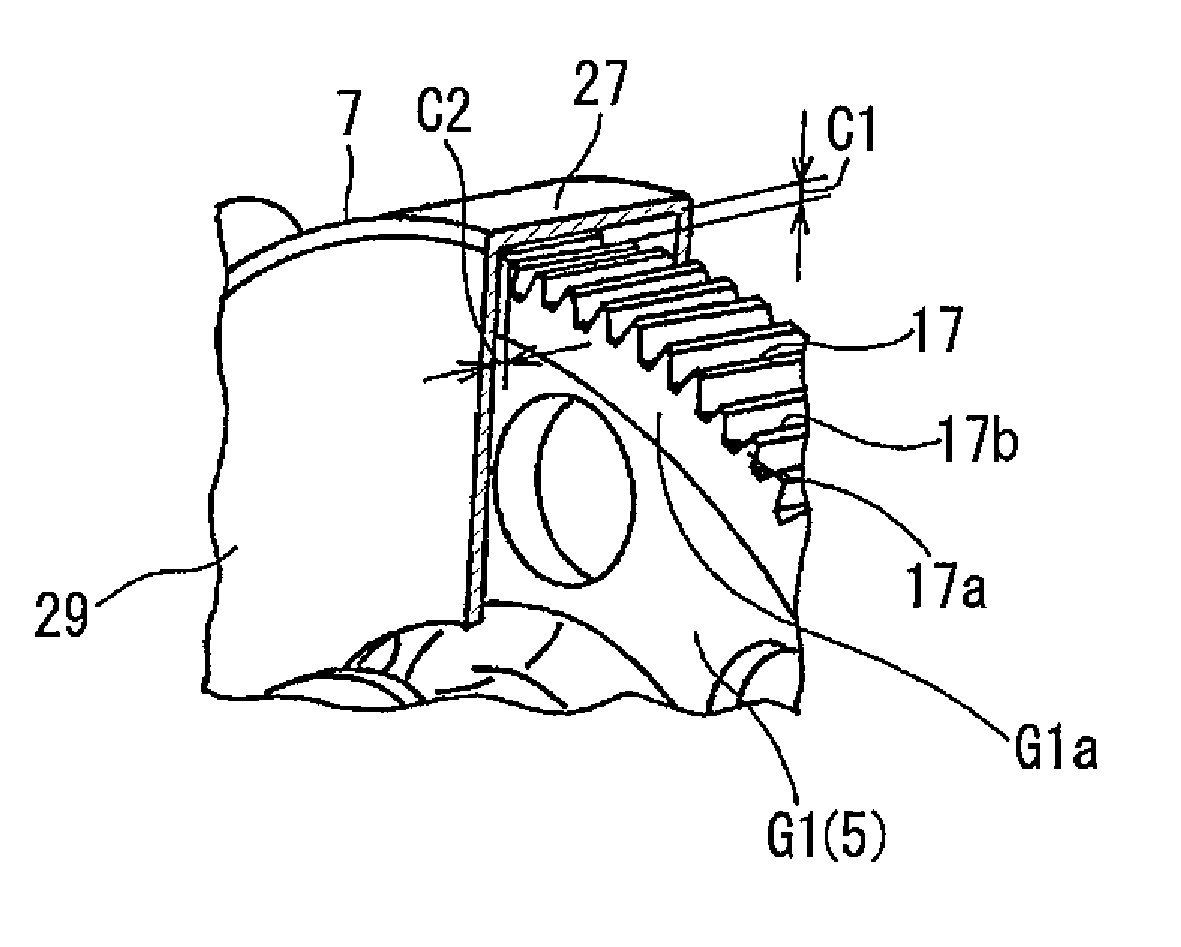

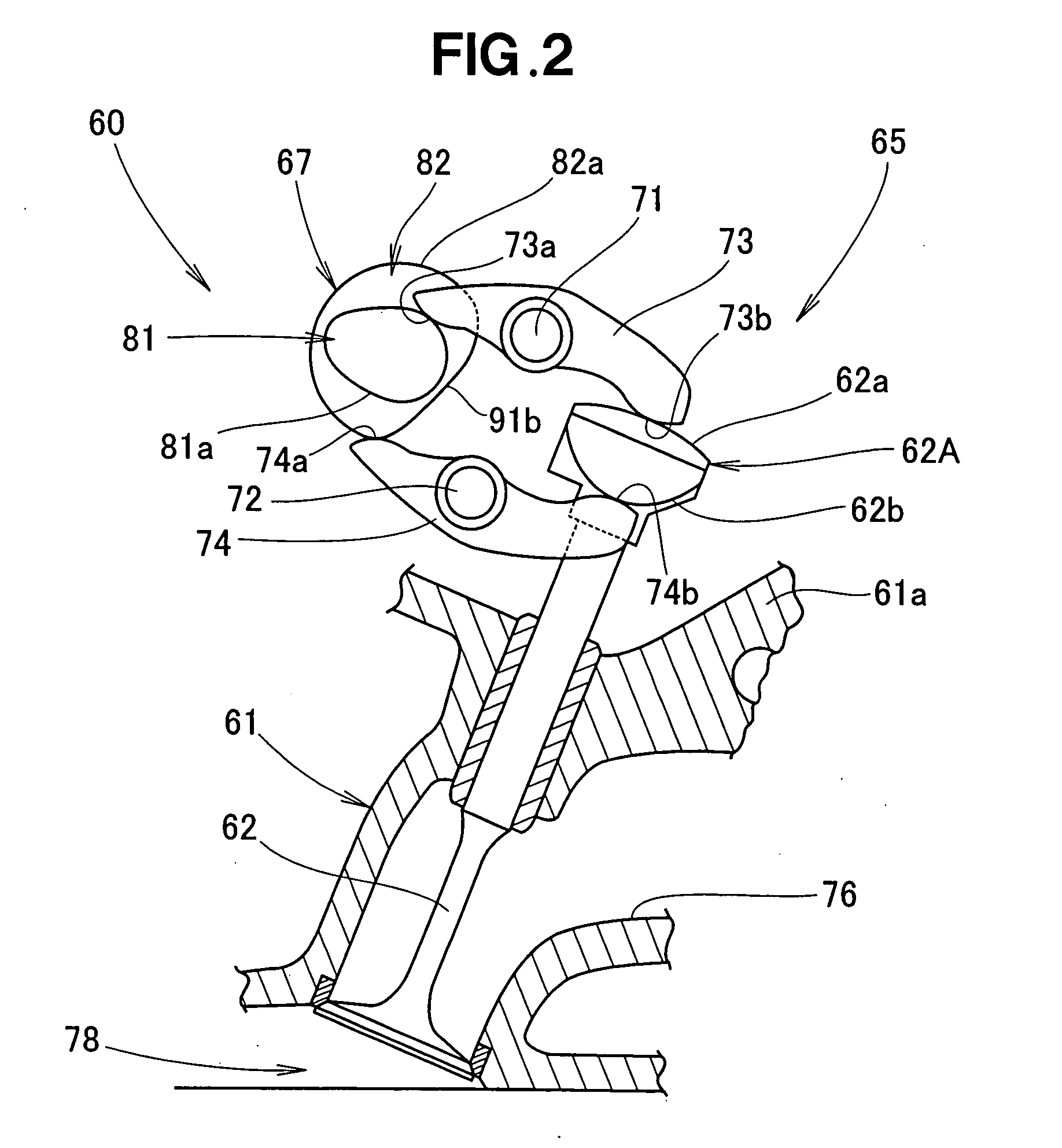

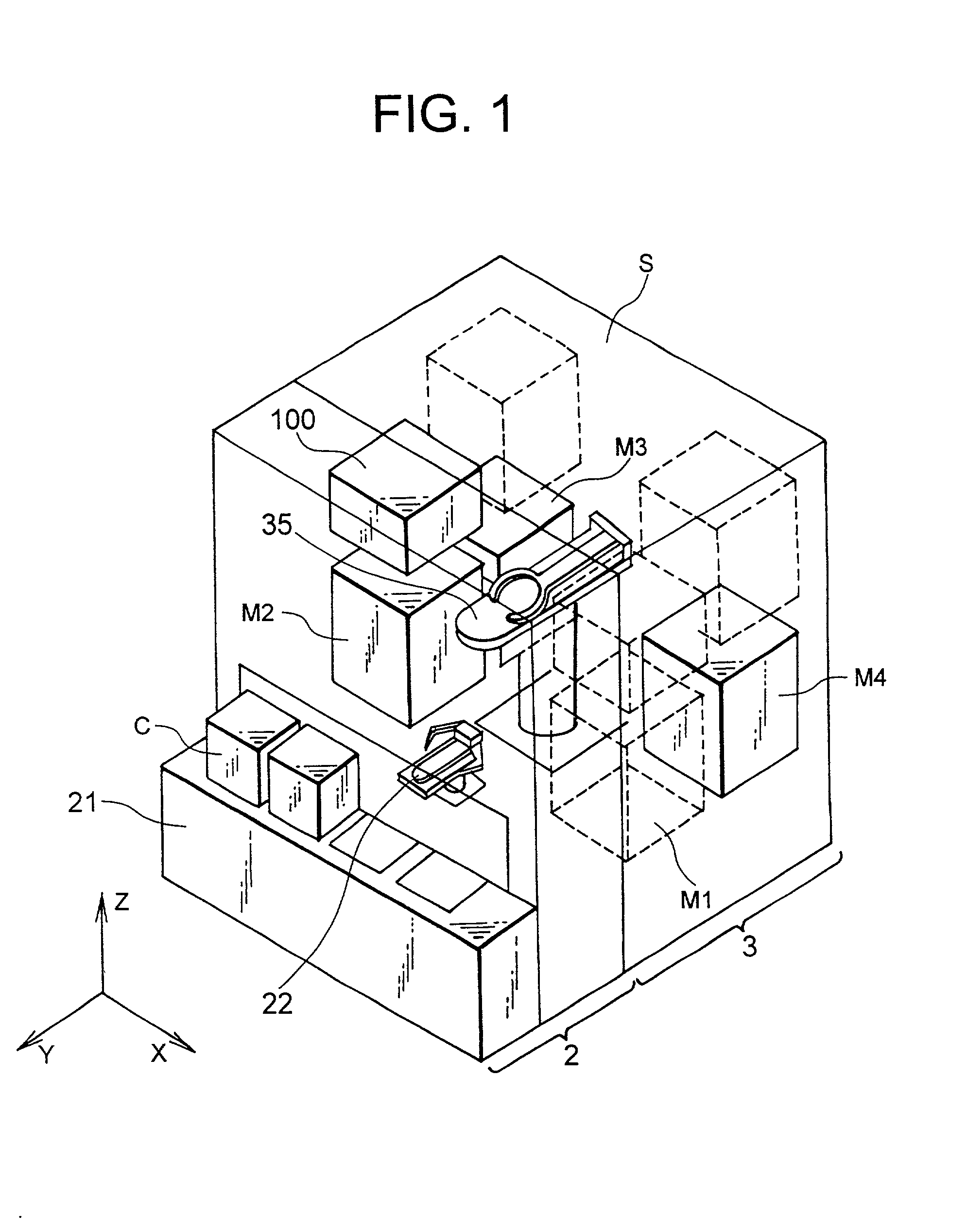

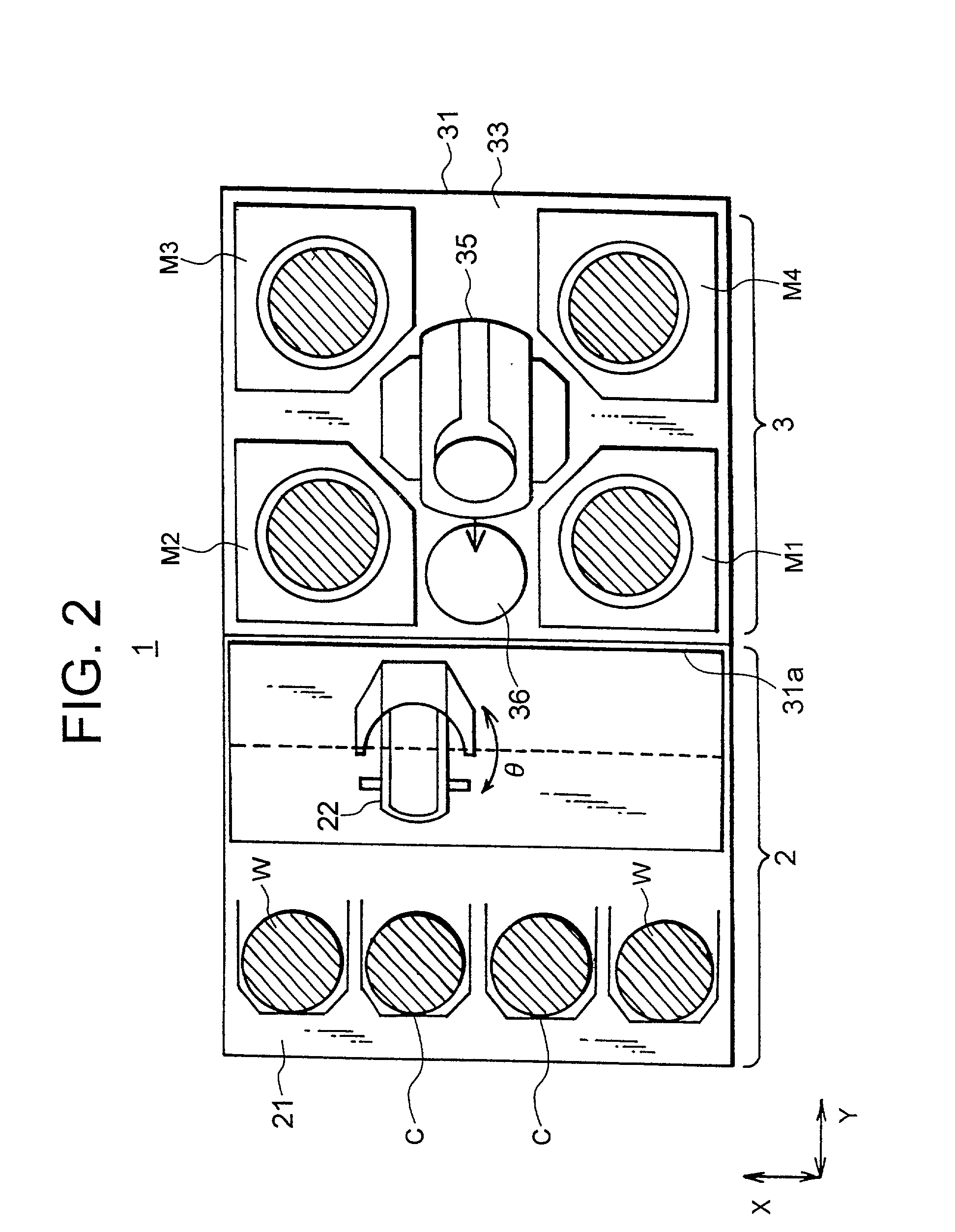

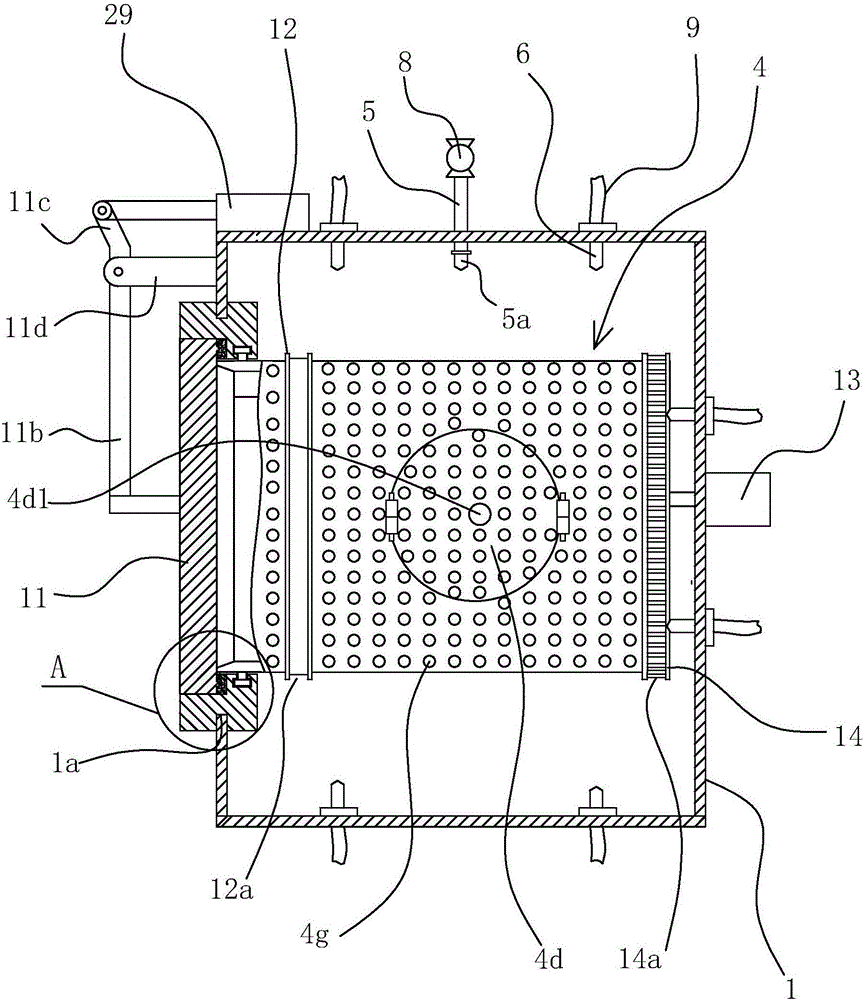

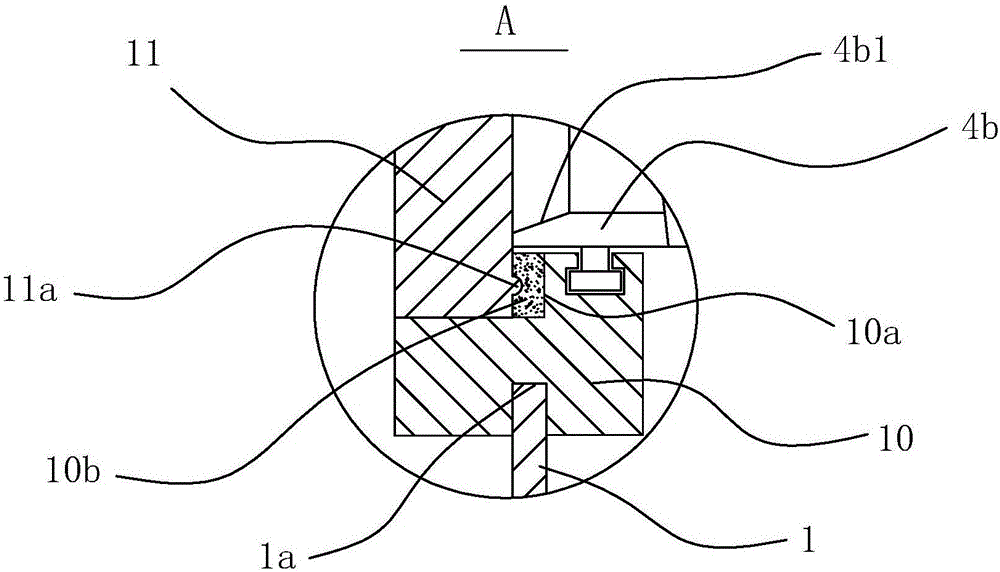

Cage for rolling bearing

InactiveUS20090060407A1Improve rigiditySmooth dischargeBall bearingsBearing componentsRolling-element bearingEngineering

A cage of the invention is equipped with a first annular portion and a second annular portion that are disposed respectively at both ends in an axial direction, and a plurality of columns which couples the first annular portion and the second annular portion to each other, and which forms a plurality of pockets in which rolling elements are accommodated. The cage is composed of a first body portion and a second body portion that are arranged in the axial direction of the bearing and that are coupled to each other via interlocking columns provided on each of the first and second body portions. At least one of the first body portion and the second body portion has an outer diameter face having recessed therein an oil groove whose base end leads to a corresponding pocket.

Owner:JTEKT CORP

Method, system and apparatus for encouraging frequent and purposeful electronic communications from caregivers to individuals with impaired memory

InactiveUS7958201B2Facilitate communicationSimplified user interfaceMedical communicationData processing applicationsCaregiver personWeb application

A computer implemented system and method for encouraging frequent and purposeful electronic communications from caregivers to individuals with impaired memory to, inter alia, alleviate feelings of isolation and improve memory. The system includes a Web-based application through which caregivers send text, image, voice and other forms of data for receipt by the sufferer on a PDA having a simple user interface. The Web application records the dates and nature (i.e., text, audio, photograph, video) of communications sent by each caregiver, processes the data in order to display it in a variety of meaningful ways to all caregivers, thus creating a peer-pressure environment to encourage more frequent communication. The Web application can also be programmed to send electronic reminders to all caregivers who opt-in to the service requesting that they send a communication to the sufferer, and more particularly to individual caregivers whose frequency of communication has been inadequate relative to a group of caregivers or to predefined expectations.

Owner:LINDSAY TED

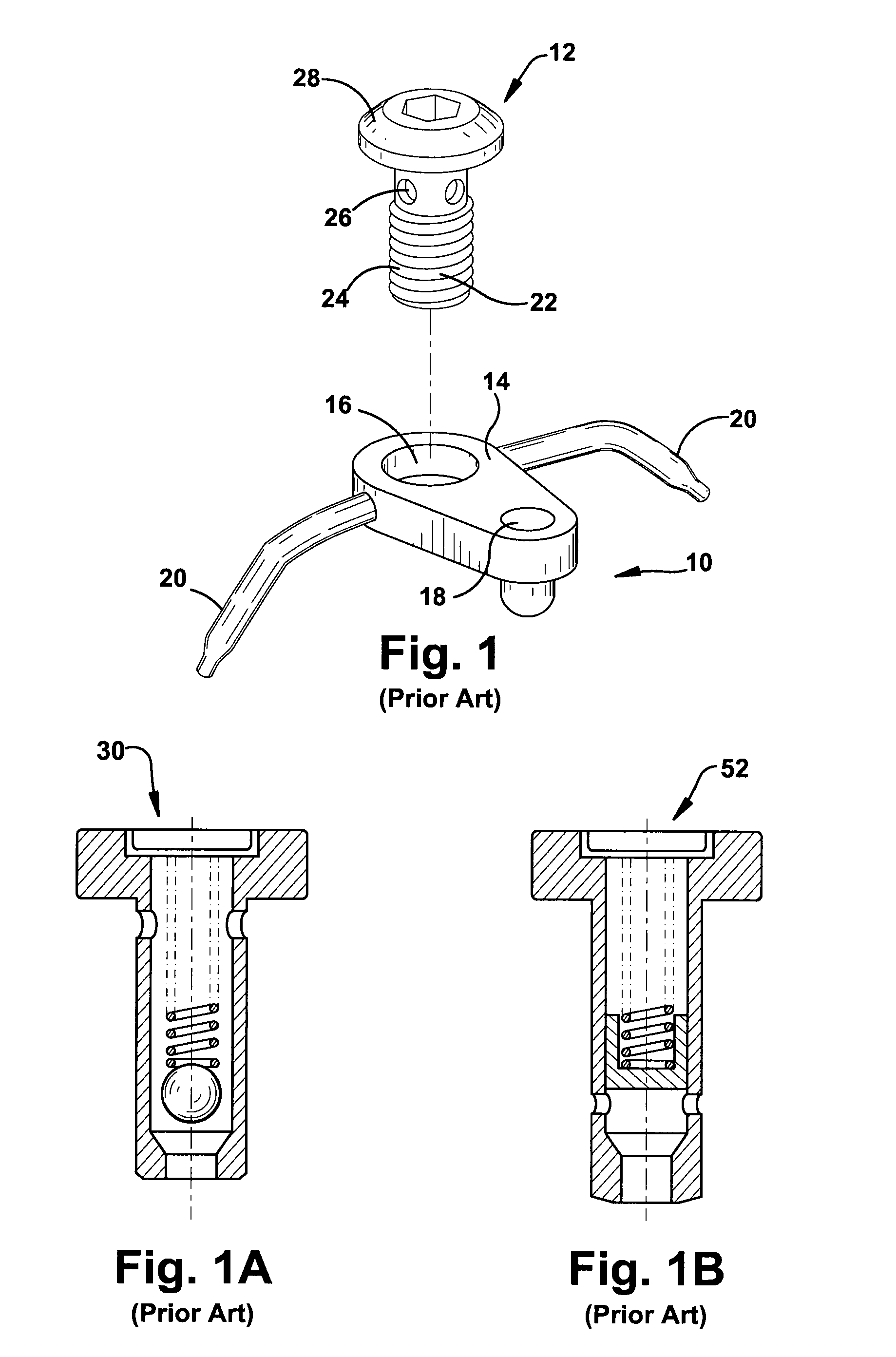

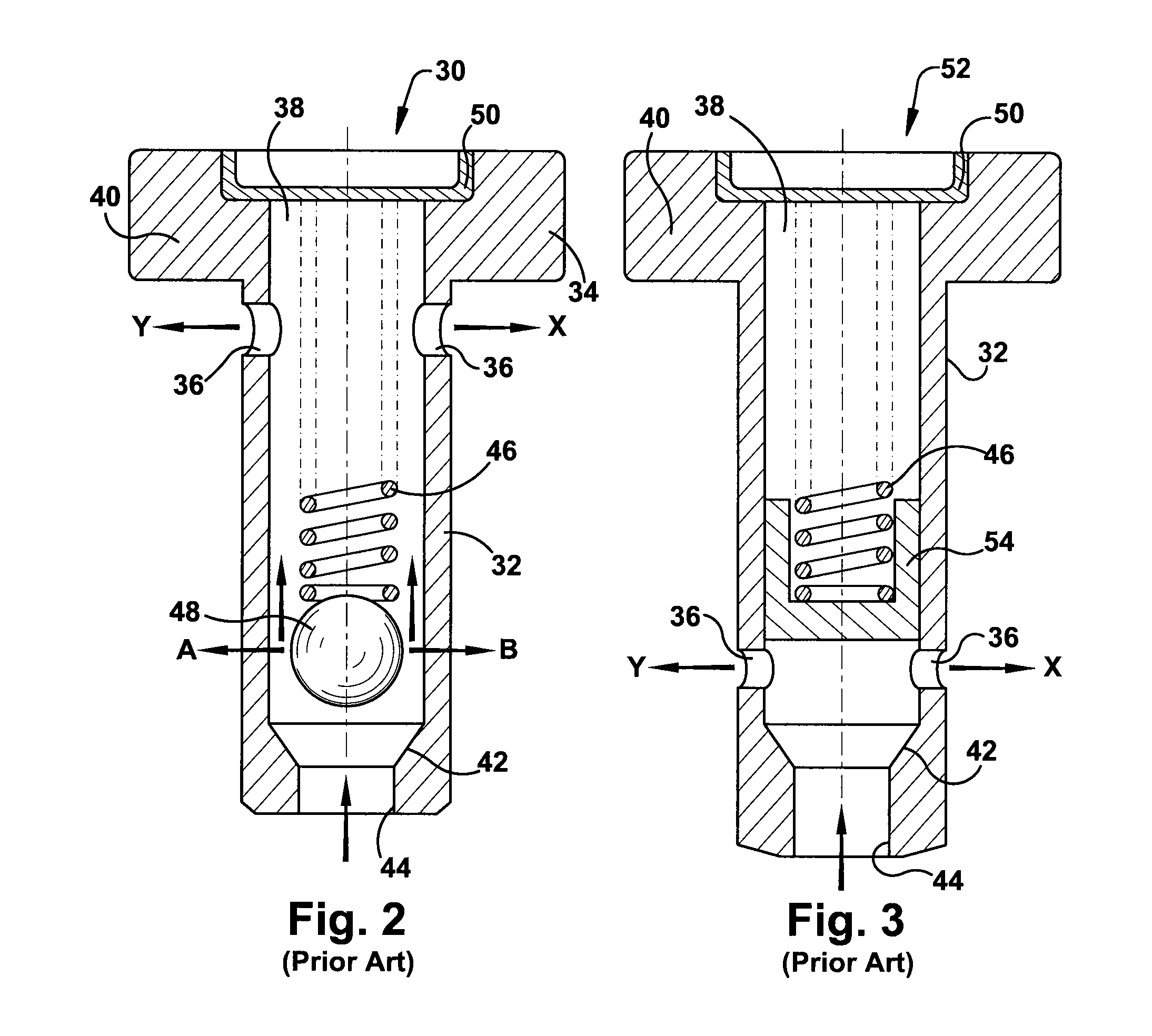

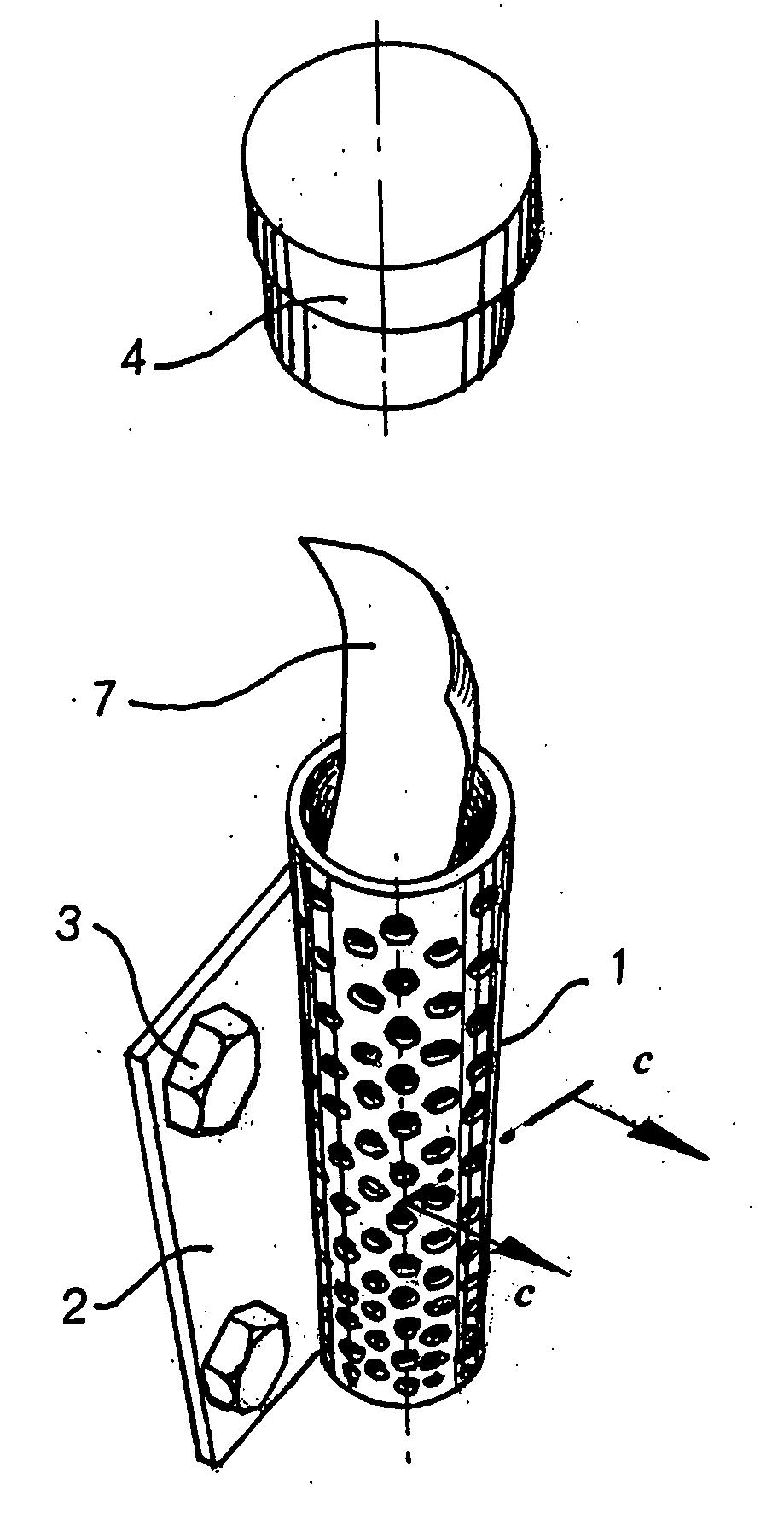

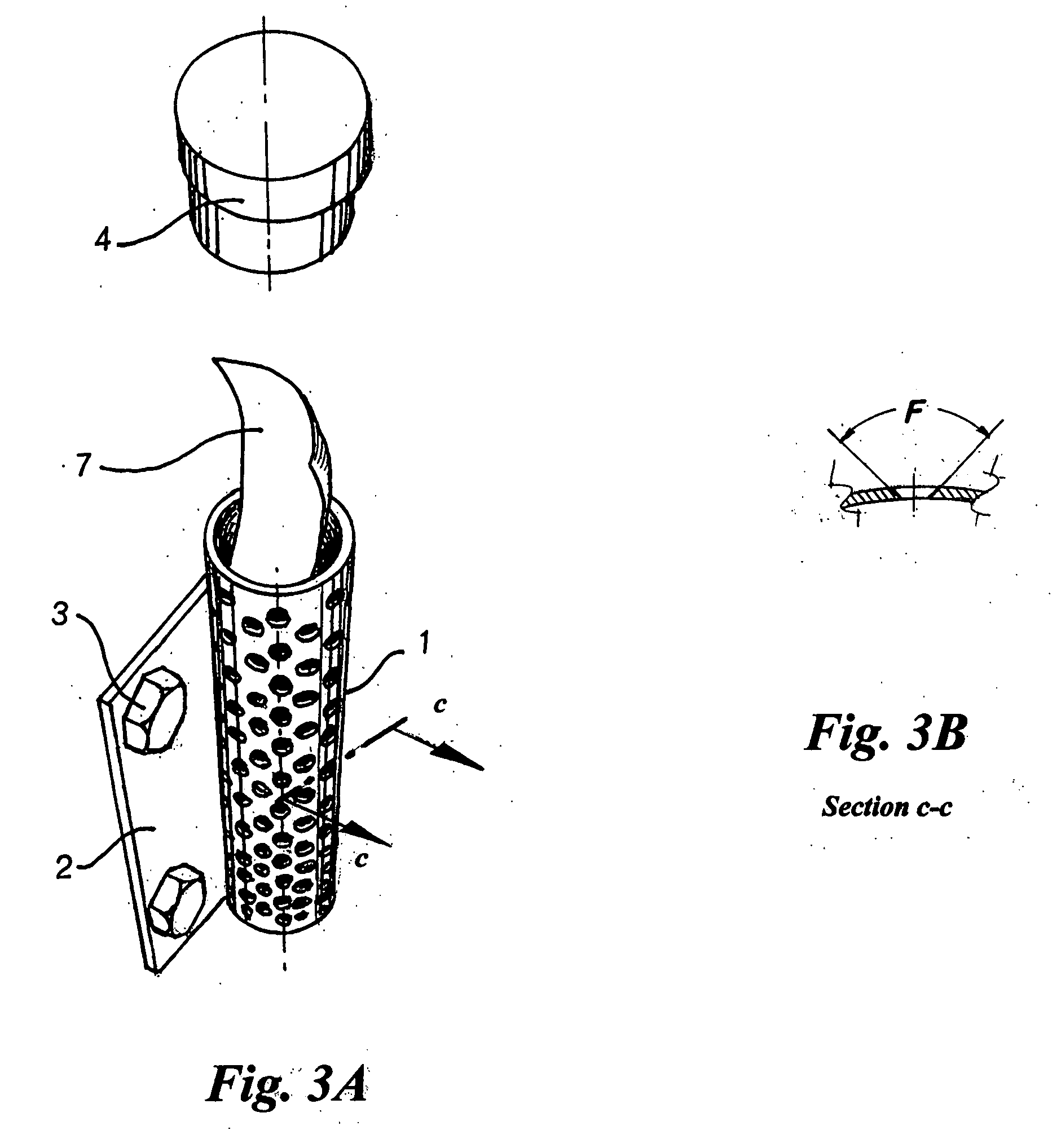

Safeguard for bio-indicators in medical waste autoclaves

InactiveUS20080063580A1Effective protectionReduce agitationMedical waste disposalGrain treatmentsInternal rotationBiomedical engineering

A bio-indicator carrier mounted on one of the rotating members in the interior of a shredding-type autoclave for use in the disintegration and sterilization of medical waste.

Owner:VON LERSNER WOLF A

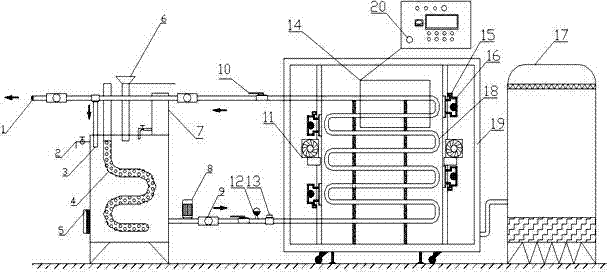

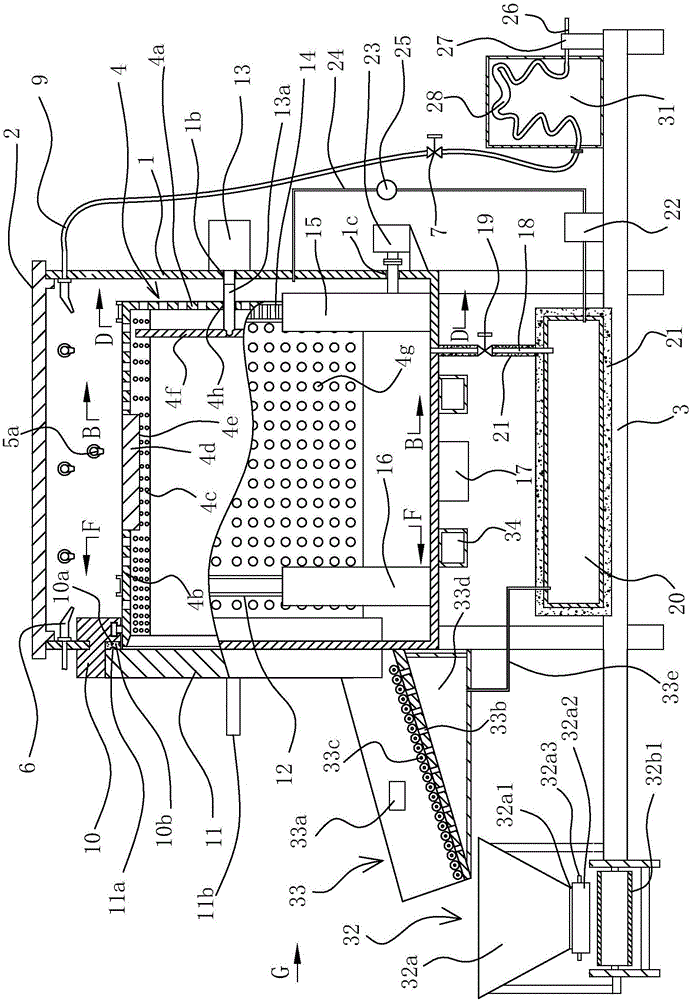

Microwave catalytic oxidation apparatus for landfill leachate treatment

InactiveCN103880229AImprove cooling efficiencyExtended service lifeWater/sewage treatment by irradiationMultistage water/sewage treatmentAutomatic controlTransformer

The invention discloses a microwave catalytic oxidation apparatus for landfill leachate treatment. The microwave catalytic oxidation apparatus mainly comprises a mixed water tank, a microwave reactor, a water cooling device, a circulating system and an automatic control system, wherein an overflow valve, a water inlet and a dosing tank are arranged on the upper part of the mixed water tank, and a water level indicator and an aeration pipe are arranged in the mixed water tank; the microwave reactor is surrounded by a housing, an outer wire, a magnetron, a transformer and a coil pipe are arranged in the microwave reactor, and the microwave reactor is connected with a cooling system; the circulating system is provided with a forward connecting pipe and a backward connecting pipe, the two of which are connected with the mixed water tank and the microwave reactor, and the connecting pipes are connected to the lower end of the coil pipe of the microwave reactor; the backward connecting pipe is provided with a water outlet and a circulating water pipe, and the circulating water pipe is communicated with the mixed water tank; and the microwave reactor and the water cooling device are connected with the automatic control system. The microwave catalytic oxidation apparatus is applied to landfill leachate treatment, and is high in microwave utilization rate, long in service life of the magnetron, good in leachate treatment effect, and also can be automatically controlled.

Owner:GUANGDONG UNIV OF TECH +2

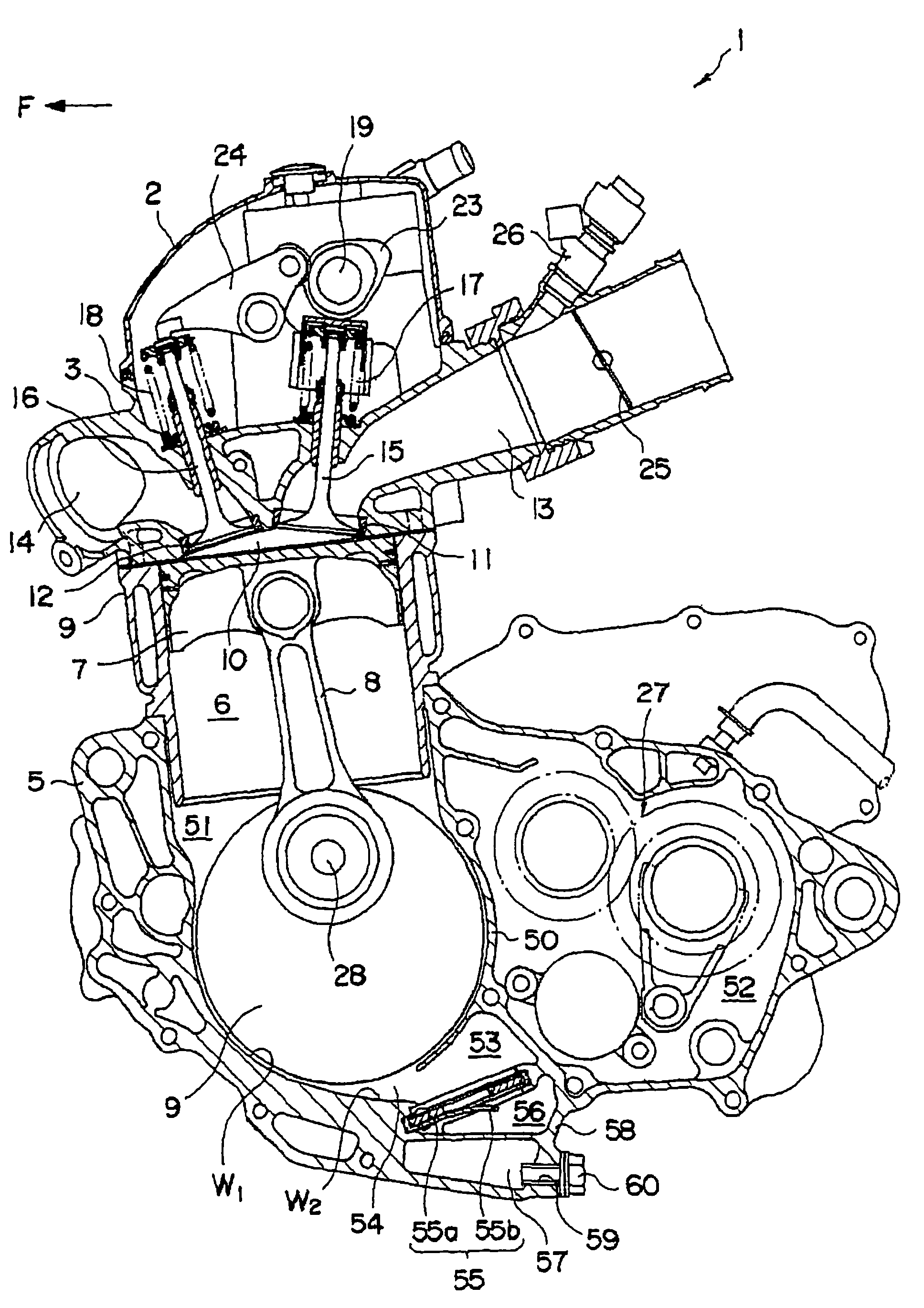

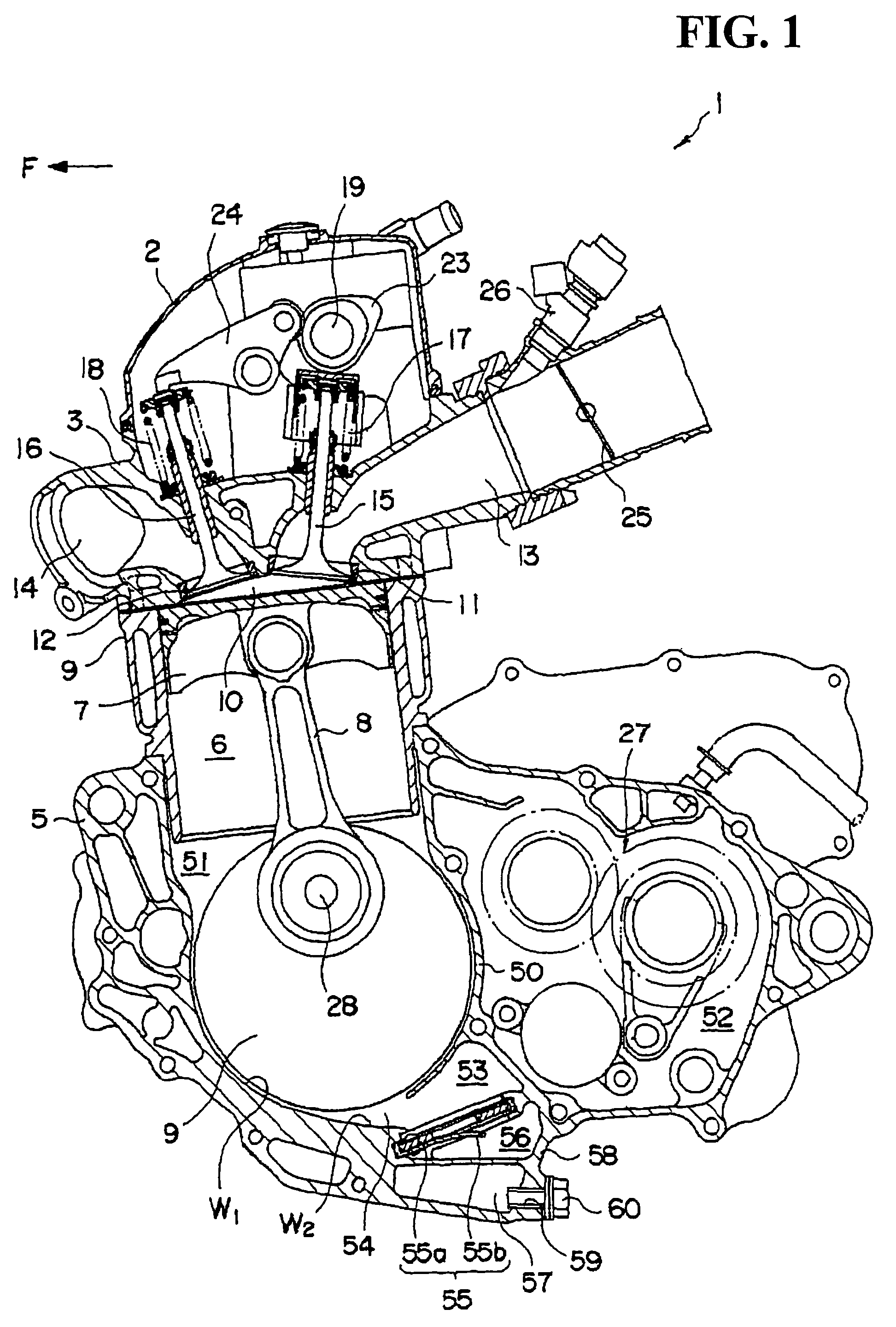

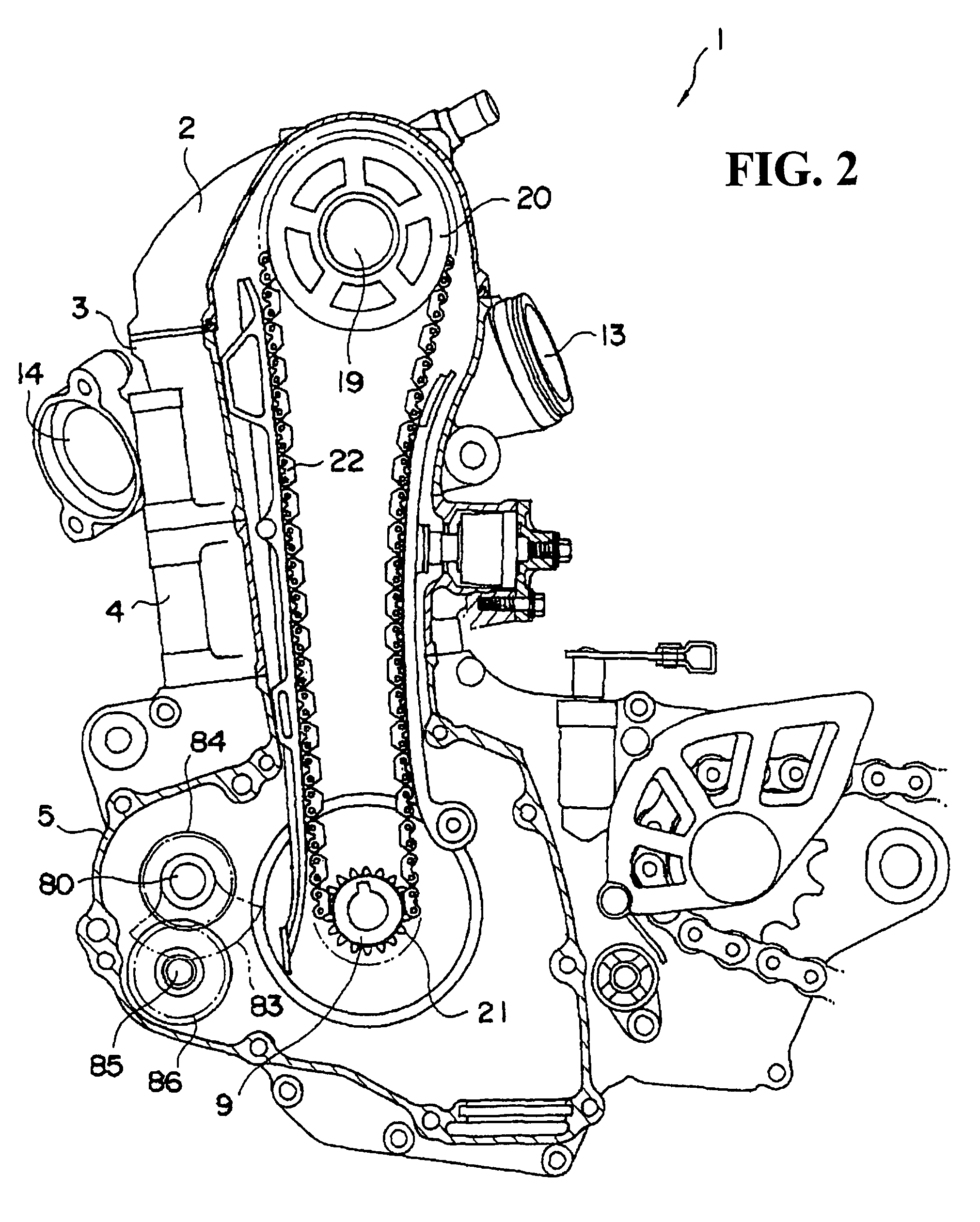

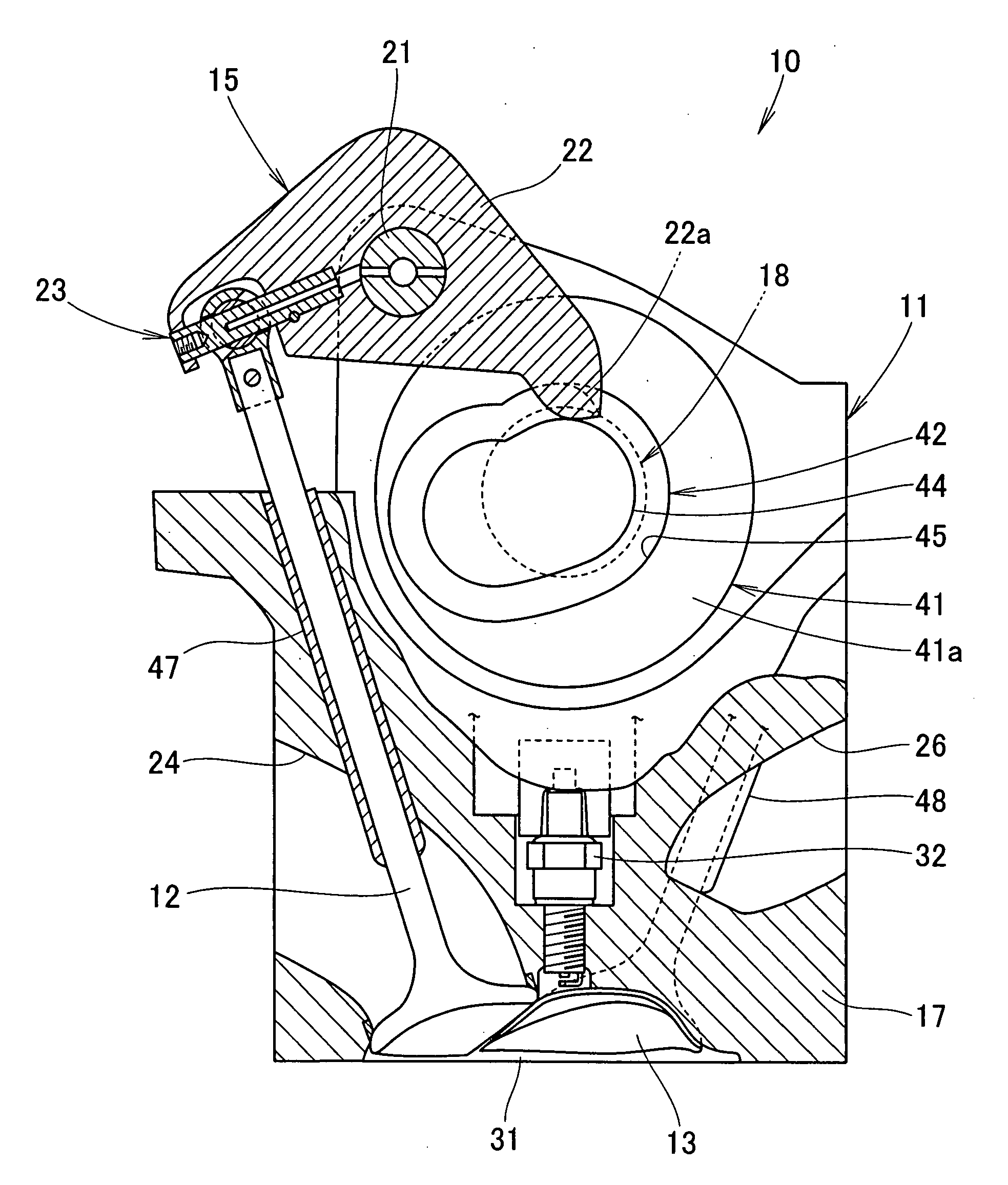

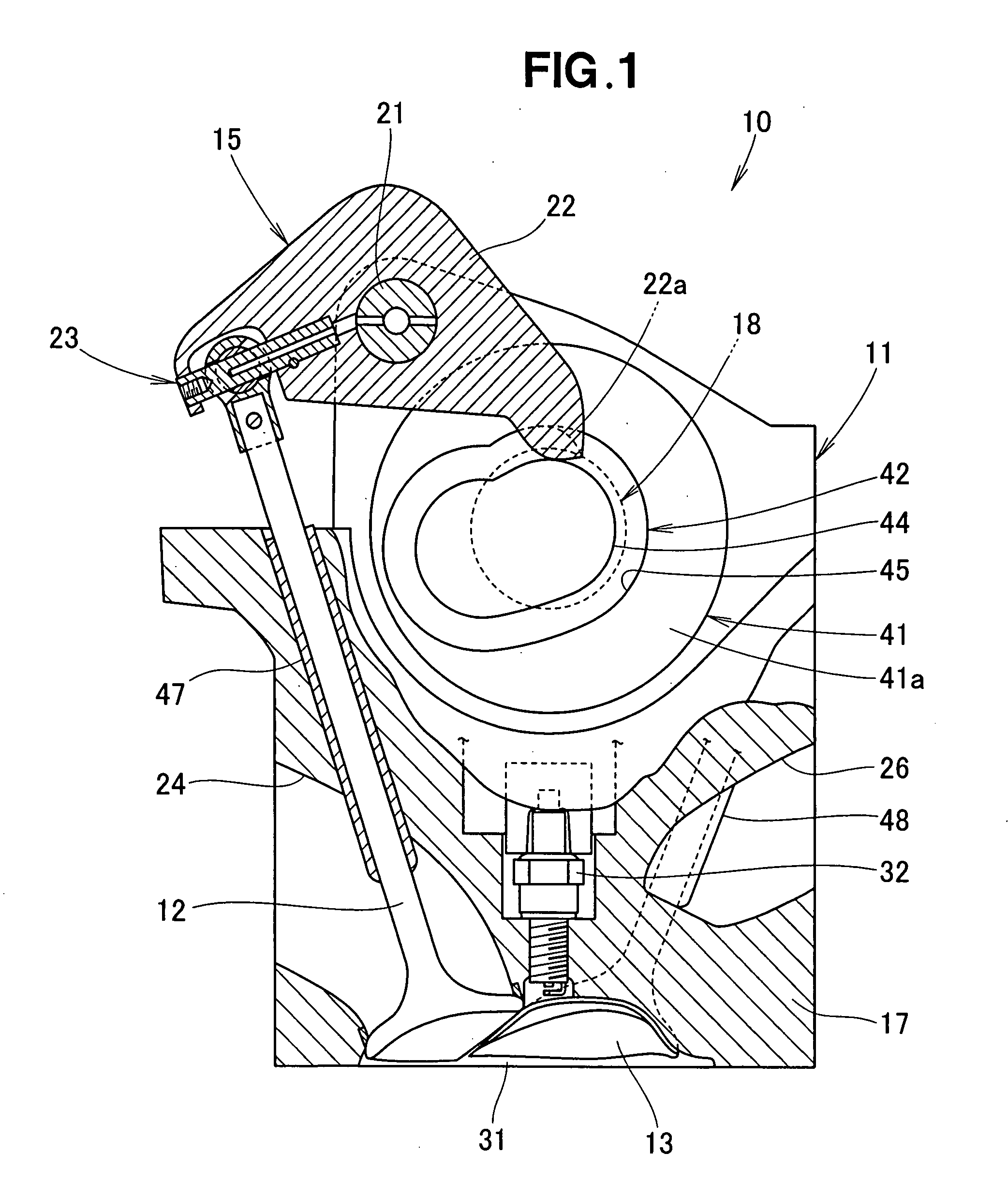

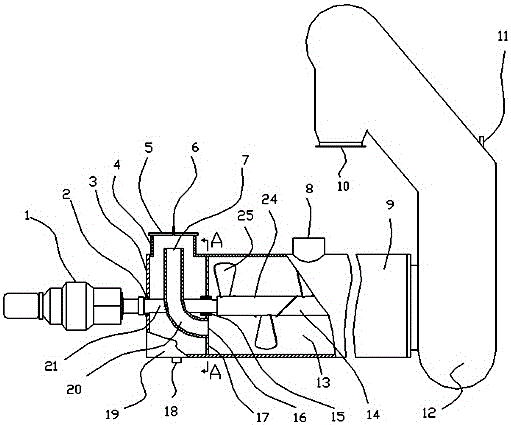

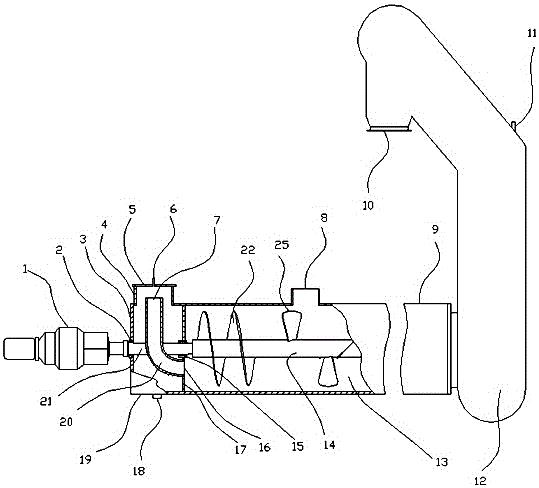

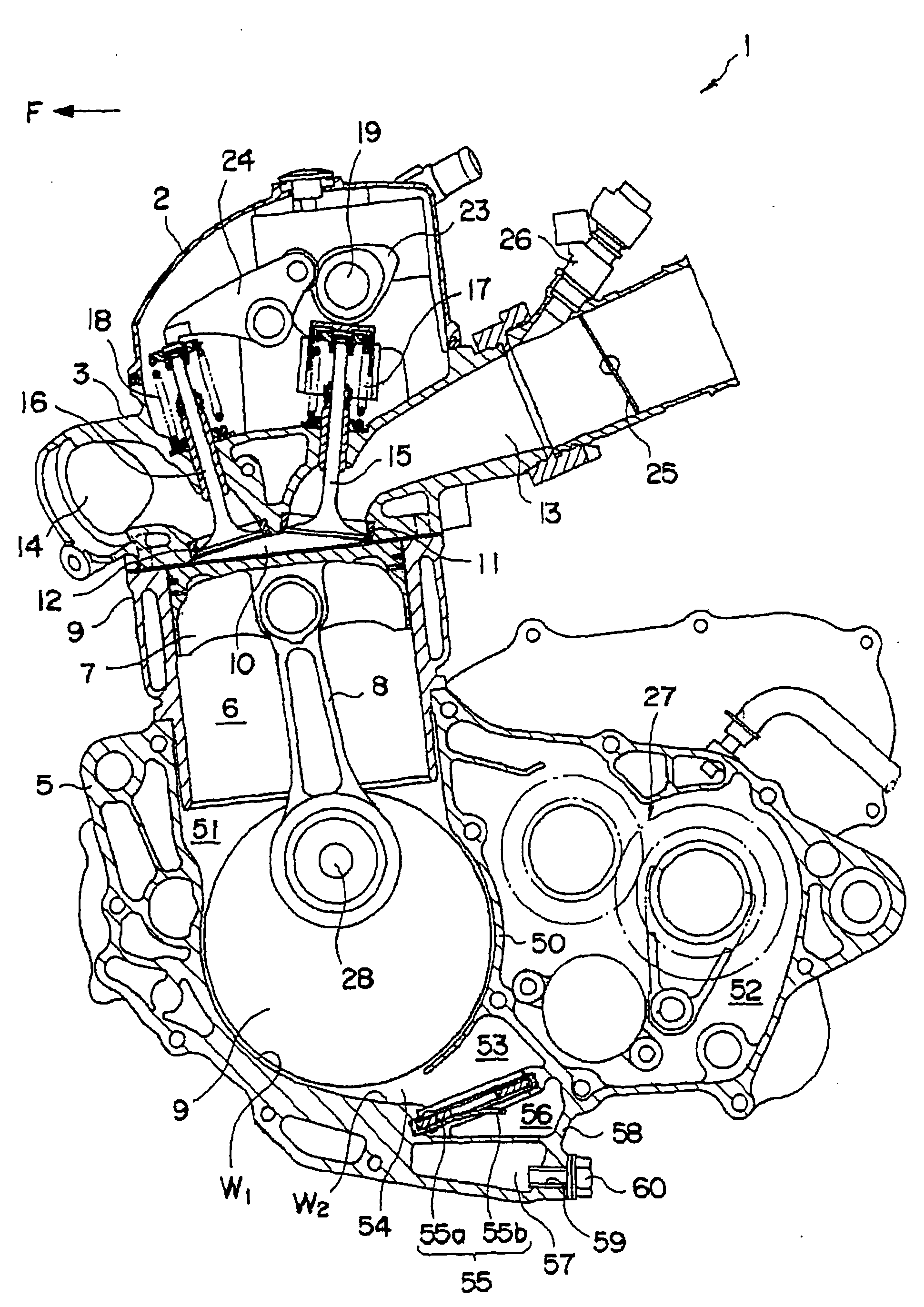

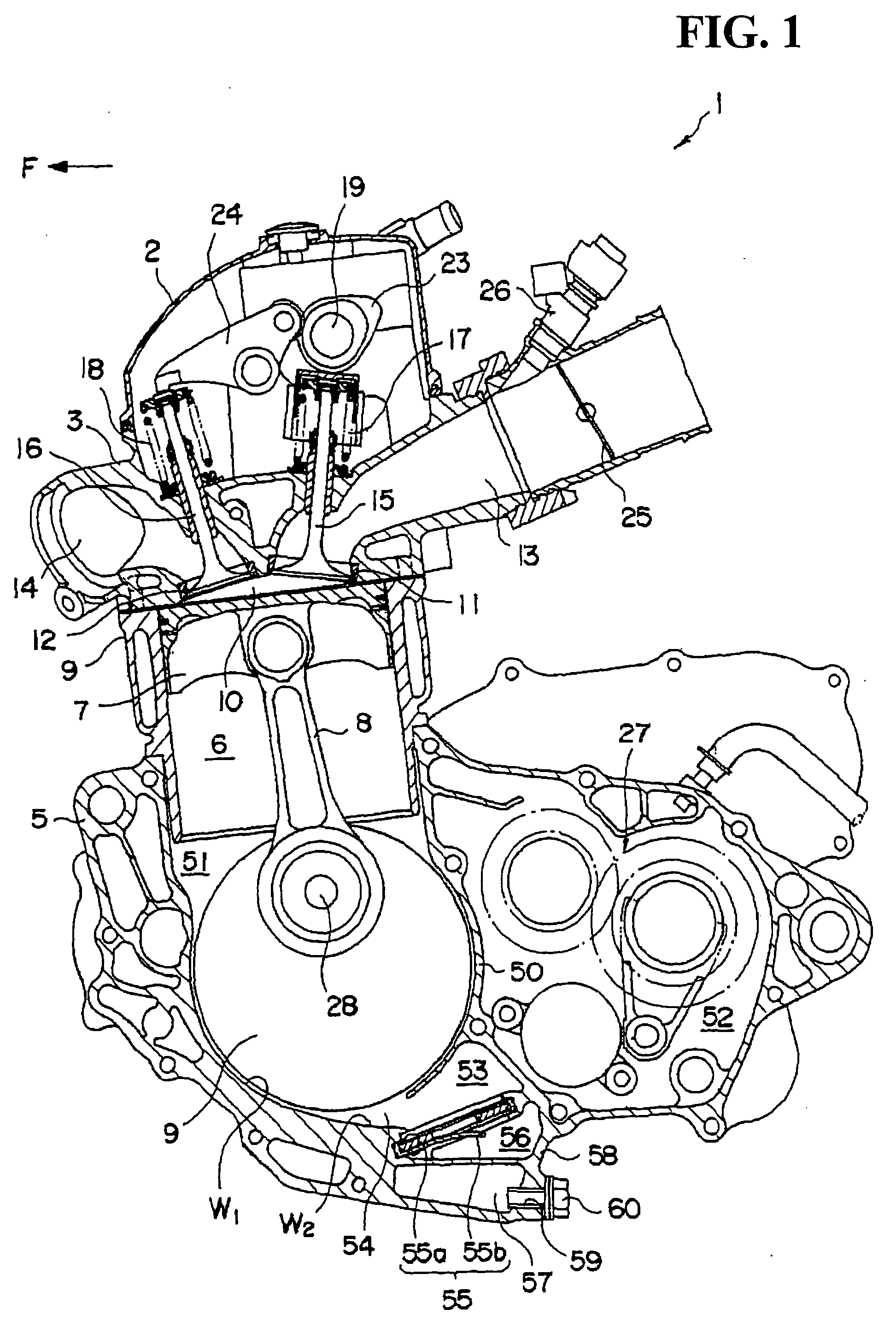

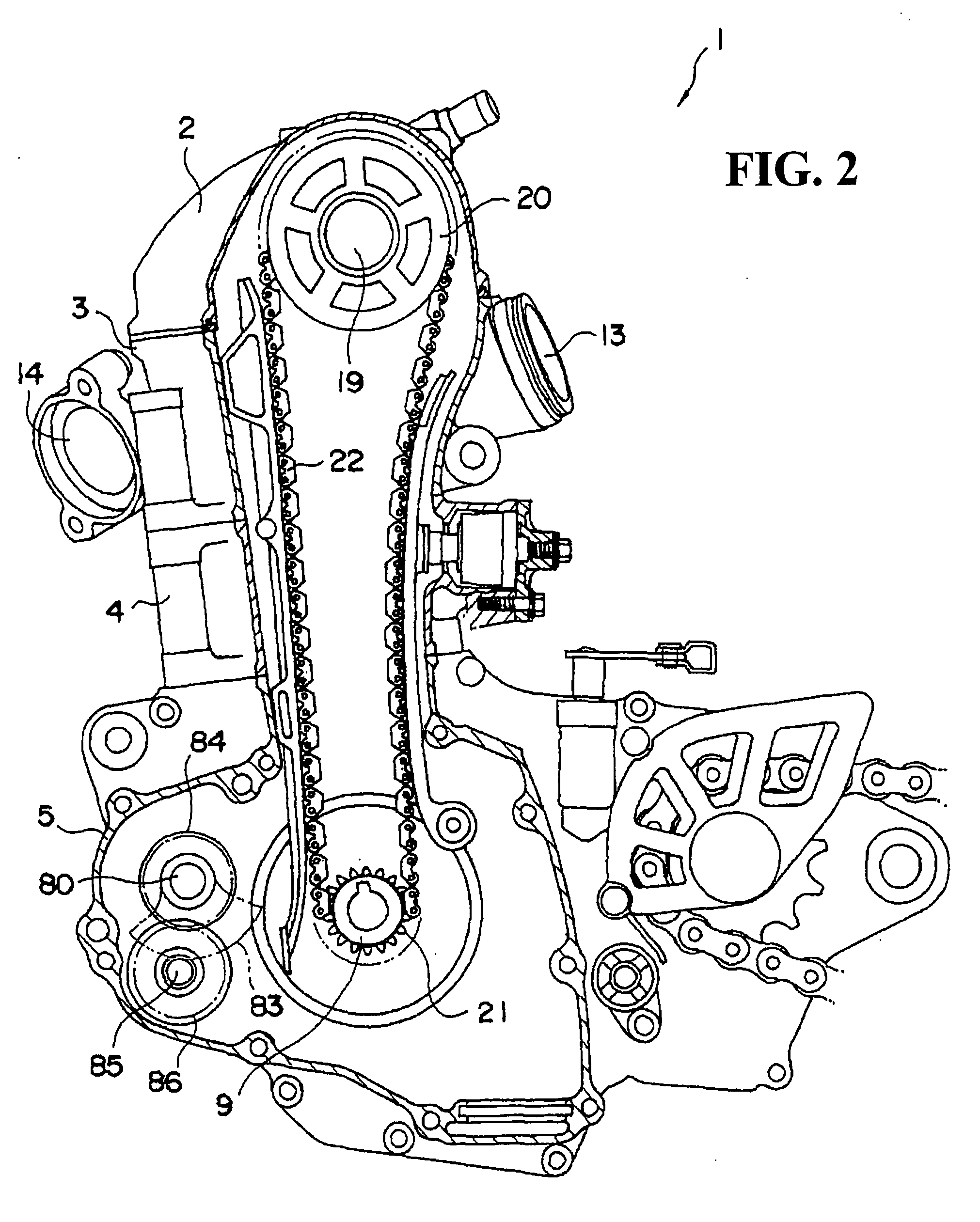

Lubrication structure of engine

ActiveUS7395804B2Reduce agitationSpeed up the flowLubrication of auxillariesLubricant conduit arrangementsEngineeringReed valve

The lubrication structure of an engine is provided with a crankcase having a crank chamber that houses a crankshaft. A first oil reservoir is in communication with the crank chamber and is formed adjacent a bottom of the crank chamber. A second oil reservoir is in communication with the first oil reservoir and is formed adjacent the side of and on the bottom of the first oil reservoir. A reed valve extends diagonally from the bottom of the first oil reservoir toward the top of the second oil reservoir in an opening where the first oil reservoir and the second oil reservoir communicate with the crankcase. The reed valve includes a valve element that opens and closes according to the variation of pressure in the crank chamber. The valve element of the reed valve is arranged on the side of the second oil reservoir.

Owner:HONDA MOTOR CO LTD

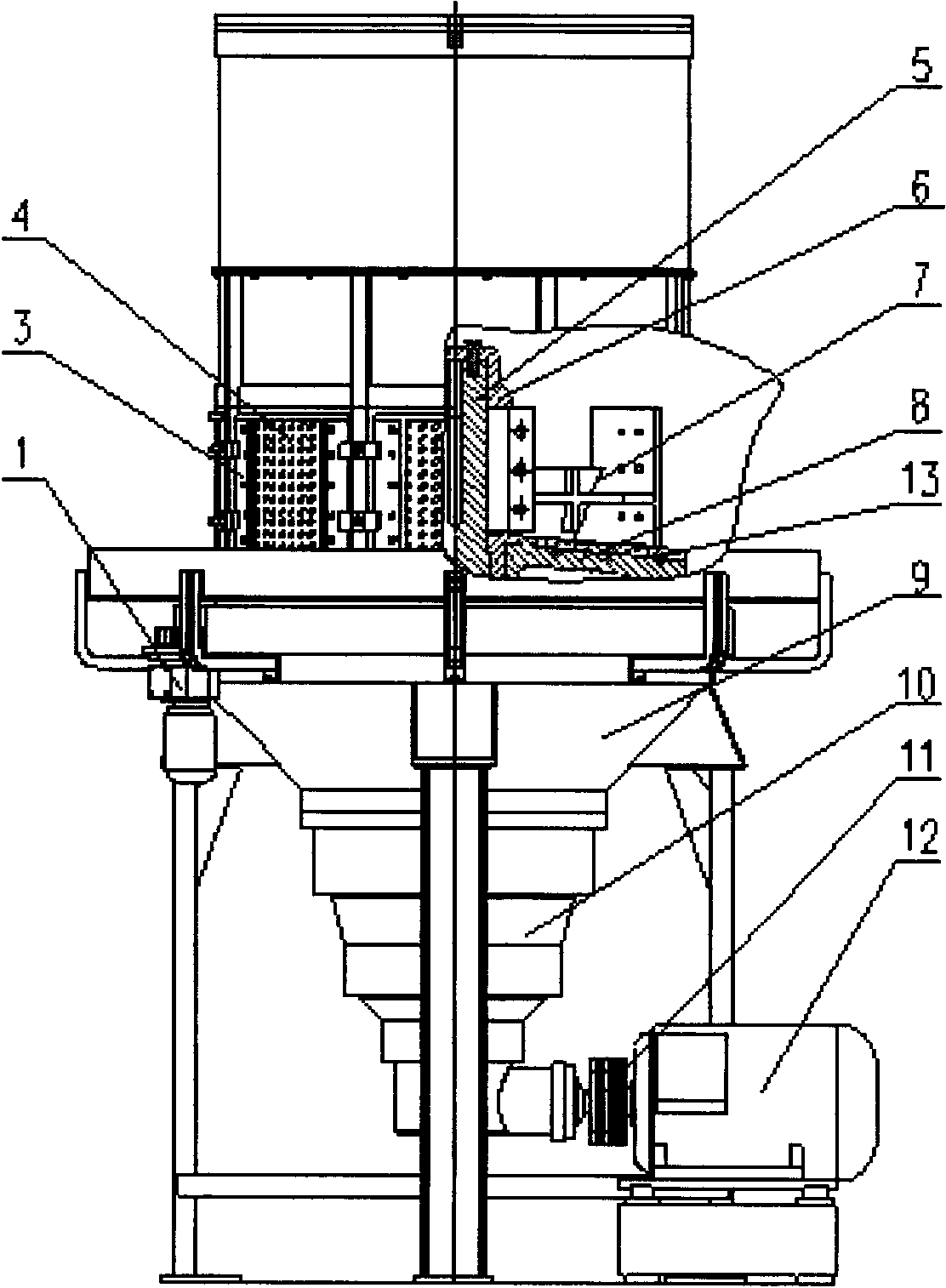

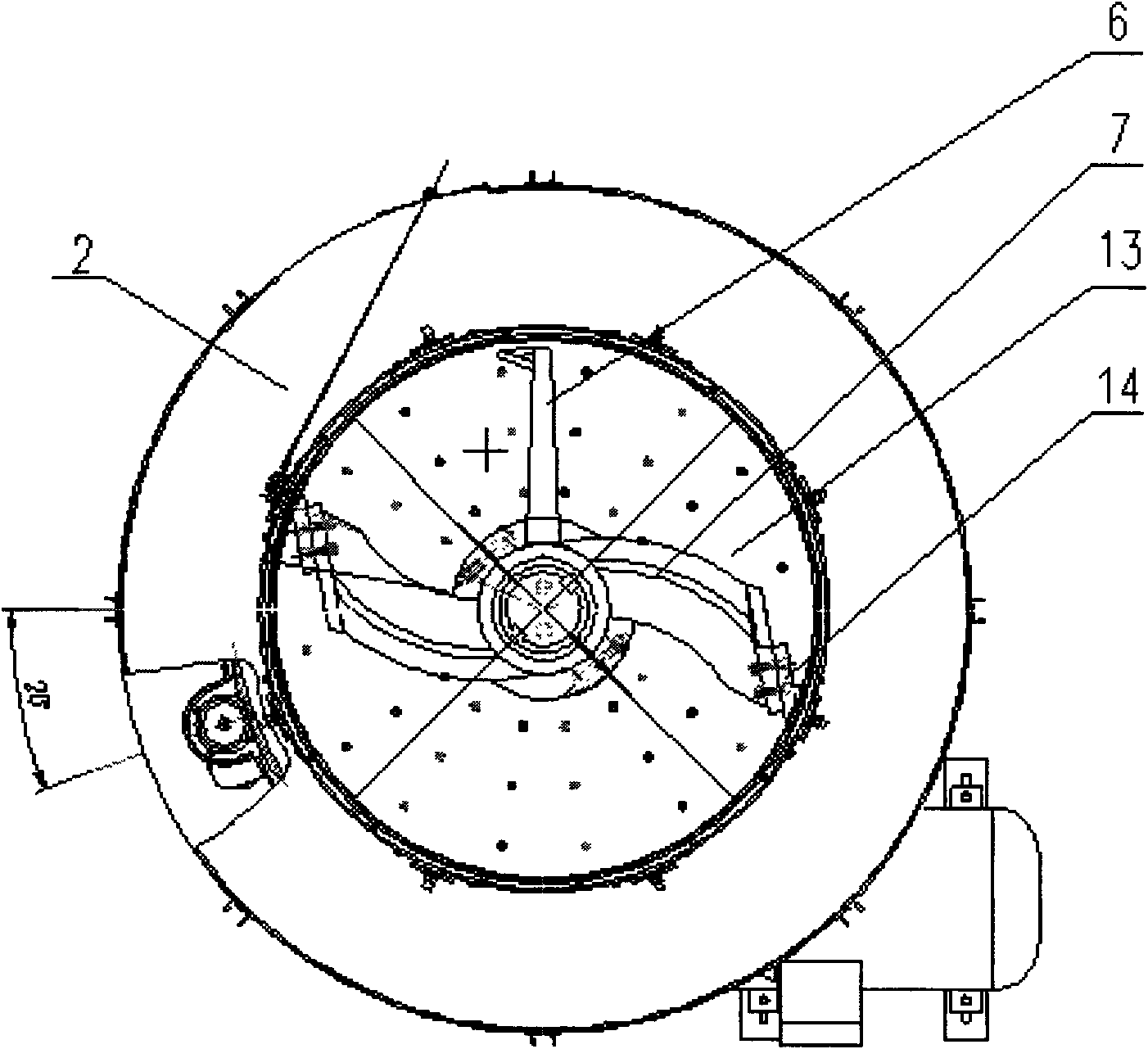

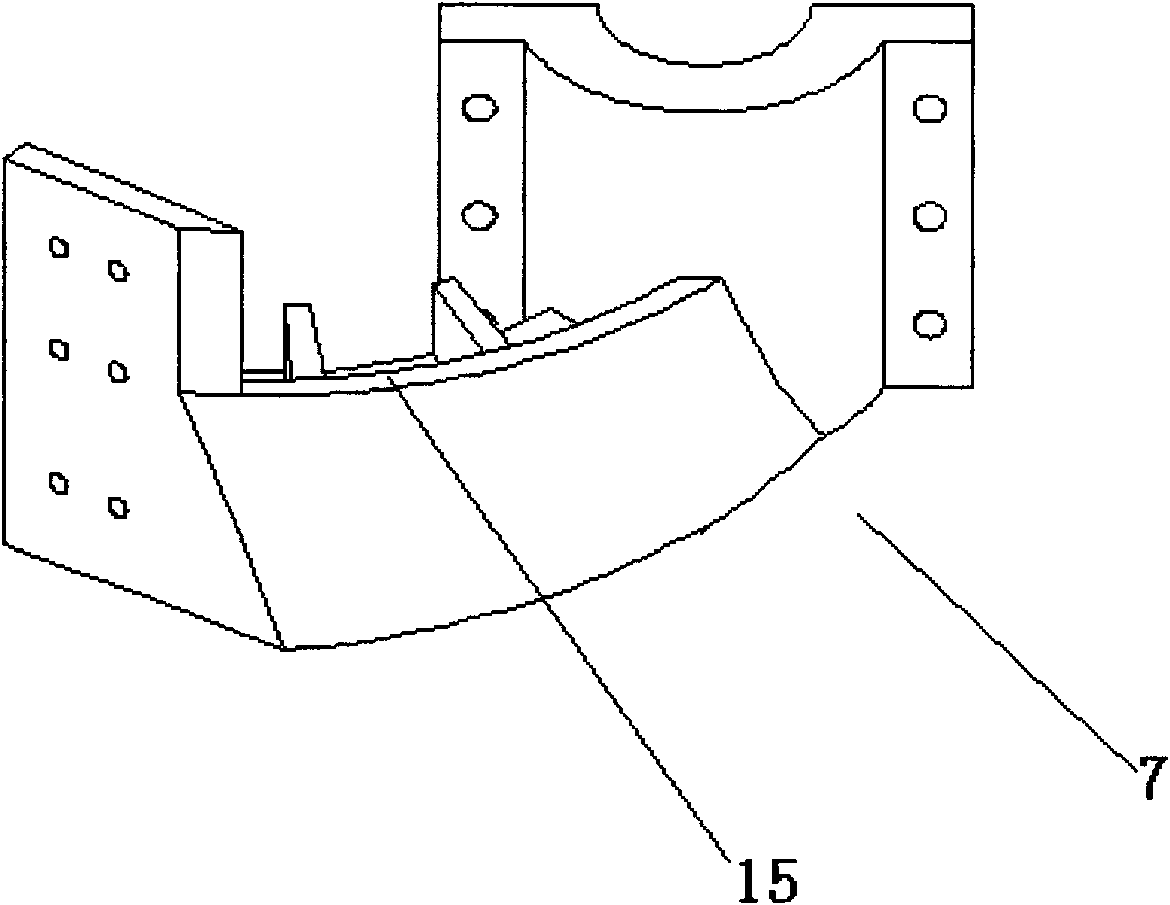

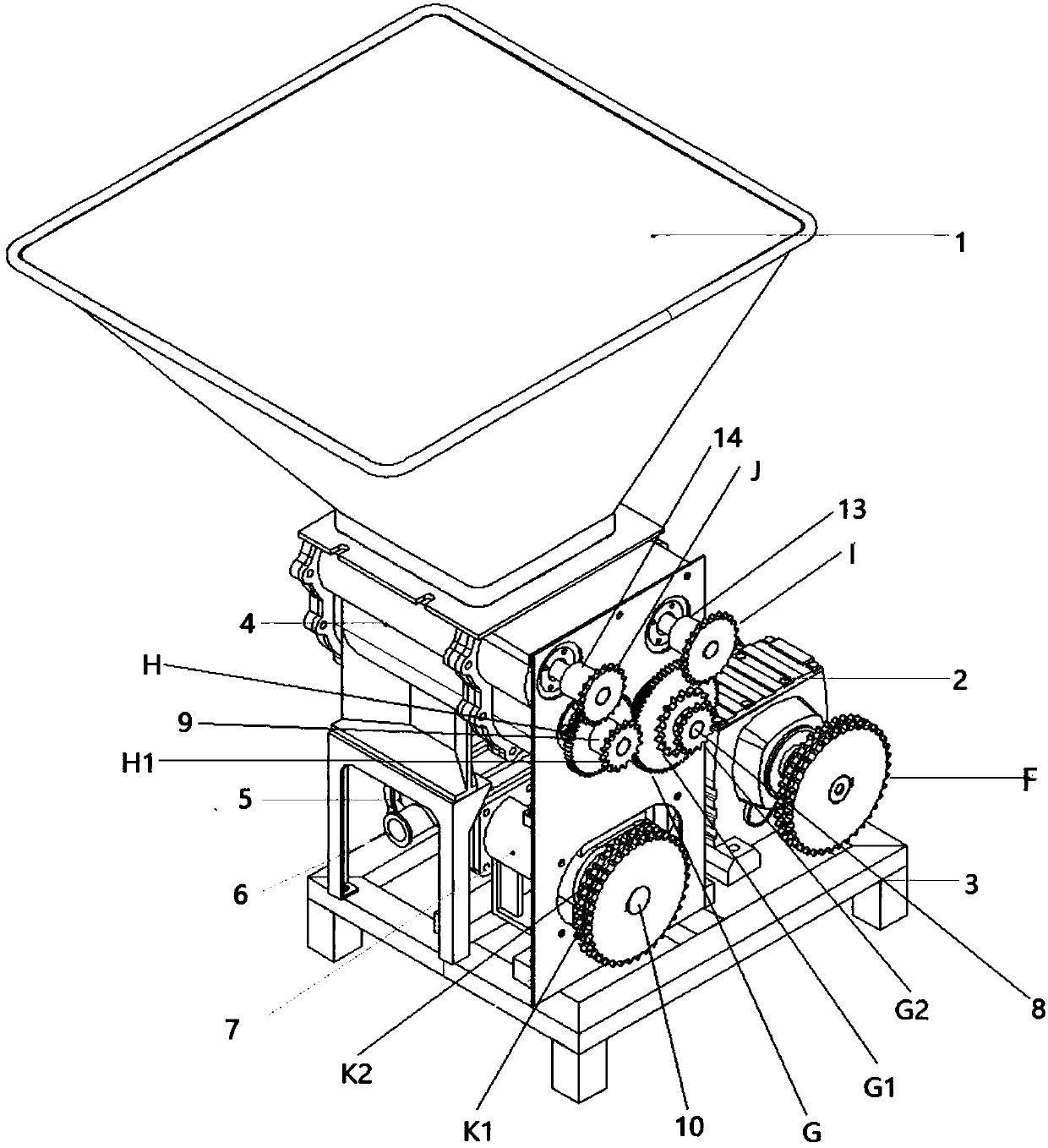

Stirring disc screen type feeding machine

The invention relates to a stirring disc screen type feeding machine which comprises a scraping arm and two extruding arms, wherein the scraping arm and the extruding arms are respectively fixedly connected to a spindle; the spindle is driven to rotate by a reduction box; the output flange of the reduction box is fixedly connected to a base, and simultaneously the reduction box is connected to a motor through a belt wheel system; and the front ends of the extruding arms are provided with wear-resisting plates, so that when a material is conveyed to a material barrel and reaches a certain height, the material can be extruded out of the material barrel under the combined action of the wear-resisting plates and a gridding plate arranged on the material barrel. The stirring disc screen type feeding machine is used for easily turning and stirring the material, fully mixing and homogenizing the material, easily gathering the material towards the inner wall of the material barrel and quicklyextruding the material. After the material is extruded out of the material barrel, the material falls onto a collecting plate which rotates under the driving of a reduction motor, thereby conveying the material to a discharging port. The stirring disc screen type feeding machine has the advantages of material stirring function, good mixing and homogenizing effect, small abrasion of extruding arm,long service life, less possibility of material drying, high production efficiency, and the like..

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

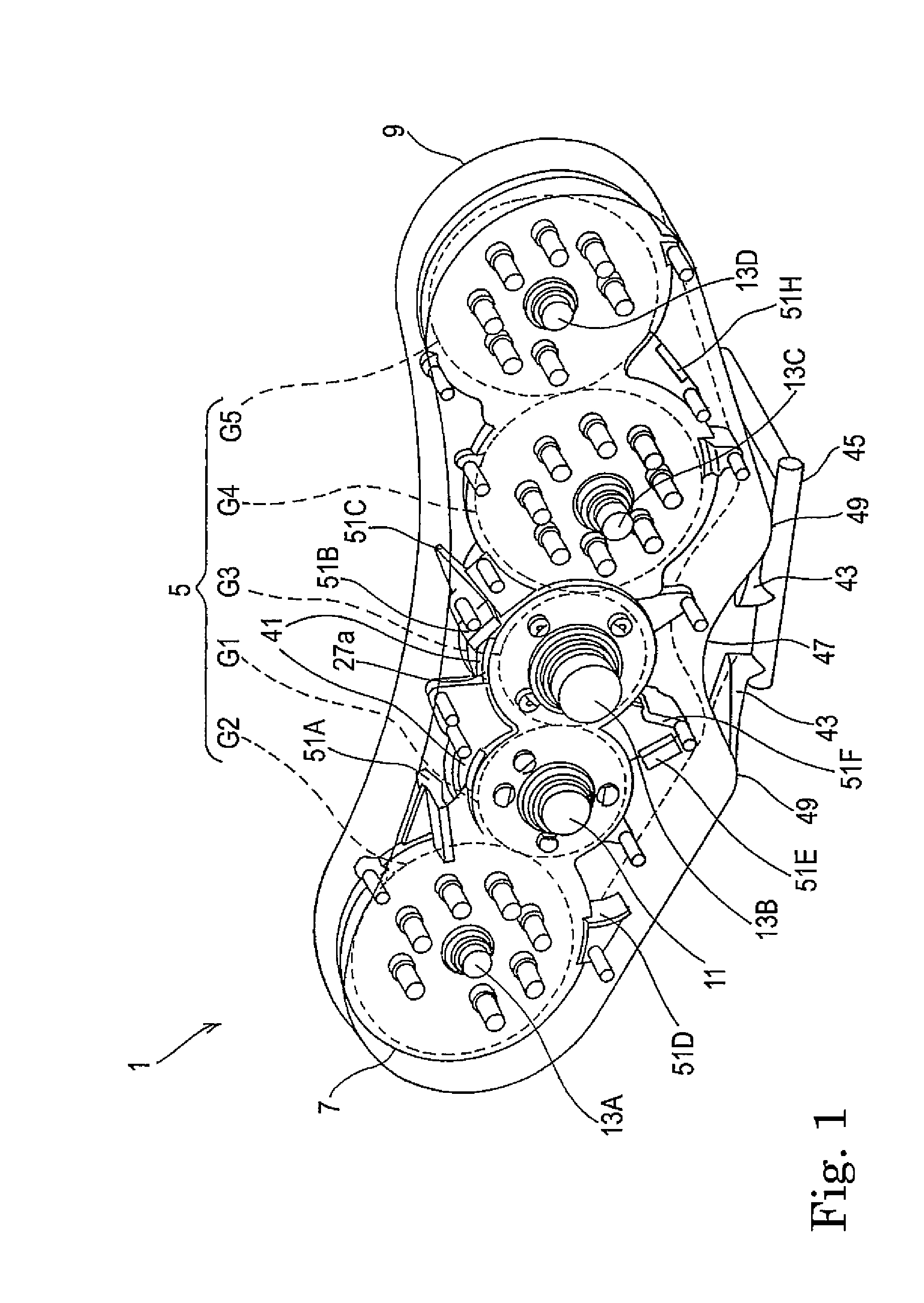

Gear train lubricating device

ActiveUS20130180803A1Suppress power lossAvoid stagnationGear lubrication/coolingWind energy generationGear wheelEngineering

A lubricating device for a gear train (5) including a plurality of gears meshing with each other includes a shroud (7) configured to cover the gear train (5) and a housing (9) configured to cover the shroud (7). The shroud (7) includes: an oil supply nozzle (25) configured to supply oil (OL) to a meshing position (21) of the gear train (5); and oil-drain ports (41) through which the oil (OL) is discharged from the shroud. The housing (9) includes, at its lower part, a draw-out port (43) through which the oil (OL) discharged from the oil-drain ports (41) is drawn to the outside of the housing. Guide members (47) are provided between the shroud (7) and the housing (9). The guide members (47) guide the oil (OL) discharged from the respective oil-drain ports (41) of the shroud (7) such that the oil (OL) flows downward through space (S) between the shroud (7) and the housing (9).

Owner:KAWASAKI HEAVY IND LTD

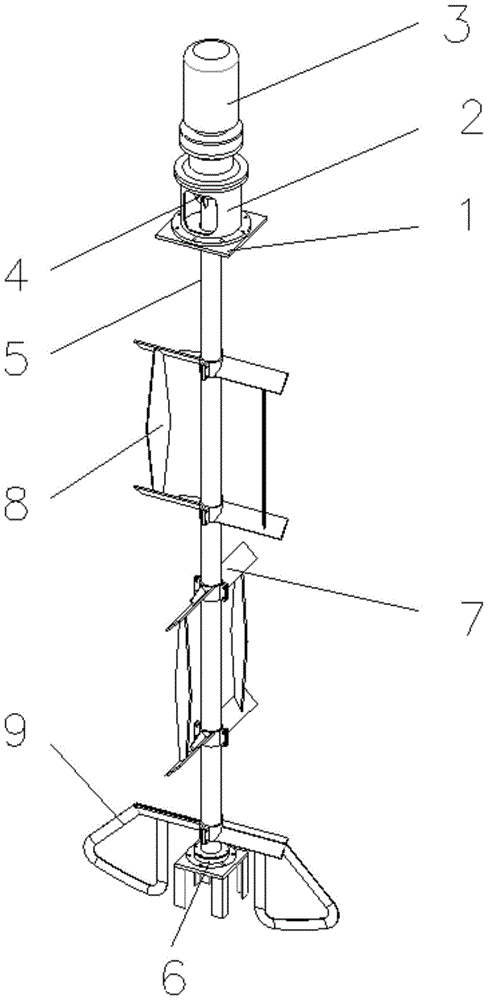

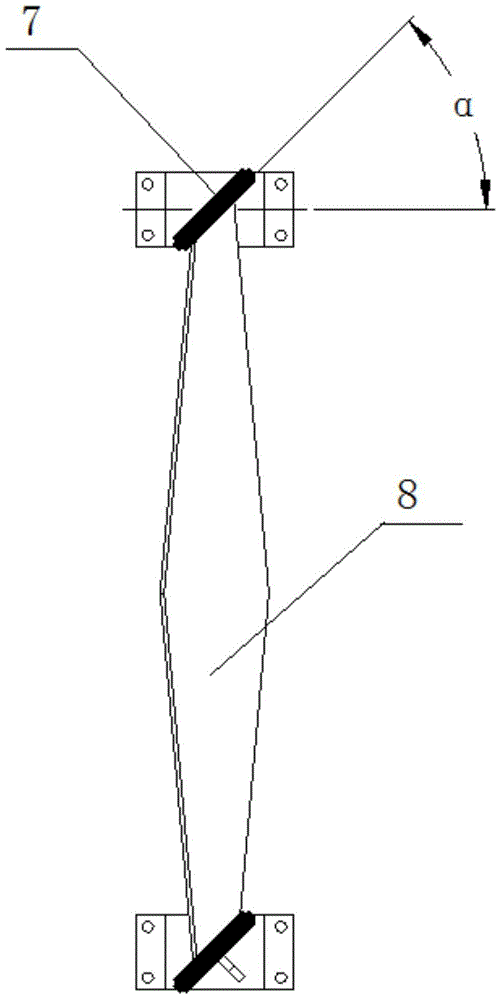

Self-feeding powder mixing device for constructional engineering

InactiveCN107224912AStir wellLarge thrustTransportation and packagingRotary stirring mixersWear resistantEngineering

The invention discloses a self-feeding powder mixing device for constructional engineering. The self-feeding powder mixing device for constructional engineering comprises a machine body; a supporting base is horizontally arranged on the lower side of the machine body; a wear-resistant concrete layer covers the outer wall of the machine body; a stirring rotating shaft is vertically arranged in the machine body; the top end of the stirring rotating shaft is connected with a driving motor; a plurality of stirring blades are arranged on the outer wall of the stirring rotating shaft; 12 stirring blades are divided into upper and lower three groups along the stirring rotating shaft circumferentially and uniformly. According to the self-feeding powder mixing device for constructional engineering, various materials can be input simultaneously, the materials do not need to be lifted to the top of the device by workers, feeding is conducted, time and labor are saved, the S-shaped stirring blades are adopted, and resistance-reducing holes are formed in the stirring blades, so the stirring uniformity is greatly improved, the left end of a stirring cylinder is jacked up to realize automatic discharging and the discharging blockage phenomenon is effectively avoided; in addition, the damping effect is good, and the noise is reduced while the stationarity is improved.

Owner:徐得强

Cam mechanism having forced-valve-opening/closing cams and cam-profile setting method

InactiveUS20080110425A1Reduce collision speedMinimize unwanted sound noiseValve drivesMetal-working apparatusValve openingCam

No-load valve lift correction curves of opening and closing cams are set by offsetting no-load curve sections of basic valve lift curves of the cams in such directions as to increase a clearance between the curves, and they are connected with remaining sections of the curves to provide normal valve lift curves of the cams. Cam profiles of the cams are set on the basis of such normal valve lift curves. The cam profiles are set so that an ultimate speed difference between jumping and landing speeds of a follower on an ultimate valve speed curve determined from ultimate valve lift curves, having first and second shift sections where the follower shifts from the opening cam to the closing cam and from the closing cam to the opening cam, is smaller than a basic speed difference between jumping and landing speeds on a basic valve speed curve.

Owner:HONDA MOTOR CO LTD

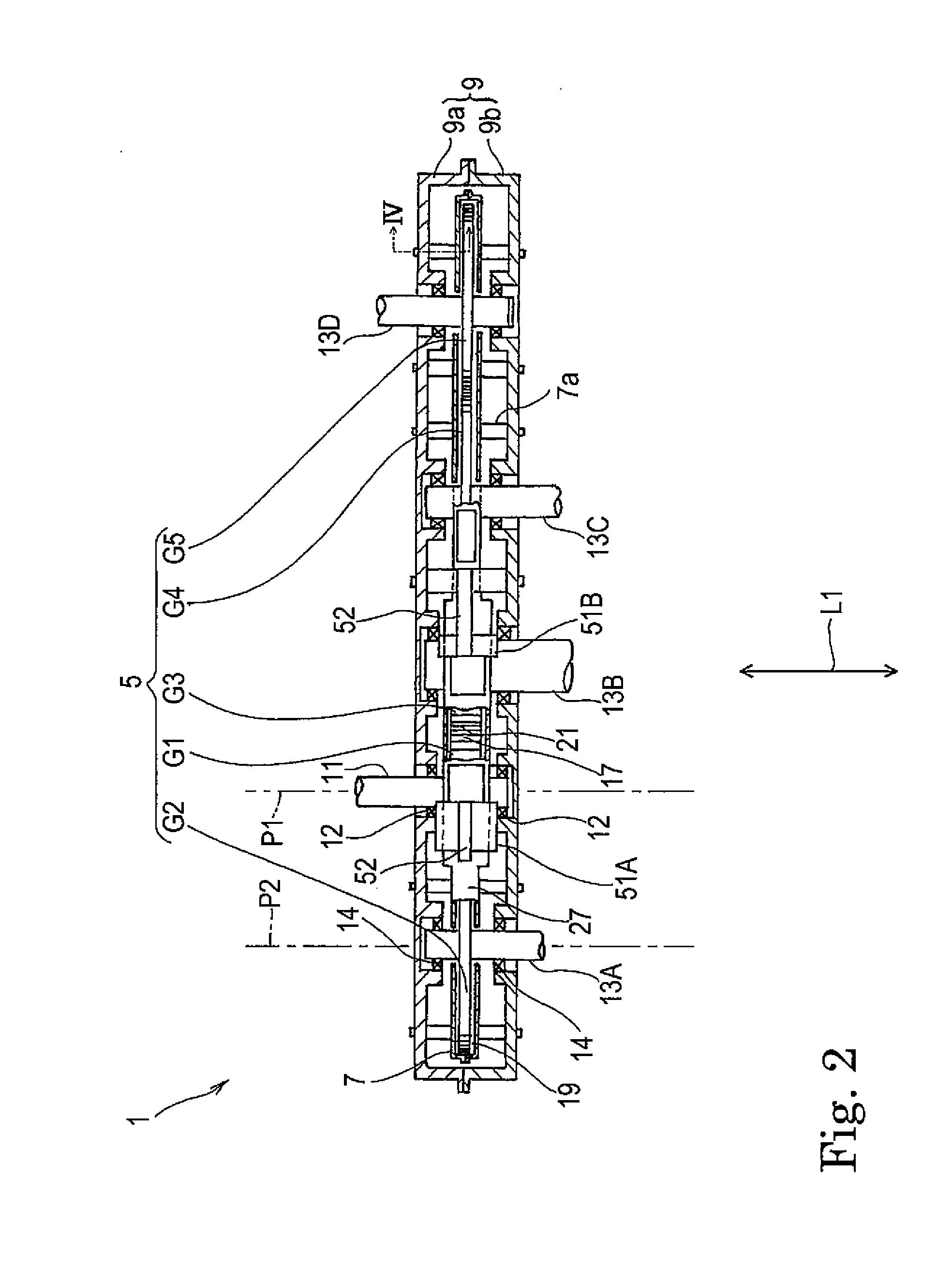

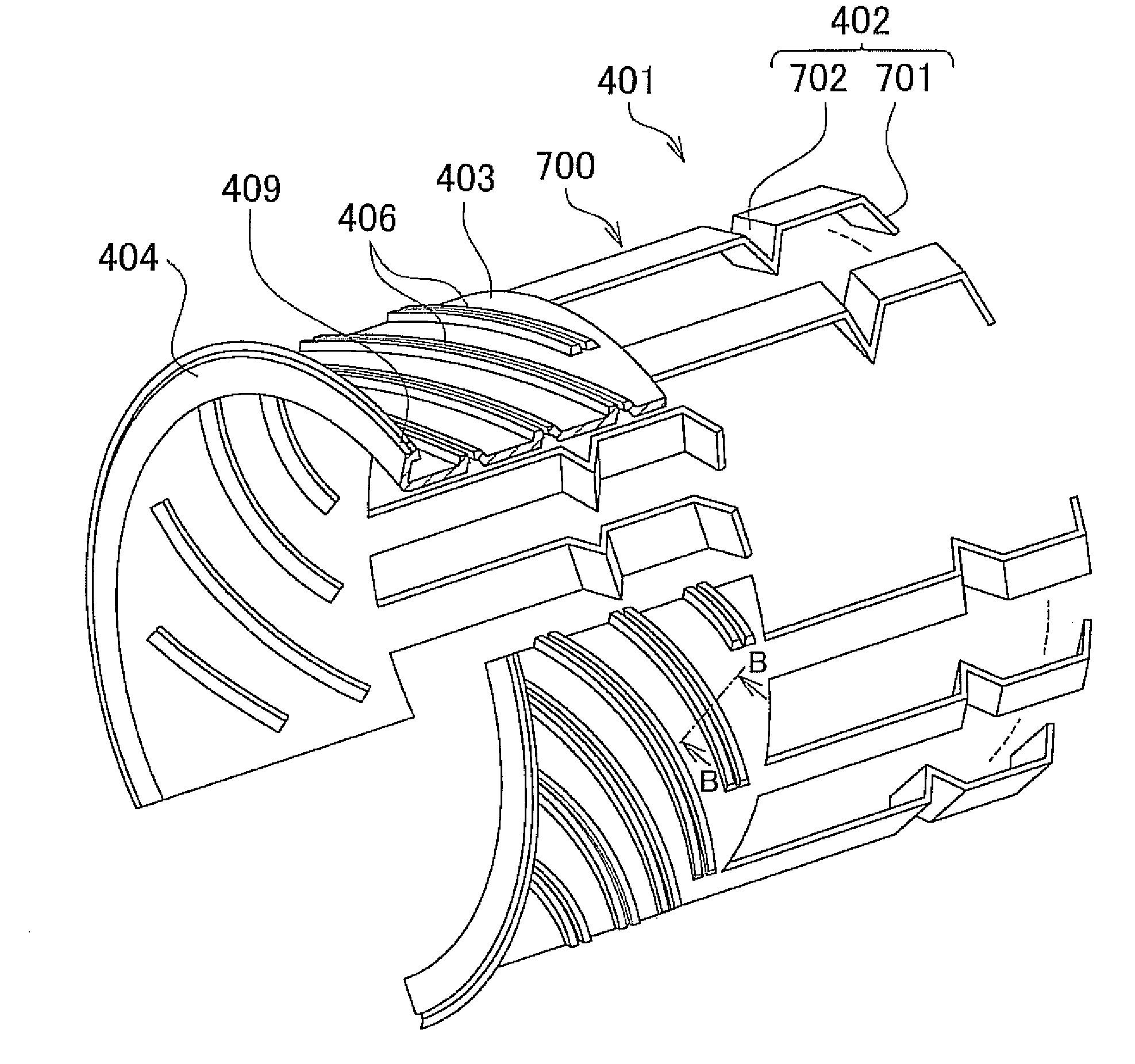

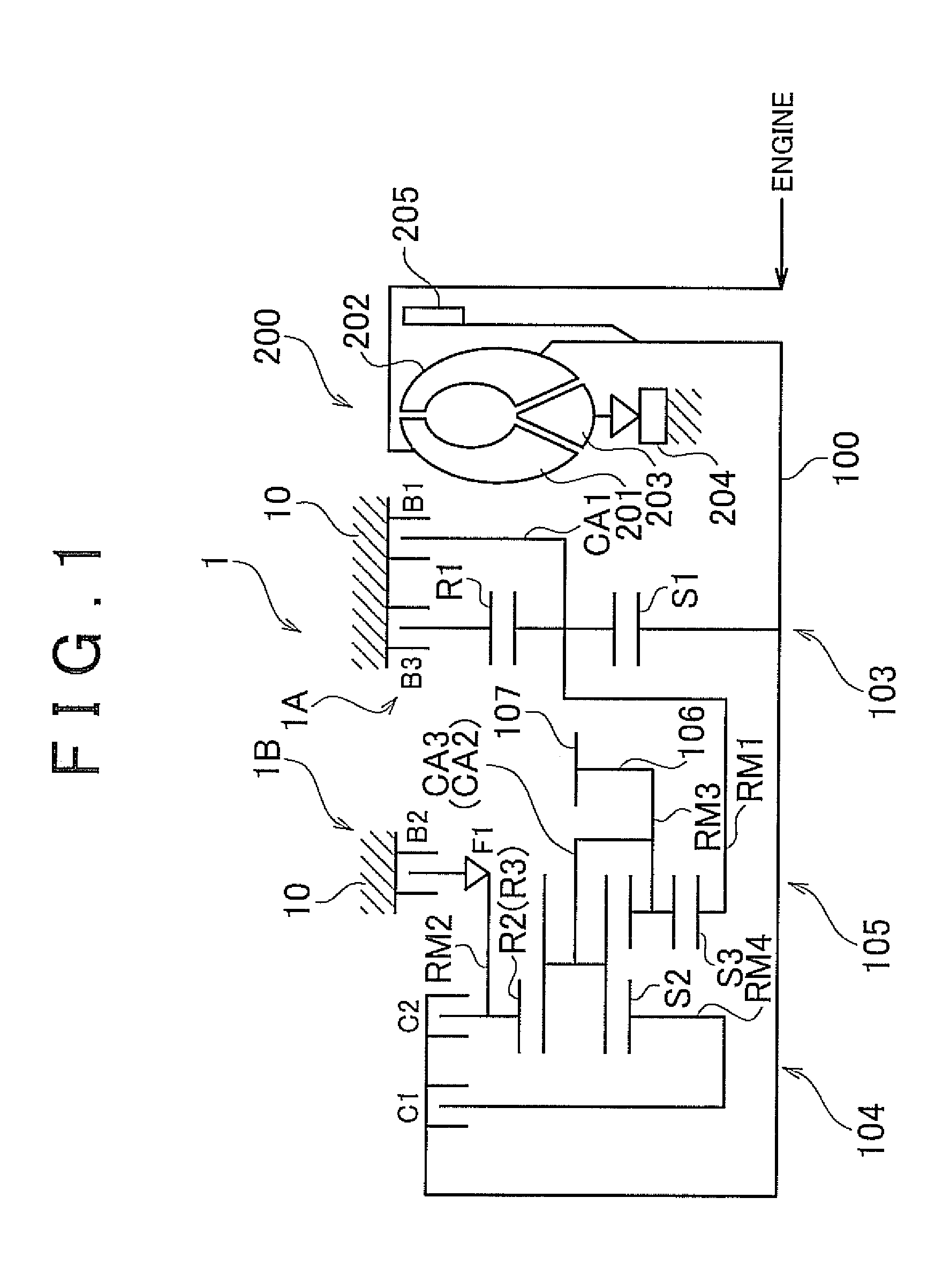

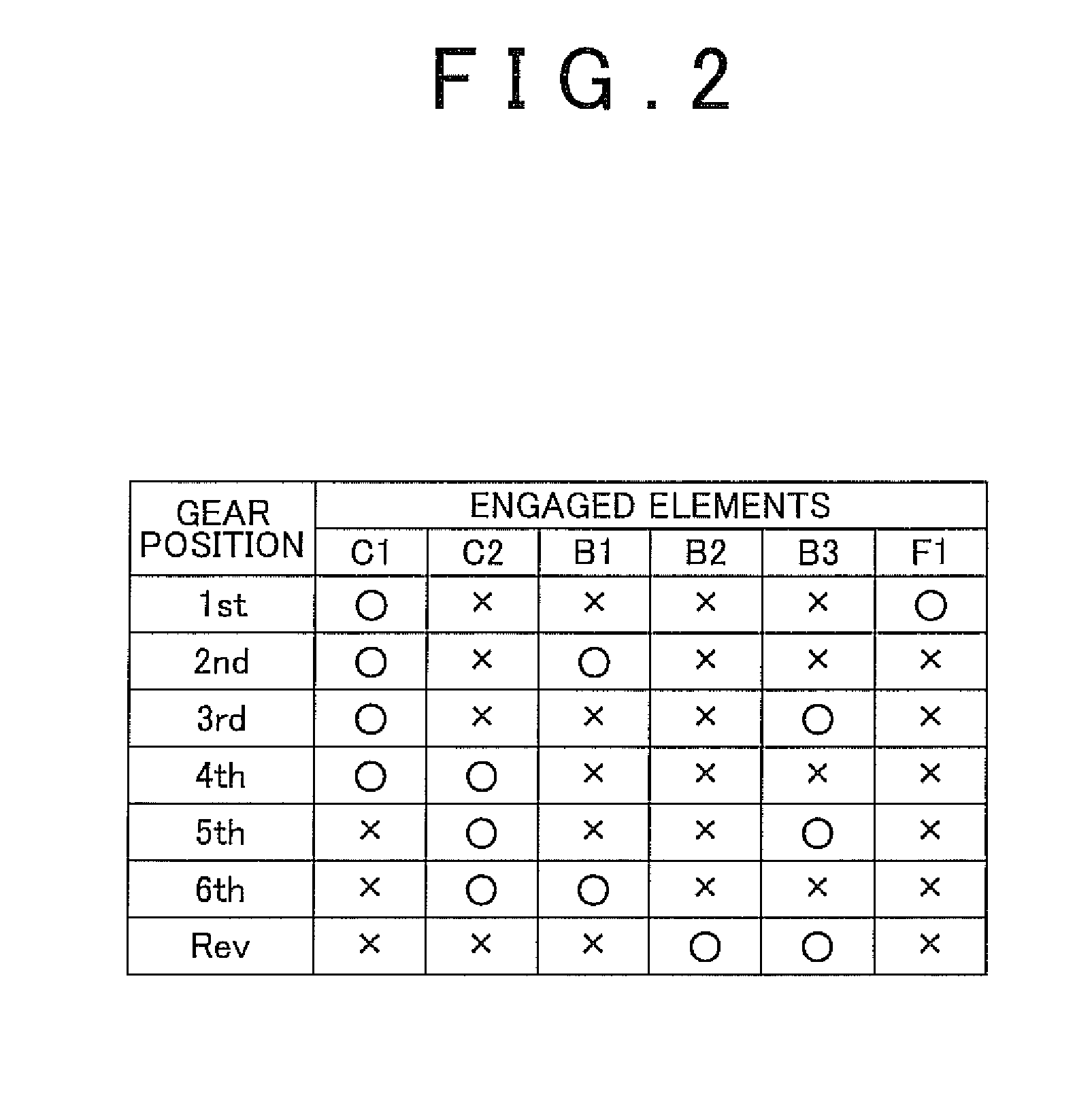

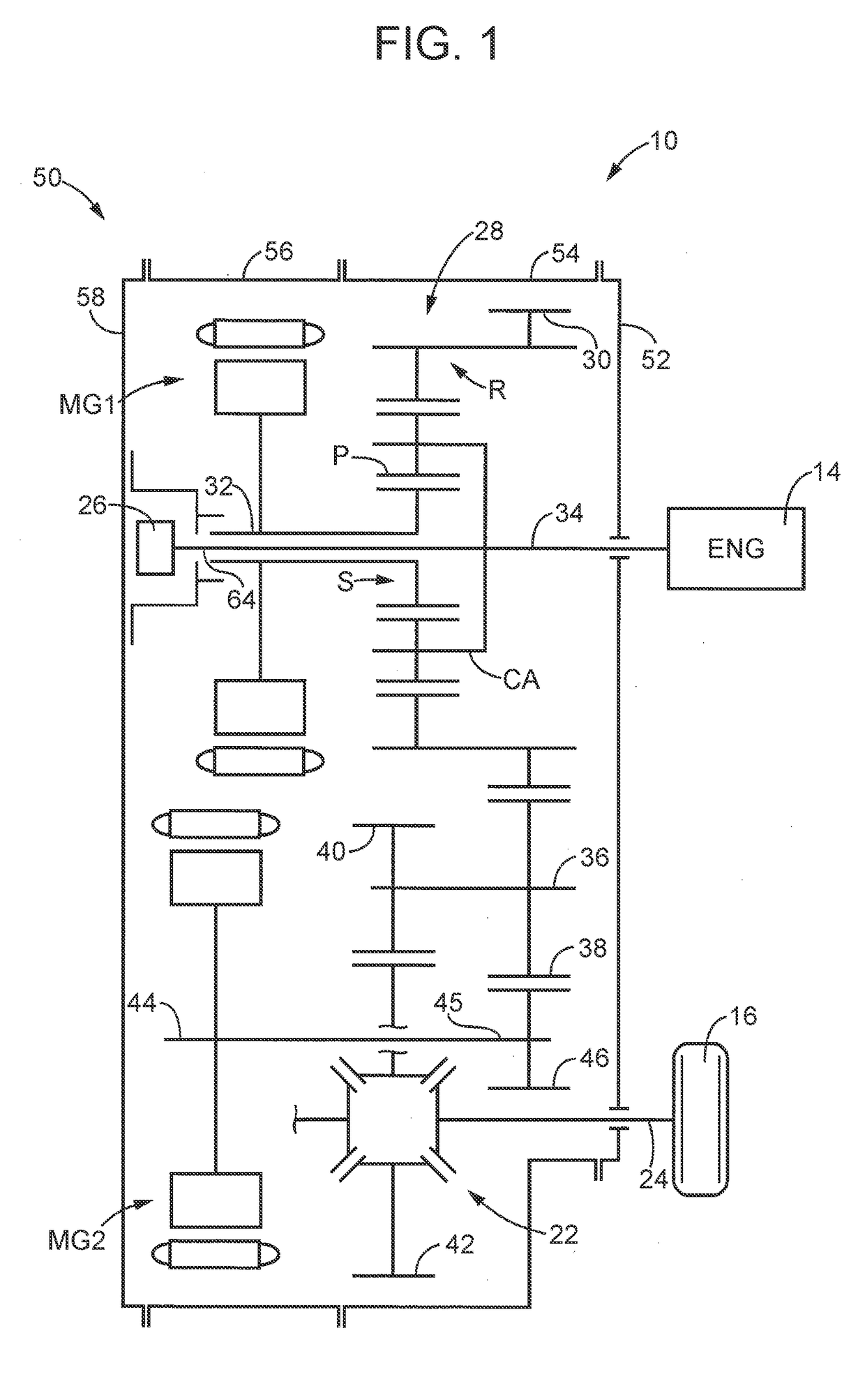

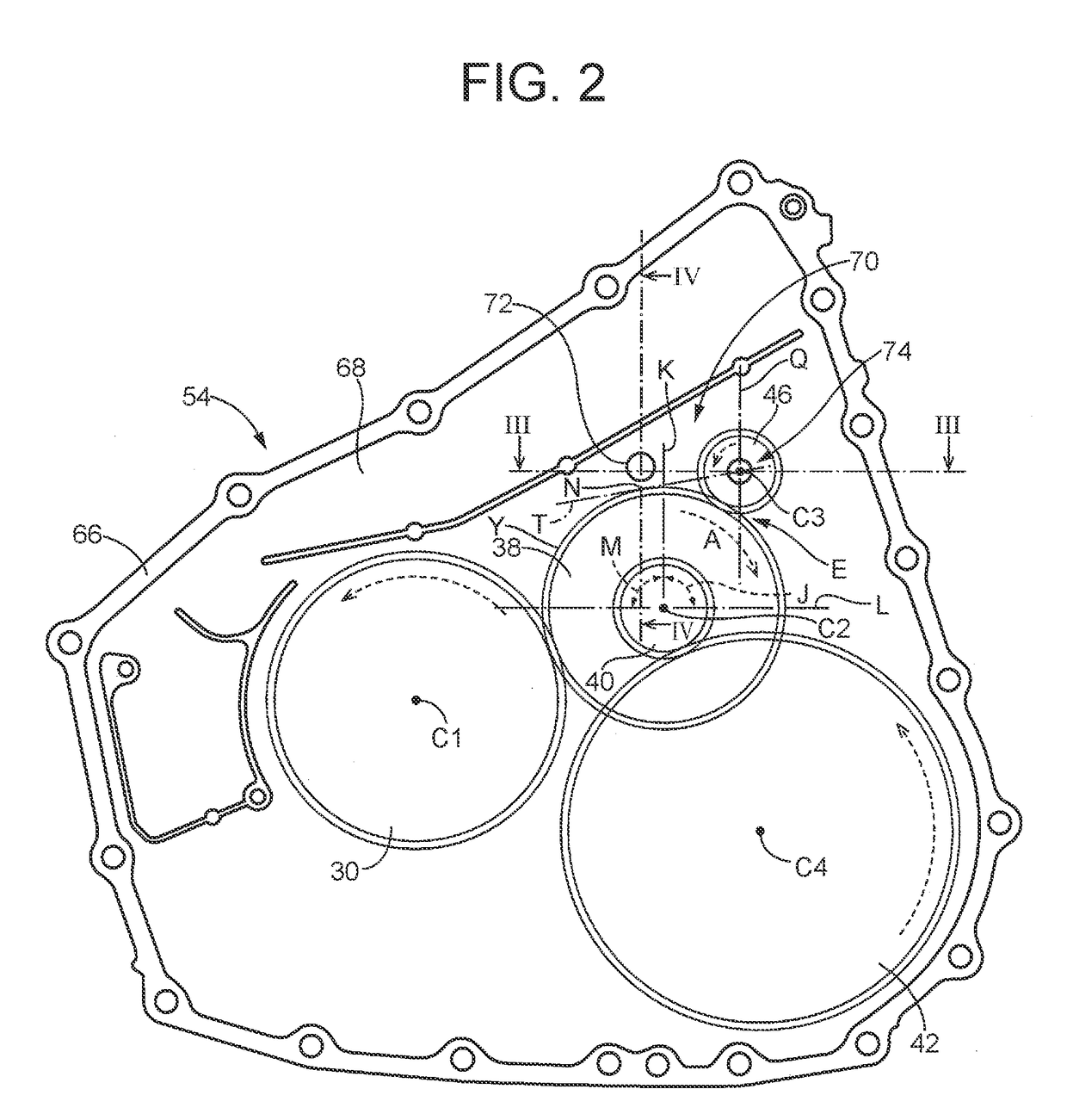

Automatic transmission

InactiveUS20100170764A1Reduce the effect of dragSpread the wordFluid actuated clutchesGear lubrication/coolingInterior spaceAutomatic transmission

An automatic transmission includes a clutch, a clutch drum, a piston, and a brake. The clutch drum, the clutch, and the brake are arranged in sequence in an interior space formed by joining a transmission case to a rear case in an axial direction from the rear case side. A separating / guiding wall that is provided in a circumferential direction so as to define a surplus lubricating oil trapping space for trapping surplus lubricating oil that gathers on an inner peripheral surface of the transmission case and in a second brake, and causes trapped surplus lubricating oil guided thereby into the surplus lubricating oil trapping space to flow downward in the circumferential direction, and a holding mechanism for restricting axial movement of the separating / guiding wall, are provided in relation to spline fitting portions formed on the inner peripheral surface of the transmission case.

Owner:TOYOTA JIDOSHA KK

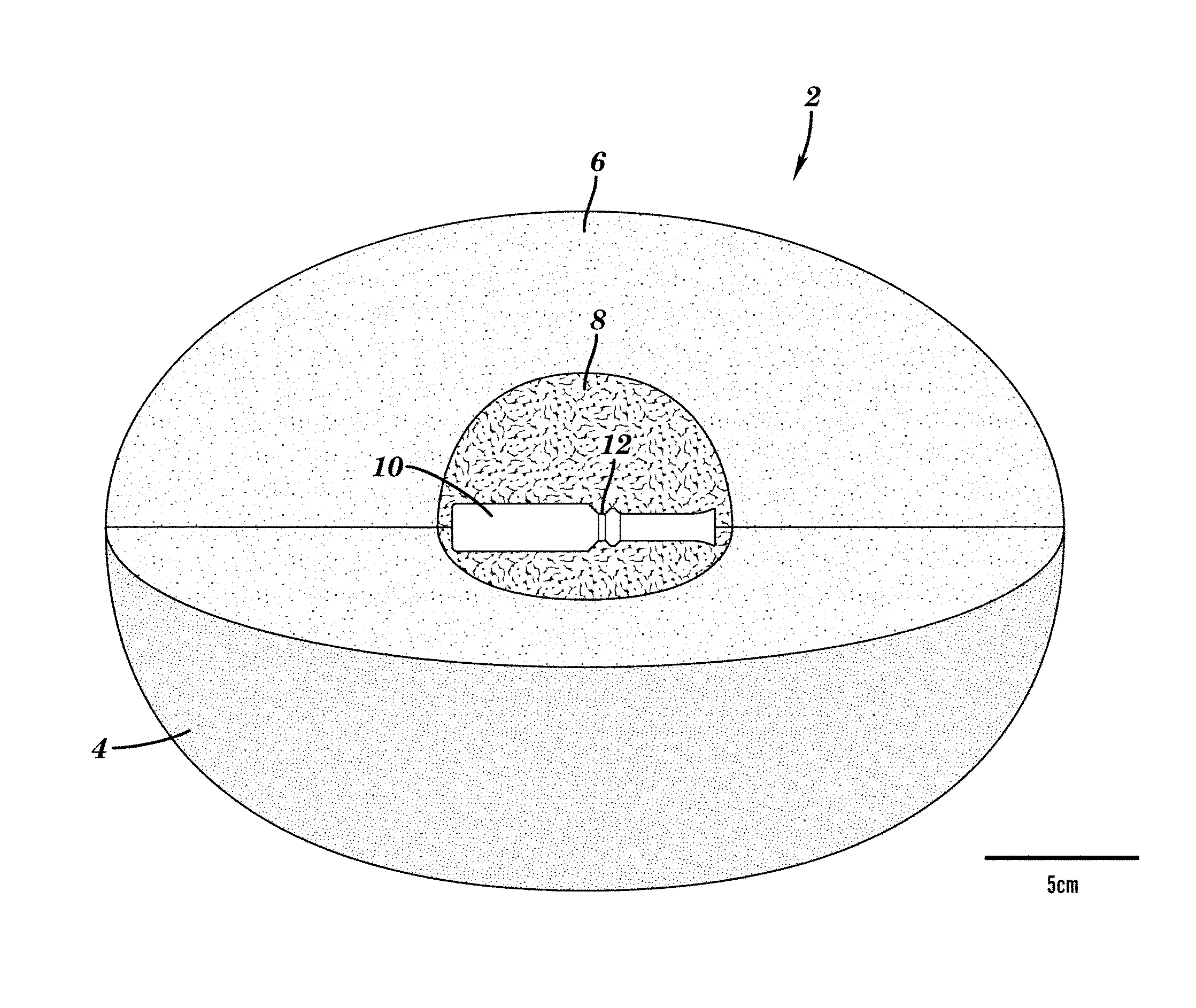

Device and method for reducing tension and stress in a subject

InactiveUS20120004498A1Reduce tensionSalivary cortisol levelSleep inducing/ending devicesFilling materialsMedicine

The present invention relates to a sensory device for reducing tension in a subject. The device includes an elastic covering, a filling material inside the elastic covering, an openable sealed reservoir located within the filling, an absorbent material surrounding the reservoir, and a calming odor releasing substance sealed within the reservoir. The present invention also relates to a method of reducing tension in a subject. This method involves providing a subject in need of tension relief with the device of the present invention. The device is manipulated to break open the reservoir and release the calming odor releasing substance. The released calming odor is inhaled in an amount sufficient to lower salivary cortisol levels in the subject and thereby reduce tension in the subject.

Owner:NEW YORK UNIV

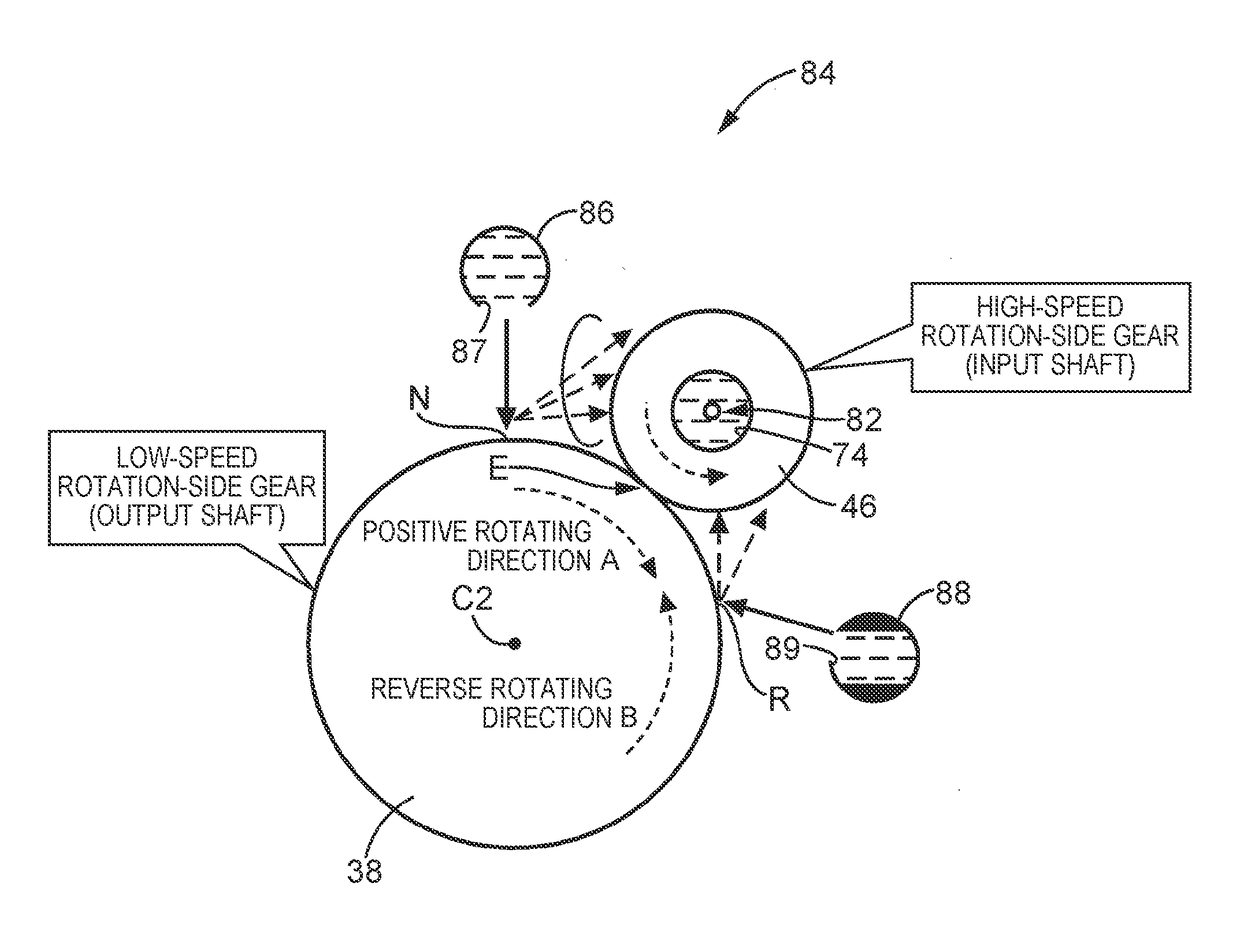

Lubricating device of gear apparatus for vehicle

ActiveUS20180045294A1Securing durabilityAgitation loss becomes greatHybrid vehiclesGear lubrication/coolingMechanical engineeringTooth surface

A lubricating device of a gear apparatus for a vehicle lubricates a low-rotation-side gear and a high-rotation-side gear meshing with the low-rotation-side gear. The lubricating device comprises a first tooth surface lubricating oil supply part configured to supply a lubricating oil directly to a tooth surface position located more upstream of a rotating direction of the low-rotation-side gear than a meshing position of the low-rotation-side gear with the high-rotation-side gear so as to spray some of the lubricating oil from the tooth surface position toward a tooth surface of the high-rotation-side gear, and an in-shaft lubricating oil supply part configured to supply the lubricating oil into a shaft of the high-rotation-side gear.

Owner:TOYOTA JIDOSHA KK

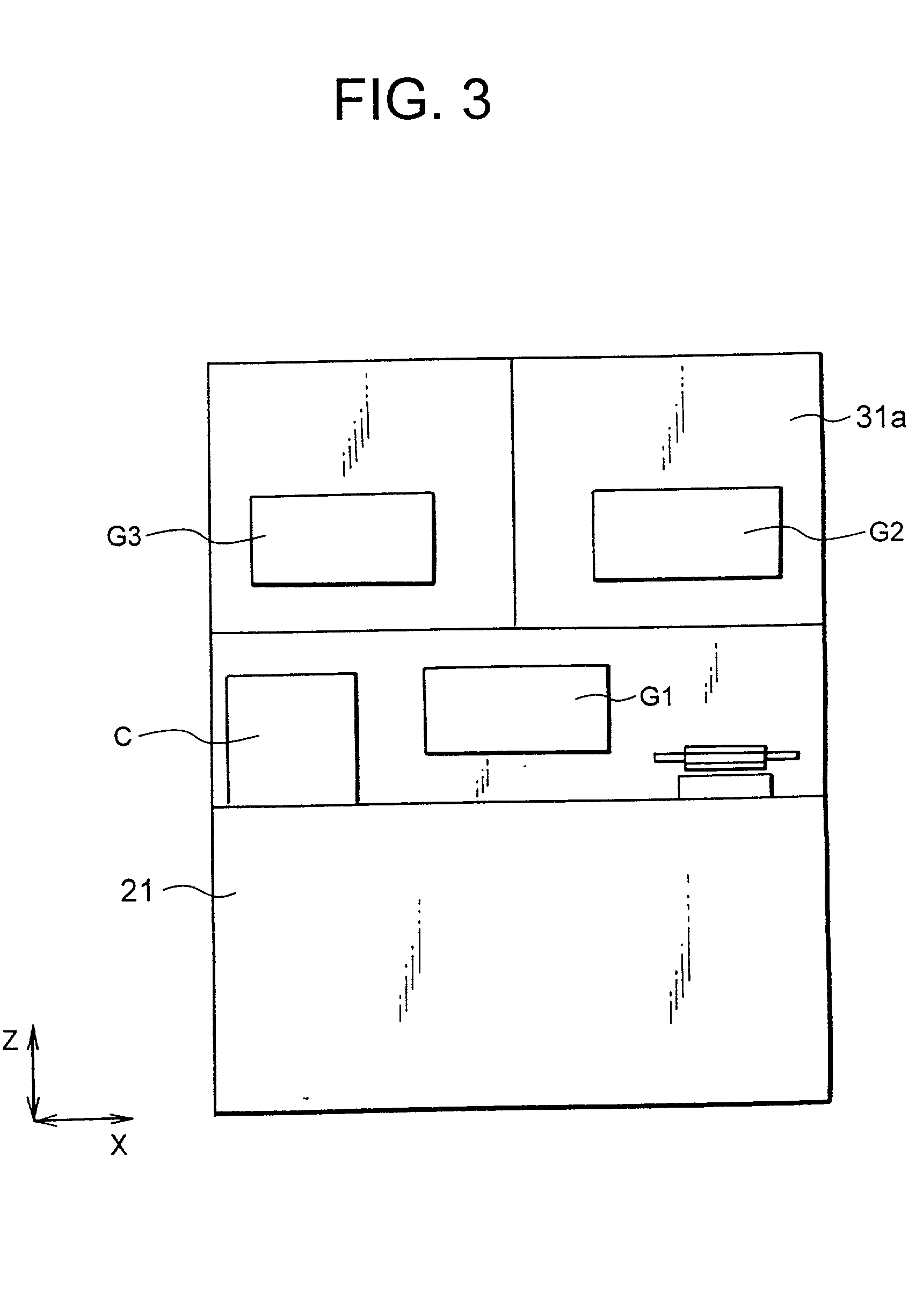

Liquid treatment equipment, liquid treatment method, semiconductor device manufacturing method, and semiconductor device manufacturing equipment

InactiveUS20010039118A1Reduce frequencyReduce agitationCellsSemiconductor/solid-state device manufacturingDecompositionEngineering

Providing liquid treatment equipment capable of largely reducing a frequency of discarding a treatment solution as a whole and capable of implementing smooth and high quality liquid treatment with less manufacturing burden. Equipment comprises a treatment solution bath capable of accommodating a treatment solution for implementing liquid treatment to a substrate to treat, a treatment solution circulating system circulating the accommodated treatment solution between the outside of the treatment solution bath, and a product removal unit removing a reaction product due to the liquid treatment contained in the circulated treatment solution. By circulating the accommodated treatment solution between the outside of the treatment solution bath, reaction products contained in the circulated treatment solution are removed by means of the product removal unit. Thereby, a chemical change substance and a decomposition product remaining in a treatment solution can be removed, resulting in preventing a treatment solution from deteriorating.

Owner:TOKYO ELECTRON LTD

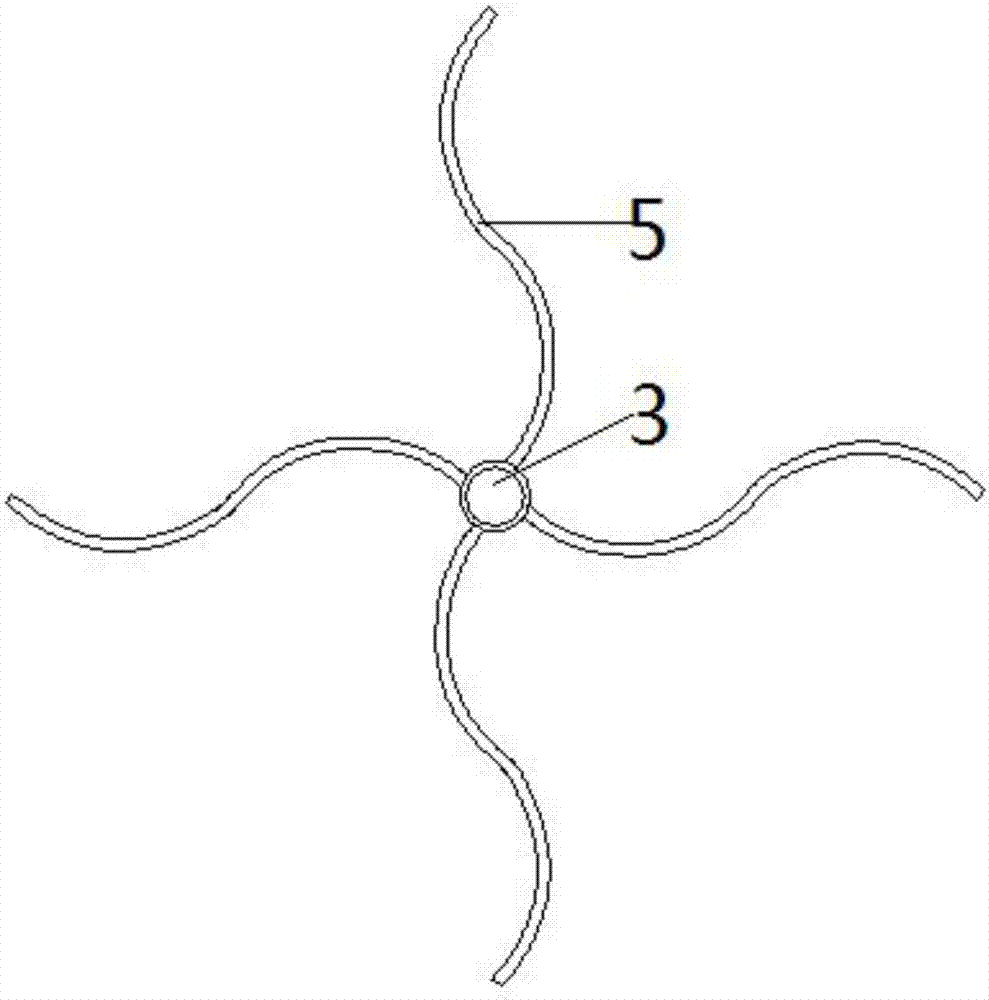

Countercurrent extraction apparatus

A countercurrent extraction apparatus comprises an extraction tube; a propeller is disposed within the extraction tube; the propeller comprises a shaft and blades. The apparatus is characterized in that the blades are sheet-shaped, and the blades are arranged at interval on the surface of the shaft along the axial direction and in spiral arrangement. The sheet-shaped blades arranged spaced axially and spirally play the role of advancing the materials; the materials under the effect of such blades churn and spread out, so as to play a role in stirring; the materials churn from one side to the other side with the rotation of the propeller; although part of the materials rotate with the blades in place, the materials do not accumulate to one side at the same time because of spaced blades; continuous closely packed body can not be formed, and journal sticking effect can be avoided, so that blockage does not form in the extraction tube. Several tests prove that even if the total volume of the materials is greater than 80% of the total volume of the extraction tube, blockage does not appear, so that the efficiency of the extraction tube plays to the maximum, and the cost performance has been significantly improved.

Owner:JINING SINOBEST BIOLOGICAL MACHINERY

Modified asphalt production stirrer

InactiveCN105696441AImprove the mixing effectImprove work efficiencyRoads maintainenceCouplingPulp and paper industry

The invention discloses a modified asphalt production stirrer. The modified asphalt production stirrer comprises a mounting bottom plate. The mounting bottom plate is fixedly connected with a rack. A stirring motor is mounted on the upper portion of the rack. A rotary shaft is arranged in the middle of the rack. A power output shaft of the stirring motor is connected with one end of the rotary shaft through a coupling. Multiple layers of horizontal paddle blades are arranged on the rotary shaft. A vertical paddle blade is arranged between every two layers of horizontal paddle blades. According to the modified asphalt production stirrer, axial divided flow and radial divided flow can be generated through the horizontal paddle blades so that surrounding materials can turn over up and down; the combined steering effect obtained after the vertical paddle blades are additionally arranged is obviously higher than that of a multi-layer paddle type stirrer, so that high-molecular polymers are evenly distributed in asphalt, and consistency of the mixture of the modified asphalt is improved greatly; and a bottom scraper welded to the lower portion of the bottom layer of the horizontal paddle blades can effectively scrap gel attached to the tank bottom or the conglomerated high-molecular polymers, and an outlet of an asphalt tank is prevented from being blocked. The modified asphalt production stirrer is reasonable in design, high in working efficiency and low in operation energy consumption.

Owner:WUXI HUATONG ASPHALT NEW TECH DEV

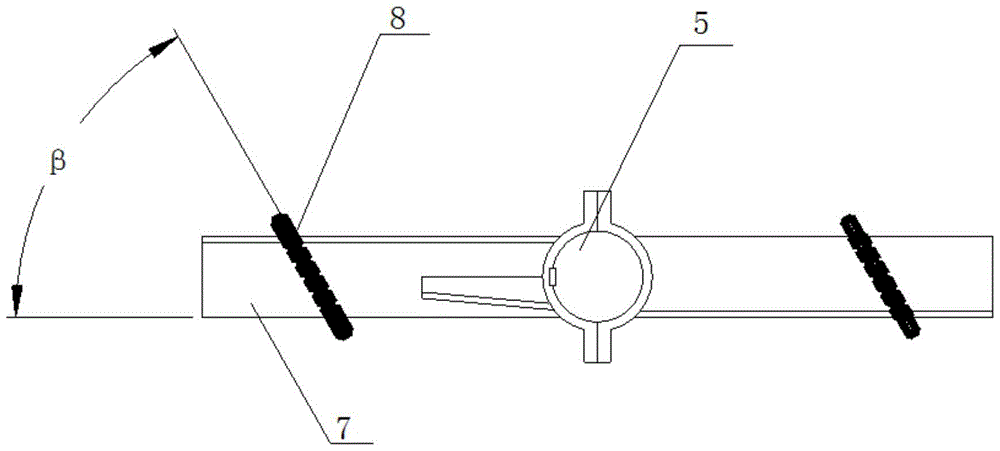

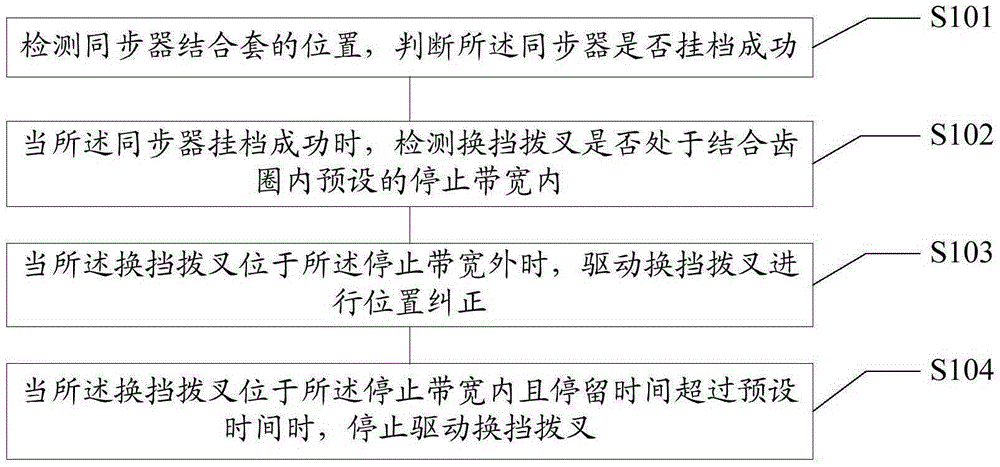

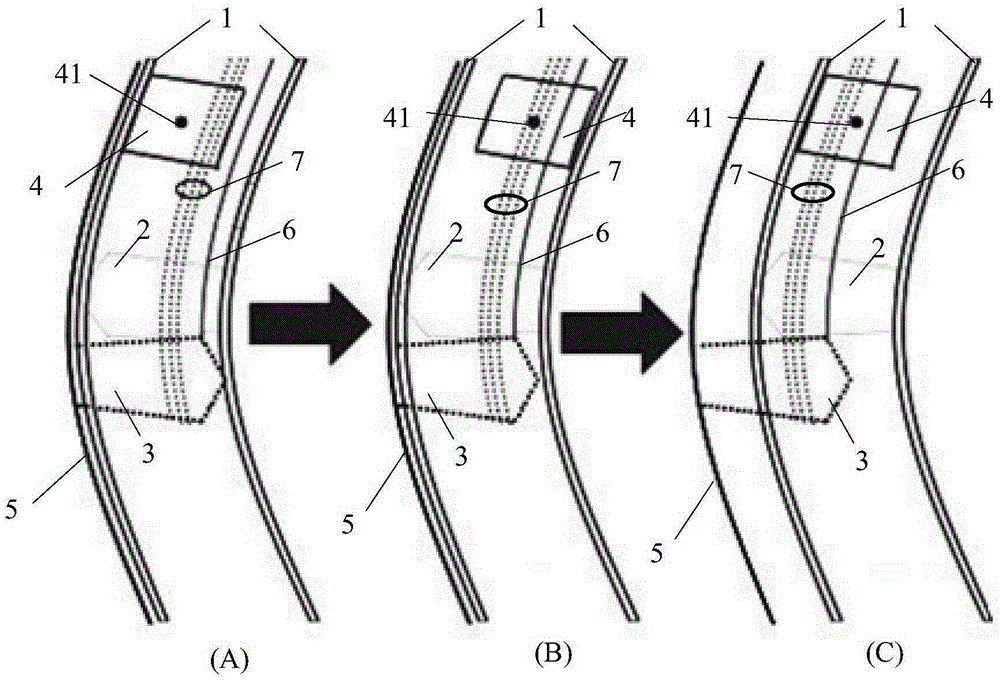

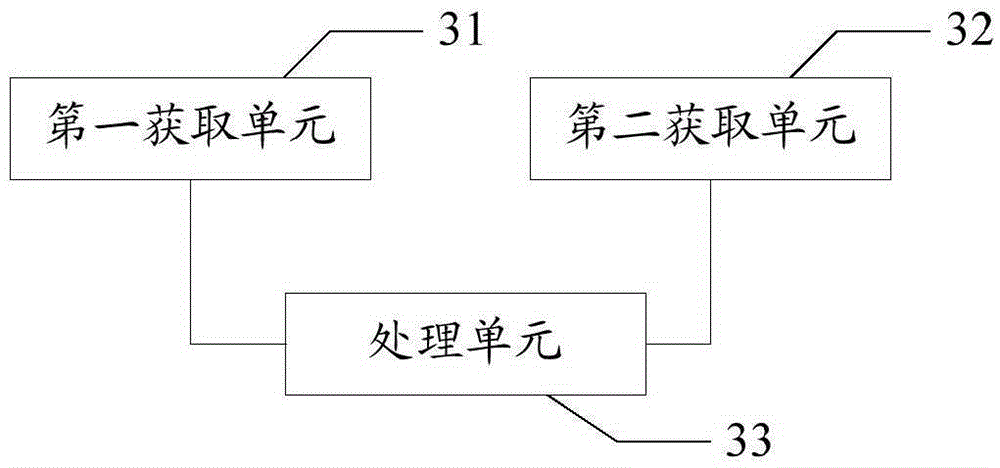

In-gear control method, device and system for synchronizer

ActiveCN106286811AAchieve lightweightSimple structureControlled membersGearing controlEngineeringControl theory

The invention provides an in-gear control method, device and system for a synchronizer. The method includes the steps that the position of a synchronizer combination sleeve is detected, and whether the synchronizer is put into gear or not is judged; when the synchronizer is put into gear, whether a gear shifting fork is located within a preset stop bandwidth in a combination gear ring or not is detected, wherein the bandwidth center of the stop bandwidth is located between the tail end of the combination gear ring and an out-of-gear boundary, a preset safety distance is kept between the bandwidth center of the stop bandwidth and the out-of-gear boundary, and the boundary of the stop bandwidth is located between the tail end of the combination gear ring and the out-of-gear boundary; when the gear shifting fork is located beyond the stop bandwidth, the gear shifting fork is driven to be corrected in position; and when the gear shifting fork is located within the stop bandwidth and the stay time is longer than the preset time, driving on the gear shifting fork is stopped. By means of the in-gear control method, device and system for the synchronizer, a gear shifting structure of the synchronizer can be simplified, the weight of a gearbox system can be lowered, and meanwhile in-gear maintaining reliability is improved.

Owner:SAIC MOTOR

Ecological algae control method for lake

The invention discloses an ecological algae control method for a lake, which comprises the following steps: setting up a fence area at an open water band or a coastal band of the lake, wherein the fence mesh is 3 to 6 centimeters; and throwing 30 to 75 / hectare of siniperca, 30 to 75 / hectare of topmouth culter and 50 to 100 g / m2 of corbicula fluminea into the fence area. The ecological algae control method can filter blue algae, reduce the biomass of algae, reduce the contents of N and P in the water body, cut down the nutrition load of the water body, has lower running cost and good recycling property and operability, and is favorable for long-term cyclic operation.

Owner:SUZHOU UNIV

Sleeve-fish steaming device for fishing boat

ActiveCN106418296ARealize automatic nestingImprove work efficiencyMeat/fish preservation by heatingSpray nozzleEngineering

The invention provides a sleeve-fish steaming device for a fishing boat, and belongs to the technical field of food processing equipment. The sleeve-fish steaming device for the fishing boat comprises a steaming box, a steaming cylinder is arranged in the steaming box, a connecting sleeve is mounted on the side wall of the steaming box, an open end of a cylinder body is rotatably connected onto the connecting sleeve, a driving mechanism is arranged between the steaming cylinder and the bottom of the steaming box, stirring vanes are arranged on the inner wall of the cylinder body, a push plate is arrange din the steaming cylinder, a power mechanism is arranged on the steaming box, a sealing door is hinged on the outer wall of the steaming box, a base is arranged on the lower portion of the steaming box, a middle water tank is arranged on the base, communicated with the bottom of the steaming box through a discharge pipe and communicated with the inside of the steaming box through a water return pipe, a plurality of spray nozzles are arranged at the upper end of the steaming box, air outlets of the spray nozzles face the steaming cylinder, a water supply pipe is arranged at the upper end of the steaming box, an exhaust gas heating pipe and a heater are arranged at the bottom of the steaming box, a discharging hopper is arranged on the outer wall of the steaming box, and conveying device for conveying sleeve-fishes is arranged on the base. The sleeve-fish steaming device has the advantages that the sleeve-fish steaming device is high in working efficiency, energy is saved and the like.

Owner:ZHEJIANG OCEAN UNIV

Lubrication structure of engine

ActiveUS20070246000A1Speed up the flowIncrease heightCasingsLubrication of auxillariesEngineeringReed valve

The lubrication structure of an engine is provided with a crankcase having a crank chamber that houses a crankshaft. A first oil reservoir is in communication with the crank chamber and is formed adjacent a bottom of the crank chamber. A second oil reservoir is in communication with the first oil reservoir and is formed adjacent the side of and on the bottom of the first oil reservoir. A reed valve extends diagonally from the bottom of the first oil reservoir toward the top of the second oil reservoir in an opening where the first oil reservoir and the second oil reservoir communicate with the crankcase. The reed valve includes a valve element that opens and closes according to the variation of pressure in the crank chamber. The valve element of the reed valve is arranged on the side of the second oil reservoir.

Owner:HONDA MOTOR CO LTD

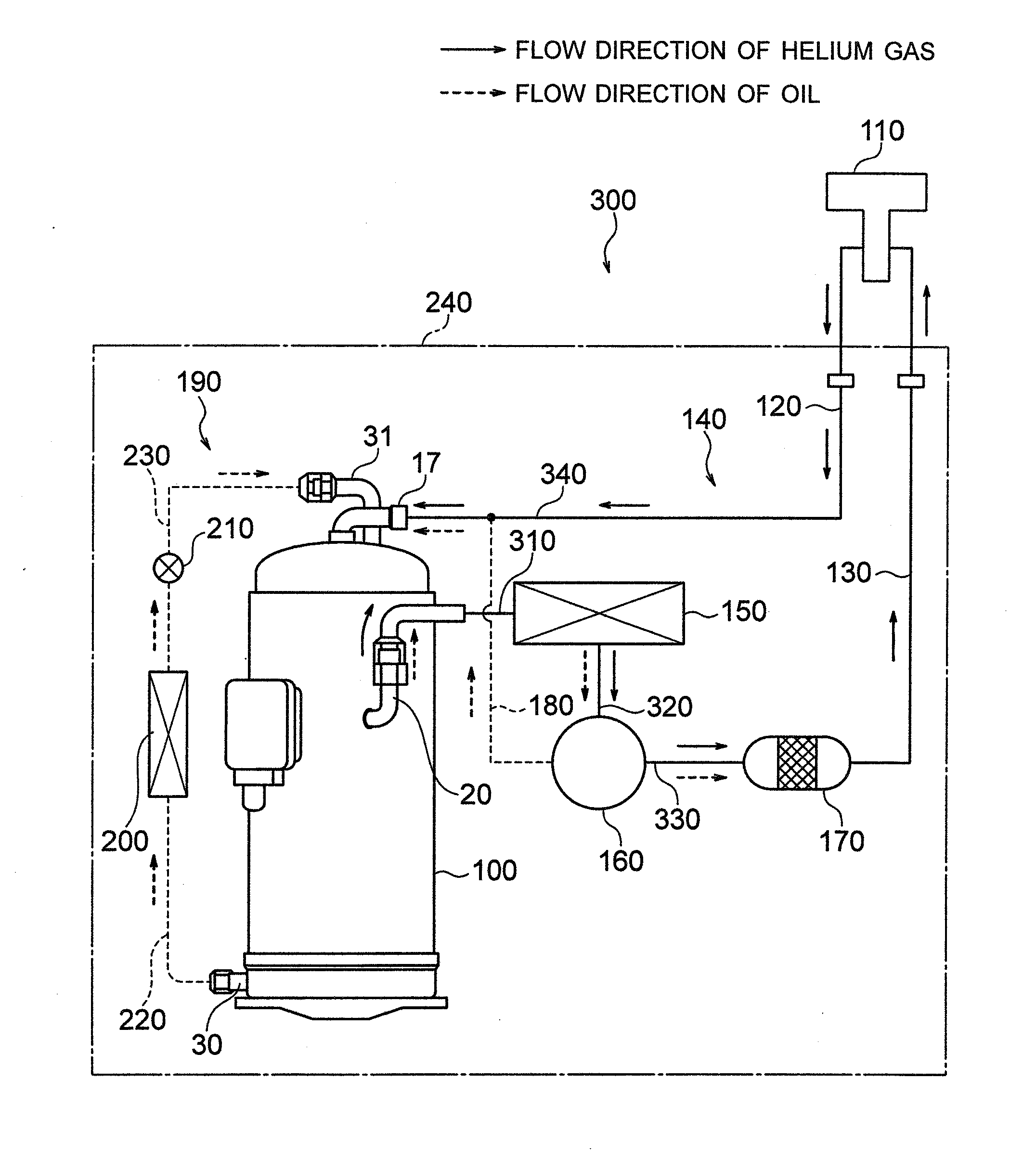

Hermetically sealed scroll compressor

ActiveUS20120156068A1Low efficiencyReduce internal leakageRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringMechanical engineering

In the hermetically sealed scroll compressor, an injection pipe for injecting a fluid to a compression chamber is connected to an injecting port of a fixed scroll. The injecting port includes a first injecting port which is provided in the vicinity of a fixed scroll inner curve and injects the fluid to an orbiting outer compression chamber, and a second injecting port 22b which is provided in the vicinity of a fixed scroll outer curve and injects the fluid to a orbiting inner compression chamber 8b. The second injecting port is placed in parallel in a radius direction with respect to the first injecting port and is placed so that an orbiting scroll wrap does not practically communicate with the orbiting outer compression chamber in the state in which the orbiting scroll wrap is in contact with the outer side of a fixed scroll wrap.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Grading filter

InactiveCN109550295APrevent regurgitationSimple structureStationary filtering element filtersEngineeringFilter cake

The invention discloses a grading filter, which comprises a feeding cylinder body, a filtering cylinder body and a reflux rinsing cylinder body, wherein the feeding cylinder body, the filtering cylinder body and the reflux rinsing cylinder body are sequentially, fixedly and integrally arranged, a first-stage filtering screen cylinder, a second-stage filtering screen, a flow stabilizing filtering screen and a one-way flow passing member are sequentially fixed in the filtering cylinder body at intervals, the side portion of the filtering cylinder body is provided with a material outlet, and a motor and a stirring shaft connected to the rotating shaft of the motor are arranged in the feeding cylinder body. According to the present invention, the grading filter has characteristics of simple structure, convenient operation, reliability, high filtering efficiency and long service life; and with the grading filter, the material is pure through the grading filtering, and the bridging phenomenon of the stirring shaft at the medium channel inlet can be avoided during the filtering, such that the small particles are blocked and are deposited on the surface of the medium to form the filter cake.

Owner:石家庄一通过滤器设备制造有限公司

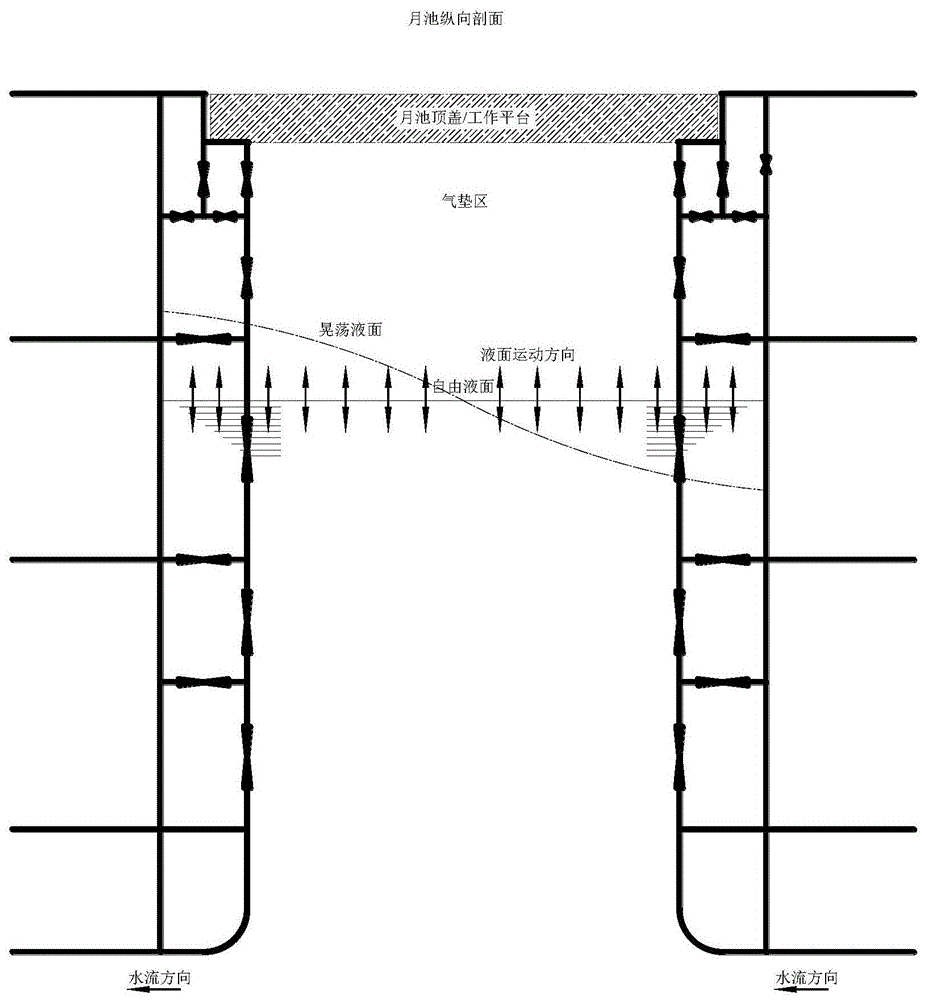

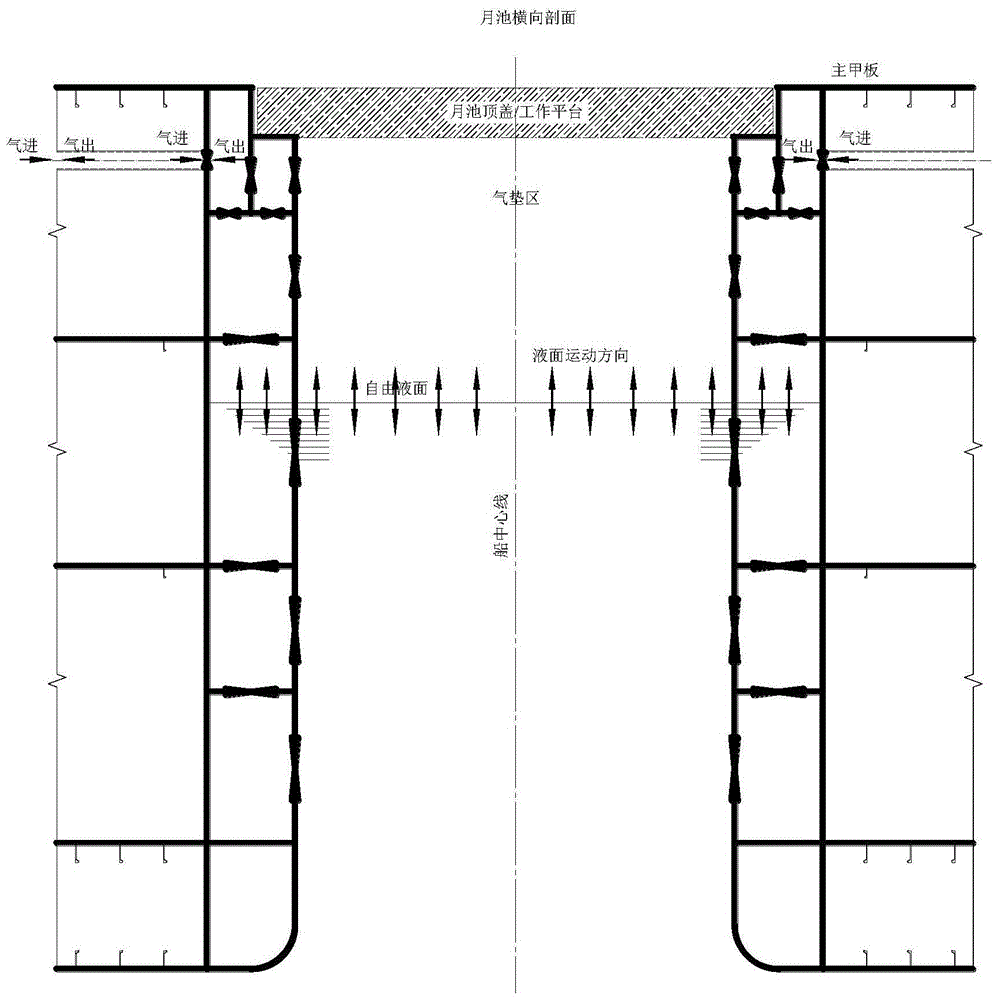

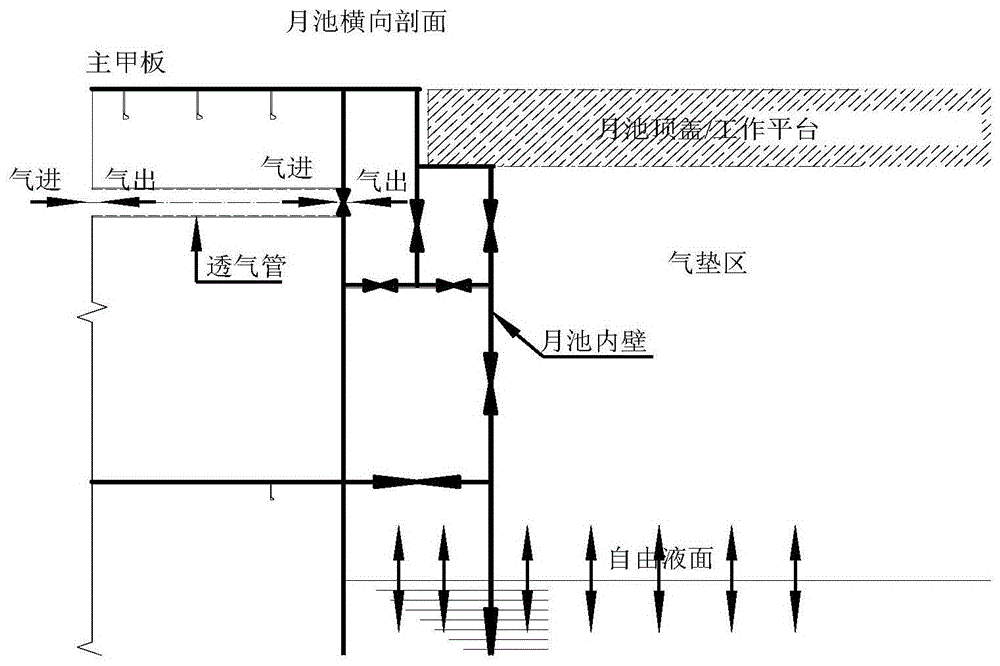

Damping plate structure to reduce fluid turbulence in moon pool cavity

ActiveCN104724248BReduce agitationReduce power consumptionWatercraft hull designHydrodynamic/hydrostatic featuresMarine engineeringWater flow

The invention belongs to the technical field of ship moon pools, and relates to a ship moon pool structure, in particular to a damping plate structure reducing the surging of fluid in a cavity of a moon pool. The damping plate structure is characterized by comprising a horizontal damping plate and a vertical damping plate; the vertical damping plate and the horizontal damping plate are provided with holes respectively, water flow enters the area between the vertical damping plate and the horizontal damping plate, and then the surging of the water flow is reduced; ventilation pipelines communicated with the outside atmosphere are arranged on the side face of an air cushion area between a moon pool top cover and a free surface in the moon pool. Because the ventilation pipelines communicated with the outside atmosphere are arranged on the side wall of the air cushion area, the pressure of the air cushion area is the same as outside pressure, the waving of water inside the moon pool is synchronized with the waving of water outside a ship as far as possible, and the surging of the water flow is reduced. In this way, the sailing resistance is reduced, and the power consumption of a motor is lowered.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

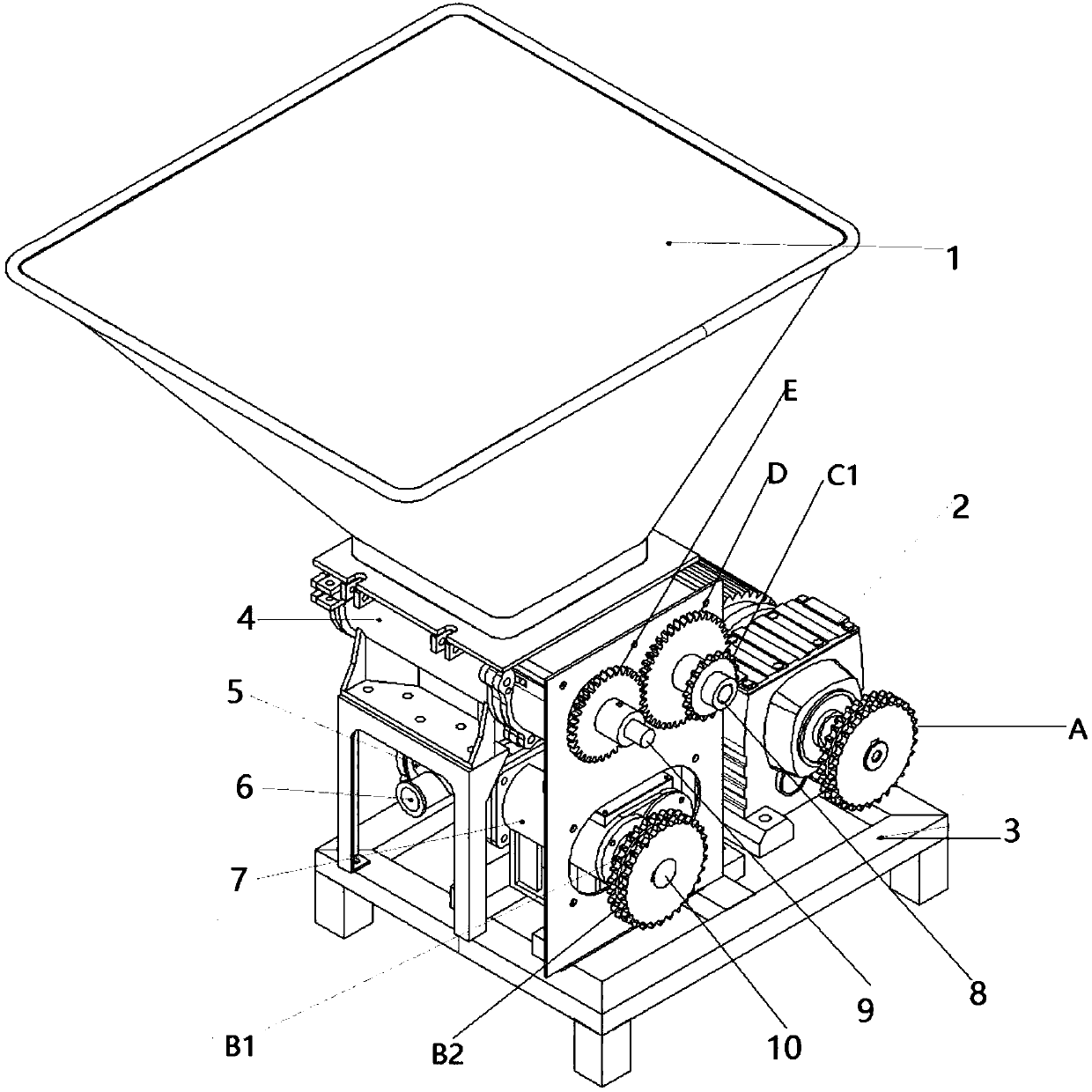

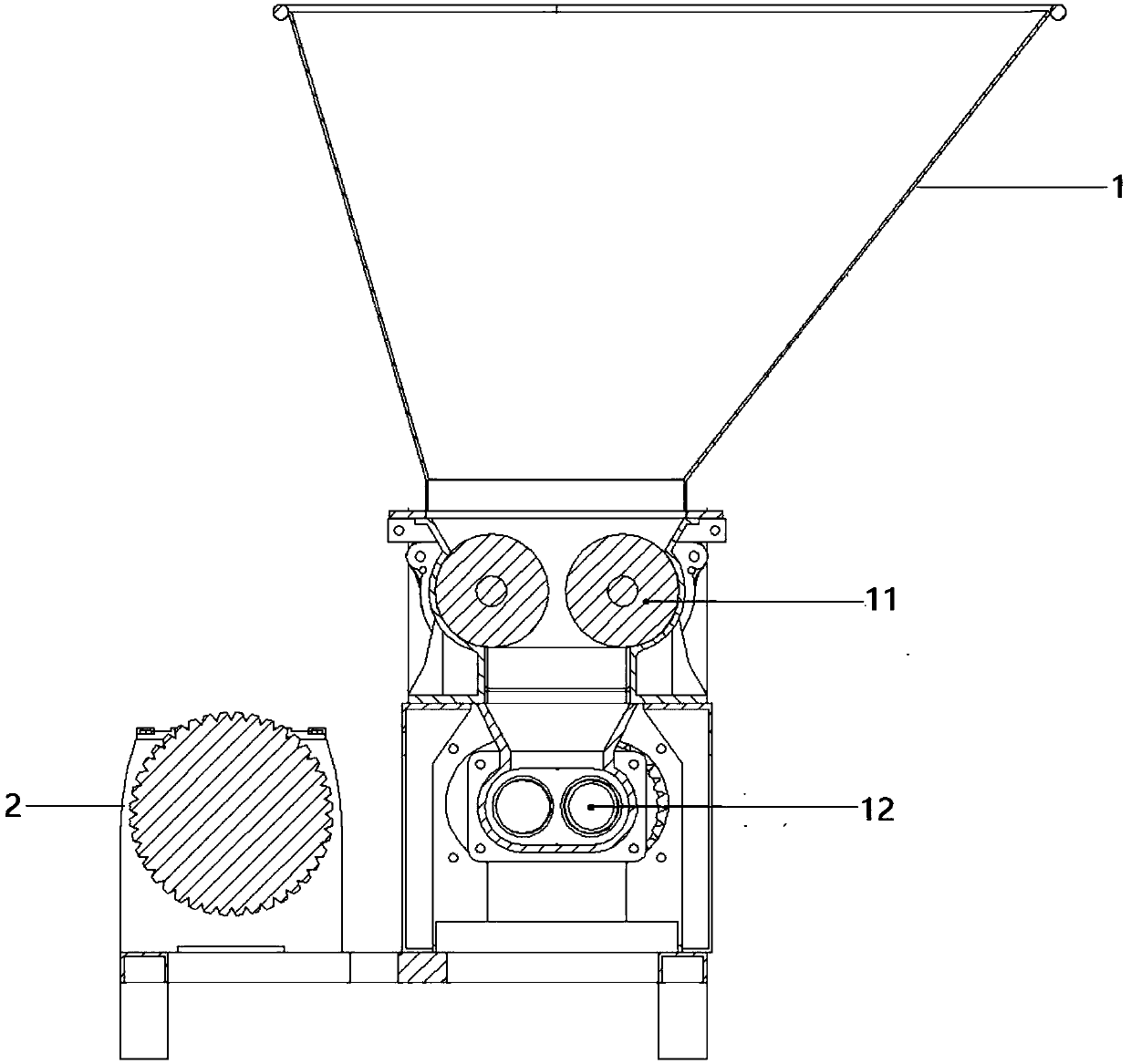

Ground conveying pump and material conveying method

PendingCN107867569AInto a stableEasily control discharge volumeLoading/unloadingGear wheelElectric machinery

The invention provides a ground conveying pump, in particular to a ground conveying pump for conveying food materials with certain viscosity. The ground conveying pump comprises a feeding device, a ground pump body and a driving motor and further comprises a roller mechanism arranged between the feeding device and the ground pump body. A rotating element is arranged in the pump body, the feeding device is connected with a roller box, the roller box is connected with a pump body box, the driving motor drives the roller and the pump body through a sprocket gear transmission system, and the roller mechanism can be in a two-roller mode or a four-roller mode. The invention further provides a material conveying method using the ground conveying pump. By means of the method, before being conveyedto a rotor pump, materials are made to pass through the roller mechanism, so that bubbles and air contained in the materials are effectively exhausted, and the materials can be conveyed into the pumpbody at a stable speed and prevented from being polluted in the pump body and then are discharged out of the pump body and conveyed to a next treating mechanism.

Owner:BEIJING AEROSPACE ORIENTAL TECH DEVCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com